Rotating Bending Fatigue Properties of 30CrNi2Mo Steel After Electropulsing-Assisted Ultrasonic Surface Rolling Process

Abstract

1. Introduction

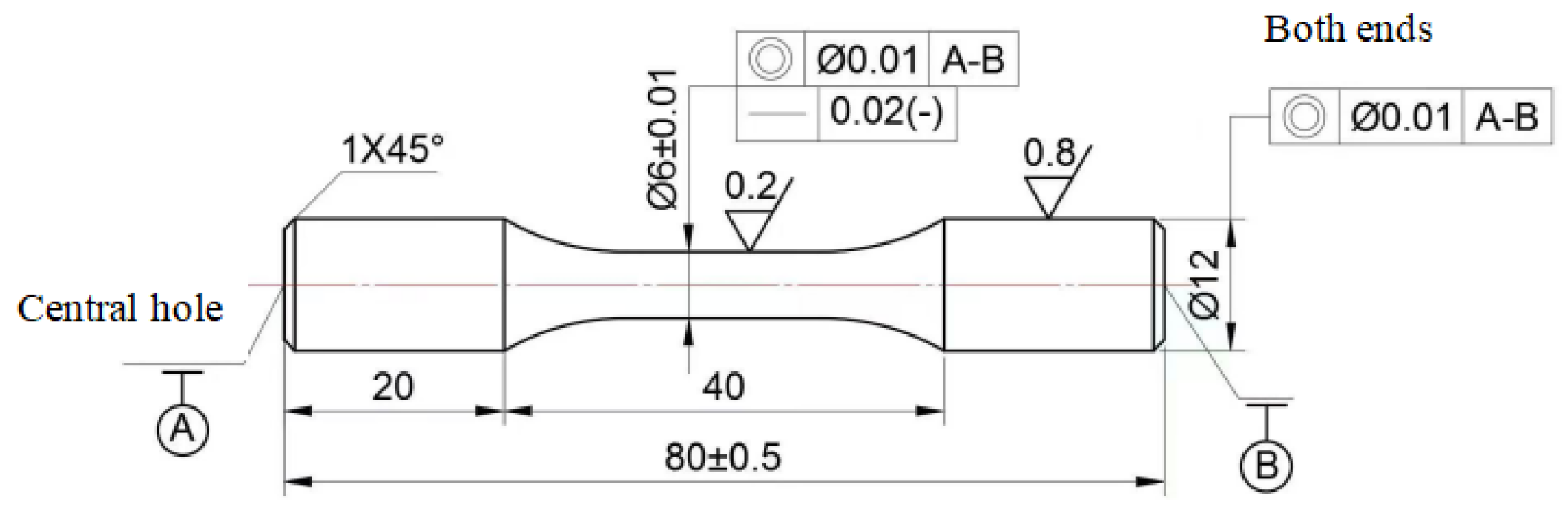

2. Materials and Methods

3. Results and Discussion

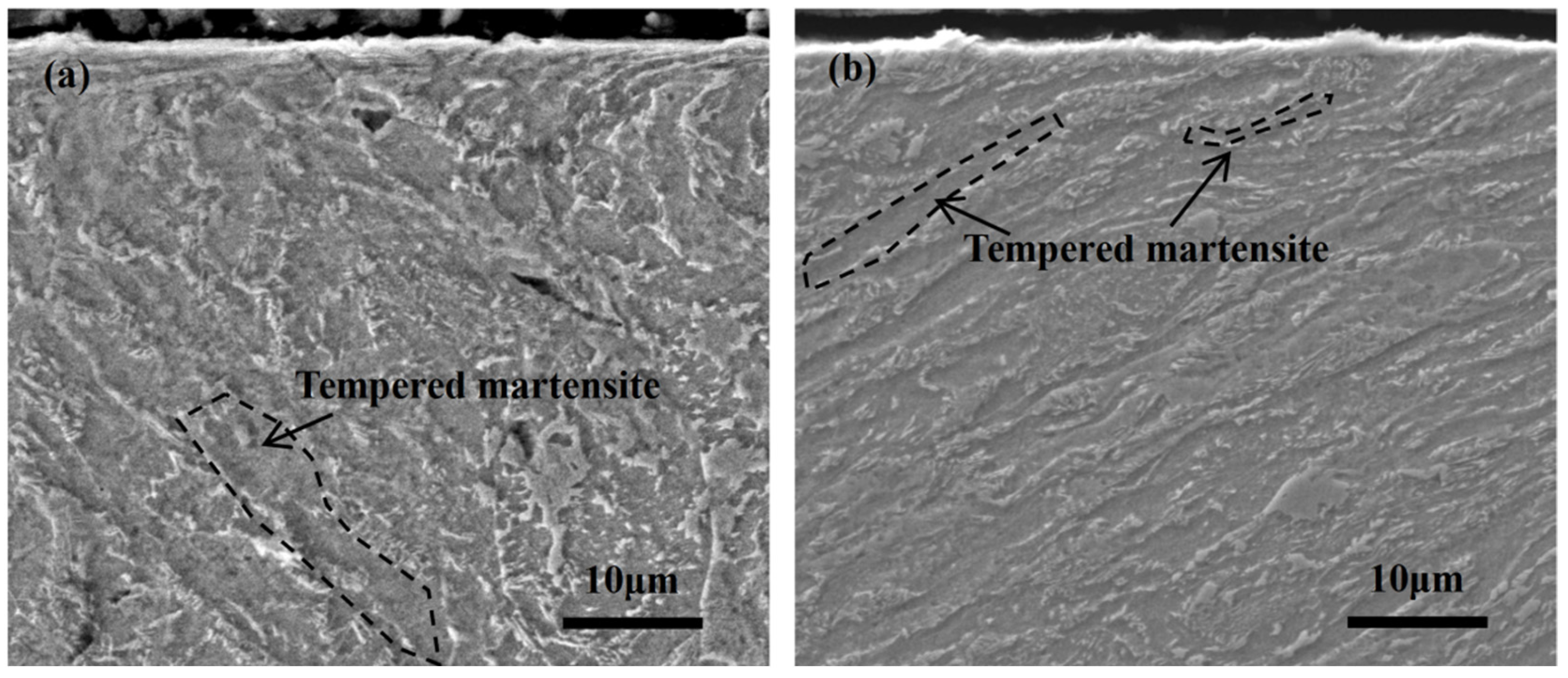

3.1. Surface Microstructure

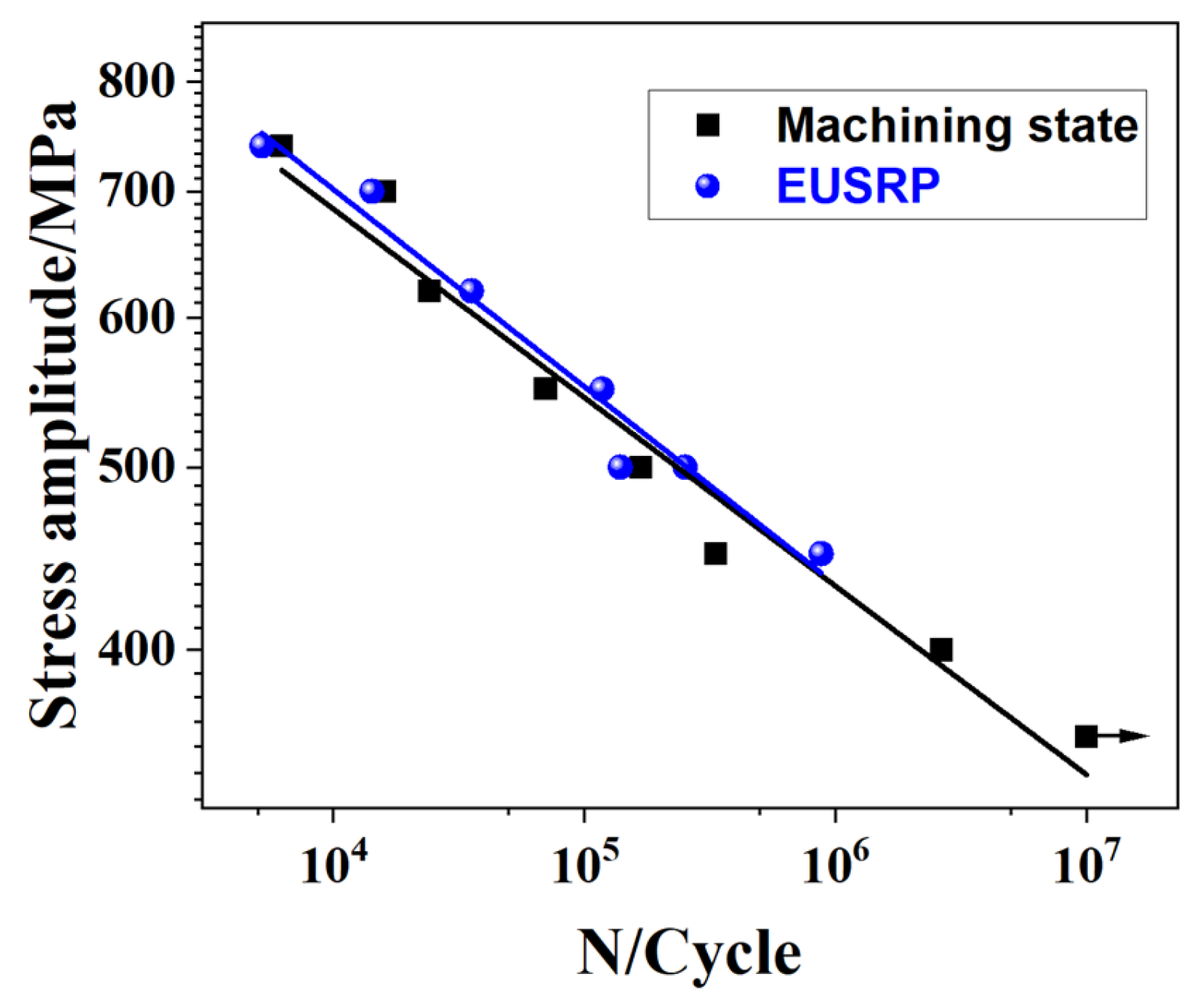

