Optimization of Welding Sequence and Improvement of Welding Process for Large-Diameter Curved Penetrations of Thick Plates

Abstract

1. Introduction

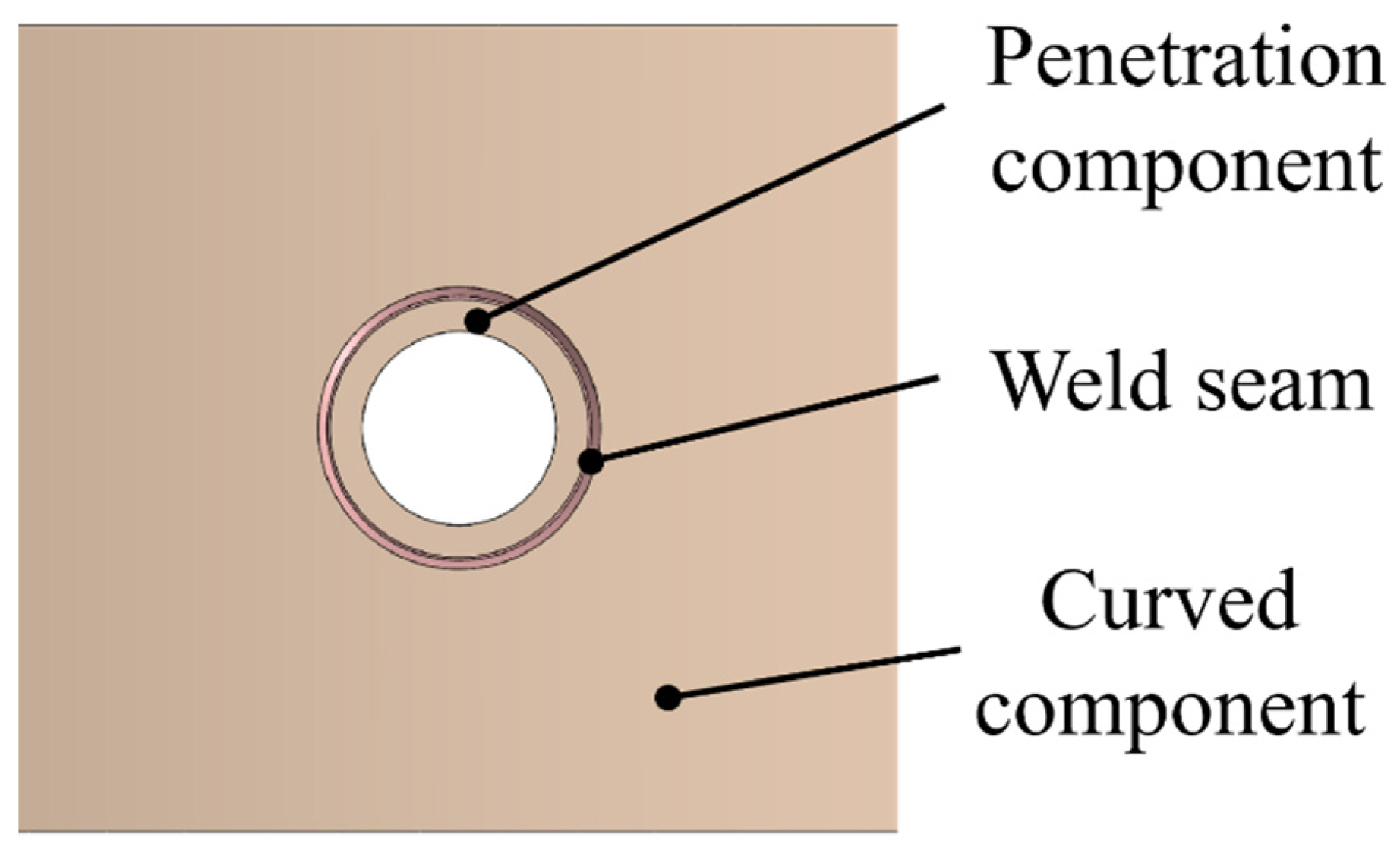

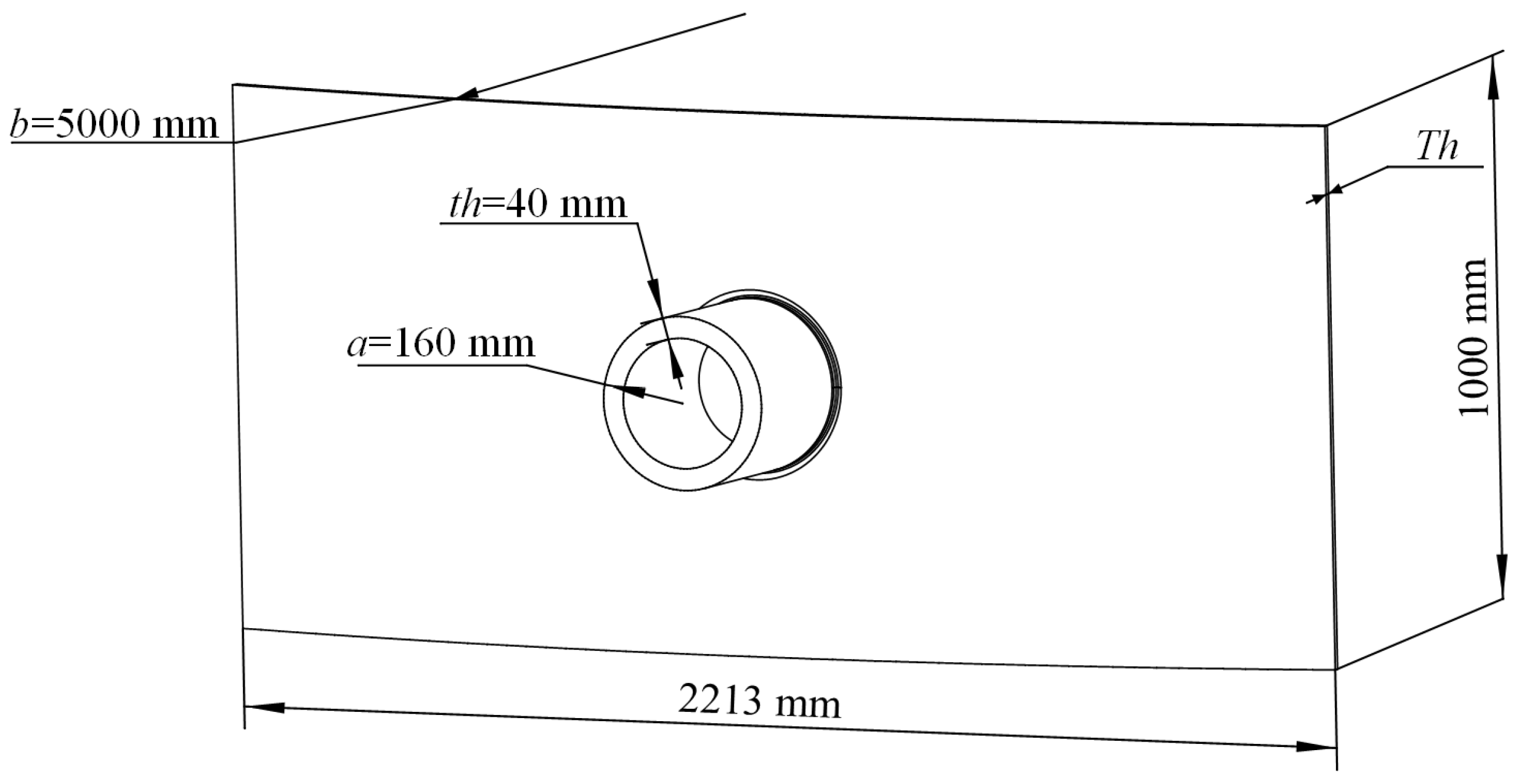

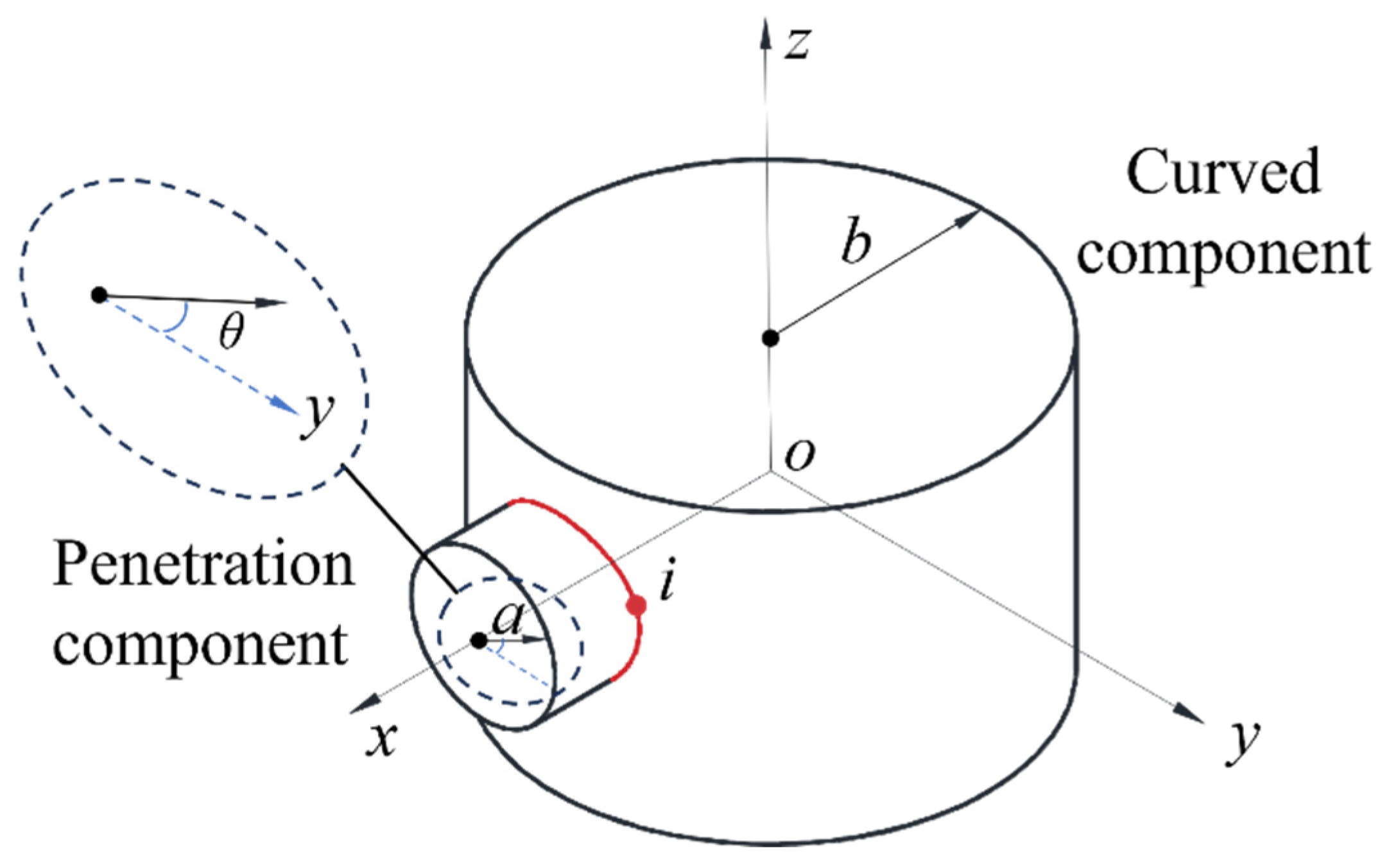

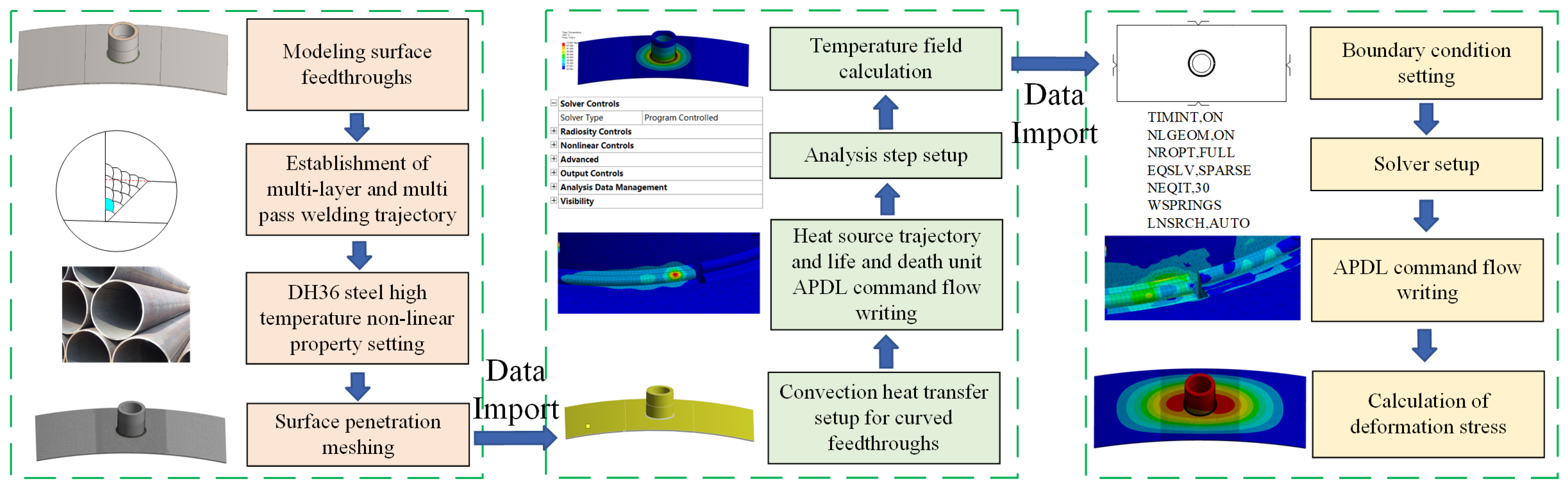

