Mechanical Properties and Modification Mechanism of Thermosetting Polyurethane-Modified Asphalt

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material

2.2. Sample Preparation

2.3. Experimental Methods

2.3.1. Rotational Viscosity Test

2.3.2. Tensile Test

2.3.3. Dynamic Mechanical Analysis Test

2.3.4. Microscopic Analysis Test

3. Results and Discussion

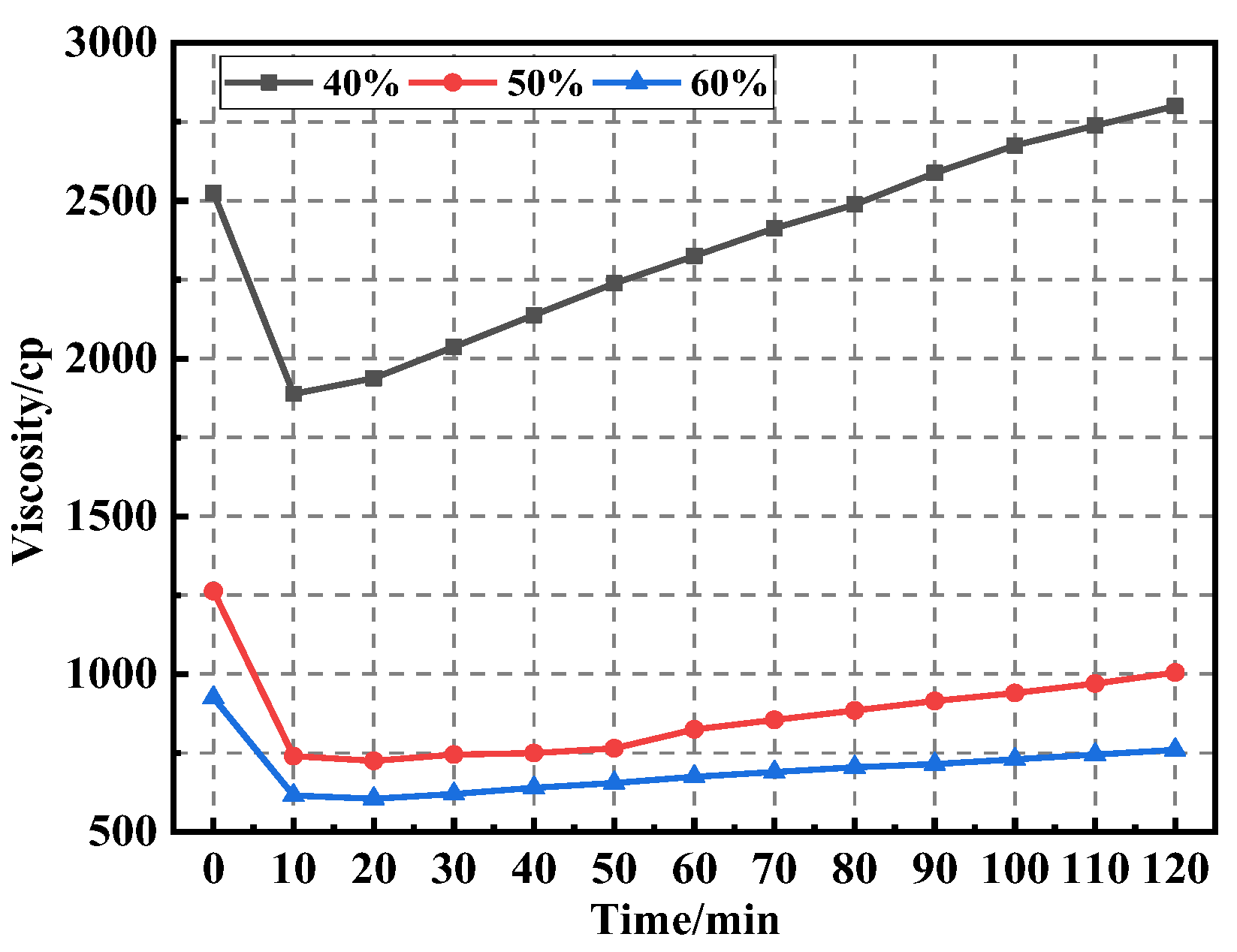

3.1. The Viscosity of Polyurethane-Modified Asphalt

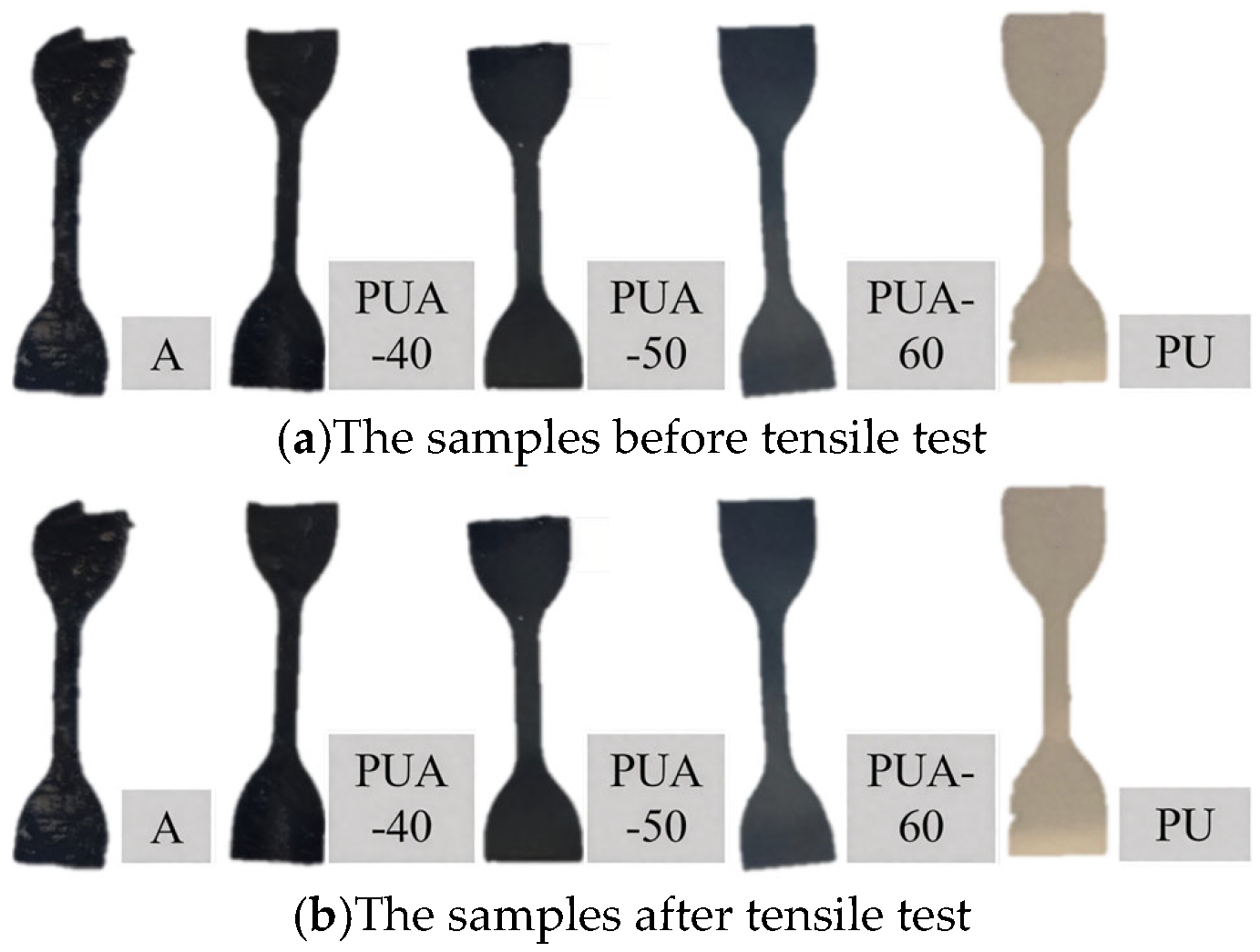

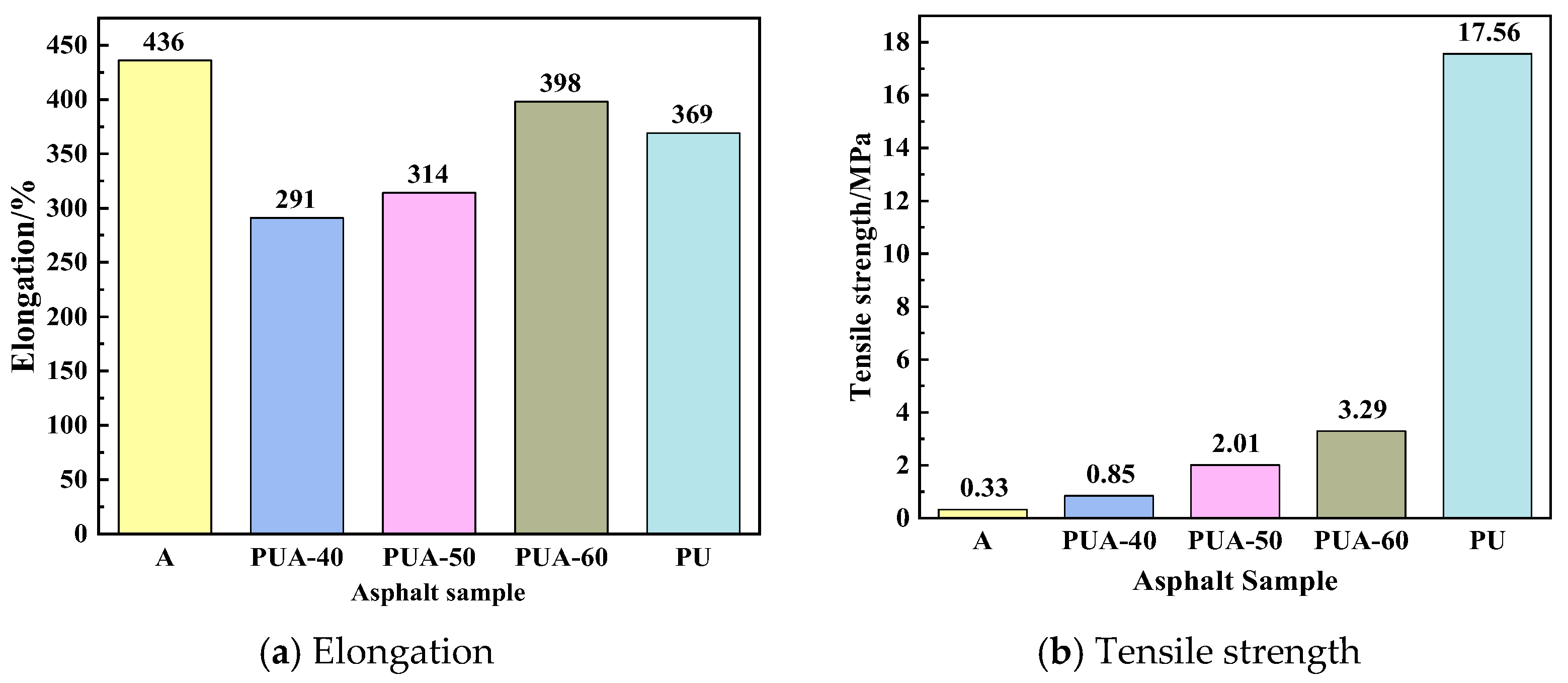

3.2. Tensile Property Analysis

3.3. Dynamic Mechanical Property Analysis

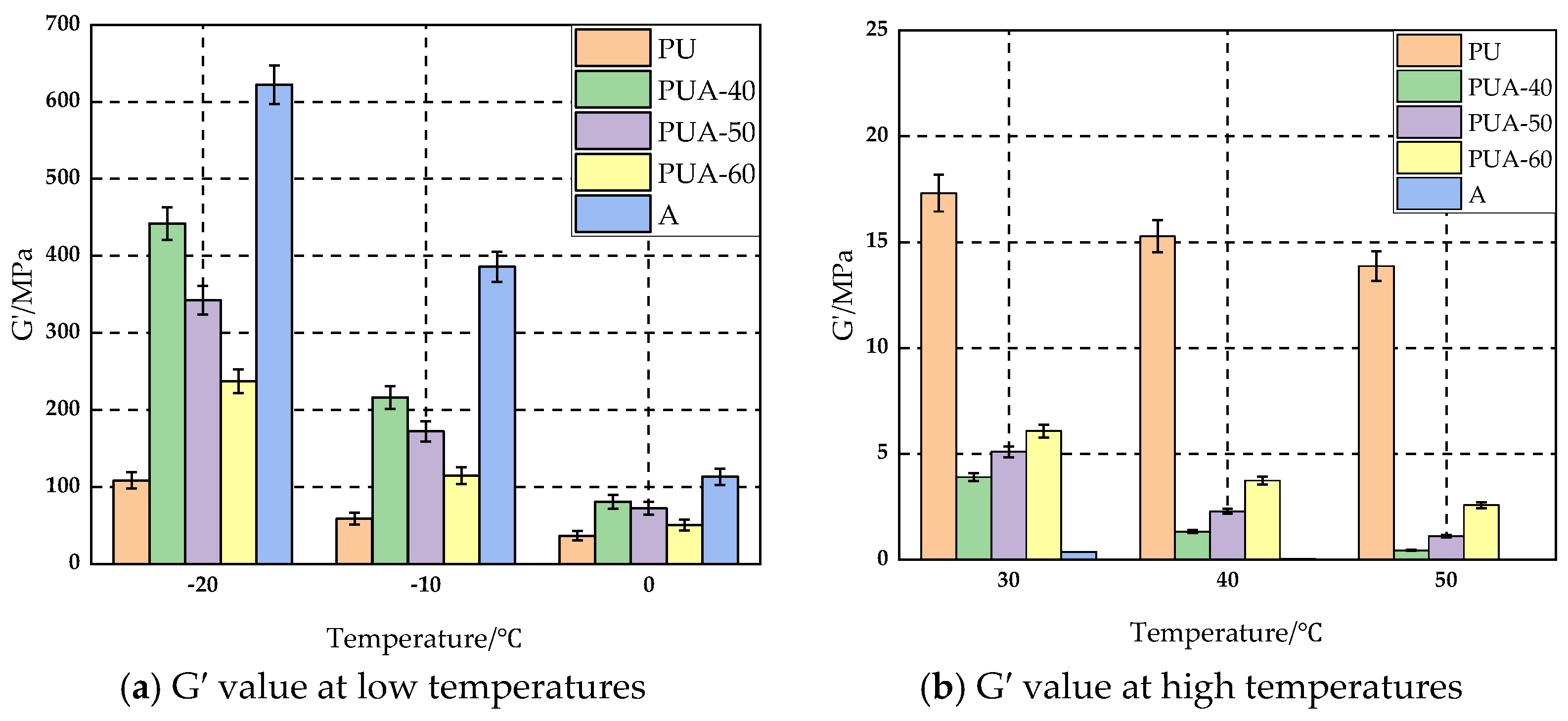

