Sintering Kinetics, Mechanical Properties, and Electrical Conductivity of Ti-67 at% Al Targets Fabricated via Spark Plasma Sintering

Abstract

1. Introduction

2. Experimental Section

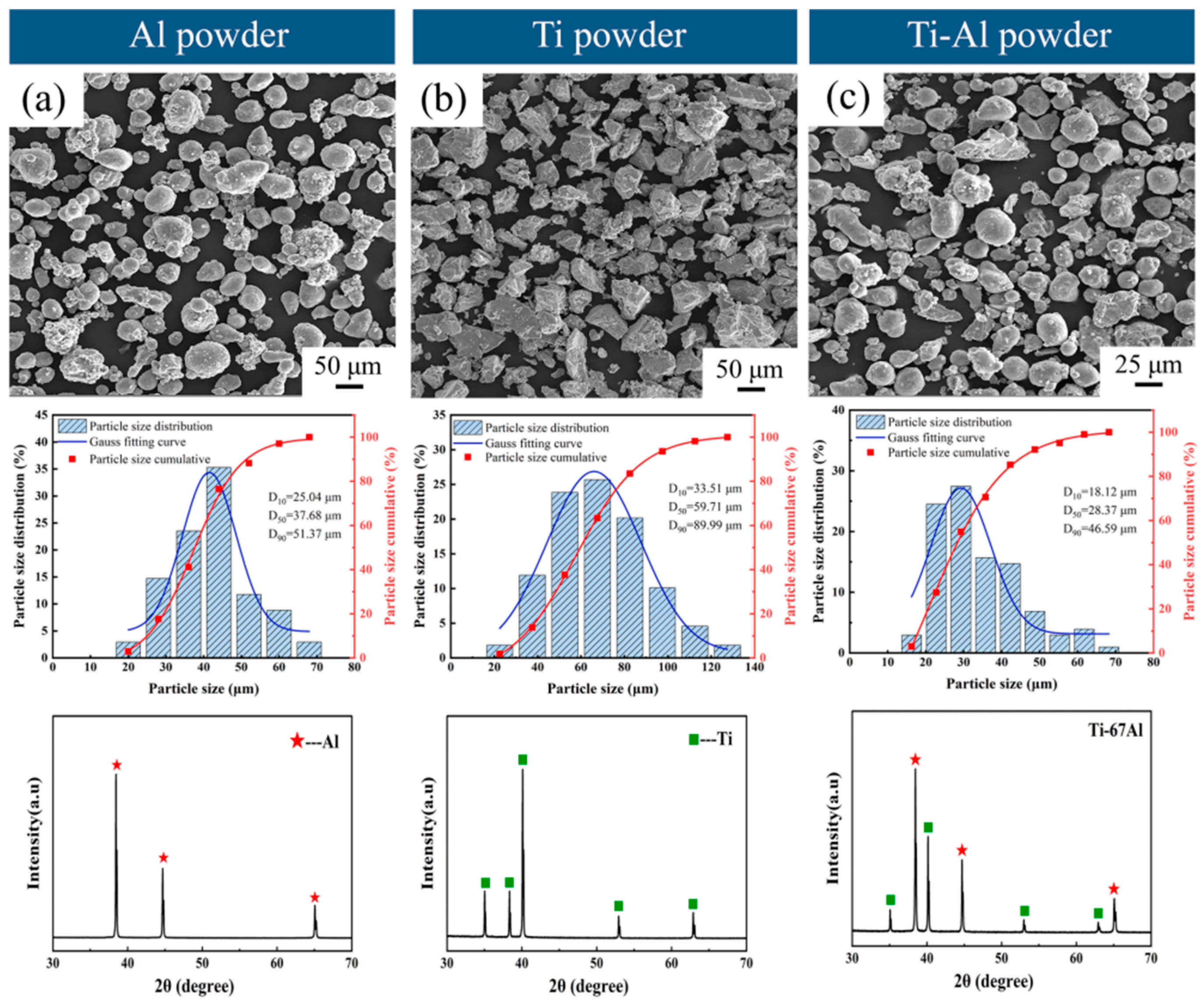

