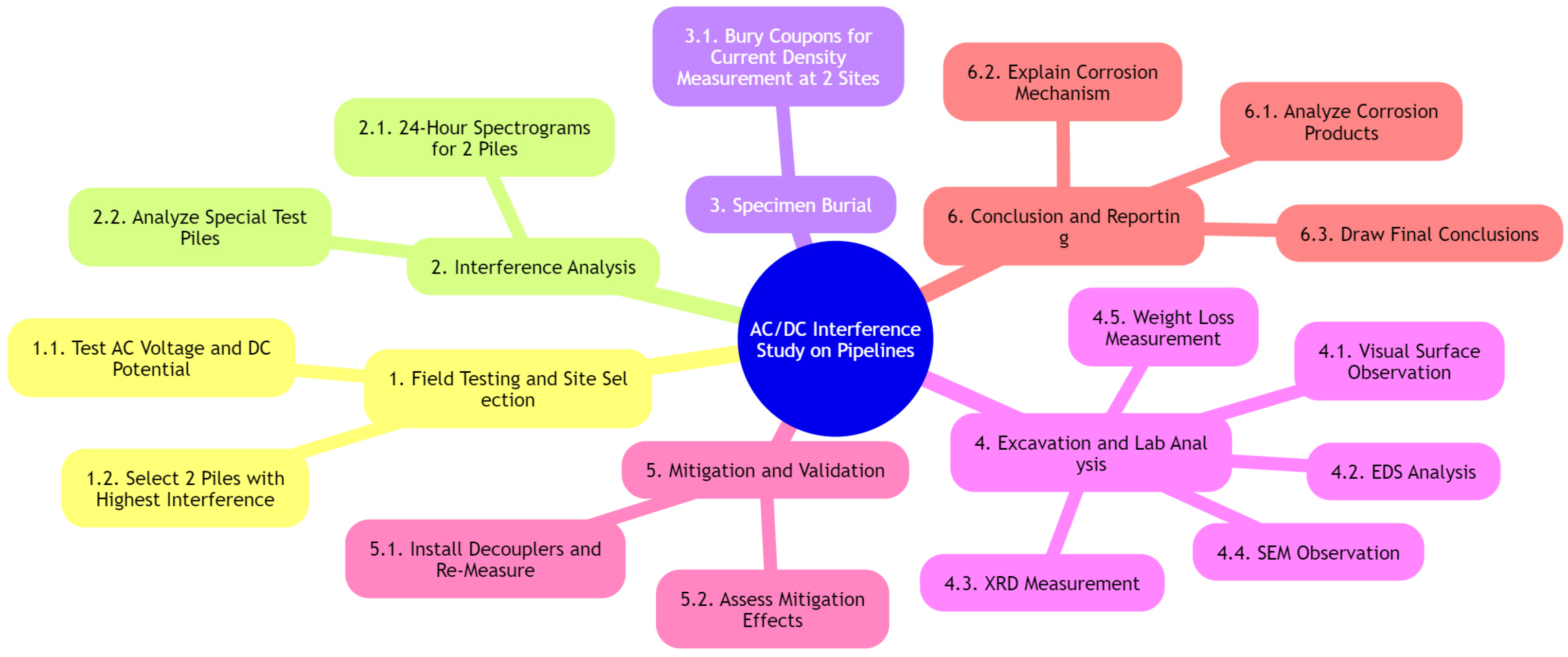

Analysis of AC and DC Interference in One Buried Gas Pipeline

Abstract

1. Introduction

2. Methods and Materials

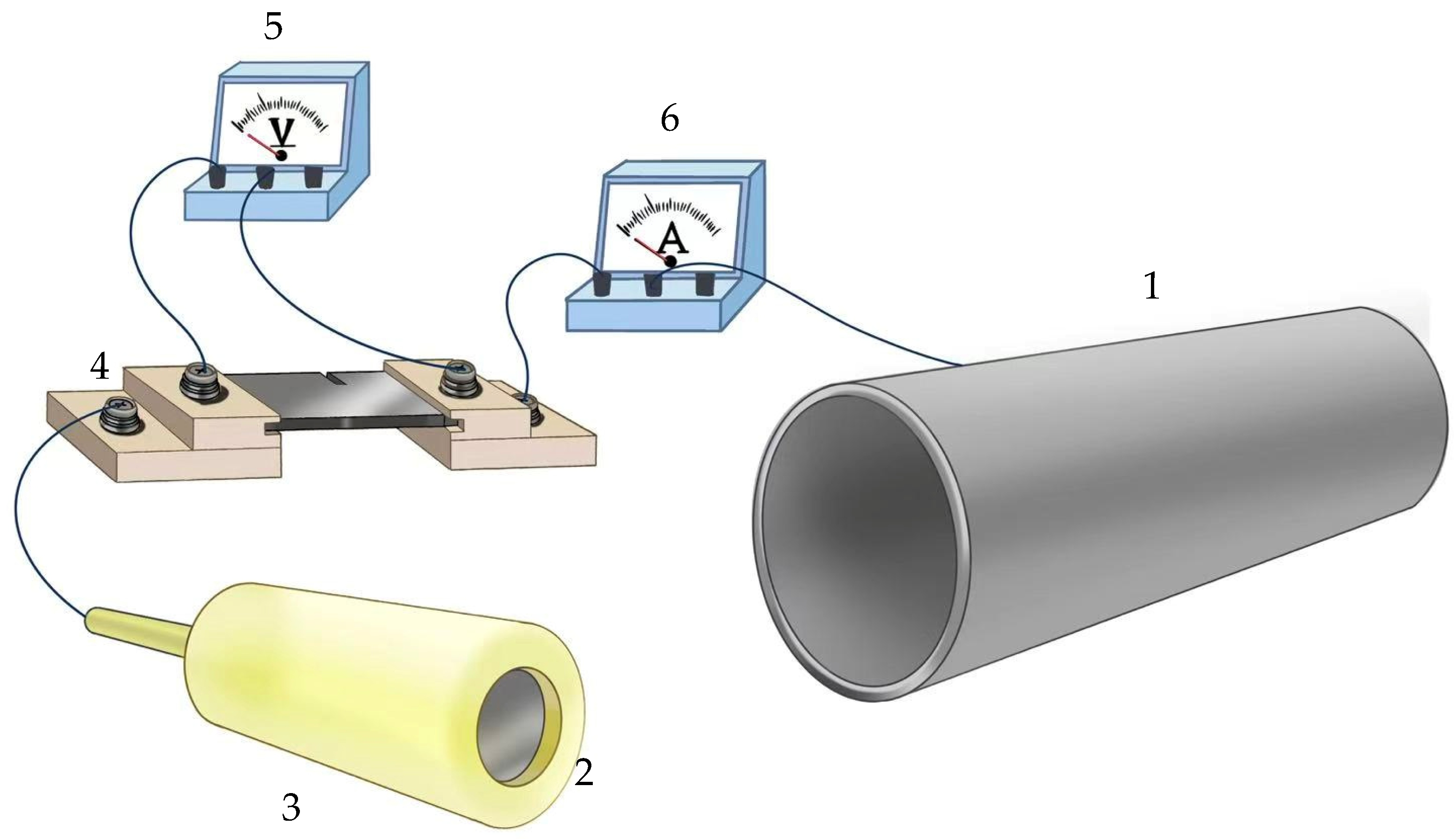

2.1. Test of AC Voltage and DC Potential

2.2. Current Density Measurement

2.3. Excavation Observation and Measurement

2.3.1. Surface Observation

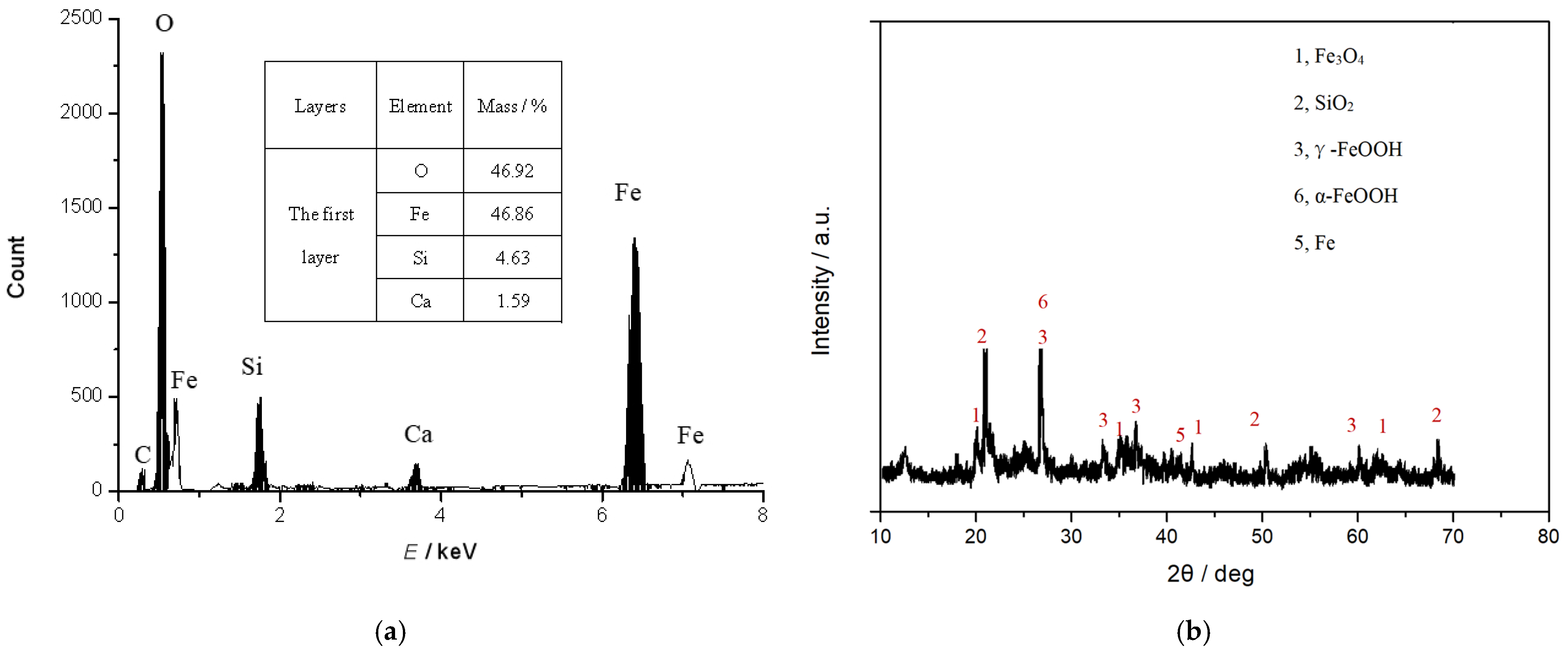

2.3.2. EDS Analysis

2.3.3. XRD Measurement

2.3.4. SEM Observation

2.3.5. Weightlessness Measurement

2.4. Measurement After Connecting the Decouplers

3. Results and Discussion

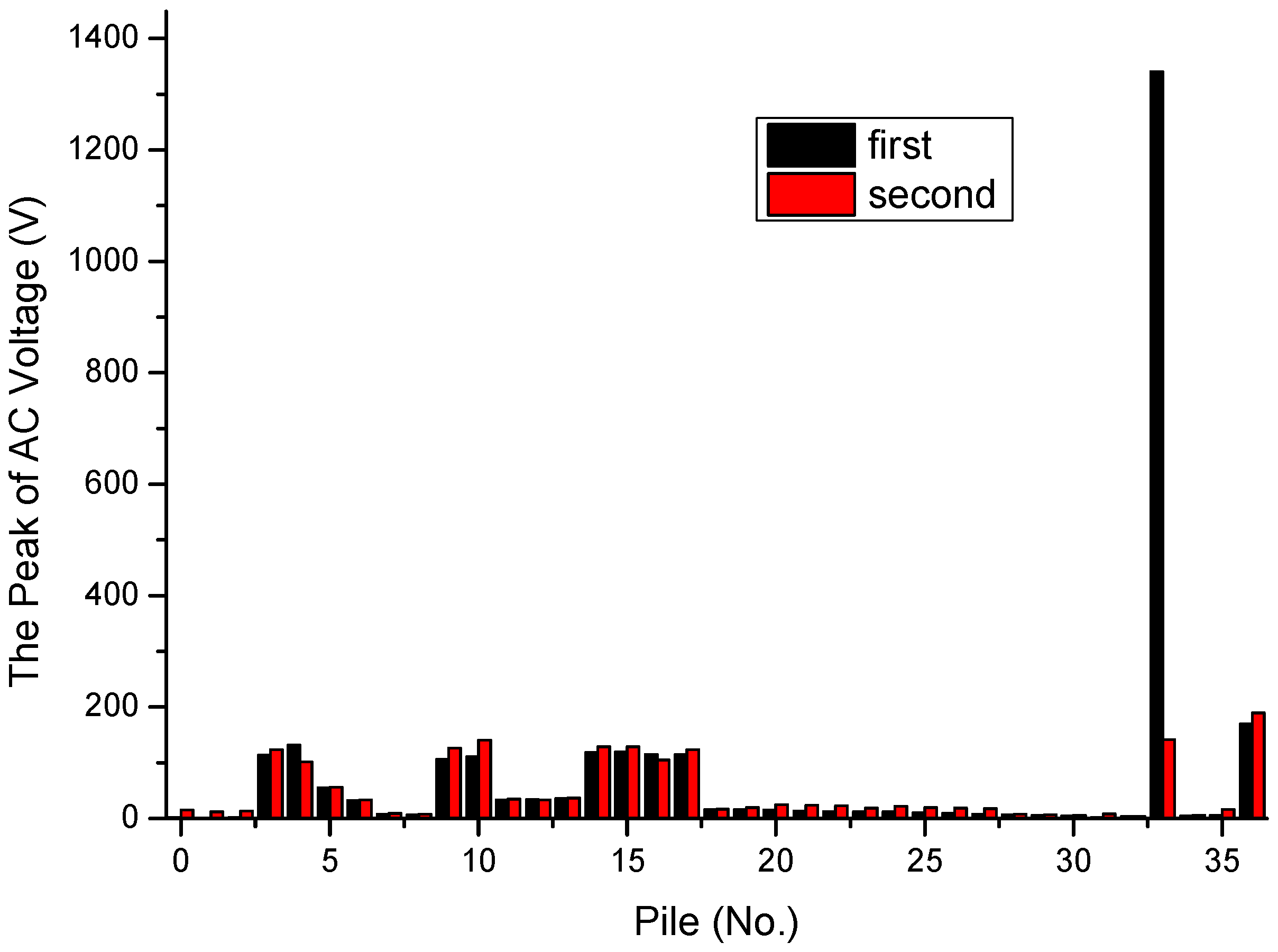

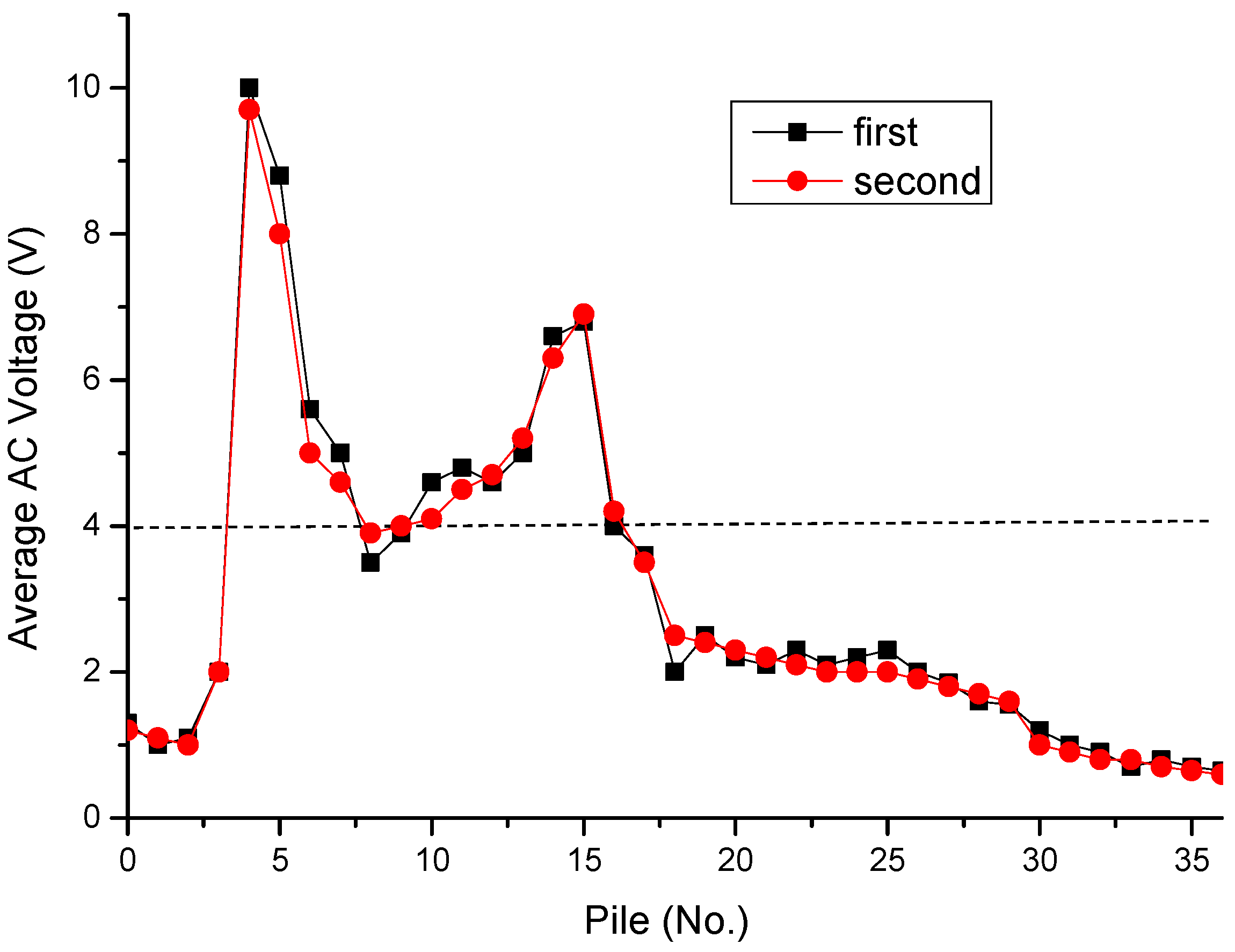

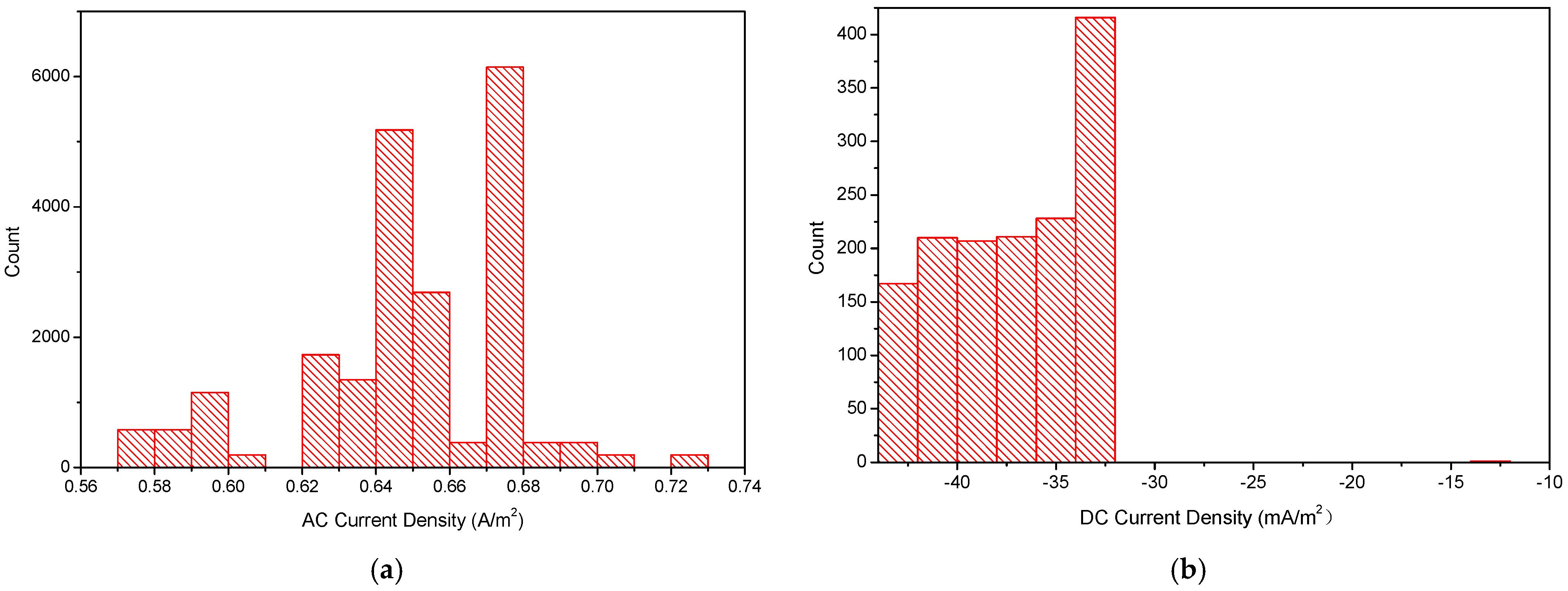

3.1. Peak and Average Value Distribution of AC Interference Voltage

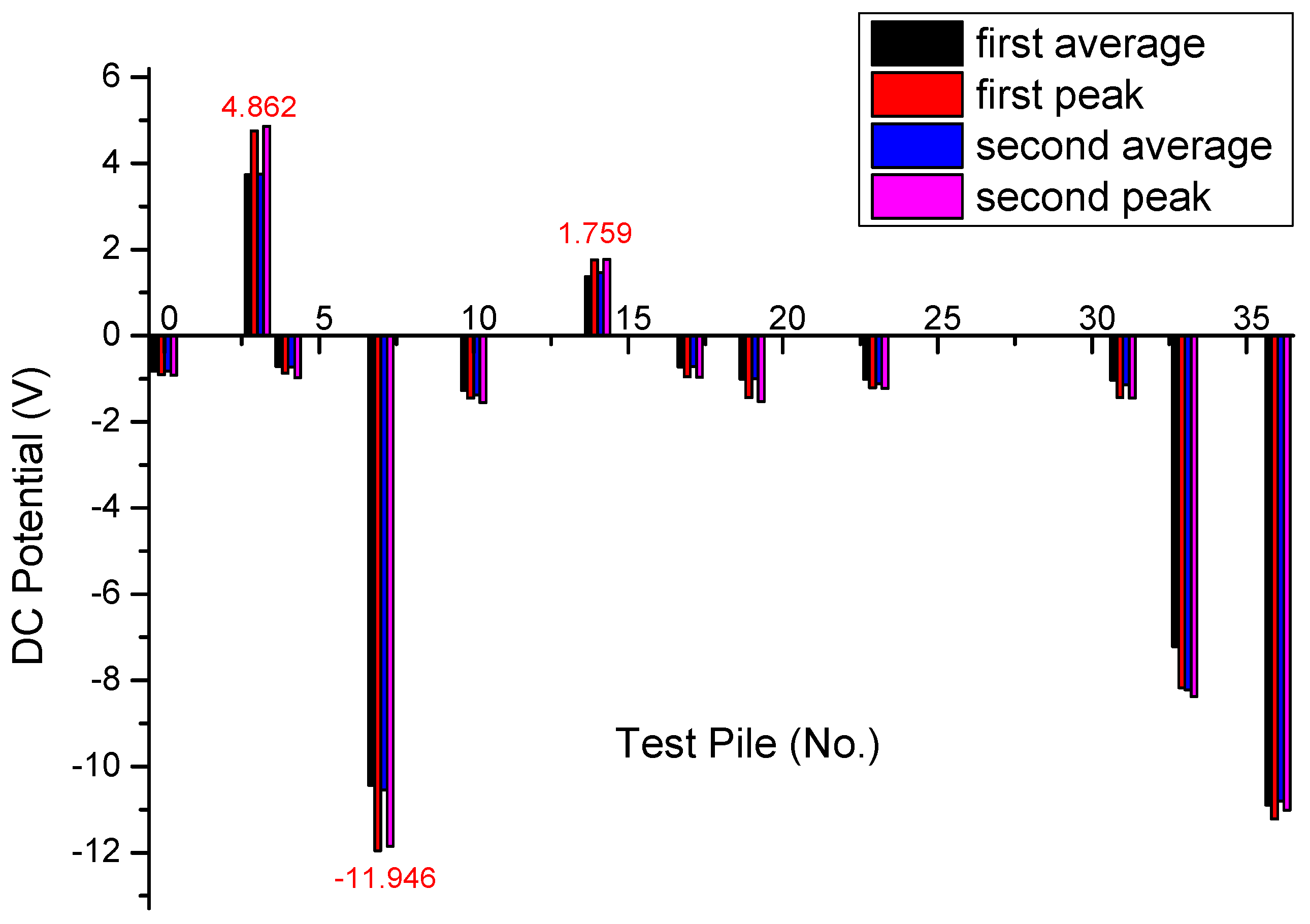

3.2. The Average and Peak Value of DC Interference Potential Distribution

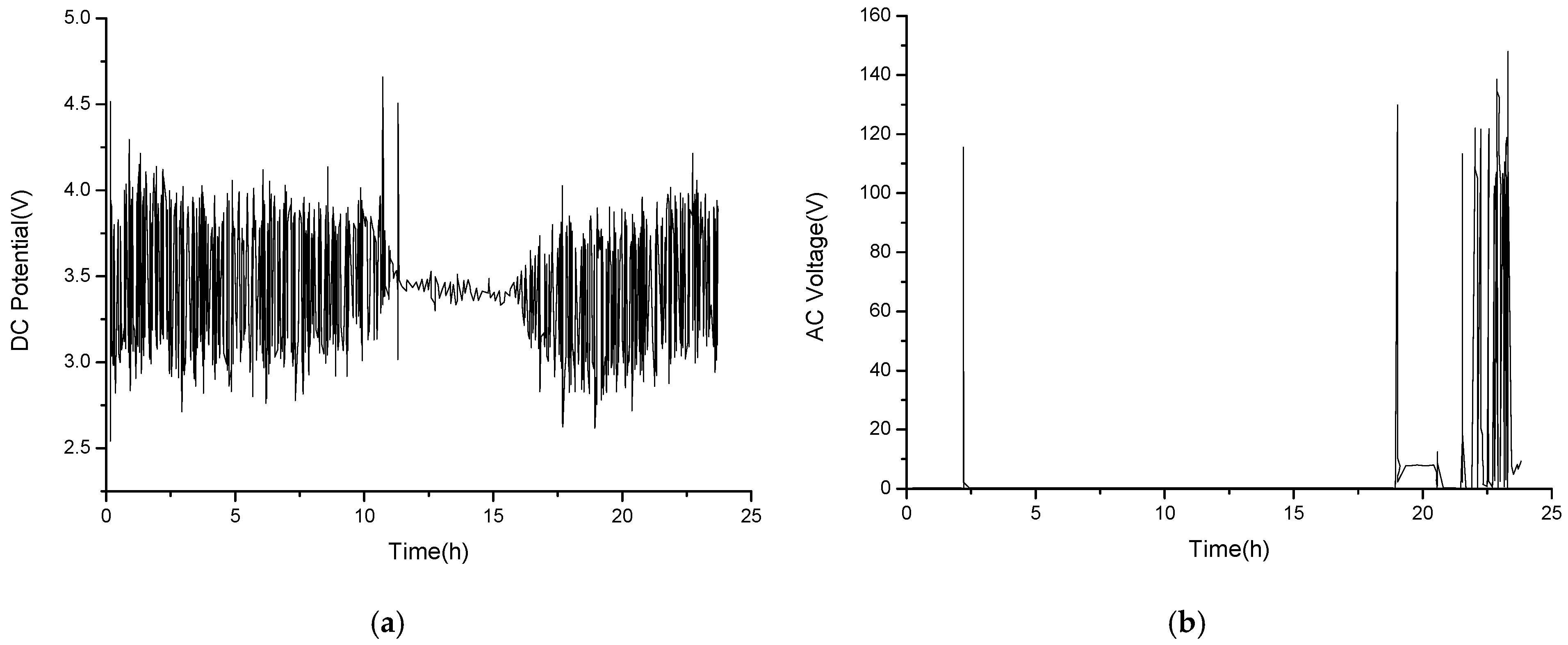