2. Establishment of Welding Model and Weld Seam Equation for Curved Penetrations

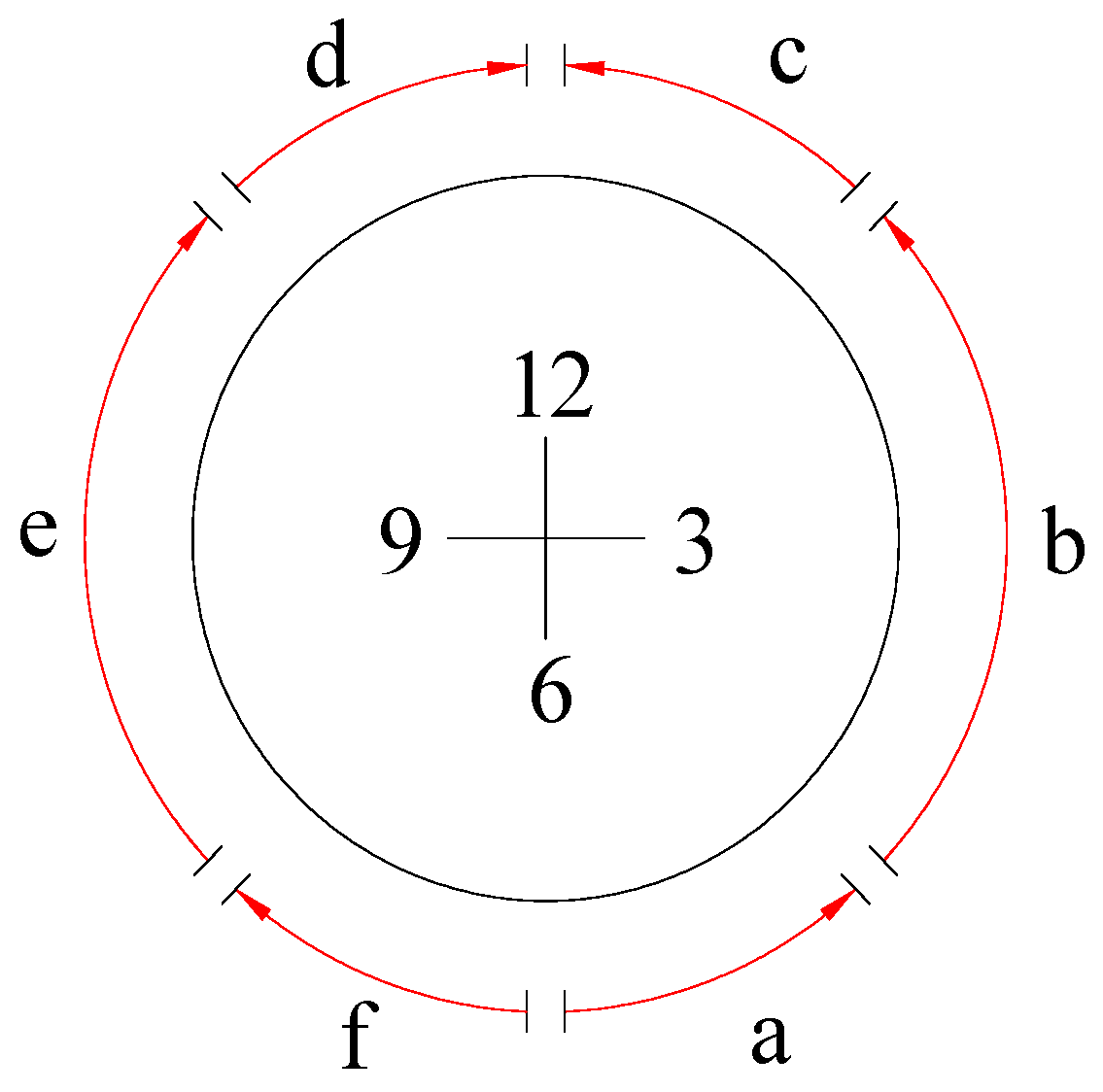

2.1. Establishment of the Welding Model

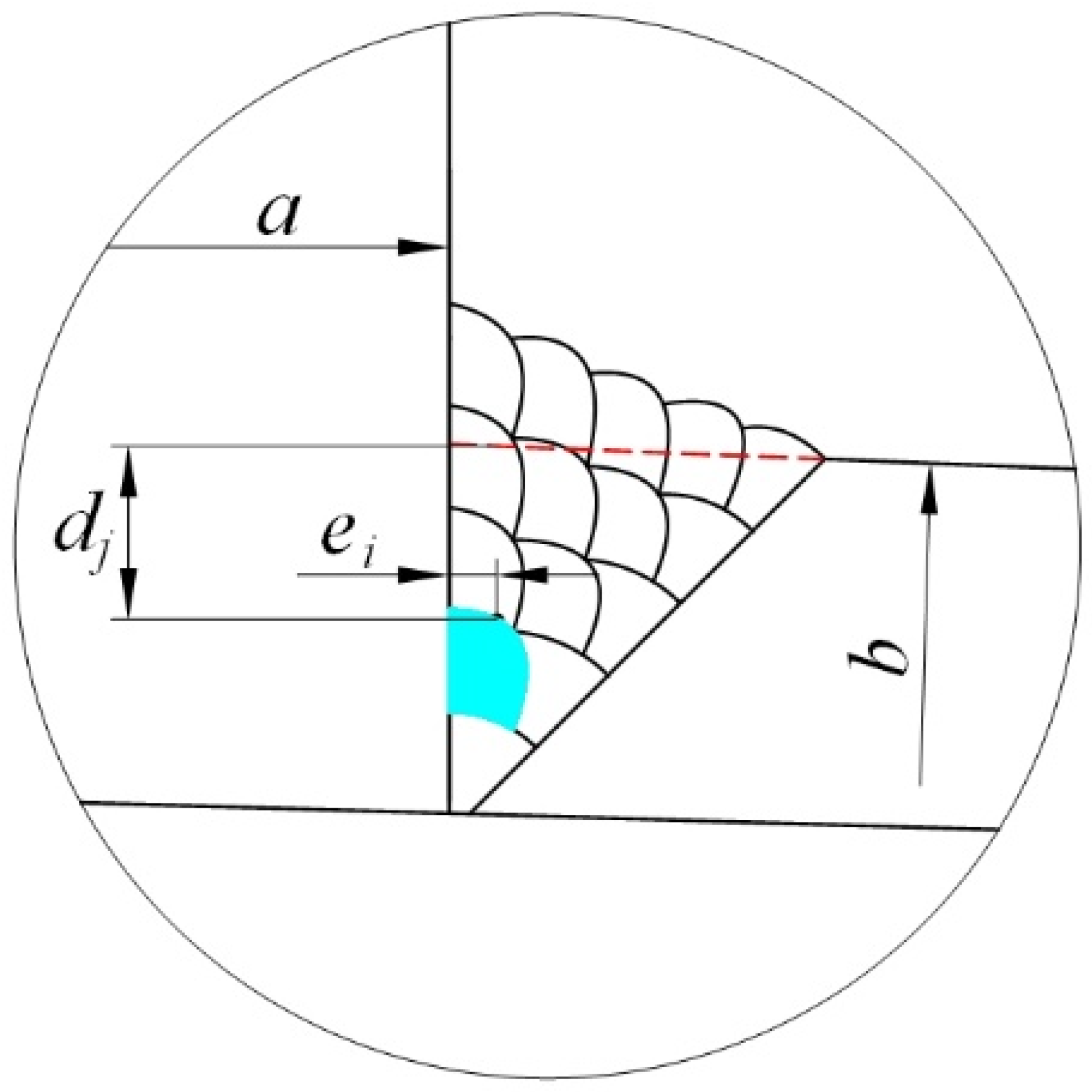

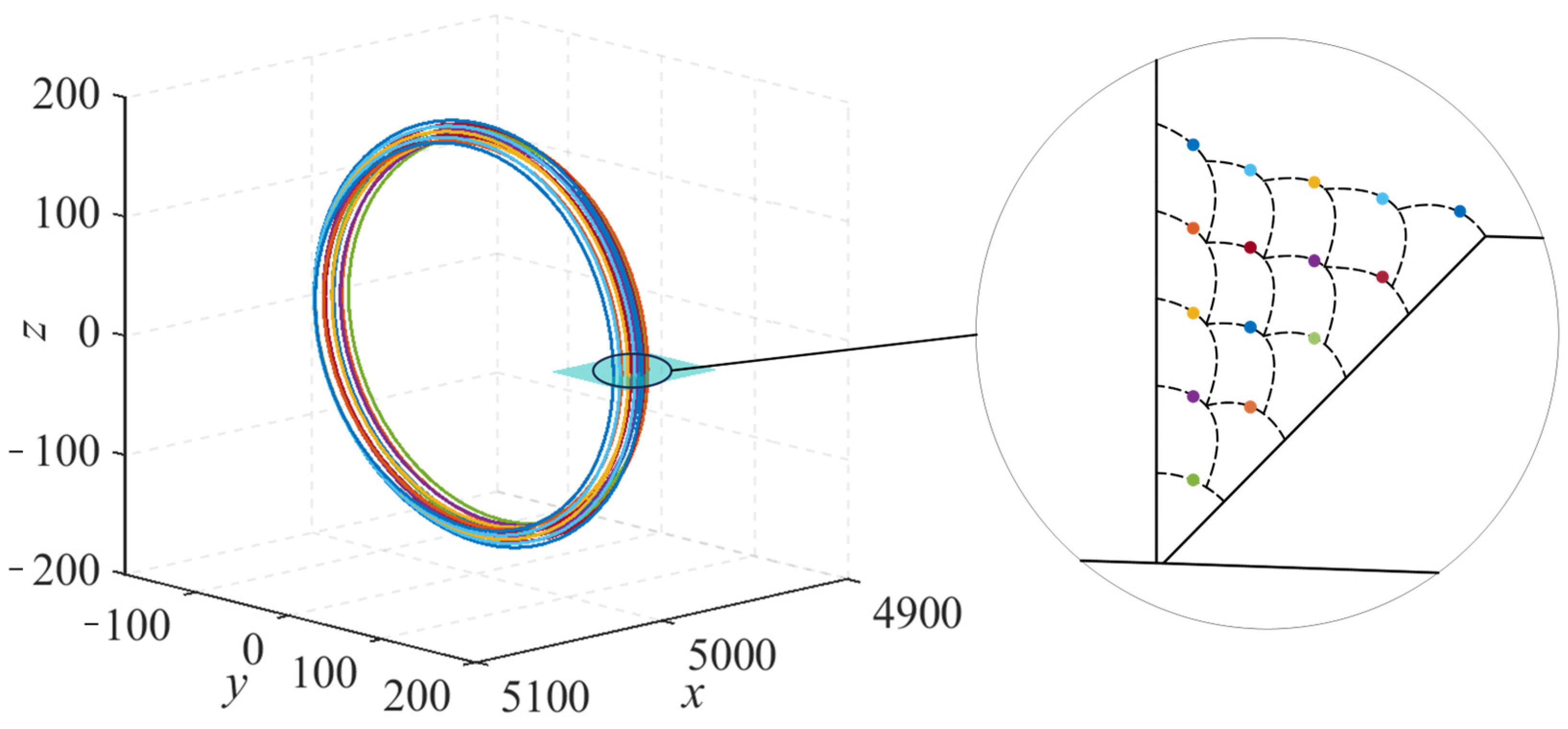

2.2. Establishment of Multi-Layer Multi-Pass Weld Seam Equation