2.1. Materials and Processing

2.2. Sintering Model

2.3. Characterization

3. Results and Discussion

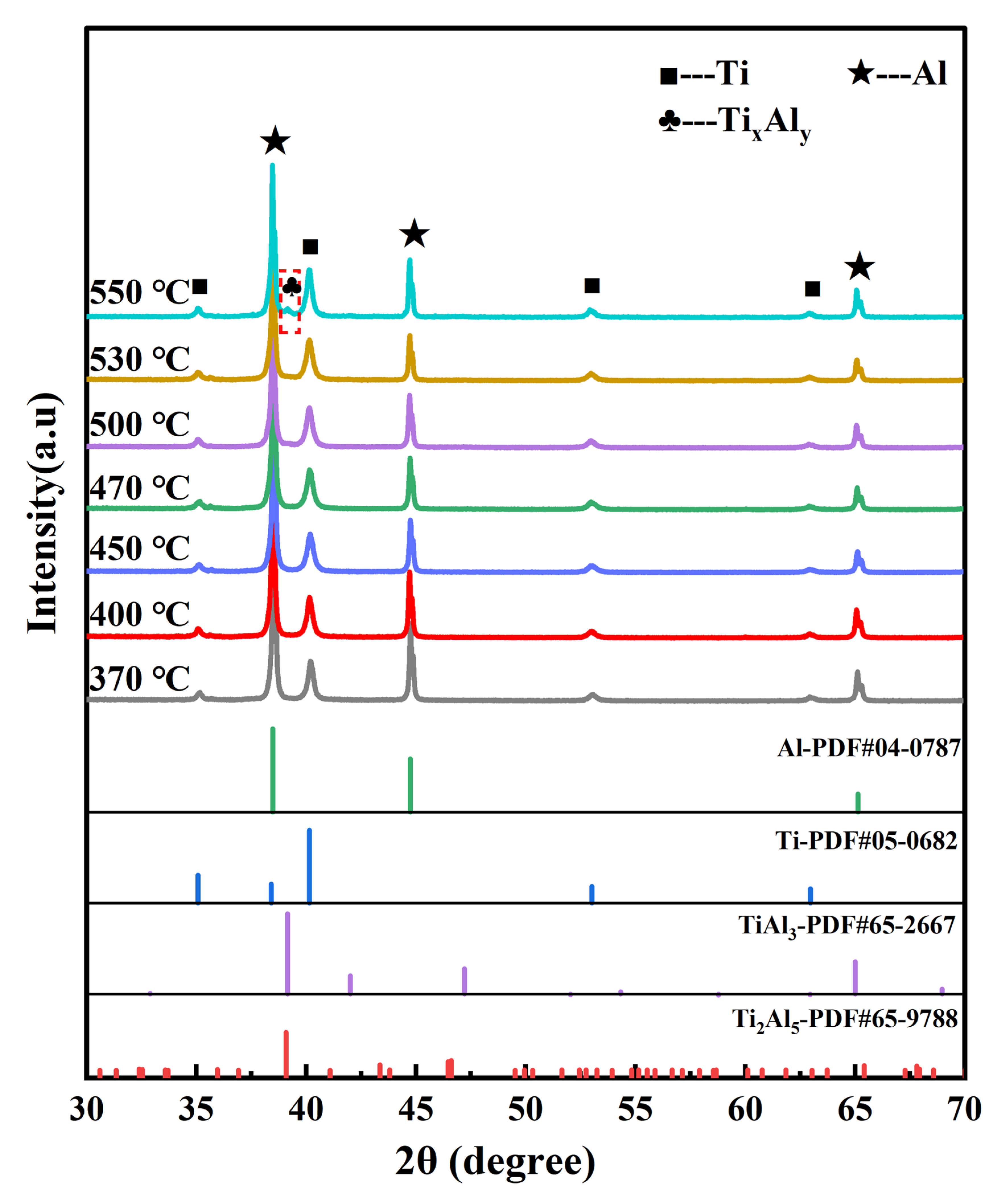

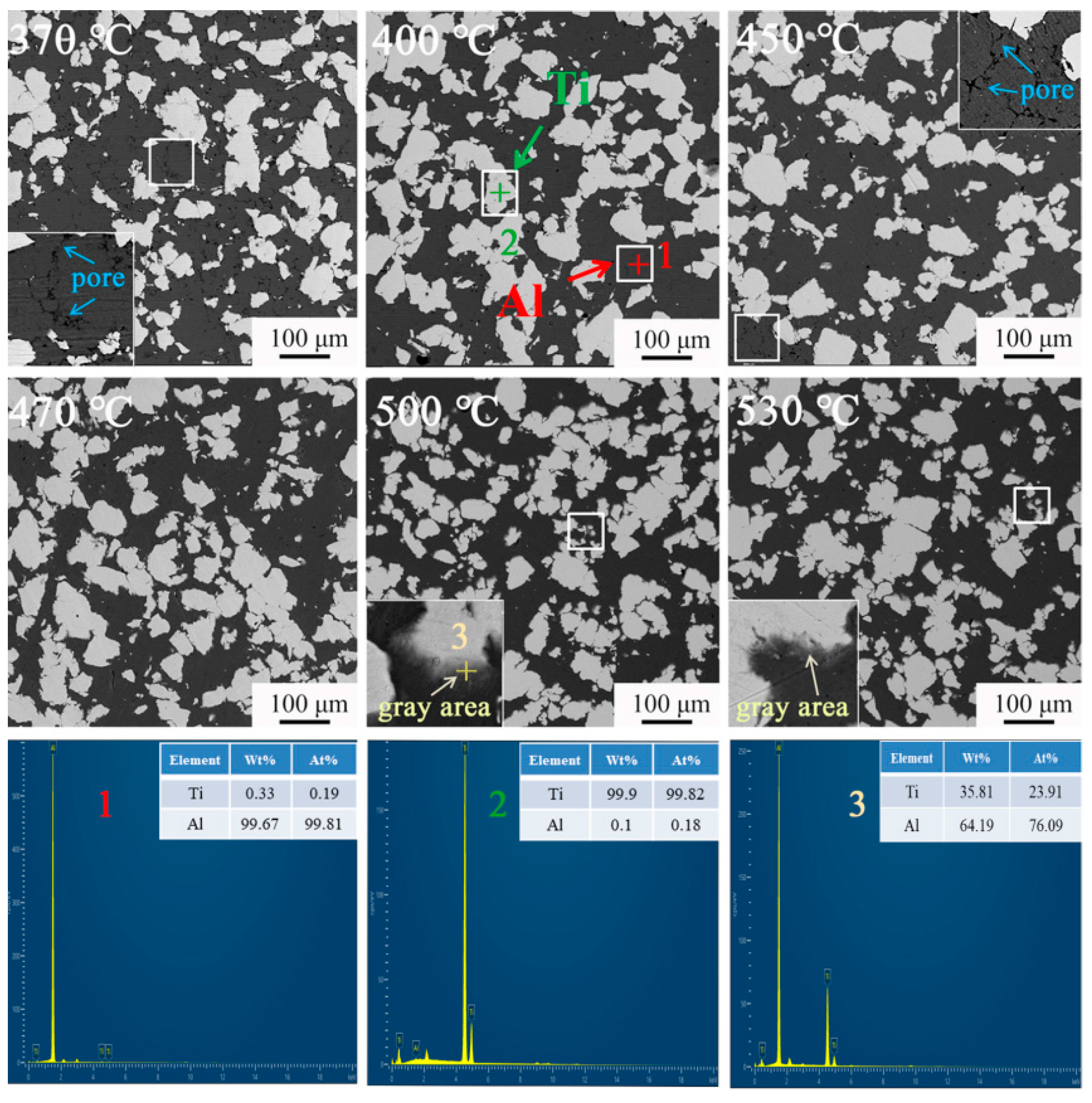