3.3.1. G′ and G″

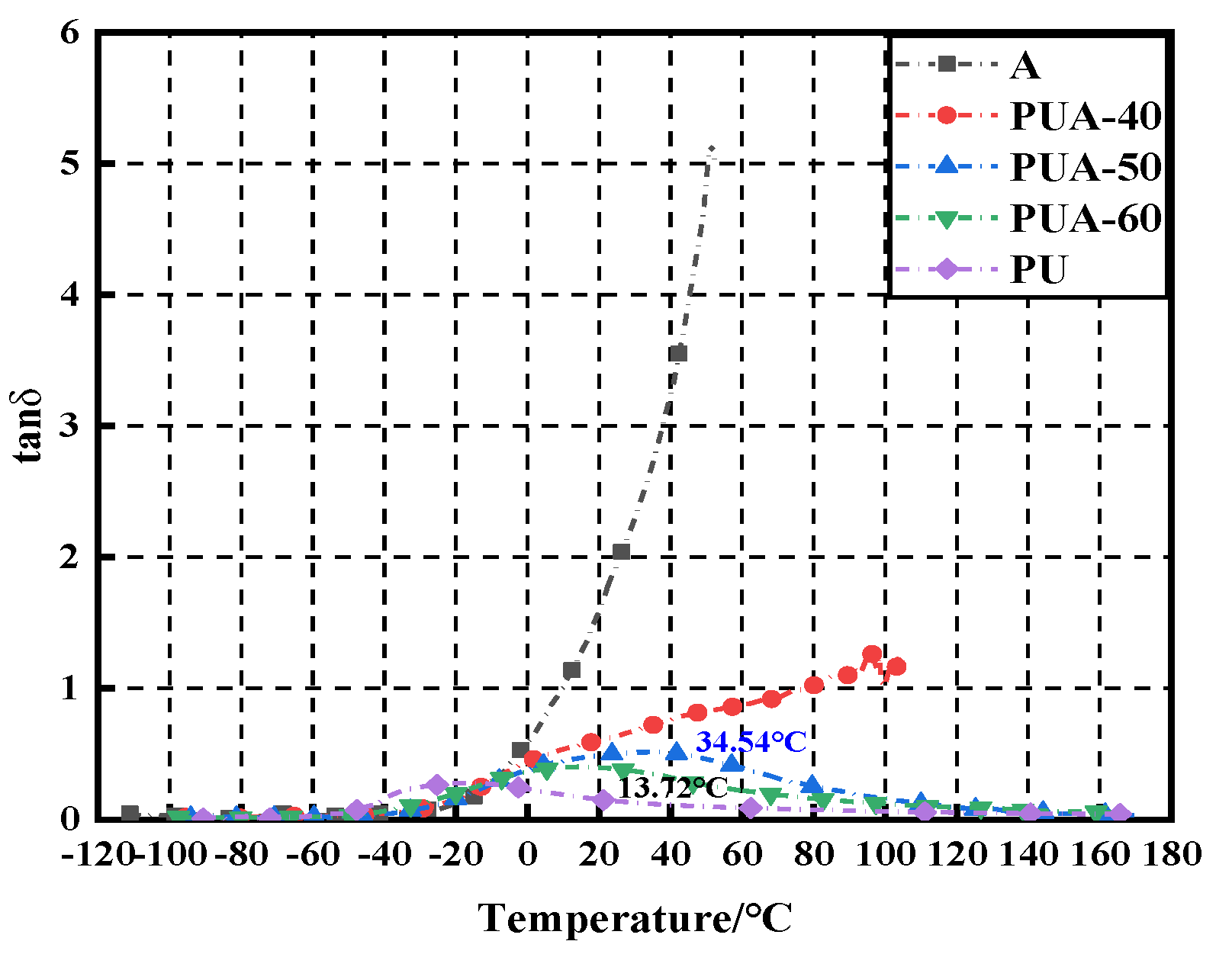

3.3.2. tanδ

3.3.3. Tg

3.4. Thermal Behavior and Microscopic Morphology of Polyurethane Asphalt

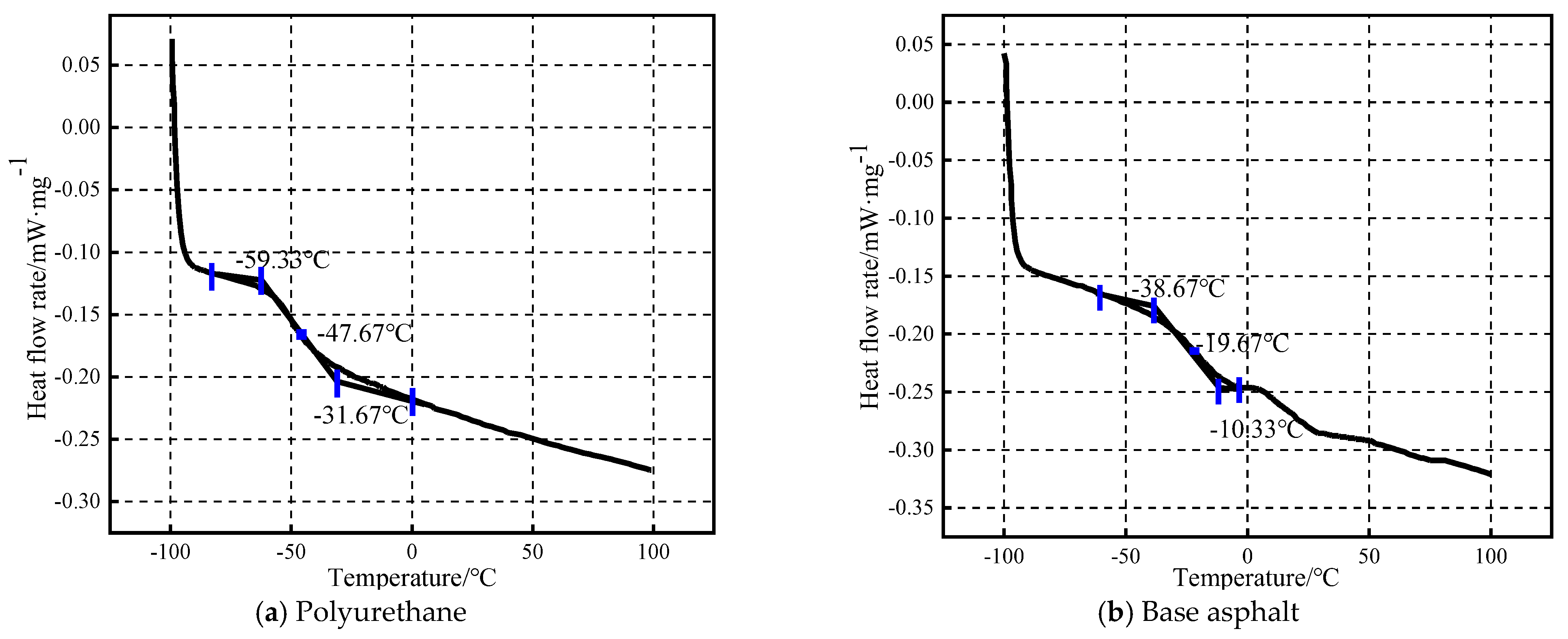

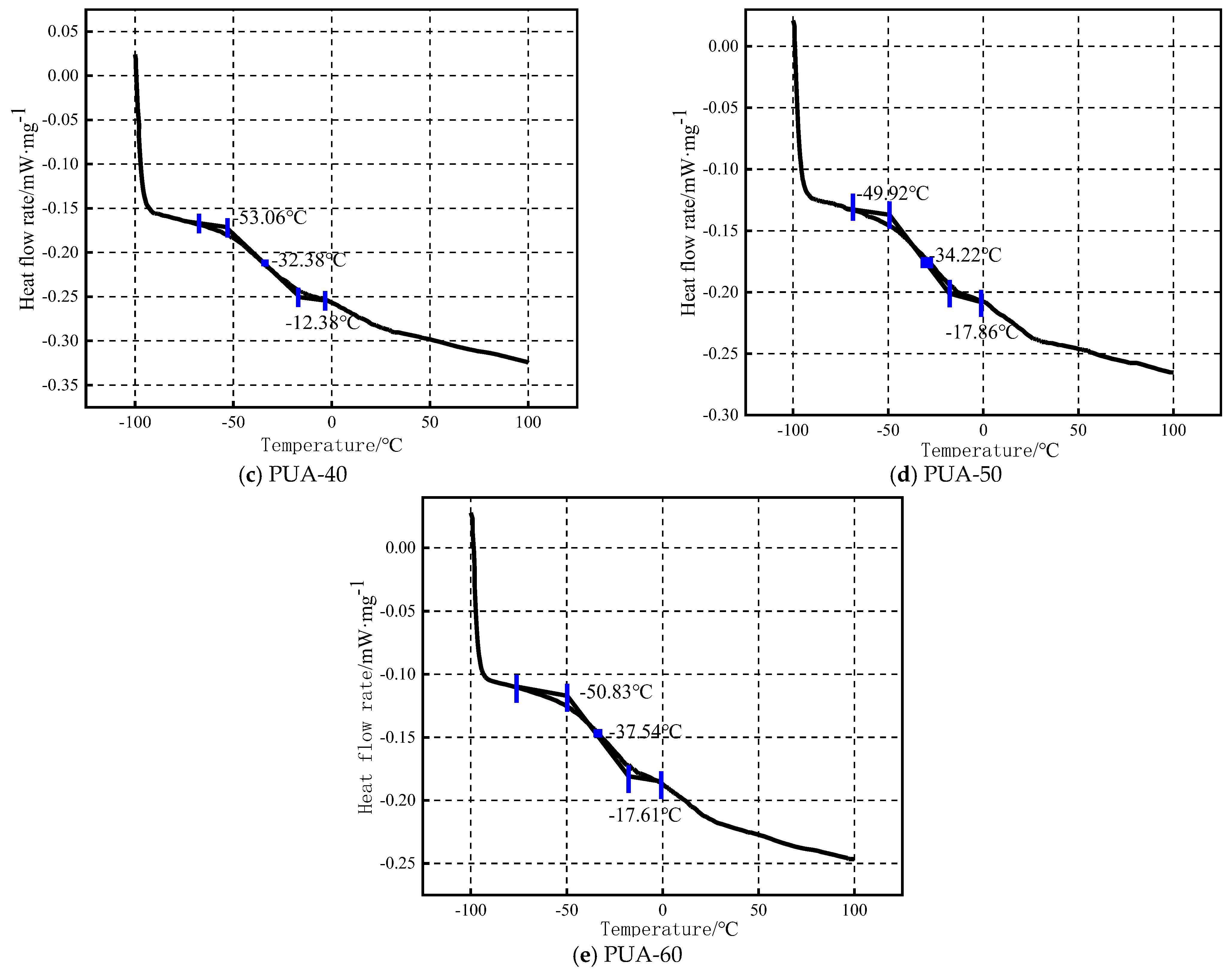

3.4.1. DSC Analysis

3.4.2. SEM Analysis

4. Conclusions

- (1)

- The addition of PU significantly enhanced the elasticity of asphalt at high temperatures, thereby improving its permanent deformation resistance in high-temperature environments. Added PU increased the viscous components of asphalt at low temperatures, ameliorating its low-temperature flexibility.

- (2)