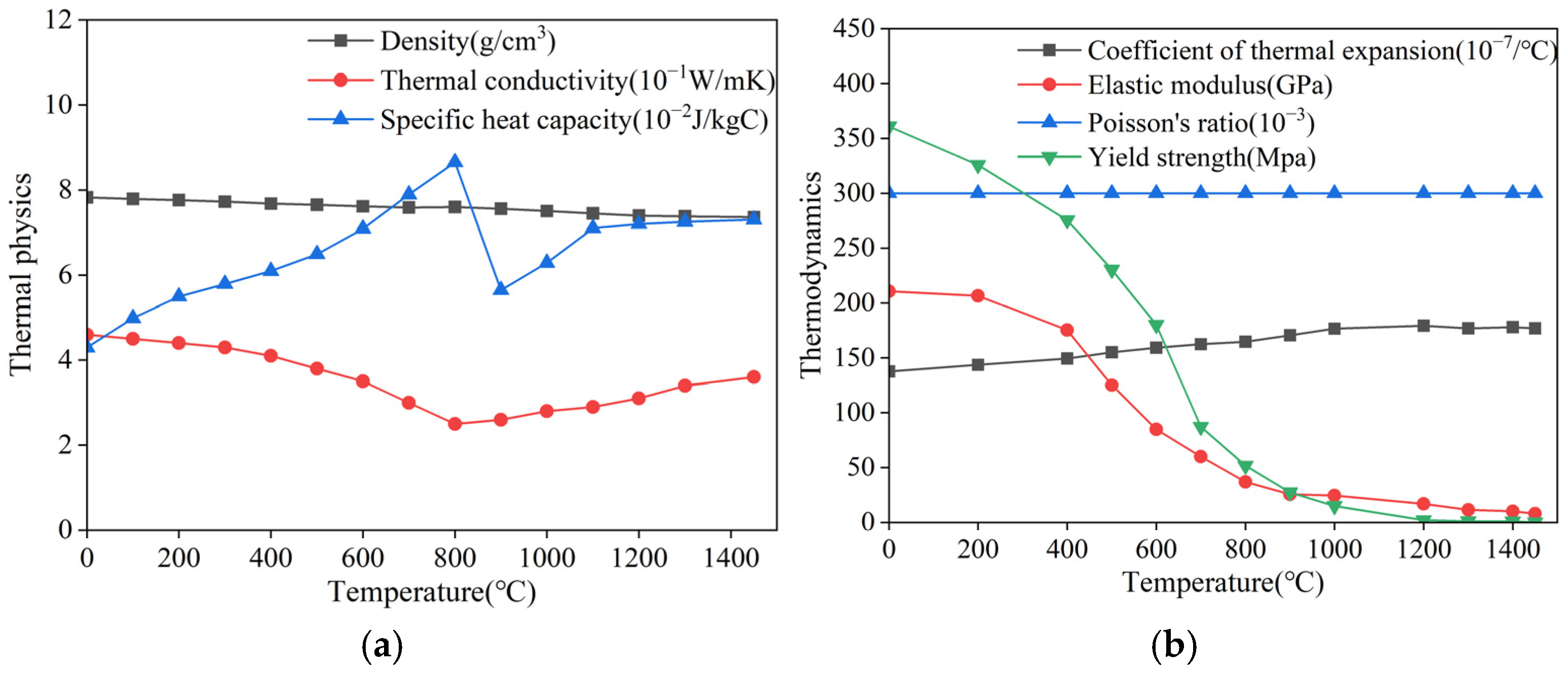

3. Numerical Calculation of Welding for Curved Penetration Components

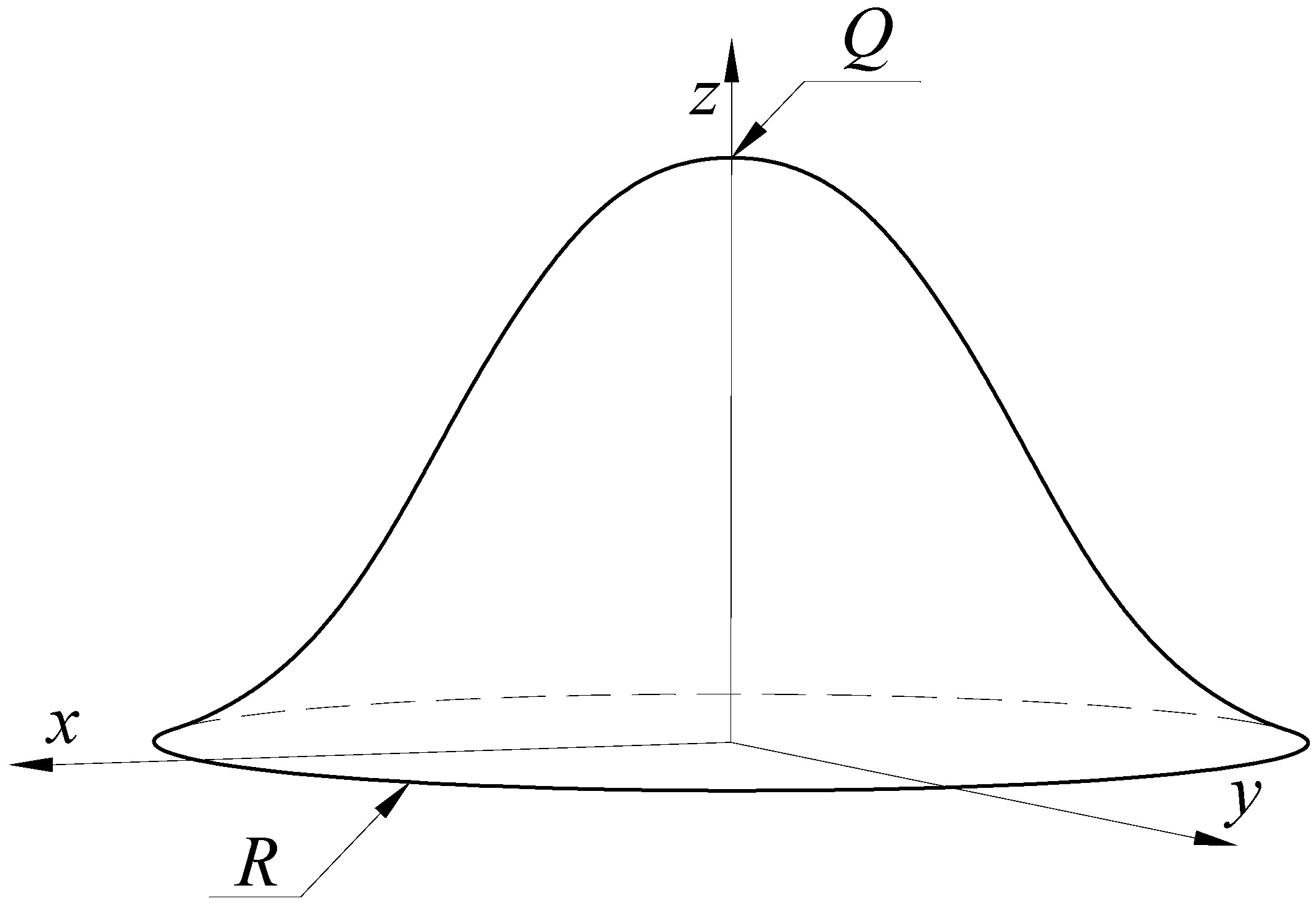

3.1. Selection of Welding Heat Source

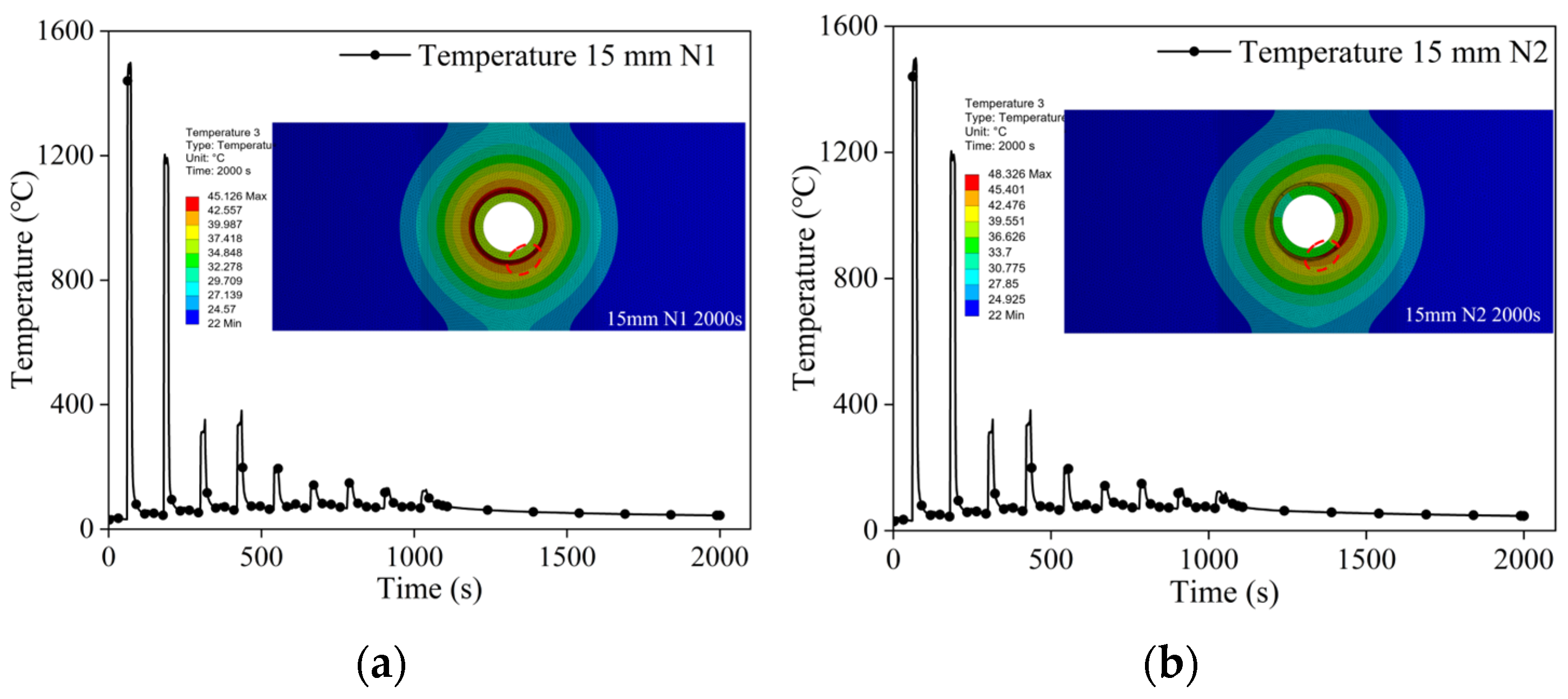

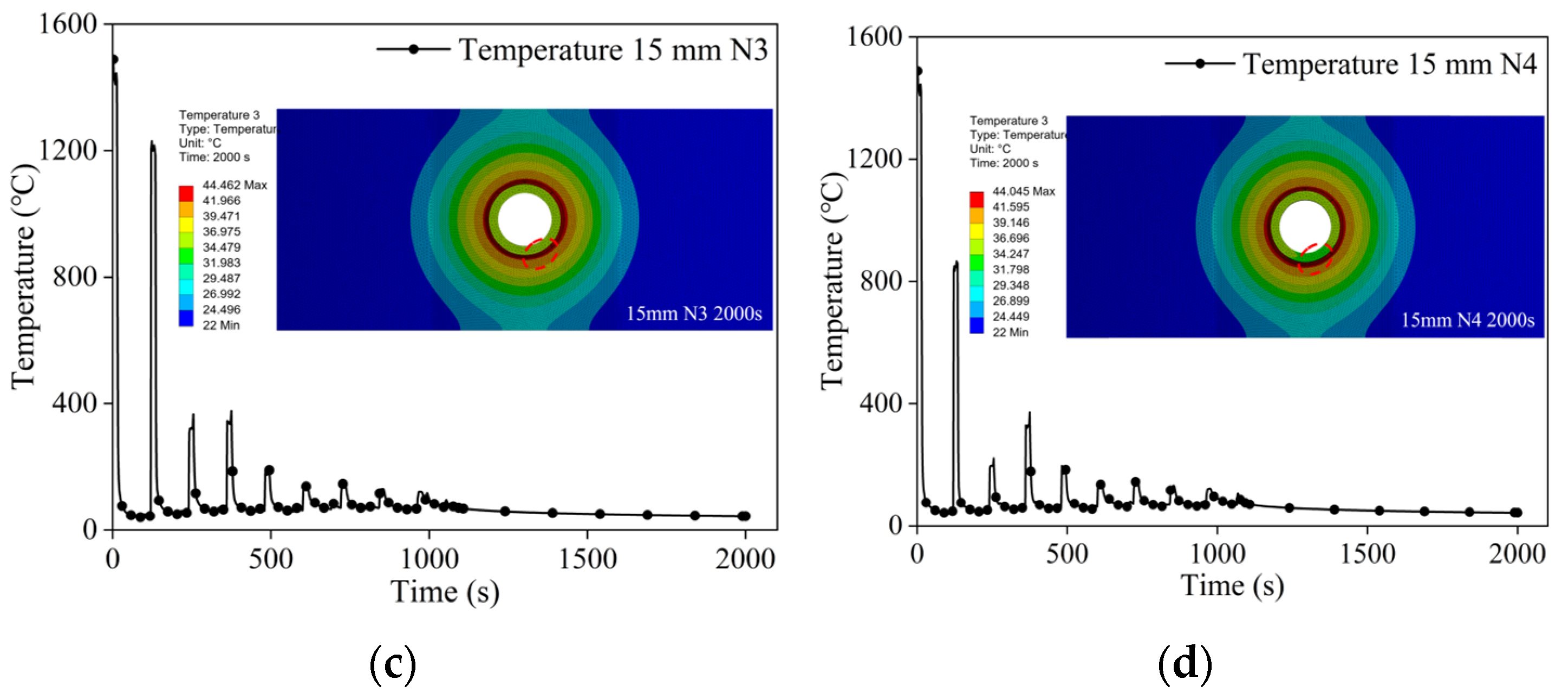