3.2. Mechanical Properties of Steel

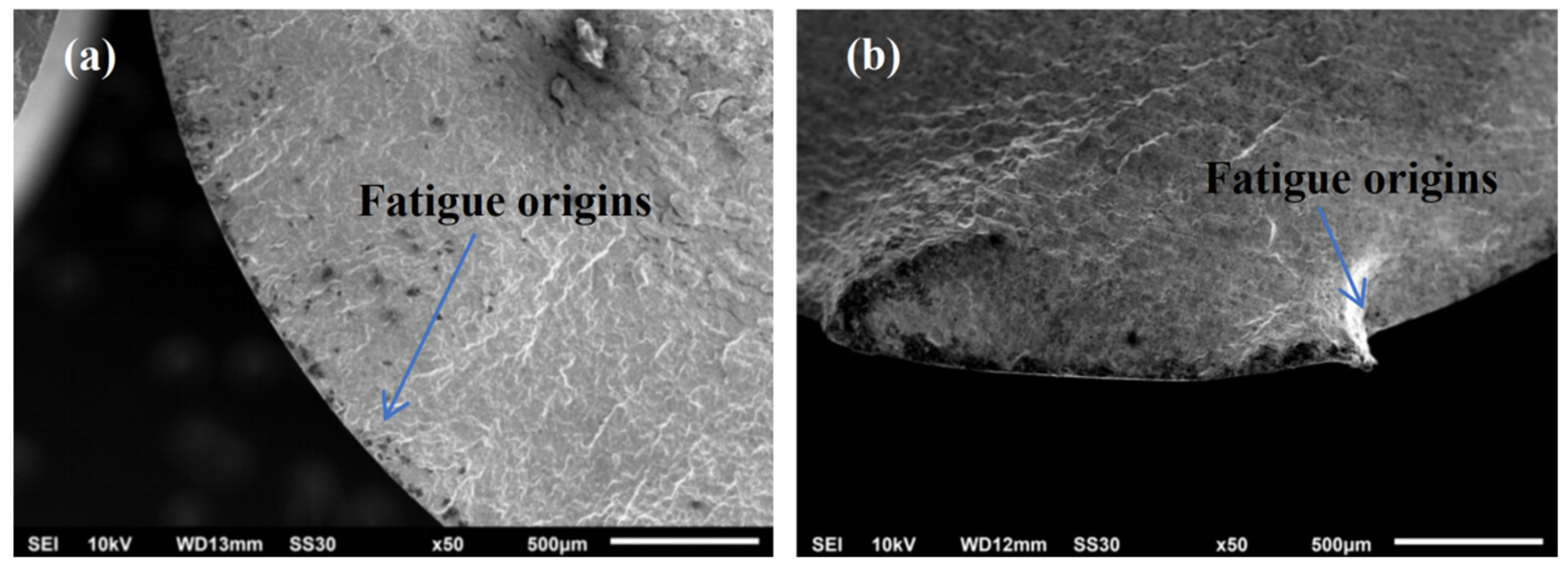

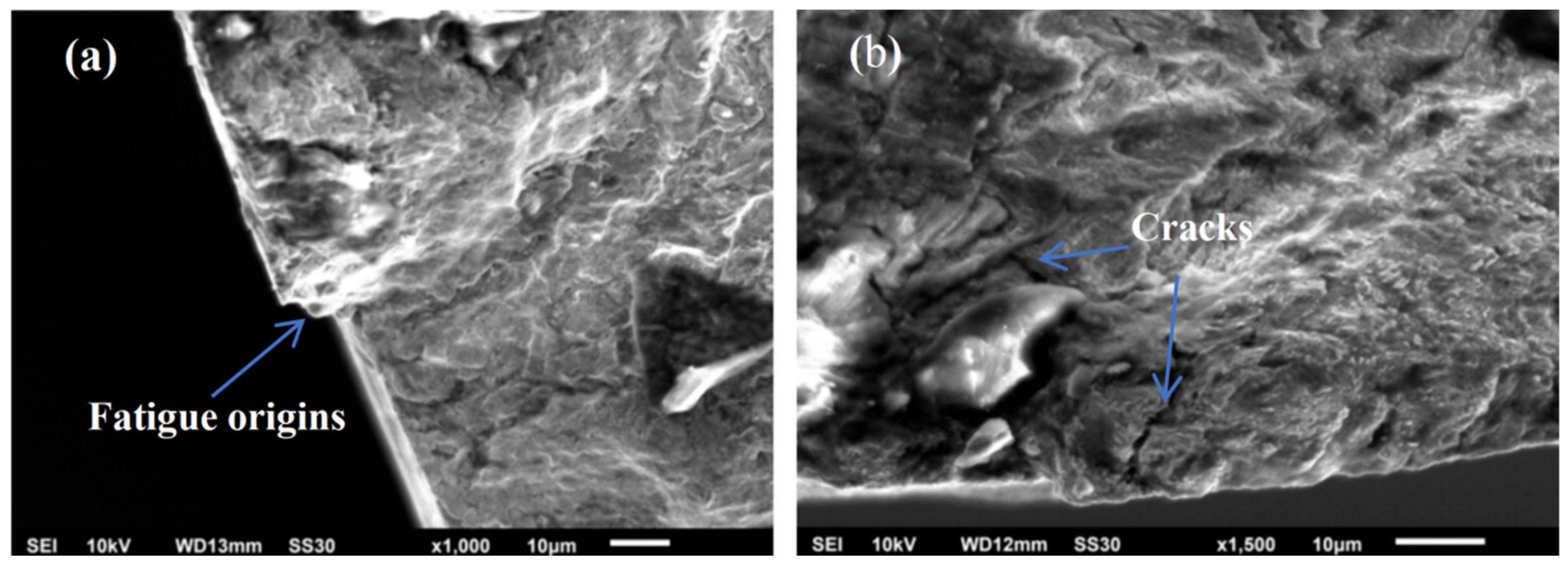

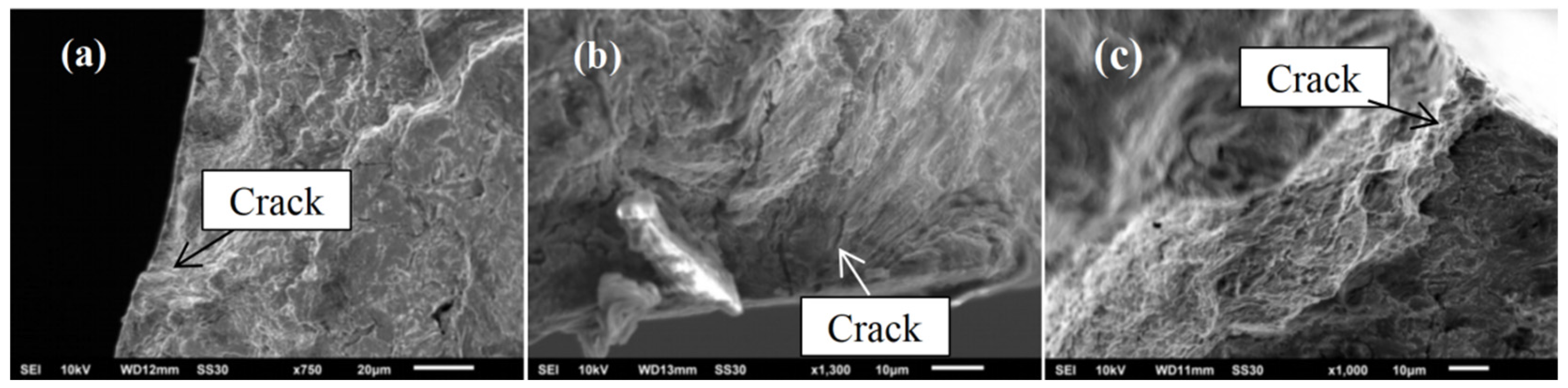

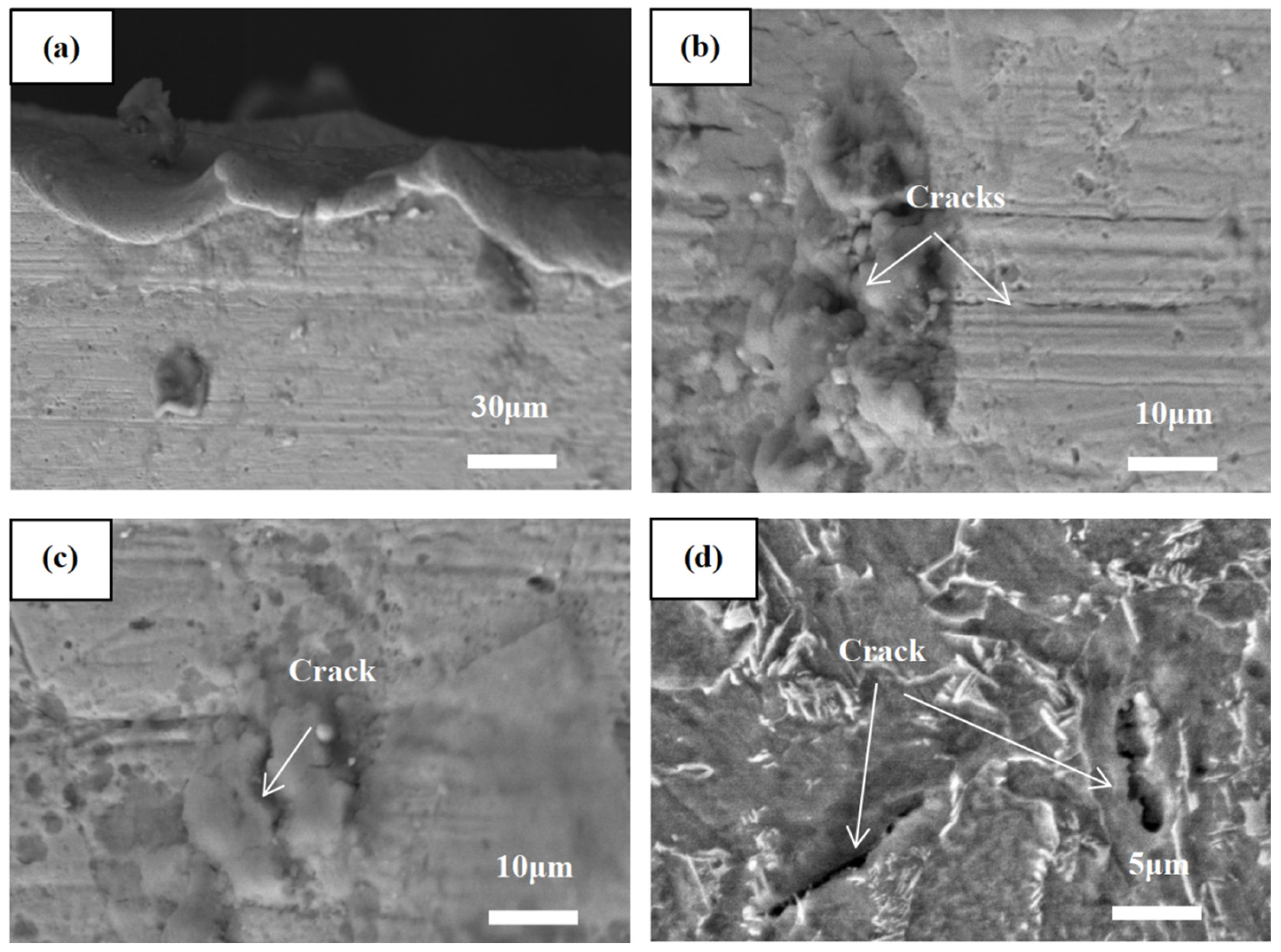

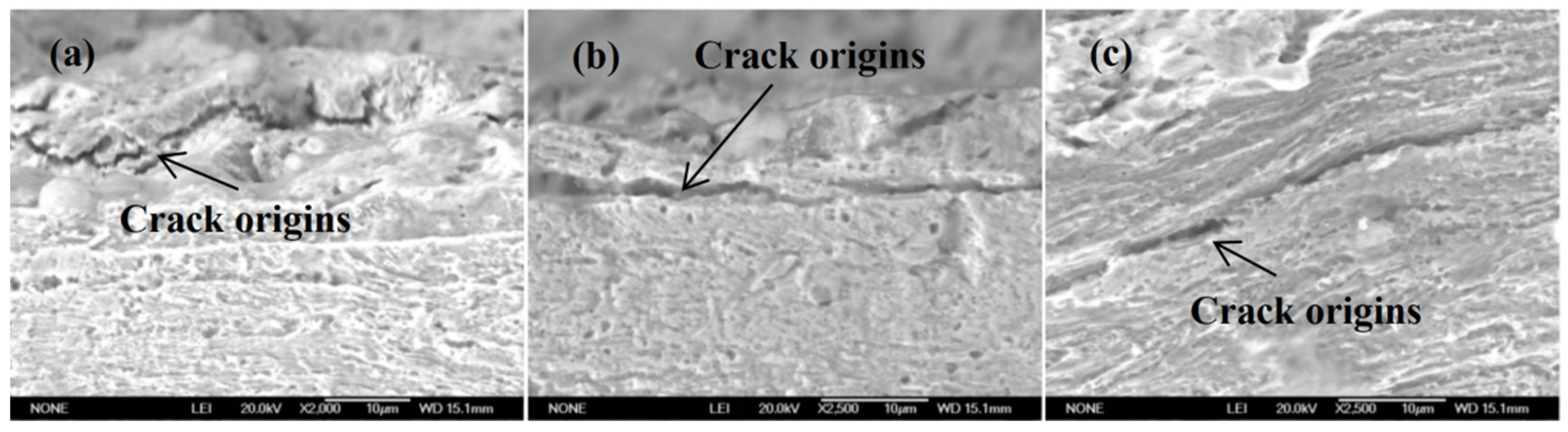

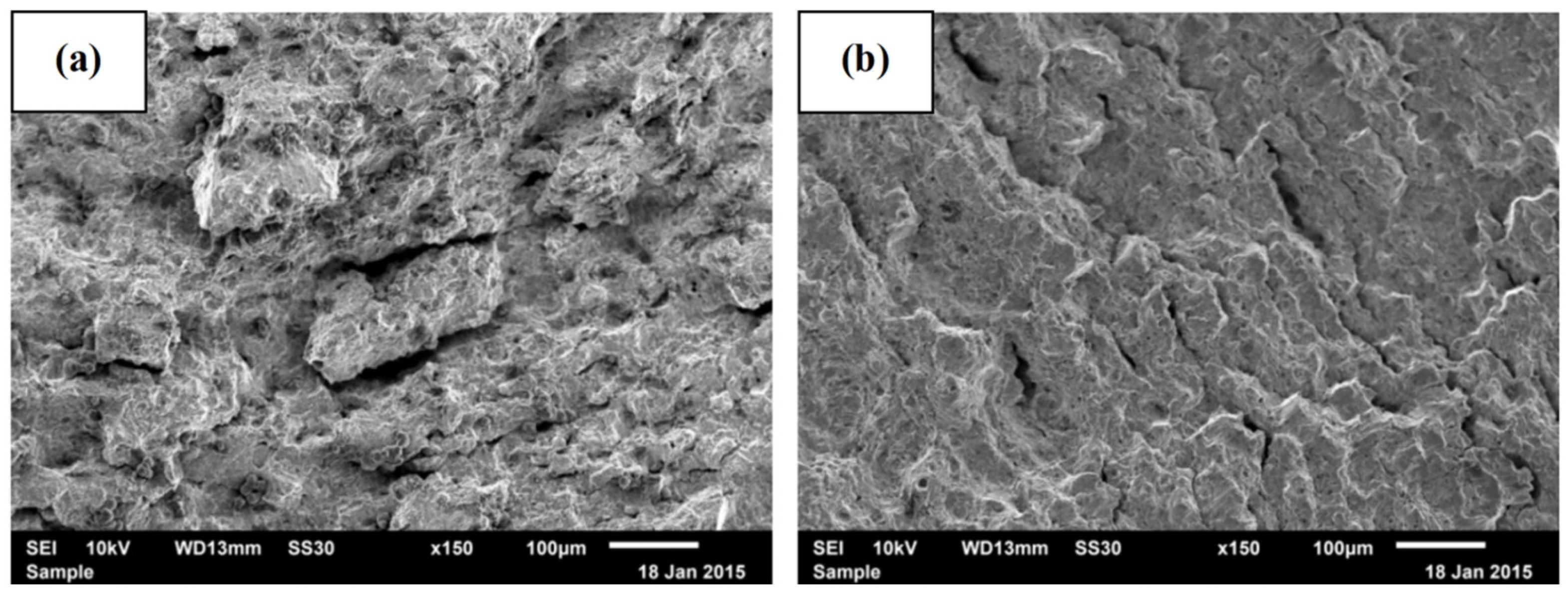

3.3. Fracture Morphology

3.4. Fatigue Crack Initiation and Growth

