Enhancing Mechanical, Impact, and Corrosion Resistance of Self-Healable Polyaspartic Ester Polyurea via Surface Modified Graphene Nanoplatelets

Abstract

1. Introduction

2. Experiment

2.1. Materials

2.2. Preparation

2.2.1. Preparation of Functionalized Graphene Nanoplatelets

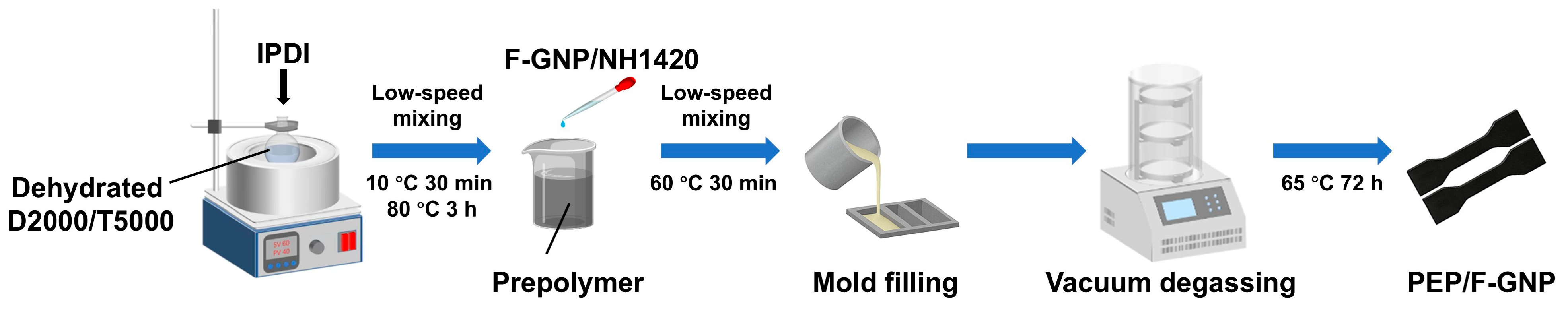

2.2.2. Preparation of PEP Nanocomposites

2.3. Characterization

3. Result and Discussion

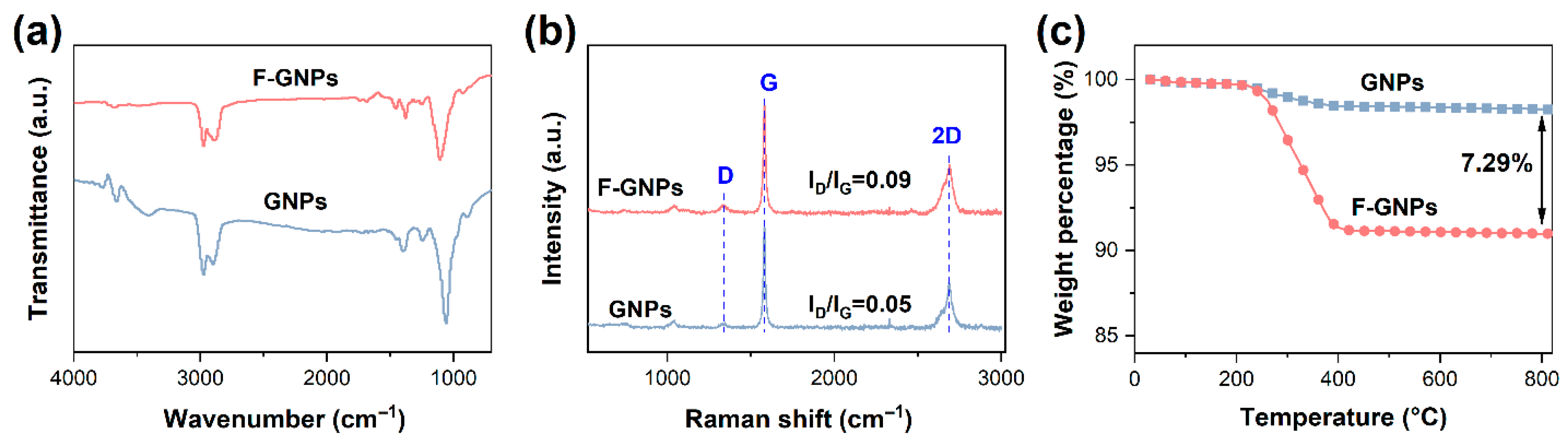

3.1. Structural and Compositional Characterization of F-GNPs

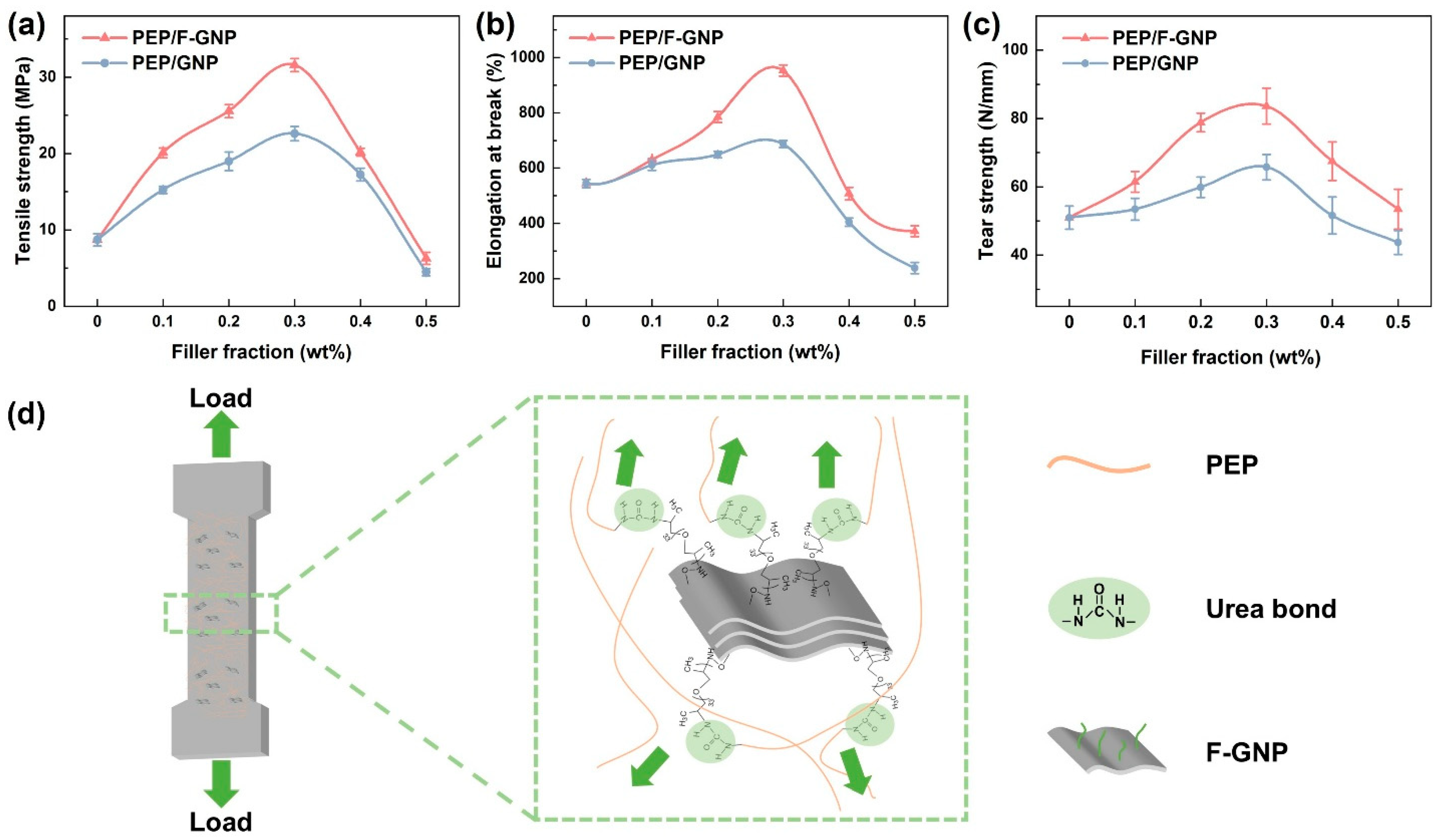

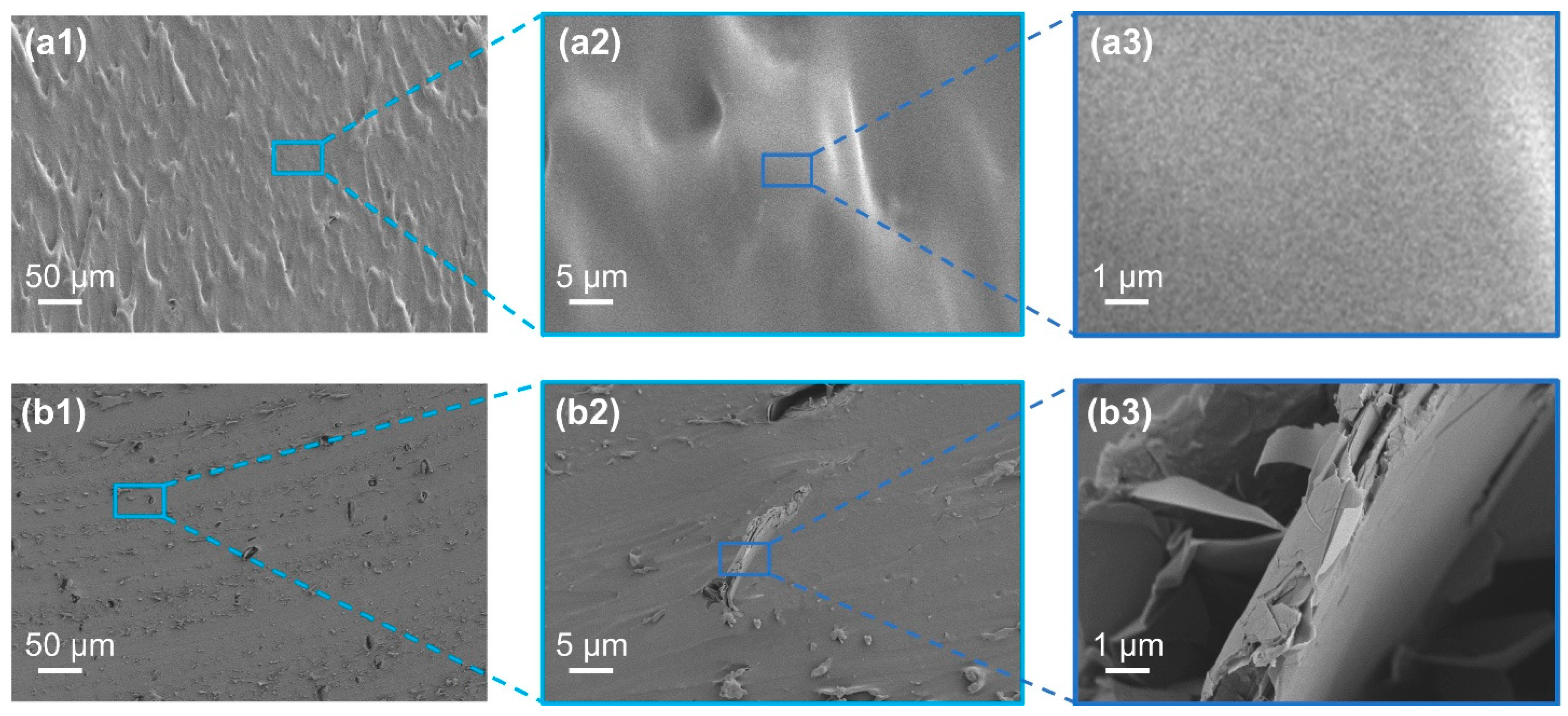

