2. General Overview of MSVD

To begin with, it should be pointed out that the PVD process is a technology that has seen significant advancements and modifications over the past few decades, primarily to enhance coating properties and improve the deposition rate [

1]. The concept emerged in the 1960s and was facilitated by the advent and integration of various technologies that included: plasma technology, vacuum techniques, thermal evaporation, and sputtering. Those innovations enabled the development of vacuum-based coating processes.

Based on the above, it can be stated that PVD is a prevalent method for depositing thin films and finds its application in various fields due to its ability to enhance tribological behavior, improve optical properties, and upgrade aesthetic appearances. Its utility is widely recognized, with established applications across diverse domains [

2,

3,

4]. The PVD process can be categorized into two main techniques for particle extraction from the target material: sputtering and evaporation [

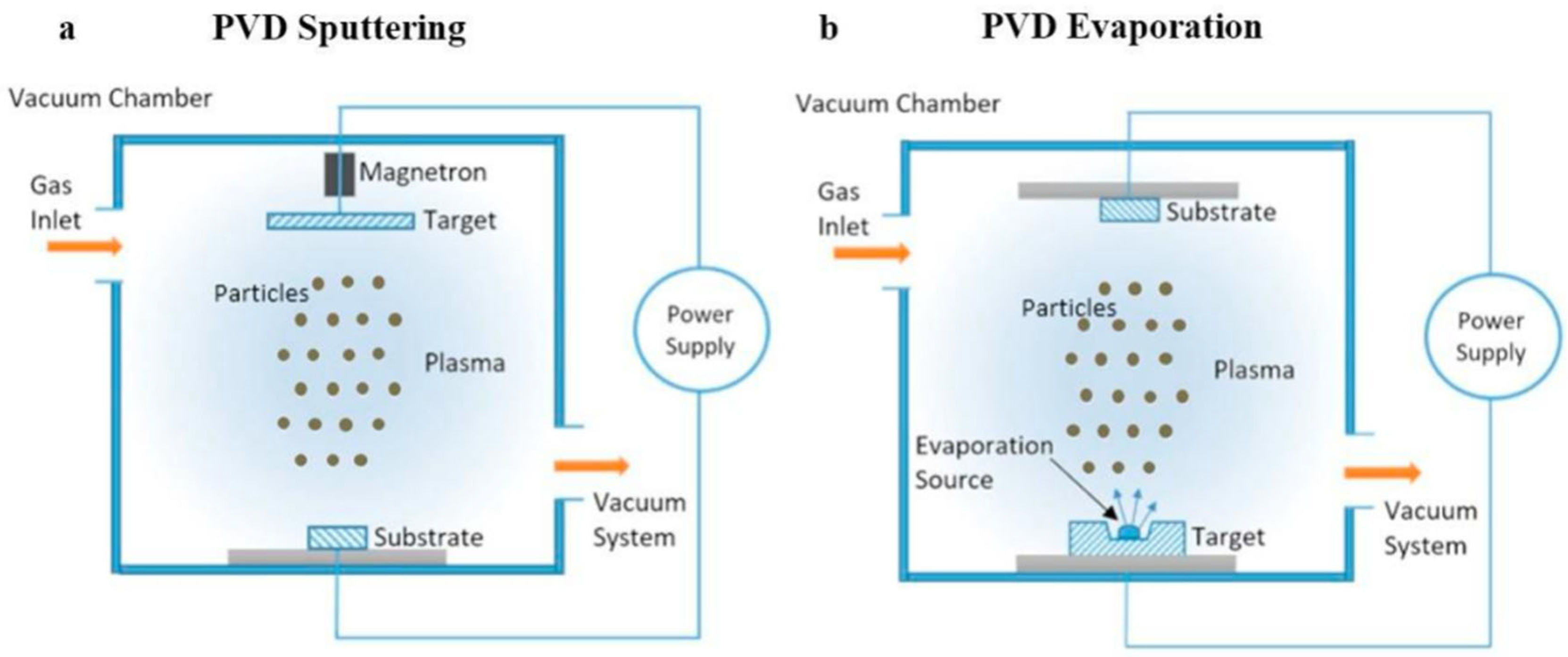

5]. Those techniques are illustrated in

Figure 1. The diagram labeled “(b) PVD Evaporation” illustrates the physical vapor deposition process based on thermal evaporation inside a vacuum chamber. In this setup, the target material is placed above an evaporation source, which provides intense heat—either through resistive heating or an electron beam—to cause the material to transition from a solid to a vapor phase. Once vaporized, the atoms of the target material disperse upward in straight-line paths due to the low-pressure vacuum environment, minimizing unwanted collisions with gas particles. These vaporized atoms travel toward the substrate, which is positioned above the target, and upon reaching its cooler surface, they condense, forming a uniform thin film. The process is powered by an external power supply and assisted by a vacuum system, which maintains the required low pressure for efficient and clean deposition. A gas inlet is also included, though in evaporation processes, it plays a minimal role compared to sputtering; it may be used to fine-tune chamber pressure or introduce reactive gases if needed. While both techniques play essential roles in PVD, there is a particular emphasis on recent developments within the sputtering deposition process. Considering the subject of the following study, the further discussion will solely refer to sputtering.

Sputtering involves the removal of atoms from a material’s surface through momentum transfer caused by collisions with energetic particles. This particular interaction leads to various surface phenomena, which might include surface neutralization, secondary electron emission, ion implantation, and radiation damage. Unlike evaporation, sputtering is often favored for applications demanding high control over roughness, grain size, and stoichiometry rather than prioritizing deposition rate. Sputter deposition is crucial in the semiconductor and display industries and traces its origins to 1852 [

6]. Sir William Robert Grove carried out groundbreaking research on the electrical conductivity of gases using a direct-current (DC) glow discharge setup. His equipment featured a glass vacuum chamber, where air was extracted with a mechanical piston pump. The system was powered by a galvanic battery in combination with an induction coil provided by Heinrich Ruhmkorff. The anode was a copper plate coated with a smooth, electroplated silver layer, while the cathode consisted of a steel needle. The gas necessary to maintain the discharge was kept in a flexible container. Grove discovered that when a hydrogen–air mixture was introduced into the chamber, and the silver-plated plate was positively charged while the steel needle functioned as the negatively charged cathode, thin coatings formed on the silver surface. These coatings consisted primarily of iron oxide, which resulted from the sputtering of the steel needle followed by a reactive deposition process. He observed that the oxide layer changed color over time, showing hues of yellow, orange, and blue, which signified variations in thickness due to optical interference effects [

7]. The overview of most common features of sputtering and evaporation has been included in

Table 2.

Based on the information included in

Table 2, sputtering and evaporation are both widely used PVD techniques for thin film deposition. Sputtering does indeed operate at a higher working gas pressure (typically 0.1 to 1 Pa), as it relies on the presence of a process gas—usually argon—to sustain a plasma that bombards the target and ejects atoms via momentum transfer. In contrast, evaporation typically takes place in ultra-high vacuum conditions (below 10

−3 Pa) without any added process gas, allowing evaporated atoms to travel directly to the substrate. However, both methods require a high-quality base vacuum before deposition begins. This means that the vacuum chamber must be pumped down to a pressure often below 10

−5 Pa or better to eliminate water vapor, oxygen, and hydrocarbons that could lead to film contamination. In this respect, sputtering systems are not exempt from stringent vacuum standards. Even though gas is intentionally introduced during sputtering, a clean and stable vacuum environment prior to plasma ignition is just as critical as in evaporation, especially when high-purity or complex films are required. Moreover, the higher working pressure in sputtering can actually increase the likelihood of gas-phase collisions, which can lead to film defects or undesired scattering effects if the background vacuum is not sufficiently clean. In evaporation, where atoms travel in ballistic paths with minimal collisions, contaminants from poor vacuum conditions have a more direct path to the growing film, making cleanliness even more crucial. Therefore, from a system engineering and process control standpoint, both techniques demand careful vacuum management to achieve high-quality, reproducible thin films. The apparent difference in working pressure does not equate to a lower standard of vacuum quality in sputtering—rather, it reflects differences in the physical mechanisms underlying the deposition process. Sputtering is characterized by higher absorption and more dispersed atomized particles, which results in high adhesion and a more uniform film with smaller grain size. Evaporation is associated with lower gas absorption, yields, and highly directional particle streams, typically resulting in films with lower adhesion and larger grain sizes. The energy of deposited species in sputtering can be relatively high (1–100 eV), while it remains low in evaporation (~0.1–0.5 eV). Additionally, evaporation offers significantly higher deposition rates compared to sputtering, as it is more suitable for rapid coating applications.

