Abstract

This paper discusses the potential of adding a self-made super-early-strength agent to produce quick-setting, quick-hardening, and high-strength concrete. A super-early-strength agent is prepared by mixing triethanolamine (TEA), aluminum sulfate (Al2(SO4)3·18H2O), formic acid (HCOOH), and sodium fluoride (NaF) with a water-reducing agent in different proportions. In this paper, the effects of super-early-strength agent ratio and dosage, water–binder ratio, silica fume content, and cementitious material content on the setting time and compressive strength of high-strength concrete were studied. The hydration characteristics were evaluated by X-ray diffraction (XRD) and TG-DSC thermal analysis. The results show that the high-strength concrete prepared by 42.5R ordinary Portland cement mixed with appropriate amount of silica fume and self-made super-early-strength agent has a compressive strength of 10 MPa in 6 h, a compressive strength of 40 MPa in 1 day, a compressive strength of not less than 80 MPa in 28 days, and a compressive strength of not shrinking in 180 days. Using conventional raw materials and general process methods, the concrete prepared according to the preparation method of this experiment can significantly shorten the setting time and improve the compressive strength. However, it is difficult to form concrete when the amount of super-early-strength agent is too large. Nevertheless, this study provides a theoretical basis for large-scale and high-value utilization of the potential of super-early-strength agents and development to improve efficiency. At the same time, it provides a reference for the application of coating technology in rapid repair engineering.

1. Introduction

Super-early-strength concrete is a highly advanced cementitious composite material. super-early-strength concrete is mainly used for the maintenance and reinforcement of concrete structures, such as bridges and ports, and the quick maintenance of concrete pavements [1,2,3,4,5,6,7,8,9,10]. The first technical path to prepare super-early-strength concrete is to use special cement with fast hardening and early-strength properties, such as high-alumina cement, setting cement, fast-hardening sulphoaluminate cement, etc. The United States, Britain, Japan, and other countries use such special cement to prepare super-early-strength concrete [11,12,13,14,15,16,17,18,19]. Professor Bovic of the United States studied a kind of special cement quick-hardening concrete, with a 1h compressive strength that reached 15–20 MPa. Condensed cement is widely used in Japan. After adding a retarder, the initial setting time of the concrete is about 40 min. A new type of cement-based composite cementitious material with sulphoaluminate cement + Portland cement and mineral admixtures containing high-aluminum components to promote cement hydration was jointly studied by the Logistics Engineering College of the People’s Liberation Army and Tongji University [20]. It has the characteristics of moderate initial setting time, quick hardening and early strength, good working performance, and long-term strength. The second way is to use early-strength agents and various additives to obtain an early-strength agent with a better early-strength effect. Professor Pu Xincheng of Chongqing University prepared a 12-h compressive strength greater than 35 MPa by using an early-strength admixture [21]. The Hangzhou Urban Construction Research Institute used the early-strength agent prepared by the super quick hardening agent, the coagulant, and the water-reducing agent to prepare the concrete with the zero period of 6 h, the compressive strength of 17.6 MPa, and the flexural strength of 4.19 MPa [22]. The JK series concrete quick repair agent was developed by Jiangsu Academy of Building Research, the prepared JK-4 type quick repair concrete, aged 24 h, has a compressive strength of 18.9 MPa and flexural strength of 3.1 MPa [23,24]. There are also some shortcomings for the above super-early-strength concrete. The early strength is high and the later strength is seriously reduced, or the material used in the configuration process of super-early-strength concrete is expensive [25,26,27,28,29]. These shortcomings affect the application of super-early-strength concrete in practical engineering. Therefore, it is still important to prepare super-early-strength concrete with easy availability of raw materials, low cost, simple construction, quick setting time, high early strength, and no shrinkage in later strength [30,31,32].

Therefore, this experiment attempts to use the super-early-strength agent and cementitious material system to prepare super-early-strength high-performance concrete. The super-early-strength agent is composed of triethanolamine (TEA), aluminum sulfate (Al2(SO4)3·18H2O), formic acid (HCOOH), sodium fluoride (NaF), and a reducing agent in different proportions. The cementitious material is composed of cement, silica fume, as well as coarse and fine aggregate, in which the cement is 42.5R ordinary Portland cement. Through this study, we try to prepare super-early high-performance concrete with easy availability of raw materials, low cost, and long-term mechanical properties. It not only enriches the high-performance concrete material system, but also provides a collaborative optimization idea for the application of coating technology in rapid repair engineering.

2. Materials and Methods

2.1. Materials

2.1.1. Cement

The cement is P.O42.5R ordinary Portland cement, which is produced by Chongqing Tianzhu Cement Co., Ltd., Chongqing, China. The chemical composition is shown in Table 1.

Table 1.

Chemical components of ordinary Portland cement.

2.1.2. Silica Fume

Due to the filling effect of silica fume and the activity of volcanic ash, the strength and performance of concrete can be improved by adding silica fume. Therefore, silica fume is used as an admixture in this experiment to prepare high-performance concrete with high early strength and late strength. The silica fume is produced by Guizhou Haitian Iron Alloy Abrasive Co., Ltd., Guizhou, China, which is green-gray. The specific surface area is 18,000 m2/kg, the density is 2.5 g/cm3, and the loose bulk density is 300 kg/m3. The chemical composition is shown in Table 2.

Table 2.

The chemical components of mineral admixtures.

2.1.3. Gravel

The gravel is from the Geleshan quarry with a particle size of 5–10 mm. The main properties of the gravel are shown in Table 3.

Table 3.

Performance of gravel.

2.1.4. Medium Sand

The medium sand produced in Yueyang is used. The sand contains a certain amount of pebbles, passing through a 4.75 mm sieve, the fineness modulus is 2.37, the apparent density is 2687 kg/m3, and the bulk density is 1642 kg/m3. The indicators of medium sand are shown in Table 4.

Table 4.

Sieve analysis of sand.

2.1.5. Preparation of Super-Early-Strength Agent

The super-early-strength agent is composed of a quick-setting early-strength component and a reducing component.

- (1)

- The quick-setting early-strength component is prepared by aluminum sulfate, triethanolamine, formic acid, and sodium fluoride. Aluminum sulfate, triethanolamine, formic acid, and sodium fluoride were all industrial reagents with a purity of 98% provided by Chongqing Dongfanghua Glass Co., Ltd., Chongqing, China, which were mixed with the mass percentage of cementitious materials, dissolved in water after mixing, and then mixed with a water reducer to prepare the super-early-strength agent. According to previous experience, the distribution ratio of the quick-setting early-strength group is selected as shown in Table 5.

Table 5. The best ratio of the quick-setting early-strength component.

Table 5. The best ratio of the quick-setting early-strength component. - (2)

- The naphthalene superplasticizer and the polyglyceric acid superplasticizer were used in the water-reducing group. The naphthalene superplasticizer was a brown-yellow powder, the polyglyceric acid superplasticizer was a brown-yellow liquid, and the solid content was 44%. They were all produced by the Chongqing Laboratory Jieshin Materials Company, Chongqing, China. In use, the mass percentage of the cementitious material is incorporated.