3.2. Mechanical Properties

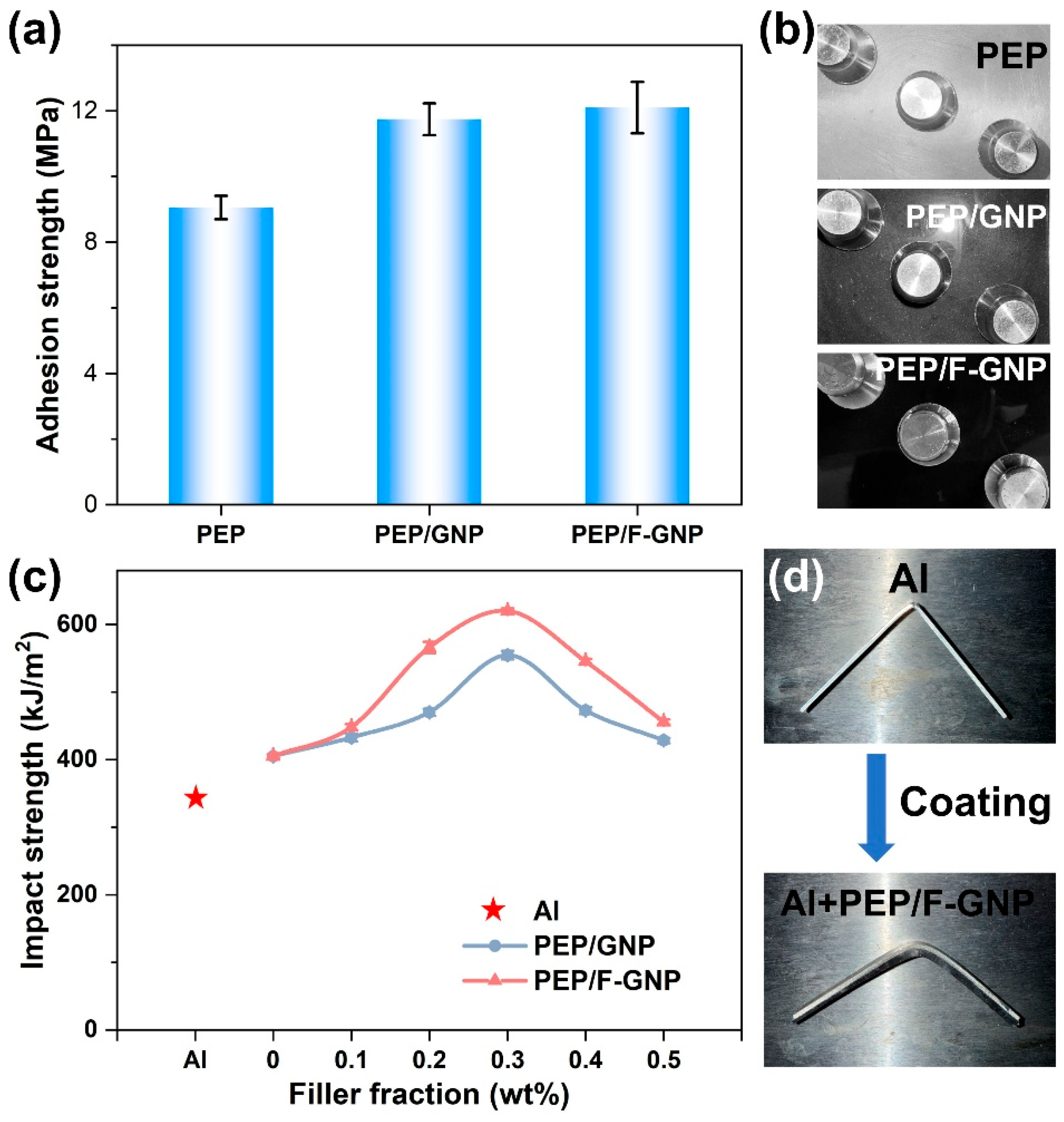

3.3. Impact Resistance

3.4. Anti-Corrosion Performance

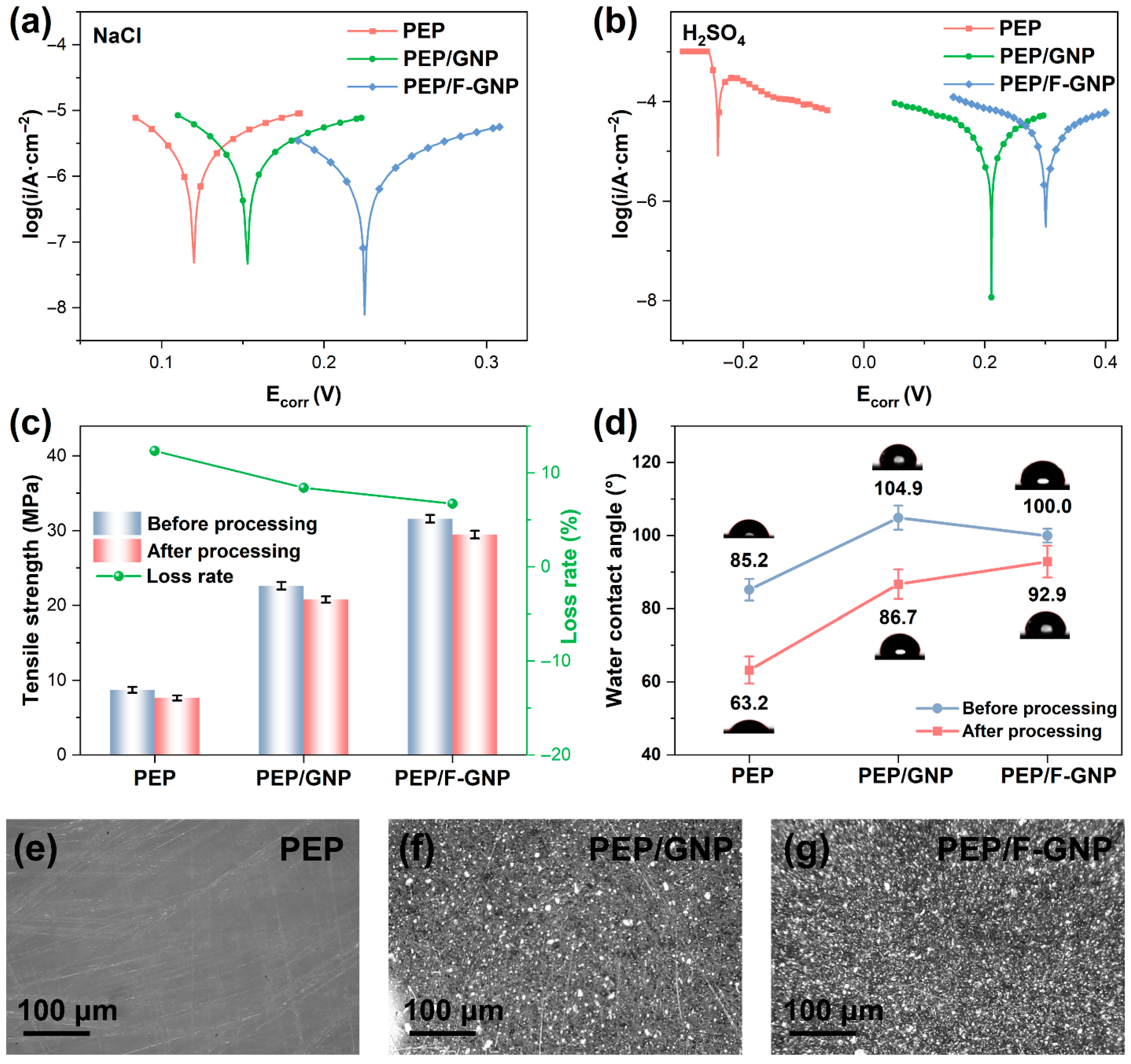

3.5. Self-Healing Properties

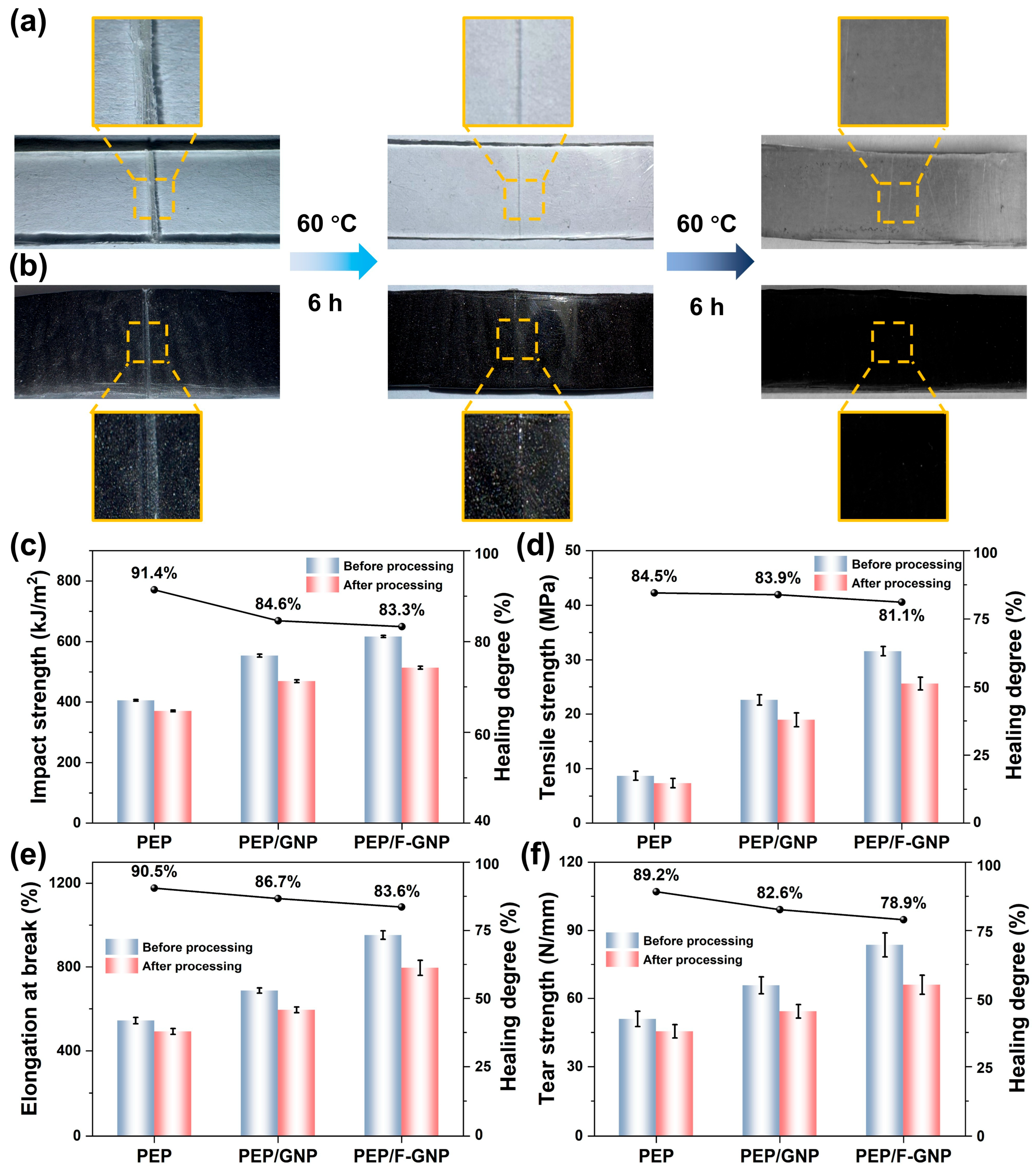

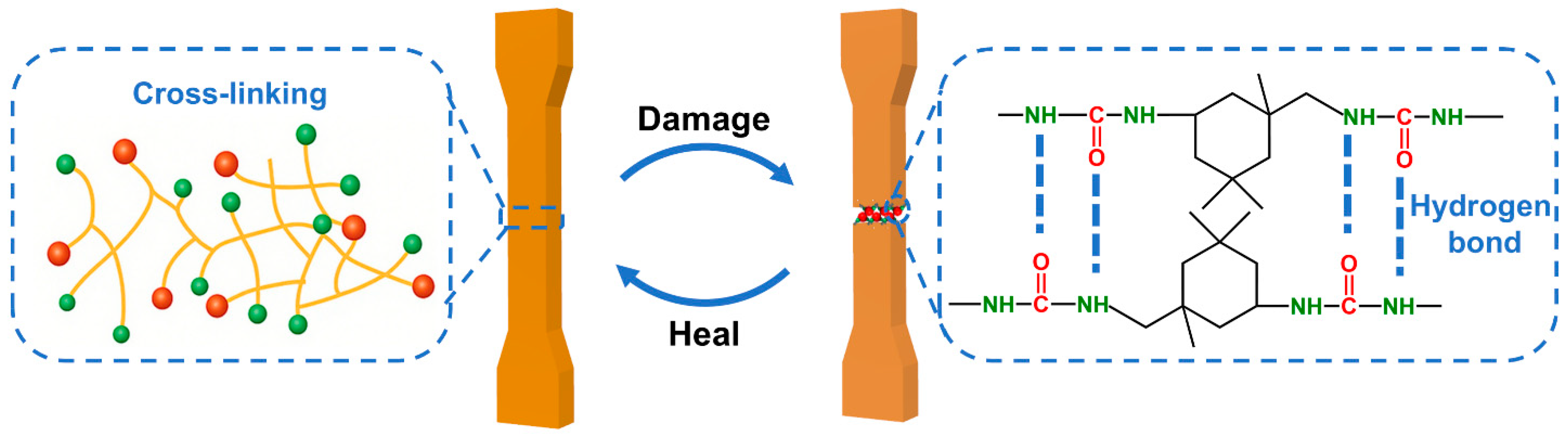

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Iqbal, N.; Sharma, P.K.; Kumar, D.; Roy, P.K. Protective polyurea coatings for enhanced blast survivability of concrete. Constr. Build. Mater. 2018, 175, 682–690. [Google Scholar] [CrossRef]