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, K.; Lv, X.M.; Wang, B.; Lai, Z.; Chen, X.; Wei, D.; Li, S.; Zhang, P. Microstructure and Wear Performance of TaC and Ta/TaC Coatings on 30CrNi2MoVA Steel. Coatings 2024, 14, 1039. [Google Scholar] [CrossRef]

- Zhang, L.; Song, Y.; Wang, X.; Zhou, S.; Ding, Z.; Jin, W.; Gao, Z.; Jiang, Y. A study of fatigue property enhancement of 1045 steel processed by surface mechanical rolling treatment with an emphasis on residual stress influence. Int. J. Fatigue 2024, 189, 108560. [Google Scholar] [CrossRef]

- Soyama, H.; Wong, K.L.; Eakins, D.; Korsunsky, A.M. The effects of submerged laser peening, cavitation peening, and shot peening on the improvement of the torsional fatigue strength of powder bed fused Ti6Al4V produced through laser sintering. Int. J. Fatigue 2024, 185, 108348. [Google Scholar] [CrossRef]

- Li, J.; Wang, L.; Wang, X.; Hu, Z. Effect of shot peening equivalent impact force on fatigue crack growth behavior and fatigue life prediction of train brake discs. Eng. Fail. Anal. 2024, 166, 108914. [Google Scholar] [CrossRef]

- Bielawski, M. Hard chromium plating alternative technologies. Can. Aeronaut. Space J. 2000, 46, 140–149. [Google Scholar]

- Vander, G.J.; Fleischer, W.; Eerden, M.; Hurmans, T. PVD coating as alternative to electroplated chromium. Galvanotechnik 2001, 92, 3058–3066. [Google Scholar]