2.1.6. Mixing Water

Mixing water that meets the requirements of ‘Concrete Mixing Water Standard’ (JGJ63-2006) is used [33].

2.2. Test Method

2.2.1. Test Technical Route

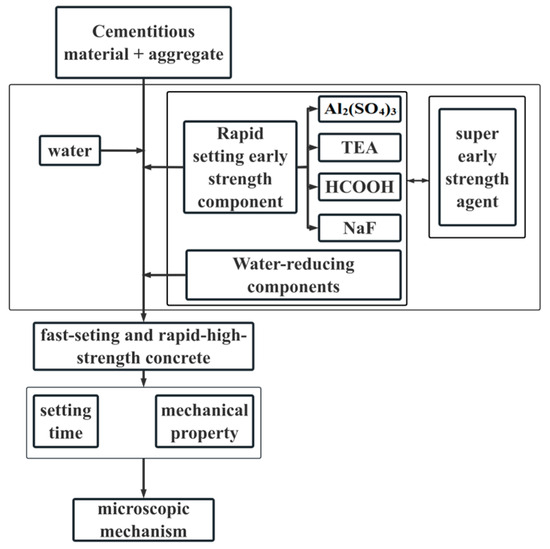

The performance test of concrete prepared in this test includes setting time and mechanical properties test. The setting time of the initial setting and final setting was mainly tested, and the compressive strength of 6 h, 1 day, 14 days, 28 days, and 180 days was tested. The hydration characteristics of the corresponding cement paste were studied. The technical route is shown in Figure 1.

Figure 1.

The detailed technical route for the preparation of quick-setting and quick high-strength concrete is introduced.

2.2.2. Mix Proportion Design

In this experiment, the volume method is used to calculate the mixture ratio, that is, it is assumed that the sum of the absolute volume of each component material and the volume of air contained in the concrete mixture is equal to the volume of the concrete mixture. The formula used is as follows:

Taking a group of cementitious materials of 800 kg/m3 as an example, α = 1, the formula is as follows:

According to the known sand ratio, the formula is as follows:

Among them:

mc is the mass of cementitious material.

ms is the quality of fine aggregate.

mg is the quality of coarse aggregate.

mw is the mass of water.

ρc is the density of cementitious material.

ρg is the density of coarse aggregate.

ρs is the density of fine aggregate.

ρw is the density of water.

α is the air volume coefficient contained in concrete mixture.

It can be obtained: ms = 579 kg/m3, mg = 868 kg/m3.

In this experiment, each group of tests is shown in Table 6, Table 7, Table 8, Table 9, Table 10 and Table 11.

Table 6.

Quick setting and quick hardening of high-strength concrete in the case of different binding material amounts.

Table 7.

Quick setting and quick hardening of high-strength concrete in case of different ratios of the quick-setting early-strength component.

Table 8.

Quick setting and quick hardening of high-strength concrete in case of different ratios of the quick-setting early-strength internal component.

Table 9.

Quick setting and quick hardening of high-strength concrete occur at different water–binder ratios.

Table 10.

Quick setting and quick hardening of high-strength concrete occur at different silica fume contents.

Table 11.

Preparation condition of the hydrated cement specimens for XRD and TG-DSC analysis.

Table 6 is used to change the total amount of cementitious materials (700 kg/m3, 800 kg/m3, and 900 kg/m3), fix other parameters (water–binder ratio 0.24, super-early-strength agent type and dosage), and explore the effect of the amount of cementitious materials.

Table 7 is based on the cementitious material 800 kg/m3, changing the content of the quick-setting early-strength component (type A) (1%, 3%, and 5%), and other parameters are fixed.

Table 8 shows three internal ratios (type A, B, and C) for comparing the quick-setting early-strength components, fixed cementitious materials 800 kg/m3, water–binder ratio of 0.24, and other parameters.

Table 9 is set to set the water–binder ratio of 0.24, 0.28, and 0.32, fixed cementitious material 800 kg/m3, and super-early-strength agent parameters to explore the influence of the water–binder ratio.

Table 10 is to change the proportion of silica fume in cementitious materials (4%, 7%, and 10%), the total amount is maintained at 800 kg/m3, and other parameters are fixed to study the effect of mineral admixtures on concrete performance.

Table 11 is the micro-mechanism research design sample, including the hydration sample with the quick-setting early-strength component (S group) at 45 min, 2 h, 6 h, and 1 d, and the blank group (K group) without mixing. The changes in hydration products were analyzed by XRD and TG-DSC tests.

2.3. Test Instruments

2.3.1. Preparation of Different Components of Ultra-Early Strength Agent

We took 1 m3 cementitious material with a mass of 800 kg, 1% of quick-setting early-strength component and 2% of water-reducing component as an example.

The preparation process of early-strength components: 15 kg of 30 °C mixing water was first added to a 25 L plastic bucket, and a high-speed stirrer was started. A total of 4.4 kg of aluminum sulfate, 0.8 kg of sodium fluoride, 1.2 kg of formic acid, and 1.6 kg of triethanolamine were successively added and continuously stirred for 3–4 min to completely dissolve to obtain a quick-setting early-strength mother liquor.

Preparation process when combined with naphthalene superplasticizer: After obtaining the early-strength component according to the above preparation process of the early strength component, another 25 kg of room-temperature mixing water was taken, and 16 kg of naphthalene superplasticizer dry powder was added while stirring, and stirring continued for 2 min until there was no particle; subsequently, the mother liquor was poured into the water-reducing agent solution in a fine flow mode, and 4 kg of flushing water was added after mixing. The total volume was about 60 L, and the density was about 1.04 g/mL.

Preparation process when combined with polycarboxylate superplasticizer: After obtaining the early-strength component according to the above preparation process of the early-strength component, another 36.4 kg of polycarboxylic acid stock solution with a solid content of 44% was weighed, diluted with 15 kg of mixed water, and slowly stirred for 2 min. Then, the mother liquor was slowly injected into the polycarboxylic acid diluent, and 4kg of flushing water was supplemented. Finally, about 75 L of uniform solution was obtained, and the density was about 1.03 g/mL.

2.3.2. Preparation Process and Maintenance System

In the course of this experiment, the prepared quick-setting early-strength component and the water-reducing component are mixed and stirred evenly to be used as a super-early-strength agent. The preparation process of concrete is as follows: firstly, the cementitious material and aggregate are stirred in the concrete mixer until the cementitious material and aggregate are dispersed evenly, and then water is added to stir for 60 s, and then the super-early-strength agent solution is added. After the slurry is produced, it is immediately poured out of the mixer. After the mold is installed, the vibration table is vibrated for 1 min, and the mixing surface is formed. Figure 2 is a concrete mixer for this test. In this experimental study, the curing system is standard curing: curing to the response age in a curing room with a temperature of (20 ± 2) °C and a relative humidity of ≥95%.

Figure 2.

HJW-60 horizontal shaft forced concrete mixer for preparing test concrete.

2.3.3. Working Performance Test

- (1)

- The setting time test of quick-setting and quick-hardening high-strength concrete is carried out with reference to the JC477-2005 ‘accelerator for shotcrete’ [34]. The setting time test of the cement paste was carried out with reference to the ‘cement paste standard consistency and setting time tester’ JC/T727-2005 [35]. Figure 3 is the Vicat instrument for the determination of the setting time of the paste in this experiment.