- Mo, Q.F.; Qin, G.M.; Ling, K.; Lv, X.Y.; Wang, N.N.; Li, W.Z. Layer-by-layer self-assembled polyurea layers onto MAO surface for enhancing corrosion protection to aluminum alloy 6063. Surf. Coat. Technol. 2021, 405, 126653. [Google Scholar] [CrossRef]

- Han, S.S.; Li, S.S.; Zhang, X.R.; Liu, D.Y.; Guo, S.; Wang, B.Z.; Meng, Q.S. Enhancing the protective performance of anti-impact, corrosion resistant and flame retardant polyurea coatings using bio-based supramolecular decorated montmorillonite. Constr. Build. Mater. 2024, 435, 136721. [Google Scholar] [CrossRef]

- Chu, D.Y.; Li, Z.J.; Yao, K.L.; Wang, Y.G.; Tian, R.; Zhuang, Z.; Liu, Z.L. Studying the strengthening mechanism and thickness effect of elastomer coating on the ballistic-resistance of the polyurea-coated steel plate. Int. J. Impact Eng. 2022, 163, 104181. [Google Scholar] [CrossRef]

- Li, D.H.; Ning, S.R.; Yu, L.; Meng, Q.S.; Zhao, S.F.; Niu, J.H.; Fang, Q.H.; Kang, H.L.; Li, L.; Zhang, M.X.; et al. Advances in the design, synthesis, properties, and applications of polyurea. Mater. Today Chem. 2024, 42, 102382. [Google Scholar] [CrossRef]

- Iqbal, N.; Tripathi, M.; Parthasarathy, S.; Kumar, D.; Roy, P.K. Polyurea spray coatings: Tailoring material properties through chemical crosslinking. Prog. Org. Coat. 2018, 123, 201–208. [Google Scholar] [CrossRef]

- Huang, Z.H.; Wang, C.Z.; Li, H.L.; Ai, J.Y.; Song, L.A.; Liu, B.H. Manual applied polyurethane-urea: High performance coating based on CO2-based polyol and polyaspartic ester. Prog. Org. Coat. 2023, 181, 107580. [Google Scholar] [CrossRef]

- Wang, Z.X.; Du, M.R.; Fang, H.Y.; Zhao, P.; Yao, X.P.; Chen, S. The development of high-strength, anticorrosive, and strongly adhesive polyaspartate polyurea coating suitable for pipeline spray repairs. J. Appl. Polym. Sci. 2024, 141, e55668. [Google Scholar] [CrossRef]

