The Influence of PEO Process Parameters on the Mechanical and Sclerometric Properties of Coatings on the Ultralight Magnesium Alloy LA141

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Material

- Step I (70 s): Linear voltage ramping from 5 V to 195 V.

- Step II (450 s): Voltage was once more linearly increased to a terminal value of 265 V. A pulsed voltage signal growing linearly from 0 V to 46 V was superimposed on the base voltage during this stage.

- Step III (200 s): Terminal voltage levels were constant. Gradual fading in intensity of the current was observed in this stage, a sign of self-limiting coating growth.

2.2. Research Methodology

3. Results and Discussion

3.1. The Thickness of the Oxide Coating

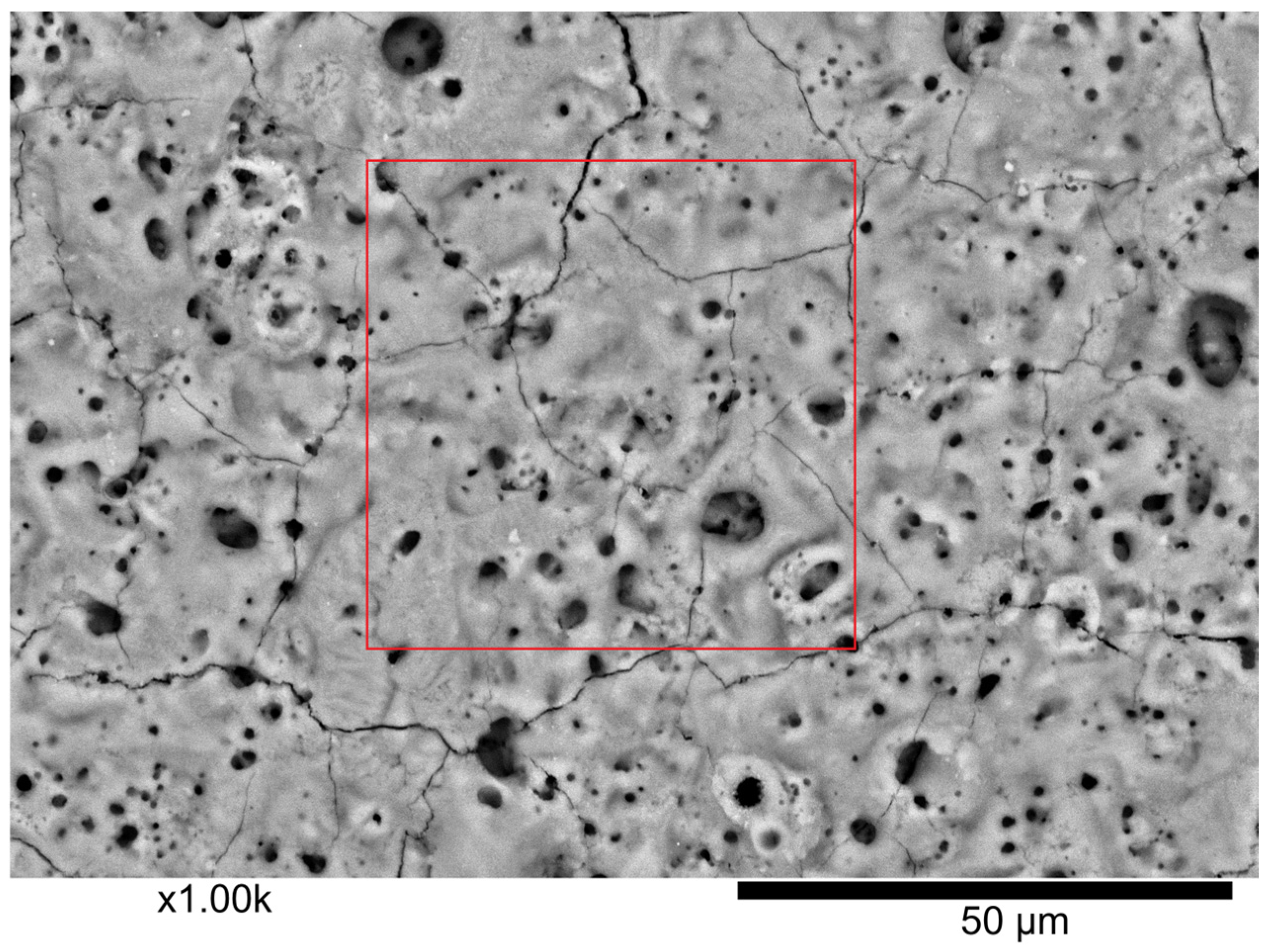

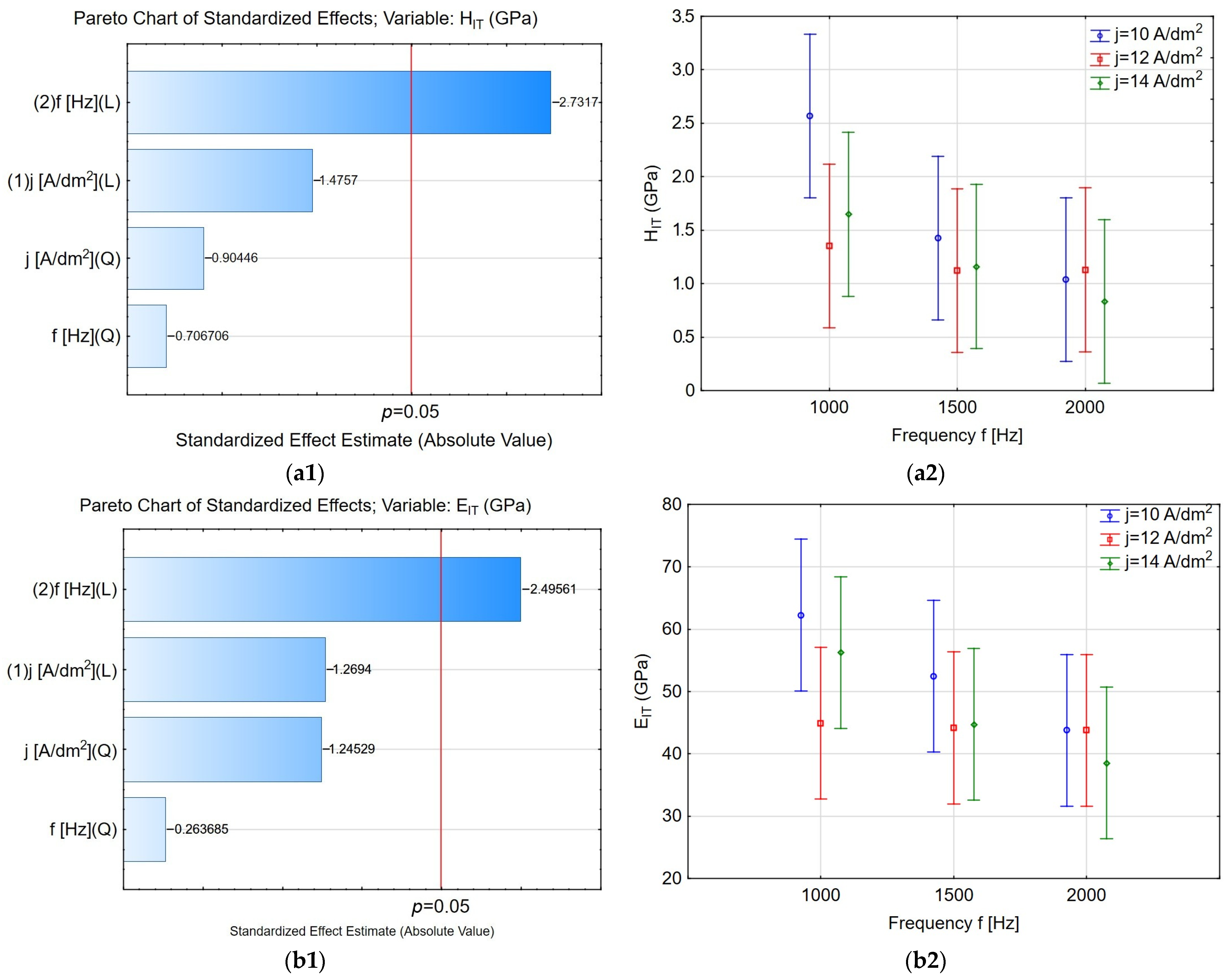

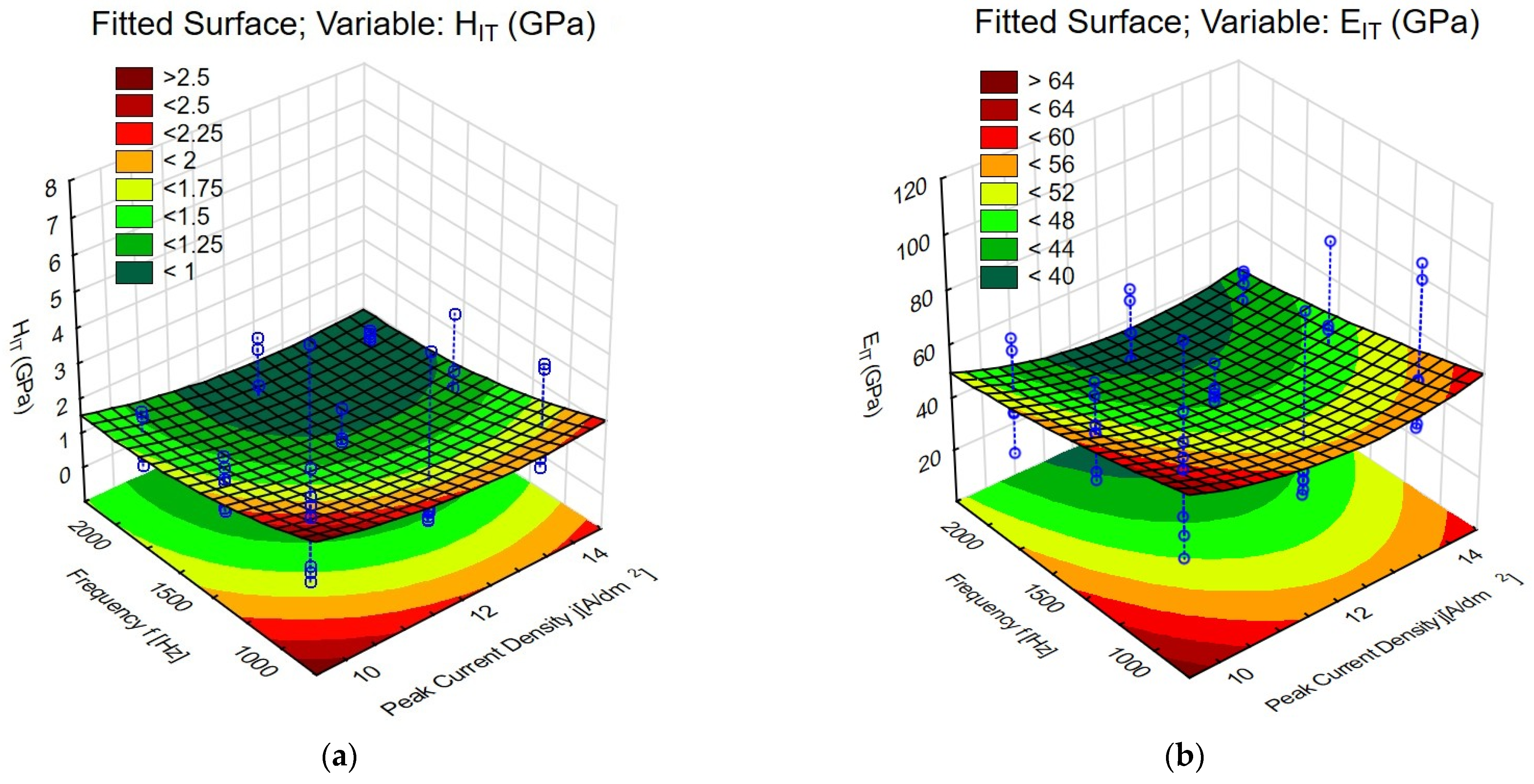

3.2. The Role of Plasma Electrolytic Oxidation in Modifying Micromechanical Properties

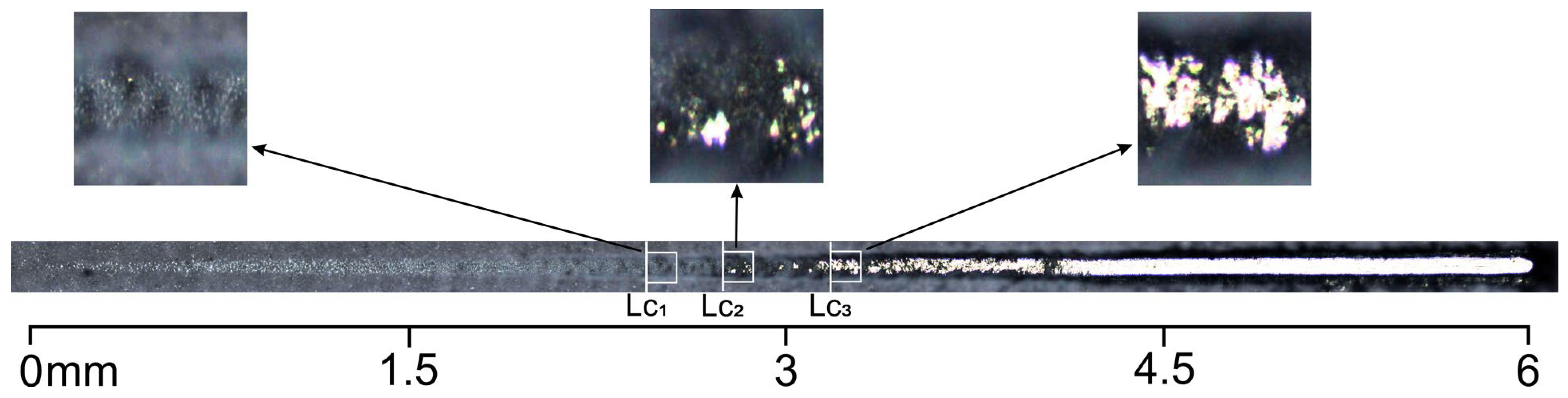

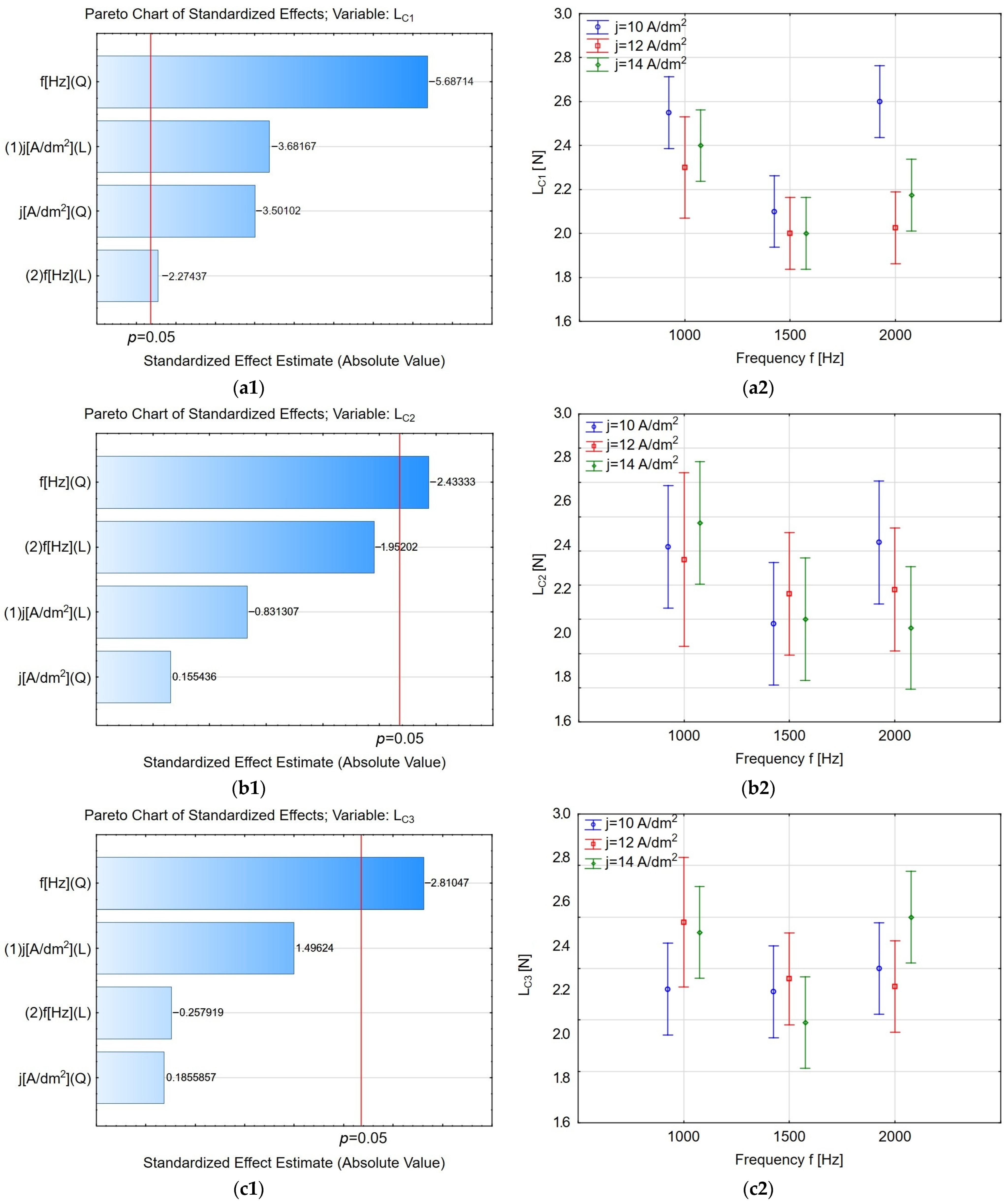

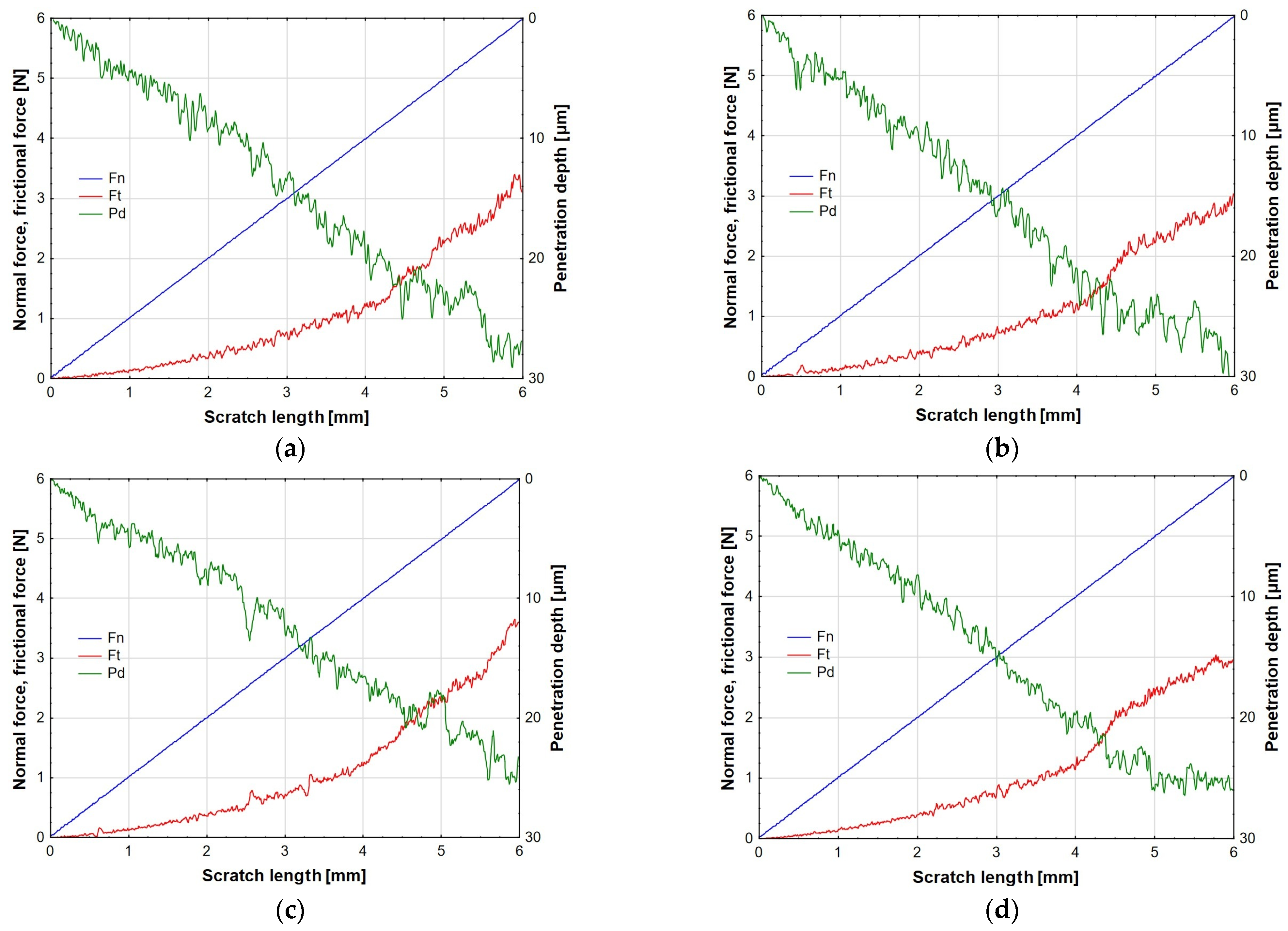

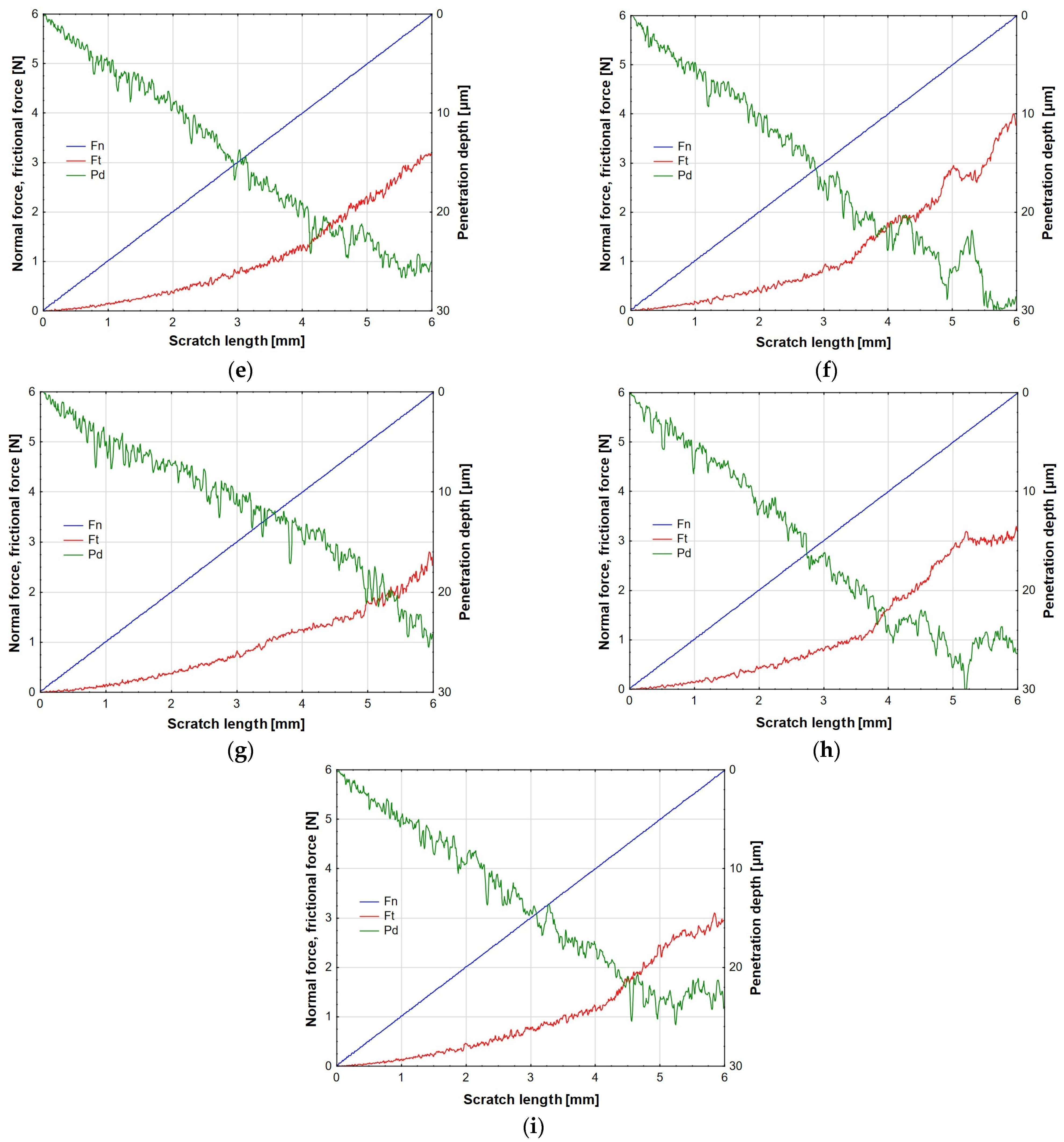

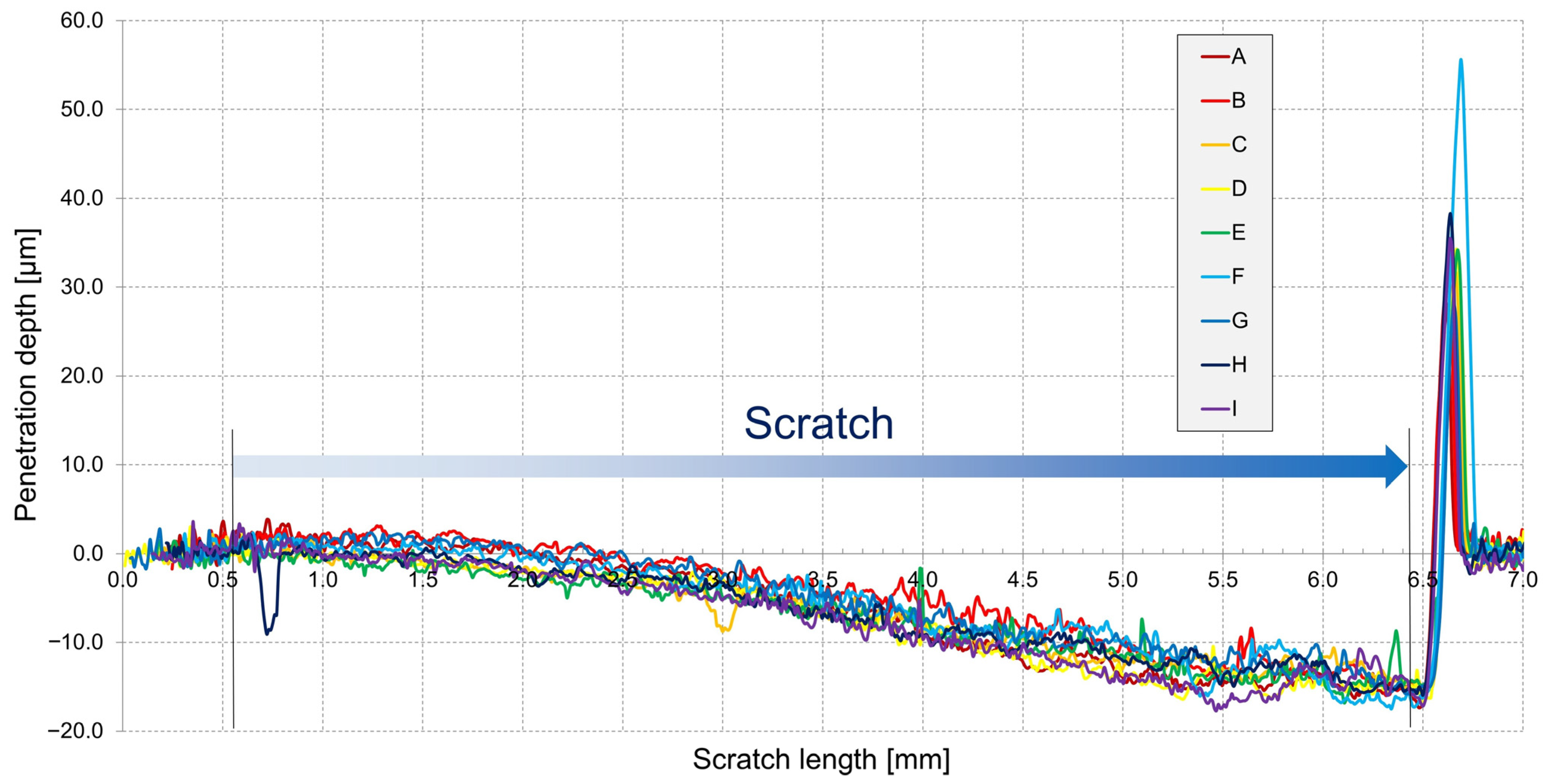