Figure 3. Vicat apparatus for determination of setting time of paste.

Figure 3. Vicat apparatus for determination of setting time of paste. - (2)

- The fluidity test of quick-setting, quick-hardening, and high-strength concrete is carried out according to the standard of the ‘ordinary concrete mixture performance test method’ GB/T50080-2002 [36].

2.3.4. Mechanical Properties Test

The test instruments and methods used in the mechanical properties test of concrete are all according to the national standard ‘ordinary concrete mechanical properties test method’ GB/T50081-2002 [37].

Figure 4 is a hydraulic press for the concrete compressive strength test in this experiment.

Figure 4.

YA-3000B hydraulic pressure testing machine for compressive strength test.

2.3.5. Hydration Performance Test

Thermal Analysis

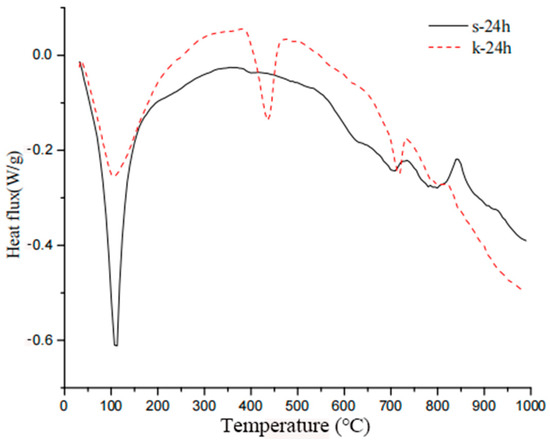

TG-DSC analysis: STA449 type synchronous thermal analyzer produced by the Netzsch company(Selb, Germany) was used to test the TG-DSC variation characteristics of hydration samples from room temperature to 1000 °C in an argon atmosphere. The flow rate was 20 mL·min−1. The heating rate was 10 °C·min−1, and the amount of sample was about 10 mg, Al2O3 crucible.

Microscopic Test Method

X-ray diffraction (XRD): The drying test was ground to 0.08 mm or less, and then the samples were tested by the Oxford Diffraction Co., Ltd. (Abingdon, British) production X-ray diffraction analyzer (D/max-IIIC). The Cu target was used, the wavelength was 0.154 nm, the operating voltage was 40 kV, the current was 30 mA, and the diffraction angle 2θ was 5 °C–70 °C.

3. Results

3.1. Setting Time and Mechanical Properties

3.1.1. Effect of Water–Binder Ratio

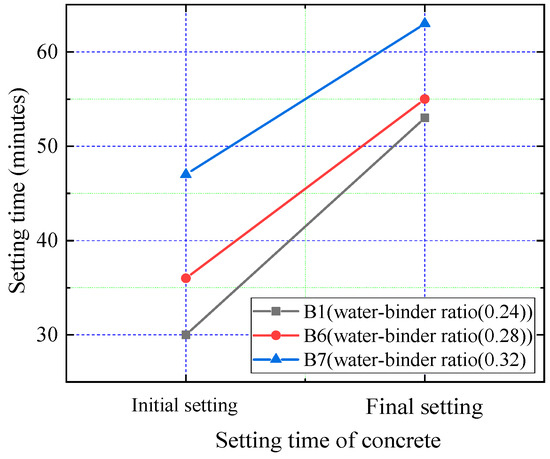

Effect on Setting Time

When the total amount of cementitious materials is fixed at 800 kg/m3, the water-reducing component is naphthalene water-reducing agent and the content is 2%, and the content of the quick-setting and early-strength component is 3%, the effects of water–binder ratio of 0.24, 0.28, and 0.32 on the setting time of fresh concrete are compared, as shown in the Figure 5.

Figure 5.

Setting time of concrete with different water–binder ratio.

It can be seen from Figure 5 that with the increase in water–binder ratio, the initial setting time and final setting time increased from 30 min and 53 min to 47 min and 63 min, respectively, both of which showed an extended trend, but the effect of the water–binder ratio on the setting time of concrete was not significant.

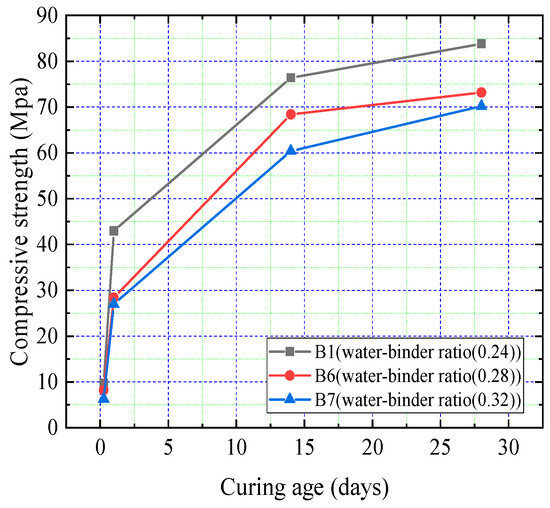

Effect on Compressive Strength

It can be seen from Figure 6 that with the increase in water–binder ratio, the compressive strength of concrete at all ages shows a decreasing trend, and the difference of compressive strength at 1 day is 16 MPa, which is the most significant. Therefore, choosing a lower water–binder ratio is beneficial to the early strength of concrete. Considering this comprehensively, the most suitable water–binder ratio in this test is 0.24.

Figure 6.

Compressive strength of concrete with different water–binder ratio.

3.1.2. The Influence of the Mix Ratio of Quick Solidification Early-Strength Components

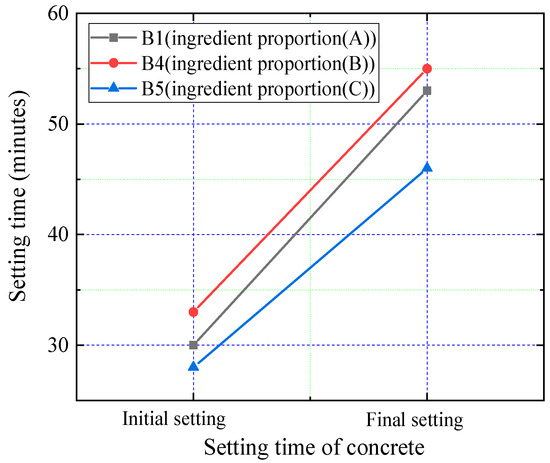

Effect on Setting Time

As shown in Figure 7, the initial setting time and final setting time of the three different ratios of the quick-setting and early-strength components were not significantly different. The coagulation time of group A and group B was shorter than that of group C.

Figure 7.

Setting time of concrete with the quick-setting early-strength component.