- Yang, L.; Lu, P. Performance of Polyaspartic Ester Polyurea in Marine Engineering Protection. Appl. Mech. Mater. 2011, 66, 1533–1538. [Google Scholar] [CrossRef]

- Meng, Q.S.; Fu, Y.X.; Dong, Y.; Meng, B.H.; Liu, J.B.; Yu, Y.; Wang, B.Z.; Han, S.S. Enhanced mechanical and anti-corrosion performance of polyurea nanocomposite coatings via amino-functionalization of boron carbide nanosheets. Polym. Compos. 2025, 46, 11074–11088. [Google Scholar] [CrossRef]

- Tzelepis, D.A.; Suzuki, J.; Su, Y.F.; Wang, Y.Y.; Lim, Y.C.; Zayernouri, M.; Ginzburg, V.V. Experimental and modeling studies of IPDI-based polyurea elastomers—The role of hard segment fraction. J. Appl. Polym. Sci. 2023, 140, e53592. [Google Scholar] [CrossRef]

- Zhao, Y.Q.; Su, Y.L.; Zou, W.C.; Chen, G.; Deng, Y.Q.; Cheng, J.; Ren, H.S.; Zhao, Q. Influence of fluorine-containing side chain on the properties of waterborne polyurethane-urea. J. Appl. Polym. Sci. 2021, 138, 50971. [Google Scholar] [CrossRef]

- Cardoso, V.F.; Correia, D.M.; Ribeiro, C.; Fernandes, M.M.; Lanceros-Méndez, S. Fluorinated Polymers as Smart Materials for Advanced Biomedical Applications. Polymers 2018, 10, 161. [Google Scholar] [CrossRef] [PubMed]

- Xie, Q.Y.; Liu, C.; Lin, X.B.; Ma, C.F.; Zhang, G.Z. Nanodiamond Reinforced Poly(dimethylsiloxane)-Based Polyurea with Self-Healing Ability for Fouling Release Coating. ACS Appl. Polym. Mater. 2020, 2, 3181–3188. [Google Scholar] [CrossRef]

- Fu, Y.H.; Xu, F.C.; Weng, D.H.; Li, X.; Li, Y.; Sun, J.Q. Superhydrophobic Foams with Chemical- and Mechanical-Damage-Healing Abilities Enabled by Self-Healing Polymers. ACS Appl. Mater. Interfaces 2019, 11, 37285–37294. [Google Scholar] [CrossRef]

- Li, M.; Chen, K.; Zhang, D.; Ye, Z.M.; Yang, Z.F.; Wang, Q.; Jiang, Z.F.; Zhang, Y.J.; Shang, Y.Y.; Cao, A.Y. Wet-Spinning Carbon Nanotube/Shape Memory Polymer Composite Fibers with High Actuation Stress and Predesigned Shape Change. Adv. Sci. 2024, 11, 2404913. [Google Scholar] [CrossRef]

- Zhang, Z.P.; Qian, L.; Cheng, J.F.; Xie, Q.Y.; Ma, C.F.; Zhang, G.Z. Room-Temperature Self-Healing Polyurea with High Puncture and Impact Resistances. Chem. Mat. 2023, 35, 1806–1817. [Google Scholar] [CrossRef]

- Qiao, J.; Zhang, Q.; Wu, C.; Wu, G.H.; Li, L.Q. Effects of Fiber Volume Fraction and Length on the Mechanical Properties of Milled Glass Fiber/Polyurea Composites. Polymers 2022, 14, 3080. [Google Scholar] [CrossRef]

- Li, X.T.; Wang, H.T.; Zhang, Z.W.; Xu, T.; Tian, J.; Tan, Y.F. Effect of covalent functionalization of multi-walled carbon nanotubes with HDI trimer on mechanical properties of polyaspartate polyurea. Mater. Res. Express 2021, 8, 075011. [Google Scholar] [CrossRef]

- Qian, X.D.; Song, L.; Tai, Q.L.; Hu, Y.; Yuen, R.K.K. Graphite oxide/polyurea and graphene/polyurea nanocomposites: A comparative investigation on properties reinforcements and mechanism. Compos. Sci. Technol. 2013, 74, 228–234. [Google Scholar] [CrossRef]

- Meng, Q.S.; Zhu, Y.Q.; Li, S.S.; Zhao, K.B.; Araby, S.; Han, S.S. Aramid nanofiber-reinforced graphene oxide frameworks for durable and flame-resistant fire warning sensors. J. Mater. Res. Technol. 2025, 35, 4175–4188. [Google Scholar] [CrossRef]

- Meng, Q.S.; Wang, P.; Yu, Y.; Liu, J.B.; Su, X.; Kuan, H.C.; Wang, B.Z.; Zhang, L.Q.; Zhang, Y.Y.; Losic, D.; et al. Polyaspartic polyurea/graphene nanocomposites for multifunctionality: Self-healing, mechanical resilience, electrical and thermal conductivities, and resistance to corrosion and impact. Thin-Walled Struct. 2023, 189, 110853. [Google Scholar] [CrossRef]

- Li, S.S.; Liu, X.Y.; Yang, Z.Y.; Han, S.S.; Gu, H.C.; Chu, L.Y.; Meng, Q.S. Enhancing the mechanical, conductive, and chemical resistance properties of SEBS nanocomposites using graphene nanoplatelets. Polym. Compos. 2025, 46, 10734–10748. [Google Scholar] [CrossRef]

- Wang, Y.; Li, S.S.; Yang, H.Y.; Luo, J. Progress in the functional modification of graphene/graphene oxide: A review. RSC Adv. 2020, 10, 15328–15345. [Google Scholar] [CrossRef] [PubMed]

- Mei, S.X.; Li, K.B.; Cui, M.J.; Wu, Y.M.; Ren, S.M. Static and dynamic mechanical properties of polyurea nanocomposites reinforced by polydopamine functionalized graphene oxide. J. Mater. Res. Technol. 2024, 29, 2889–2901. [Google Scholar] [CrossRef]

