Influence of Chitosan–Sodium Tripolyphosphate-Coated Tung Oil Microcapsules on the UV Coating Performance of Cherry Wood Surface

Abstract

1. Introduction

2. Test Materials and Methods

2.1. Experimental Equipment and Materials

2.2. The Preparation of Tung Oil Microcapsules Coated with Chitosan and Sodium Tripolyphosphate

2.3. Coating Method

2.4. Test and Characterization

2.4.1. Optical Performance Test

2.4.2. Self-Healing Performance Test

2.4.3. Microstructural Morphology of Coatings

2.4.4. Chemical Composition Characterization of Paint Film

2.4.5. Mechanical Performance Testing

3. Results and Discussion

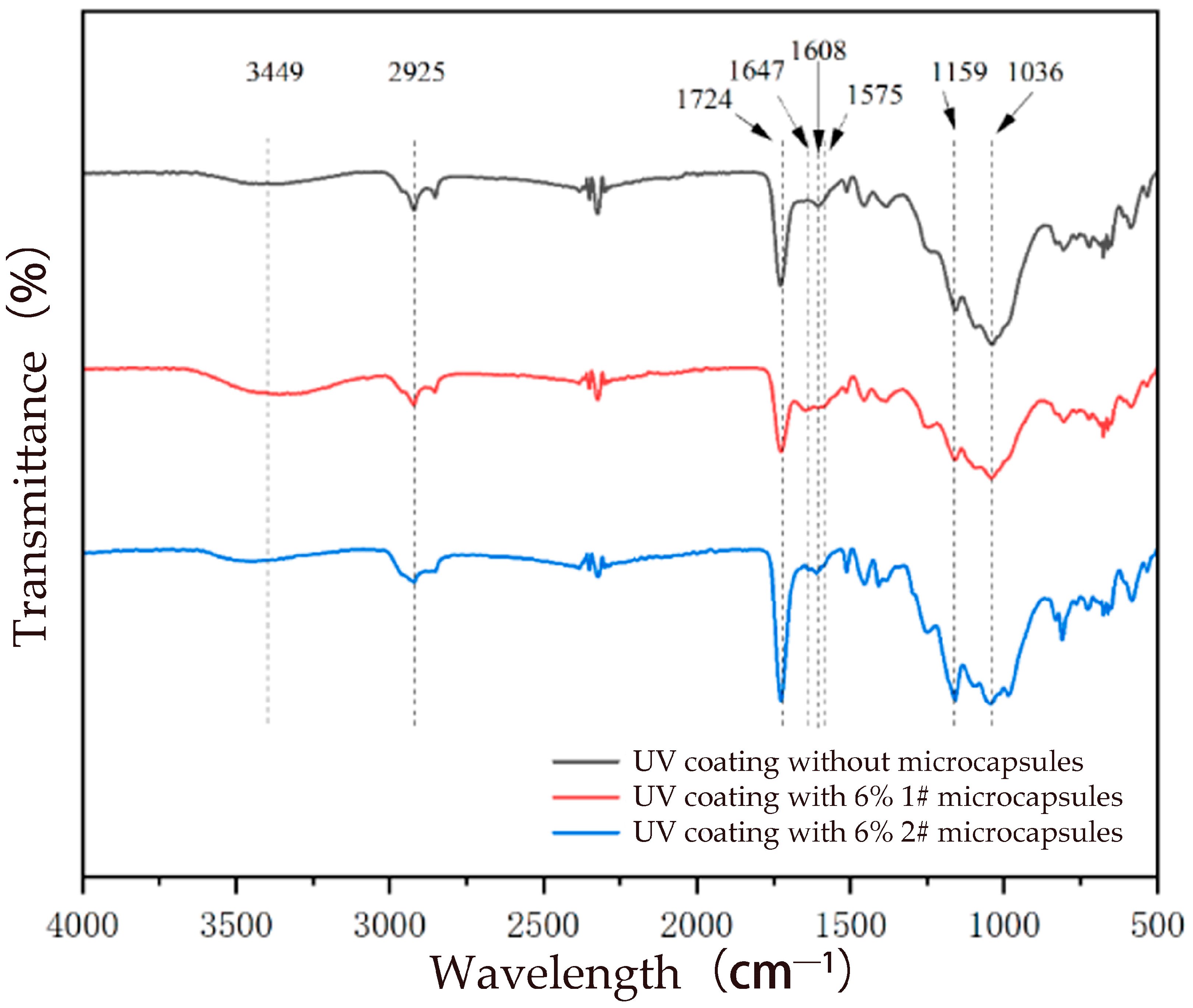

3.1. Chemical Composition of UV-Cured Coating on Cherry Wood Board Incorporated with Chitosan–Sodium Tripolyphosphate-Coated Tung Oil Microcapsules