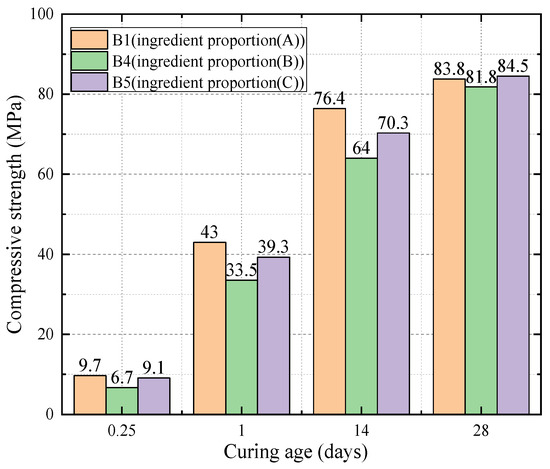

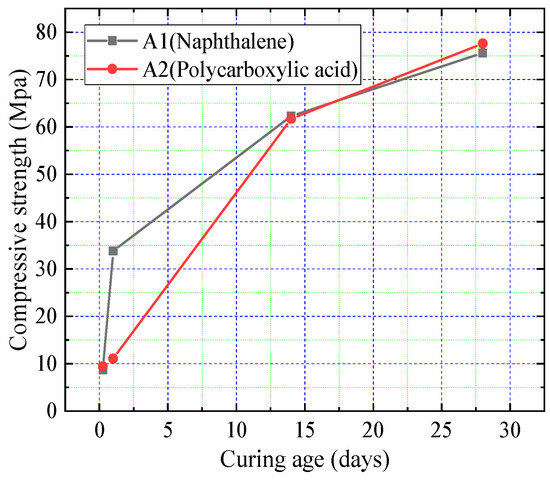

Effect on Compressive Strength

As shown in Figure 8, comparing the three different ratios, it was found that the compressive strength of 6 h and 1 day was A > C > B, and the compressive strength of 14 days A > C. Therefore, A is the optimal quick-setting early-strength component in this experiment.

Figure 8.

Compressive strength of concrete with different ratios of the quick-setting early-strength component.

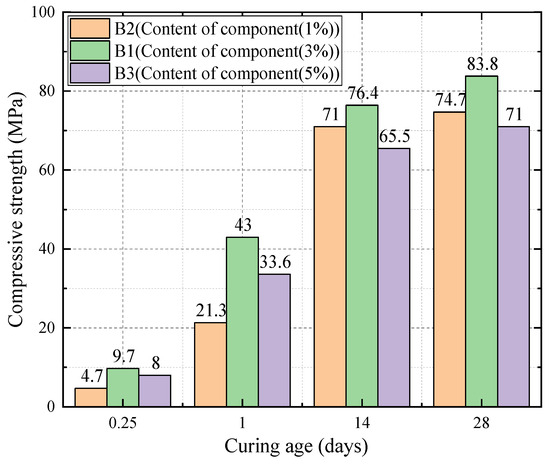

3.1.3. Effect of Quick-Setting Early-Strength Component Content

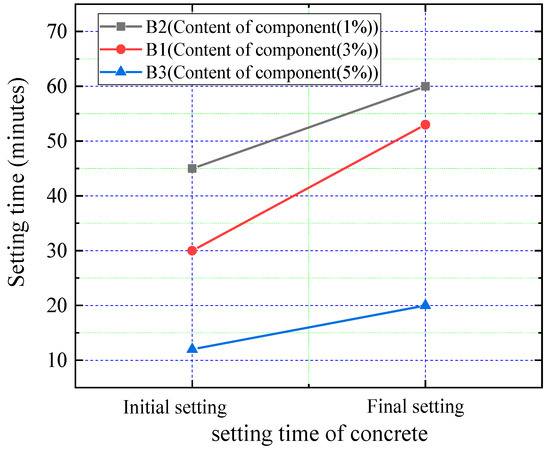

Effect on Setting Time

From Figure 9, it can be seen that the setting time of concrete decreases with the increase in the content of quick-setting early-strength components. When the dosage is 1%, the solidification time of concrete is 60 min. When the dosage reaches 5%, the solidification time of concrete is shortened to 20 min, which makes the fluidity of fresh concrete poor and difficult to compact.

Figure 9.

Concrete curing time of different dosage of super-early-strength agent.

Effect on Compressive Strength

As shown in Figure 10, when the content of the quick-setting early-strength component is 3%, the strength of concrete at various ages is higher, and the compressive strength of 1 d reaches more than 40 MPa, while the compressive strength of 6 h at 1% and 5% is lower than that at 3%. When the content is 5%, the concrete mixture has quick setting and hardening, poor fluidity, uncompacted concrete structure, and reduced strength. Therefore, considering this comprehensively, the optimum content of the quick-setting early-strength component in this experiment is 3%.

Figure 10.

Compressive strength of concrete with different quick-setting early-strength component dosages.

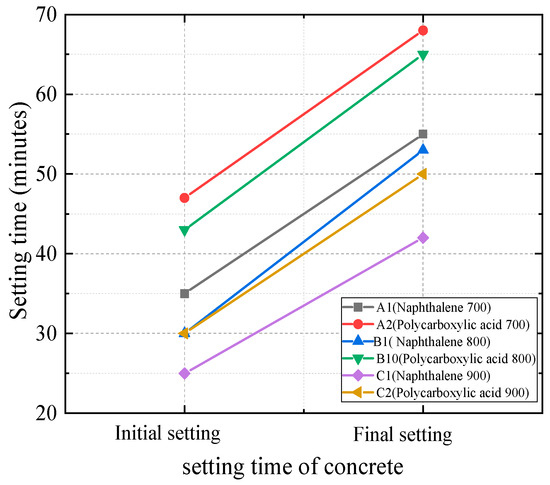

3.1.4. Effect of Cementitious Materials and Water-Reducing Components

Effect on Setting Time

As shown in Figure 11, due to the retarding effect of the poly acid water reducer, when the mass of the unit volume of the incorporated cementitious material is the same, the initial setting time and final setting time of the concrete using the naphthalene water reducer are shorter than those using the poly acid water reducer. When the same water-reducing agent component is used, with the increase in the total amount of cementitious materials, the initial setting time and final setting time of concrete are shortened, because with the increase in cementitious materials in unit volume, the amount of super-early-strength agent will also increase, resulting in shortened setting time.

Figure 11.

Setting time of concrete with different cementitious material consumption and types of water-reducing component.