- Mansourian-Tabaei, M.; Majdoub, M.; Sengottuvelu, D.; Stoddard, D.L.; Thirumalai, R.; Ucak-Astarlioglu, M.G.; Al-Ostaz, A.; Nouranian, S. Polyurea/Aminopropyl Isobutyl Polyhedral Oligomeric Silsesquioxane-Functionalized Graphene Nanoplatelet Nanocomposites for Force Protection Applications. ACS Appl. Mater. Interfaces 2024, 16, 19625–19641. [Google Scholar] [CrossRef] [PubMed]

- Chung, D.D.L. A review of exfoliated graphite. J. Mater. Sci. 2016, 51, 554–568. [Google Scholar] [CrossRef]

- GB/T 528-2009; Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress–Strain Properties. Standards Press of China: Beijing, China, 2009.

- GB/T 529-2008; Rubber, Vulcanized or Thermoplastic—Determination of Tear Strength (Trouser, Angle and Crescent Test Pieces). Standards Press of China: Beijing, China, 2008.

- GB/T 5210-2006; Paints and varnishes—Pull-off test for adhesion. Standards Press of China: Beijing, China, 2006.

- ISO 179-1:2000; Plastics—Determination of Charpy Impact Properties—Part 1: Non-Instrumented Impact Test. International Organization for Standardization: Geneva, Switzerland, 2000.

- ISO 16773-1:2016; Electrochemical Impedance Spectroscopy (EIS) on Coated and Uncoated Metals—Part 1: Terms and Definitions. International Organization for Standardization: Geneva, Switzerland, 2016.

- Zhang, L.B.; Wang, J.Q.; Wang, H.G.; Xu, Y.; Wang, Z.F.; Li, Z.P.; Mi, Y.J.; Yang, S.R. Preparation, mechanical and thermal properties of functionalized graphene/polyimide nanocomposites. Compos. Pt. A-Appl. Sci. Manuf. 2012, 43, 1537–1545. [Google Scholar] [CrossRef]

- Seo, J.M.; Jeon, I.Y.; Baek, J.B. Mechanochemically driven solid-state Diels-Alder reaction of graphite into graphene nanoplatelets. Chem. Sci. 2013, 4, 4273–4277. [Google Scholar] [CrossRef]

- Tang, G.Q.; Jiang, Z.G.; Li, X.F.; Zhang, H.B.; Yu, Z.Z. Simultaneous functionalization and reduction of graphene oxide with polyetheramine and its electrically conductive epoxy nanocomposites. Chin. J. Polym. Sci. 2014, 32, 975–985. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Wang, S.; Bao, X.H.; Liu, Z.J.; Meng, Q.S. Simple and low-cost preparation of functionalised graphene by microwave expansion combined with ball milling grafting. Polym. Compos. 2024, 45, 17294–17306. [Google Scholar] [CrossRef]

- Zhao, X.M.; Yuan, Y.H.; Li, P.P.; Song, Z.J.; Ma, C.X.; Pan, D.; Wu, S.D.; Ding, T.; Guo, Z.H.; Wang, N. A polyether amine modified metal organic framework enhanced the CO2 adsorption capacity of room temperature porous liquids. Chem. Commun. 2019, 55, 13179–13182. [Google Scholar] [CrossRef]

- Ngo, T.D.; Ton-That, M.T.; Hoa, S.V.; Cole, K.C. Reinforcing effect of organoclay in rubbery and classy epoxy resins, part 1: Dispersion and properties. J. Appl. Polym. Sci. 2008, 107, 1154–1162. [Google Scholar] [CrossRef]

- Xue, C.; Gao, H.Y.; Hu, Y.C.; Hu, G.X. Hyperelastic characteristics of graphene natural rubber composites and reinforcement and toughening mechanisms at multi-scale. Compos. Struct. 2019, 228, 111365. [Google Scholar] [CrossRef]

- Guo, K.; Qu, J.; Chen, R.R.; Liu, Q.; Yu, J.; Liu, J.Y.; Zhu, J.H.; Sun, G.H.; Liu, P.L.; Wang, J. A hierarchical energy dissipation strategy for impact-resistant polyurea driven by multiple hydrogen bonds. Constr. Build. Mater. 2025, 487, 142056. [Google Scholar] [CrossRef]

- Sadeghi, H.; Sangtarash, S.; Lambert, C. Robust Molecular Anchoring to Graphene Electrodes. Nano Lett. 2017, 17, 4611–4618. [Google Scholar] [CrossRef]

- Knaup, J.M.; Köhler, C.; Frauenheim, T.; Blumenau, A.T.; Amkreutz, M.; Schiffels, P.; Schneider, B.; Hennemann, O.D. Computational studies on polymer adhesion at the surface of γ-Al2O3.: I.: The adsorption of adhesive component molecules from the gas phase. J. Phys. Chem. B 2006, 110, 20460–20468. [Google Scholar] [CrossRef] [PubMed]

- Wu, G.; Ji, C.; Wang, X.; Gao, F.Y.; Zhao, C.X.; Liu, Y.J.; Yang, G.L. Blast response of clay brick masonry unit walls unreinforced and reinforced with polyurea elastomer. Def. Technol. 2022, 18, 643–662. [Google Scholar] [CrossRef]

- Wu, G.; Wang, X.; Ji, C.; Liu, Q.; Xie, X.B.; Zhao, C.X.; Liu, P.L. Damage response of polyurea-coated steel plates under combined blast and fragments loading. J. Constr. Steel. Res. 2022, 190, 107126. [Google Scholar] [CrossRef]