3.3. Adhesive Properties of Anodic Oxide Coatings

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mordike, B.L.; Ebert, T. Magnesium Properties-Applications-Potential. Mater. Sci. Eng. A 2001, 302, 37–45. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, R.; Liu, X.; Wang, D.; Zhang, H.; Shen, X.; Shen, D.; Li, D. Influence of Different Electrolyte Additives and Structural Characteristics of Plasma Electrolytic Oxidation Coatings on AZ31 Magnesium Alloy. Coatings 2020, 10, 817. [Google Scholar] [CrossRef]

- Toulabifard, A.; Rahmati, M.; Raeissi, K.; Hakimizad, A.; Santamaria, M. The Effect of Electrolytic Solution Composition on the Structure, Corrosion, and Wear Resistance of PEO Coatings on AZ31 Magnesium Alloy. Coatings 2020, 10, 937. [Google Scholar] [CrossRef]

- Yang, C.; Chen, P.; Wu, W.; Sheng, L.; Zheng, Y.; Chu, P.K. A Review of Corrosion-Resistant PEO Coating on Mg Alloy. Coatings 2024, 14, 451. [Google Scholar] [CrossRef]

- Li, Z.; Yuan, Y.; Sun, P.; Jing, X. Ceramic Coatings of LA141 Alloy Formed by Plasma Electrolytic Oxidation for Corrosion Protection. ACS Appl. Mater. Interfaces 2011, 3, 3682–3690. [Google Scholar] [CrossRef] [PubMed]

