Effect of Absolute Ethanol and Thermal Treatment on Shrinkage and Mechanical Properties of TPU Electrospun Nanofiber Membranes

Abstract

1. Introduction

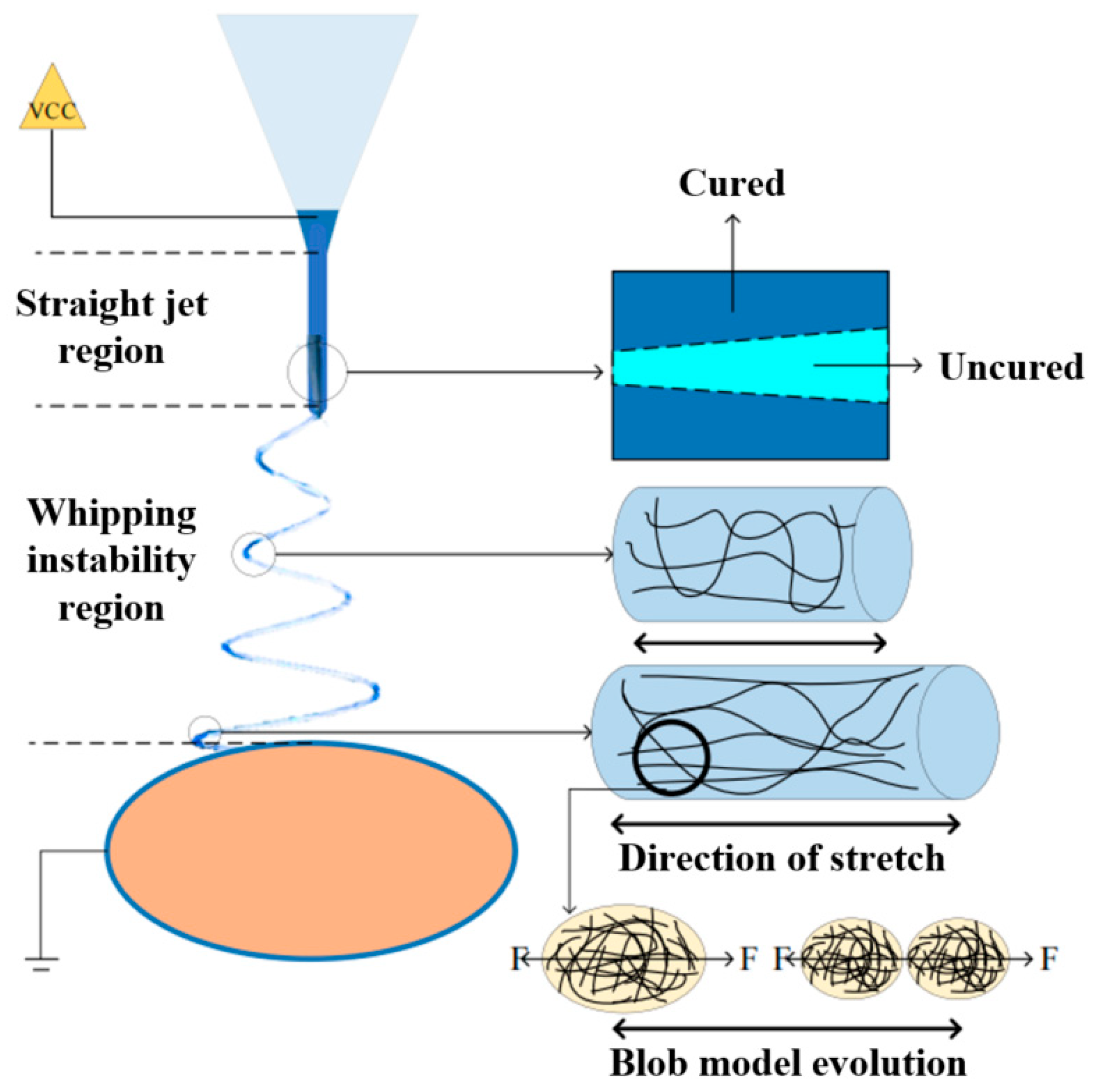

2. Formation Mechanism of Electrospun Nanofiber Membranes

3. Shrinkage Mechanism of TPU Nanofibers

4. Experimental Section

4.1. Materials