3.2. Numerical Calculation of Welding Temperature Field

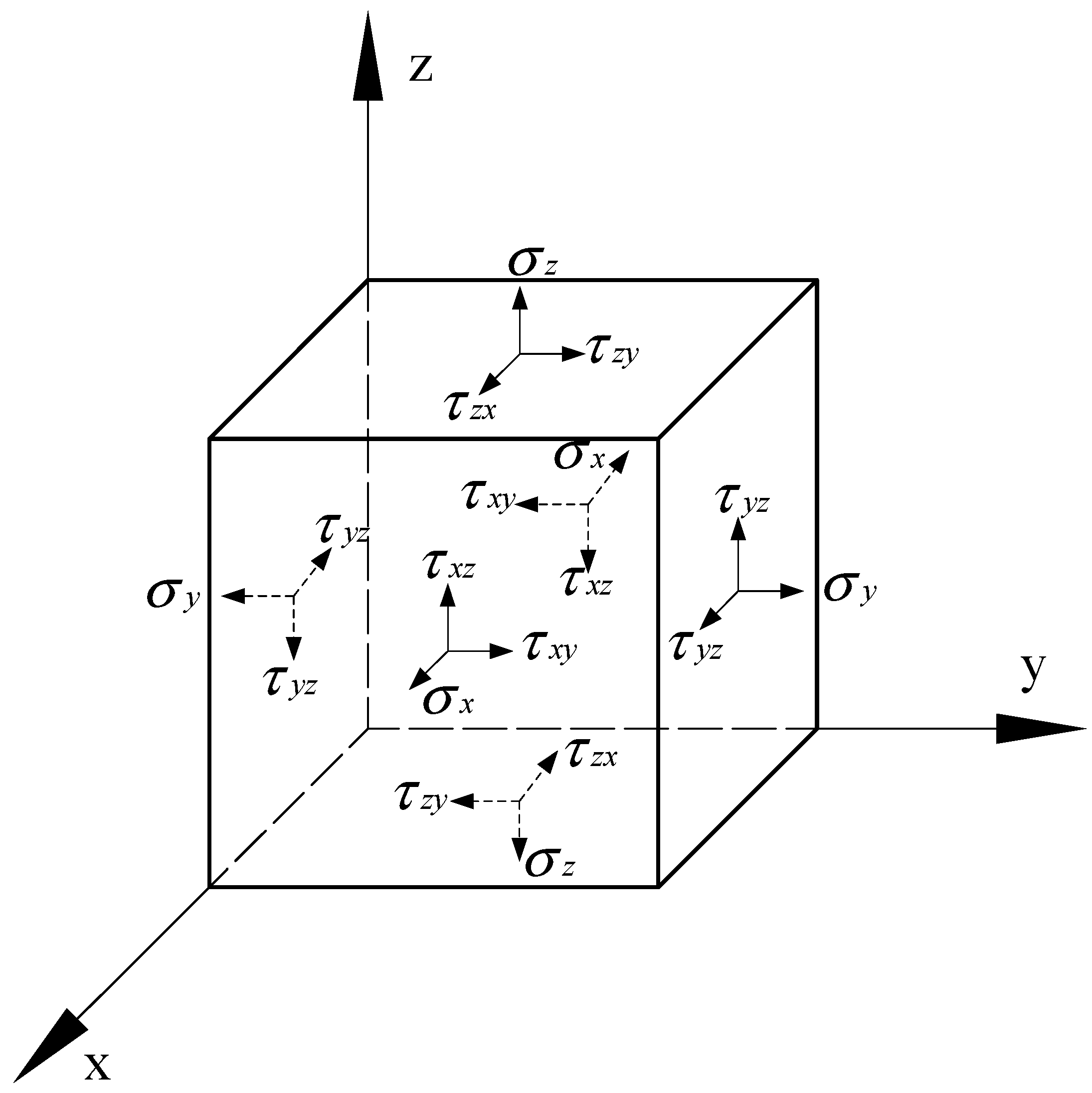

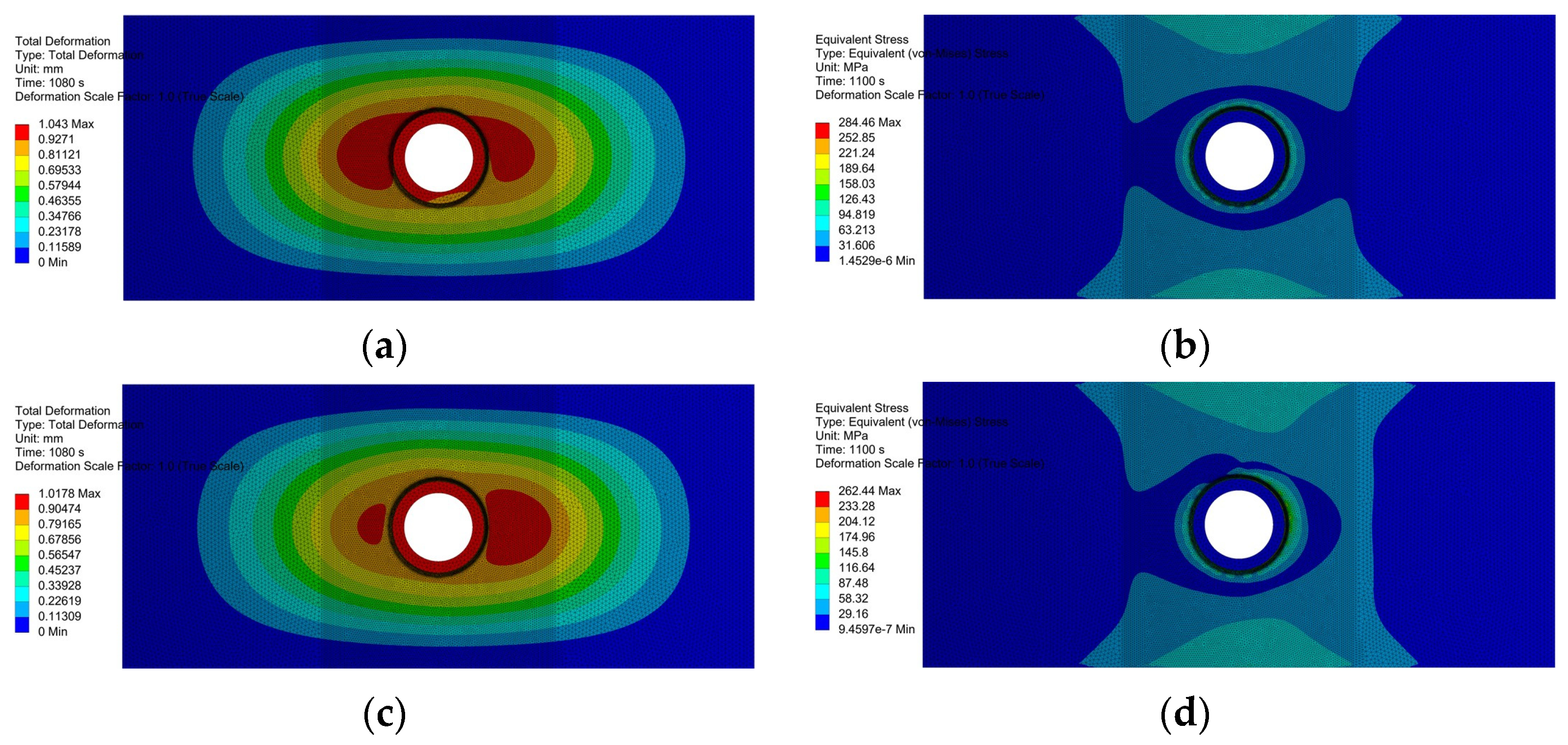

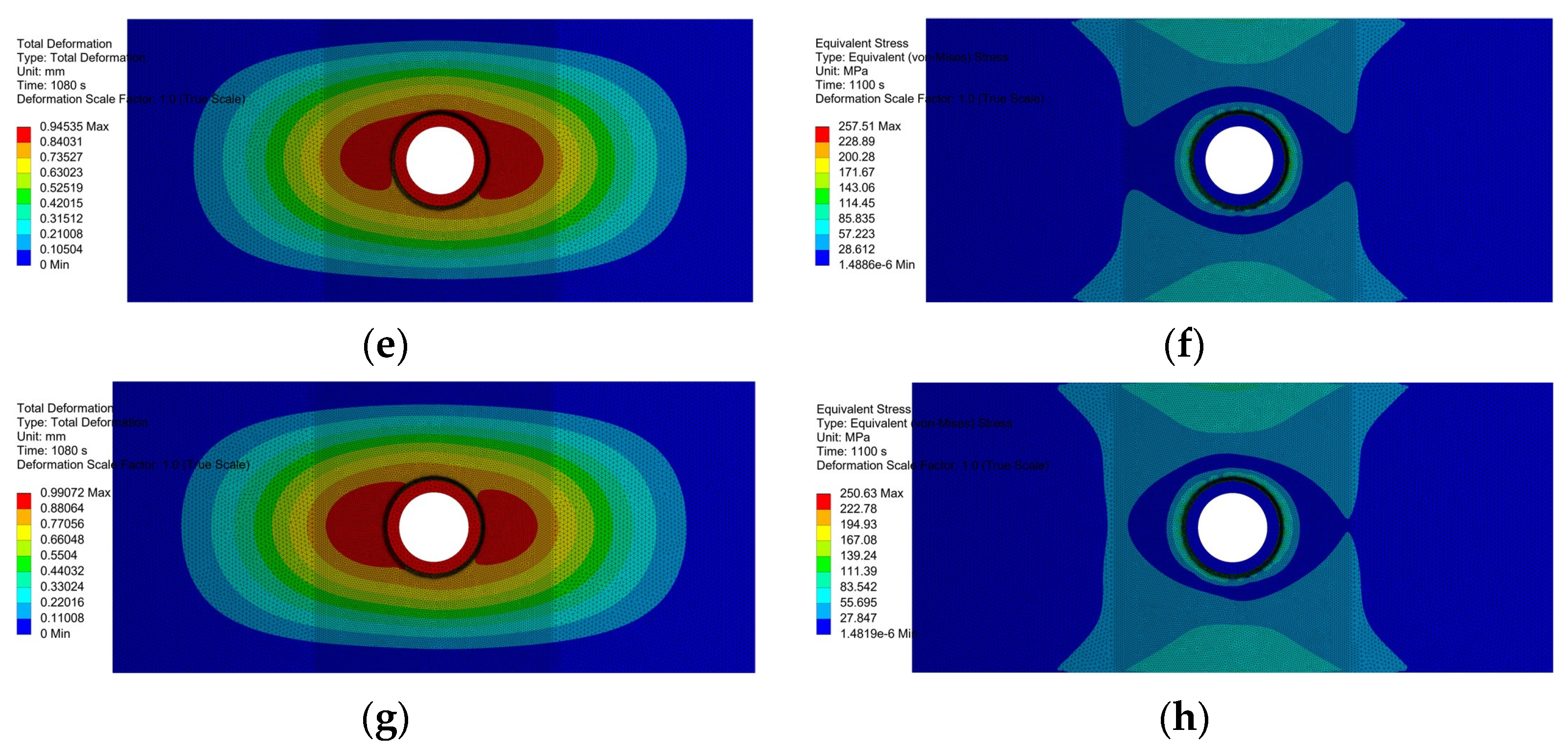

3.3. Numerical Calculation of Welding Stress and Deformation

4. Numerical Simulation of Welding Sequence for Curved Penetration Components