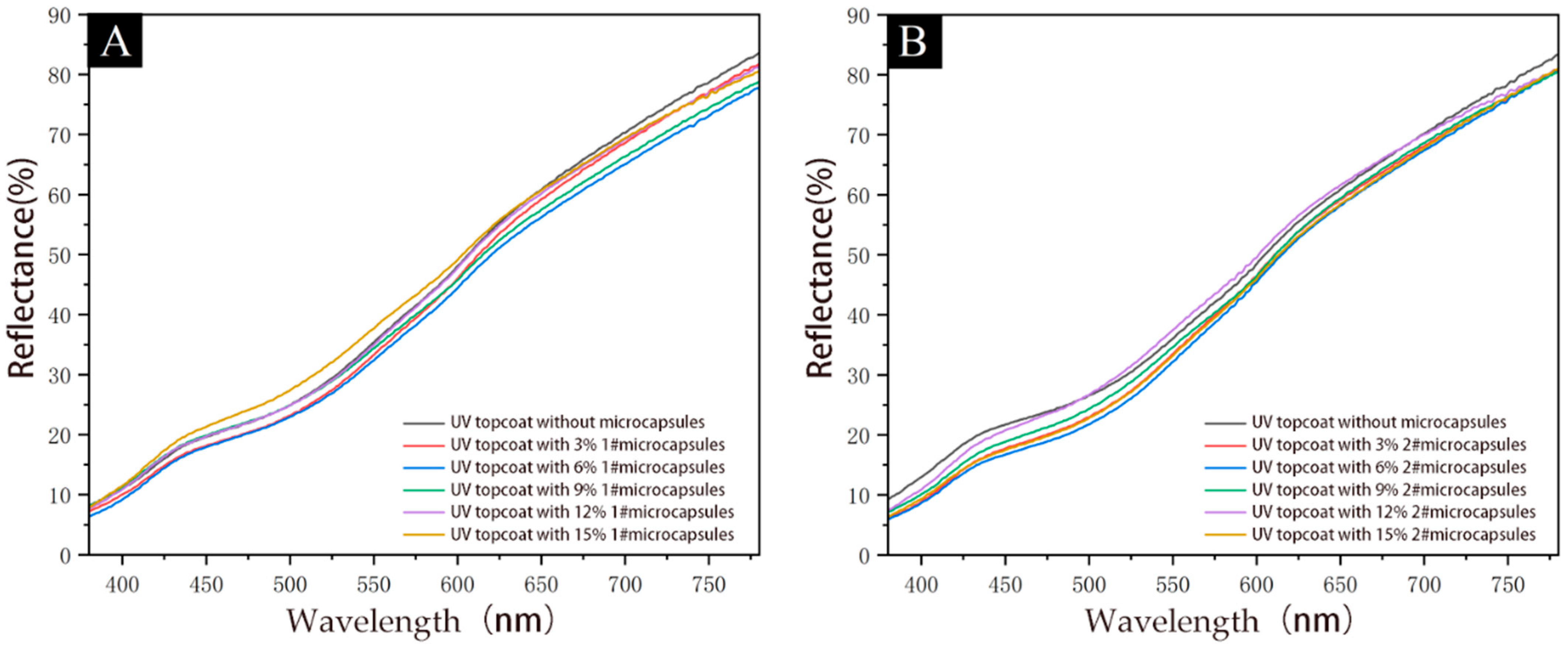

3.2. Optical Properties of UV Coating on Cherry Wood Surface

3.3. Mechanical Properties of UV Coatings on Cherry Wood Surfaces

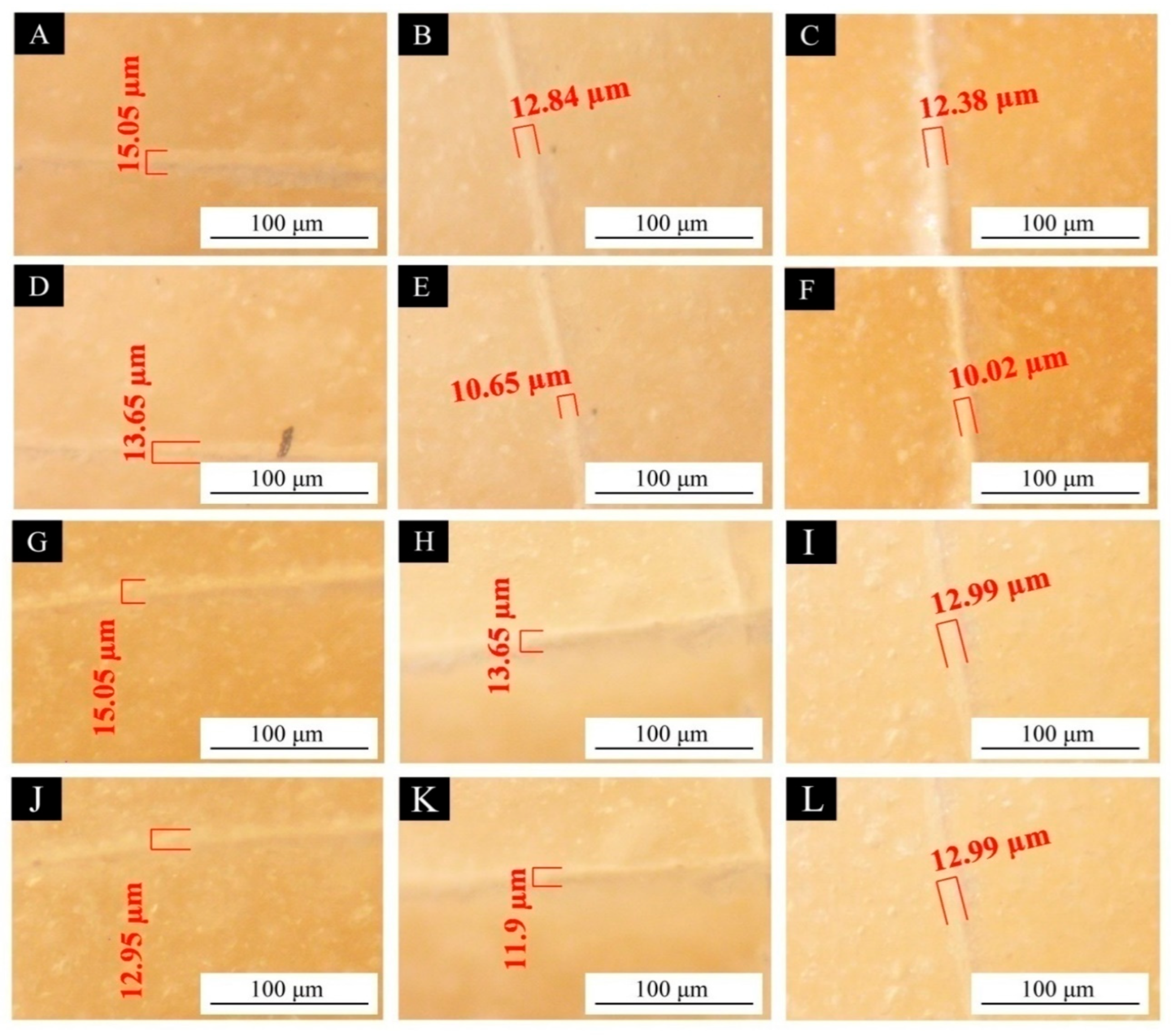

3.4. Self-Healing Performance of UV Coating on Surface of Cherry Wood Boards

3.5. Microscopic Morphology of UV Coating on Surface of Cherry Wood Boards

3.6. Comparison of Surface Coating Properties of Cherry Wood Boards with Two Types of Microcapsules Added and Self-Healing Mechanism of Coatings

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Han, Y.; Yan, X.X.; Tao, Y. Effect of number of impregnations of microberlinla sp with microcapsule emulsion on the performance of self-repairing coatings on wood surfaces. Coatings 2022, 12, 989. [Google Scholar] [CrossRef]

- Hu, J.; Liu, Y.; Xu, W. Influence of cell characteristics on the construction of structural color layers on wood surfaces. Forests 2024, 15, 676. [Google Scholar] [CrossRef]

- Wang, C.; Li, J.Y.; Wang, T.Y.; Chu, Q.; Wang, X.W. Fused deposition 3D printing of bonsai tree guiding mold based on acrylonitrile-butadiene-styrene copolymer. BioResources 2024, 19, 5839–5846. [Google Scholar] [CrossRef]

- Wang, C.; Li, J.Y.; Wang, T.Y.; Chu, Q.; Wen, S.Q. Design and rapid prototyping of packaging liner for rosewood craft based on Gyroid infill structure. BioResources 2025, 20, 842–851. [Google Scholar] [CrossRef]

- Xue, J.X.; Xu, W.; Zhou, J.C.; Mao, W.G.; Wu, S.S. Effects of high-temperature heat treatment modification by impregnation on physical and mechanical properties of poplar. Materials 2022, 15, 7334. [Google Scholar] [CrossRef]

- Hu, W.; Luo, M.; Yu, R.; Zhao, Y. Effects of the selected factors on cyclic load performance of T-shaped mortise-and-tenon furniture joints. Wood Mater. Sci. Eng. 2024, 18, 1–10. [Google Scholar] [CrossRef]

