Dynamic Response Analysis of Steel Bridge Deck Pavement Using Analytical Methods

Abstract

1. Introduction

2. Materials and Methods

2.1. Modal Function for Equal-Span Continuous Beams

2.2. Calculation of Bending Stiffness for Composite Beams

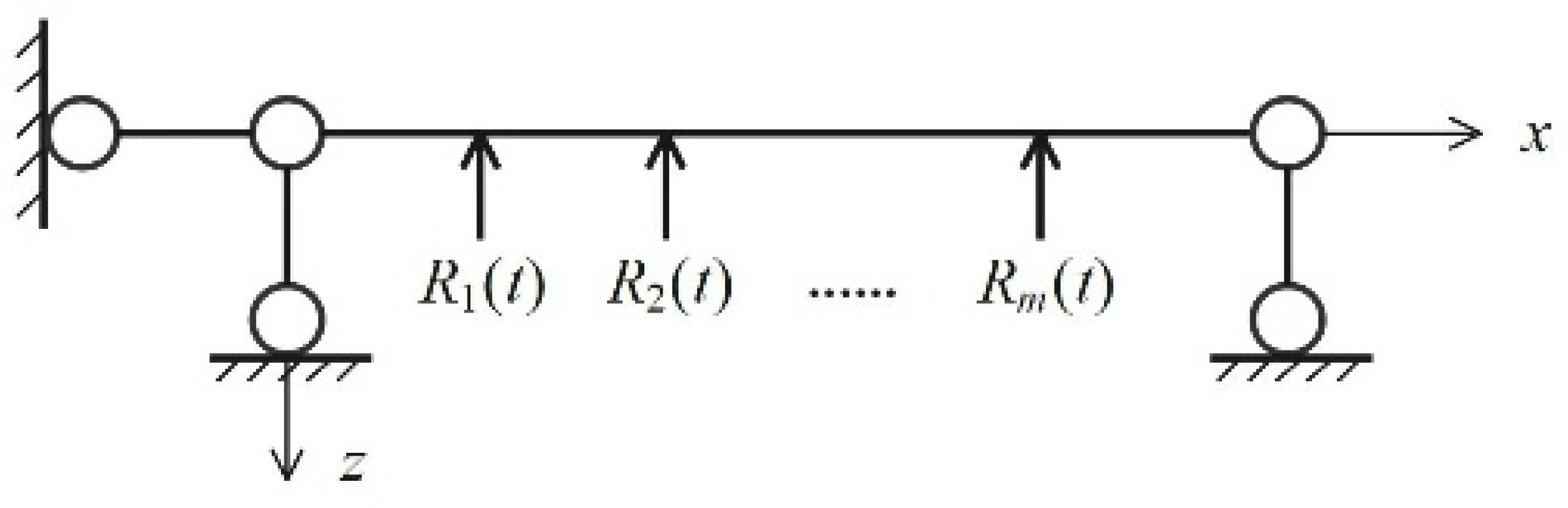

2.3. Forced Vibration Calculation of a Three-Equal-Span Composite Beam

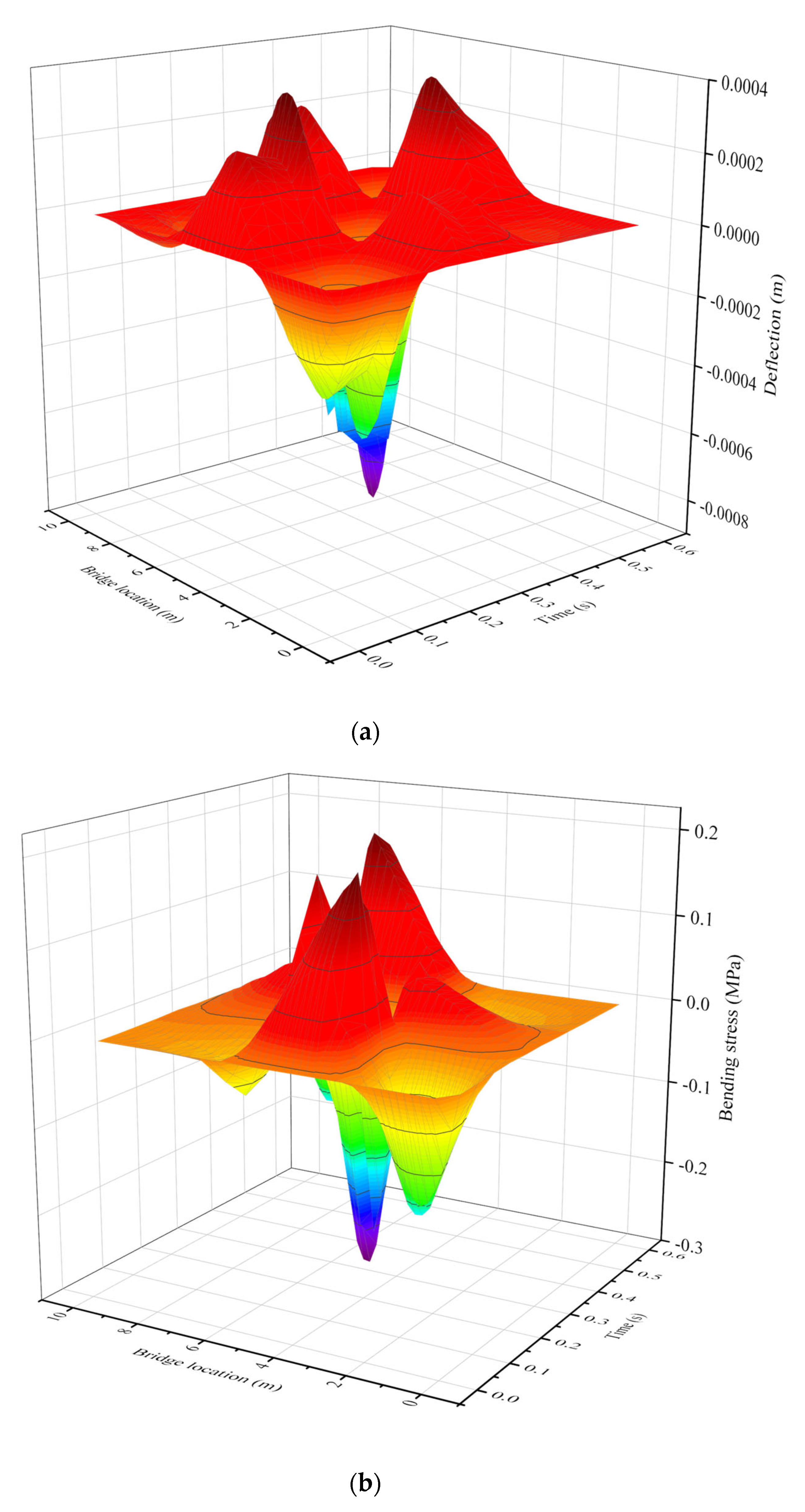

3. Results and Discussions

3.1. Evaluation of Analytical Solution

3.2. Influence of Structural Parameters on Dynamic Response

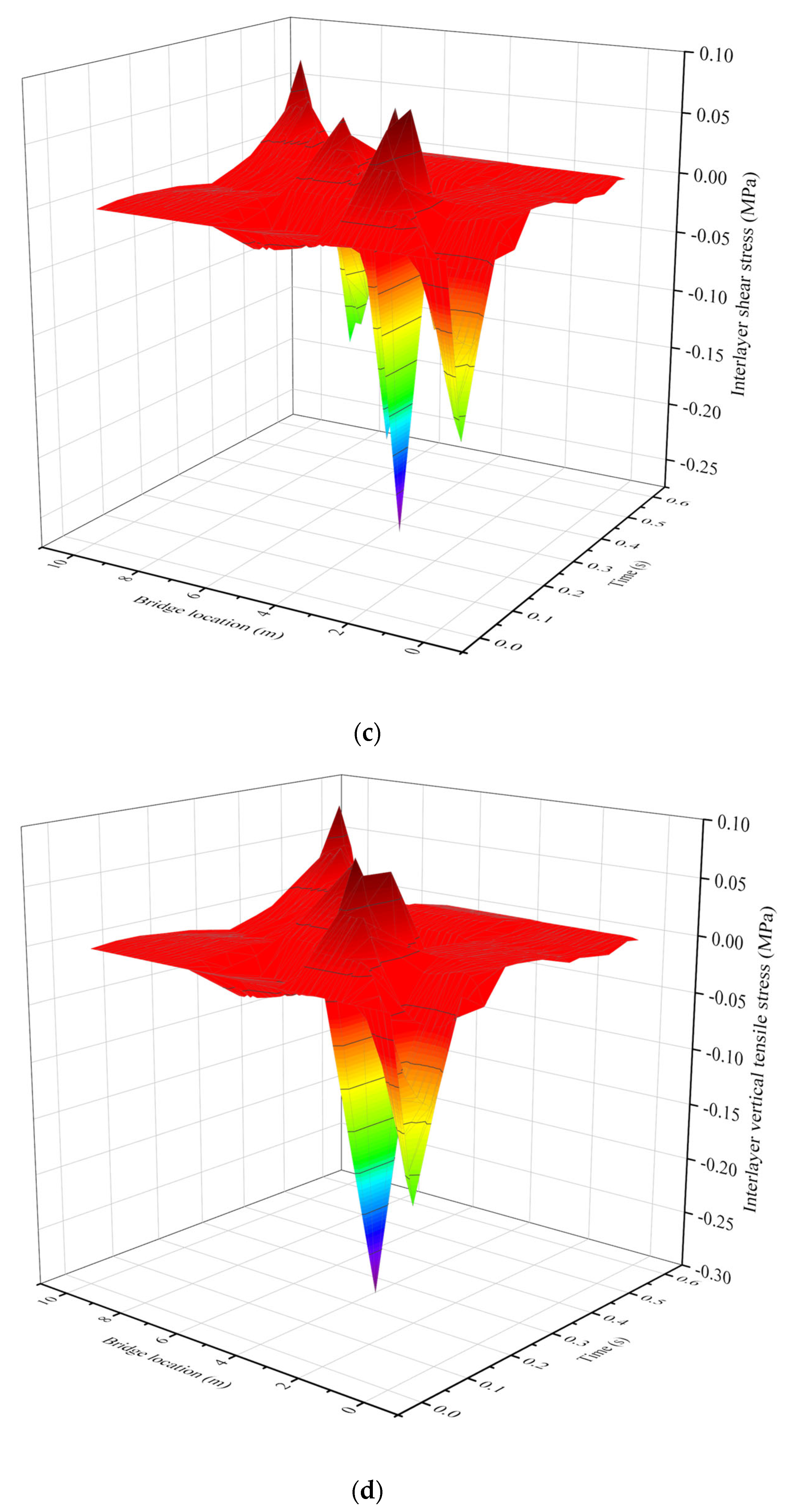