In

Table 3 are located three prominent thin film deposition techniques, each with unique principles, advantages, and limitations. CVD relies on chemical reactions of gaseous precursors that occur at the surface of the substrate, resulting in the formation of a solid thin film. It typically operates at medium to high temperatures and offers relatively high deposition rates. The method is well-suited for a broad range of materials and provides dense, high-purity films. Its conformality is generally good, depending on process conditions, though it may be limited when dealing with highly complex geometries. ALD is a specialized form of CVD that uses alternating, self-limiting surface reactions to achieve extremely precise control over film thickness. This technique is particularly valued for its ability to deposit highly uniform and conformal films, even on substrates with complex, three-dimensional structures. It typically operates at lower temperatures than conventional CVD, making it compatible with a wider range of substrates. However, its main drawback is the low deposition rate, as the film is grown one atomic layer at a time. Despite the slower growth, ALD is considered essential for applications where film uniformity and nanoscale precision are critical. MSVD, on the other hand, belongs to the family of physical vapor deposition methods. It uses plasma generated by an applied electric field, enhanced by a magnetron to increase plasma density and efficiency. In this process, ions from the plasma bombard a solid target material, ejecting atoms that then condense on the substrate to form a film. The method is primarily physical rather than chemical and typically operates at low to medium temperatures. It allows for moderate to high deposition rates and is particularly effective for metallic and hard coatings. However, because it is a line-of-sight technique, it offers limited conformality compared to ALD and CVD, especially on substrates with deep trenches or high aspect ratio features. In terms of process complexity, ALD is the most intricate due to the precise timing and separation of precursor pulses, as well as the need for effective purging between cycles. CVD and MSVD are generally simpler, though sputtering systems used in MSVD require careful plasma control and may involve challenges related to target poisoning or film stress. All three techniques are widely used in industry, with CVD dominating large-scale semiconductor and solar applications, ALD playing a critical role in advanced nanoelectronics and battery technology, and MSVD being essential for coatings in optics, microelectronics, and tools. Each method brings distinct advantages depending on the application. ALD offers unmatched precision and conformality, CVD provides speed and material versatility, and MSVD excels in physical robustness and compatibility with a wide range of functional materials. The choice of technique depends on specific process requirements, including desired film thickness, uniformity, substrate complexity, temperature sensitivity, and industrial scalability [

10,

11].

Braun observes that sputtering is the process in which particles such as atoms, ions, and clusters are ejected from a surface that is bombarded by energetic ions, though the term is sometimes more broadly used to describe erosion caused by impacts from atoms, molecules, neutrons, or electrons [

12]. It is possible to distinguish two major forms of sputtering: chemical and physical. The former involves reactions between the incoming particles and the target material, which results in the formation of surface compounds that are then sputtered due to continuous bombardment. Physical sputtering, on the contrary, occurs when energetic particles penetrate the target material, triggering collision cascades or thermal spikes, ultimately leading to the ejection of material. Typically, the term

sputtering refers to this physical process. It is now important to clearly indicate that magnetron sputtering is a prominent technique within sputtering, which is continuously refined to enhance metal ionization, optimize target usage, reduce target poisoning, increase deposition rates, and manage electrical instabilities like arcs. The ongoing evolution of the method is typically driven by the demand for functional coating and high-quality layered structures. Key aspects of magnetron sputtering contain increasing sputtered material quantity via enhanced ionization and employing magnetic fields near the target surface through horseshoe magnets. In magnetron sputtering, the plasma is enhanced by a magnetic field that traps electrons near the target surface, increasing ionization efficiency and sustaining a dense plasma. While ion–electron separation and sheath formation occur in all sputtering systems, the magnetic confinement of electrons is specific to magnetron configurations. The magnetron’s geometry can vary, with circular, square, and cylindrical designs available, the latter often rotating around internal magnets. Five common target configurations used in magnetron sputtering could be defined: planar circular, planar rectangular, rotatable cylindrical, confocal, and tapered. Each target shape is optimized for specific applications. Planar targets are commonly used for general thin-film deposition, while rotatable targets are ideal for large-scale industrial use due to their higher material utilization. Confocal targets allow for co-sputtering and compositional control, and tapered targets improve coating conformity on complex or 3D surfaces. The choice of target shape directly influences deposition efficiency, uniformity, and coating performance [

13]. Both permanent magnets and electromagnets are used, though the latter offers more flexibility despite adding complexity to the magnetron’s design [

8,

9]. Various magnetron sputtering methods, such as DC magnetron sputtering and high-power impulse magnetron sputtering, are well-established [

12].

Furthermore, it is also interesting to point out the differences between reactive and non-reactive sputter deposition. First of all, it should be stated that for applications in electronics and semiconductor industries, compounded coatings or thin films are often necessary since they exhibit a broader range of desirable electrical, mechanical, and chemical properties as compared to single-element coatings [

14]. The sputtering process involves plasma–ion interactions that cause the ejection of atoms from the target material, which subsequently form a film on the substrate [

14]. In reactive sputtering, one or more reactive gases (such as O

2, N

2, or C

2H

2) are introduced alongside or without inert gas to chemically react with the sputtered material, which forms compound layers (oxides, nitrides, or carbides) on the substrate. This specific approach allows for the deposition of compound films via controlled chemical reactions. It may result in challenges, including target poisoning, due to the formation of a compound layer on the target surface, which can reduce sputtering efficiency [

15]. The formation of these layers can be influenced by the reactivity of the target material. Energy and types of particles arriving at the target surface also have significant meaning. It is related to chemosorption and recoil implantation of atoms [

15]. On the other hand, non-reactive sputtering is based upon using the target material itself (e.g., a TiN target) along with an inert gas to directly deposit the required compound layer, such as a Titanium Nitride (TiN) layer. Contrary to reactive sputtering, this specific method avoids complex chemical reactions and is assessed as more straightforward. Non-reactive sputtered films are distinguished by improved hardness, wear resistance, and corrosion protection due to the reduced presence of oxynitride impurities and larger crystalline domains, enhancing their durability [

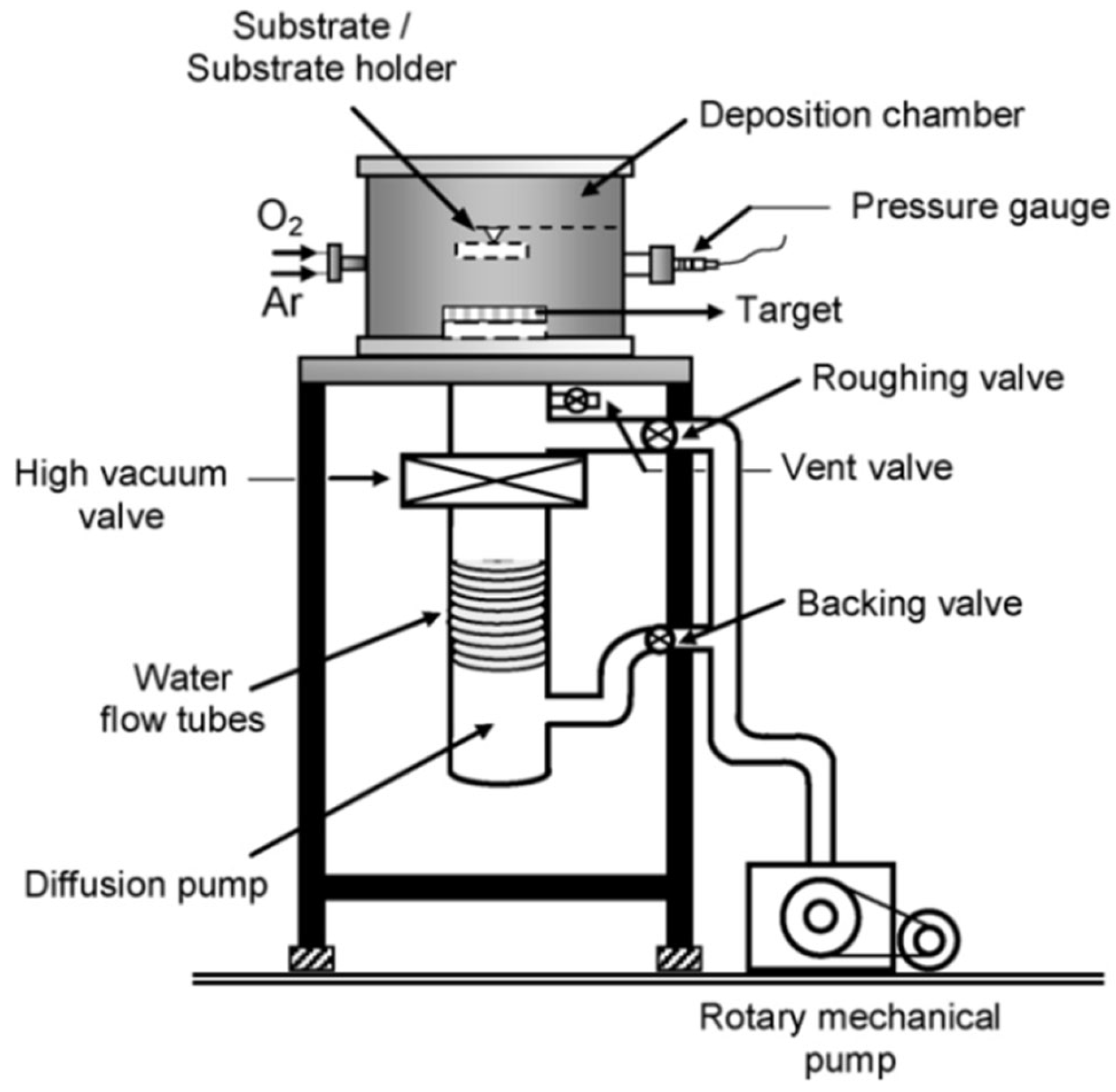

16]. A schematic diagram of reactive magnetron sputtering is illustrated in

Figure 2.