- Joost, W.J.; Krajewski, P.E. Towards Magnesium Alloys for High-Volume Automotive Applications. Scr. Mater. 2017, 128, 107–112. [Google Scholar] [CrossRef]

- Bai, J.; Yang, Y.; Wen, C.; Chen, J.; Zhou, G.; Jiang, B.; Peng, X.; Pan, F. Applications of Magnesium Alloys for Aerospace: A Review. J. Magnes. Alloys 2023, 11, 3609–3619. [Google Scholar] [CrossRef]

- Dziubińska, A.; Gontarz, A.; Dziubiński, M.; Barszcz, M. The Forming of Magnesium Alloy Forgings for Aircraft and Automotive Applications. Adv. Sci. Technol. Res. J. 2016, 10, 158–168. [Google Scholar] [CrossRef]

- Mathaudhu, S.N.; Nyberg, E.A. Magnesium Alloys in U.S. Military Applications: Past, Current and Future Solutions. In Essential Readings in Magnesium Technology; Springer International Publishing: Cham, Switzerland, 2016; pp. 71–76. [Google Scholar]

- Song, G. Recent Progress in Corrosion and Protection of Magnesium Alloys. Adv. Eng. Mater. 2005, 7, 563–586. [Google Scholar] [CrossRef]

- Wu, R.; Yan, Y.; Wang, G.; Murr, L.E.; Han, W.; Zhang, Z.; Zhang, M. Recent Progress in Magnesium–Lithium Alloys. Int. Mater. Rev. 2015, 60, 65–100. [Google Scholar] [CrossRef]

