Influence of Wood Fiber on Mechanical and Thermal Insulation Properties of Lightweight Mortar

Abstract

1. Introduction

2. Experiment Overview

2.1. Experimental Materials

2.2. Sample Design

2.3. Test Method

2.3.1. Mechanical Property Test

2.3.2. Tensile Bond Strength

2.3.3. Thermal Conductivity Testing Method

2.3.4. LF-NMR Measurements

2.3.5. Scanning Electron Microscopy (SEM)

3. Results and Discussion

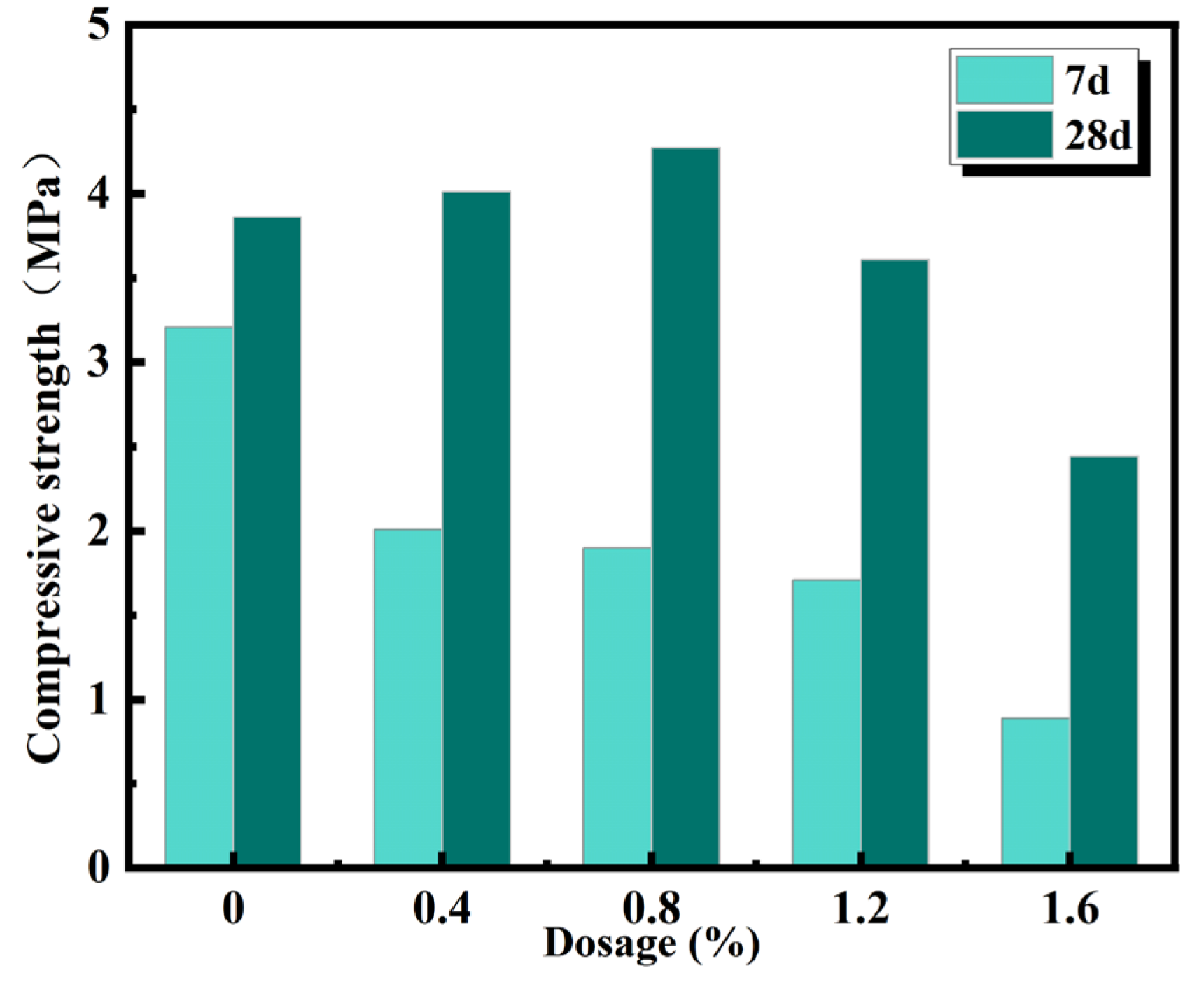

3.1. Compressive Strength Test

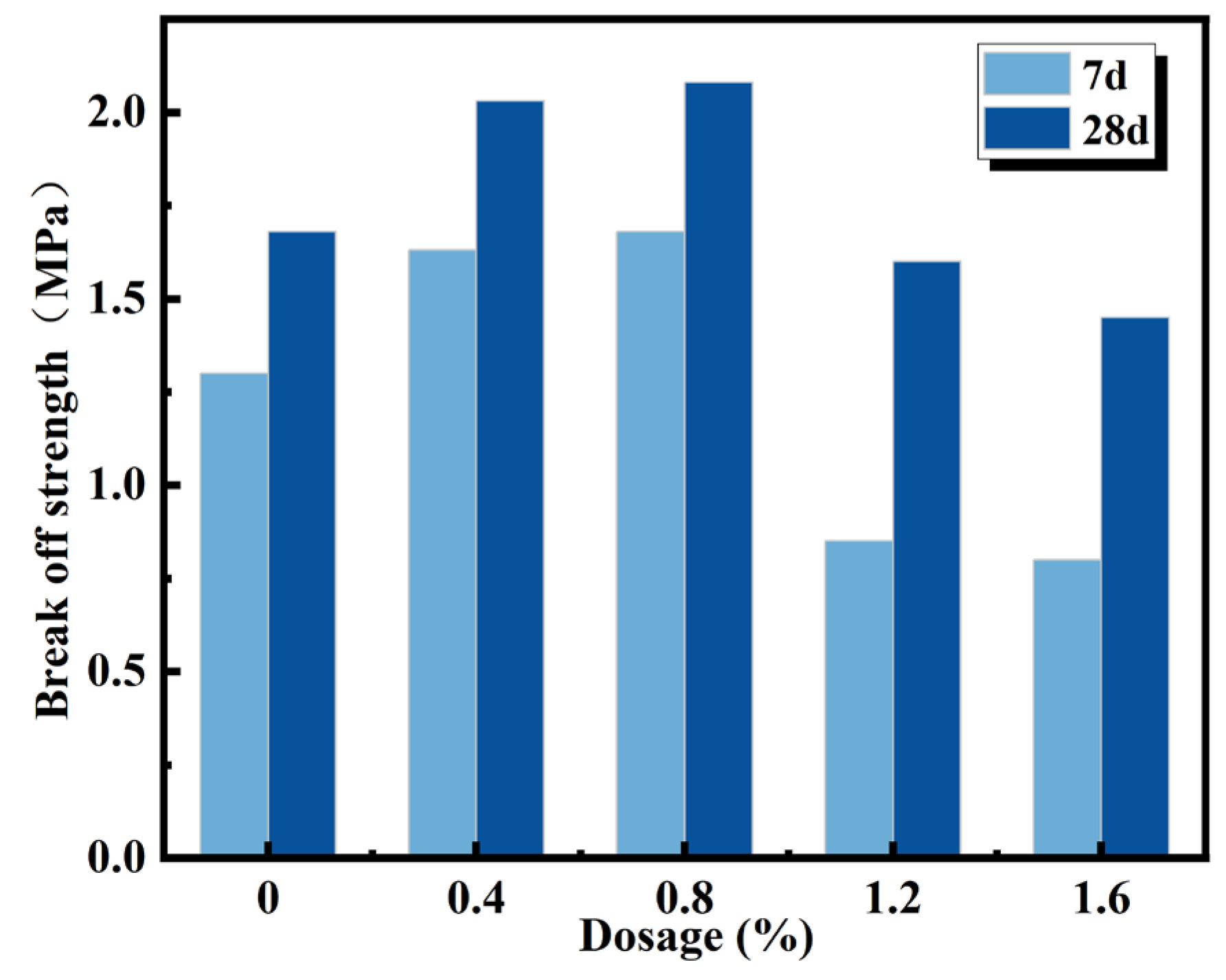

3.2. Flexural Strength Test

3.3. Tensile Bond Testing of Mortars

3.4. Thermal Conductivity Test

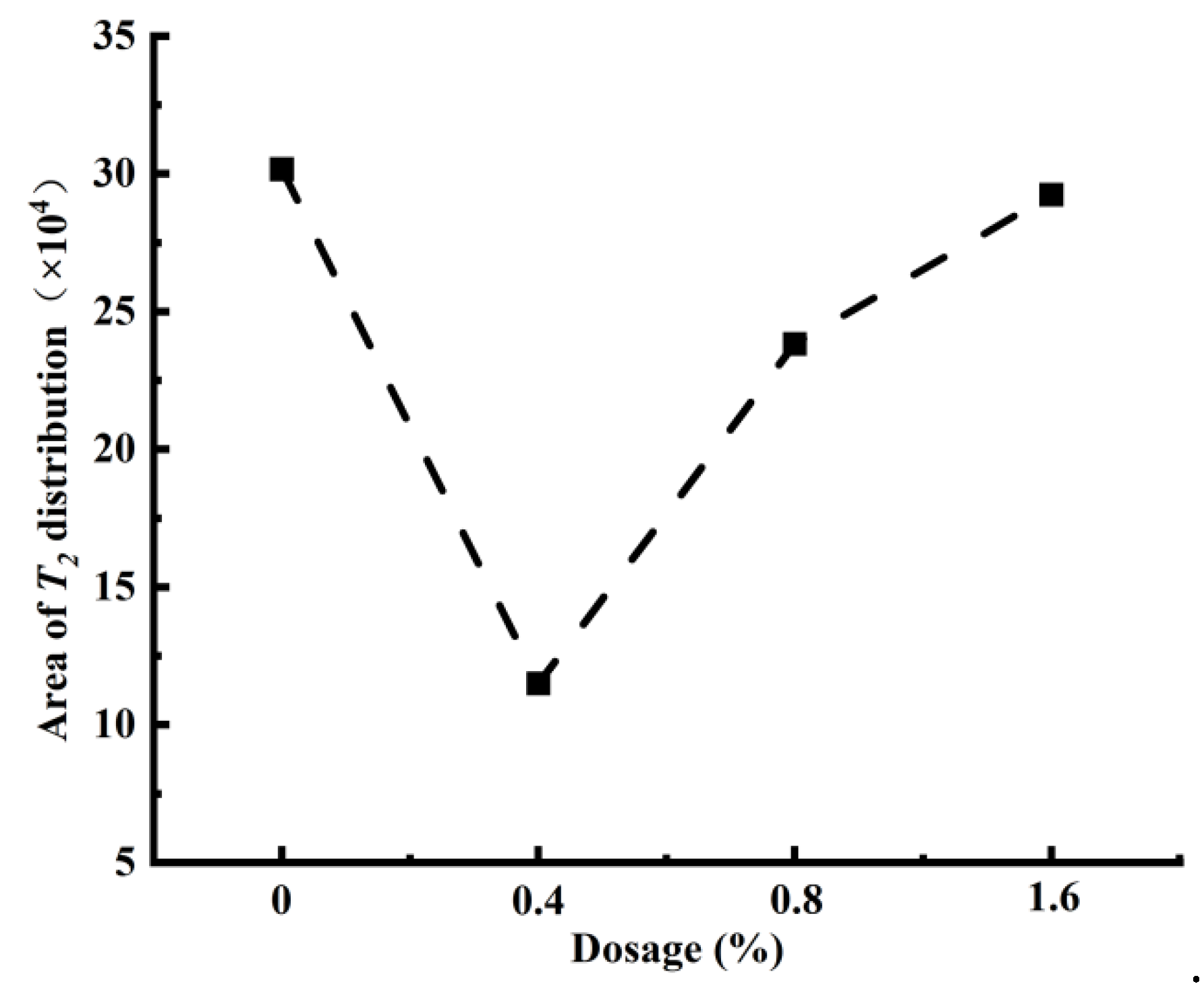

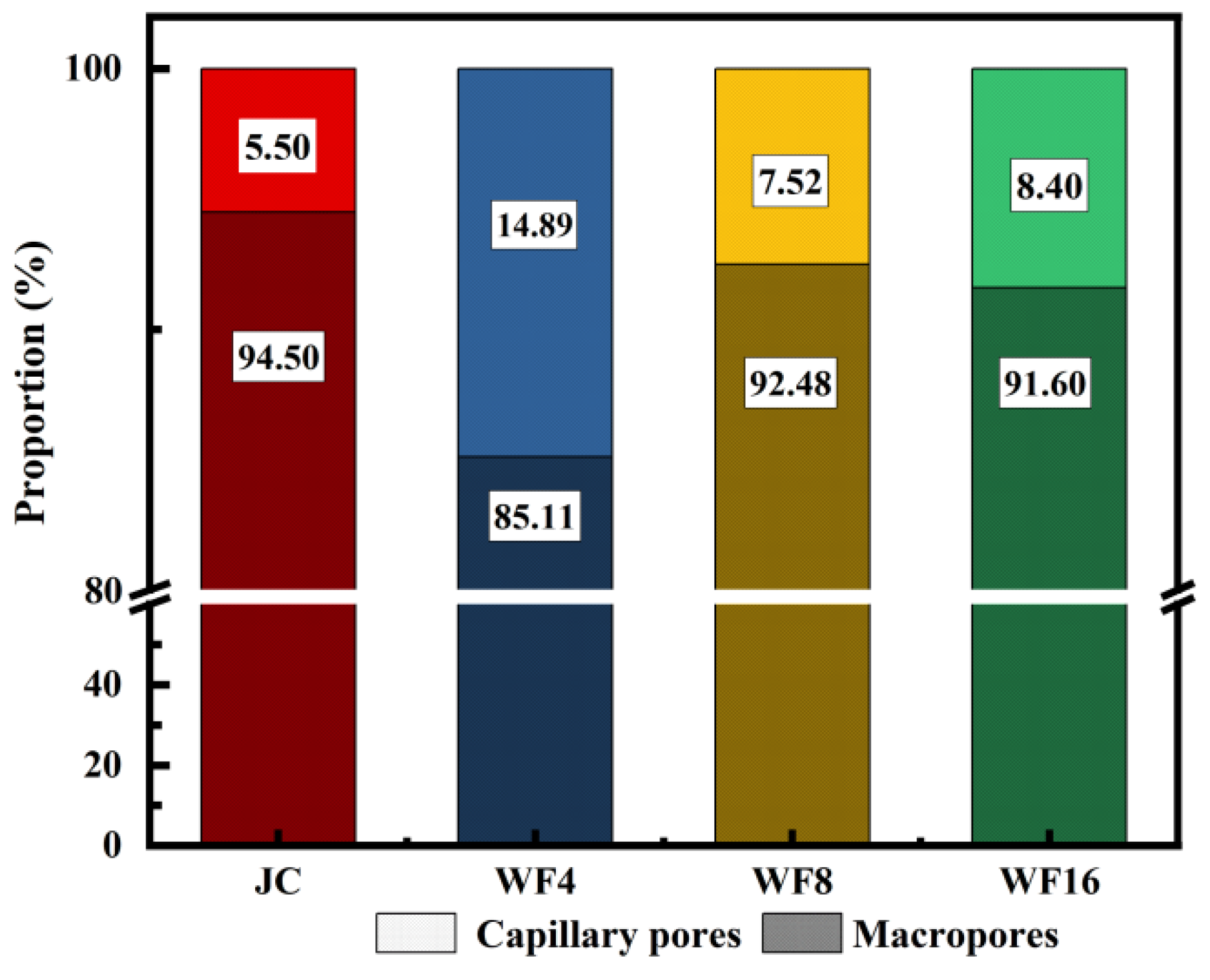

3.5. T2 Spectrum of Mortar

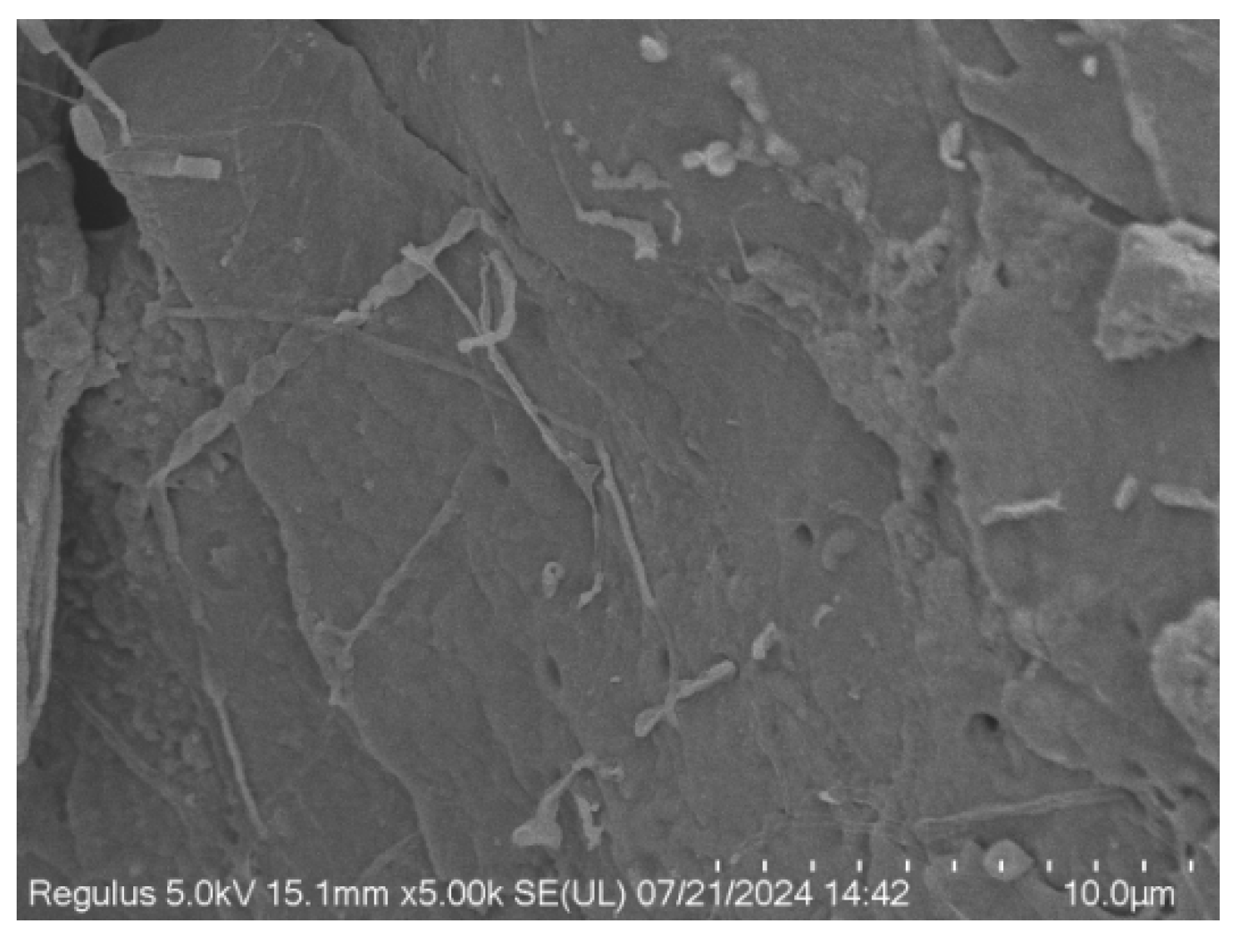

3.6. SEM Analysis of the Interface Between Plant Fiber and Lightweight Mortar

4. Conclusions

- Appropriate wood fiber dosages (0.4%–0.8%) significantly improved the mechanical properties of lightweight mortar. At 28 days, compressive strength increased by up to 10.6%, while flexural strength and tensile bond strength were enhanced by approximately 23.8% and 14.8%, respectively. These improvements can be attributed to the fibers’ ability to fill voids, form reinforcing skeleton structures, and bridge microcracks.

- Wood fibers exhibited a positive effect on the thermal performance of mortar. At a dosage of 0.4%, the thermal conductivity decreased to a minimum of 0.16 W/(m·K), owing to the fibers’ hollow and porous structures combined with their uniform dispersion, which optimized pore morphology, reduced heat conduction pathways, and suppressed convective heat transfer.

- Pore structure analysis revealed that low fiber dosages markedly reduced total porosity (by as much as 61.9%) while simultaneously increasing the proportion of capillary pores. This dual effect contributed to both improved thermal insulation and enhanced mechanical strength. However, when the fiber dosage reached or exceeded 1.2%, agglomeration effects introduced structural heterogeneity and stress concentrations, leading to performance deterioration.