Inert gas sputtering typically does not involve chemical reactions between the sputtered species and the surrounding gas. However, in reactive sputtering, the sputtered atoms may undergo chemical reactions not only with ionic species, but also with neutral, excited, or dissociated species of the reactive gas present in the plasma. However, introducing a reactive gas into the sputtering environment leads to interactions between the sputtered particles and reactive gas molecules or atoms [

17]. At lower partial pressures, all the reactive gas is consumed through these reactions, which mirrors the improved pumping effect of an ion pump, and is known as the metallic mode of sputtering. When the partial pressure of the reactive gas rises and surpasses the reaction rate with sputtered species, reactions start to occur on the target’s surface, resulting in the formation of compounds on its surface. If the compound formed on the target surface has a lower sputter yield than the pure material, it leads to a decrease in the deposition rate, regardless of whether the compound is electrically insulating [

17]. This specific process is commonly illustrated through a hysteresis curve, showing the relationship between deposition rate and reactive gas concentration. Once the target is poisoned, reducing the reactive gas pressure will not immediately restore the deposition rate until the reacted material is removed from the cathode’s surface [

18]. At this point of the discussion, it is worth referring to the Closed Field Unbalanced Magnetron Sputtering Technique (CFUBMS), which is characterized by the formation of closed magnetic field lines between magnetrons that create a confined trap for electrons within the plasma. This configuration minimizes electron loss to the chamber walls, thereby sustaining dense plasma in the substrate region, which enhances ion bombardment during film growth. CFUBMS systems are versatile as they are used to deposit both pure metal and alloy films, as well as a wide variety of reactively sputtered coatings on different components [

19].

It should be stated that this specific technique allows precise control over the reactive sputtering process through methods that include plasma emission monitoring or managing the partial pressure of reactive gases, which enables fine-tuning of the coating composition and properties. In addition to that, CFUBMS also supports the production of coatings with graded properties, including multilayer structured coatings that significantly improve the adhesion of diamond-like carbon (DLC) coatings to substrates, enhancing their practical applications. Moreover, this technique has been successfully employed for creating highly corrosion-resistant aluminium–magnesium alloy coatings, offering a promising alternative to cadmium in the aerospace industry [

20]. Another technique of magnetron sputtering that is worth overviewing in the following study is Pulsed Magnetron Sputtering (PMS), which is particularly useful for depositing dielectric materials. In this regard, by applying a pulsed discharge at medium frequencies (ranging from 20 to 350 kHz), it mitigates the primary challenge faced in continuous DC reactive sputtering of such materials—namely, arc formation on the target. This is accomplished by discharging the “poisoned” areas of the target during the reverse voltage or “pulse off” phase. Proper adjustment of parameters like frequency, duty cycle, and reverse voltage allows for prolonged arc-free operation, even with highly insulating materials. This arc suppression stabilizes the deposition process and minimizes film defects, enabling the production of films, such as alumina, titanium, and silica, with enhanced structural, electrical, and optical characteristics compared to those formed through continuous DC sputtering [

21,

22,

23].

The commercial use of pulsed sputtering spans applications in large-area multiple magnetron systems, such as solar control and low-emissivity coatings, barrier layers for packaging, flat panel displays, and solar cells, with benefits that might include improved long-term stability and lower defect densities, as well as superior film properties together with enhanced dynamic deposition rates [

22]. The introduction of pulsed techniques into vacuum coating processes has improved plasma stability and reduced substrate heating, enabling effective coating of temperature-sensitive substrates. While pulsing can enhance film properties, uniform deposition on complex geometries typically depends on additional factors such as ion assistance, substrate biasing, and deposition angle. This specific approach can produce layers with numerous phase boundaries at higher pulse rates, which provides an alternative to alloy target sputtering. Initial experiments have demonstrated stable reactive sputtering conditions, even with targets exhibiting significant variations in discharge voltage. For such applications, high-performance bipolar power supplies with adjustable pulse duty factors are essential, and tailored cathode configurations may be necessary when using different materials to achieve diverse layer compositions [

24].

Eventually, while elaborating on overall features of magnetron sputtering, it is also worth referring to several key physical phenomena that govern this particular process, which can be categorized based on their location: at the target surface, between the target and the substrate, and at the substrate or growing film surface. In the first case, the primary phenomena include magnetron plasma generation and ballistic sputtering. A magnetron gun emits a flux of particles similar to other physical vapor deposition (PVD) sources but with more complex characteristics. The emitted particle flux originates from a “racetrack” region where plasma electrons are confined by orthogonal electric and magnetic fields, resulting in a distributed, rather than point-like, source. This leads to broad energy and angular distributions of emitted particles, with an energy of sputtered particles (1–100 eV), significantly higher than the thermal energies typical of evaporative sources. The behavior of magnetized plasmas is still not fully understood, and the output from magnetron sources varies greatly depending on their design and operational conditions, necessitating reliance on empirical data for process development [

25]. Between the target and substrate, gas-phase atomic scattering is a critical phenomenon. This involves collisions and charge exchange processes between the sputtered atoms and the sputter gas (commonly argon due to its inertness, low cost, and adequate sputter yields for most materials). These interactions alter the charge state, energy, and angular distributions of the sputtered atoms. Other gases (e.g., neon or xenon) may also be used for non-reactive processes to enhance sputter yields or reduce back-reflection of ions. It should be underlined that in case of reactive sputtering processes, gases such as oxygen, nitrogen, and hydrocarbons are typically employed to form oxides, nitrides, or carbides, respectively. These interactions between the gas and sputtered species play a significant role in determining the characteristics of the deposited films [

26].

Eventually, at the substrate surface, the phenomena involve film growth and radiation effects, representing a critical and complex stage in magnetron sputter deposition. Film growth remains one of the least comprehended aspects, despite advances in modeling and simulations over recent decades [

25]. This process is typically highly non-equilibrium and dynamic, as it encompasses different factors, which include atom mobility, reactivity, phase nucleation, growth patterns, mechanical deformation, and radiation-induced defect dynamics. It is important to bear in mind that the film’s development is influenced by the flux, energies, and impact angles of the depositing particles, which are determined by the plasma conditions, ballistic sputtering dynamics, and gas-phase scattering interactions described earlier. As such, these three interconnected classes of phenomena—target surface interactions, gas-phase processes, and substrate surface dynamics—must all be considered holistically to optimize the coating process.

3. Development of MSVD

To begin with, it is necessary to point out that the research regarding the equipment and principles of magnetron sputtering is rooted in the development of the sputtering process, which dates back to 1852 when it was first used to create metallic films, aided by advancements in vacuum technology. Despite the initial utility of the process, early sputtering methods had significant limitations, which mostly included low deposition rates and inefficient ionization, as well as excessive heating of substrates [

27]. These particular challenges were addressed with the invention of the planar magnetron cathode in 1974, which led to the rapid growth of magnetron sputtering technology, which is now widely used for producing a diverse range of high-functionality industrial films [

7].

As already noted, the magnetron sputtering process involves bombarding a target material with energetic ions, typically derived from an inert gas such as Argon (Ar+) or Neon (Ne+) [

28]. The equipment’s magnetron field confines the motion of secondary electrons close to the target, significantly enhancing the likelihood of electron–atom ionizing collisions and, thus, creating a dense plasma near the target’s surface. This approach allows for higher sputtering and deposition rates, improved ionization efficiency, and operation at lower pressures and voltages compared to basic sputtering processes [

29].

It should be borne in mind that over the past 170 years, sputter deposition has evolved from scientific curiosity into a critical platform for exploring solid-state physics through the interplay of atomic-scale collisions and quantum mechanics. Today, it serves as a key technology for the mass production of industrial thin-film products. It is interesting to mention that since the early 2000s, numerous books, e.g., [

9,

30,

31,

32], have been dedicated to the application of sputter deposition in manufacturing.

During the past 20 years, magnetron sputtering has become one of the most rapidly evolving vapor-phase thin-film deposition methods since it gained widespread use across various applications. Unlike chemical vapor deposition (CVD), sputtering is a physical deposition process governed by momentum transfer, which makes it relatively insensitive to deposition temperatures. This characteristic allows its application on thermally sensitive substrates without causing damage. Furthermore, sputtering facilitates the controlled deposition of alloys more easily than evaporation, as sputter yields are consistent across different metals, whereas evaporation rates vary dramatically at a particular temperature. Additionally, the technique enables low-energy ion and fast-neutral atom bombardment of the film growth surface, enhancing control over the film’s nanostructure and composition while minimizing surface roughness. Approaches like unbalanced magnetron sputtering exemplify these benefits [

33,

34,

35].

Figure 3 depicts the timeline of major developments in terms of magnetron sputtering.

These advantages make sputtering particularly suitable for producing multilayer giant-magnetoresistance devices [

36]. The development of ultra-high-vacuum systems, combined with magnetically unbalanced magnetrons and reactive sputtering with partial-pressure control, has facilitated the growth of exceptionally high-quality single-crystal thin films. This specific capability has allowed researchers to delve deeply into fundamental material properties. Some key achievements include exploring electron/phonon coupling and superconductivity in group-IV transition-metal and rare-earth nitrides [

37]. Elucidating the tetragonal-to-cubic phase transition in vanadium nitride (VN) due to strongly anharmonic phonon vibrations above 250 K also has key meanings for development of discussed method [

38]. Resolving disputes over vacancy-induced hardening mechanisms in under stoichiometric compounds like TiNx (with x < 1.0) while providing a comprehensive set of elastic constants is another example of research direction [

39]. Ceramic alloys such as V

0.5Mo

0.5N

x and V

1−xW

xN exhibit not only increased hardness but also enhanced ductility through electronic–structure effects, resulting in remarkable toughness [

40,

41,

42]. This development highlights magnetron sputtering’s pivotal role in advancing both the applied and fundamental material sciences.

