Ultrasonic-Assisted Spinning V-Groove Moulding Mechanism and Accuracy Research

Abstract

1. Introduction

2. Material and Methods

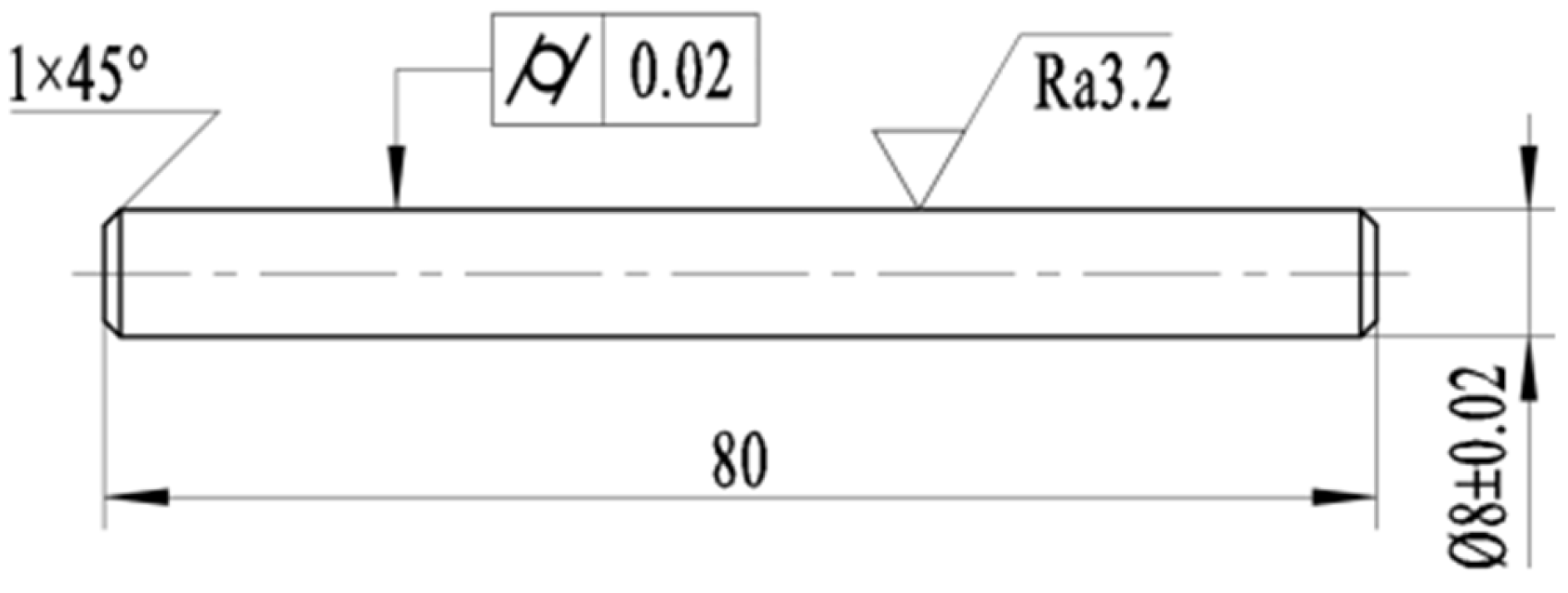

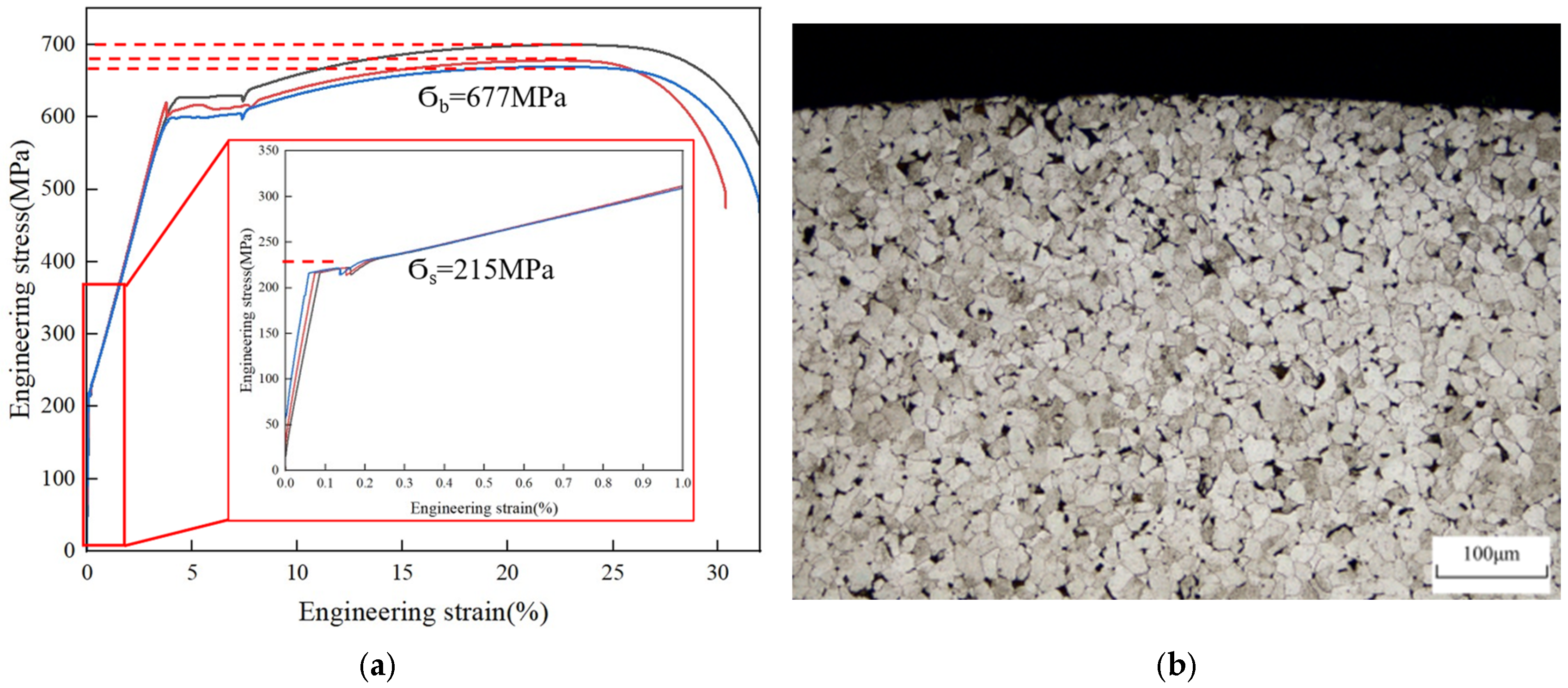

2.1. Materials and Preparation

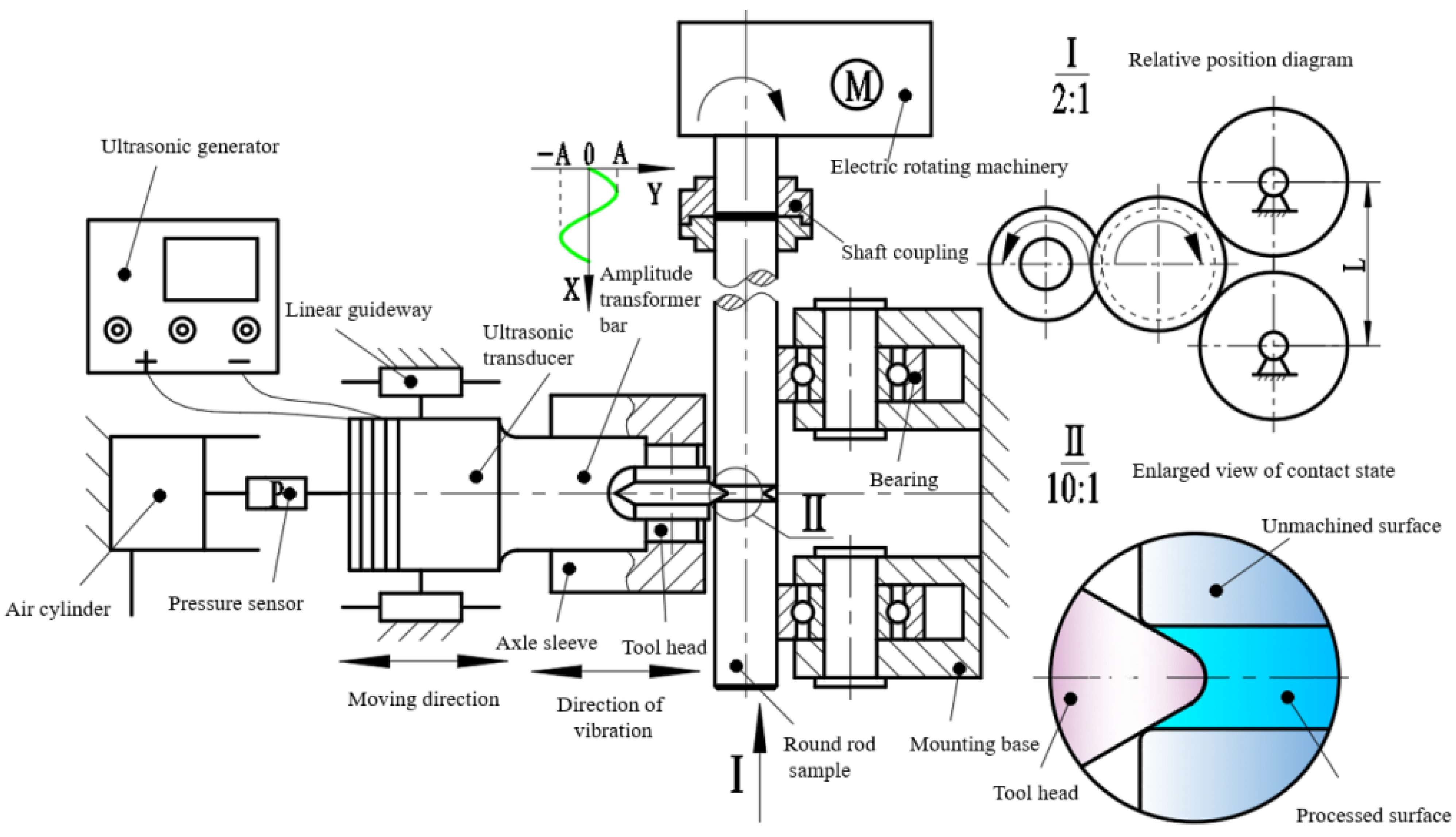

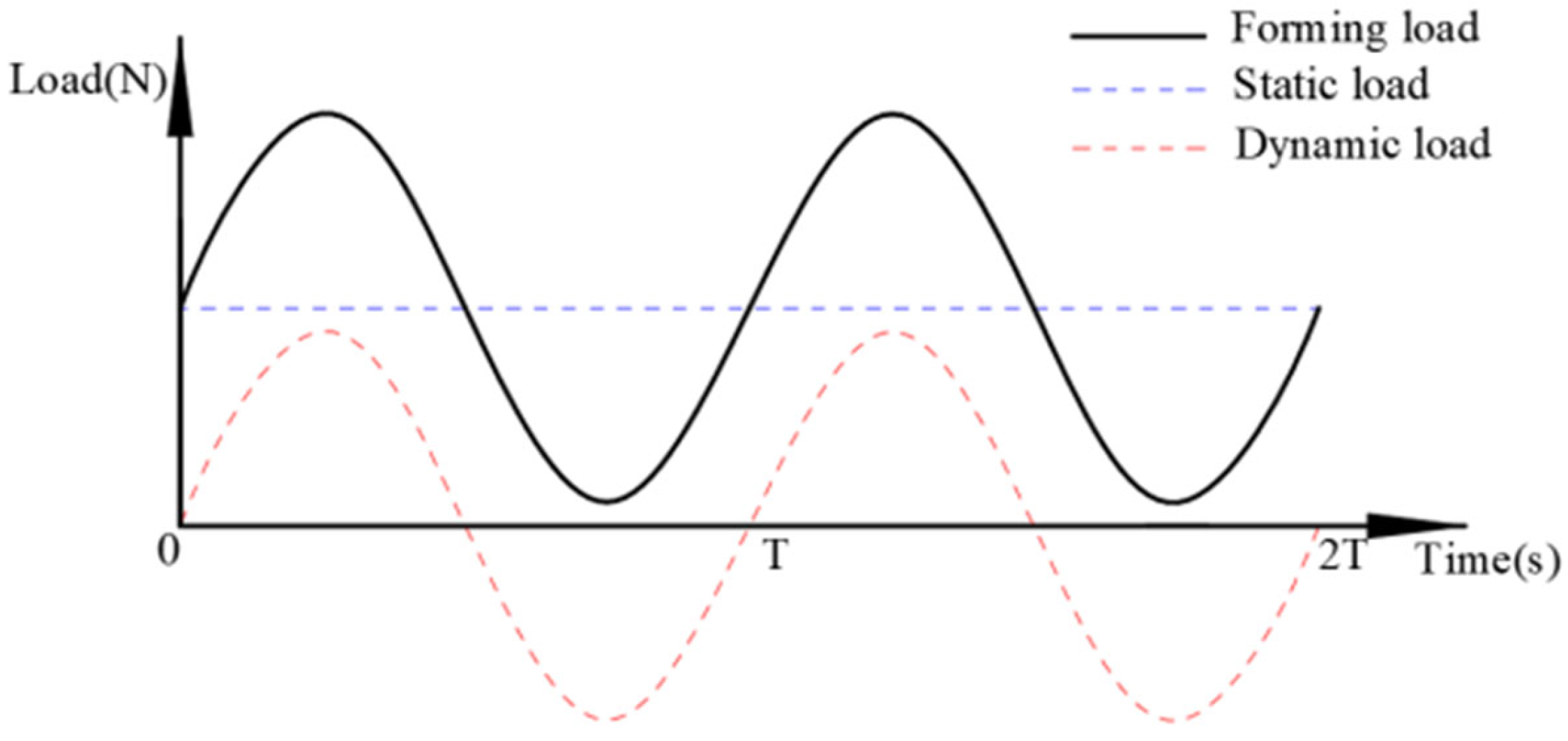

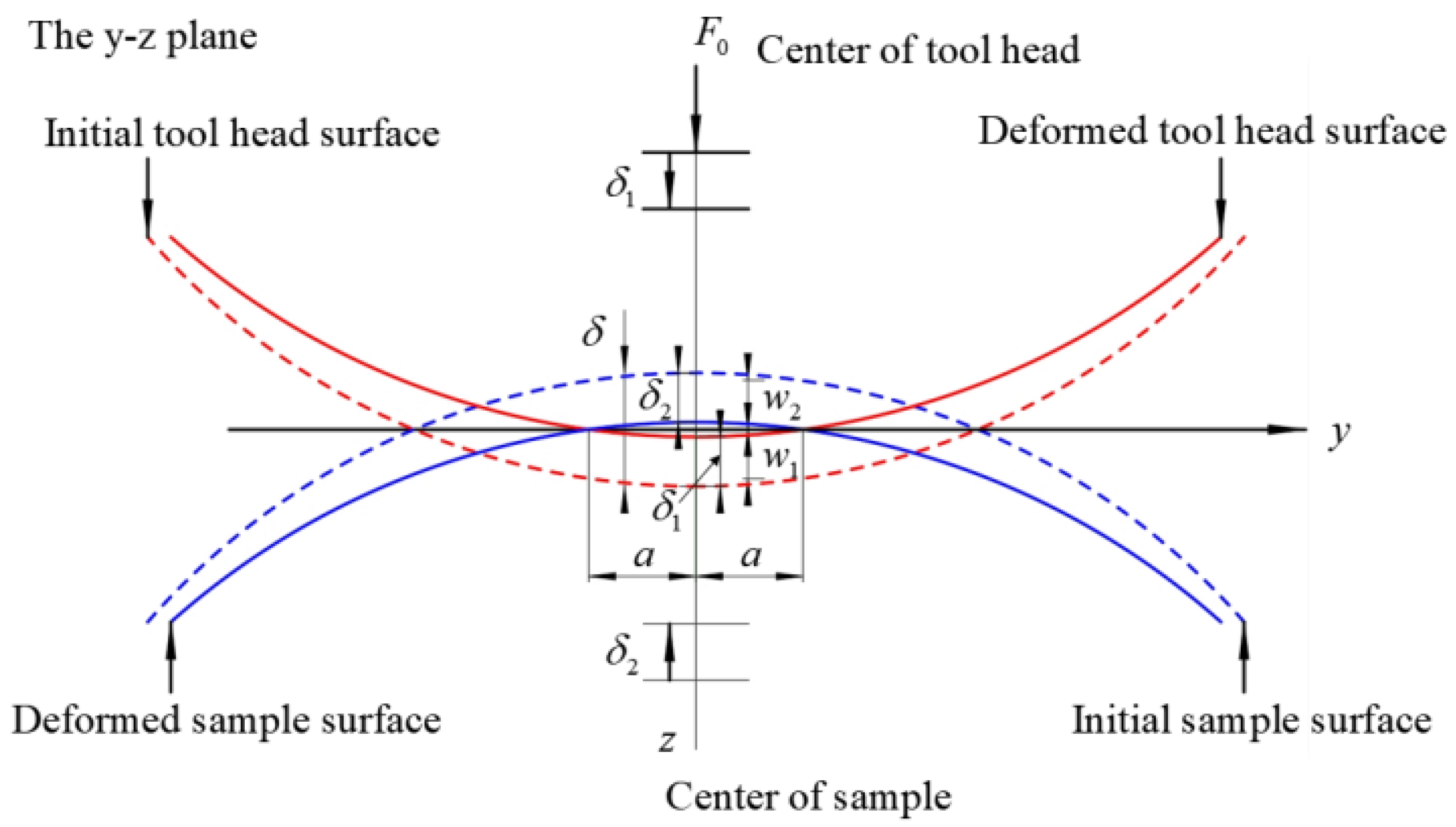

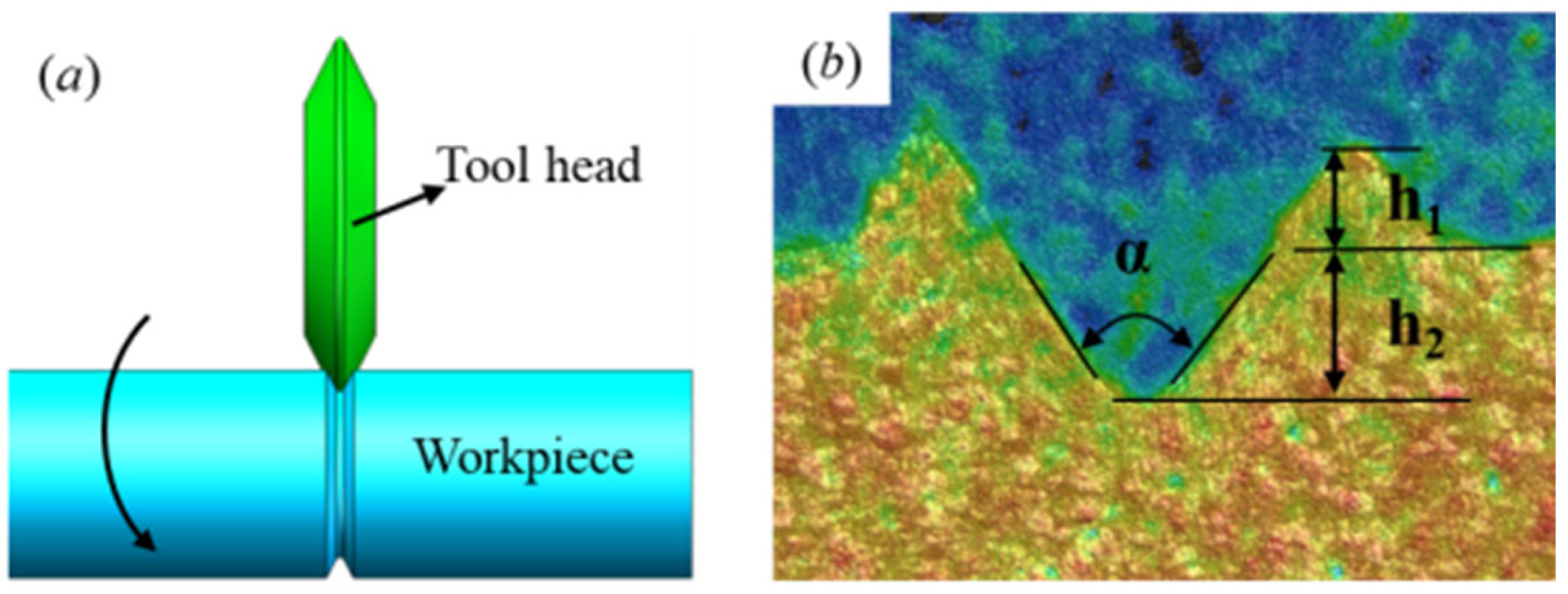

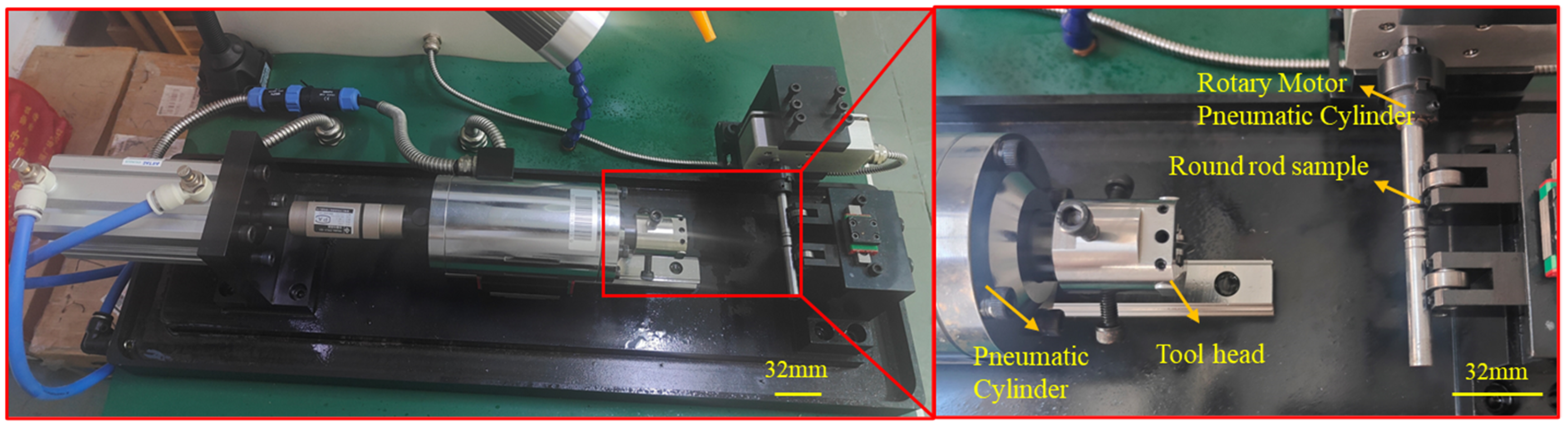

2.2. Ultrasonic-Assisted Spinning Device Working Principle and Force Analysis

2.3. Ultrasonic-Assisted Spinning Experiment Programme

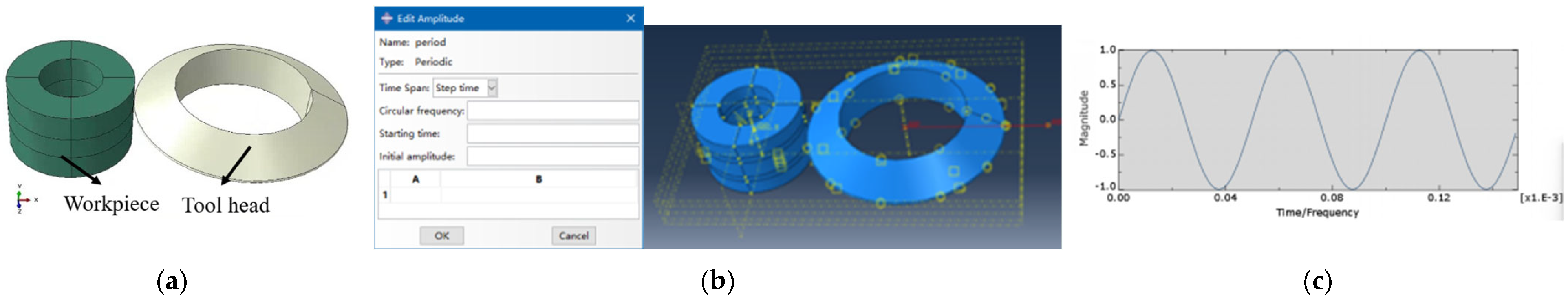

2.4. Simulation Modelling Pre-Processing