3.3. Analysis for DC Potential and AC Voltage Based on Monitoring of Two Test Piles

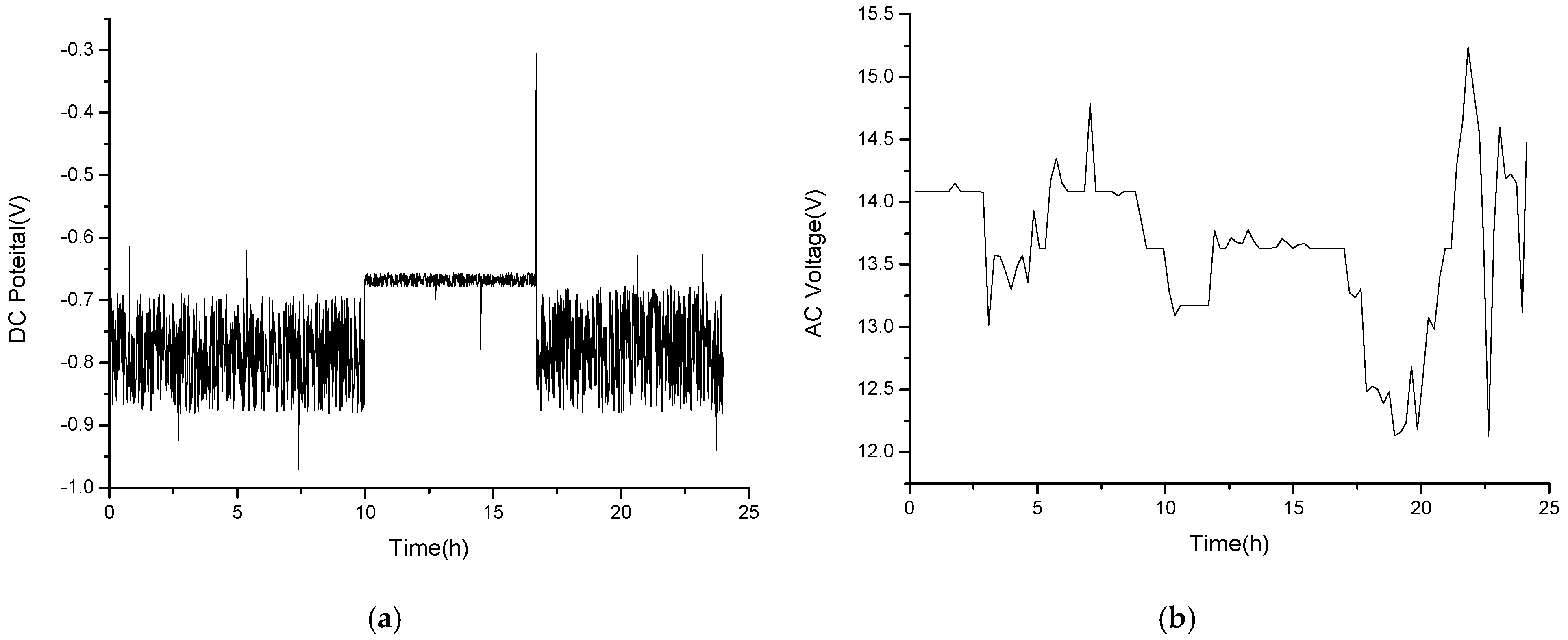

3.4. Analysis for Measurement Results of Current Density

3.5. Analysis of the Decouplers’ Efficiency

3.6. Excavation Observation and Measurement Analysis

4. Conclusions

- (1)

- Four types of interference sources were monitored and analyzed: high-voltage tower fault, induced coupling of high-voltage power line, rail transit DC interference, and 380 V machinery interference in factory.

- (2)

- At Pile 33, the maximum AC interference voltage between the pipeline and the steel electrode was 1341.8 V in the first measurement. However, the peak value obtained from the second measurement at pile 33 decreased from 1341.8 V to 143.7 V, indicating that the 1341.8 V may be caused by a sudden grounding of the electrode, while the 143.7 V may be caused by the induced voltage. Meanwhile, at