- Abdullaev, R.N.; Khairulin, R.A.; Kozlovskii, Y.M.; Agazhanov, A.S.; Stankus, S.V. Density of Magnesium and Magnesium-Lithium Alloys in Solid and Liquid States. Trans. Nonferrous Met. Soc. China 2019, 29, 507–514. [Google Scholar] [CrossRef]

- Xu, C.; Feng, X.; Deng, H.; Zhong, T.; Zou, C.; Wu, R.; Yu, Z.; Ma, X. The Impact of Mn Alloying and Rolling Processing on the Microstructure and Mechanical Properties of LA141 Alloy. J. Alloys Compd. 2025, 1010, 178052. [Google Scholar] [CrossRef]

- Arrabal, R.; Matykina, E.; Hashimoto, T.; Skeldon, P.; Thompson, G.E. Characterization of AC PEO Coatings on Magnesium Alloys. Surf. Coat. Technol. 2009, 203, 2207–2220. [Google Scholar] [CrossRef]

- Sikdar, S.; Menezes, P.V.; Maccione, R.; Jacob, T.; Menezes, P.L. Plasma Electrolytic Oxidation (Peo) Process—Processing, Properties, and Applications. Nanomaterials 2021, 11, 1375. [Google Scholar] [CrossRef]

- Arun, S.; Hariprasad, S.; Saikiran, A.; Ravisankar, B.; Parfenov, E.V.; Mukaeva, V.R.; Rameshbabu, N. The Effect of Graphite Particle Size on the Corrosion and Wear Behaviour of the PEO-EPD Coating Fabricated on Commercially Pure Zirconium. Surf. Coat. Technol. 2019, 363, 301–313. [Google Scholar] [CrossRef]

- Ostapiuk, M. Corrosion Resistance of PEO and Primer Coatings on Magnesium Alloy. J. Asian Ceram. Soc. 2021, 9, 40–52. [Google Scholar] [CrossRef]

- Pastorek, F.; Štrbák, M.; Kajánek, D.; Jacková, M.; Pastorková, J.; Florková, Z. Corrosion Behaviour of Preserved Peo Coating on Az31 Magnesium Alloy. Commun. Sci. Lett. Univ. Zilina 2021, 23, B76–B88. [Google Scholar] [CrossRef]

- Tian, G.; Wang, J.; Wang, S.; Xue, C.; Yang, X.; Su, H. An Ultra-Light Mg-Li Alloy with Exceptional Elastic Modulus, High Strength, and Corrosion-Resistance. Mater. Today Commun. 2023, 35, 105623. [Google Scholar] [CrossRef]

- Niedźwiedź, M.; Bara, M.; Korzekwa, J.; Barylski, A.; Kaptacz, S. The Influence of the Plasma Electrolytic Oxidation Parameters of the Mg-AZ31B Alloy on the Micromechanical and Sclerometric Properties of Oxide Coatings. Coatings 2024, 14, 1446. [Google Scholar] [CrossRef]

- Niedźwiedź, M.; Bara, M.; Korzekwa, J.; Kaptacz, S.; Sowa, M.; Olesiński, A.; Simka, W. Tribological Properties and Surface Wettability of Coatings Produced on the Mg-AZ31B Alloy by Plasma Electrolytic Oxidation. Coatings 2024, 14, 780. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, P.; Du, Y.; Zhang, W.; Cao, H. Correlations between the Growth Mechanism and Corrosion Resistance of Plasma Electrolytic Oxidation Coatings on AZ31B Magnesium Alloy. Int. J. Electrochem. Sci. 2019, 14, 10465–10479. [Google Scholar] [CrossRef]

- Korzynski, M.; Zarski, T. Slide Diamond Burnishing Influence on of Surface Stereometric Structure of an AZ91 Alloy. Surf. Coat Technol. 2016, 307, 590–595. [Google Scholar] [CrossRef]

- Feng, X.; Deng, H.; Ma, X.; Yang, Z.; Zhang, H.; Yu, Z.; Liu, W.; Wang, J.; Hou, L.; Qian, B.; et al. Balancing Strength and Ductility of LA141 Alloy with a Micro-Nano Laminated Structure. J. Magnes. Alloys 2024, in press. [Google Scholar] [CrossRef]

- Mou, F.; Wang, Z.; Zeng, H.; Ma, Y.; Guo, F.; Chai, L.; She, Z.; Zhang, L. Fabricating a Corrosion-Protective Li2CO3/Mg(OH)2 Composite Film on LA141 Magnesium lithium Alloy by Hydrothermal Method. Surf. Coat Technol. 2023, 472, 129939. [Google Scholar] [CrossRef]

- Xu, N.; Qiu, Z.; Song, Q.; Liu, Z.; Ji, X.; Wang, D. Enhanced Mechanical Properties and Corrosion Resistance of Friction-Stir Processed Ultralight LA141 Magnesium-Lithium-Aluminum Alloy. J. Mater. Res. Technol. 2024, 30, 1553–1571. [Google Scholar] [CrossRef]

- ISO 14577-4; Metallic Materials—Instrumented Indentation Test for Hardness and Materials Parameters—Part 4: Test Method for Metallic and Non-Metallic Coatings. ISO: Geneva, Switzerland, 2016.

- Oliver, W.C.; Pharr, G.M. An Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- ISO 19252:2008; Plastics—Determination of Scratch Properties. ISO: Geneva, Switzerland, 2008.

- ISO 20502:2005; Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Determination of Adhesion of Ceramic Coatings by Scratch Testing. ISO: Geneva, Switzerland, 2005.

