Effect of Nanoclay on the Performance Characteristics of SBS-Modified Asphalt Concrete Mixtures

Abstract

1. Introduction

2. Materials and Methods

2.1. Base Asphalt Binders

2.2. SBS Polymer Modifier

2.3. Nanoclay

2.4. Aggregates

2.5. Mix Design and Sample Preparation

3. Experimental Testing Program

3.1. Indirect Tensile Strength (ITS) Test and Tensile Strength Ratio (TSR)

3.2. Indirect Tensile Resilient Modulus

3.3. Hamburg Wheel Tracking Test (HWTT)

3.4. Visco-Plastic and Moisture Resistance Quantification

- represents the visco-plastic resistance index.

- is the failure cycle at 12.5 mm rut depth (or test termination at 20,000 cycles if the failure does not occur).

- is the visco-plastic deformation depth at .

- is the moisture resistance index.

- is the stripping-induced rut depth at .

4. Results and Discussion

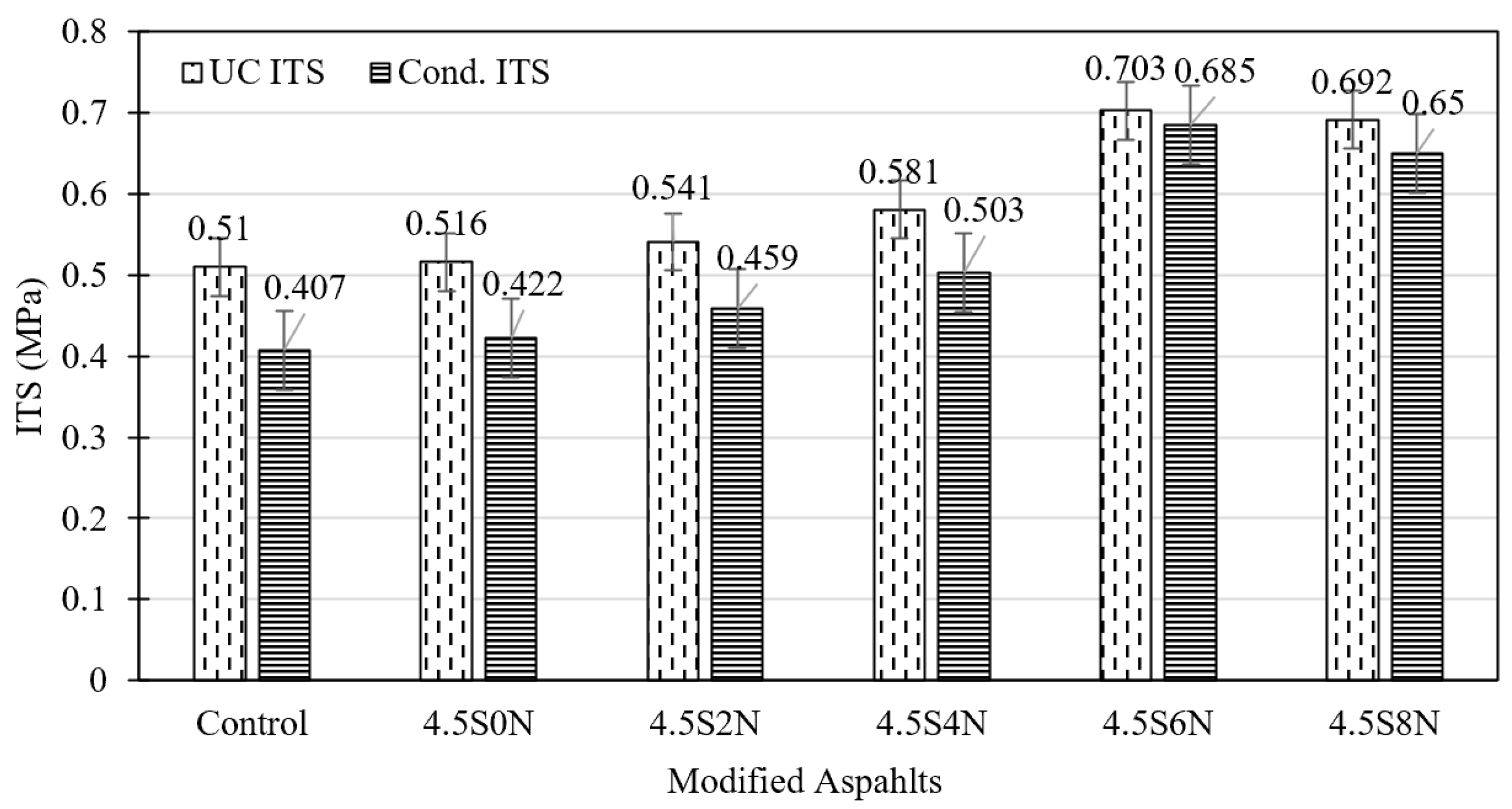

4.1. Effect of SBS Modifiers on ITS Values

4.2. Effect of SBS–Nanoclay Modifiers on ITS Values

4.3. Moisture Susceptibility Analysis

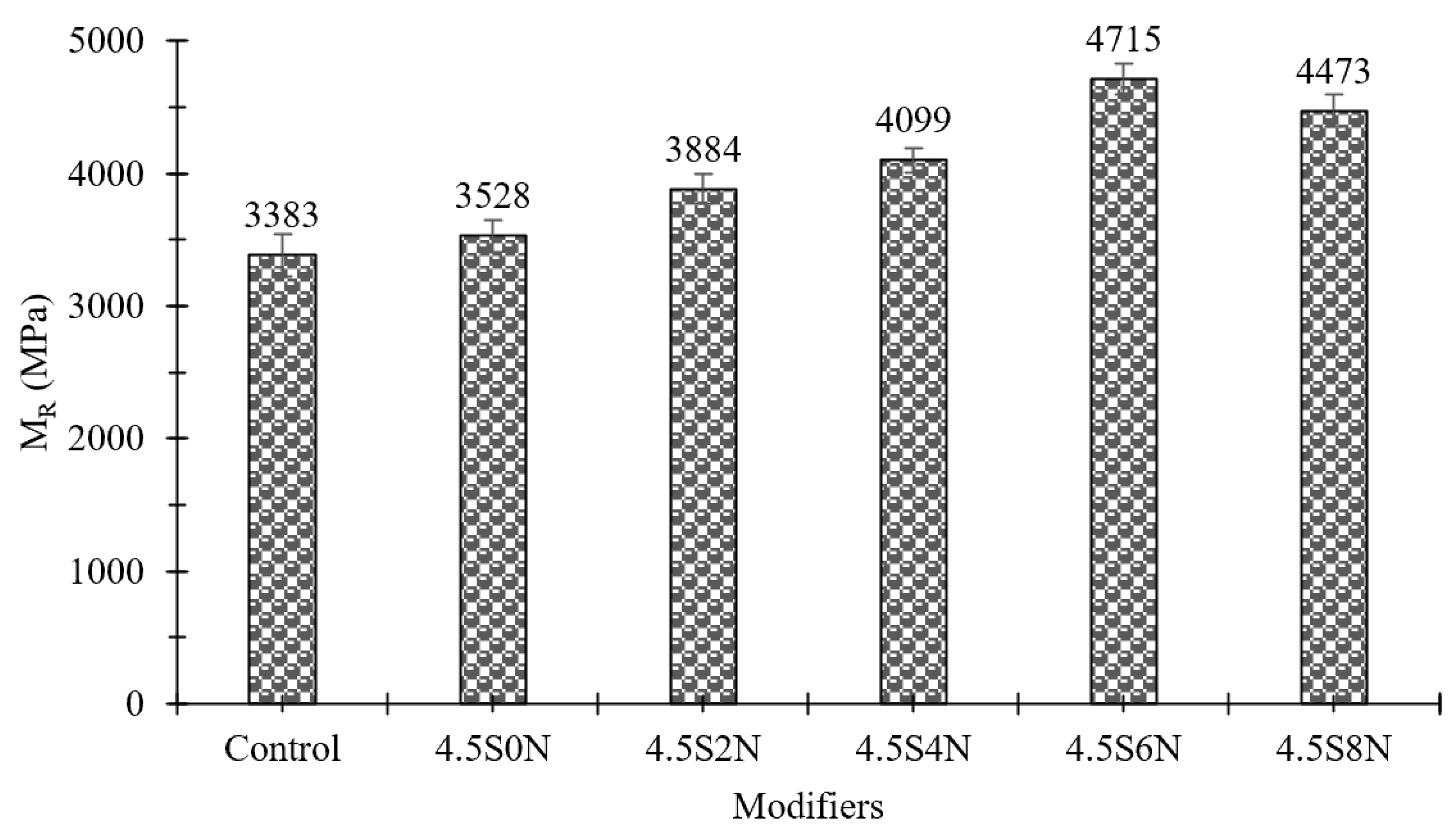

4.4. Resilient Modulus Results

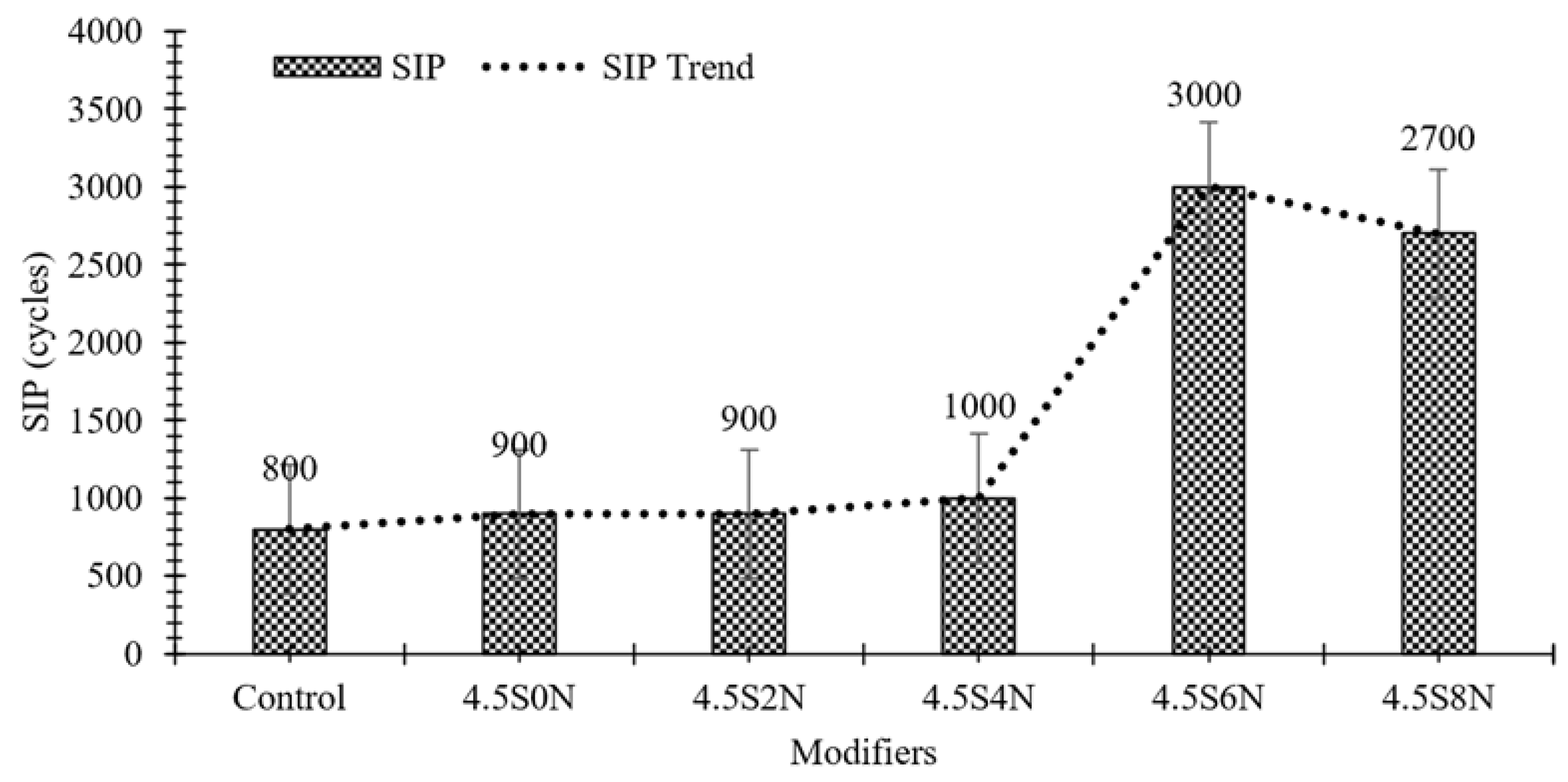

4.5. Hamburg Wheel Tracking Test Result

5. Conclusions