Based on the information included in the available literature, it is necessary to point out the following major developments in magnetron sputtering:

3.1. Ionized-Metal Magnetron Sputter Deposition

In the early 1990s, the technique of magnetron sputtering emerged to address challenges in the semiconductor industry, particularly the coating of vias and trenches with increasing aspect ratios that impeded uniform thin film distribution due to the inherent non-directional nature of the sputtered-atom flux. In order to address this, Steve Rossnagel and Jeff Hopwood at IBM developed ionized-metal sputter deposition in 1993. Their solution involved ionizing the sputtered metal flux and employing an electric field to control the directionality of metal atoms, enhancing coating uniformity. This ionization process was achieved by introducing a water-cooled coil to couple RF power to the plasma between the target and substrate. The technique demonstrated improved ionization probabilities for metal atoms compared to inert sputtering gases due to their lower ionization energies, enabling higher ionization fractions at elevated pressures. Films produced by this method (e.g., aluminum) exhibited larger grain sizes and a stronger orientation with lower stress, enhancing their reliability in metal interconnects [

43,

44].

3.2. High-Power Impulse Magnetron Sputter Deposition (HiPIMS)

HiPIMS emerged in the mid- to late-1990s and represents another significant advancement in magnetron sputtering. This method, known as High-Power Impulse Magnetron Sputtering (HiPIMS), applies high-power pulses with peak power densities typically ranging from 0.5 to 5 kW/cm

2. These pulses generate transient plasmas with electron densities on the order of 10

18 to 10

19 m

−3, which is one to two orders of magnitude higher than the ~10

16 to 10

17 m

−3 typically observed in conventional DC magnetron sputtering. The pulses, lasting 50–200 microseconds, are delivered with low duty cycles to maintain manageable heat loads, typically dissipated via water-cooled target holders. It is worth stating that early research in high-power pulsed plasmas began in the 1960s, but it was not until the introduction of magnetic confinement by Russian researchers in the 1980s that the potential for film deposition using pulsed magnetrons was explored. HiPIMS excels in producing a high degree of metal atom ionization (up to 70%–90%), enabling precise control over film microstructure and composition while reducing surface roughness and minimizing rare-gas ion trapping. The method also permits synchronization of substrate bias to enhance film properties. Nevertheless, it is necessary to underline the fact that HiPIMS faces challenges such as reduced deposition rates due to metal ion return to the target, though hybrid HiPIMS/DC sputtering systems have shown promise in overcoming these limitations [

13,

45,

46,

47].

3.3. Modulated-Pulse-Power (MPP) Magnetron Sputtering

MPP magnetron sputtering is an extension of HiPIMS, and it was developed following a patent by Roman Chistyakov in 2002 and commercialized in 2006. MPP uses longer pulse widths (500–3000 microseconds) but introduces flexibility through micro-pulses within each macropulse, allowing for independent control of on and off times. This yields a higher duty cycle (up to 25%) and provides enhanced peak current tuning capabilities. MPP aims to maintain high metal ionization probabilities while achieving higher deposition rates than HiPIMS. Though promising, further comparative data with HiPIMS are required to fully evaluate MPP’s advantages and capabilities [

48,

49,

50,

51]. HiPIMS operates with very short high-voltage pulses ranging from 10 to 200 microseconds, achieving peak power densities typically in the range of 1–3 kW/cm

2, and in some cases, exceeding 5 kW/cm

2. These short bursts generate extremely dense plasmas, but due to the low duty cycle (often below 10%), the average power delivered to the target remains moderate, typically between 50 and 300 W. In contrast, MPP MS extends the pulse duration significantly, often from 500 microseconds up to several milliseconds, and introduces modulation within each pulse. This creates a smoother discharge with reduced instabilities. The average power in MPP systems is generally higher, ranging from 300 to 1000 W, offering better throughput while still benefiting from enhanced ionization. HiPIMS is well-known for its very high plasma and electron densities, in the order of 10

17 to 10

19 electrons per cubic meter, and it achieves ionization levels of the target material between 70% and 90%, depending on the element (e.g., Ti, Cr, Nb). This high ionization leads to excellent film density, adhesion, and uniformity at the nanoscale. MPP MS, while slightly less intense, still operates at plasma densities between 10

16 and 10

18 m

−3, and target ionization levels between 40% and 70%. This is sufficient to produce high-quality films, but with higher deposition rates and better process stability. Due to its low duty cycle and energy-intensive pulses, HiPIMS typically has a lower deposition rate, often 10–30 nm/min, depending on target material, gas flow, and power settings. Despite this, the films are very dense, often reaching >95% of the bulk material density, which is critical for high-performance coatings like TiN or CrN. MPP MS offers a higher deposition rate, commonly 50–120 nm/min, and in some studies, reaching over 200 nm/min. This improvement is especially relevant for industrial-scale production. The films remain dense and smooth, although marginally less so than those produced by HiPIMS. HiPIMS exhibits moderate target utilization (30%–50%) due to localized erosion zones (the “racetrack” effect) and potential target poisoning in reactive sputtering. MPP MS improves on this, achieving 60%–70% utilization, attributed to the extended pulse and uniform plasma spread. In terms of control, HiPIMS systems offer limited flexibility—typically adjusting only pulse width and repetition rate. MPP MS, however, enables dynamic control within each pulse, including voltage step-downs, arc suppression, and duty cycle modulation, offering a more stable and tunable process, particularly in reactive environments. HiPIMS is predominantly used in high-end applications where maximum film quality and performance are required. These include cutting tools, aerospace components, and optical layers where adhesion, hardness, and compactness are crucial. However, adoption is still limited by equipment costs and low throughput. MPP MS strikes a balance between performance and productivity, making it attractive for decorative coatings, wear-resistant layers, and even some microelectronics. Its higher deposition rate and stability make it more scalable for broader industrial use, such as in automotive components, tools, and consumer devices [

52,

53]. Detailed comparison between HiPIMS and MPP can be found in

Table 4.

3.4. Continuous High-Power Magnetron Sputtering (C-HPMS)

Continuous High-Power Magnetron Sputtering (C-HPMS) is a recently developed thin-film deposition technology that builds upon the advantages of High-Power Impulse Magnetron Sputtering (HiPIMS) while addressing some of its key limitations. Unlike HiPIMS, which operates by delivering high-intensity power in short pulses followed by off-times, C-HPMS applies a sustained high power to the target in a continuous mode. This continuous operation eliminates the low duty cycle associated with pulsed systems, thereby significantly increasing the average power delivered to the plasma and improving the overall deposition rate. One of the major advantages of C-HPMS is its ability to maintain a highly ionized, stable plasma without interruption, even in reactive sputtering environments that typically challenge process stability. In HiPIMS, the combination of pulsed discharges and reactive gases can lead to unstable plasma behavior and arcing, as well as lower deposition efficiency. In contrast, C-HPMS provides a more stable discharge, reducing the risk of target poisoning and allowing for more consistent film growth, particularly when depositing compound materials such as oxides and nitrides. By maintaining continuous high power, C-HPMS achieves a balance between the excellent film quality associated with HiPIMS and the higher throughput required for industrial-scale applications. As a result, it has become a promising alternative for large-area coatings, reactive sputtering processes, and applications where both film performance and production efficiency are essential [

54].

3.5. Low-Temperature Magnetron Sputtering

Low-temperature magnetron sputtering is a specialized form of physical vapor deposition (PVD) designed for the fabrication of thin films on substrates that are sensitive to heat. Traditional sputtering processes often involve elevated substrate temperatures—sometimes exceeding 300 °C—to promote film adhesion, crystallinity, and densification. However, many emerging applications, including flexible electronics, polymer-based devices, and temperature-sensitive optics, demand deposition techniques that do not compromise substrate integrity. In response to this, low-temperature magnetron sputtering techniques have been developed to allow high-quality film growth while maintaining substrate temperatures typically below 200 °C and, in many cases, even lower. The core principle of magnetron sputtering remains unchanged: plasma ions, typically Ar+, accelerated toward a negatively biased target material, ejecting atoms through momentum transfer. These atoms then travel through a vacuum and condense on a substrate, forming a film. In the low-temperature variant, the challenge lies in promoting surface diffusion and film densification without the thermal assistance usually provided by a heated substrate. Low-temperature magnetron sputtering is particularly advantageous when working with materials that have low glass transition temperatures (Tg), such as polyethylene terephthalate (PET), polyimide, or other flexible polymers. It enables the integration of functional coatings—such as transparent conductors, barrier layers, or semiconducting films—into flexible or stretchable devices. In biomedical applications, it allows the deposition of coatings onto polymeric implants and instruments without degrading their surface or mechanical properties. Moreover, in optical systems, low-temperature sputtering enables multilayer coatings on plastic lenses and displays without distortion. Despite its advantages, the technique poses several technical challenges. Achieving crystalline or highly ordered film structures is more difficult without thermal activation, and deposition rates may be lower due to reduced atomic mobility. However, as highlighted by Greczynski and Hultman [

55] in Applied Physics Reviews, recent advances in plasma control, ion-assisted deposition, and magnetron design have significantly improved film quality, even at room temperature. Substrate biasing plays a critical role by enhancing ion energy at the surface, promoting densification, and improving adhesion through momentum transfer and localized surface heating. In conclusion, low-temperature magnetron sputtering offers a powerful solution for coating heat-sensitive materials without sacrificing film integrity. Through process optimization, including advanced pulsing techniques, HiPIMS, and substrate bias control, it is possible to achieve dense, adherent, and functionally robust films across a wide range of applications. As demand grows for flexible, lightweight, and temperature-sensitive devices, the importance and sophistication of low-temperature sputtering techniques continue to increase [

56].