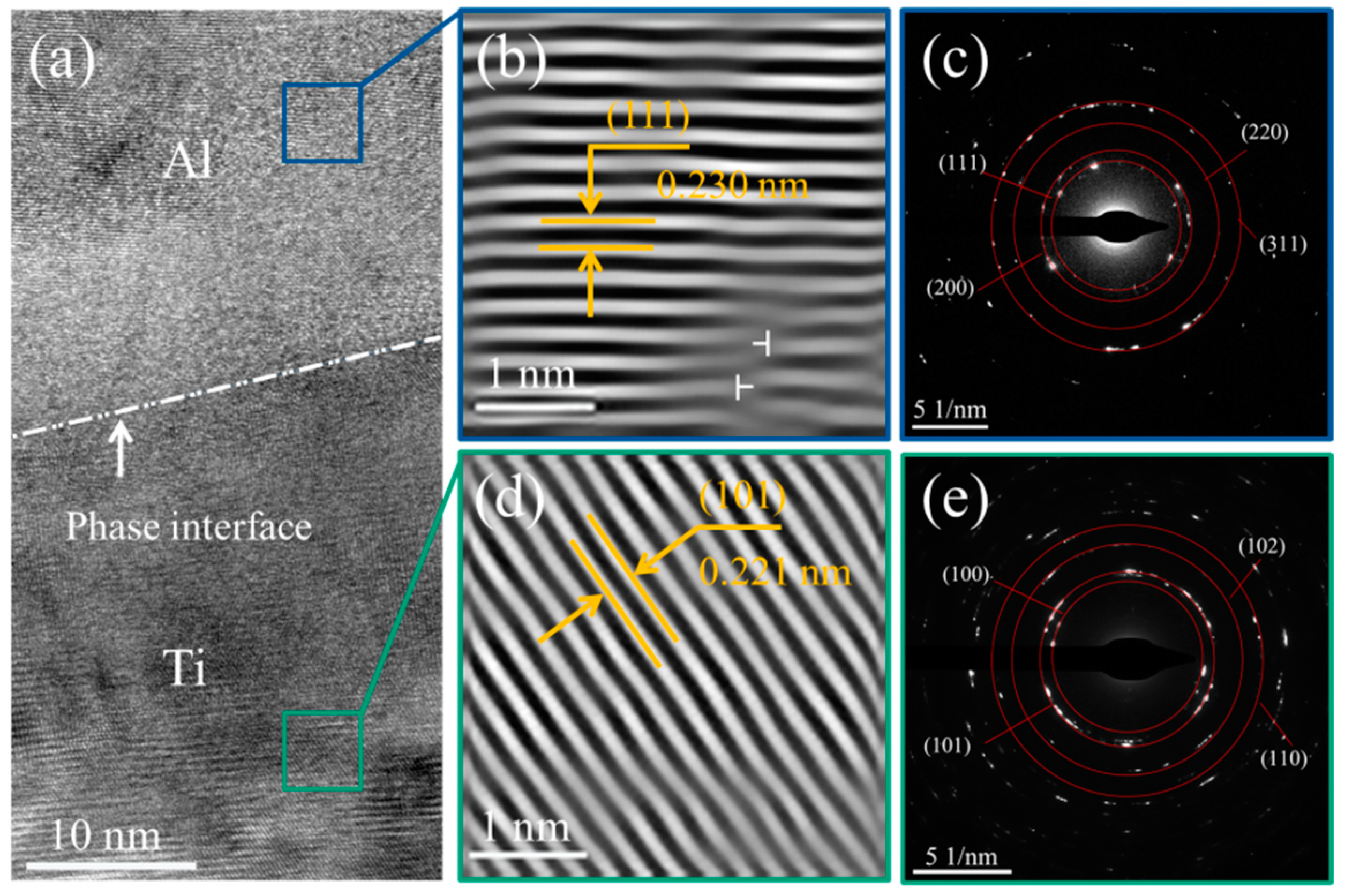

3.1. Microstructural Evolution of Ti-67 at% Al Targets

3.2. Comprehensive Characterization of Ti-67 at% Al Targets

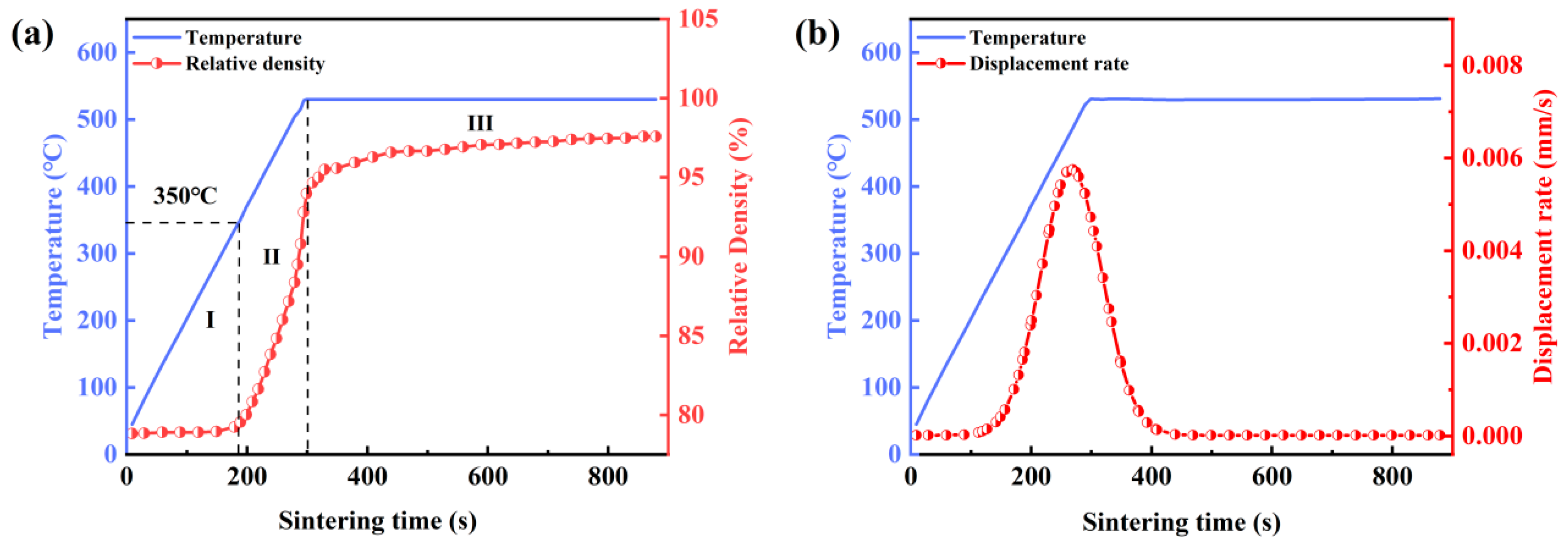

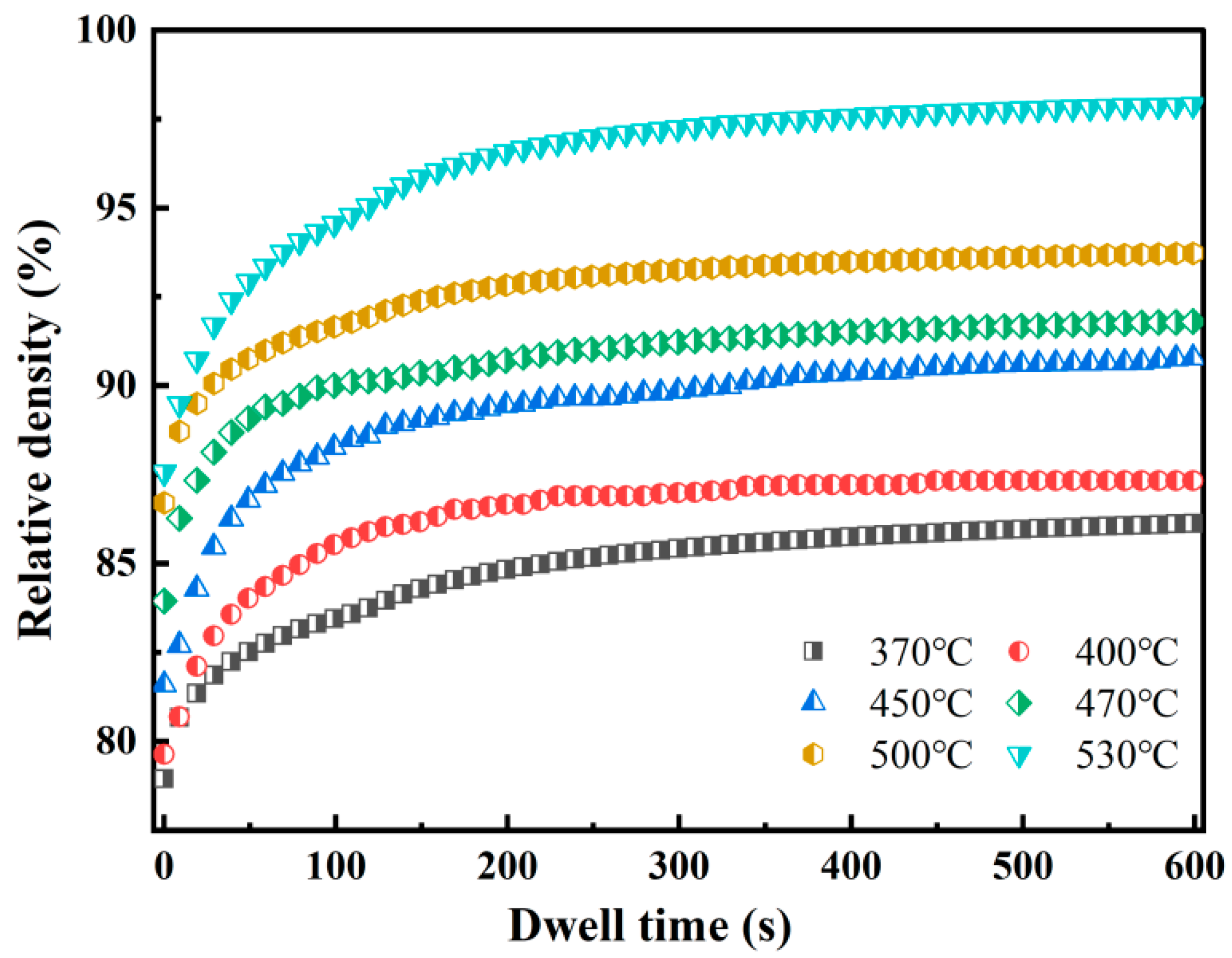