- The optimal modifier content was established at 4.5% SBS combined with 6% nanoclay, which maximized performance benefits across all evaluated parameters while maintaining economic feasibility.

- Significant improvements in mechanical properties were achieved, with indirect tensile strength increasing by 38% under dry conditions and 68% under wet conditions compared to control mixtures, demonstrating enhanced structural integrity and load-bearing capacity.

- Moisture resistance showed remarkable enhancement, with the Tensile Strength Ratio (TSR) improving from 79.53% in control samples to 97.14% in optimally modified mixtures, effectively addressing critical durability concerns in pavement applications.

- The quantitative analysis revealed strong correlations between performance indicators (TSR, SIP, VR, and MR), validating the comprehensive improvements and providing a rigorous methodology for evaluating modified asphalt mixtures.

- Uniform dispersion of nanoclay particles at optimal content created an effective reinforcement network, with their layered silicate structure facilitating improved stress distribution and stronger interfacial bonding within the asphalt matrix.

- Exceeding 6% nanoclay content resulted in performance deterioration due to particle agglomeration, establishing clear practical limitations for modification levels in pavement applications.

- Future research should focus on investigating long-term aging characteristics, performance under varying environmental conditions, cost-effectiveness analysis, and field validation through test sections to strengthen the applicability of these laboratory findings to real-world pavement construction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| HWTT | Hamburg Wheel Tracking Test |

| ERI | Indirect Tensile Resilient Modulus |

| ITS | Indirect Tensile Strength |

| MR | Moisture Resistance |

| NMAS | normal maximum aggregate size |

| PB | End-blocks and polybutadiene |

| PS | Polystyrene |

| SBS | Styrene–Butadiene–Styrene |

| SIP | Stripping inflection point |

| TSR | Tensile Strength Ratio |

| VR | Visco-plastic resistance |

References

- Datta, D.; Khattak, N.; Ghabchi, R. Aging Mechanisms of Polymer-and Non-Polymer-Modified Asphalt Binders. In Proceedings of the International Conference on Transportation and Development, Atlanta, GA, USA, 15–18 June 2024; pp. 349–358. [Google Scholar]

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer modification of bitumen: Advances and challenges. Eur. Polym. J. 2014, 54, 18–38. [Google Scholar] [CrossRef]