- The tensile properties of asphalt were significantly improved by PU addition. Compared with the base asphalt, the tensile strength of PUA-50 increased by 509%, which was significantly higher than the 157% increase in PUA-40 and achieved a more balanced performance between strength and flexibility than PUA-60. This highlights that 50% PU content optimizes the trade-off between tensile strength and elongation at break.

- (3)

- The incorporation of PU significantly enhanced the elastic properties of asphalt at high temperatures, thereby improving its resistance to permanent deformation in high-temperature environments. In the high-temperature range, the storage modulus of PU-modified asphalt increased with higher PU content, with PUA-50 and PUA-60 exhibiting substantially higher G′ values compared to the base asphalt and PUA-40, indicating a marked improvement in high-temperature deformation resistance. At the same time, PU increased the viscous components of asphalt at low temperatures, effectively improving its low-temperature flexibility.

- (4)

- When the dose of PU was 50% or more, the interface between asphalt and PU was well integrated with a smooth and flat surface, forming a more uniform and stable cross-linked network structure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Polacco, G.; Filippi, S.; Merusi, F.; Stastna, G. A review of the fundamentals of polymer-modified asphalts: Asphalt/polymer interactions and principles of compatibility. Adv. Colloid Interface Sci. 2015, 224, 72–112. [Google Scholar] [CrossRef]

- Si, J.J.; Wang, J.Y.; Yu, X.; Ding, G.Y.; Ruan, W.; Xing, M.M.; Xie, R.X. Influence of thermal-oxidative aging on the mechanical performance and structure of cold-mixed epoxy asphalt. J. Clean. Prod. 2022, 337, 130482. [Google Scholar] [CrossRef]

- Liu, Y.M.; Zheng, M.L.; Zhu, Y.M.; Zhu, L.L.; Li, H.Y.; Liu, P. Preparation and performance of oxidized crumb rubber (OCR)/nano-SiO2 composite-modified asphalt. Constr. Build. Mater. 2021, 279, 122488. [Google Scholar] [CrossRef]

- Zhong, K.; Tian, J.; Wei, X.; Ma, X. The performance test and evaluation of rock asphalt modified asphalt and mixture. Bulg. Chem. Commun. 2017, 49, 520–526. [Google Scholar]

- Wang, Q.; Li, S.; Wu, X.Y.; Wang, S.F.; Ouyang, C.F. Weather aging resistance of different rubber modified asphalts. Constr. Build. Mater. 2016, 106, 443–448. [Google Scholar] [CrossRef]

- Hui, Y.; Zhanping, Y.; Liang, L.; Xianming, S.; Wei, G.S.; Mills-Beale, J.; Wingard, D. Performance of asphalt binder blended with non-modified and polymer-modified nanoclay. Constr. Build. Mater. 2012, 35, 159–170. [Google Scholar]