3. Results and Analysis

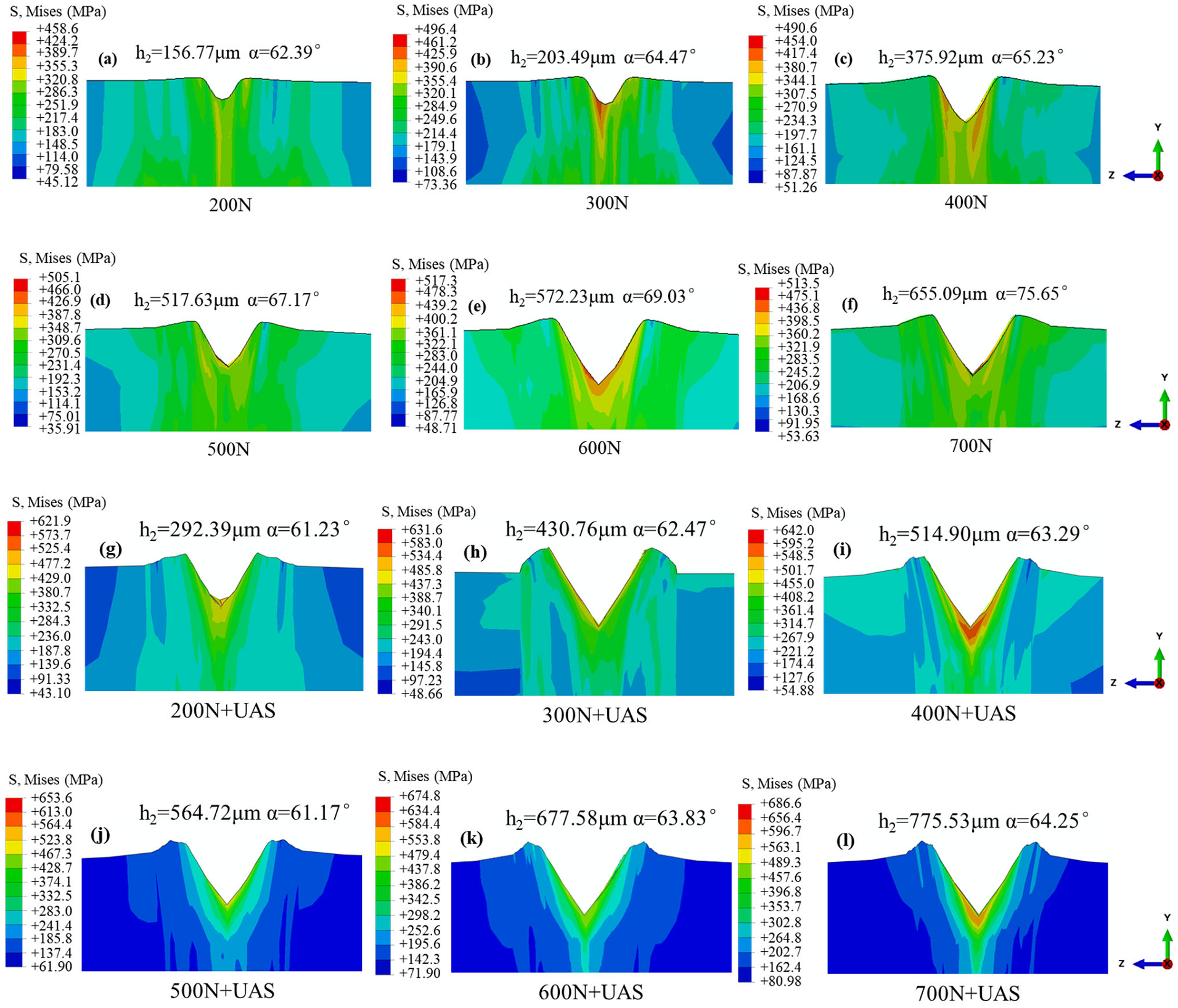

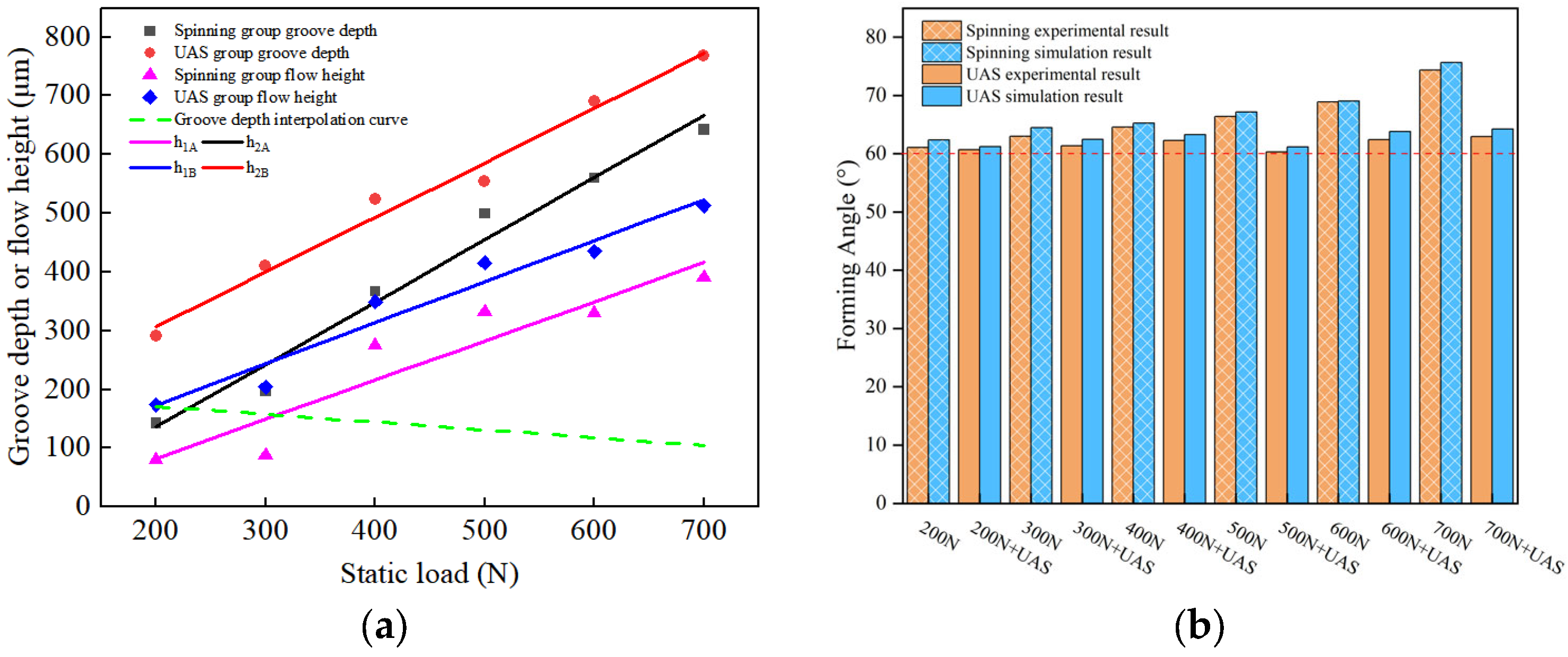

3.1. Analysis of Forming Accuracy Results of Ultrasound-Assisted Spinning Experiment

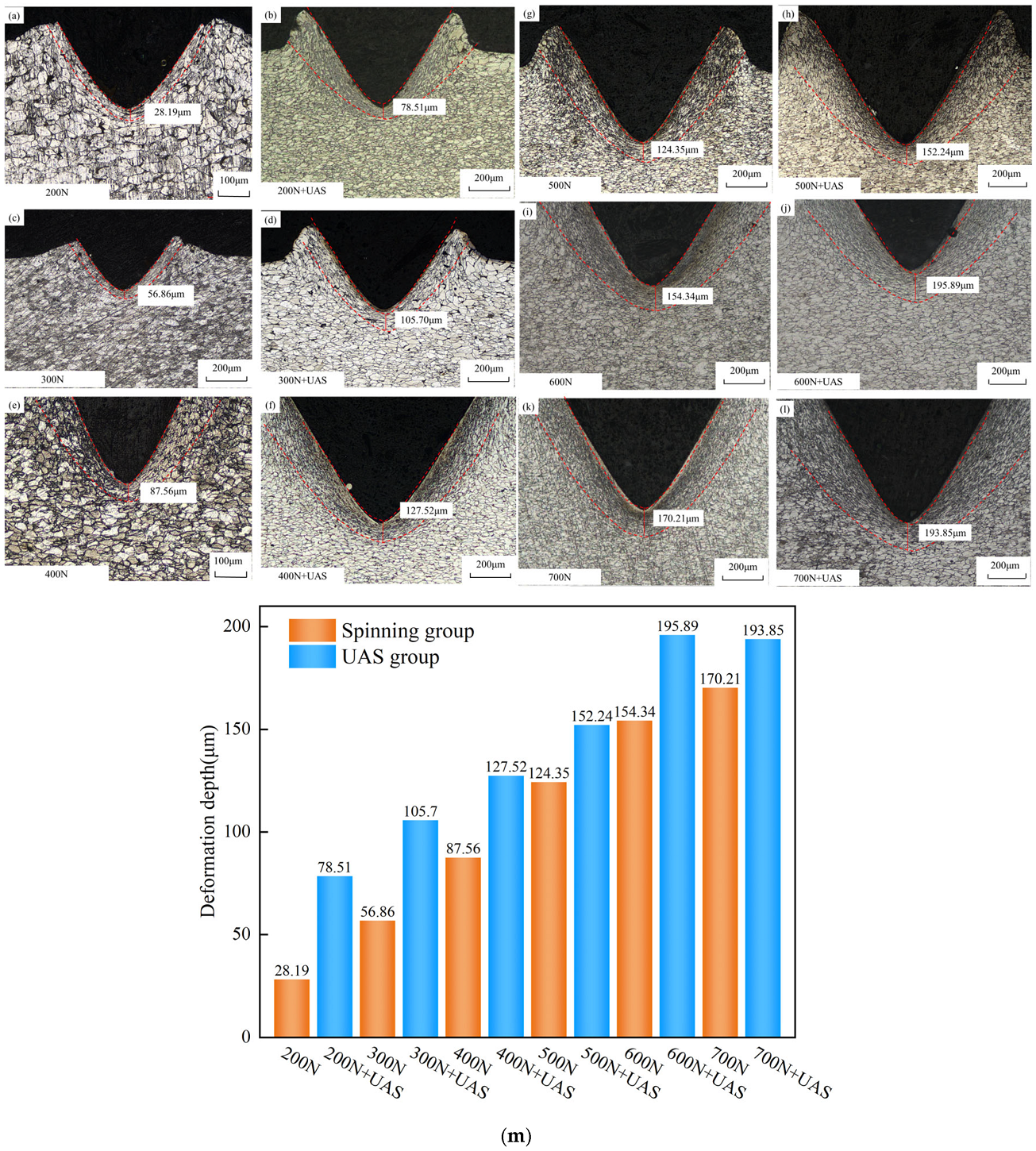

3.2. Metallographic Microstructure Analysis (OM Microstructure Analysis)

3.3. Analysis of Microhardness Results

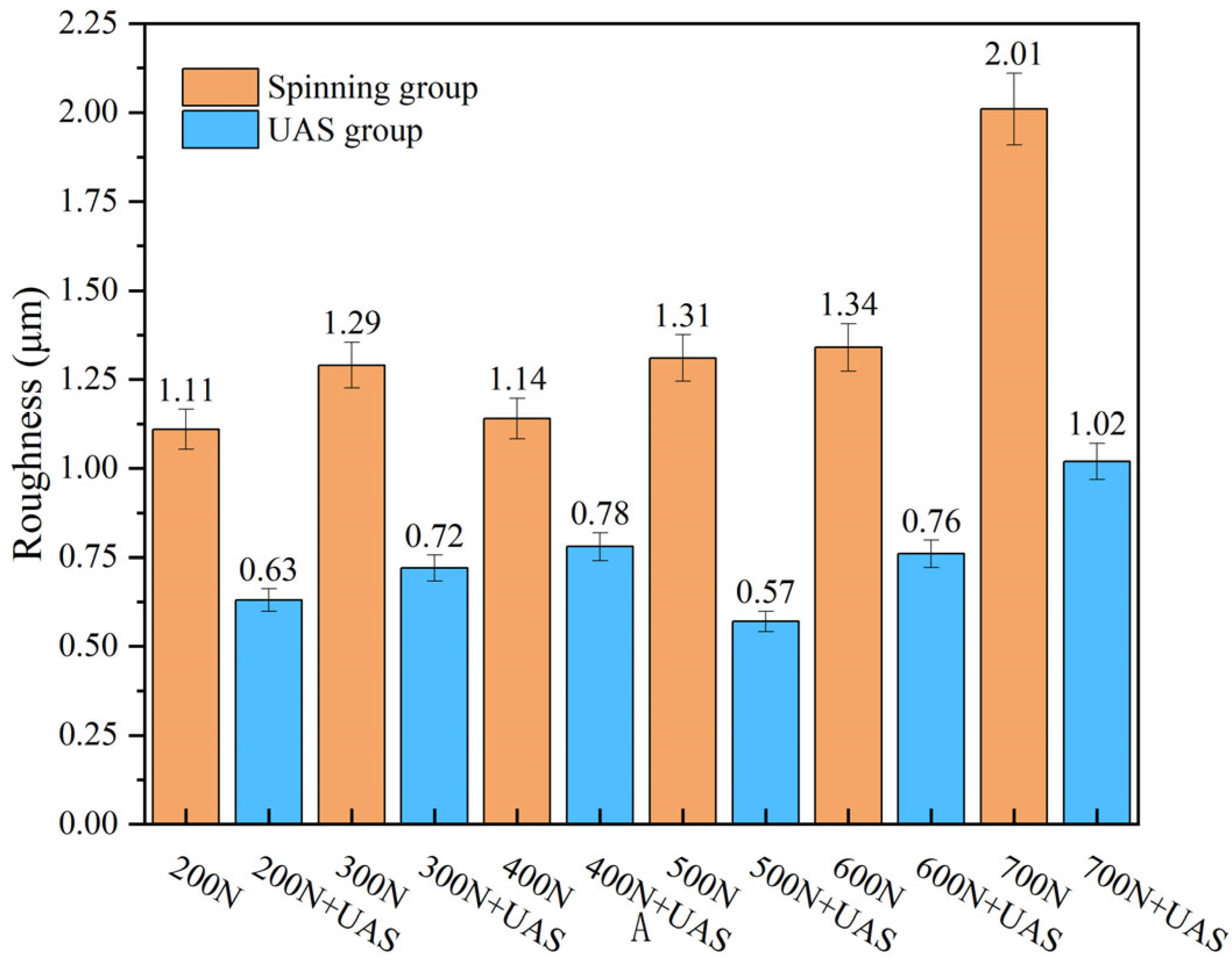

3.4. Measurement and Analysis of Surface Roughness of Groove Bottom

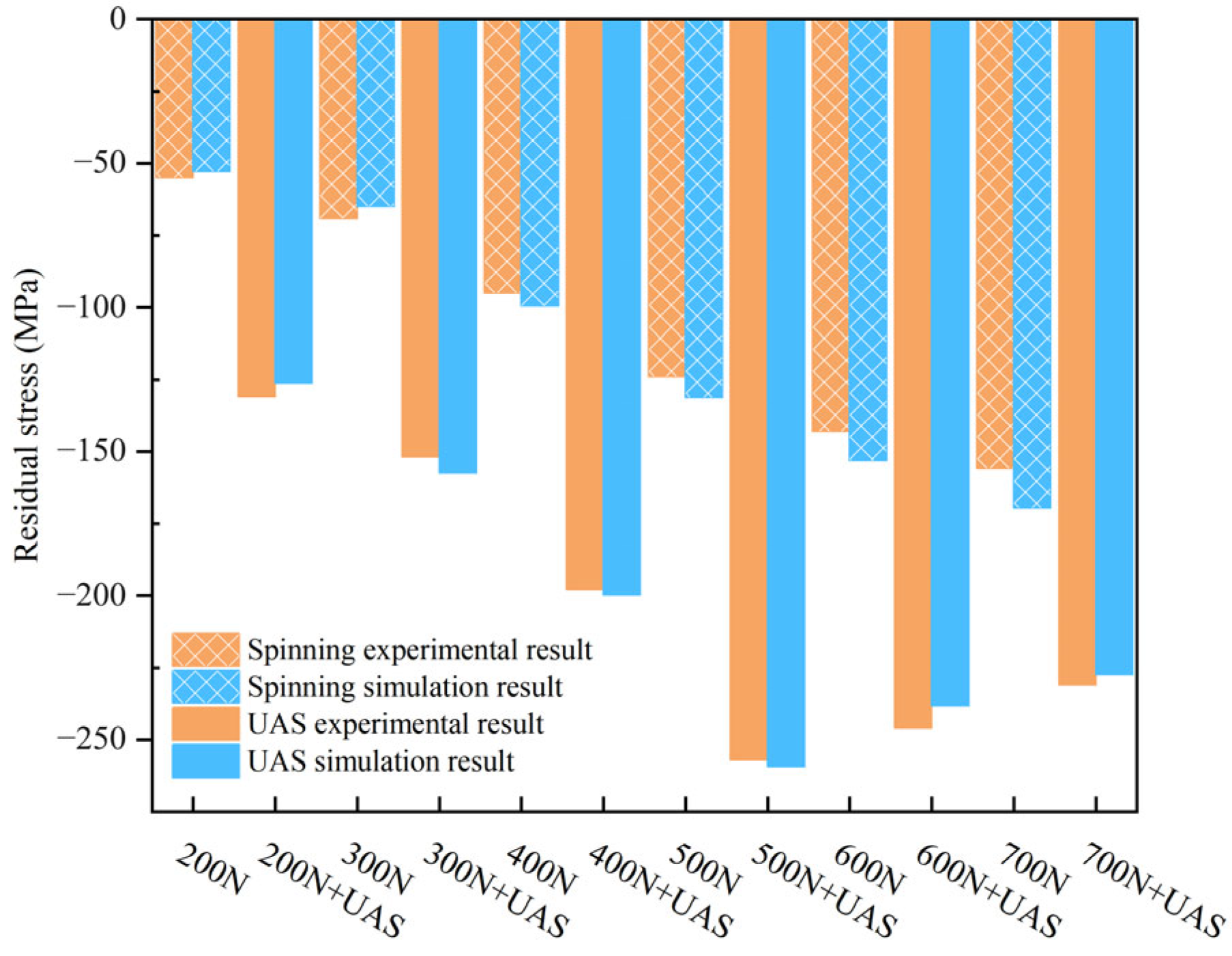

3.5. Residual Stresses

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Music, O.; Allwood, J.M.; Kawai, K. A Review of the Mechanics of Metal Spinning. J. Mater. Process. Technol. 2010, 210, 3–23. [Google Scholar] [CrossRef]