- Ren, S.; Liu, X.; Wang, H.; Fan, W.; Erkens, S. Evaluation of rheological behaviors and anti-aging properties of recycled asphalts using low-viscosity asphalt and polymers. J. Clean. Prod. 2020, 253, 120048. [Google Scholar] [CrossRef]

- Yildirim, Y. Polymer modified asphalt binders. Constr. Build. Mater. 2007, 21, 66–72. [Google Scholar] [CrossRef]

- Lesueur, D. The colloidal structure of bitumen: Consequences on the rheology and on the mechanisms of bitumen modification. Adv. Colloid Interface Sci. 2009, 145, 42–82. [Google Scholar] [CrossRef]

- Airey, G.D. Rheological properties of styrene butadiene styrene polymer modified road bitumens☆. Fuel 2003, 82, 1709–1719. [Google Scholar] [CrossRef]

- Nan, H.; Sun, Y.; Chen, J.; Gong, M. Investigation of fatigue performance of asphalt binders containing SBS and CR through TS and LAS tests. Constr. Build. Mater. 2022, 361, 129651. [Google Scholar] [CrossRef]

- Abualia, A.; Akentuna, M.; Mohammad, L.N.; Cooper, S.B.; Cooper, S.B. Improving Asphalt Binder Durability Using Sustainable Materials: A Rheological and Chemical Analysis of Polymer-, Rubber-, and Epoxy-Modified Asphalt Binders. Sustainability 2024, 16, 5379. [Google Scholar] [CrossRef]