- Hu, W.; Yu, R. Mechanical and acoustic characteristics of four wood species subjected to bending load. Maderas-Cienc. Tecnol. 2023, 25, 39. [Google Scholar] [CrossRef]

- Hu, W.; Zhao, Y.; Xu, W.; Liu, Y. The influences of selected factors on bending moment capacity of case furniture joints. Appl. Sci. 2024, 14, 10044. [Google Scholar] [CrossRef]

- Hu, W.; Yang, P.; Wang, Y.; Zhang, J. Damage zone analysis and its effect on the elastic constants of beech blocks with different grain orientations under compression. Wood Sci. Technol. 2025, 59, 62. [Google Scholar] [CrossRef]

- Zhou, C.; Yu, R.; Kaner, J. Evaluating functional ability in older adults’ object retrieval behavior from kitchen furniture using OpenPose and REBA. Sci. Rep. 2024, 14, 25560. [Google Scholar] [CrossRef]

- Hu, W.; Yu, R. Study on the strength mechanism of the wooden round-end mortise-and-tenon joint using the digital image correlation method. Holzforschung 2024, 78, 519–530. [Google Scholar] [CrossRef]

- Hu, W.; Fu, W.; Zhao, Y. Optimal design of the traditional Chinese wood furniture joint based on experimental and numerical method. Wood Res. 2024, 69, 50–59. [Google Scholar] [CrossRef]

- Hu, W.; Luo, M.; Liu, Y.; Xu, W.; Konukcu, A.C. Experimental and numerical studies on the mechanical properties and behaviors of a novel wood dowel reinforced dovetail joint. Eng. Fail. Anal. 2023, 152, 107440. [Google Scholar] [CrossRef]

- Wang, C.; Huang, H.; Wang, X.; Wang, Y.; Zhu, Y. Effect of drying treatment on the physical and mechanical properties of material extrusion-based 3D-printed PETG models. BioResources 2025, 20, 7000–7009. [Google Scholar] [CrossRef]

- Wang, C.; Li, J.; Wang, T.; Wang, X.; Chu, Q. Effect of optimised infill parameters on the tensile properties of MEX co-polyester models. Mater. Plast. 2024, 61, 129–136. [Google Scholar] [CrossRef]

- De Ligne, L.; De Muynck, A.; Caes, J.; Baetens, J.; De Baets, B.; Van Hoorebeke, L.; Van Acker, J.; Van den Bulcke, J. Studying the spatio-temporal dynamics of wood decay with X-ray CT scanning. Holzforschung 2022, 76, 408–420. [Google Scholar] [CrossRef]

- Hu, W.; Luo, M.; Hao, M.; Tang, B.; Wan, C. Study on the effects of selected factors on the diagonal tensile strength of oblique corner furniture joints constructed by wood dowel. Forests 2023, 14, 1149. [Google Scholar] [CrossRef]

- Borges, C.C.; Tonoli, G.H.D.; Cruz, T.M.; Duarte, P.J.; Junqueira, T.A. Nanoparticles-based wood preservatives: The next generation of wood protection? Cerne 2018, 24, 397–407. [Google Scholar] [CrossRef]

- Wang, C.; Li, J.; Wang, T.; Wang, X. Additive manufacturing of furniture corner guards based on thermoplastic polyurethane filament. BioResources 2025, 20, 5398–5406. [Google Scholar] [CrossRef]

- Liu, Q.; Gao, D.; Xu, W. Effect of paint process on the performance of modified poplar wood antique. Coatings 2021, 11, 1174. [Google Scholar] [CrossRef]

- Femat-Diaz, A.; Terol-Villalobos, I.; Torres-Gonzalez, J.; Manrıquez-Guerrero, F.; Vargas-Vazquez, D. Microcrack parameters characterization in hard-coatings using moments for image processing. Electrochem. Sci. 2013, 8, 9677–9691. [Google Scholar] [CrossRef]

- Liu, C.; Xu, W. Effect of coating process on properties of two-component waterborne polyurethane coatings for wood. Coatings 2022, 12, 1857. [Google Scholar] [CrossRef]

- Chang, Y.J.; Yan, X.X.; Wu, Z.H. Application and prospect of self-healing microcapsules in surface coating of wood. Colloid Interface Sci. Commun. 2023, 56, 100736. [Google Scholar] [CrossRef]

- Evans, A.; Hutchinson, J. On the mechanics of delamination and spalling in compressed films. Int. J. Solids Struct. 1984, 20, 455–466. [Google Scholar] [CrossRef]

- Scheiner, M.; Dickens, T.J.; Okoli, O. Progress towards self-healing polymers for composite structural applications. Polymer 2016, 83, 260–282. [Google Scholar] [CrossRef]