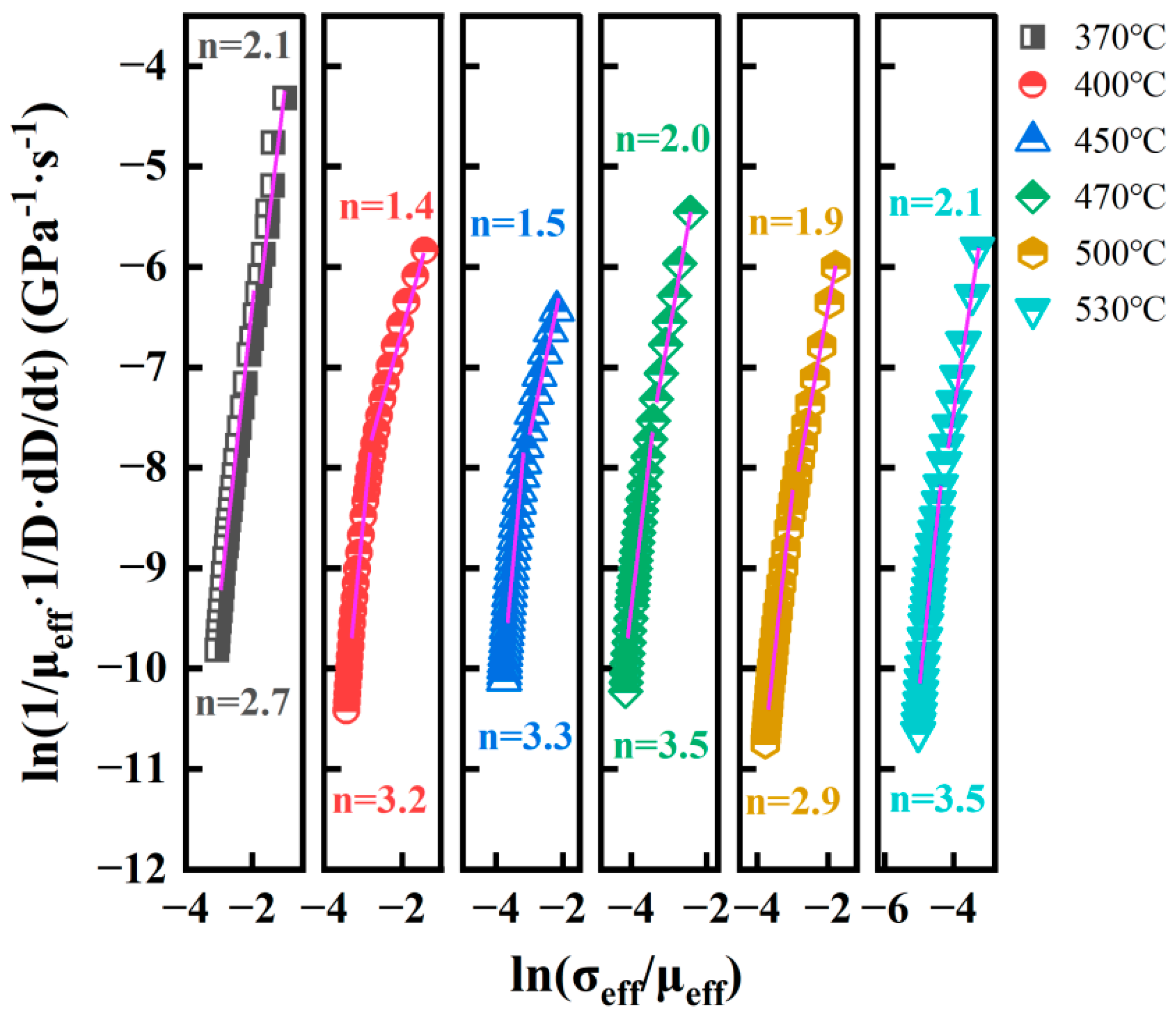

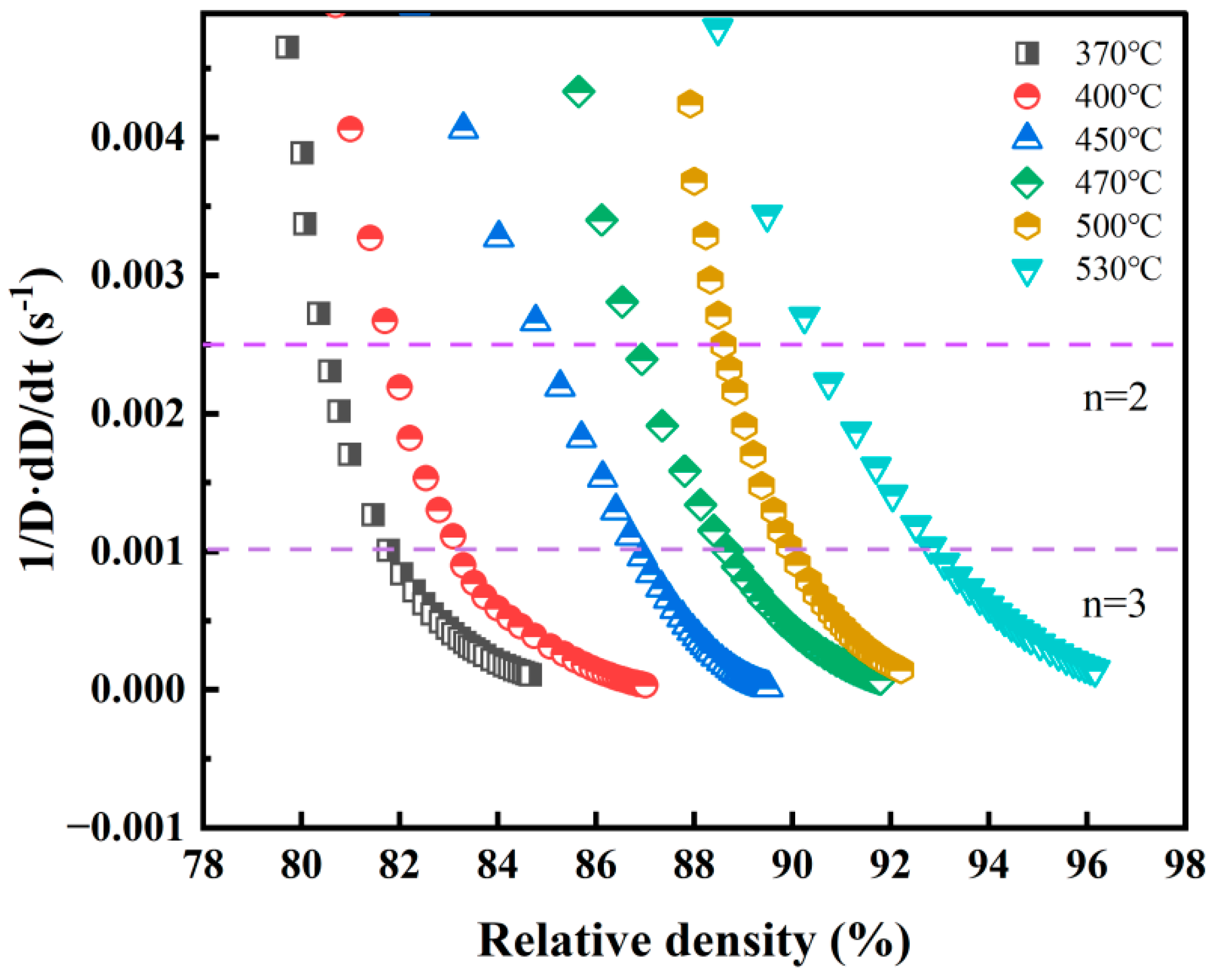

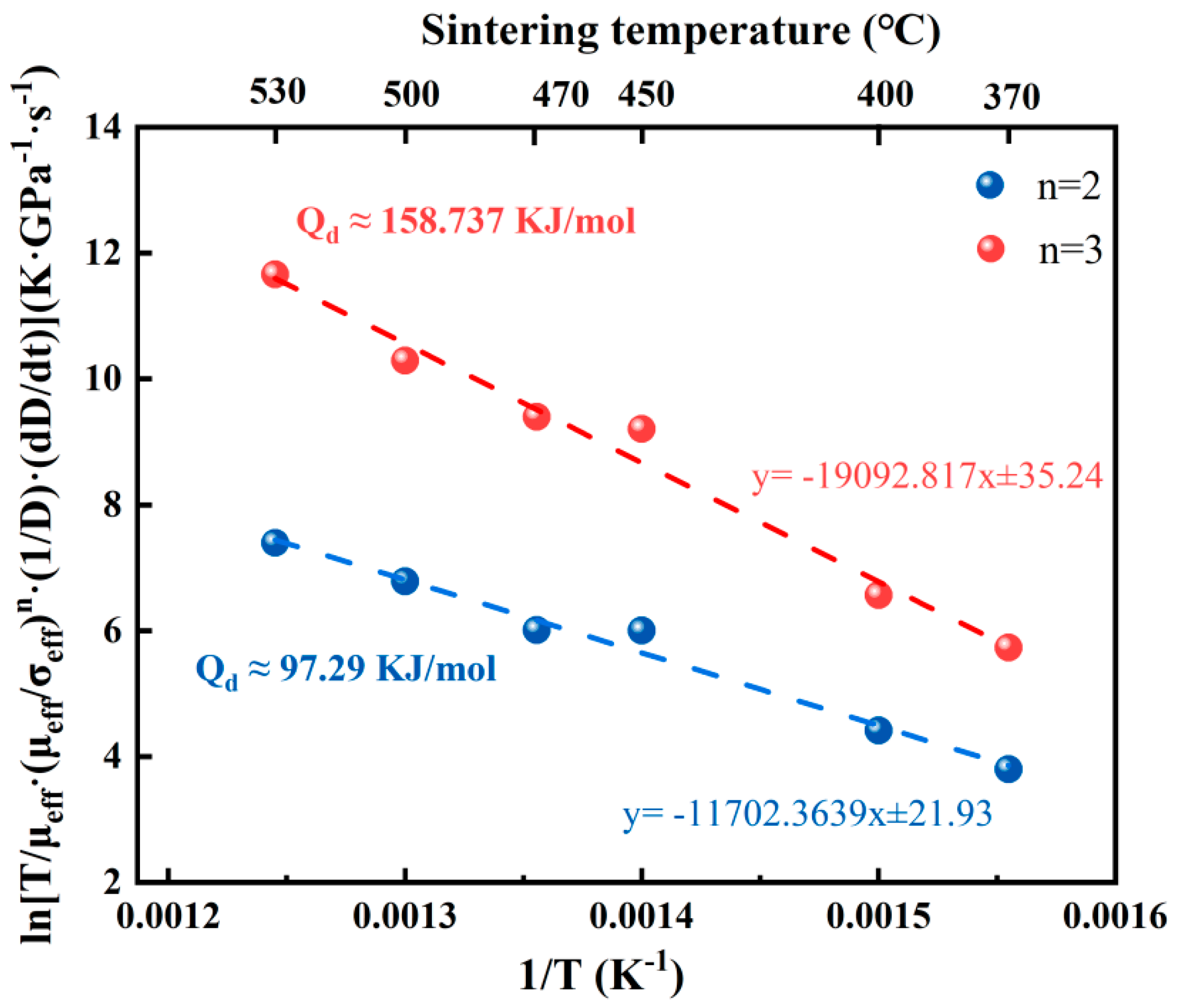

3.3. Densification Mechanism of Ti-67 at% Al Targets

3.4. Performance Comparison and Discussion

4. Conclusions

- A high relative density of 98.25% was obtained at 530 °C. Densification dominated in the sintering range of 370–530 °C, while grain size remained relatively constant.