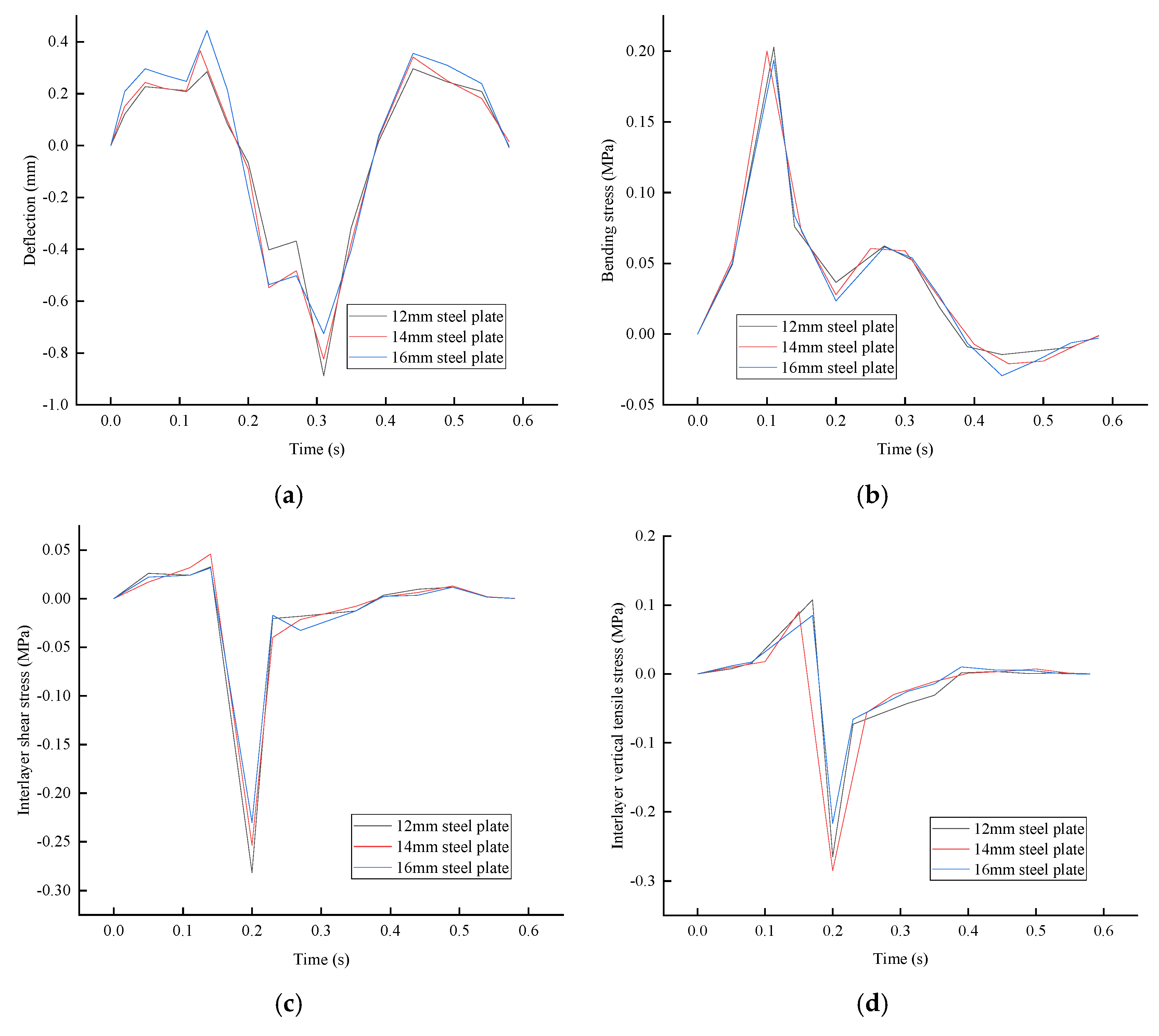

3.2.1. Steel Plate Thickness

3.2.2. UHPC Thickness

3.2.3. SMA Thickness

4. Conclusions

- The proposed analytical model demonstrates exceptional accuracy, with deviations of less than 1% in natural frequencies compared to FEM results, validating its effectiveness in capturing dynamic characteristics.

- All key response indicators derived from the analytical formulas show strong agreement with finite element simulations, confirming the reliability and general applicability of the theoretical framework.

- A significant finding is the identification of critical response locations: maximum deflection occurs near the midspan of the second span, while the most unfavorable conditions for bending stress, UHPC-SMA interlayer shear stress, and vertical tensile stress are consistently located at the beginning of the second span.

- This study quantitatively demonstrates that increasing the thickness of key components—namely the steel plate, UHPC layer, and asphalt pavement—effectively reduces peak dynamic responses and enhances overall mechanical performance under dynamic loads, providing practical guidance for optimized design. At the same time, within the range of parameters discussed, the optimal structural combination plan is: 16 mm steel plate + 80 mmUHPC + 40 mmSMA.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Han, Y.J.; Zhang, Z.; Tian, J.H.; Ni, F.J. Long-term in situ performance evaluation of epoxy asphalt concrete for long-span steel bridge deck pavement. Coatings 2023, 13, 545. [Google Scholar] [CrossRef]

- Deng, S.W.; Zhou, H.Y.; Shao, X.D.; Mo, R.; Wag, Y. Effects of moving traffic on fresh UHPC retrofit orthotropic steel decks. Constr. Build. Mater. 2025, 491, 142614. [Google Scholar] [CrossRef]