- The optimal wood fiber content in lightweight mortar should be kept below 0.8%, within which it can significantly improve mechanical and thermal insulation properties while promoting the reuse of forestry residues and supporting green building. Future work will verify these findings on larger elements and under on-site conditions to assess feasibility and long-term performance.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wan, Y.; Zhang, W.; Chen, R.; Zhang, L.; Zhang, Y. A novel cellulose ether cross-linking modification and its effect mechanism on the properties of cementitious materials. Constr. Build. Mater. 2024, 447, 138150. [Google Scholar] [CrossRef]

- Liu, S.; Li, Q.; Zhang, J.; Zhao, K.; Wang, L.; Zhang, Z. Research on mechanical properties of high-strength thermal insulation mortar. Constr. Build. Mater. 2024, 420, 135260. [Google Scholar] [CrossRef]

- Zelder, S.; Rosin, A.; Helling, D.; Gerdes, T.; Scharfe, F.; Schafföner, S. Mineral composite plaster containing hollow glass microspheres and CSA cement for building insulation. Appl. Sci. 2022, 12, 1152. [Google Scholar] [CrossRef]

- Romero, M.; Padilla, I.; García Calvo, J.L.; Carballosa, P.; Pedrosa, F.; López-Delgado, A. Development of lightweight mortars using sustainable low-density glass aggregates from secondary raw materials. Materials 2023, 16, 6281. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, C.; Lin, X.; Ye, Y.; Ye, X.; Ji, T. Bond between alkali-activated steel slag/fly ash lightweight mortar and concrete substrates: Strength and microscopic interactions. Constr. Build. Mater. 2024, 449, 138401. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, W.; Zhang, S.; Hou, J. Performance study of lightweight insulating mortar reinforced with straw fiber. Materials 2023, 16, 2266. [Google Scholar] [CrossRef] [PubMed]

- Wyrzykowski, M.; Trtik, P.; Münch, B.; Weiss, J.; Vontobel, P.; Lura, P. Plastic shrinkage of mortars with shrinkage reducing admixture and lightweight aggregates studied by neutron tomography. Cem. Concr. Res. 2015, 73, 238–245. [Google Scholar] [CrossRef]

- Solak, A.M.; Tenza-Abril, A.J.; Baeza-Brotons, F.; Benavente, D. Proposing a new method based on image analysis to estimate the segregation index of lightweight aggregate concretes. Materials 2019, 12, 3642. [Google Scholar] [CrossRef] [PubMed]

- Guo, W.; Wang, Z.; Bao, F.; Chang, L. The status and trend of natural fiber/biodegradable plastic bio-composites. Sci. Silvae Sin. 2008, 44, 157–162. [Google Scholar]

- Adamu, M.; Alanazi, F.; Ibrahim, Y.E.; Alanazi, H.; Khed, V.C. A comprehensive review on sustainable natural fiber in cementitious composites: The date palm fiber case. Sustainability 2022, 14, 6691. [Google Scholar] [CrossRef]

- Jaffur, N.; Jeetah, P. Production of low cost paper from Pandanus utilis fibres as a substitution to wood. Sustain. Environ. Res. 2019, 29, 20. [Google Scholar] [CrossRef]

- Sari, N.H.; Wardana, I.N.G.; Irawan, Y.S.; Siswanto, E. The effect of sodium hydroxide on chemical and mechanical properties of corn husk fiber. Orient. J. Chem. 2017, 33, 3037–3042. [Google Scholar] [CrossRef]

- Merta, I.; Tschegg, E.K. Fracture energy of natural fibre reinforced concrete. Constr. Build. Mater. 2013, 40, 991–997. [Google Scholar] [CrossRef]

- Teixeira, F.P.; Lima, V.N.; Moutinho, D.J.C.; Fujiyama, R.T. Mechanical properties and fractography of cement-based composites reinforced by natural piassava and jute fibers. Cerâmica 2022, 68, 60–66. [Google Scholar] [CrossRef]

- Alvarez, V.A.; Ruscekaite, R.A.; Vazquez, A. Mechanical properties and water absorption behavior of composites made from a biodegradable matrix and alkaline-treated sisal fibers. J. Compos. Mater. 2003, 37, 1575–1588. [Google Scholar] [CrossRef]

- Soltan, D.G.; das Neves, P.; Olvera, A.; Junior, H.S.; Li, V.C. Introducing a curauá fiber reinforced cement-based composite with strain-hardening behavior. Ind. Crops Prod. 2017, 103, 1–12. [Google Scholar] [CrossRef]

- Chen, X. Appendix 1 Assessment of wood residues in China. In ASIA-PACIFIC FORESTRY COMMISSION, Trash or Treasure? Logging and Mill Residues in Asia and the Pacific; FAO: Rome, Italy, 2001. [Google Scholar]