- Bhushan, B. Self-healing materials and defense mechanisms. In Biomimetics: Bioinspired Hierarchical-Structured Surfaces for Green Science and Technology, 3rd ed.; Springer: Cham, Switzerland, 2018; pp. 911–958. [Google Scholar]

- Hu, J.F.; Chen, H.Q.; Zhang, Z.B. Mechanical properties of melamine formaldehyde microcapsules for self-healing materials. Mater. Chem. Phys. 2009, 118, 63–70. [Google Scholar] [CrossRef]

- Miao, Q.J.; Fang, Z.P.; Cai, G.P. Research progress of self-healing composite materials. J. Mater. Sci. Eng. 2004, 22, 301–303. [Google Scholar]

- Wang, H.P.; Rong, Z.M.; Zhang, M.Q. Microcapsule Filling Self-repairing Polymers and Their Composites. Chem. Prog. 2010, 22, 2397–2407. [Google Scholar]

- Teixeira, V. Mechanical integrity in PVD coatings due to the presence of residual stresses. Thin Solid Film. 2001, 392, 276–281. [Google Scholar] [CrossRef]

- Yuan, Y.C.; Rong, M.Z.; Zhang, M.Q. Preparation and characterization of microencapsulated polythiol. Polymer 2008, 49, 2531–2541. [Google Scholar] [CrossRef]

- Yuan, L.; Liang, G.; Xie, J.; Li, L.; Guo, J. Preparation and characterization of poly (urea-formaldehyde) microcapsules filled with epoxy resins. Polymer 2006, 47, 5338–5349. [Google Scholar] [CrossRef]

- Fereidoon, A.; Ahangari, M.G.; Jahanshahi, M. Effect of nanoparticles on the morphology and thermal properties of self-healing poly (urea-formaldehyde) microcapsules. J. Polym. Res. 2013, 20, 151. [Google Scholar] [CrossRef]

- Tong, X.M.; Zhang, M.; Wang, M.S.; Fu, Y. Effects of surface modification of self healing poly (melamine urea formaldehyde) microcapsules on the properties of unsaturated polyester composites. Appl. Polym. Sci. 2013, 127, 3954–3961. [Google Scholar] [CrossRef]

- White, S.R.; Sottos, N.; Geubelle, P.; Moore, J.; Kessler, M.R.; Sriram, S. Autonomic healing of polymer composites. Nature 2001, 409, 794–797. [Google Scholar] [CrossRef] [PubMed]

- Chang, Y.J.; Yan, X.X. Preparation and self-repairing properties of MF-coated shellac water-based microcapsules. Coatings 2020, 10, 778. [Google Scholar] [CrossRef]

- Lv, L.T.; Wang, Y.T.; Dai, J.; Yang, Z.Y.; Yang, Q.L. The study on preparation, stability and anti-allergic efficacy of phycocyanin microcapsules. Food Res. Int. 2024, 201, 115530. [Google Scholar] [CrossRef] [PubMed]

- Meng, Q.Y.; Zhong, S.L.; Wang, J.; Gao, Y.; Cui, X.J. Advances in chitosan-based microcapsules and their applications. Carbohydr. Polym. 2023, 300, 120265. [Google Scholar] [CrossRef] [PubMed]

- Dong, Y.; Deng, J.Z.; Yan, X.X. Preparation of tung oil microcapsules coated with chitosan-sodium tripolyphosphate and their effects on coating film properties. Coatings 2025, 15, 867. [Google Scholar] [CrossRef]

- Liu, Q.; Gao, D.; Xu, W. Influence of the bottom color modification and material color modification process on the performance of modified poplar. Coatings 2021, 11, 660. [Google Scholar] [CrossRef]

- Liu, Q.; Gao, D.; Xu, W. Effect of sanding processes on the surface properties of modified poplar coated by primer compared with mahogany. Coatings 2020, 10, 856. [Google Scholar] [CrossRef]

- GB/T 4893.6-2013; Test of Surface Coatings of Furniture—Part 6: Determination of Gloss Value. Standardization Administration of China: Beijing, China, 2013.

- Li, R.R.; He, C.J.; Wang, X.D. Evaluation and modeling of processability of laser removal technique for bamboo outer layer. Jom 2021, 73, 2423–2430. [Google Scholar] [CrossRef]

- GB/T 6739-2022; Paints and Varnishes—Determination of Film Hardness by Pencil Test. Standardization Administration of China: Beijing, China, 2022.

- GB/T 4893.4-2023; Test of Surface Coating of Furniture—Part 4: Determination of Adhesion by Cross-Cut. Standardization Administration of China: Beijing, China, 2023.

- GB/T 4893.9-2013; Test of Surface Coatings of Furniture—Part 9: Determination of Resistance to Impact. Standardization Administration of China: Beijing, China, 2013.