Pile 7, the most negative DC interference potential between the pipeline and the copper/copper sulphate reference electrode was −11.946 V. At Pile 3, the most positive DC interference potential between the pipeline and the copper/copper sulphate reference electrode was 4.862 V in the second measurement.

- (3)

- The maximum DC current density was 240 mA/m2 at Pile 3, and the maximum AC current density was 0.615 A/m2 at Pile 4. After excavating the piece at the maximum DC interference point at Pile 3, there was obvious pitting corrosion characteristics under the combined effect of AC and DC currents. The corrosion products of the test piece at Pile 3 were mainly γ-FeOOH and Fe3O4. At the point of Pile 3, it was the coupling effect of the long-term higher positive DC current density and the short-term higher AC current density.

- (4)

- After the test piece at the maximum AC interference point, Pile 4, was excavated, the test piece did not have obvious AC and DC corrosion characteristics. The coupling of long-term low AC current density and long-term negative low DC current density at Pile 4 did not cause obvious corrosion.

- (5)

- The decouplers in this measurement can significantly reduce AC interference above 2 V. However, the isolation of transient AC shock and AC interference below 2 V was not obvious. The decouplers needs to improve its transient shock and low voltage isolation function.

- (6)

- In addition to considering the measured value, the duration time of AC and DC interference is also an important factor. Instantaneous sharp peaks cannot represent the long-term average voltage or potential current density. The average value should be used as the main basis for judgement, and the instantaneous value should be used as the secondary basis.

- (7)