- Fang, W.; Evangeliou, N.; Eckhardt, S.; Xing, J.; Zhang, H.; Xiao, H.; Zhao, M.; Kim, S.-W. Increased contribution of biomass burning to haze events in Shanghai since China’s clean air actions. Commun. Earth Environ. 2023, 4, 310. [Google Scholar] [CrossRef]

- Qiu, Y.; Pang, Q.; He, Y.; Cui, X. Extraction of xylan from sugarcane bagasse through mild hydrothermal treatment with phosphoric acid-based porous geopolymers. J. Clean. Prod. 2024, 448, 141640. [Google Scholar] [CrossRef]

- GB/T 17671-2021; Test Method for Strength of Cementitious Sand (ISO Method). Chinese Standard Press: Beijing, China, 2021. (In Chinese)

- JGJ/T70-2009; Standard Test Methods for Basic Performance of Building Mortar. Chinese Standard Press: Beijing, China, 2009. (In Chinese)

- GB/T 10295-2008; Determination of Steady-State Thermal Resistance and Related Properties of Thermal Insulation Materials—Heat Flow Meter Method. Chinese Standard Press: Beijing, China, 2008. (In Chinese)

- Li, G.; Yu, Y.; Li, J.; Wang, Y. Research on adaptability between crop-stalk fibers and cement. Cem. Concr. Res. 2004, 34, 1081–1085. [Google Scholar] [CrossRef]

- Chakraborty, S.; Kundu, S.P.; Roy, A.; Adhikari, B.; Majumder, S. Polymer modified jute fibre as reinforcing agent controlling the physical and mechanical characteristics of cement mortar. Constr. Build. Mater. 2013, 49, 214–222. [Google Scholar] [CrossRef]

- Santos, R.F.; Ribeiro, J.C.L.; De Carvalho, J.M.F.; Magalhães, W.L.E.; Pedroti, L.G.; Nalon, G.H.; De Lima, G.E.S. Nanofibrillated cellulose and its applications in cement-based composites: A review. Constr. Build. Mater. 2021, 288, 123122. [Google Scholar] [CrossRef]

- Gbekou, F.K.; Boudenne, A.; Eddhahak, A.; Benzarti, K. Mechanical and thermal properties of cement mortar composites incorporating micronized miscanthus fibers. J. Mater. Res. Technol. 2023, 26, 7649–7664. [Google Scholar] [CrossRef]

- Zhao, K.; Xue, S.; Zhang, P.; Tian, Y.; Li, P. Application of natural plant fibers in cement-based composites and the influence on mechanical properties and mass transport. Materials 2019, 12, 3498. [Google Scholar] [CrossRef]

- Jiang, D.; Lv, S.; Cui, S.; Sun, S.; Song, X.; He, S.; Zhang, J.; An, P. Effect of thermal insulation components on physical and mechanical properties of plant fibre composite thermal insulation mortar. J. Mater. Res. Technol. 2020, 9, 12996–13013. [Google Scholar] [CrossRef]

- Ajabshir, S.; Gupta, R. Effects of Pretreatment Methods and Physical Properties of Cellulose Fibers on Compatibility of Fiber-Cement Composites: A Review. In Interdisciplinary Symposium on Smart & Sustainable Infrastructures; Springer Nature: Cham, Switzerland, 2023; pp. 253–264. [Google Scholar]

- Awwad, E.; Mabsout, M.; Hamad, B.; Farran, M.T.; Khatib, H. Studies on fiber-reinforced concrete using industrial hemp fibers. Constr. Build. Mater. 2012, 35, 710–717. [Google Scholar] [CrossRef]

- Mydin, M.A.O.; Abdullah, M.M.A.B.; Sor, N.H.; Omar, R.; Dulaimi, A.; Awoyera, P.O.; Althoey, F.; Deifalla, A.F. Thermal conductivity, microstructure and hardened characteristics of foamed concrete composite reinforced with raffia fiber. J. Mater. Res. Technol. 2023, 26, 850–864. [Google Scholar] [CrossRef]

- Yu, B.; Li, S.; Zhu, H.; Jiang, Q.; Wang, D.; Chen, Y. A composite phase change material for improving the freeze–thaw resistance performance of cement mortars. Constr. Build. Mater. 2023, 387, 131657. [Google Scholar] [CrossRef]

- Yu, L.; Zhang, J.; Zhang, J.; Ma, B. Quantitative relationship model between macroscopic properties and pore structure of cement concrete. J. Harbin Eng. Univ. 2015, 36, 1459–1464. (In Chinese) [Google Scholar]