4. Advantages and Disadvantages of Magnetron Sputtering

Based on the discussion included in the further subsections of this paper, it is possible to assume that the fundamental principle of magnetron sputtering involves electrons colliding with argon atoms as they move towards the substrate under the influence of an electric field (E), leading to the formation of positively charged argon ions and additional electrons. The newly generated electrons are accelerated away from the cathode and generally move toward the anode under the influence of the electric field, while argon ions are accelerated toward the negatively biased target, striking its surface with high energy and ejecting target atoms through the sputtering process. It has also been pointed out that since its introduction, magnetron sputtering has experienced rapid development and broad adoption, significantly influencing other coating techniques. Therefore, at this point of the study, it seems of the utmost importance to elaborate on major advantages and disadvantages of magnetron sputtering.

To begin with, it should be observed that magnetron sputtering offers numerous advantages that make it a highly desirable technique for thin-film deposition in a wide range of applications. First, it features a high deposition speed with minimal substrate temperature rise, thereby reducing the risk of thermal damage to sensitive substrates. This quality is particularly important for temperature-sensitive applications and materials that require low-heat processing [

29]. Consequently, there is no denying that the ability to produce films with minimal damage is a significant factor in the wide adoption of magnetron sputtering for advanced applications in electronics and optics.

In addition to the above, the sputtering process is remarkably versatile because it allows for the deposition of a broad range of materials, if the target materials can be manufactured. This adaptability extends to various metals, alloys, and oxides, which can be deposited singly or simultaneously. This process allows complex, multifunctional coatings in a single step. The films produced via magnetron sputtering exhibit excellent adhesion to the substrate due to the energetic nature of the sputtered particles, which promotes strong bonding at the interface. Moreover, the films have high purity and good compactness, with uniform film formation, making them suitable for critical applications where material consistency and integrity are paramount [

41].

Another key advantage of MSVD that should be referred at this point of the discussion is the high repeatability of the sputtering process, which ensures that films of uniform thickness can be produced consistently over large areas. This property is essential for industrial-scale applications, where reproducibility and scalability are crucial. Furthermore, the process parameters in magnetron sputtering, such as pressure, power, and magnetic field configuration, can be adjusted to control the particle size of the deposited film, offering a high degree of flexibility in tailoring the microstructure and properties of the films. The microstructure of the film is strongly influenced by deposition parameters such as working pressure, power, substrate temperature, and substrate bias. Low pressure and higher substrate temperatures promote surface diffusion, leading to denser and smoother coatings. Applying a negative substrate bias increases bombardment, enhancing film densification and adhesion. The final properties of the coating—such as hardness, wear resistance, electrical conductivity, and corrosion resistance—are directly linked to its microstructure. Dense, well-adhered coatings generally exhibit superior mechanical and functional performance. Therefore, careful control of sputtering conditions is essential to optimize coating quality for specific applications [

51].

Based on the information above, it becomes apparent that magnetron sputtering can easily be industrialized, as the process is efficient and well-suited to large-scale production environments. The application of a vortex motion of electrons helps to reduce the impact of electron collisions on both the substrate and the thin film, minimizing defects and enhancing film quality. The low impact of substrate temperature rise ensures that even thermally delicate materials, such as certain dielectrics and semiconductors, can be sputtered with consistent high deposition rates [

21].

Moreover, it has also been pointed out that the analyzed method allows for both sputtering and reactive sputtering of dielectric materials, such as SiO

2 and Al

2O

3, and maintains a constant deposition rate at a particular input power, with deviations typically within ±10%. This stability in deposition rate is advantageous for maintaining consistent film properties and thicknesses. In addition to that, it is also possible to reduce thin film thickness precisely by using a tailored array of permanent magnets and applying appropriate shielding configurations, which further enhances the control over film uniformity and material usage [

56].

Eventually, it should also be pointed out that the ease with which film uniformity can be adjusted also adds to the attractiveness of magnetron sputtering, making it possible to fine-tune film properties and achieve consistent results across complex geometries and large substrates. The high degree of control and customization afforded by magnetron sputtering, combined with its scalability, versatility, and high-quality output, underscores its significant advantages in the field of thin-film deposition and its growing importance in modern industrial and scientific applications [

19,

23,

29,

32].

To continue the above discussion, it should be stated that despite its widespread use and numerous advantages, magnetron sputtering technology presents several notable disadvantages that must be considered for its effective application. One of the primary limitations lies in the utilization of the ring magnetic field, which directs secondary electrons to move within a defined circular path around this magnetic field. As a result, the region under the control of the annular magnetic field becomes the area with the highest plasma density, as it causes significant ion bombardment and leads to the formation of a ring-shaped groove on the target surface. This focused sputtering action often results in uneven target erosion, reducing the target’s effective utilization rate to generally below 40%. Once the sputtering groove penetrates the target, the entire target must be discarded, which significantly increases material costs and lowers efficiency [

48].

Another critical drawback of the analyzed method is plasma instability, which can impact the consistency and quality of the thin films being deposited. In the context of reactive magnetron sputtering, plasma instabilities typically refer to the nonlinear and often abrupt transitions in discharge characteristics that arise during the introduction of reactive gases such as oxygen or nitrogen. These instabilities are strongly linked to the phenomenon of hysteresis in the target voltage and partial pressure behavior, which leads to uncontrollable shifts between metallic and compound sputtering modes. This occurs due to target poisoning and changes in surface coverage, causing variations in sputter yield and ionization rates. A well-known theoretical treatment of this phenomenon is offered by Berg’s model, which explains the instability using a balance of reactive gas flow, gettering at the target, and compound formation. Methods to suppress or mitigate plasma instabilities include the implementation of optical emission monitoring (OEM), plasma emission feedback control, and pulsed DC power supplies, which dynamically stabilize the deposition regime by maintaining constant stoichiometry and discharge conditions. For example, electrical feedback loops have been successfully used to regulate the transition zone between the metallic and compound sputtering regimes, reducing process drift and improving film reproducibility. Fluctuations in plasma density or energy levels may lead to variations in the film’s properties and made it challenging to achieve high-quality, uniform coatings across different batches or substrate areas [

56].

Recent advances have focused on mitigation strategies such as peak current regulation in HiPIMS, 3D plasma confinement analysis, and optimized magnetron design. Peak discharge current control has been shown to stabilize reactive sputtering by maintaining consistent ionization conditions, while studies on plasma confinement have highlighted the role of double layers and localized flares in inducing instabilities. Furthermore, innovations in magnetron source design—including magnetic field configuration and cathode geometry—are contributing to more stable and efficient sputtering systems [

49]. Furthermore, it is important to consider that the high sputtering rates achievable with energetic ion bombardment (ion energies commonly in the range of 1 to 100 eV) can enable effective thin film growth at substrate temperatures as low as 25–150 °C, depending on material and process conditions.” This particular limitation prevents the addition of external magnetic fields near the target surface, thereby reducing the potential for further enhancing the sputtering efficiency. To overcome this, the magnetic field must be designed to enter and exit perpendicular to the target surface, but this can pose additional technical challenges [

40].

In addition to the above, target consumption is also a significant concern while elaborating on the effectiveness of magnetron sputtering. This results from the fact that selective sputtering near the magnetic field leads to inefficient use of the target material. As a result, thin targets, typically ranging from 1/″ to 1/3″ in thickness, are often used, which can increase the frequency of target replacement and associated downtime, further diminishing operational productivity. These inherent disadvantages highlight the need for careful optimization and innovative approaches to maximize the efficiency and reliability of magnetron sputtering processes [

57]. To summarize the above discussion, major advantages and disadvantages of magnetron sputtering have been summarized in

Table 5.

Among the notable benefits is its ability to achieve high deposition rates while maintaining low substrate temperatures, which minimizes thermal damage and makes the process suitable for temperature-sensitive materials. Magnetron sputtering supports a wide variety of target materials, provided they can be fabricated into sputtering targets, allowing for broad applicability across metals, alloys, and oxides. The technique is also known for producing high-purity, dense films with excellent adhesion to the substrate and a uniform microstructure, which is essential in microelectronics, optics, and functional coatings. Furthermore, it offers high repeatability, enabling consistent film thickness and quality over large surface areas. The tunability of film properties, such as particle size, through process parameters adds another layer of control. Importantly, magnetron systems can be configured for co-sputtering, allowing the deposition of multi-component or composite films and are easily scaled up for industrial production. However, the technique is not without limitations. One challenge is the low target utilization rate, often caused by uneven erosion patterns on the target surface, which leads to inefficient material usage. Additionally, plasma instabilities can arise, especially during reactive sputtering, negatively affecting film uniformity and quality. Magnetron sputtering also faces limitations in the high-speed deposition of strongly magnetic materials, particularly at low temperatures. On average, only about 25% of the target material is effectively used, with the remainder lost due to inefficient sputtering geometry or process constraints. Finally, because the process often requires thin targets, the frequency of target replacement increases, which can result in more frequent system downtime and higher operational costs [

58].