- Zhang, J.; Zhu, K.; Qiu, G.; Yang, Z.; Zhang, Y. Pavement performance of environmentally friendly asphalt modifier in hot and humid environment. In Proceedings of the 7th Global Conference on Materials Science and Engineering (CMSE), Xian, China, 1–4 November 2018. [Google Scholar]

- Kumar, A.; Choudhary, R.; Kandhal, P.S.; Julaganti, A.; Behera, O.P.; Singh, A.; Kumar, R. Fatigue characterisation of modified asphalt binders containing warm mix asphalt additives. Road Mater. Pavement Des. 2020, 21, 519–541. [Google Scholar] [CrossRef]

- Sun, M.; Zheng, M.L.; Qu, G.Z.; Yuan, K.; Bi, Y.F.; Wang, J. Performance of polyurethane modified asphalt and its mixtures. Constr. Build. Mater. 2018, 191, 386–397. [Google Scholar] [CrossRef]

- Zhang, F.; Hu, C.; Zhang, Y. Influence of montmorillonite on ageing resistance of styrene-ethylene/butylene-styrene-modified asphalt. J. Therm. Anal. Calorim. 2018, 133, 893–905. [Google Scholar] [CrossRef]

- Li, T.; Lu, G.; Liang, D.; Zhang, Y.; Xu, J.; Luo, S.; Wang, D.; Hong, B.; Oeser, M. Polyurethane-precursor-based Chemically Modified Asphalt and Its Modification Mechanism. China J. Highw. Transp. 2021, 34, 45–59. [Google Scholar]

- Cong, L.; Yang, F.; Guo, G.H.; Ren, M.D.; Shi, J.C.; Tan, L. The use of polyurethane for asphalt pavement engineering applications: A state-of-the-art review. Constr. Build. Mater. 2019, 225, 1012–1025. [Google Scholar] [CrossRef]

- Li, S.; Xu, W.Y.; Zhang, F.F.; Wu, H.; Ge, Q.X. Effect of Graphene Oxide on Aging Properties of Polyurethane-SBS Modified Asphalt and Asphalt Mixture. Polymers 2022, 14, 3496. [Google Scholar] [CrossRef]

- Wu, H.; Yang, M.; Song, W.M.; Wu, Z.Z.; Chen, D.W.; Chen, X.B. Mechanical and rheological properties of polyurethane-polyurea (PU-PUa) modified asphalt binder. Constr. Build. Mater. 2024, 411, 134798. [Google Scholar] [CrossRef]

- Xia, L.; Cao, D.W.; Zhang, H.Y.; Guo, Y.S. Study on the classical and rheological properties of castor oil-polyurethane pre polymer (C-PU) modified asphalt. Constr. Build. Mater. 2016, 112, 949–955. [Google Scholar] [CrossRef]

- Zhang, Z.P.; Huang, T.; Sun, J.; Wang, Z.F.; Wang, L.; Li, X.; Liu, H.; Zhang, D.L. Laboratory Study and Molecular Dynamics Simulation of High- and Low-Temperature Properties of Polyurethane-Modified Asphalt. J. Mater. Civ. Eng. 2023, 35, 04023257. [Google Scholar] [CrossRef]

- Terry, E.C.; Berard, R.A.; Pinholster, D.F. Polyurethane Modified Bitumen Coating Composition. U.S. Patent US5981010A, 9 November 1999. [Google Scholar]

- Awazhar, N.A.; Khairuddin, F.H.; Rahmad, S.; Fadzil, S.M.; Omar, H.A.; Yusoff, N.I.M.; Badri, K.H. Engineering and leaching properties of asphalt binders modified with polyurethane and Cecabase additives for warm-mix asphalt application. Constr. Build. Mater. 2020, 238, 117699. [Google Scholar] [CrossRef]

- Zhang, Z.P.; Sun, J.; Jia, M.; Qi, B.; Zhang, H.L.; Lv, W.J.; Mao, Z.Y.; Chang, P.T.; Peng, J.; Liu, Y.C. Study on a thermosetting polyurethane modified asphalt suitable for bridge deck pavements: Formula and properties. Constr. Build. Mater. 2020, 241, 118122. [Google Scholar] [CrossRef]

- Zhang, Z.P.; Sun, J.; Huang, Z.G.; Wang, F.; Jia, M.; Lv, W.J.; Ye, J.J. A laboratory study of epoxy/polyurethane modified asphalt binders and mixtures suitable for flexible bridge deck pavement. Constr. Build. Mater. 2021, 274, 122084. [Google Scholar] [CrossRef]

- He, Q.; Zhang, H.; Li, J.; Duan, H. Performance evaluation of polyurethane/epoxy resin modified asphalt as adhesive layer material for steel-UHPC composite bridge deck pavements. Constr. Build. Mater. 2021, 291, 123364. [Google Scholar] [CrossRef]

- ASTM D4402; Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. American Society for Testing Materials (ASTM): West Conshohocken, PA, USA, 2015.