- A creep model was applied to analyze the densification mechanism in detail. Intergranular diffusion dominated during the early stage of holding from 370 to 530 °C, while dislocation climbing dominated in the later stage of holding at 370 to 530 °C. Furthermore, the activation energies calculated at n = 2 and n = 3 were 97.29 and 158.737 kJ/mol, respectively.

- As the temperature increased, the Vickers hardness of the target rose from 61.56 to 129.66 HV, while its electrical conductivity also increased from 0.23 to 0.86 S/cm. This improvement was primarily due to the increase in the target’s relative density.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, L.M.; Li, W.H.; Sun, H.L.; Wang, G.X. Effects of Ti target purity and microstructure on deposition rate, microstructure and properties of Ti films. Materials 2022, 15, 2661. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.-K.; Yang, W.-H.; Wang, Y.-P.; Zhao, G.-H.; Zhan, S.-S.; Wang, D.; Tang, B.; Bao, M.-D. Effect of target grain size on target sputter etching morphology and performance. Vacuum 2022, 201, 111083. [Google Scholar] [CrossRef]

- Chen, L.; Yang, Y.; Wu, M.J.; Xu, Y.X.; Du, Y.; Kolozsvári, S. Correlation between arc evaporation of Ti-Al-N coatings and corresponding Ti0.50Al0.50 target types. Surf. Coat. Technol. 2015, 275, 309–315. [Google Scholar] [CrossRef]

- Zhou, W.; Liang, J.; Zhang, F.; Mu, J.; Zhao, H. A comparative research on TiAlN coatings reactively sputtered from powder and from smelting TiAl targets at various nitrogen flow rates. Appl. Surf. Sci. 2014, 313, 10–18. [Google Scholar] [CrossRef]

- Wu, Z.; Mei, F.; Chen, W.; Yang, Y.; Lin, X.; Yuan, T.; Lin, J. Effects of the phase composition and grain size of Cr particles in Al-Cr targets on the microstructure and properties of AlCrN coatings. Ceram. Int. 2022, 48, 35267–35279. [Google Scholar] [CrossRef]

- Huang, L.; Pan, Y.; Zhang, J.; Du, Y.; Zhang, Y. Spark plasma sintering of W-30Si refractory targets: Microstructure, densification and mechanical properties. Int. J. Refract. Met. Hard Mater. 2022, 105, 105833. [Google Scholar] [CrossRef]

- Huang, L.; Pan, Y.; Zhang, J.; Du, Y.; Zhang, Y.; Zhang, S. Densification, grain growth mechanism and mechanical properties of Mo-10Nb refractory targets fabricated by SPS. Int. J. Refract. Met. Hard Mater. 2021, 99, 105575. [Google Scholar] [CrossRef]

- Zhang, M.; Yuan, T.; Li, R.; Xie, S.; Wang, M.; Weng, Q. Densification mechanisms and microstructural evolution during spark plasma sintering of boron carbide powders. Ceram. Int. 2018, 44, 3571–3579. [Google Scholar] [CrossRef]

- Huang, L.; Zhang, J.; Pan, Y.; Du, Y. Spark plasma sintering of W-10Ti high-purity sputtering target: Densification mechanism and microstructure evolution. Int. J. Refract. Met. Hard Mater. 2020, 92, 105313. [Google Scholar] [CrossRef]

- Lou, W.; Li, X.; Wei, S.; Wang, Q.; Liang, J.; Chen, L.; Xu, L.; Zhou, Y. Effect of Nano-Y2O3 on the microstructure and mechanical properties of Cu-10W composites prepared by spark plasma sintering. Ceram. Int. 2023, 49, 36251–36264. [Google Scholar] [CrossRef]

- Boztemur, B.; Bayrak, K.G.; Gökçe, H.; Ayas, E.; Balcı-Çağıran, Ö.; Derin, B.; Ağaoğulları, D.; Öveçoğlu, M.L. Mechanically alloyed and spark plasma sintered WNbMoVTa refractory high entropy alloys: Effects of Cr and Al on the microstructural and mechanical properties. J. Alloys Compd. 2023, 965, 171415. [Google Scholar] [CrossRef]

- Liu, J.; Li, F.; Yi, J.; Liu, Y.; Eckert, J.; Zuo, Q. Microstructure evolution and mechanical properties of functionally graded Fe–8Cr-xNi alloys fabricated by spark plasma sintering. Mater. Sci. Eng. A 2023, 866, 144648. [Google Scholar] [CrossRef]

- Bernard-Granger, G.; Guizard, C. Spark plasma sintering of a commercially available granulated zirconia powder: I. Sintering path and hypotheses about the mechanism(s) controlling densification. Acta Mater. 2007, 55, 3493–3504. [Google Scholar] [CrossRef]

- Gendre, M.; Maître, A.; Trolliard, G. A study of the densification mechanisms during spark plasma sintering of zirconium (oxy-)carbide powders. Acta Mater. 2010, 58, 2598–2609. [Google Scholar] [CrossRef]

- Wang, C.B.; Cheng, Y.X.; Hu, S.M.; Kang, K.J.; Han, Y.Z.; Zhang, X.D.; Dai, X.P.; Luo, G.Q. Densification mechanism, and microstructural evolution of W-Si-C composite consolidated via field assisted sintering. Int. J. Refract. Met. Hard Mater. 2023, 116, 106378. [Google Scholar] [CrossRef]

- Kang, K.; Yu, B.; Liu, S.; Wu, L.; Hu, S.; Tu, R.; Luo, G.; Wei, R. Densification and properties of WC-CoCrFeNi/Co cemented carbide fabricated via spark plasma sintering. Ceram. Int. 2024, 50, 52356–52368. [Google Scholar] [CrossRef]

- Shima, S.; Oyane, M. Plasticity theory for porous metals. Int. J. Mech. Sci. 1976, 18, 285–291. [Google Scholar] [CrossRef]

- Bernard-Granger, G.; Guizard, C. Densification mechanism involved during spark plasma sintering of a codoped α-alumina material: Part I. Formal sintering analysis. J. Mater. Res. 2009, 24, 179–186. [Google Scholar] [CrossRef]

- Deng, S.; Yuan, T.; Li, R.; Zeng, F.; Liu, G.; Zhou, X. Spark plasma sintering of pure tungsten powder: Densification kinetics and grain growth. Powder. Technol. 2017, 310, 264–271. [Google Scholar] [CrossRef]

- Dong, C.; Bi, X.; Yu, J.; Liu, R.; Zhang, Q.X. Microstructural evolution and sintering kinetics during spark plasma sintering of pure tantalum powder. J. Alloys Compd. 2019, 781, 84–92. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Zhang, M.; Zhou, Z.H.; Wang, M.B.; Xie, S.Y.; Zhao, Y.Z.; Xu, Y.B.; Yuan, T.C.; Li, R.D. Multi-stage spark plasma sintering to study the densification mechanisms of boron carbide. Int. J. Refract. Met. Hard Mater. 2020, 93, 105351. [Google Scholar] [CrossRef]