All things considered, the discussion included in this subsection allows noting that magnetron sputtering offers numerous advantages, such as fast deposition speeds, excellent film adhesion, and high purity, which make it a widely used technology for thin-film deposition across diverse applications. Its ability to precisely control film properties and accommodate various materials enhances its appeal for industrial use. Nevertheless, it has also been pointed out that the technique has notable limitations, which mostly include low target utilization rates, plasma instability, and inefficiencies in handling strong magnetic materials. These drawbacks can lead to increased costs and reduced operational efficiency. In general, it can be concluded that optimizing magnetron sputtering requires balancing its strengths with careful management of its inherent challenges.

5. Industrial Applications of MSVD

The purpose of this subsection is to elaborate on the applications of magnetron sputtering in terms of industry. First of all, it should be pointed out that in order to enhance this particular method of deposition, numerous studies have focused on optimizing the PVD process by increasing plasma ionization, reducing non-deposition zones within the reactor (dark areas), and improving target utilization, boosting atomic bombardment efficiency, as well as by increasing deposition rates and also refining gas selection [

59,

60,

61]. Nevertheless, those efforts to improve the energy efficiency of the process in an industrial setting have not been the primary focus of these studies.

The industry offers a diverse scope of vacuum chambers specifically designed for coating tools and components [

62,

63]. Over time, these specific systems have evolved to become more automated and self-sufficient, which emphasized mass production to enhance profitability while minimizing maintenance and operational costs. It should be observed that this evolution also aims to reduce the reliance on human labor, thereby providing a distinct advantage. Additionally, ongoing advancements in software aim to make the coating process more user-friendly and support remote control capabilities, which reflects a focus on technological progress [

64,

65,

66].

The global market for magnetron sputtering systems reflects the growing adoption of this technology across multiple sectors, including automotive. In 2018, the market was valued at approximately USD 2.1 billion and is projected to reach over USD 3.5 billion by 2027, growing at a compound annual growth rate (CAGR) of 6.1% during the forecast period. Global Magnetron Sputtering System Market was valued at USD 2523.33 million in 2024. While specific statistics on the adoption rate of magnetron sputtering within the automotive sector are limited, the industry’s increasing focus on advanced manufacturing techniques suggests a positive trajectory. The demand for high-quality, durable coatings in automotive applications is driving the integration of MSVD technology into production processes. However, challenges such as the high cost of sputter-coated components have historically limited broader market penetration. For instance, magnetron sputtering can add up to 35% to the price of a tool, compared to an 8% increase when using gas nitro-carburizing treatment. Despite this, the significant improvement in tool life—up to 32 times that of uncoated tools—offsets the initial investment, making it a viable option for enhancing component performance and longevity. In summary, magnetron sputtering is increasingly recognized in the automotive industry for its ability to produce high-performance coatings that meet the sector’s stringent durability and aesthetic standards. As technology becomes more cost-effective and its benefits more widely acknowledged, its adoption in industrial coating applications is expected to continue growing [

67,

68].

It is interesting to point out that the adaptability of the analyzed technology allows it to be applied to a wide range of materials and geometries. Presently, the ease of accessing the coating zone simplifies substrate loading and unloading for operators. Therefore, the key features and parameters of available reactors include: (a) the diameter of usable vacuum chambers, which dictates working pressures and substrate size, typically ranging from 400 mm to 650 mm [

66,

67], but reaching up to 2500 mm [

68]; (b) the number of coating access doors, varying from one to three; (c) relatively short cycle times, with a 3 μm deposition generally taking less than 5–6 h; (d) power and number of pumps; (e) weight and dimensions; (f) type of gas used; (g) number and size of sputter cathodes; and (h) substrate rotation. Studies on industrial PVD machines have examined substrate rotation systems, revealing that rotation speed significantly influences the deposition sequence, thereby affecting the macroscopic properties of coated substrates. When the rotation speed is slow, the substrate is exposed to each individual target for a longer time, allowing for a layered or sequential deposition effect. This can lead to the formation of compositionally modulated multilayers or graded interfaces, depending on the materials and power applied to each target. In such cases, the coating may exhibit anisotropic or stratified properties, such as direction-dependent hardness, stress distribution, or optical response. In contrast, at higher rotation speeds, the substrate spends less time facing each target per revolution, effectively blending the deposition from different sources into a more uniform or co-deposited mixture. This can result in more homogeneous alloy coatings, where the film composition and structure are more consistent throughout the thickness. This difference in deposition dynamics directly affects the macroscopic properties of the coated substrate, such as mechanical strength, wear resistance, corrosion resistance, and electrical or optical behavior [

69,

70,

71].

It has already been acknowledged that sputtering encompasses methods such as Ion Beam, Diode, Triode, Reactive Sputter Deposition, and Magnetron, with notable advancements in magnetron reactors [

72]. In recent years, new pulsed techniques have broadened potential applications [

73]. DC magnetron sputtering is recognized for its cost-effectiveness and straightforward process control, though it often yields lower sputter rates, while RF sources are used for non-conductive targets [

74]. Typical systems include a vacuum chamber, gas inlet, and either a DC or RF power source [

75]. Dual Magnetron Sputtering (DMS) operating at mid-frequency is favored for large-scale reactive deposition. In this case, techniques such as Reactive Bipolar Pulsed Dual Magnetron Sputtering (BPDMS) achieve high deposition rates and minimize arc formation. As it has been observed in the previous subsection, the recent studies focus on improving process stability, gas flow optimization, and enhancing ionization sputtering for industrial applications [

76]. HiPIMS/HPPMS methods, introduced in the 1990s, offer enhanced ionization using pulsed power but can face challenges with consistency [

77].

As far as the industrial perspective is concerned, one shall assume that High-Power Pulsed Magnet Technologies show immense potential, because they prompt the ongoing research within the scientific community to further enhance these pulsed methods. These innovative technologies enable substantially higher ionization rates that reach up to 30% and achieve higher charge states of the target ions. Among their numerous benefits is the uniform distribution of films on complex geometries and outstanding adhesion, attributed to the elevated ionization levels [

78]. A notable variation of HIPIMS/HPPMS is Modulated Pulsed Power Magnetron Sputtering (MPPMS), which offers considerable advantages over traditional magnetron sputtering methods [

79]. The industrial sector has shown strong interest in adopting the HPPMS/HIPIMS techniques due to their versatility in reactor power supply applications.

Considering the fact that magnetron sputtering processes play a significant role in physical vapour deposition for industrial applications, which is mostly driven by technological advancements that respond to evolving industry demands, these processes are widely used in sectors such as plastics production. This results from the fact that in those procedures, PVD coatings combined with injection molding and including laser micro-structuring techniques, have demonstrated improved durability of micro-structures, enhanced component quality, and increased replication ratios by up to 30% [

61]. The application of (Cr, Al)N coatings in tribological research has shown notable reductions in the friction coefficient and indicated their potential for efficiency enhancements.

Furthermore, it is also necessary to acknowledge that the research on co-coating films using pulsed laser deposition has further explored the influence of external magnetic fields on the structural and magnetic properties of deposited films. By employing simulation software, the correlation between vapor flux, film surface properties, and deposition rates was validated, demonstrating how external fields can optimize deposition processes [

80]. Magnetron sputtering has emerged as a cornerstone technique in the fabrication of advanced thin-film solar cells due to its excellent control over film uniformity, thickness, and stoichiometry. It enables low-temperature deposition of highly adherent and dense films, which is critical for substrate compatibility and scalability. In recent years, its application in the deposition of buffer layers, transparent conductive oxides (TCOs), and absorber layers has attracted significant attention in both perovskite and CIGS (copper indium gallium selenide) photovoltaic technologies. For example, magnetron-sputtered Zn(O,S) buffer layers improved the interface quality and band alignment in CIGS solar cells, resulting in higher open-circuit voltage and fill factor. Additionally, reactive magnetron sputtering enables the fabrication of uniform and pinhole-free NiOx hole transport layers (HTLs) for perovskite solar cells, contributing to enhanced thermal stability and power conversion efficiency exceeding 22%. These advances underscore the versatility and scalability of magnetron sputtering in producing functional layers with tailored optoelectronic properties, supporting the development of cost-effective, high-efficiency, and environmentally stable solar energy devices [

81].