- ASTM C1624-22(2022); Standard Test Method for Adhesion Strength and Mechanical Failure Modes of Ceramic Coatings by Quantitative Single Point Scratch Testing. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D7027-20(2020); Standard Test Method for Evaluation of Scratch Resistance of Polymeric Coatings and Plastics Using an Instrumented Scratch Machine. ASTM International: West Conshohocken, PA, USA, 2020.

| Sample | Controlled Factors | |||

|---|---|---|---|---|

| On a Natural Scale | On a Standard Scale | |||

| Peak Current Density j [A/dm2] | Frequency f [Hz] | x1 | x2 | |

| A | 10 | 1000 | −1 | −1 |

| B | 14 | 1000 | 1 | −1 |

| C | 10 | 2000 | −1 | 1 |

| D | 14 | 2000 | 1 | 1 |

| E | 10 | 1500 | −1 | 0 |

| F | 14 | 1500 | 1 | 0 |

| G | 12 | 1000 | 0 | −1 |

| H | 12 | 2000 | 0 | 1 |

| I | 12 | 1500 | 0 | 0 |

| Mg | O | Na | Si | P |

|---|---|---|---|---|

| 40.83 | 25.38 | 0.50 | 31.08 | 2.21 |

| Sample | Oxide Coatings Thickness d [μm] | Standard Deviation [μm] |

|---|---|---|

| A | 10.22 | 0.74 |

| B | 9.92 | 0.86 |

| C | 8.40 | 0.76 |

| D | 8.51 | 0.74 |

| E | 8.91 | 0.62 |

| F | 8.62 | 0.81 |

| G | 8.31 | 0.59 |

| H | 8.17 | 0.81 |

| I | 8.58 | 0.68 |

| Sample | HIT [GPa] | EIT [GPa] |

|---|---|---|

| A | 2.57 ± 1.96 | 62.25 ± 23.77 |

| B | 1.65 ± 0.52 | 56.25 ± 22.13 |

| C | 1.04 ± 0.52 | 43.78 ± 12.94 |

| D | 0.83 ± 0.37 | 38.55 ± 11.95 |

| E | 1.43 ± 0.51 | 52.46 ± 11.43 |

| F | 1.16 ± 0.91 | 44.73 ± 17.10 |

| G | 1.35 ± 1.49 | 44.85 ± 20.47 |

| H | 1.12 ± 0.74 | 43.80 ± 11.87 |

| I | 1.12 ± 0.43 | 44.17 ± 6.96 |

| Sample | Lc1 [N] | Lc2 [N] | Lc3 [N] |

|---|---|---|---|

| A | 2.55 ± 0.05 | 2.83 ± 0.03 | 3.30 ± 0.10 |

| B | 2.40 ± 0.00 | 2.97 ± 0.12 | 3.85 ± 0.05 |

| C | 2.60 ± 0.00 | 2.85 ± 0.10 | 3.50 ± 0.10 |

| D | 2.18 ± 0.03 | 2.35 ± 0.20 | 4.00 ± 0.10 |

| E | 2.10 ± 0.00 | 2.38 ± 0.28 | 3.28 ± 0.13 |

| F | 2.00 ± 0.00 | 2.40 ± 0.20 | 2.98 ± 0.03 |

| G | 2.30 ± 0.00 | 2.23 ± 0.53 | 4.73 ± 0.78 |

| H | 2.03 ± 0.03 | 2.58 ± 0.03 | 3.33 ± 0.03 |

| I | 2.00 ± 0.00 | 2.55 ± 0.05 | 3.40 ± 0.00 |

| Sample | Sa [µm] | Sz [µm] |

|---|---|---|

| A | 0.847 | 8.776 |

| B | 0.848 | 8.966 |

| C | 0.686 | 7.094 |

| D | 0.801 | 6.538 |

| E | 0.760 | 7.299 |

| F | 0.852 | 7.950 |

| G | 0.735 | 7.111 |

| H | 0.810 | 6.871 |

| I | 0.878 | 7.269 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niedźwiedź, M.; Korzekwa, J.; Bara, M.; Kaptacz, S.; Aniołek, K.; Sowa, M.; Simka, W. The Influence of PEO Process Parameters on the Mechanical and Sclerometric Properties of Coatings on the Ultralight Magnesium Alloy LA141. Coatings 2025, 15, 961. https://doi.org/10.3390/coatings15080961

Niedźwiedź M, Korzekwa J, Bara M, Kaptacz S, Aniołek K, Sowa M, Simka W. The Influence of PEO Process Parameters on the Mechanical and Sclerometric Properties of Coatings on the Ultralight Magnesium Alloy LA141. Coatings. 2025; 15(8):961. https://doi.org/10.3390/coatings15080961

Chicago/Turabian StyleNiedźwiedź, Mateusz, Joanna Korzekwa, Marek Bara, Sławomir Kaptacz, Krzysztof Aniołek, Maciej Sowa, and Wojciech Simka. 2025. "The Influence of PEO Process Parameters on the Mechanical and Sclerometric Properties of Coatings on the Ultralight Magnesium Alloy LA141" Coatings 15, no. 8: 961. https://doi.org/10.3390/coatings15080961

APA StyleNiedźwiedź, M., Korzekwa, J., Bara, M., Kaptacz, S., Aniołek, K., Sowa, M., & Simka, W. (2025). The Influence of PEO Process Parameters on the Mechanical and Sclerometric Properties of Coatings on the Ultralight Magnesium Alloy LA141. Coatings, 15(8), 961. https://doi.org/10.3390/coatings15080961