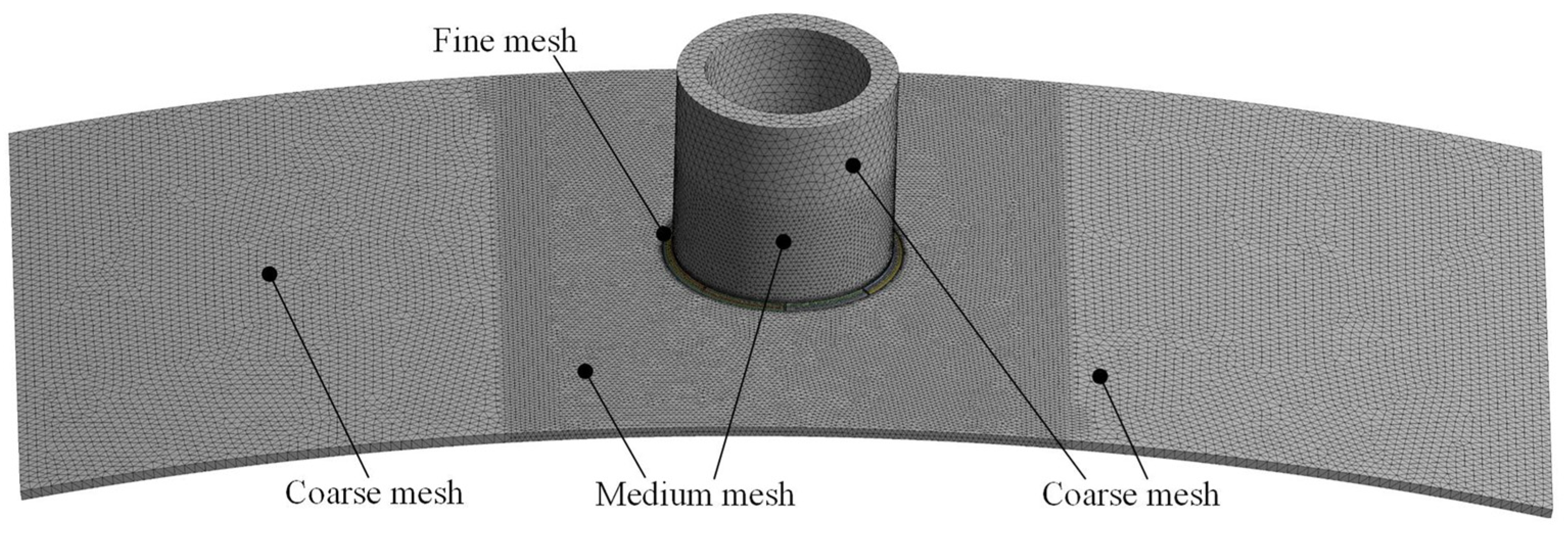

4.1. Preprocessing for Numerical Simulation

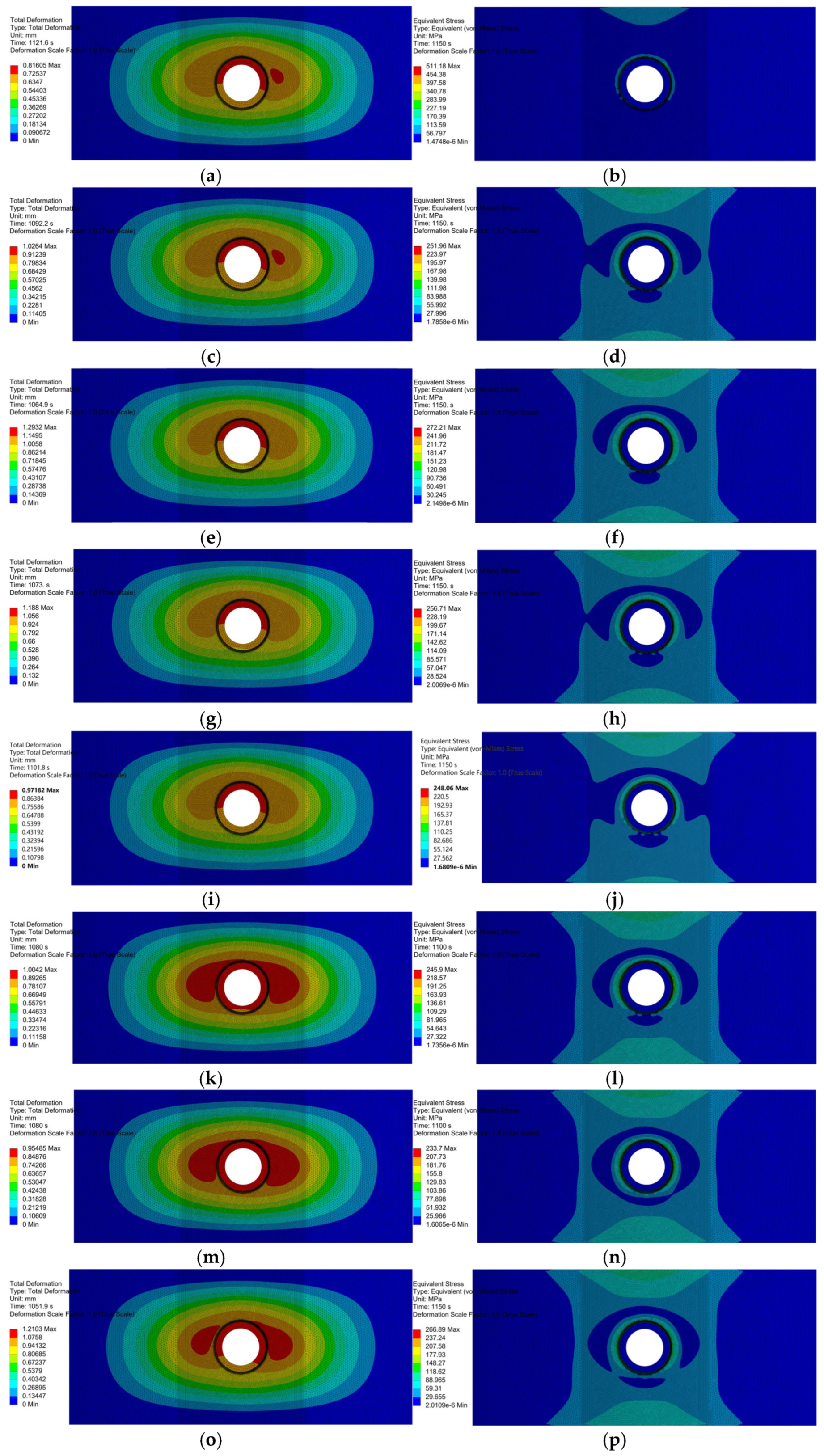

4.2. Numerical Simulation Analysis

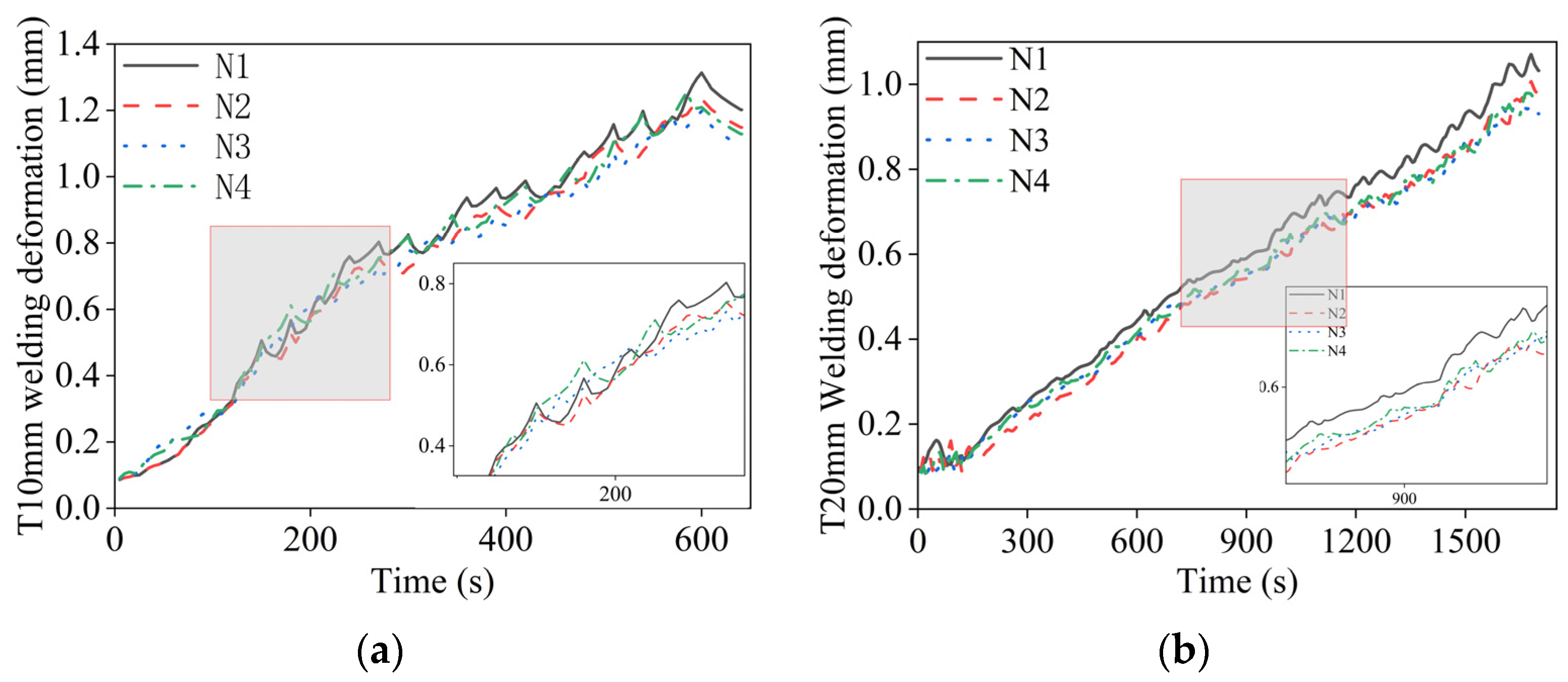

5. Improvement of Welding Process

6. Conclusions

- (1)

- The weld planning is carried out using the equal area method, and a multi-layer, multi-pass welding trajectory equation is established for thick plate curved penetrations, ensuring the accurate simulation of segmented welding for different thicknesses of curved plates under various welding sequences in subsequent stages;