- Canestrari, F.; Ingrassia, L.P. A review of top-down cracking in asphalt pavements: Causes, models, experimental tools and future challenges. J. Traffic Transp. Eng. 2020, 7, 541–572. [Google Scholar] [CrossRef]

- Liang, M.; Xin, X.; Fan, W.; Luo, H.; Wang, X.; Xing, B. Investigation of the rheological properties and storage stability of CR/SBS modified asphalt. Constr. Build. Mater. 2015, 74, 235–240. [Google Scholar] [CrossRef]

- Fu, H.; Xie, L.; Dou, D.; Li, L.; Yu, M.; Yao, S. Storage stability and compatibility of asphalt binder modified by SBS graft copolymer. Constr. Build. Mater. 2007, 21, 1528–1533. [Google Scholar] [CrossRef]

- Osman, H.; Rodzey, M.Z.I.M.; Hasan, M.R.M.; Wong, T.L.X.; Ghazali, M.F.H.M.; Zakaria, Z.; Jameel, M. Review of bonding behavior, mechanisms, and characterization approach in bituminous materials under different conditions. J. Traffic Transp. Eng. 2024, 11, 1291–1316. [Google Scholar] [CrossRef]

- You, Z.; Mills-Beale, J.; Foley, J.M.; Roy, S.; Odegard, G.M.; Dai, Q.; Goh, S.W. Nanoclay-modified asphalt materials: Preparation and characterization. Constr. Build. Mater. 2011, 25, 1072–1078. [Google Scholar] [CrossRef]

- Khattak, N.U.; Irfan, M.; Hoy, M.; Khan, A. Effects of synergistic combined Bakelite and Nano clay modification on asphalt mixture performance properties. Road Mater. Pavement Des. 2025, 1–17. [Google Scholar] [CrossRef]

- Yu, J.; Wang, L.; Zeng, X.; Wu, S.; Li, B. Effect of montmorillonite on properties of styrene–butadiene–styrene copolymer modified bitumen. Polym. Eng. Sci. 2007, 47, 1289–1295. [Google Scholar] [CrossRef]

- Lu, X.; Isacsson, U. Modification of road bitumens with thermoplastic polymers. Polym. Test. 2000, 20, 77–86. [Google Scholar] [CrossRef]

- Khattak, M.J.; Khattab, A.; Rizvi, H.R.; Zhang, P. The impact of carbon nano-fiber modification on asphalt binder rheology. Constr. Build. Mater. 2012, 30, 257–264. [Google Scholar] [CrossRef]

- Babagoli, R.; Mohammadi, R.; Ameri, M. The rheological behavior of bitumen and moisture susceptibility modified with SBS and nanoclay. Pet. Sci. Technol. 2017, 35, 1085–1090. [Google Scholar] [CrossRef]

- Ghanoon, S.A.; Tanzadeh, J.; Mirsepahi, M. Laboratory evaluation of the composition of nano-clay, nano-lime and SBS modifiers on rutting resistance of asphalt binder. Constr. Build. Mater. 2020, 238, 117592. [Google Scholar] [CrossRef]

- You, L.; You, Z.; Dai, Q.; Zhang, L. Assessment of nanoparticles dispersion in asphalt during bubble escaping and bursting: Nano hydrated lime modified foamed asphalt. Constr. Build. Mater. 2018, 184, 391–399. [Google Scholar] [CrossRef]

- Galooyak, S.S.; Dabir, B.; Nazarbeygi, A.E.; Moeini, A. Rheological properties and storage stability of bitumen/SBS/montmorillonite composites. Constr. Build. Mater. 2010, 24, 300–307. [Google Scholar] [CrossRef]

- Taherkhani, H.; Tajdini, M. Comparing the effects of nano-silica and hydrated lime on the properties of asphalt concrete. Constr. Build. Mater. 2019, 218, 308–315. [Google Scholar] [CrossRef]

- Arabani, M.; Faramarzi, M. Characterization of CNTs-modified HMA’s mechanical properties. Constr. Build. Mater. 2015, 83, 207–215. [Google Scholar] [CrossRef]