- Zou, Y.M.; Xia, Y.X.; Yan, X.X. Effect of UV top coating microcapsules on the coating properties of fiberboard surfaces. Polymers 2024, 16, 2098. [Google Scholar] [CrossRef] [PubMed]

- Dong, Y.; Deng, J.Z.; Yan, X.X. Effect of chitosan gum arabic-coated tung oil microcapsules on the performance of UV coating on cherry wood surface. Coatings 2025, 15, 873. [Google Scholar] [CrossRef]

| Equipment Name | Model | Manufacturer |

|---|---|---|

| Pencil hardness tester | HT-6510P | Quzhou Aipu Measuring Instrument Co., Ltd., Quzhou, China |

| Paint film impactor | QCJ-40 | Quzhou Aipu Measuring Instrument Co., Ltd., Quzhou, China |

| Paint film adhesion tester | QFH-A | Quzhou Aipu Measuring Instrument Co., Ltd., Quzhou, China |

| Forced convection drying oven | DHG-9240A | Shanghai Aozhen Instrument Manufacturing Co., Ltd., Shanghai, China |

| UV curing machine | 620# | Huzhou Tongxu Machinery Equipment Co., Ltd., Nanxun, China |

| Optical microscope | AX-10 | Carl Zeiss Co., Ltd., Baden-Württemberg, Germany |

| Fourier transform infrared (FTIR) spectrometer | VERTEX 80V | Bruker Technology Co., Ltd., Hamburg, Germany |

| Scanning electron microscope (SEM) | QUANTA-200 | Thermo Fisher Scientific Co., Ltd., Waltham, MA, USA |

| Precision roughness tester | J8-4C | Shanghai Taiming Optical Instrument Co., Ltd., Shanghai, China |

| Gloss meter | HG268 | Shenzhen 3nh Technology Co., Ltd., Shenzhen, China |

| Colorimeter | CR7 | Shenzhen 3nh Technology Co., Ltd., Shenzhen, China |

| Universal mechanical testing machine | AGS-X | Shimadzu Seisakusho, Kyoto, Japan |

| UV–Vis spectrophotometer | U-3900 | Hitachi Instruments (Suzhou) Co., Ltd., Suzhou, China |

| Heat-collecting constant-temperature heating magnetic stirrer | DF-101Z | Shanghai Yixin Scientific Instrument Co., Ltd., Shanghai, China |

| Ultrasonic emulsifying disperser | BILONG-500 | Shanghai Bilang Instrument Co., Ltd., Shanghai, China |

| Small-scale spray dryer | JA-PWGZ100 | Shenyang Jingao Instrument Technology Co., Ltd., Shenyang, China |

| Circulating water vacuum pump | SHZ-D | Shanghai Simate Instrument & Equipment Co., Ltd., Shanghai, China |

| Name | Molecular Formula | CAS No. | Manufacturer |

|---|---|---|---|

| Polyoxyethylene sorbitan monooleate (T-80) | C24H44O6 | 9005-65-6 | Fangzheng Reagent Factory, Beichen District, Tianjin, China |

| Sodium dodecylbenzene sulfonate (SDBS) | CH3(CH2)11C6H4SO3Na | 25155-30-0 | Tianjin Zhiyuan Chemical Reagent Co., Ltd., Tianjin, China |

| Sodium tripolyphosphate (STPP) | Na5P3O10 | 7758-29-4 | Sinopharm Group Chemical Reagent Co., Ltd., Shanghai, China |

| Chitosan | (C6H11NO4)n | 9012-76-4 | Sinopharm Group Chemical Reagent Co., Ltd., Shanghai, China |

| Acetic acid | C2H4O2 | 64-19-7 | Sinopharm Group Chemical Reagent Co., Ltd., Shanghai, China |

| Tung oil | C65H100O14 | - | Shanghai Shenmeng Home Furnishing Co., Ltd., Shanghai, China |

| Tannic acid | C76H52O46 | 1401-55-4 | Tianjin Zhonglian Chemical Reagent Co., Ltd., Tianjin, China |

| Sample | Chitosan (g) | 1% Acetic Acid (g) | Tung Oil (g) | T-80 (g) | SDBS (g) | Use Pure Water for Emulsification (g) | STPP (g) | STPP Used Pure Water (g) |

|---|---|---|---|---|---|---|---|---|

| 1# | 0.800 | 79.200 | 1.600 | 0.940 | 1.410 | 76.050 | 0.400 | 9.600 |

| 2# | 0.800 | 79.200 | 1.600 | 1.058 | 1.292 | 76.050 | 0.400 | 9.600 |

| Coating | The Types of Added Microcapsules | Microcapsule Content (%) | Quality of UV Primer (g) | Quality of UV Topcoat (g) | Microcapsule Quality (g) |