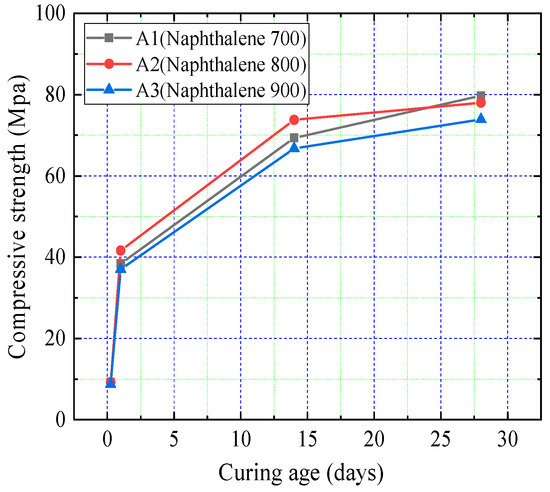

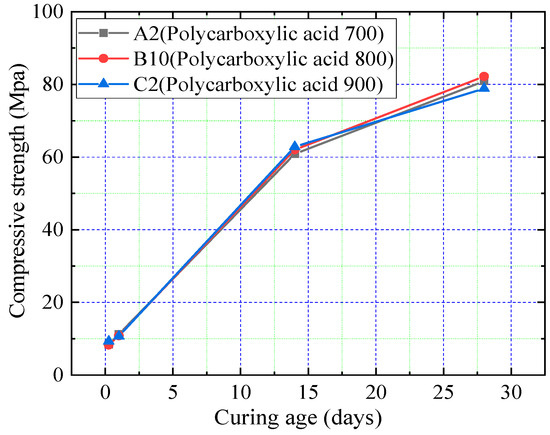

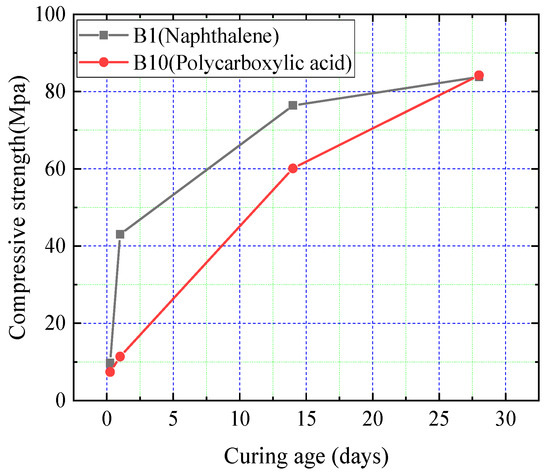

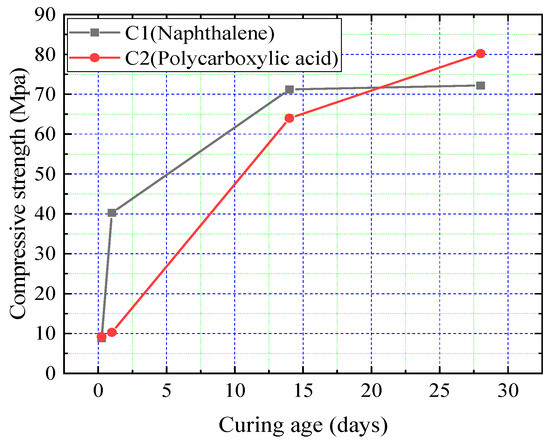

Effect on Compressive Strength

From Figure 12, Figure 13, Figure 14, Figure 15 and Figure 16, it can be seen that the compressive strength of B1 and C1 groups of concrete in 6 h reaches 10 MPa, the compressive strength of 1 day reaches 40 MPa, and the compressive strength of 28 days is 83.8 MPa and 72.2 MPa, respectively. Obviously, the strength of the B1 group is greater than the compressive strength of the C1 group. The compressive strength of 6 h, 1 day, 14 days, and 28 days when the cementitious material is 800 kg/m3 is higher than that when the cementitious material is 700 kg/m3 and 900 kg/m3. The water-reducing component utilizes a polyglyceric acid-based water-reducing agent. When the unit volume of the cementitious material is different, the strength of the concrete at each age is not much different. In summary, in this experiment, the optimum dosage of cementitious material is 800 kg/m3, and the best water-reducing component is naphthalene series water-reducing agent.

Figure 12.

The influence of consumption of cementitious material on the compressive strength of concrete for using FDN.

Figure 13.

The influence of consumption of cementitious material on compressive strength of concrete using polycarboxylate superplasticizer.

Figure 14.

The influence of types of the water-reducing component on compressive strength of concrete for using 700 kg/m3 cementitious material.

Figure 15.

The influence of the types of water-reducing component on the compressive strength of concrete for using 800 kg/m3 cementitious material.

Figure 16.

The influence of types of water-reducing components on the compressive strength of concrete for using 900 kg/m3 cementitious material.

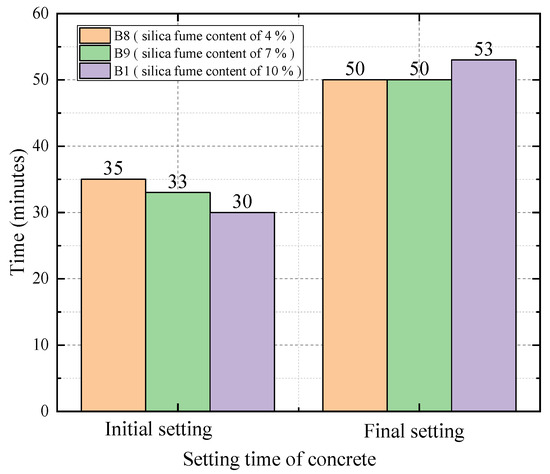

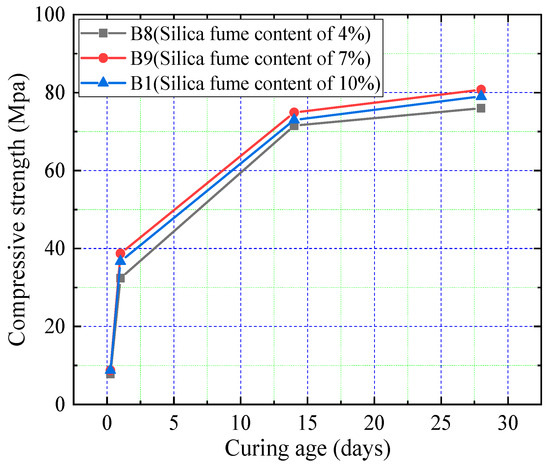

3.1.5. Effect of Silica Fume Content

Effect on Setting Time

It can be seen from Figure 17 that the setting time of concrete is not significantly different when the silica fume content is 4%, 7%, and 10%.

Figure 17.

Setting time of concrete with different silica fume content.

Effect on Compressive Strength

Figure 18 shows that when the content of silica fume is less than 10%, the compressive strength of concrete at each age increases with the increase in silica fume content, and the compressive strength is the highest when the content of silica fume is 10%. Therefore, combined with the influence of silica fume content on the initial and final setting time, the best silica fume content is 10% in this experiment.

Figure 18.

The influence of silica fume contents on compressive strength of concrete.

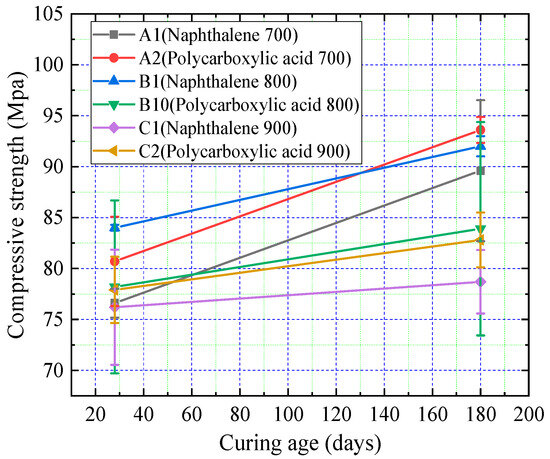

3.1.6. Long-Term Compressive Strength

In order to verify whether the long-term strength of concrete will shrink, the compressive strength of concrete 180 was tested and compared with the compressive strength of 28 days.