- Hu, M.; Tang, Y.Y.; Han, X.; Guo, C.; Lu, X.; Pan, M. Failure behavior of Cr coating on PCrNi3MoVA steel under thermal-mechanical factors. Mater. Chem. Phys. 2024, 312, 128691. [Google Scholar] [CrossRef]

- Han, X.; Hu, M.; Tang, Y.Y.; Gao, P.; Gao, Y.; Li, Z. Thermal erosion behavior of electroplating and multi-arc ion plating Cr coatings on PCrNi3MoVA steel. J. Phys. Conf. Ser. 2024, 2921, 012003. [Google Scholar] [CrossRef]

- Xu, C.; Wang, X.; Geng, Y.; Wang, Y.; Sun, Z.; Yu, B.; Tang, Z.; Dai, S. Effect of shot peening on the surface integrity and fatigue property of gear steel 16Cr3NiWMoVNbE at room temperature. Int. J. Fatigue 2023, 172, 107668. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, L.; Shi, D.; Wang, Z.; Jin, H.; Liu, L.; Qu, S.; Ji, V. Surface integrity and tribological behavior of 17Cr2Ni2MoVNb steel under combined carburizing treatment and ultrasonic rolling. Surf. Coat. Technol. 2023, 461, 129371. [Google Scholar] [CrossRef]

- Zhang, Q.; Hu, Z.; Su, W.; Zhou, H.; Liu, C.; Yang, Y.; Qi, X. Microstructure and surface properties of 17—4PH stainless steel by ultrasonic surface rolling technology. Surf. Coat. Technol. 2017, 321, 64–73. [Google Scholar] [CrossRef]

- Wang, P.; Guo, H.; Wang, D.; Duan, H.; Zhang, Y. Microstructure and tribological performances of M50 bearing steel processed by ultrasonic surface rolling. Tribol. Int. 2022, 175, 107818. [Google Scholar] [CrossRef]

- Torres, M.A.; Voorwald, H.J. An evaluation of shot peening, residual stress and stress relaxation on the fatigue life of AISI 4340 steel. Int. J. Fatigue 2002, 877, 877–886. [Google Scholar] [CrossRef]

- Kikuchi, M.; Komine, A.; Kibayashi, Y. Influence of internal oxides on the fatigue strength of carburized steel. J. Soc. Mater. Sci. 1989, 38, 111–116. [Google Scholar] [CrossRef]

- Yang, C.L.; Yang, H.J.; Zhang, Z.J.; Zhang, Z.F. Recovery of tensile properties of twinning-induced plasticity steel via electropulsing induced void healing. Scr. Mater. 2018, 147, 88–92. [Google Scholar] [CrossRef]

- Tan, C.; Yang, T.; Huang, C.; Zhang, J.; Wang, X.; Lu, H.; Wen, L.; Zhang, G. Enhanced strength–ductility synergy in Ti55531 titanium alloys through gradient microstructural design strategy. Mater. Sci. Eng. A 2024, 909, 146823. [Google Scholar] [CrossRef]

- Bao, T.; Tan, C.; Huang, C.; Li, Q.; Fan, Y.; Zhang, G.; Guo, P. Multiscale microstructure regulation and synergistic strengthening mechanisms in Ti-6Al-4V alloy via electropulsing treatment. J. Alloys Compd. 2025, 1035, 181526. [Google Scholar] [CrossRef]

- Zhou, Y.; Xu, X.; Zhao, Y.; Yan, X.; Wei, L.; Wu, Z.; Wu, C. Introducing ω and O′ nanodomains in Ti-6Al-4V: The mechanism of accelerating α→ β transformation kinetics via electropulsing. J. Mater. Sci. Technol. 2023, 162, 109–117. [Google Scholar] [CrossRef]

- Chen, K.; Zhan, L.; Yu, W. Rapidly modifying microstructure and mechanical properties of AA7150 Al alloy processed with electropulsing treatment. J. Mater. Sci. Technol. 2021, 95, 172–179. [Google Scholar] [CrossRef]

- Gao, J.B.; Ben, D.D.; Yang, H.J.; Meng, L.; Ji, H.; Lian, D.; Chen, J.; Yi, J.; Wang, L.; Li, P.; et al. Effects of electropulsing on the microstructure and microhardness of a selective laser melted Ti6Al4V alloy. J. Alloys Compd. 2021, 875, 160044. [Google Scholar] [CrossRef]

- GB/T4337-2015; Metallic Materials—Fatigue Testing—Rotating Bar Bending Method. National Standard of the People’s Republic of China: Beijing, China, 2015.