|---|---|---|---|---|---|

| 0 | no | 0 | 0.800 | 0.800 | 0.000 |

| 1 | Microcapsule 1# | 3 | 0.800 | 0.776 | 0.024 |

| 2 | 6 | 0.800 | 0.752 | 0.048 | |

| 3 | 9 | 0.800 | 0.728 | 0.072 | |

| 4 | 12 | 0.800 | 0.704 | 0.096 | |

| 5 | 15 | 0.800 | 0.680 | 0.120 | |

| 6 | Microcapsule 2# | 3 | 0.800 | 0.776 | 0.024 |

| 7 | 6 | 0.800 | 0.752 | 0.048 | |

| 8 | 9 | 0.800 | 0.728 | 0.072 | |

| 9 | 12 | 0.800 | 0.704 | 0.096 | |

| 10 | 15 | 0.800 | 0.680 | 0.120 |

| Coating | Add the Types of Microcapsules | Microcapsule Content (%) | Reflectance (%) |

|---|---|---|---|

| 0 | no | 0 | 44.96 ± 1.21 |

| 1 | Microcapsule 1# | 3 | 42.94 ± 1.27 |

| 2 | 6 | 41.14 ± 0.84 | |

| 3 | 9 | 42.74 ± 0.81 | |

| 4 | 12 | 44.03 ± 0.82 | |

| 5 | 15 | 45.19 ± 1.44 | |

| 6 | Microcapsule 2# | 3 | 42.64 ± 1.39 |

| 7 | 6 | 41.77 ± 0.61 | |

| 8 | 9 | 43.33 ± 0.81 | |

| 9 | 12 | 45.24 ± 1.48 | |

| 10 | 15 | 42.42 ± 0.39 |

| Coating | Add the Types of Microcapsules | Microcapsule Content (%) | Chromaticity Value | Color Difference Value ΔE | ||

|---|---|---|---|---|---|---|

| Lightness Value L | Red and Green Values a | Yellow-Blue Value b | ||||

| 0 | no | 0 | 62.35 | 15.60 | 24.15 | - |

| 1 | Microcapsule 1# | 3 | 59.91 | 14.17 | 24.43 | 2.84 ± 0.08 |

| 2 | 6 | 58.35 | 13.96 | 25.32 | 4.47 ± 0.09 | |

| 3 | 9 | 59.24 | 12.63 | 24.94 | 4.37 ± 0.12 | |

| 4 | 12 | 58.32 | 13.63 | 26.85 | 5.21 ± 0.11 | |

| 5 | 15 | 57.46 | 11.44 | 28.90 | 7.98 ± 0.07 | |

| 6 | Microcapsule 2# | 3 | 61.83 | 14.71 | 23.31 | 1.34 ± 0.02 |

| 7 | 6 | 59.31 | 13.70 | 25.47 | 3.80 ± 0.06 | |

| 8 | 9 | 58.27 | 13.93 | 25.15 | 4.51 ± 0.09 | |

| 9 | 12 | 57.62 | 12.68 | 24.60 | 5.58 ± 0.16 | |

| 10 | 15 | 57.34 | 11.13 | 27.44 | 7.46 ± 0.10 | |

| Coating | The Types of Added Microcapsules | Microcapsule Content (%) | Glossiness (GU) | Loss of Light Rate (%) | ||

|---|---|---|---|---|---|---|

| Incident Angle 20° | Incident Angle 60° | Incident Angle 85° | ||||

| 0 | no | 0 | 22.10 | 57.30 | 58.50 | - |

| 1 | Microcapsule 1# | 3 | 9.50 | 32.90 | 30.90 | 42.58 ± 0.32 |

| 2 | 6 | 5.10 | 19.00 | 14.80 | 66.84 ± 0.33 | |

| 3 | 9 | 4.40 | 9.30 | 2.50 | 83.77 ± 1.00 | |

| 4 | 12 | 2.50 | 10.30 | 4.20 | 82.02 ± 1.08 | |

| 5 | 15 | 1.60 | 5.70 | 1.50 | 90.05 ± 0.84 | |

| 6 | Microcapsule 2# | 3 | 10.60 | 38.40 | 37.10 | 32.98 ± 0.22 |

| 7 | 6 | 5.40 | 18.10 | 16.40 | 68.41 ± 0.76 | |

| 8 | 9 | 2.80 | 11.80 | 7.50 | 79.41 ± 0.86 | |

| 9 | 12 | 1.90 | 6.20 | 2.80 | 89.18 ± 0.74 | |

| 10 | 15 | 1.20 | 4.80 | 1.70 | 91.62 ± 0.91 | |

| Coating | The Types of Added Microcapsules | Microcapsule Content (%) | Roughness (μm) |