As shown in Figure 19, the 180-day compressive strength of the concrete prepared by the self-made super-early-strength agent in this test increases with the development of the age, which has no adverse effect on the long-term strength of the concrete.

Figure 19.

Compressive strength of concrete at the curing age of 28 d and 180 d.

3.2. Micro-Mechanism Analysis

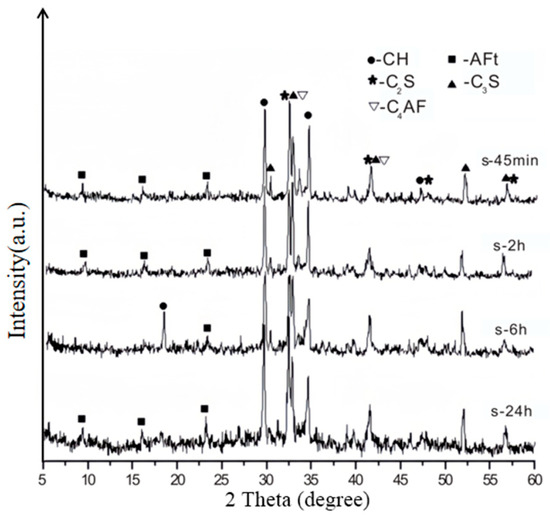

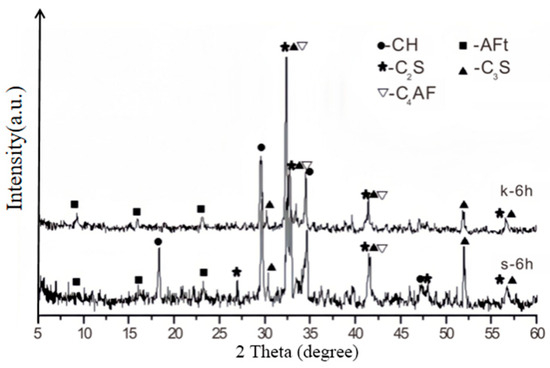

3.2.1. XRD Analysis

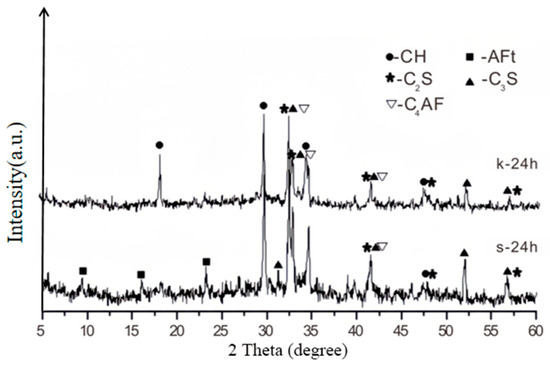

Figure 20 is the XRD pattern of cement hydration samples with 3% quick-setting early-strength component and 2% water-reducing component at different hydration times. Figure 21 and Figure 22 are the XRD patterns of cement hydration samples with 2% water-reducing component and 3% quick-setting early-strength component and blank cement hydration samples with only 2% water-reducing component and no quick-setting early-strength component at 6 h and 24 h, respectively.

Figure 20.

XRD pattern of hydrated specimens with 3% quick-setting early-strength component.

Figure 21.

XRD pattern of hydrated cement paste specimens at 6 h.

Figure 22.

XRD pattern of hydrated cement paste specimens at 24 h.

As shown in Figure 20 and Figure 21: In the S group, the presence of ettringite can be detected at each hydration age, and with the extension of age, the ettringite is more. At 24 h, a large amount of ettringite is formed, and the cement slurry loses fluidity quickly. The setting time of cement is shortened, and the hydrated calcium silicate gel is interspersed in the middle of ettringite to form a dense cement stone, which greatly enhances the early strength. By observing the diffraction peaks of Ca(OH)2 (d = 4.8760 A, I = 116, 2θ = 18.221), it can be found that in the S group, the number of Ca(OH)2 hydrated for 6 h increased, while the hydration for 45 min, 2 h, and 24 h is weak. In the K group, a large amount of Ca(OH)2 has not been produced at 6 h, but until 24 h, C3S hydrates in large quantities and produces a large amount of Ca(OH)2 crystals, indicating that the self-made super-early-strength agent accelerates the process of cement hydration.

There was a significant Ca(OH)2 diffraction peak in the K group at 24 h, while the Ca2+ concentration in the S group decreased significantly, and the concentration of ettringite increased. It shows that the self-made super-early-strength agent greatly promotes the hydration of 6 h and 24 h. During this period, Ca2+ forms a large amount of ettringite. At the same time, the hydrated calcium silicate and other hydrated products produced fill the ettringite skeleton, making the cement stone more dense and higher strength. It can be seen from Figure 22 that ettringite, hydrated calcium silicate, and calcium hydroxide crystals can be detected in the hydration products of the S group and K group, but the number of hydration products is different, indicating that the addition of self-made super-early-strength agent does not change the hydration products, which also explains the problem that the strength of concrete does not shrink in the later stage after the quick-setting and early-strength components are added.

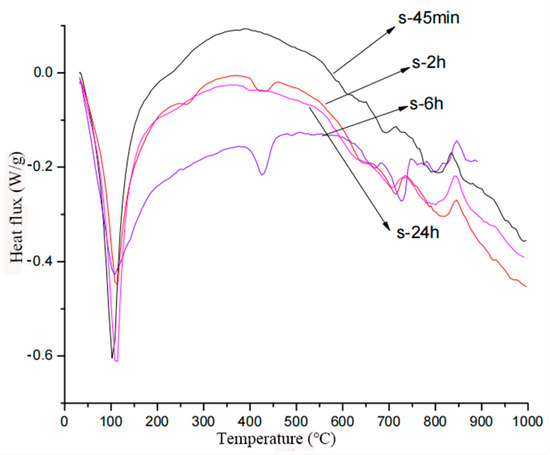

3.2.2. TG-DSC Analysis

It can be seen from Figure 23 that the samples in group S have different endothermic peaks at about 120 °C, and the endothermic effect is the most obvious in 24 h. According to the relevant spectra, the peak generated by this endothermic effect is actually the removal of the two weakest molecular waters in the ettringite structure of the sample. Therefore, the size of this endothermic effect also indirectly reflects the amount of ettringite formation. This is consistent with the results of XRD analysis.

Figure 23.

DSC patterns of hydrated cement paste specimens with 3% quick-setting early-strength component.

In addition, the hydration age of the sample at 2 h and 6 h has an obvious endothermic peak at about 440 °C in the DSC curve. There is Ca(OH)2 in the hydration sample, but it is not obvious at 45 min and 24 h. In the hydration age of 2 h and 6 h, ettringite and Ca(OH)2 are quickly generated due to the incorporation of self-made super-early-strength agent, especially when the hydration of 6 h Ca(OH)2 is generated in large quantities, which is also consistent with the XRD analysis results. Therefore, the incorporation of self-made super-early-strength has a significant effect on accelerating the early hydration of cement.