- Li, R.; Xiao, F.; Amirkhanian, S.; You, Z.; Huang, J. Developments of nano materials and technologies on asphalt materials—A review. Constr. Build. Mater. 2017, 143, 633–648. [Google Scholar] [CrossRef]

- Latifi, H.; Hayati, P. Evaluating the effects of the wet and simple processes for including carbon Nanotube modifier in hot mix asphalt. Constr. Build. Mater. 2018, 164, 326–336. [Google Scholar] [CrossRef]

- Amin, I.; El-Badawy, S.M.; Breakah, T.; Ibrahim, M.H.Z. Laboratory evaluation of asphalt binder modified with carbon nanotubes for Egyptian climate. Constr. Build. Mater. 2016, 121, 361–372. [Google Scholar] [CrossRef]

- Omrani, H.; Ghanizadeh, A.R.; Tanakizadeh, A. Effect of SBS polymer and anti-stripping agents on the moisture susceptibility of hot and warm mix asphalt mixtures. Civ. Eng. J. 2017, 3, 987–996. [Google Scholar] [CrossRef]

- ASTM D5 06; Standard Test Method for Penetration of Bituminous Materials. ASTM International: Philadelphia, PA, USA, 2006.

- ASTM D36 06; Standard Test Method for Softening Point of Bitumen (Ring and Ball Apparatus). ASTM International: Philadelphia, PA, USA, 2006.

- ASTM D70/D70M 21; Standard Test Method for Specific Gravity (Relative Density) and Density of Semi Solid Asphalt Binder (Pycnometer Method). ASTM International: Philadelphia, PA, USA, 2021.

- ASTM D4402/D4402M 15; Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. ASTM International: Philadelphia, PA, USA, 2015.

- ASTM D113 17; Standard Test Method for Ductility of Asphalt Materials. ASTM International: Philadelphia, PA, USA, 20 December 2017; (approved December 2023).

- ASTM D92 16b; Standard Test Method for Flash and Fire Points by Cleveland Open Cup Tester. ASTM International: Philadelphia, PA, USA, 2016.

- ASTM D2042-22; Standard Test Method for Solubility of Asphalt Materials in Trichloroethylene or Toluene. ASTM International: Philadelphia, PA, USA, 2022.

- AASHTO T85-14; Standard Method of Test for Specific Gravity and Absorption of Coarse Aggregate. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2014.

- AASHTO T96-19; Standard Method of Test for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2019.

- BS 812-110:1990; Testing Aggregates – Part 110: Methods for Determination of Aggregate Crushing Value (ACV). British Standards Institution (BSI): London, UK, 1990.

- ASTM D1559-89; Standard Test Method for Resistance to Plastic Flow of Bituminous Mixtures Using Marshall Apparatus. ASTM International: West Conshohocken, PA, USA, 1989.

- Islam, S.S.; Singh, S.K.; Ransinchung, G.D.R.N.; Ravindranath, S.S. Effect of property deterioration in SBS modified binders during storage on the performance of asphalt mix. Constr. Build. Mater. 2021, 272, 121644. [Google Scholar] [CrossRef]

- ASTM D6931-24; Standard Test Method for Indirect Tensile (IDT) Strength of Asphalt (Bituminous) Mixtures. ASTM International: West Conshohocken, PA, USA, 2024.

- AASHTO T283-14; Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced Damage. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2014.

- ASTM D7369-20 ; Standard Test Method for Determining the Resilient Modulus of Asphalt Mixtures by Indirect Tension Test. ASTM International: West Conshohocken, PA, USA, 2020.

- AASHTO T324-17; Standard Method of Test for Hamburg Wheel-Track Testing of Compacted Asphalt Mixtures. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2017.