- Bernard-Granger, G.; Addad, A.; Fantozzi, G.; Bonnefont, G.; Guizard, C.; Vernat, D. Spark plasma sintering of a commercially available granulated zirconia powder: Comparison with hot-pressing. Acta Mater. 2010, 58, 3390–3399. [Google Scholar] [CrossRef]

- Ramond, L.; Bernard-Granger, G.; Addad, A.; Guizard, C. Sintering of a quasi-crystalline powder using spark plasma sintering and hot-pressing. Acta Mater. 2010, 58, 5120–5128. [Google Scholar] [CrossRef]

- Martins, D.; Grumbach, F.; Simoulin, A.; Sallot, P.; Mocellin, K.; Bellet, M.; Estournès, C. Spark plasma sintering of a commercial TiAl 48-2-2 powder: Densification and creep analysis. Mater. Sci. Eng. A 2018, 711, 313–316. [Google Scholar] [CrossRef]

- Helle, A.S.; Easterling, K.E.; Ashby, M.F. Hot-isostatic pressing diagrams: New developments. Acta Metall. 1985, 33, 2163–2174. [Google Scholar] [CrossRef]

- Lam, D.C.C.; Lange, F.F.; Evans, A.G. Mechanical properties of partially dense alumina produced from powder compacts. J. Am. Ceram. Soc. 1994, 77, 2113–2117. [Google Scholar] [CrossRef]

- Sun, Y.; Kulkarni, K.; Sachdev, A.K.; Lavernia, E.J. Synthesis of γ-TiAl by reactive spark plasma sintering of cryomilled Ti and Al powder blend, Part I: Influence of processing and microstructural evolution. Metall. Mater. Trans. A 2014, 45, 2750–2758. [Google Scholar] [CrossRef]

- Jeje, S.O.; Shongwe, M.B.; Maledi, N.; Olubambi, P.A.; Babalola, B.J. Spark plasma sintering of Ti-48Al intermetallic using elemental powder. Int. J. Adv. Manuf. Technol. 2019, 103, 3025–3032. [Google Scholar] [CrossRef]

- Liu, G.; Li, R.; Yuan, T.; Zhang, M.; Zeng, F. Spark plasma sintering of pure TiCN: Densification mechanism, grain growth and mechanical properties. Int. J. Refract. Met. Hard Mater. 2017, 66, 68–75. [Google Scholar] [CrossRef]

- Liu, T.; Zhang, W.; Zhai, X. Dense ternary-size particles interstitial filling gradation stacking model for preparing high-quality indium tin oxide targets. Chem. Eng. Sci. 2022, 248, 117165. [Google Scholar] [CrossRef]

- Flaureau, A.; Weibel, A.; Chevallier, G.; Estournès, C. Study of the densification and grain growth mechanisms occurring during spark plasma sintering of different submicronic yttria-stabilized zirconia powders. J. Eur. Ceram. Soc. 2021, 41, 3581–3594. [Google Scholar] [CrossRef]

- Hwa, L.G.; Chao, W.C. Velocity of sound and elastic properties of lanthanum gallo-germanate glasses. Mater. Chem. Phys. 2005, 94, 37–41. [Google Scholar] [CrossRef]

- Weertman, J. Steady-state creep of crystals. J. Appl. Phys. 1957, 28, 1185–1189. [Google Scholar] [CrossRef]

- Muramatsu, M.; Suzuki, T.; Nakasone, Y. Effects of microstructure on material properties of modified 9Cr-1Mo steel subject to creep-fatigue. J. Mech. Sci. Technol. 2015, 29, 121–129. [Google Scholar] [CrossRef]

- Wen, Z.; Zhang, D.; Li, S.; Yue, Z.; Gao, J. Anisotropic creep damage and fracture mechanism of nickel-base single crystal superalloy under multiaxial stress. J. Alloys Compd. 2017, 692, 301–312. [Google Scholar] [CrossRef]

- Rajaguru, M.; Keralavarma, S.M. A discrete dislocation dynamics model of creeping single crystals, Modelling Simul. Mater. Sci. Eng. 2018, 26, 035007. [Google Scholar] [CrossRef]

- Wen, Z.X.; Liang, J.W.; Liu, C.Y.; Pei, H.Q.; Wen, S.F.; Yue, Z.F. Prediction method for creep life of thin-wall specimen with film cooling holes in Ni-based single-crystal superalloy. Int. J. Mech. Sci. 2018, 141, 276–289. [Google Scholar] [CrossRef]

- Liu, H.-W.; Bishop, D.P.; Plucknett, K.P. Densification behaviour and microstructural evolution of Ti-48Al consolidated by spark plasma sintering. J. Mater. Sci. 2017, 52, 613–627. [Google Scholar] [CrossRef]

- Li, X.R.; Ju, Y.P.; Zhao, Z.L.; Wang, Y.C. Effect of sintering temperature on properties of TiAl target. Nonferr. Met. Process. 2024, 53, 17–21. [Google Scholar]

- Syed, B.; Jöesaar, M.J.; Polcik, P.; Kolozsvari, S.; Håkansson, G.; Johnson, L.; Ahlgren, M.; Odén, M. Effect of work function and cohesive energy of the constituent phases of Ti-50 at.% Al cathode during arc deposition of Ti-Al-N coatings. Surf. Coat. Technol. 2019, 357, 393–401. [Google Scholar] [CrossRef]

| Powders | Suppliers | Average Particle Size (μm) | Purity (%) |

|---|---|---|---|

| Ti | Shanghai Aladdin Bio-Chem Technology Co., Ltd. (Shanghai, China) | 59.71 | 99.5 |