- Duan, C.; Qu, S.; Hu, X.; Jia, S.; Li, X. Microstructures and fatigue behaviors of 25CrNi2MoV steel under electropulsing-assisted ultrasonic surface rolling. Int. J. Fatigue 2022, 158, 106733. [Google Scholar] [CrossRef]

- Gao, M.; Zeng, R.; Hu, J.; Zhang, C.; Hu, X.; Xia, S.; Huang, R.; Li, Q. Further enhancement of surface mechanical properties of carburized 9310 steel by electropulsing-assisted ultrasonic surface rolling process. Surf. Coat. Technol. 2024, 480, 130593. [Google Scholar] [CrossRef]

- Yin, F.; Yi, Y.; Chen, Y.; Cheng, G.J.; Hua, L. Understanding the mechanisms of microstructure refinement and plasticity enhancement of M50 bearing steel fabricated by the electrical pulse assisted cold ring rolling technology. J. Mater. Res. Technol. 2025, 36, 3906–3920. [Google Scholar] [CrossRef]

- Ji, R.; Yang, Z.; Jin, H.; Liu, Y.; Wang, H.; Zheng, Q.; Cheng, W.; Cai, B.; Li, X. Surface nanocrystallization and enhanced surface mechanical properties of nickel-based superalloy by coupled electric pulse and ultrasonic treatment. Surf. Coat. Technol. 2019, 375, 292–302. [Google Scholar] [CrossRef]

- Liu, D.; Ke, Y.; Huang, H.; Tan, C.; Xu, Q.; Li, H. Improvement of Surface Properties of 30CrNi2MoVA Steel with Ultrasonic Composite Strengthening Modification. Coatings 2025, 15, 183. [Google Scholar] [CrossRef]

- Wang, H.; Dang, E.; Jiang, S.; Fan, Y.; Tan, C. Corrosion Fatigue Failure Mechanism of Steels for Hydraulic Fracturing Pump Valve Box. J. Mater. Eng. Perform. 2025, 34, 4217–4229. [Google Scholar] [CrossRef]

- Kermajani, M.; Ghaini, F.M.; Miresmaeili, R.; Baghi-Abadi, M.; Mousavi-Nasab, M. Damage mechanisms in the ultra-low cycle fatigue loading. Eng. Fract. Mech. 2020, 223, 106772. [Google Scholar] [CrossRef]

- Sun, P.; Qu, S.; Duan, C.; Hu, X.; Li, X. Improving the high cycle fatigue property of Ti6Al4V ELI alloy by optimizing the surface integrity through electric pulse combined with ultrasonic surface rolling process. J. Mater. Sci. Technol. 2024, 170, 103–121. [Google Scholar] [CrossRef]

- Qu, S.; Ren, Z.; Hu, X.; Lai, F.; Sun, F.; Li, X.; Yang, C. The effect of electric pulse aided ultrasonic rolling processing on the microstructure evolution, surface properties, and fatigue properties of a titanium alloy Ti5Al4Mo6V2Nb1Fe. Surf. Coat. Technol. 2021, 421, 127408. [Google Scholar] [CrossRef]

- Cong, J.; Gao, J.; Zhou, S.; Wang, N.; Wang, J.; Hui, L. Effect of ultrasonic rolling on crack propagation behavior of Ti6Al4V titanium alloy laser welded joints. Eng. Fract. Mech. 2023, 292, 109618. [Google Scholar]

| Name/Stress Amplitude | 450 MPa | 550 MPa | 620 MPa |

|---|---|---|---|

| Machining state. | 333,087 | 7000 | 24,275 |

| EUSRP. | 877,065 | 117,339 | 35,516 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, D.; Huang, H.; Shen, Y.; Liu, J.; Tan, C.; Fan, H.; Ke, Y. Rotating Bending Fatigue Properties of 30CrNi2Mo Steel After Electropulsing-Assisted Ultrasonic Surface Rolling Process. Coatings 2025, 15, 1075. https://doi.org/10.3390/coatings15091075

Liu D, Huang H, Shen Y, Liu J, Tan C, Fan H, Ke Y. Rotating Bending Fatigue Properties of 30CrNi2Mo Steel After Electropulsing-Assisted Ultrasonic Surface Rolling Process. Coatings. 2025; 15(9):1075. https://doi.org/10.3390/coatings15091075

Chicago/Turabian StyleLiu, Dan, Hongsheng Huang, Yalin Shen, Jie Liu, Changsheng Tan, Haonan Fan, and Yinglin Ke. 2025. "Rotating Bending Fatigue Properties of 30CrNi2Mo Steel After Electropulsing-Assisted Ultrasonic Surface Rolling Process" Coatings 15, no. 9: 1075. https://doi.org/10.3390/coatings15091075

APA StyleLiu, D., Huang, H., Shen, Y., Liu, J., Tan, C., Fan, H., & Ke, Y. (2025). Rotating Bending Fatigue Properties of 30CrNi2Mo Steel After Electropulsing-Assisted Ultrasonic Surface Rolling Process. Coatings, 15(9), 1075. https://doi.org/10.3390/coatings15091075