- Qiu, S.L.; Yang, W.H.; Wang, X.; Hu, Y. Phthalocyanine zirconium diazo passivation of black phosphorus for efficient smoke suppression, flame retardant and mechanical enhancement. Chem. Eng. J. 2023, 453, 139759. [Google Scholar] [CrossRef]

- Jia, W.H.; Cao, H.J.; Wang, T.E.; Min, Y.L.; Xu, Q.J. Electrochemical behavior and anti-corrosion property of Ti3C2Tx MXene/LDH heterostructured coating on aluminum alloy. Surf. Coat. Technol. 2023, 463, 129551. [Google Scholar] [CrossRef]

- Guo, R.Q.; Ding, C.Y.; Liu, Y.; Cheng, X.L.; Zhang, L.; Zhao, W.L.; Sheng, X.X. In situ growth of layered double hydroxides on zirconium phosphate for reinforcing anti-corrosion and wear resistance of waterborne epoxy coatings. Polymer 2025, 319, 128048. [Google Scholar] [CrossRef]

- Jiang, L.; Lei, Y.A.; Xiao, Y.; Fu, X.W.; Kong, W.B.; Wang, Y.C.; Lei, J.X. Mechanically robust, exceptionally recyclable and shape memory cross-linked network based on reversible dynamic urea bonds. J. Mater. Chem. A 2020, 8, 22369–22378. [Google Scholar] [CrossRef]

- Wang, Z.H.; Gangarapu, S.; Escorihuela, J.; Fei, G.X.; Zuilhof, H.; Xia, H.S. Dynamic covalent urea bonds and their potential for development of self-healing polymer materials. J. Mater. Chem. A 2019, 7, 15933–15943. [Google Scholar] [CrossRef]

- Xia, L.L.; Tu, H.J.; Zeng, W.; Yang, X.L.; Zhou, M.; Li, L.K.; Guo, X. A room-temperature self-healing elastomer with ultra-high strength and toughness fabricated via optimized hierarchical hydrogen-bonding interactions. J. Mater. Chem. A 2022, 10, 4344–4354. [Google Scholar] [CrossRef]

- Luo, X.; Wu, Y.P.; Guo, M.L.; Yang, X.; Xie, L.Y.; Lai, J.J.; Li, Z.Y.; Zhou, H.W. Multi-functional polyurethane composites with self-healing and shape memory properties enhanced by graphene oxide. J. Appl. Polym. Sci. 2021, 138, 50827. [Google Scholar] [CrossRef]

- Zhang, H.T.; You, Y.Y.; Jia, Y.S.; Hu, J.N.; Li, P.B.; Xie, Q.M. Tensile Properties and Fracture Mechanism of Thermal Spraying Polyurea. Polymers 2023, 15, 41. [Google Scholar] [CrossRef]

- Dural, S.; Camadanli, S.; Apohan, N.K. Partially Biobased Self-Repairing Poly(Aspartic Ester Polyurea) Coatings. Polym. Eng. Sci. 2025, 65, 4155–4169. [Google Scholar] [CrossRef]

- Dural, S.; Camadanli, S.S.; Apohan, N.K. Improving the mechanical, thermal and surface properties of polyaspartic ester bio-based polyurea coatings by incorporating silica and titania. Mater. Today Commun. 2024, 38, 107654. [Google Scholar] [CrossRef]

- Cheng, X.; Liu, Q.; Ye, Y.; Xie, S.C.; Xu, H.T. Polyisocyanate bridged hexagonal boron nitride/polyaspartic nanocomposite coatings with superior tribological and anticorrosion performance. Prog. Org. Coat. 2025, 200, 109027. [Google Scholar] [CrossRef]

| Additive | Loading | Tensile Strength (MPa) | Matrix Tensile Strength (MPa) | Mechanical Improvement (%) | Repair Rate (%) | Ref. |

|---|---|---|---|---|---|---|

| F-GNPs | 0.3 wt% | 31.6 | 8.7 | 263.0 | 83.3 | This work |

| IP-GNP | 0.05 vol% | 15.72 | 7.55 | 108.2 | 72 | [22] |

| DSPU | / | 4.18 | 8.42 | 101.4 | 88 | [53] |

| TiO2 | 3 wt% | 29.8 | 25.7 | 15.9 | / | [54] |

| MDIBN | / | 20.64 | 17.47 | 18.1 | / | [55] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, M.; Zhang, J.; Li, Y.; Qi, Z.; Liu, J.; Liu, Z.; Han, S. Enhancing Mechanical, Impact, and Corrosion Resistance of Self-Healable Polyaspartic Ester Polyurea via Surface Modified Graphene Nanoplatelets. Coatings 2025, 15, 1111. https://doi.org/10.3390/coatings15091111

Xu M, Zhang J, Li Y, Qi Z, Liu J, Liu Z, Han S. Enhancing Mechanical, Impact, and Corrosion Resistance of Self-Healable Polyaspartic Ester Polyurea via Surface Modified Graphene Nanoplatelets. Coatings. 2025; 15(9):1111. https://doi.org/10.3390/coatings15091111

Chicago/Turabian StyleXu, Mingyao, Jisheng Zhang, Yuhui Li, Ziyu Qi, Jiahua Liu, Zhanjun Liu, and Sensen Han. 2025. "Enhancing Mechanical, Impact, and Corrosion Resistance of Self-Healable Polyaspartic Ester Polyurea via Surface Modified Graphene Nanoplatelets" Coatings 15, no. 9: 1111. https://doi.org/10.3390/coatings15091111

APA StyleXu, M., Zhang, J., Li, Y., Qi, Z., Liu, J., Liu, Z., & Han, S. (2025). Enhancing Mechanical, Impact, and Corrosion Resistance of Self-Healable Polyaspartic Ester Polyurea via Surface Modified Graphene Nanoplatelets. Coatings, 15(9), 1111. https://doi.org/10.3390/coatings15091111