4.2. Preparation of TPU Nanofibers

4.3. Shrinkage Test

4.4. Tensile Test

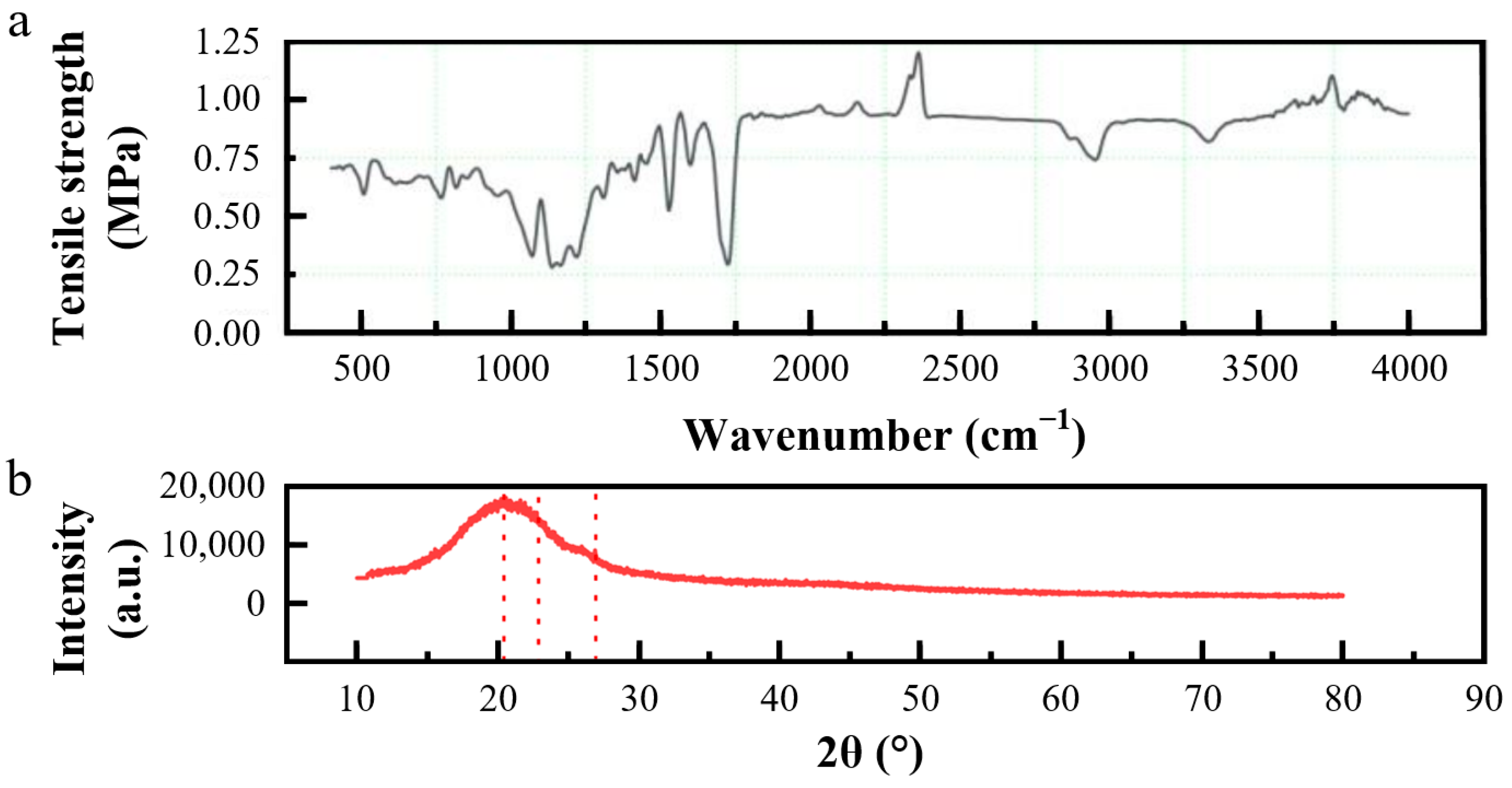

4.5. Material Characterization

5. Results and Discussion

5.1. Effect of Absolute Ethanol Immersion at Room and Elevated Temperatures on Macroscopic Shrinkage Behavior and Tensile Mechanical Properties of Nanofiber Membranes