- GB/T 528-2009; Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China (AQSIQ): Beijing, China, 2009.

- Yu, H.A.; Yao, D.; Qian, G.P.; Zhu, X.; Shi, C.Y. Research on time-temperature-ultraviolet ageing degree superposition of asphalt mortar based on DMA test. Int. J. Pavement Eng. 2022, 23, 4697–4707. [Google Scholar] [CrossRef]

- Wei, K.; Shi, W.S.; Ma, B.A.; Shi, J.H.; Wang, S.F.; Cheng, P.; Liu, Z. Low-temperature performance of asphalt based on temperature stress tests in dynamic cooling conditions. Mater. Today Commun. 2022, 30, 103185. [Google Scholar] [CrossRef]

- Xie, H.F.; Li, C.X.; Wang, Q.J. A critical review on performance and phase separation of thermosetting epoxy asphalt binders and bond coats. Constr. Build. Mater. 2022, 326, 126792. [Google Scholar] [CrossRef]

- Caro, S.; Sánchez, D.B.; Caicedo, B. Methodology to characterise non-standard asphalt materials using DMA testing: Application to natural asphalt mixtures. Int. J. Pavement Eng. 2015, 16, 1–10. [Google Scholar] [CrossRef]

- Yim, Y.-J.; Rhee, K.Y.; Park, S.-J. Fracture toughness and ductile characteristics of diglycidyl ether of bisphenol-A resins modified with biodegradable epoxidized linseed oil. Compos. Part B-Eng. 2017, 131, 144–152. [Google Scholar] [CrossRef]

- Fu, Q.; Xie, Y.; Long, G.; Niu, D.; Song, H. Dynamic mechanical thermo-analysis of cement and asphalt mortar. Powder Technol. 2017, 313, 36–43. [Google Scholar] [CrossRef]

| Indicators | Penetration (25 °C)/0.1 mm | Ductility (10 °C)/cm | Brookfield Rotational Viscosity (135 °C)/mPa·s | Softening Point/°C | Flash Point/°C | Dynamic Viscosity (60 °C)/Pa·s | Density (15 °C)/(g·cm−3) |

|---|---|---|---|---|---|---|---|

| Test value | 65.3 | 56 | 2200 | 48 | 330 | 203 | 1.036 |

| Standard value | 60~80 | ≥10 | — | ≥43 | ≥260 | ≥180 | — |

| Indicators | Unit | Standard Value | Test Value |

|---|---|---|---|

| Ambient state | / | / | Yellow liquid |

| Viscosity (25 °C) | mPa·s | 800–2200 | 1660 |

| Density (25 °C) | g·cm−3 | 1.05~1.11 | 1.10 |

| Tensile strength (25 °C) | MPa | ≥5 | 11.9 |

| Elongation at break (25 °C) | % | ≥80 | 330 |

| Name | Molecular Formula | Appearance (25 °C) | Density (25 °C) | Purity |

|---|---|---|---|---|

| Diethylene Glycol | C4H10O3 | Colorless, transparent, viscous liquid | 1.118 g/cm3 | ≥99% |

| Samples | Asphalt | PUA-40 | PUA-50 | PUA-60 | PU |

|---|---|---|---|---|---|

| Tg/°C | −9.95 | −14.86 | −19.39 | −30.38 | −39.46 |

| Material | Glass Transition Temperature from Glassy State to Highly Elastic State/°C | Initial Transition Temperature from Highly Elastic State to Viscous-Flow State/°C |

|---|---|---|

| Base asphalt | −19.67 | −4.67 |

| PUA-40 | −32.38 | −3.37 |

| PUA-50 | −34.22 | −0.83 |

| PUA-60 | −37.54 | −0.66 |

| Polyurethane | −47.67 | 2.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhuang, W.; Ding, T.; Pang, C.; Jiao, X.; Geng, L.; Sun, M. Mechanical Properties and Modification Mechanism of Thermosetting Polyurethane-Modified Asphalt. Coatings 2025, 15, 912. https://doi.org/10.3390/coatings15080912

Zhuang W, Ding T, Pang C, Jiao X, Geng L, Sun M. Mechanical Properties and Modification Mechanism of Thermosetting Polyurethane-Modified Asphalt. Coatings. 2025; 15(8):912. https://doi.org/10.3390/coatings15080912

Chicago/Turabian StyleZhuang, Wei, Tingting Ding, Chuanqin Pang, Xuwang Jiao, Litao Geng, and Min Sun. 2025. "Mechanical Properties and Modification Mechanism of Thermosetting Polyurethane-Modified Asphalt" Coatings 15, no. 8: 912. https://doi.org/10.3390/coatings15080912

APA StyleZhuang, W., Ding, T., Pang, C., Jiao, X., Geng, L., & Sun, M. (2025). Mechanical Properties and Modification Mechanism of Thermosetting Polyurethane-Modified Asphalt. Coatings, 15(8), 912. https://doi.org/10.3390/coatings15080912