- Because there were so many test piles, current density testing could not be performed on all of them. Due to difficulties with excavation, only single-specimen samples were used in the testing. Future research should include denser testing, multi-specimen testing, and enhanced corrosion product analysis.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liang, H.; Wu, Y.; Han, B.; Lin, N.; Wang, J.; Zhang, Z.; Guo, Y. Corrosion of buried pipelines by stray current in electrified railways: Mechanism, influencing factors, and protection. Appl. Sci. 2025, 15, 264. [Google Scholar] [CrossRef]

- Ma, S.; Du, Y.; Che, K.; Qin, H.; Su, Y. Research on corrosion assessment model for buried steel pipelines under dynamic DC stray current based on machine learning. Mater. Corros. 2022, 73, 540–549. [Google Scholar] [CrossRef]

- Chen, L.; DU, Y.; Liang, Y.; Tian, N.; Zhu, Z.; Zhang, L. Research on dynamic alternating current corrosion behavior of X65 pipeline steel under cathodic protection. Corrosion 2023, 79, 471–485. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.; Qin, H.; Liu, J.; Tang, D. Research on corrosion rate assessment of buried pipelines under dynamic metro stray current. Mater. Corros. 2021, 72, 1038–1050. [Google Scholar] [CrossRef]

- Feng, J.; Chen, Z.; Xie, Y.; Wu, C.; Qin, C. Influence of urban rail transit on corrosion of buried steel gas pipeline. Int. J. Electrochem. Sci. 2021, 16, 210617. [Google Scholar] [CrossRef]

- Peng, X.; Huang, Z.; Chen, B.; Liu, D.; Li, H. On the interference mechanism of stray current generated by DC tram on pipeline corrosion. Eng. Fail. Anal. 2020, 116, 104760. [Google Scholar] [CrossRef]

- Zhang, H.; DU, Y.; Qin, R.; Xu, Z.; Gu, Q. Study on corrosion behavior of X80 steel in Guangdong soil with different water contents under HVDC interference. Electrochemistry 2020, 88, 1–7. [Google Scholar] [CrossRef]