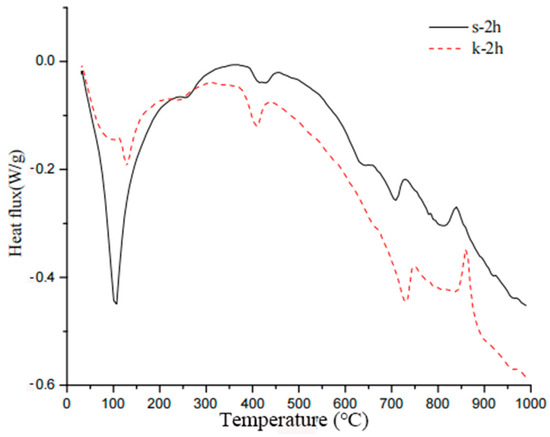

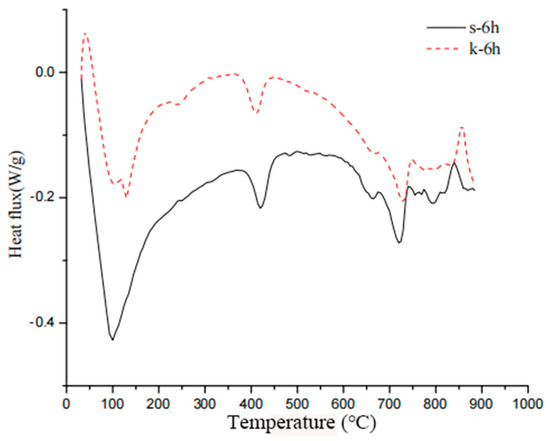

It can be seen from Figure 24, Figure 25 and Figure 26 that the endothermic effect of the group S samples at about 120 °C is much larger than that of the group K samples. The addition of super-early-strength agent significantly promotes the formation of hydration products such as ettringite and accelerates cement hydration. At the same time, at the temperature of 440 °C, the endothermic effect of the S group sample is much smaller than that of the K group sample. When the hydration age is 6 h to 24 h, the addition of the super-early-strength agent consumes Ca2+ and converts to ettringite, which greatly reduces the amount of Ca(OH)2 and increases the amount of ettringite. Therefore, the endothermic effect is that the endothermic peak at 120 °C is obvious at 24 h of hydration and there is no endothermic peak at 440 °C, which is consistent with the XRD analysis results.

Figure 24.

DSC patterns of hydrated cement paste specimens at 2 h.

Figure 25.

DSC patterns of hydrated cement specimens at 6 h.

Figure 26.

DSC patterns of hydrated cement paste specimens at 24 h.

In summary, the endothermic effect of the samples in group S at about 120 °C is much larger than that of the samples in group K at the same hydration age, indicating that the self-made super-early-strength agent can significantly accelerate the hydration of cement and accelerate the formation of hydration products such as ettringite. At the same time, with the extension of hydration age, the super-early-strength agent can accelerate the conversion of Ca(OH)2 to ettringite. When the temperature is about 440 °C, the endothermic peak of Ca(OH)2 is obvious at 6 h and the endothermic peak does not appear at 24 h.

From the above XRD analysis and DSC analysis, it can be seen that the two results are consistent; that is, the self-made super-early-strength agent in this test can promote the early hydration and hardening of cement, accelerate the formation of cement hydration products, especially the formation of Ca(OH)2 and ettringite, and promote the transformation of Ca(OH)2 to ettringite, thus generating a large amount of ettringite in the early stage. The increasing amounts of ettringite intertwine with each other, and C-S-H condensation fills it to form a dense spatial structure, thereby shortening the condensation time and improving the early strength.

4. Conclusions

- (1)

- High-strength concrete can be prepared by using 42.5R ordinary Portland cement and adding a super-early-strength agent. The optimum ratio is as follows: the total amount of cementitious material is 800 kg/m3 (including 10% silica fume), the water–binder ratio is 0.24, the content of quick-setting early-strength component A is 3%, and the content of naphthalene water-reducing component is 2%. The compressive strength of the prepared concrete was the highest at 6 h, 1 day, and 28 days. The compressive strength of 28 days reached 80 MPa, and the compressive strength of 180 days did not shrink and showed a slow growth trend.

- (2)

- Comparing the different dosages of 1%, 3%, and 5% in the quick-setting early-strength component, the best dosage is 3%. When it is lower than 3%, the setting time is short, and when it is higher than 3%, the setting time is too quick, resulting in the concrete not being dense. With the increase in water–binder ratio, the compressive strength of concrete decreases, and the optimum water–binder ratio is 0.24. The setting time of high-strength concrete with naphthalene water-reducing component is shorter than that of high-strength concrete with polyacid water-reducing element, but the difference is not significant. When the content of silica fume is less than 10%, the performance of concrete is improved with the increase in silica fume content.

- (3)

- The results of the XRD test analysis and TG-DSC test analysis are consistent. The self-made super-early gun machine can promote the hydration of cement to generate a large number of ettringite crystals and calcium hydroxide crystals and promote the conversion of calcium hydroxide to ettringite, which greatly improves the early strength.

Author Contributions

Conceptualization, H.L.; methodology, H.L.; validation, N.S., Z.Y. and Y.Z.; formal analysis, H.L.; investigation, N.S.; resources, X.F.; data curation, Y.Z.; writing—original draft preparation, H.L. and N.S.; writing—review and editing, N.S.; supervision, H.L.; project administration, Z.Y.; funding acquisition, H.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by North China Institute of Aerospace Engineering, BKY-2020-37.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Scrivener, K.; Ouzia, A.; Juilland, P.; Mohamed, A.K. Advances in understanding cement hydration mechanisms. Cem. Concr. Res. 2019, 124, 105823. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, Y.; He, R.; Wang, P. Effects of super absorbent polymer on the early hydration of Portland cement highlighted by thermal analysis. J. Therm. Anal. Calorim. 2017, 129, 45–52. [Google Scholar] [CrossRef]

- Zhang, S.M. Preparation and Mechanism Analysis of High-Efficiency early Strength Agent. Adv. Mater. Res. 2012, 535–537, 2483–2487. [Google Scholar] [CrossRef]

- Aggoun, S.; Cheikh-Zouaoui, M.; Chikh, N.; Duval, R. Effect of some admixtures on the setting time and strength evolution of cement pastes at early ages. Constr. Build. Mater. 2008, 22, 106–110. [Google Scholar] [CrossRef]

- Ren, G.; Tian, Z.; Wu, J.; Gao, X. Effects of combined accelerating admixtures on mechanical strength and microstructure of cement mortar. Constr. Build. Mater. 2021, 304, 124642. [Google Scholar] [CrossRef]

- Xie, H.; Liu, X.; Zheng, Y.; Chi, B.; Guo, J.; Dai, X.; Zhang, Z.; Sun, M.; Duan, L.; Wang, Z.; et al. Effect of complexation of alkanolamine in accelerators on the initial stage of cement hydration. Constr. Build. Mater. 2023, 393, 132105. [Google Scholar] [CrossRef]