- (2)

- Based on the multi-layer, multi-pass welding trajectory equation and the use of a Gaussian heat source, the multi-layer, multi-pass moving Gaussian heat source is calculated. Finite-element theory is applied to obtain the temperature and stress fields during the segmented welding of intersecting welds, laying the foundation for optimizing the welding sequence and improving the welding process;

- (3)

- For the three thicknesses of the curved penetrations, numerical simulations of segmented welding are carried out under four welding sequences. The results show that the optimal welding sequence is first a skew-symmetric sequence followed by a left–right symmetric sequence, which effectively suppresses welding deformation and residual stresses;

- (4)

- For the three thicknesses of curved plates, orthogonal experiments are conducted for nine welding parameter schemes. Through these experiments, the best welding parameters for each thickness of the curved plate are determined. Additionally, it is observed that, as the plate thickness increases, the welding process parameters for each weld segment should not differ too much, as this helps effectively suppress welding residual stress and deformation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y. Research on united planning of welding trajectory and parameters of welding robot for intersecting pipes. Master’s Thesis, Tianjin University, Tianjin, China, 2020. [Google Scholar] [CrossRef]

- Liu, S.; Wu, Z.Q.; Zhou, W.H.; Zhou, H.G.; Zhang, K.K.; Yin, D.Q.; Lei, Y.P.; Qiu, Y.F. A review of welding simulation methods for large components. Prog. Nat. Sci. Mater. Int. 2023, 33, 551–568. [Google Scholar] [CrossRef]

- Li, Y.; Hou, J.Y.; Gu, L.J.; Li, L.B.; Wan, Z.G. Influence of hardening model on the simulation calculation of thermal-mechanical coupling in ti80 thick plate welding. Electr. Weld. Mach. 2024, 54, 50–63. [Google Scholar] [CrossRef]

- Park, J.U.; An, G.B. Effect of welding sequence to minimize fillet welding distortion in a ship’s small component fabrication using joint rigidity method. Proc. Inst. Mech. Eng. Part B-J. Eng. Manuf. 2016, 230, 643–653. [Google Scholar] [CrossRef]

- Huo, L.; Ren, Y.L. Optimization of cylindrical structure and welding process based on welding deformation control. MW Met. Form. 2024, 2, 30–33. [Google Scholar] [CrossRef]

- Bi, X.S.; Li, Z.B.; Gao, W.G.; Shang, P. Effect of welding parameters on stainless steel lap weld formation. Hot Work. Technol. 2025, 53, 49–52. [Google Scholar] [CrossRef]

- Wang, X.K. Research on numerical simulation and deformation control of construction hoist cage skeleton welding. Master’s Thesis, Shandong Jianzhu University, Jinan, China, 2024. [Google Scholar] [CrossRef]

- Li, J. Research on the welding characteristics and properties of 16mndr steel using gmaw/fcaw. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2025. [Google Scholar] [CrossRef]

- Hu, X.; Feng, G.J.; Wang, Y.F.; Zhang, C.H.; Deng, D. Influence of lumping passes on calculation accuracy and efficiency of welding residual stress of thick-plate butt joint in boiling water reactor. Eng. Struct. 2020, 222, 111136. [Google Scholar] [CrossRef]

- Gadallah, R.; Murakawa, H.; Shibahara, M. Investigation of fracture parameters for a surface-cracked multi-pass t-joint considering welding residual stress. Theor. Appl. Fract. Mech. 2023, 127, 104080. [Google Scholar] [CrossRef]

- Mi, D.W.; Shen, T.K.; Su, X.H.; Guo, B.C.; Zou, X.P.; Sun, G.; Wu, C.P. Simulation of welding temperature field and stress-strain field of canopy welded seam in control rod drive mechanism of nuclear power plant. J. Netshape Form. Eng. 2024, 16, 182–189. [Google Scholar] [CrossRef]

- Lian, C.; Zhou, F. Design and research of welding robot for saddle-shaped welds in heavy pressure vessels. Equip. Manag. Maint. 2024, 14, 140–143. [Google Scholar]

- Fang, H.C.; Ong, S.K.; Nee, A. Robot Path Planning Optimization for Welding Complex Joints. Int. J. Adv. Manuf. Technol. 2017, 90, 3829–3839. [Google Scholar] [CrossRef]

- Xiong, J.H.; Fu, Z.T.; Chen, H.; Pan, J.B.; Gao, X.S.; Chen, X.B. Simulation and Trajectory Generation of Dual-Robot Collaborative Welding for Intersecting Pipes. Int. J. Adv. Manuf. Technol. 2020, 111, 2231–2241. [Google Scholar] [CrossRef]

- Song, D.Z.; Yun, C.; Wei, W.H. Welding Groove Model Analysis of the Intersecting Pipe. Mach. Des. Manuf. 2013, 11, 171–174. [Google Scholar] [CrossRef]

- Chen, C.R.; Zhou, S.S.; He, H.; Lian, G.F.; Huang, X.; Feng, M.Y. Arrangement Planning of V-Groove Weld Beads Based on a Parabolic Model. Trans. China Weld. Inst. 2023, 44, 79–88. [Google Scholar] [CrossRef]

- Ma, Y.L.; Zhu, J.; Zhang, L.M.; Ren, Z.Q.; Zhao, Y.; Wang, W.Y.; Wang, X.M.; Hui, X.D.; Wu, Y.L.; Zheng, H.Y. Numerical Simulation and Experimental Study of Hybrid Laser-Electric Arc Welding between Dissimilar Mg Alloys. J. Cent. South Univ. 2022, 29, 3476–3488. [Google Scholar] [CrossRef]

- Jang, H.L.; Ryu, H.; Kang, S. A Study on the Effects of Welding Deformation According to Weld Sequence in Overlay-Welded Structures. Metals 2024, 14, 684. [Google Scholar] [CrossRef]

- Yuan, M.X.; Liu, S.D.; Gao, Y.Q.; Sun, H.W.; Liu, C.; Shen, Y. Immune Optimization of Welding Sequence for Arc Weld Seams in Ship Medium-Small Assemblies. Coatings 2022, 12, 703. [Google Scholar] [CrossRef]

- Li, L.; Ren, S.; Wang, P.Y.; Dai, K.Y. Study on Subsection Welding Sequence Simulation and Deformation Prediction of Large Ship Sides. Hot Work. Technol. 2018, 47, 206–211. [Google Scholar] [CrossRef]

- Miao, Y.G.; Wang, L.; Wang, Z.R.; Zhuo, Z.J.; Lin, C.X.; Tan, G.P.; Xie, Z.K. Numerical Simulation and Experimental Analysis of Residual Stress and Deformation in DH36 High-strength Ship Plate Steel Butt Welding. J. Wuhan Univ. Technol. 2023, 45, 104–111. [Google Scholar] [CrossRef]

- Prasad, M.J.H.; Sudhakar, I.; Adinarayana, S.; Rao, D.V.N.J.J. Simulation and Validation of Experimental Residual Stresses of Dissimilar AA2124 and AA7075 TIG Weld Joint Using ANSYS APDL. Int. J. Interact. Des. Manuf. 2024, 18, 71–82. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Gong, M.C.; Zhou, L.Z.; Gao, M. A Review of Numerical Simulation of Laser-Arc Hybrid Welding. Materials 2023, 16, 3561. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Zhu, Y.; Sun, A. Analysis of Dynamic Stress-Strain Characteristics of AH36 Steel Welded Joint. Trans. China Weld. Inst. 2024, 45, 50–58. [Google Scholar] [CrossRef]

- Ji, W.; Zhang, P. Simulation Analysis and Experimental Research on T-Joint Welding of Corrugated Steel Web Girders. J. Harbin Eng. Univ. 2024, 45, 691–698. [Google Scholar] [CrossRef]

- Lu, W.; Sun, J.; Su, H.; Gao, C.; Zhang, X.B. Experimental Research of Welding Residual Stress of Butt Welded Joint of Thick Steel Plate. Metals 2023, 13, 120. [Google Scholar] [CrossRef]

| Curved Panel Thickness/Th (mm) | Curved Panel Radius/b (mm) | Penetration Radius/a (mm) | Penetration Plate Thickness/th (mm) |

|---|---|---|---|

| 10 | 5000 | 160 | 40 |

| 15 | 5000 | 160 | 40 |

| 20 | 5000 | 160 | 40 |

| Mass Fractions (%) | C | Si | Mn | P | S | Cu | Cr | Nb | V |

|---|---|---|---|---|---|---|---|---|---|

| DH36 | ≤0.18 | ≤0.5 | 0.9–1.6 | ≤0.025 | ≤0.025 | ≤0.35 | ≤0.2 | 0.02–0.05 | 0.05–0.1 |

| Horizontal Welding | Vertical Welding | Overhead Welding | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Voltage U/V | Current I/A | Speed v/(mm/s) | Voltage U/V | Current I/A | Speed v/(mm/s) | Voltage U/V | Current I/A | Speed v/(mm/s) | |

| 1 | 25.2 | 230 | 8.6 | 24.4 | 210 | 8 | 24 | 200 | 7.7 |

| 2 | 25.6 | 240 | 8.9 | 24.8 | 220 | 8.3 | 24.4 | 210 | 8 |

| 3 | 26 | 250 | 9.2 | 25.2 | 230 | 8.6 | 24.8 | 220 | 8.3 |

| Experimental Plan | Horizontal Welding | Vertical Welding | Overhead Welding | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Voltage U/V | Current I/A | Speed v/(mm/s) | Voltage U/V | Current I/A | Speed v/(mm/s) | Voltage U/V | Current I/A | Speed v/(mm/s) | |