- Xu, Z.; Du, Y.; Du, Y.; Qin, R.; Zhang, H. Research status of interference caused by HVDC grounding in buried metal pipeline. Corros. Prot. 2020, 41, 63–69. [Google Scholar] [CrossRef]

- Xu, Z.; Du, Y.; Qin, R.; Zhang, H. Study of Corrosion Behavior of X80 Steel in Clay Soil with Different Water Contents under HVDC Interference. Int. J. Electrochem. Sci. 2020, 15, 3935–3954. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Sun, T.; Rasool, G.; Yang, L.; Qi, Y. Study on the influence of the transmission tower on the AC interference distribution on the surface of a buried steel pipeline under steady-state conditions. Electr. Power Syst. Res. 2023, 225, 109852. [Google Scholar] [CrossRef]

- Chen, L.; Du, Y.; Liang, Y.; Li, J. Research on corrosion behaviour of X65 pipeline steel under dynamic AC interference. Corros. Eng. Sci. Technol. 2021, 56, 219–229. [Google Scholar] [CrossRef]

- Chen, L.; Du, Y.; Liang, Y.; Zhuang, D.; Zhu, Z.; Jiang, Z.; Zhang, L. Research on numerical modeling of AC interference from high-speed railway to nearby buried pipeline. Electr. Power Syst. Res. 2024, 228, 110047. [Google Scholar] [CrossRef]

- Chen, L.; Du, Y.; Guo, L.; Zhu, Z.; Liang, Y.; Zhang, L. Corrosion behavior and evaluation method of pipeline steel under dynamic ac interference: A study. Mater. Corros. 2025, 76, 305–315. [Google Scholar] [CrossRef]

- Wang, C.; Xu, S.; Li, W.; Wang, Y.; Shen, G.; Wang, S. Multi-physics coupled simulation and experimental investigation of alternating stray current corrosion of buried gas pipeline adjacent to rail transit system. Mater. Des. 2024, 247, 113394. [Google Scholar] [CrossRef]

- Moraes, C.M.; Matos, G.H.d.S.; Martins-Britto, A.G.; Silva, K.M.; Lopes, F.V. Total AC interferences between a power line subject to a single-phase fault and a nearby pipeline with multilayered soil. IEEE Trans. Electromagn. Compat. 2023, 65, 585–594. [Google Scholar] [CrossRef]

- Lucca, G.; Sandrolini, L.; Popoli, A.; Simonazzi, M.; Cristofolini, A. Assessment of AC Corrosion Probability in Buried Pipelines with a FEM-Assisted Stochastic Approach. Appl. Sci. 2023, 13, 7669. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Y.; Sun, T.; Yang, X.; Yang, L.; Qi, Y. Study of transmission line AC interference with steel-buried pipelines under lightning strikes. Electr. Power Syst. Res. 2023, 218, 109226. [Google Scholar] [CrossRef]

- Wang, C.; Liang, X.; Adajar, E.P. A Systematic Approach for AC Electromagnetic Interference Study Between Railways and Nearby Power Lines. IEEE Trans. Ind. Appl. 2023, 59, 5527–5538. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Y.; Sun, T.; Yang, X.; Yang, L.; Qi, Y. Study of the coupling interference of high-voltage transmission lines on adjacent buried steel pipelines based on CDEGS. Electr. Power Syst. Res. 2023, 217, 109125. [Google Scholar] [CrossRef]

- Mostafa, M.A.; Al-Gabalawy, M.; Shaalan, E.M.; Hamza, A.S. Mitigation of the AC corrosion of the metallic pipelines using the hydroxide and solid-state polarization cells; A comparative study. Electr. Power Syst. Res. 2022, 202, 107585. [Google Scholar] [CrossRef]

- Al-Gabalawy, M.; Mostafa, M.A.; Hamza, A.S. Implementation of different intelligent controllers for mitigating the AC corrosion of metallic pipelines considering all HVOHTLs operation conditions. ISA Trans. 2021, 117, 251–273. [Google Scholar] [CrossRef]

- Gouda, O.E.; Al-Gabalawy, M.A. Overhead transmission lines impacts on neighboring buried metallic gas pipelines. Electr. Eng. 2021, 103, 3119–3137. [Google Scholar] [CrossRef]

- Gouda, O.E.; Al-Gabalawy, M.A. Screening of the high voltage overhead transmission lines impacts on the neighboring metallic gas pipelines based on the distributed KOH-PCs. Egypt. J. Pet. 2021, 30, 45–53. [Google Scholar] [CrossRef]

- Wang, Q.-W.; Zhang, J.-X.; Gao, Y.; Dai, N.-W.; Chen, Y.-X.; Lin, D.-Y.; Xia, X.-J. Galvanic Effect and Alternating Current Corrosion of Steel in Acidic Red Soil. Metals 2022, 12, 296. [Google Scholar] [CrossRef]

- SY/T 0017-2006; Standard of DC Drainage Protection for Buried Steel Pipelines. Petroleum Industry Press: Beijing, China, 2006.

- GBT40377-2021; Corrosion of Metals Corrosion of Metals and Alloys-Determination of AC Corrosion-Protection Criteria. China Standard Press: Beijing, China, 2021.

- Thakur, A.K.; Arya, A.K.; Sharma, P. Corrosion of pipe steels under alternating current. Int. J. Electrochem. Sci. 2021, 16, 211245. [Google Scholar] [CrossRef]

- SY/T 0087.4-2023; Corrosion Evaluation Standards for Steel Pipelines and Storage Tanks Part 4: Evaluation of DC Interference Corrosion for Buried Steel Pipelines. Petroleum Industry Press: Beijing, China, 2023.

- SY0087.6-2021; Standards for Corrosion Evaluation of Steel Pipelines and Storage Tanks Part 6: Evaluation of AC Interference Corrosion of Buried Steel Pipelines. Petroleum Industry Press: Beijing, China, 2021.