- Lv, Q.; Lu, J.; Tang, X.; Hu, Y.; Yan, C. Evaluation of the moisture resistance of rubberized asphalt using BBS/UTM bonding test, TSR and HWT test. Constr. Build. Mater. 2022, 340, 127831. [Google Scholar] [CrossRef]

- Albayati, A.H.; Al-Kheetan, M.J.; Moudhafar, M.M.; Mohammed, A.M. Nanomaterials in asphalt cement: Exploring their single and combined effects on the physical and rheological properties. Results Eng. 2024, 24, 103225. [Google Scholar] [CrossRef]

- Mohammed, A.M.; Abed, A.H. Enhancing asphalt binder performance through nano-SiO2 and nano-CaCO3 additives: Rheological and physical insights. Case Stud. Constr. Mater. 2023, 19, e02492. [Google Scholar] [CrossRef]

- Yu, J.; Zeng, X.; Wu, S.; Wang, L.; Liu, G. Preparation and properties of montmorillonite modified asphalts. Mater. Sci. Eng. A 2007, 447, 233–238. [Google Scholar] [CrossRef]

- Behbahani, H.; Hamedi, G.H.; Gilani, V.N.M. Predictive model of modified asphalt mixtures with nano hydrated lime to increase resistance to moisture and fatigue damages by the use of deicing agents. Constr. Build. Mater. 2020, 265, 120353. [Google Scholar] [CrossRef]

- Nazir, M.S.; Kassim, M.H.M.; Mohapatra, L.; Gilani, M.A.; Raza, M.R.; Majeed, K. Characteristic Properties of Nanoclays and Characterization of Nanoparticulates and Nanocomposites. In Nanoclay Reinforced Polymer Composites: Nanocomposites and Bionanocomposites; Jawaid, M., Qaiss, A.E.K., Bouhfid, R., Eds.; Springer: Singapore, 2016; pp. 35–55. [Google Scholar]

- Zhu, X.; Wang, Y.; Miljković, M.; Li, R.; Hao, G. Effects of polymer structure on the physicochemical and performance-related properties of SBS-modified asphalt binders subjected to short-term aging. Constr. Build. Mater. 2024, 411, 134446. [Google Scholar] [CrossRef]

- Yao, H.; Wang, Q.; Zhang, Z.; Zhou, X.; Cao, Y. Effect of styrene–butadiene–styrene triblock copolymer structure on the rheological properties of high content SBS polymer modified asphalts. Constr. Build. Mater. 2023, 400, 132738. [Google Scholar] [CrossRef]

- Taherkhani, H.; Afroozi, S.; Javanmard, S. Comparative Study of the Effects of Nanosilica and Zyco-Soil Nanomaterials on the Properties of Asphalt Concrete. J. Mater. Civ. Eng. 2017, 29, 04017054. [Google Scholar] [CrossRef]

- Hossain, Z.; Zaman, M.; Hawa, T.; Saha, M.C. Evaluation of Moisture Susceptibility of Nanoclay-Modified Asphalt Binders through the Surface Science Approach. J. Mater. Civ. Eng. 2015, 27, 04014261. [Google Scholar] [CrossRef]

- Santagata, E.; Baglieri, O.; Tsantilis, L.; Chiappinelli, G. Fatigue and healing properties of nano-reinforced bituminous binders. Int. J. Fatigue 2015, 80, 30–39. [Google Scholar] [CrossRef]

- Crucho, J.M.L.; Neves, J.M.C.D.; Capitão, S.D.; Picado-Santos, L.G.D. Mechanical performance of asphalt concrete modified with nanoparticles: Nanosilica, zero-valent iron and nanoclay. Constr. Build. Mater. 2018, 181, 309–318. [Google Scholar] [CrossRef]

- Saharudin, M.S.; Hasbi, S.; Nazri, M.N.A.; Inam, F. A Review of Recent Developments in Mechanical Properties of Polymer–Clay Nanocomposites: Selected articles from ICMMPE. In Advances in Manufacturing Engineering; Springer: Singapore, 2019; pp. 107–129. [Google Scholar]

- Martinho, F.C.G.; Farinha, J.P.S. An overview of the use of nanoclay modified bitumen in asphalt mixtures for enhanced flexible pavement performances. Road Mater. Pavement Des. 2019, 20, 671–701. [Google Scholar] [CrossRef]

- Abdelrahman, M.; Katti, D.R.; Ghavibazoo, A.; Upadhyay, H.B.; Katti, K.S. Engineering Physical Properties of Asphalt Binders through Nanoclay–Asphalt Interactions. J. Mater. Civ. Eng. 2014, 26, 04014099. [Google Scholar] [CrossRef]