- Xia, Q.; Xiao, G.; Long, H.; Cheng, X.; Sheng, X. A Review of Process Advancement of Novel Metal Spinning. Int. J. Mach. Tools Manuf. 2014, 85, 100–121. [Google Scholar] [CrossRef]

- Zhang, S.G. Research on Deformation Stability in Spinning and Molding of Pulley Hub. Ph.D. Thesis, Hefei University of Technology, Hefei, China, 2014. [Google Scholar]

- Pan, Y.; Xue, G.L.; Zhe, C.; Yang, Y. Roller Spinning Forming Regularity. J. Meas. Eng. 2017, 5, 229–234. [Google Scholar] [CrossRef][Green Version]

- Ahmed, K.I.; Gadala, M.S.; El-Sebaie, M.G. Deep Spinning of Sheet Metals. Int. J. Mach. Tools Manuf. 2015, 97, 72–85. [Google Scholar] [CrossRef]

- Xue, K.; Zhou, J.; Yan, S.; Li, P. Flow Diversion Mechanisms and Control Methodology in the Asymmetric Spinning of Special-Shaped Multi-Wedge Belt Pulley. Int. J. Adv. Manuf. Technol. 2022, 120, 5289–5302. [Google Scholar] [CrossRef]

- Razani, N.A.; Jalali Aghchai, A.; Mollaei Dariani, B. Flow-Forming Optimisation Based on Hardness of Flow-Formed AISI321 Tube Using Response Surface Method. Int. J. Adv. Manuf. Technol. 2014, 70, 1463–1471. [Google Scholar] [CrossRef]

- Molladavoudi, H.R.; Djavanroodi, F. Experimental Study of Thickness Reduction Effects on Mechanical Properties and Spinning Accuracy of Aluminium 7075-O during Flow Forming. Int. J. Adv. Manuf. Technol. 2011, 52, 949–957. [Google Scholar] [CrossRef]