- Dong, M.; Li, S.; Yu, B.; Jiang, Q.; Zhu, H.; Zhao, J.; Huang, J.; Tao, S. Experimental investigation on the freeze-thaw durability of a phase change concrete in cold regions. Cold Reg. Sci. Technol. 2024, 218, 104102. [Google Scholar] [CrossRef]

- Xiong, H.; Yuan, K.; Xu, J.; Wen, M. Pore structure, adsorption, and water absorption of expanded perlite mortar in external thermal insulation composite system during aging. Cem. Concr. Compos. 2021, 116, 103900. [Google Scholar] [CrossRef]

| Property | PH Value | Chemical Content (mg/L) | Carbonate Content (mg/L) | Bicarbonate Content (mg/L) |

|---|---|---|---|---|

| Value | 7.3 | 51 | 65 | 60 |

| Specific Surface Area (m2/kg) | Setting Time (min) | Flexural Strength (MPa) | Compressive Strength (MPa) | Loss on Ignition (%) | |||

|---|---|---|---|---|---|---|---|

| Initial setting | Final setting | 3 d | 28 d | 3 d | 28 d | ||

| 364 | 158 | 256 | 5.7 | 8.5 | 27.5 | 53.6 | 3.16 |

| Apparent Density (kg/m3) | Loose Bulk Density (kg/m3) | Voids Ratio (%) | Content of Fine Particles (%) | Content of Mud Lumps (%) | Water Content (%) | Crushing Value (%) |

|---|---|---|---|---|---|---|

| 2520 | 1510 | 40 | 10.9 | 1.2 | 20 | 2.3 |

| Property | Density (Kg/m3) | Compressive Strength (KPa) | Thermal Conductivity (W/(m·K)) | Water Absorption Rate (%) | Surface Porosity (%) | Water Retention Rate (%) |

|---|---|---|---|---|---|---|

| Performance | 102 | 196 | 0.042 | 16 | 95 | 93 |

| Fiber Type | Water Absorption Rate (%) | Water Content (%) | Bulk Density (kg/m3) | Length to Diameter Ratio (%) |

|---|---|---|---|---|

| Wood Fiber | 310.5 | 12 | 170 | 1.14–3.28 |

| Sample | Cement (g) | Mechanical Sand (g) | Glass Microspheres (g) | Water (g) | Cellulose (g) | Expansive Agent Powder (g) | Fiber (%) |

|---|---|---|---|---|---|---|---|

| JC | 350 | 500 | 150 | 400 | 2.5 | 4 | 0 |

| WF4 | 350 | 500 | 150 | 400 | 2.5 | 4 | 4 |

| WF8 | 350 | 500 | 150 | 400 | 2.5 | 4 | 8 |

| WF12 | 350 | 500 | 150 | 400 | 2.5 | 4 | 12 |

| WF16 | 350 | 500 | 150 | 400 | 2.5 | 4 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, M.; Ban, G.; Luo, Y.; Hu, Q.; Zhang, J.; Yu, K.; Hong, X.; Zhong, H. Influence of Wood Fiber on Mechanical and Thermal Insulation Properties of Lightweight Mortar. Coatings 2025, 15, 1094. https://doi.org/10.3390/coatings15091094

Zhou M, Ban G, Luo Y, Hu Q, Zhang J, Yu K, Hong X, Zhong H. Influence of Wood Fiber on Mechanical and Thermal Insulation Properties of Lightweight Mortar. Coatings. 2025; 15(9):1094. https://doi.org/10.3390/coatings15091094

Chicago/Turabian StyleZhou, Mo, Guimeng Ban, Yuanming Luo, Qin Hu, Jintuan Zhang, Ke Yu, Xue Hong, and Huixin Zhong. 2025. "Influence of Wood Fiber on Mechanical and Thermal Insulation Properties of Lightweight Mortar" Coatings 15, no. 9: 1094. https://doi.org/10.3390/coatings15091094

APA StyleZhou, M., Ban, G., Luo, Y., Hu, Q., Zhang, J., Yu, K., Hong, X., & Zhong, H. (2025). Influence of Wood Fiber on Mechanical and Thermal Insulation Properties of Lightweight Mortar. Coatings, 15(9), 1094. https://doi.org/10.3390/coatings15091094