In addressing industry concerns regarding low electron efficiency and ionization rates of metal particles, HiPIMS/HPPMS techniques have shown promise due to their higher ionization rates [

82]. However, improvements in electron utilization remain necessary. Efforts by Li focused on enhancing plasma characteristics through external magnetic fields, leading to a more efficient discharge process [

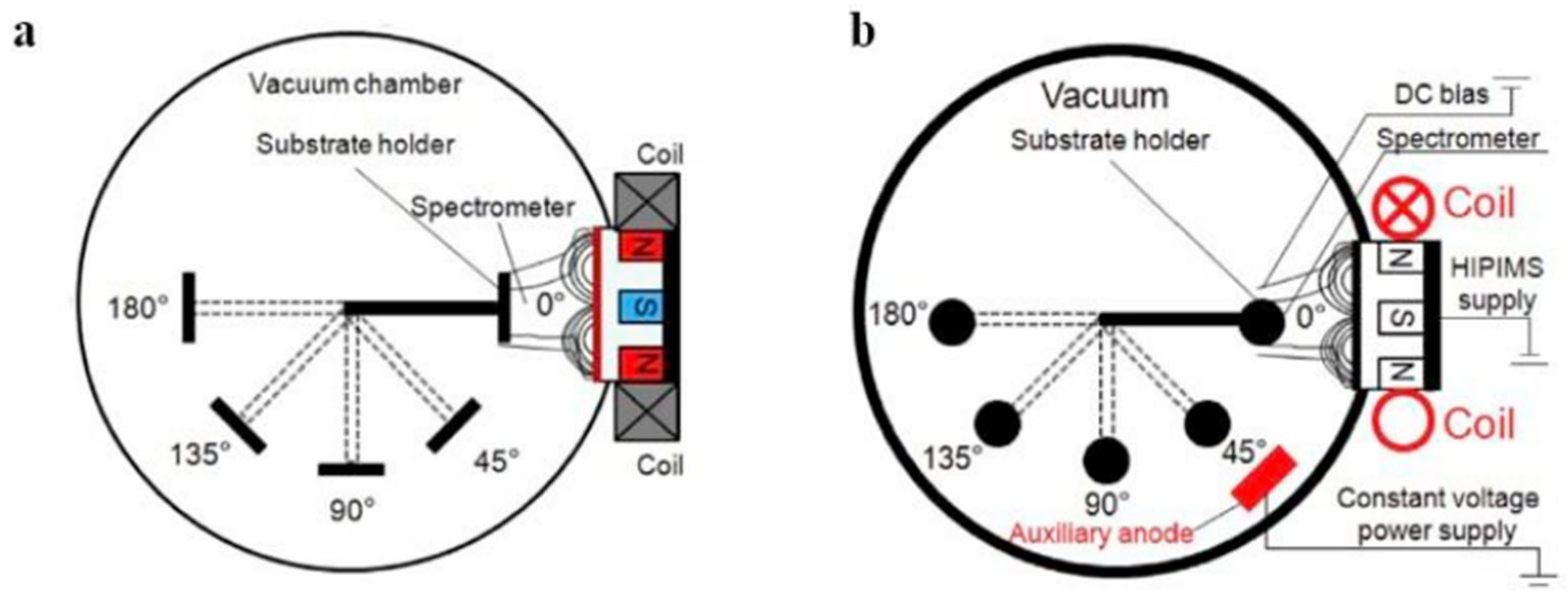

83]. The introduction of a coaxial electromagnetic coil optimized the magnetic field distribution, as illustrated in

Figure 4b, enhancing plasma density and discharge efficiency.

Further research by Li and others utilized an external unbalanced magnetic field with a conventional magnetron and a coaxial electro-solenoid coil and modulated the current to optimize ion flow distribution at various angles, as shown in

Figure 4b. The results indicated increased plasma density and substrate ion current, demonstrating the benefits of this approach [

84,

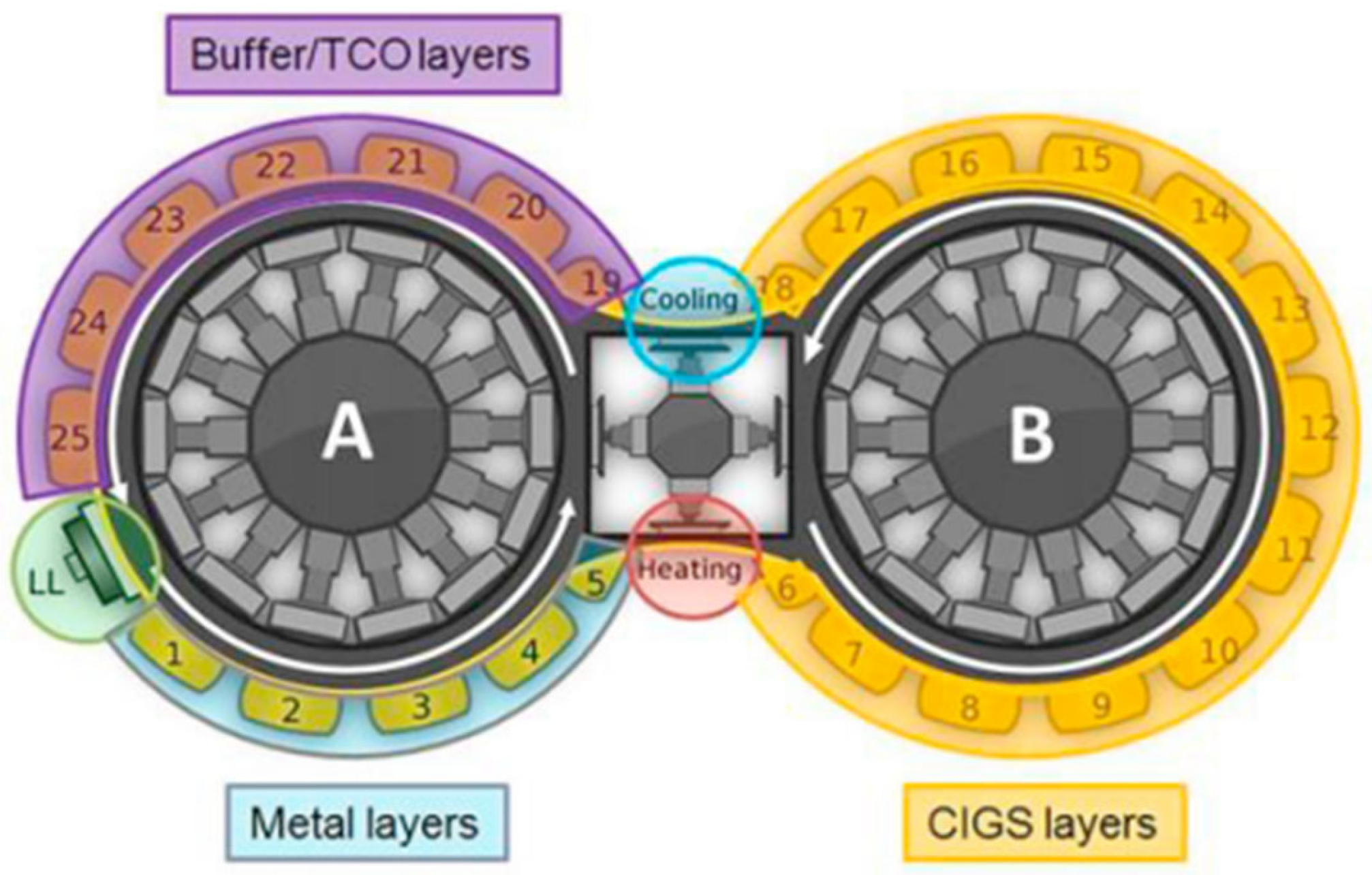

85]. Other advancements (e.g., the in-line vacuum solar cell manufacturing systems like the Midsummer

® duo, depicted in

Figure 5) present how PVD techniques are integrated with external systems to enhance deposition efficiency and product performance. The figure shows a dual-chamber rotary magnetron sputtering system designed to enhance deposition efficiency and optimize product performance through integration with external thermal management systems. Chamber A, located on the left side, is designated for the deposition of metal layers, while Chamber B, on the right, is dedicated to the deposition of CIGS (Copper Indium Gallium Selenide) absorber layers. Each chamber is equipped with multiple sputtering targets arranged in a circular configuration around a rotating substrate holder, allowing for continuous film deposition as the substrate moves from one station to the next. Between the two chambers, the system incorporates external heating and cooling zones. These zones are critical for controlling substrate temperature as it transitions between different coating environments. The cooling unit, positioned at the top, reduces substrate temperature before the buffer or transparent conductive oxide (TCO) layers are deposited, thereby preventing unwanted interdiffusion or thermal stress. The heating unit, located at the bottom, preheats the substrate prior to entering the CIGS chamber, which is essential for promoting proper crystalline structure and improving film quality. This integrated setup allows for precise thermal control, uniform layer deposition, and uninterrupted vacuum processing, all of which contribute to higher throughput, better layer adhesion, and improved functional performance of the final multilayer thin-film product [

85].

All things considered, the discussion included in the above subsection allows stating that the PVD process in terms of magnetron sputtering remains a focal point of extensive research, with recent efforts shifting from solely enhancing film properties to improving reactor efficiency and incorporating external devices in industrial settings. Undeniably, the demand for multilayer coatings with distinct properties between layers reflects evolving market needs. As technology advances, simulations using dedicated software are becoming more prevalent, offering new opportunities for process optimization. The reduction of the energy consumption in magnetron processes (particularly during the coating step) is an important concern due to their high energy demands compared to CVD. The development of new techniques and the use of advanced sources like HiPIMS/HPPMS continue to drive innovation in coating technologies that meet the industry requirements and offer potential for further advancements.

6. Applications of MSVD in High-Tech Industry

The purpose of the following subsection is to elaborate on the applications of magnetron sputtering in the high-tech industry, with the utmost attention paid to the automotive industry. First of all, it is interesting to observe that magnetron sputtering has a wide range of applications within the high-tech industry because it significantly contributes to advancements in a plethora of sectors, which will be thoroughly investigated below.