- Wu, J.T.; Ye, F.; Wu, H.R.; Jia, X.Y. Dynamic strain response of asphalt pavement on steel bridge deck under real bridge loading. J. Tongji Univ. (Nat. Sci.) 2014, 42, 378–385. [Google Scholar]

- Cheng, H.L.; Liu, L.P.; Sun, L.J. Experimental study on dynamic strain response of asphalt mixture pavement on steel bridge deck. China Civ. Eng. J. 2019, 52, 100–109. [Google Scholar]

- Ye, F.; Song, Q.Q. Mechanical response of ultra-high performance concrete pavement on steel bridge deck under real bridge loading. J. Tongji Univ. (Nat. Sci.) 2020, 48, 982–989. [Google Scholar]

- Si, C.; Su, X.; Chen, E.; Yan, Z. Comparative study on dynamic response of deck pavement of two kinds of box girder bridges under moving loads. Shock Vib. 2019, 2019, 6052745. [Google Scholar] [CrossRef]

- Zeng, G.D.; Xu, W.; Huang, H.M. Study of the strain response of asphalt pavements on orthotropic steel bridge decks through field testing and numerical simulation. J. Test. Eval. 2020, 48, 1615–1633. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, L.; Liu, G.; Qian, Z. Dynamic response of multitower suspension bridge deck pavement under random vehicle load. Adv. Mater. Sci. Eng. 2021, 2021, 6667853. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, C.; Sun, R. Response analysis of orthotropic steel deck pavement based on interlayer contact bonding condition. Sci. Rep. 2021, 11, 23692. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Hui, B.; Rahman, A. Interlayer shear characteristics of bridge deck pavement through experimental and numerical analysis. Materials 2022, 15, 7001. [Google Scholar] [CrossRef] [PubMed]

- Cui, Y.; Si, C.; Li, S.; Fan, T. Comparative study of the mesomechanical response of asphalt bridge deck pavement under multiple loads. Coatings 2022, 12, 1665. [Google Scholar] [CrossRef]

- Chen, L.; Liu, G.; Pan, G.; Qian, Z.D. Investigation on the pore water pressure in steel bridge deck pavement under the coupling effect of water and vehicle load. Constr. Build. Mater. 2023, 409, 134021. [Google Scholar] [CrossRef]

- Liu, Y.; Qian, Z.D.; Zhang, M. Fatigue damage analysis of epoxy asphalt pavement for steel bridges considering coupled effects of heavy load and temperature variations. J. Southeast Univ. 2017, 33, 478–483. [Google Scholar]

- Da Silva, J.G.S. Dynamical performance of highway bridge decks with irregular pavement surface. Comput. Struct. 2004, 82, 871–881. [Google Scholar] [CrossRef]

- Seible, F.; Latham, C.T. Horizontal load transfer in structural concrete bridge deck overlays. J. Struct. Eng. 2015, 116, 2691–2710. [Google Scholar] [CrossRef]

- Wang, H.; Hu, C.S.; Wang, B.G. Structural analysis of continuous deck pavement at simply-supported beam bridge end. J. Xi’an Highway Univ. 2000, 20, 1–3. [Google Scholar]

- Zhao, F.J.; Li, Y.Z.; Yi, W.J. Simplified model for interlayer stress analysis of bridge deck asphalt pavement. China Civ. Eng. J. 2007, 40, 100–104. [Google Scholar]

- Ge, W.F. Study on Deformation Compatibility Between Steel Bridge Deck Pavement and Steel Box Girder Top Plate. Master’s Thesis, Southeast University, Nanjing, China, 2012. [Google Scholar]

- Pei, Z.Y.; Wu, P.; Zhou, D.; Xu, X.L. Stress analysis of steel bridge deck pavement based on elastic mechanics. J. Nanjing Tech Univ. (Nat. Sci. Ed.) 2021, 43, 497–502+522. [Google Scholar]

- Li, J. A method for determining exact solutions of natural vibration in multi-span continuous beams. Mech. Eng. 1992, 2, 27–29. [Google Scholar]