- Debin, S.; Guoping, Y.; Wenchen, X. Deformation History and the Resultant Microstructure and Texture in Backward Tube Spinning of Ti-6Al-2Zr-1Mo-1V. J. Mater. Process. Technol. 2009, 209, 5713–5719. [Google Scholar] [CrossRef]

- Fazeli, A.R.; Ghoreishi, M. Investigation of Effective Parameters on Surface Roughness in Thermomechanical Tube Spinning Process. Int. J. Mater. Form. 2009, 2, 261–270. [Google Scholar] [CrossRef]

- Abedini, A.; Rash Ahmadi, S.; Doniavi, A. Roughness Optimization of Flow-Formed Tubes Using the Taguchi Method. Int. J. Adv. Manuf. Technol. 2014, 72, 1009–1019. [Google Scholar] [CrossRef]

- Wei, L.W. Ultrasound-Assisted Spinning and Molding Process of Oxygen-Free Copper TU1 Sheet. Ph.D. Thesis, Yanshan University, Qinhuangdao, China, 2022. [Google Scholar]

- Pang, S.Y. Development of Single-Excitation Ultrasound-Assisted Spinning and Pressing Device for Sheet Metal. Ph.D. Thesis, Yanshan University, Qinhuangdao, China, 2022. [Google Scholar]

- Li, X.K.; Zhao, Y.X.; Yu, Z.Q.; Zhu, B.X.; Cui, J.H. Simulation Study on the Ultrasonic-Assisted Spinning of Aluminium Alloy Reinforced Members. J. Shanghai Jiao Tong Univ. 2021, 55, 394–402. [Google Scholar]

- Rasoli, M.A.; Abdullah, A.; Farzin, M.; Tehrani, A.F.; Taherizadeh, A. Influence of Ultrasonic Vibrations on Tube Spinning Process. J. Mater. Process. Technol. 2012, 212, 1443–1452. [Google Scholar] [CrossRef]

- Bagherzadeh, S.; Abrinia, K.; Han, Q. Analysis of Plastic Deformation Behavior of Ultrafine-Grained Aluminum Processed by the Newly Developed Ultrasonic Vibration Enhanced ECAP: Simulation and Experiments. J. Manuf. Process. 2020, 50, 485–497. [Google Scholar] [CrossRef]

- Zhang, T.; Li, H.; Gong, H.; Wu, Y. Study on Surface Properties and Fatigue Performance of Aluminum Alloy Plate with Prestressed Ultrasonic Peening. Proc. Inst. Mech. Eng. Part. B J. Eng. Manuf. 2023, 237, 326–337. [Google Scholar] [CrossRef]