Based on the discussion included in the previous parts of this study, it is possible to assume that a key feature of the magnetron sputtering technique is its ability to precisely control the nanostructure and composition of deposited films. This results from the fact that it enables the creation of thin films with uniform thickness, customized surface morphology, and carefully optimized chemical and physical properties through the adjustment of deposition parameters, including substrate temperature, gas composition, target material, deposition time, applied power, and bias voltage, among others [

87,

88]. For example, variations in substrate temperature can alter the mobility of adatoms, thereby affecting the crystallinity and morphology of the deposited film [

89]. By fine-tuning these parameters, nanostructured coatings can be engineered with specific crystalline structures, phase compositions, and surface morphologies, such as nanowires, nanorods, or nanoparticle arrays. It is necessary to bear in mind that this precise control has led to significant advancements in the fabrication of functionalized thin films, featuring properties such as hydrophobicity, self-cleaning capabilities, antibacterial characteristics, and improved optical performance [

27,

90,

91].

Another notable advancement in this regard is the development of nanostructured heterojunctions that leverage the synergistic effects of two or more materials that result in superior performance when compared to individual films. For instance, the combination of metallic and ceramic nanoparticles can produce thin films with enhanced hardness, wear resistance, and thermal stability. This makes them suitable for harsh environments [

92]. Additionally, the capacity to create gradient and layered structures enables the tailoring of interfacial properties and significantly broadens the potential applications of these films [

93]. Within magnetron sputtering, specialized techniques such as co-sputtering, high-power impulse magnetron sputtering, and reactive magnetron sputtering facilitate the simultaneous deposition of multiple materials and eventually lead to the production of more complex and functionalized thin films.

Moreover, it can be also stated that for data storage, magnetron sputtering has played a pivotal role in the production of various storage devices such as DVDs, laser disks, hard disks, floppy disks, micro-electric flash memory, and CDs, while also contributing to the manufacturing process of nanostructured materials. Furthermore, in the electronics industry, these films play a crucial role in the advancement of high-performance transistors, capacitors, and sensors. Their distinct electrical characteristics contribute to enhanced device efficiency that allows for greater speed and reduced power consumption. For example, nanostructured films with high electron mobility are being explored for their potential applications in next-generation field-effect transistors (FETs) and high-frequency technologies [

94].

In addition to the above, it is also worth mentioning that ceramic coatings are widely utilized to protect manufactured components from thermal and corrosive degradation, provide wear resistance through increased surface hardness, and reduce frictional losses while preserving the core material’s toughness and ductility. As a result, they are commonly applied to inner surfaces of combustion engines, cutting tool working surfaces, and forming dies [

95]. Transition metal (TM) nitride films are particularly valued for their favorable properties, including thermal conductivity and wear and chemical resistance, as well as their aesthetic appeal [

96,

97,

98]. Among these, CrN stands out as a film suitable for tribological applications due to its exceptional hardness (up to ~11.9 GPa), wear resistance (wear rate reduced to ~4.77 × 10

−7 mm

3/N·m), and corrosion protection, even under high-temperature and dry-sliding conditions [

99]. Notably, CrN coatings can lower the friction coefficient from ~0.14 (uncoated) to ~0.10 following electrochemical post-treatment (EP) and reduce wear by over 37% compared to untreated CrN surfaces [

100]. In this regard, rock–salt fcc-structured CrN coatings are used in automotive combustion engines [

101]. The incorporation of aluminum into the CrN lattice, forming a substitutional solid solution with Cr and resulting in a Cr

1-xAl

xN composition, further enhances mechanical properties, thermal stability, and wear resistance of CrN-based films [

102,

103,

104]. CrN-coated liners exhibited significantly reduced wear and friction under dry sliding conditions compared to uncoated liners. The coatings also showed enhanced hardness and surface uniformity, contributing to improved durability and performance of engine components. These findings suggest that CrN coatings are a promising solution for extending the service life of internal combustion engine parts and enhancing fuel efficiency through reduced mechanical losses [

102]. Furthermore, magnetron sputtering is vital in the manufacture of sensors. This results from the fact that it highly contributes to the development of high-precision devices for industrial, environmental, and medical applications. In electronics, it is widely used to create components such as gate dielectrics, passive thin-film elements, interlayer dielectrics, printed circuit boards, and surface acoustic wave devices, underlining its importance in electronic appliance production. The energy sector also leverages this technology for gas turbine blade coatings, outdoor display systems, and solar panels, all of which contribute to energy generation and efficiency [

87].

To continue the above discussion, it is also worth pointing out that in the renewable energy sector, MSVD nanostructured coatings play a vital role in solar cell technology by enhancing light absorption and charge transport in photovoltaic devices [

105]. The application of nanostructured films, such as antireflection coatings, can significantly boost the efficiency of solar panels. Beyond these advancements, the rising demand for sustainable and energy-efficient solutions is driving the development of nanostructure-based coatings, which contribute to reducing energy consumption, minimizing environmental impact, and promoting renewable energy initiatives.

Moreover, in the biomedical field, MSVD nanostructured films are used to create biocompatible surfaces for implants, drug delivery systems, and diagnostic devices. For example, coatings produced through magnetron sputtering are tailored for orthopedic implants to encourage osteointegration, leading to improved healing processes. Likewise, nanostructured films in drug delivery systems enable the controlled release of medications, enhancing therapeutic effectiveness and reducing adverse effects.

As far as the application of magnetron sputtering into the automotive industry is concerned, it should be assumed that a plethora of everyday objects in this industry consist of metal-coated plastic components that have replaced traditional metallic materials. These metallized plastics offer a combination of low density, flexibility, design adaptability, and also cost-effective production while preserving the shiny finish, high reflectivity, and electrical conductivity characteristic of metals [

106,

107]. Typically, these components are produced through injection molding and subsequently undergo metallization using electroplating and electroless techniques [

108]. However, the electroplating of nonconductive parts often involves the use of hazardous substances such as hexavalent chromium during surface activation or chrome plating [

109]. In response, the European Union introduced a legislative directive aimed at minimizing the use of this harmful compound due to its risks to human health and the environment [

110]. This regulation has driven the industry to seek alternative coating methods for polymers.

As a result, both industry and researchers are focused on developing new surface technologies that are more environmentally friendly to replace traditional chrome plating. Therefore, some most important alternatives include processes such as CVD and PVD, which encompass MSVD techniques and thermal spraying and are tailored to modify surfaces for applications like valves, decorative elements, and other tools [

111,

112]. Magnetron vapor sputtering, which is a technique used to deposit thin films of material onto a substrate by ejecting atoms from a solid target using energetic plasma, with the assistance of a magnetron to enhance the process. It is also a promising technique for metalizing a wide range of polymers. It offers reduced environmental impact and is increasingly used for depositing chromium nitride (CrN) films, making it an attractive industrial solution for polymer coating [

106,

107,

108].

At this point of the discussion, it is necessary to underline that the primary polymers used in the automotive industry include acrylonitrile butadiene styrene (ABS), polycarbonate (PC), and PC/ABS blends, with growing interest in fiber-glass reinforced polyamide (PA) [

113]. Polycarbonate is increasingly sought after for optical and technical applications. Its common uses include optical data storage devices, bulletproof windows, and food packaging, attributed to its desirable properties (optical transparency, excellent thermal, flame resistance, high impact strength, and environmental stability). All of those features make it valuable across various industrial sectors, including automotive [

114]. The process of metallizing polymers with thin metallic layers using magnetron sputtering dates back to 1994, when Grimberg et al. [

115] deposited TiN onto ABS substrates. The authors emphasized that for successful TiN coating, two conditions were necessary: (1) ensuring strong adhesion through the addition of Cu and Ni layers by electroplating and (2) maintaining a low deposition temperature to prevent polymer degradation. To meet this latter condition, the deposition temperature was kept around 100–110 °C. Later, Sukwisute et al. [

116] utilized reactive DC magnetron sputtering to deposit CrN coatings onto ABS substrates, resulting in enhanced wear resistance with a hardness of up to 9.6 GPa, though voids and cracks were observed. More recently, Pedrosa and team [

117] explored the effects of reactive magnetron sputtering conditions on Cr-N coating for ABS substrates. The authors aimed to achieve protective and decorative properties comparable to those obtained through traditional electroplating methods.

Furthermore, it is interesting to point out that PVD equipment manufacturers can produce a wide range of metal colors by combining different metals and gases within the vacuum chamber. Additionally, the topcoat can be adjusted to create satin or low-gloss finishes, which are particularly popular for interior automotive applications. While similar color effects can be achieved through chrome plating, this method requires an extensive preparation process. Furthermore, tinted clearcoats can be formulated to create various design effects [

118]. To continue the above discussion, it should also be stated that the inclusion of pigments and colorants in UV-cured coatings significantly influences their curing process and performance, as it allows for distinguishing them from clear coatings. In consequence, it is essential for formulators to comprehend the output properties of the curing system, the absorption characteristics of photo initiators, and the spectral properties of pigments. If any of these parameters are not properly aligned, it can lead to reduced curing efficiency and suboptimal coating performance. Additionally, some matting agents, when added to UV coatings, may alter curing properties, necessitating careful selection during formulation [

119].