- Li, D.; Yang, H.; Ma, J.J.; Wang, J.; Wang, C.S.; Guo, Y. Analytical investigation on the dynamic behavior of multi-span continuous beams supported on soil with finite depth. Coatings 2024, 14, 864. [Google Scholar] [CrossRef]

| Symbol | Definition Context | Symbol | Definition Context |

|---|---|---|---|

| bending stiffness | natural frequency | ||

| density | modulus of each layer | ||

| area of cross section | thickness of each layer | ||

| dirac delta function | position of the neutral axis | ||

| deflection | modal function | ||

| modal coordinate | the generalized force |

| Structural Component | Value | Structural Component | Value |

|---|---|---|---|

| U-rib spacing | 600 mm | deck width | 600 mm |

| U-rib opening width | 300 mm | diaphragm spacing | 3200 mm |

| U-rib closed width | 170 mm | pavement scheme | 14 mm (210 GPa) + 70 mmUHPC (35,500 MPa) + 40 mm SMA (7200 MPa) |

| U-rib height | 280 mm | ||

| U-rib thickness | 8 mm | number of diaphragm | 4 |

| Modal Order | Analytical Solution Result (Hz) | FEM Result (Hz) | Error (‰) |

|---|---|---|---|

| 1 | 62.02 | 61.94 | 1.3 |

| 2 | 79.44 | 78.85 | 7.4 |

| 3 | 115.05 | 114.73 | 2.8 |

| 4 | 247.98 | 247.99 | 0.040 |

| 5 | 282.67 | 280.73 | 6.9 |

| Steel Plate Thickness (mm) | 12 | 14 | 16 |

|---|---|---|---|

| peak deflection (mm) | 0.888 | 0.824 | 0.726 |

| peak bending stress (MPa) | 0.209 | 0.200 | 0.193 |

| peak UHPC-SMA interlayer shear stress (MPa) | 0.281 | 0.254 | 0.230 |

| peak UHPC-SMA interlayer vertical tensile stress (MPa) | 0.108 | 0.0903 | 0.0848 |

| UHPC Thickness (mm) | 60 | 70 | 80 |

|---|---|---|---|

| peak deflection (mm) | 0.864 | 0.824 | 0.808 |

| peak bending stress (MPa) | 0.212 | 0.200 | 0.179 |

| peak UHPC-SMA interlayer shear stress (MPa) | 0.284 | 0.254 | 0.233 |

| peak UHPC-SMA interlayer vertical tensile stress (MPa) | 0.0998 | 0.0903 | 0.0787 |

| SMA Thickness (mm) | 30 | 35 | 40 |

|---|---|---|---|

| peak deflection (mm) | 0.848 | 0.832 | 0.824 |

| peak bending stress (MPa) | 0.215 | 0.202 | 0.200 |

| peak UHPC-SMA interlayer shear stress (MPa) | 0.265 | 0.240 | 0.254 |

| peak UHPC-SMA interlayer vertical tensile stress (MPa) | 0.111 | 0.104 | 0.0903 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.; Zhou, Z.; Zhang, Y.; Li, K. Dynamic Response Analysis of Steel Bridge Deck Pavement Using Analytical Methods. Coatings 2025, 15, 1019. https://doi.org/10.3390/coatings15091019

Yang S, Zhou Z, Zhang Y, Li K. Dynamic Response Analysis of Steel Bridge Deck Pavement Using Analytical Methods. Coatings. 2025; 15(9):1019. https://doi.org/10.3390/coatings15091019

Chicago/Turabian StyleYang, Shuyao, Zhigang Zhou, Yinghui Zhang, and Kai Li. 2025. "Dynamic Response Analysis of Steel Bridge Deck Pavement Using Analytical Methods" Coatings 15, no. 9: 1019. https://doi.org/10.3390/coatings15091019

APA StyleYang, S., Zhou, Z., Zhang, Y., & Li, K. (2025). Dynamic Response Analysis of Steel Bridge Deck Pavement Using Analytical Methods. Coatings, 15(9), 1019. https://doi.org/10.3390/coatings15091019