- Zhou, J.; Li, Z.; Liu, J.; Xing, X.; Cui, G.; Zhang, S.; Cheng, R.; Wang, Y. Effect of AC interference on hydrogen evolution reaction of x80 steel. Anti-Corros. Methods Mater. 2020, 67, 197–204. [Google Scholar] [CrossRef]

- Wan, H.; Song, D.; Liu, R.; Wang, Y.; Cai, W. Effects of Alternating Current Corrosion Behavior of X80 Pipeline Steel under Delaminated Coating Defects. J. Mater. Eng. Perform. 2025, 34, 3425–3435. [Google Scholar] [CrossRef]

- Olesen, A.J.; Dideriksen, K.; Nielsen, L.V.; Møller, P. Corrosion rate measurement and oxide investigation of AC corrosion at varying AC/DC current densities. Corrosion 2019, 75, 1026–1033. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, F.; Zou, G.; Sun, W.; Li, C. Study on corrosion behavior of X65 steel of buried pipeline under dynamic stray current interference. AIP Adv. 2025, 15, 065005. [Google Scholar] [CrossRef]

- Liang, Y.; Du, Y.; Tang, D.; Chen, L.; Zhang, L.; Qiao, L. Research on AC corrosion behavior and corrosion product film evolution of X70 steel under the combined action of AC interference and CP. Corros. Sci. 2022, 197, 110085. [Google Scholar] [CrossRef]

- Markić, M.; Arat, S.; Fürbeth, W. Effect of AC interference on the corrosion behavior of cathodically protected mild steel in an artificial soil solution. Part I: Investigation on formed corrosion product layer. Mater. Corros. 2021, 73, 45–54. [Google Scholar] [CrossRef]

- Chen, L.; Du, Y.; Wang, M.; Liu, Y.; Liang, Y.; Zhu, Z.; Zhang, L. In situ and ex situ investigation on the product films evolution of pipeline steel under AC interference and high cathodic protection conditions. J. Electroanal. Chem. 2024, 967, 118308. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, L.; Qin, H.; Jiang, Z.; Du, Y.; Lu, M. Research on fluctuation characteristics of AC interference parameters and corrosion behavior of buried gas pipelines. Int. J. Electrochem. Sci. 2023, 19, 100396. [Google Scholar] [CrossRef]

| Performance Items | DC | AC |

|---|---|---|

| Potential or voltage resolution | ±1 mV | 2 mV |

| Input impedance of instrument | >1.0 × 1013 Ω | >1.0 × 106 Ω |

| Sampling step rate | 1 s/once | 1 millisecond/once |

| Measurement range | ±7 V | 2000 V |

| Measurement electrodes | Cu/CuSO4 electrode | Steel electrode |

| Field heat resistance temperature | >70 Degrees Celsius | >70 Degrees Celsius |

| AC Voltage | DC Potential | AC Current Density | |||

|---|---|---|---|---|---|

| Interference | Voltage (V) | Interference | Value (V) | Interference | Current Density (A/m2) |

| Weak | ≤4 | Corrosion | −0.85 | Weak | <30 |

| Further assessment | >4 | Hydrogen evolution | −1.2 | Moderate | ≥30 and <100 |

| Strong | ≥100 | ||||

| Incident Log | |

|---|---|

| Accident phenomenon | About 7:15, thunderstorm, the video camera detected a sudden spark coming from Tower A. |

| Handling process | Arranged for workers to go to the site to check the situation. |

| Feedback from workers | No abnormalities were observed in the Tower A. Further observation was required. |

| Emergency response | Set up warning signs to prevent people or animals from approaching. |

| On-site inspection | After approximately one hour of observation, the thunderstorm ceased, and no further sparks were observed. |

| Cause of the malfunction | Possibly caused by lightning. |

| Handling result | No accident occurred and normal power supply was not affected. |

| On duty | Hidden |

| Date | Hidden |

| Daily Production Schedule | |

|---|---|

| 10 h to 17 h | Rest |

| 17 h to 19 h | Prepare building materials |

| 19 h to 24 h | Turned on the 380 V machinery |

| 24 h to 10 h | Transportation of building materials |

| Pile No. | Monitoring Maximum Value (V) | Monitoring Minimum Value (V) | Average Value (V) | Standard Deviation (V) | Percent Reductions in Time-Above-Threshold Values |

|---|---|---|---|---|---|

| 0 (without decoupler) | 1.9062 | 0 | 1.1596 | 0.6998 | |

| 0 (with decoupler) | 94.26 | 0.0007 | 1.4394 | 9.376 | No |

| 1 (without decoupler) | 113.7 | 0.0185 | 0.0255 | 1.608 | |

| 1 (with decoupler) | 0.3167 | 0 | 0.0429 | 0.0963 | 100% |

| 9 (without decoupler) | 106.77 | 0 | 3.7336 | 14.87 | |

| 9 (with decoupler) | 2.214 | 1.755 | 1.9872 | 0.1227 | 100% |

| 17 (without decoupler) | 114.25 | 0 | 3.6308 | 11.18 | |

| 17 (with decoupler) | 12.512 | 0 | 3.589 | 2.225 | 98.6% |

| 33 (without decoupler) | 1341.8 | 0.1472 | 0.7273 | 18.97 | |

| 33 (with decoupler) | 0.2003 | 0 | 0.0337 | 0.0588 | 100% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Liu, H.; Liu, J.; Liu, Y.; Ding, Y.; Zhang, J. Analysis of AC and DC Interference in One Buried Gas Pipeline. Coatings 2025, 15, 1056. https://doi.org/10.3390/coatings15091056

Wang Z, Liu H, Liu J, Liu Y, Ding Y, Zhang J. Analysis of AC and DC Interference in One Buried Gas Pipeline. Coatings. 2025; 15(9):1056. https://doi.org/10.3390/coatings15091056

Chicago/Turabian StyleWang, Zaifeng, Haishan Liu, Jianqing Liu, Yang Liu, Yu Ding, and Jie Zhang. 2025. "Analysis of AC and DC Interference in One Buried Gas Pipeline" Coatings 15, no. 9: 1056. https://doi.org/10.3390/coatings15091056

APA StyleWang, Z., Liu, H., Liu, J., Liu, Y., Ding, Y., & Zhang, J. (2025). Analysis of AC and DC Interference in One Buried Gas Pipeline. Coatings, 15(9), 1056. https://doi.org/10.3390/coatings15091056