|---|---|---|---|

| 0 | no | 0 | 0.42 ± 0.01 |

| 1 | Microcapsule 1# | 3 | 0.58 ± 0.01 |

| 2 | 6 | 1.11 ± 0.02 | |

| 3 | 9 | 1.91 ± 0.02 | |

| 4 | 12 | 3.22 ± 0.03 | |

| 5 | 15 | 4.00 ± 0.05 | |

| 6 | Microcapsule 2# | 3 | 0.57 ± 0.01 |

| 7 | 6 | 1.32 ± 0.01 | |

| 8 | 9 | 2.21 ± 0.02 | |

| 9 | 12 | 3.25 ± 0.04 | |

| 10 | 15 | 4.27 ± 0.02 |

| Coating | The Types of Added Microcapsules | Microcapsule Content (%) | Impact Resistance Grade | Adhesion Grade | Hardness |

|---|---|---|---|---|---|

| 0 | no | 0 | 5 | 1 | 4H |

| 1 | Microcapsule 1# | 3 | 5 | 1 | 3H |

| 2 | 6 | 4 | 1 | 3H | |

| 3 | 9 | 3 | 2 | 2H | |

| 4 | 12 | 3 | 3 | H | |

| 5 | 15 | 3 | 3 | H | |

| 6 | Microcapsule 2# | 3 | 4 | 1 | 4H |

| 7 | 6 | 4 | 2 | 3H | |

| 8 | 9 | 3 | 2 | 3H | |

| 9 | 12 | 3 | 3 | 2H | |

| 10 | 15 | 3 | 3 | H |

| Coating | The Types of Added Microcapsules | Microcapsule Content (%) | The Width of the Scratch Before Repair (μm) | The Width of the Scratch After Repair (μm) | Repair Rate (%) |

|---|---|---|---|---|---|

| 0 | no | 0 | 12.99 | 12.99 | - |

| 1 | Microcapsule 1# | 3 | 15.05 | 13.65 | 9.30 ± 0.11 |

| 2 | 6 | 12.84 | 10.65 | 17.06 ± 0.12 | |

| 3 | 9 | 12.38 | 10.02 | 19.06 ± 0.37 | |

| 4 | 12 | 15.05 | 12.95 | 13.95 ± 0.28 | |

| 5 | 15 | 13.65 | 11.90 | 12.82 ± 0.13 | |

| 6 | Microcapsule 2# | 3 | 12.65 | 11.47 | 9.33 ± 0.16 |

| 7 | 6 | 12.95 | 10.85 | 16.22 ± 0.15 | |

| 8 | 9 | 15.25 | 12.62 | 17.25 ± 0.31 | |

| 9 | 12 | 15.06 | 13.65 | 9.36 ± 0.19 | |

| 10 | 15 | 18.02 | 15.75 | 12.60 ± 0.40 |

| Coating Name | Self-Healing Performance | Optical Performance | Mechanical Properties | |||||

|---|---|---|---|---|---|---|---|---|

| Repair Rate (%) | Visible Light Reflectance (%) | Loss of Light Rate (%) | Color Difference Value | Impact Resistance Grade | Adhesion Grade | Hardness | Roughness (μm) | |

| Cherry wood coating containing 6% chitosan/arabic gum-encapsulated tung oil microcapsules | 22.61 | 45.25 | 13.44 | 1.31 | 4 | 2 | 4H | 0.71 |

| Cherry wood coating containing 6% chitosan–sodium tripolyphosphate-coated tung oil microcapsules 1# | 17.06 | 41.14 | 66.84 | 4.47 | 4 | 1 | 3H | 1.11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, W.; Deng, J.; Yan, X. Influence of Chitosan–Sodium Tripolyphosphate-Coated Tung Oil Microcapsules on the UV Coating Performance of Cherry Wood Surface. Coatings 2025, 15, 949. https://doi.org/10.3390/coatings15080949

Chang W, Deng J, Yan X. Influence of Chitosan–Sodium Tripolyphosphate-Coated Tung Oil Microcapsules on the UV Coating Performance of Cherry Wood Surface. Coatings. 2025; 15(8):949. https://doi.org/10.3390/coatings15080949

Chicago/Turabian StyleChang, Wenjing, Jinzhe Deng, and Xiaoxing Yan. 2025. "Influence of Chitosan–Sodium Tripolyphosphate-Coated Tung Oil Microcapsules on the UV Coating Performance of Cherry Wood Surface" Coatings 15, no. 8: 949. https://doi.org/10.3390/coatings15080949

APA StyleChang, W., Deng, J., & Yan, X. (2025). Influence of Chitosan–Sodium Tripolyphosphate-Coated Tung Oil Microcapsules on the UV Coating Performance of Cherry Wood Surface. Coatings, 15(8), 949. https://doi.org/10.3390/coatings15080949