- Zhou, H.; Cui, H.; Qin, Q.H. Influence of Ultrasonic Vibration on the Plasticity of Metals during Compression Process. J. Mater. Process. Technol. 2018, 251, 146–159. [Google Scholar] [CrossRef]

- Wen, X.; Tan, J.; Li, X. Optimization of Spinning Process Parameters for the Large-Diameter Thin-Walled Cylinder Based on the Drum Shape. Int. J. Adv. Manuf. Technol. 2020, 108, 2315–2335. [Google Scholar] [CrossRef]

- Zhang, H.D.; Dang, L.; Wang, X.Y.; Jin, J.S. Progress of Vibration-Assisted Plastic Moulding Mechanism and Application. Aerosp. Manuf. Technol. 2020, 63, 22–31. [Google Scholar]

- Lei, Y.L.; Han, G.C.; Peng, Z.; Sheng, C.J. Overview of Ultrasound-Assisted Plastic Forming Process Based on Different Vibration Modes. Electromach. Mold. 2018, 6, 48–52. [Google Scholar]

- Wu, G.; Meng, Z.; Zhou, C.; Liu, X.-B.; Huang, T. HMPT-BOF-RH-CSP Process for SPHE Substrate of Cold Rolled Deep Drawing Steel. J. Cent. South Univ. 2013, 20, 871–876. [Google Scholar] [CrossRef]

- Zhang, M.; Deng, J.; Liu, Z.; Zhou, Y. Investigation into Contributions of Static and Dynamic Loads to Compressive Residual Stress Fields Caused by Ultrasonic Surface Rolling. Int. J. Mech. Sci. 2019, 163, 105144. [Google Scholar] [CrossRef]

- Jiao, F.; Lan, S.; Zhao, B.; Wang, Y. Theoretical Calculation and Experiment of the Surface Residual Stress in the Plane Ultrasonic Rolling. J. Manuf. Process. 2020, 50, 573–580. [Google Scholar] [CrossRef]

- Miao, H.Y.; Larose, S.; Perron, C.; Lévesque, M. An Analytical Approach to Relate Shot Peening Parameters to Almen Intensity. Surf. Coat. Technol. 2010, 205, 2055–2066. [Google Scholar] [CrossRef]

- Sangkharat, T.; Dechjarern, S. Spinning Process Design Using Finite Element Analysis and Taguchi Method. Procedia Eng. 2017, 207, 1713–1718. [Google Scholar] [CrossRef]

- Wu, M.; Xu, X.; Xia, Q.; Cheng, X. Effect of Spinning Process Parameters on the Forming Quality of Inner and Outer Teeth Shaped Parts. J. Phys. Conf. Ser. 2020, 1549, 032125. [Google Scholar] [CrossRef]

- Qian, B.A.I.; He, Y.; Mei, Z. Finite Element Modeling of Power Spinning of Thin-Walled Shell with Hoop Inner Rib. Trans. Nonferrous Met. Soc. China 2008, 18, 6–13. [Google Scholar] [CrossRef]

- Liu, Y.H.; Zhang, D.; Geng, D.X.; Shao, Z.; Zhou, Z.; Sun, Z.; Jiang, Y.; Jiang, X. Ironing Effect on Surface Integrity and Fatigue Behavior during Ultrasonic Peening Drilling of Ti-6Al-4V. Chin. J. Aeronaut. 2023, 36, 486–498. [Google Scholar] [CrossRef]

- Yang, Z.; Zhu, L.; Wang, S.; Ning, J.; Dun, Y.; Meng, G.; Xue, P.; Xu, P.; Xin, B. Effects of Ultrasound on Multilayer Forming Mechanism of Inconel 718 in Directed Energy Deposition. Addit. Manuf. 2021, 48, 102462. [Google Scholar] [CrossRef]

- Liu, Z.H.; Zhang, T.Z.; Yang, M.J.; Dai, Q.L.; Zhang, Y.X. Analysis of Surface Metamorphic Layer Properties of Ultrasonically Rolled 18CrNiMo7-6 Gear Steel. J. Zhengzhou Univ. (Eng. Ed.) 2020, 41, 44–49+79. [Google Scholar]

- Zhao, Y.; Zhai, J.; Guan, Y.; Chen, F.; Liu, Y.; Li, Y.; Lin, J. Molecular Dynamics Study of Acoustic Softening Effect in Ultrasonic Vibration Assisted Tension of Monocrystalline/Polycrystalline Coppers. J. Mater. Process. Technol. 2022, 307, 117666. [Google Scholar] [CrossRef]

- Bieler, T.R.; Eisenlohr, P.; Zhang, C.; Phukan, H.; Crimp, M. Grain Boundaries and Interfaces in Slip Transfer. Curr. Opin. Solid State Mater. Sci. 2014, 18, 212–226. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | P | S | Alt | Cr | Cu | Ni |

|---|---|---|---|---|---|---|---|---|---|

| Measured value/% | 0.04 | 0.01 | 0.24 | 0.011 | 0.006 | 0.048 | 0.008 | 0.07 | 0.005 |

| Standard range value/% | ≤0.10 | ≤0.05 | ≤0.50 | ≤0.030 | ≤0.035 | ≥0.10 | ≤0.015 | ≤0.20 | ≤0.015 |

| Specimen Group | Static Load (N) | Ultrasonic Frequency (kHz) | Amplitude (μm) |

|---|---|---|---|

| A (spinning) | 200, 300, 400, 500, 600, 700 | 0 | 0 |

| B (ultrasound-assisted spinning) | 200, 300, 400, 500, 600, 700 | 20 | 12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Wang, W.; Jiang, Q.; Gao, J.; Lai, Y.; Liu, Y.; Xu, Z.; Zhao, Z. Ultrasonic-Assisted Spinning V-Groove Moulding Mechanism and Accuracy Research. Coatings 2025, 15, 1073. https://doi.org/10.3390/coatings15091073

Chen S, Wang W, Jiang Q, Gao J, Lai Y, Liu Y, Xu Z, Zhao Z. Ultrasonic-Assisted Spinning V-Groove Moulding Mechanism and Accuracy Research. Coatings. 2025; 15(9):1073. https://doi.org/10.3390/coatings15091073

Chicago/Turabian StyleChen, Shiqi, Weiqing Wang, Qingshan Jiang, Jiashun Gao, Yongqing Lai, Yuhong Liu, Zhilong Xu, and Zhenye Zhao. 2025. "Ultrasonic-Assisted Spinning V-Groove Moulding Mechanism and Accuracy Research" Coatings 15, no. 9: 1073. https://doi.org/10.3390/coatings15091073

APA StyleChen, S., Wang, W., Jiang, Q., Gao, J., Lai, Y., Liu, Y., Xu, Z., & Zhao, Z. (2025). Ultrasonic-Assisted Spinning V-Groove Moulding Mechanism and Accuracy Research. Coatings, 15(9), 1073. https://doi.org/10.3390/coatings15091073