- Pang, C.M.; Tang, Z.Y.; Yang, Z.Y.; Huang, P. Early Strengthening Agent in Cementitious Composites and Its Function Mechanism: A Review. Mater. Rep. 2023, 37, 21110247-11. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Juilland, P.; Monteiro, P.J. Advances in understanding hydration of Portland cement. Cem. Concr. Res. 2015, 78, 38–56. [Google Scholar] [CrossRef]

- Yuan, D.F.; Shao, C.X. Research on Dosage of Quick Setting Hardener for Cement Grout. Mine Constr. Technol. 2015, 36, 43–45. [Google Scholar] [CrossRef]

- Wan, D.; Liu, R.; Gao, T.; Jing, D.; Lu, F. Effect of Alkanolamines on the Early-Age Strength and Drying Shrinkage of Internal Curing of Mortars. Appl. Sci. 2022, 12, 9536. [Google Scholar] [CrossRef]

- Cheung, J.; Jeknavorian, A.; Roberts, L.; Silva, D. Impact of admixtures on the hydration kinetics of Portland cement. Cem. Concr. Res. 2011, 41, 1289–1309. [Google Scholar] [CrossRef]

- Xu, Q.; Stark, J. Early hydration of ordinary Portland cement with an alkaline shotcrete accelerator. Adv. Cem. Res. 2005, 17, 1–8. [Google Scholar] [CrossRef]

- Ye, Q.; Zhang, Z.N.; Kong, D.Y.; Chen, R.S. Influence of nano-SiO2 addition on properties of hardened cement paste as compared with silica fume. Constr. Build. Mater. 2007, 21, 539–545. [Google Scholar] [CrossRef]

- Heinz, D.; Göbel, M.; Hilbig, H.; Urbonas, L.; Bujauskaite, G. Effect of TEA on fly ash solubility and early age strength of mortar. Cem. Concr. Res. 2010, 40, 392–397. [Google Scholar] [CrossRef]

- García-Lodeiro, I.; Macphee, D.E.; Palomo, A.; Fernández-Jiménez, A. Effect of alkalis on fresh C–S–H gels. FTIR analysis. Cem. Concr. Res. 2009, 39, 147–153. [Google Scholar] [CrossRef]

- Kapeluszna, E.; Kotwica, Ł.; Nocuń-Wczelik, W. Comparison of the effect of ground waste expanded perlite and silica fume on the hydration of cements with various tricalcium aluminate content—Comprehensive analysis. Constr. Build. Mater. 2021, 303, 124434. [Google Scholar] [CrossRef]

- Hoang, K.; Justnes, H.; Geiker, M. Early age strength increase of fly ash blended cement by a ternary hardening accelerating admixture. Cem. Concr. Res. 2016, 81, 59–69. [Google Scholar] [CrossRef]

- Demirboğa, R.; Karagöl, F.; Polat, R.; Kaygusuz, M.A. The effects of urea on strength gaining of fresh concrete under the cold weather conditions. Constr. Build. Mater. 2014, 64, 114–120. [Google Scholar] [CrossRef]

- Hassan, T.; Rizkalla, S. Flexural Strengthening of Prestressed Bridge Slabs with FRP Systems. PCI J. 2002, 47, 76–93. [Google Scholar] [CrossRef]

- Deng, A.Z.; Tian, Q.; Cheng, H.; Zhang, X. Research on new cement-based ultra-fast repair materials. In Proceedings of the Chinese Society of Civil Engineering Soil Mechanics and Geotechnical Engineering Academic Conference, Chongqing, China, 2 November 2007. [Google Scholar]

- Pu, X.C.; Wang, Z.J.; Wang, C.; Yan, W.N.; Wang, Y.W. Study on mechanical properties of ultra-high strength and high performance concrete. J. Build. Struct. 2002, 23, 49–55. [Google Scholar]

- Ye, W.; Qiu, L.M. Development and engineering application of HC series fast hardening and early strength concrete. Zhejiang Constr. 2000, 3, 2. [Google Scholar] [CrossRef]

- Li, H.; Liao, C.W.; Jin, Z.Q. Cement Concrete Pavement Repair Technology, 2nd ed.; People’s Transportation Publishing House: Beijing, China, 1999. [Google Scholar]

- Huang, M.D. Repairing concrete pavement with JK-24 rapid repair agent. Zhongnan Highw. Proj. 1998, 23, 3. [Google Scholar]

- Brykov, A.S.; Vasil’ev, A.S.; Mokeev, M.V. Hydration of portland cement in the presence of aluminum-containing setting accelerators. Russ. J. Appl. Chem. 2013, 86, 793–801. [Google Scholar] [CrossRef]

- Gao, Z.G.; Han, Y.F.; Wang, C.R. Research on Confection and the Mechanism of Alkali-Free Concrete Hardening Accelerator. J. Wuhan Univ. Technol. 2009, 31, 81–83. [Google Scholar] [CrossRef]

- Heikal, M. Effect of calcium formate as an accelerator on the physicochemical and mechanical properties of pozzolanic cement pastes. Cem. Concr. Res. 2004, 34, 1051–1056. [Google Scholar] [CrossRef]

- Lee, T.; Lee, J.; Kim, Y. Effects of admixtures and accelerators on the development of concrete strength for horizontal form removal upon curing at 10 °C. Constr. Build. Mater. 2020, 237, 117652. [Google Scholar] [CrossRef]

- Liu, J.; Ji, X.; Luo, Q.; Xue, J.; Ma, M. Improvement of early age properties of Portland cement by ternary hardening-accelerating admixture. Mag. Concr. Res. 2021, 73, 195–203. [Google Scholar] [CrossRef]

- Zhang, J.J.; Tan, H.B.; He, X.Y.; Zhao, R.X.; Yang, J.; Su, Y. Nano particles prepared from hardened cement paste by wet grinding and its utilization as an accelerator in Portland cement. J. Clean. Prod. 2021, 283, 124632. [Google Scholar] [CrossRef]

- Wang, S.D.; Liu, B.; Zhao, P.Q.; Lu, L.C.; Cheng, X. Effect of early-strength-enhancing agents on setting time and early mechanical strength of belite-barium calcium sulfoaluminate cement. J. Therm. Anal. Calorim. 2018, 131, 2337–2343. [Google Scholar] [CrossRef]

- Chen, H.; Feng, P.; Ye, S.; Li, Q.; Hou, P.; Cheng, X. The influence of inorganic admixtures on early cement hydration from the point of view of thermodynamics. Constr. Build. Mater. 2020, 259, 119777. [Google Scholar] [CrossRef]

- JGJ 63-2006; Water Standard for Concrete. Industry Standard. Construction Industry: Beijing, China, 2006.

- JC477-2005; Accelerator for Shotcrete. Industry Standard. Construction Industry: Beijing, China, 2005.

- JC/T727-2005; Cement Paste Standard Consistency and Setting Time Tester. Industry Standard. Construction Industry: Beijing, China, 2005.

- GB/T 50080-2002; Standard for Performance Test Method of Ordinary Concrete Mixture. National Standard. Construction Industry: Beijing, China, 2003.

- GB/T 50081-2002; Standard for Test Methods of Mechanical Properties of Ordinary Concrete. National Standard. Construction Industry: Beijing, China, 2003.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).