- Mousavinezhad, S.H.; Shafabakhsh, G.H.; Ani, O.J. Nano-clay and styrene-butadiene-styrene modified bitumen for improvement of rutting performance in asphalt mixtures containing steel slag aggregates. Constr. Build. Mater. 2019, 226, 793–801. [Google Scholar] [CrossRef]

- Saboo, N.; Sukhija, M. Evaluating the Suitability of Nanoclay-Modified Asphalt Binders from 10 °C to 70 °C. J. Mater. Civ. Eng. 2020, 32, 04020393. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Structure Type | Linear |

| Purity | >95% |

| Physical Form | White granules |

| Styrene/Butadiene Ratio | 30/70 |

| Solution Viscosity | 2.24 Pa·s |

| Tensile Strength | 20 MPa |

| Hardness | 76 A |

| Property | Value |

|---|---|

| Color | Greyish yellow |

| Montmorillonite Content | >75% |

| Moisture Content | Max. 10% |

| API Water Loss | Max. 15% cm3 |

| pH | 9.5 |

| Particle Size Distribution | 99% passing No. 200 sieve |

| Free Swell Index | 600% |

| Liquid Limit | 292% |

| Plastic Limit | 48.55% |

| Shrinkage Limit | 25.7% |

| Chemical Composition | Al2H2Na2O13Si4 |

| Sieve Size (mm) | 19.0 | 12.5 | 9.5 | 4.75 | 2.38 | 1.18 | 0.075 | Pan |

|---|---|---|---|---|---|---|---|---|

| Upper and lower boundary | 100 | 75–90 | 60–80 | 40–60 | 20–40 | 5–15 | 3–8 | - |

| Aggregate | 100 | 82.5 | 70 | 50 | 30 | 10 | 5.5 | - |

| Property | Test Method | Coarse Aggregate | Fine Aggregate | Specification Limits |

|---|---|---|---|---|

| Bulk Specific Gravity | AASHTO T85 [35] | 2.65 | 2.62 | - |

| Water Absorption (%) | AASHTO T85 [35] | 1.8 | 2.1 | Max 2.5 |

| Los Angeles Abrasion (%) | AASHTO T96 [36] | 25.5 | - | Max 30 |

| Aggregate Crushing Value (%) | BS 812-110 [37] | 22.3 | - | Max 25 |

| Marshall Variables | Results | Specification Criteria | Status |

|---|---|---|---|

| Optimum Binder Content (OBC) | 4.3% | - | Achieved |

| Bulk Specific Gravity | 2.36 | - | - |

| Voids in Mineral Aggregate (VMA) | 13.6% | Min. 13% | Pass |

| Voids Filled with Asphalt (VFA) | 70.3% | 65%–75% | Pass |

| Stability | 15.2 kN | Min. 8.006 kN | Pass |

| Flow | 2.6 mm | 2.0–3.5 mm | Pass |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, A.; Ahmed, S.; Khattak, N.U.; Hoy, M.; Se, C. Effect of Nanoclay on the Performance Characteristics of SBS-Modified Asphalt Concrete Mixtures. Coatings 2025, 15, 984. https://doi.org/10.3390/coatings15090984

Khan A, Ahmed S, Khattak NU, Hoy M, Se C. Effect of Nanoclay on the Performance Characteristics of SBS-Modified Asphalt Concrete Mixtures. Coatings. 2025; 15(9):984. https://doi.org/10.3390/coatings15090984

Chicago/Turabian StyleKhan, Asmat, Sarfraz Ahmed, Naqeeb Ullah Khattak, Menglim Hoy, and Chamroeun Se. 2025. "Effect of Nanoclay on the Performance Characteristics of SBS-Modified Asphalt Concrete Mixtures" Coatings 15, no. 9: 984. https://doi.org/10.3390/coatings15090984

APA StyleKhan, A., Ahmed, S., Khattak, N. U., Hoy, M., & Se, C. (2025). Effect of Nanoclay on the Performance Characteristics of SBS-Modified Asphalt Concrete Mixtures. Coatings, 15(9), 984. https://doi.org/10.3390/coatings15090984