| 1 | 25.2 | 230 | 8.6 | 24.4 | 210 | 8 | 24 | 200 | 7.7 |

| 2 | 25.6 | 240 | 8.9 | 24.8 | 220 | 8.3 | 24 | 200 | 7.7 |

| 3 | 26 | 250 | 9.2 | 25.2 | 230 | 8.6 | 24 | 200 | 7.7 |

| 4 | 26 | 250 | 9.2 | 24.8 | 220 | 8.3 | 24.4 | 210 | 8 |

| 5 | 25.6 | 240 | 8.9 | 24.4 | 210 | 8 | 24.4 | 210 | 8 |

| 6 | 25.2 | 230 | 8.6 | 25.2 | 230 | 8.6 | 24.4 | 210 | 8 |

| 7 | 25.2 | 230 | 8.6 | 24.8 | 220 | 8.3 | 24.8 | 220 | 8.3 |

| 8 | 25.6 | 240 | 8.9 | 25.2 | 230 | 8.6 | 24.8 | 220 | 8.3 |

| 9 | 26 | 250 | 9.2 | 24.4 | 210 | 8 | 24.8 | 220 | 8.3 |

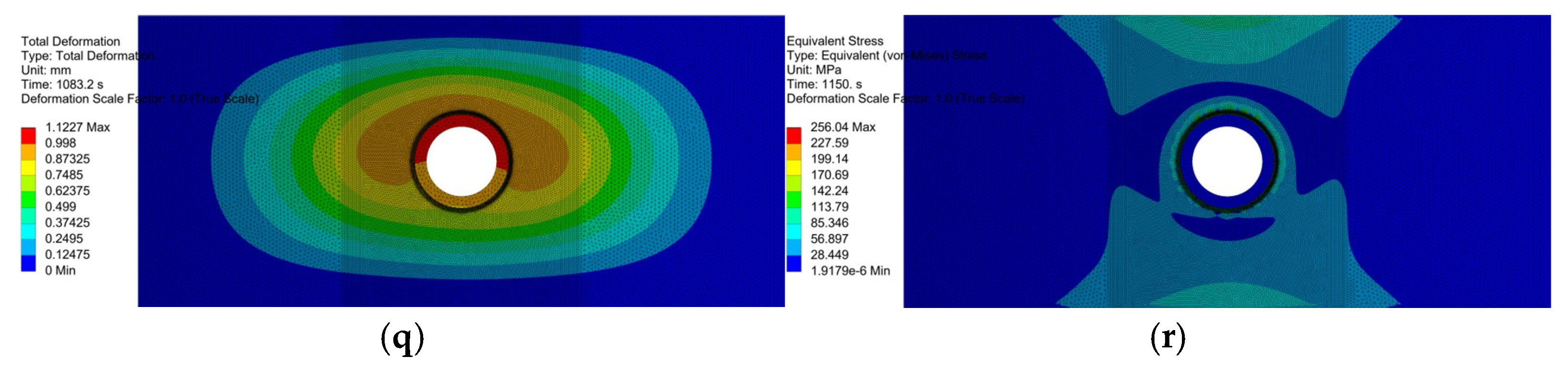

| Experimental Plan | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| Distortion/mm | 0.81605 | 1.0264 | 1.2932 | 1.1879 | 0.9718 | 1.0042 | 0.95485 | 1.2103 | 1.1227 |

| Residual stress/MPa | 511.18 | 251.96 | 272.21 | 256.71 | 248.06 | 245.89 | 233.7 | 266.89 | 256.04 |

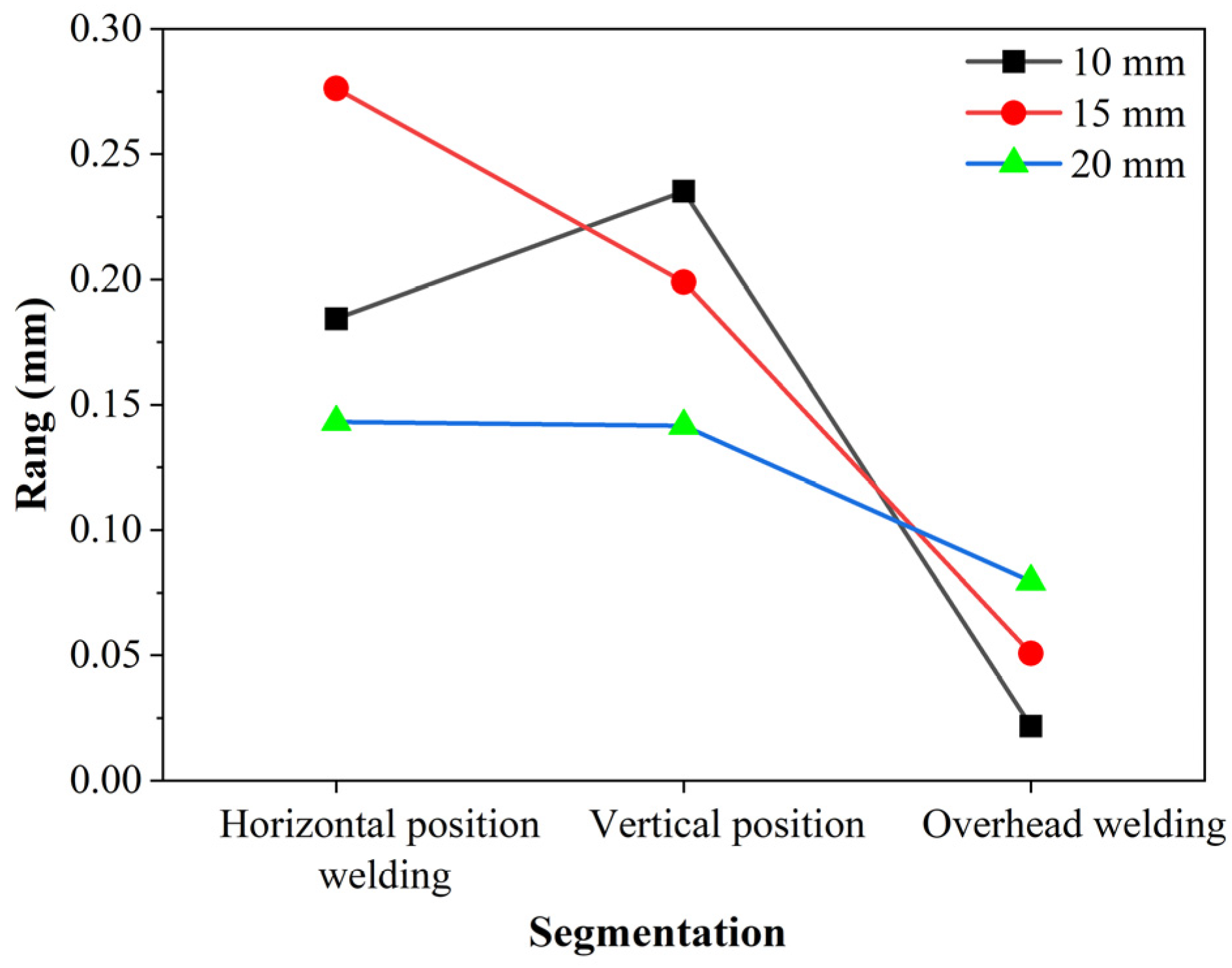

| 15 mm Curved Component | Horizontal Welding | Vertical Welding | Overhead Welding |

|---|---|---|---|

| K1/mm | 2.7751 | 2.9106 | 3.1357 |

| K2/mm | 3.2085 | 3.1691 | 3.1639 |

| K3/mm | 3.6038 | 3.5077 | 3.2878 |

| /mm | 0.9250 | 0.9702 | 1.0452 |

| /mm | 1.0695 | 1.0564 | 1.0546 |

| /mm | 1.2013 | 1.1692 | 1.0959 |

| Rang/mm | 0.2762 | 0.1990 | 0.0507 |

| Experimental Plan | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| 10 mm Welding Distortion | 1.0623 | 1.2791 | 1.4827 | 1.3744 | 1.1695 | 1.3036 | 1.2048 | 1.4177 | 1.2666 |

| 10 mm Residual Stress | 236.07 | 243.43 | 261.52 | 244.67 | 231.97 | 253.21 | 240.43 | 254.28 | 240.26 |

| 20 mm Welding Distortion | 0.73418 | 0.89395 | 1.0315 | 0.99039 | 0.86632 | 0.9336 | 0.89586 | 1.0312 | 0.97106 |

| 20 mm Residual Stress | 421.74 | 305.59 | 336.44 | 327.93 | 321.5 | 314.24 | 286.82 | 299.16 | 335.6 |

| Plate Thickness | 10 mm | 20 mm | ||||

|---|---|---|---|---|---|---|

| Horizontal Welding c,d | Vertical Welding b,e | Overhead Welding a,f | Horizontal Welding c,d | Vertical Welding b,e | Overhead Welding a,f | |

| K1/mm | 3.5707 | 3.4984 | 3.8241 | 2.5636 | 2.5716 | 2.6596 |

| K2/mm | 3.8663 | 3.8583 | 3.8475 | 2.7915 | 2.7802 | 2.7903 |

| K3/mm | 4.1237 | 4.2040 | 3.8891 | 2.9930 | 2.9963 | 2.8981 |

| /mm | 1.1902 | 1.1661 | 1.2747 | 0.8545 | 0.8572 | 0.8865 |

| /mm | 1.2888 | 1.2861 | 1.2825 | 0.9305 | 0.9267 | 0.9301 |

| /mm | 1.3746 | 1.4013 | 1.2964 | 0.9977 | 0.9988 | 0.9660 |

| Rang/mm | 0.1843 | 0.2352 | 0.0217 | 0.1431 | 0.1416 | 0.0795 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miao, H.; Shen, Y.; Xue, W.; Zhang, S.; Yuan, M. Optimization of Welding Sequence and Improvement of Welding Process for Large-Diameter Curved Penetrations of Thick Plates. Coatings 2025, 15, 923. https://doi.org/10.3390/coatings15080923

Miao H, Shen Y, Xue W, Zhang S, Yuan M. Optimization of Welding Sequence and Improvement of Welding Process for Large-Diameter Curved Penetrations of Thick Plates. Coatings. 2025; 15(8):923. https://doi.org/10.3390/coatings15080923

Chicago/Turabian StyleMiao, Haipeng, Yi Shen, Wenbo Xue, Sheng Zhang, and Mingxin Yuan. 2025. "Optimization of Welding Sequence and Improvement of Welding Process for Large-Diameter Curved Penetrations of Thick Plates" Coatings 15, no. 8: 923. https://doi.org/10.3390/coatings15080923

APA StyleMiao, H., Shen, Y., Xue, W., Zhang, S., & Yuan, M. (2025). Optimization of Welding Sequence and Improvement of Welding Process for Large-Diameter Curved Penetrations of Thick Plates. Coatings, 15(8), 923. https://doi.org/10.3390/coatings15080923