| Al | Hunan Jinhao Technology Co., Ltd. (Luxi, China) | 37.68 | 99.85 |

| Jar composition | Polyethylene |

| Milling media | Zirconium oxide |

| Rotation speed | 150 rpm |

| Ball-to-powder weight ratio | 5:1 |

| Milling time | 5 h |

| Process control agent | Ethanol |

| Volume of the jar | 105 mL |

| Balls number (by quantity ratio) | Large–medium–small = 1:1:2 |

| Ti-67 at% Al Powder | Measured Value | Unit | |

|---|---|---|---|

| Composition | Al | 66.85 | at% |

| Impurity | Fe | 8.258 | ppm |

| Si | 4.104 | ppm | |

| Cu | 2.15 | ppm | |

| Ga | 0.03 | ppm | |

| Zn | 3.44 | ppm | |

| Cl | 0.007 | ppm | |

| Ni | 0.06 | ppm | |

| Zr | 1.75 | ppm | |

| As | 0.001 | ppm | |

| Gas element | O | 920 | ppm |

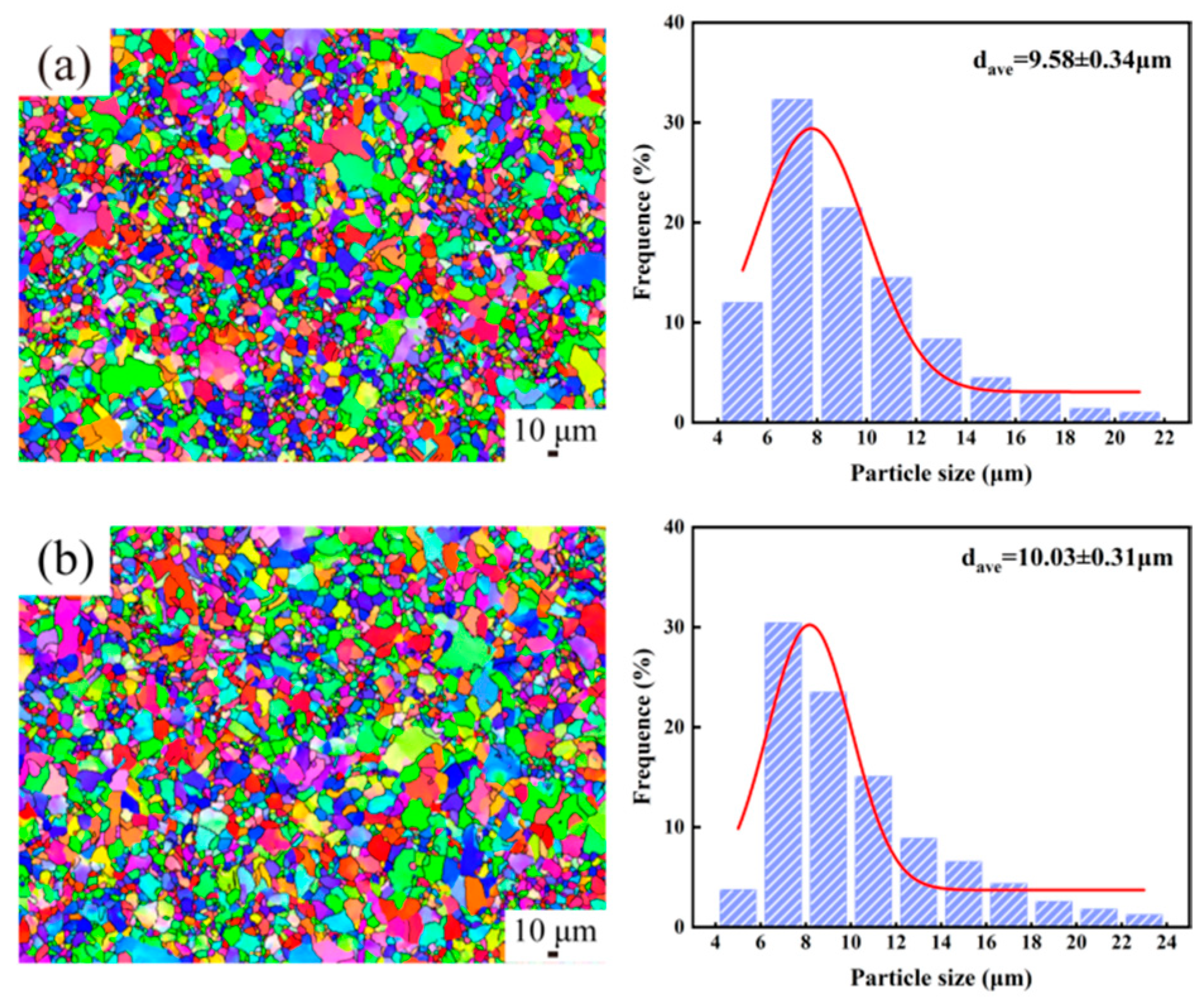

| Temperature (°C) | Relative Density (%) | Grain Size (μm) | Hardness (HV) | Electrical Conductivity (S/cm) |

|---|---|---|---|---|

| 370 | 86.14 ± 0.43 | 9.34 ± 0.93 | 61.56 ± 11.69 | 0.23 ± 0.02 |

| 400 | 87.32 ± 0.44 | 9.58 ± 0.34 | 69.3 ± 20.69 | 0.40 ± 0.03 |

| 450 | 91.78 ± 0.46 | 9.86 ± 0.78 | 74.87 ± 20.33 | 0.59 ± 0.04 |

| 470 | 92.8 ± 0.46 | 10.03 ± 0.37 | 80.37 ± 22.01 | 0.70 ± 0.04 |

| 500 | 95.72 ± 0.42 | 10.44 ± 0.56 | 97.2 ± 11.86 | 0.76 ± 0.03 |

| 530 | 98.25 ± 0.43 | 10.86 ± 1.08 | 129.66 ± 7.50 | 0.86 ± 0.04 |

| Alloy (at%) | Powder | Method | T/°C | Relative Density/% | Microstructure | Hardness/HV | Grain Size/μm |

|---|---|---|---|---|---|---|---|

| Ti-67Al | Ti, Al | SPS | 530 | 98.25 | Ti, Al | 129.66 | 10.86 ± 1.08 |

| Ti-48Al [28] | Ti, Al | SPS | 600 | 99.5 | Ti, γ, α2 | <100 | / |

| Ti-48Al [38] | pre-alloyed Ti-48Al | SPS | 1200 | 98 | Γ, α2 | <100 | / |

| Ti-50Al [39] | Ti, Al | HIP | 1250 | 99.72 | γ | 339.7 | 78.7 |

| Commercial Ti-67Al | / | HIP | / | 99.35 | Ti, Al | 135.4 | 12.68 ± 2.38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Wang, W.; Su, Y.; Han, Y.; Yang, M.; Goto, T.; Tu, R. Sintering Kinetics, Mechanical Properties, and Electrical Conductivity of Ti-67 at% Al Targets Fabricated via Spark Plasma Sintering. Coatings 2025, 15, 1029. https://doi.org/10.3390/coatings15091029

Li Q, Wang W, Su Y, Han Y, Yang M, Goto T, Tu R. Sintering Kinetics, Mechanical Properties, and Electrical Conductivity of Ti-67 at% Al Targets Fabricated via Spark Plasma Sintering. Coatings. 2025; 15(9):1029. https://doi.org/10.3390/coatings15091029

Chicago/Turabian StyleLi, Qizhong, Weiyan Wang, Yibing Su, Yuzhe Han, Meijun Yang, Takashi Goto, and Rong Tu. 2025. "Sintering Kinetics, Mechanical Properties, and Electrical Conductivity of Ti-67 at% Al Targets Fabricated via Spark Plasma Sintering" Coatings 15, no. 9: 1029. https://doi.org/10.3390/coatings15091029

APA StyleLi, Q., Wang, W., Su, Y., Han, Y., Yang, M., Goto, T., & Tu, R. (2025). Sintering Kinetics, Mechanical Properties, and Electrical Conductivity of Ti-67 at% Al Targets Fabricated via Spark Plasma Sintering. Coatings, 15(9), 1029. https://doi.org/10.3390/coatings15091029