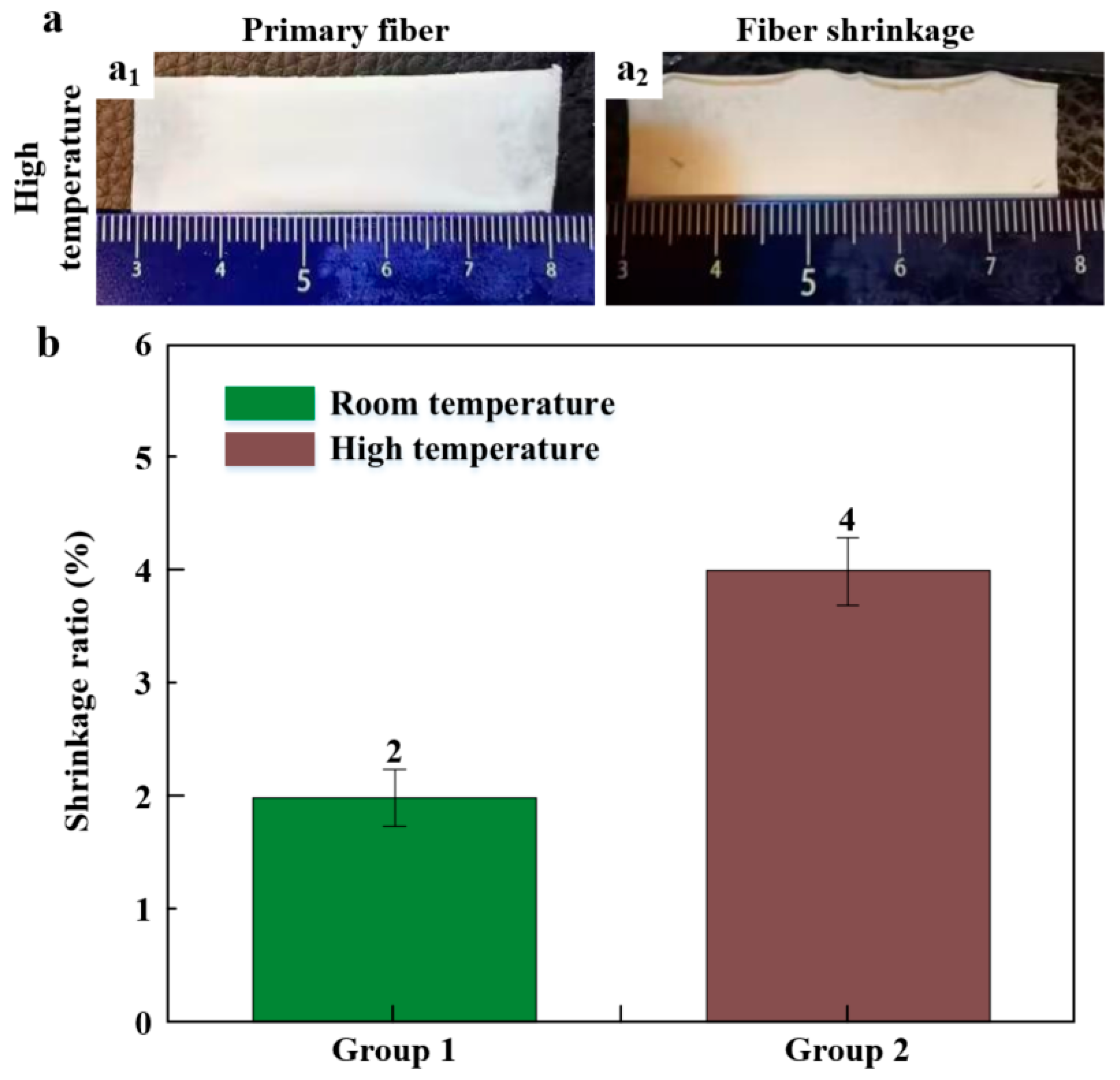

5.1.1. Analysis of Macroscopic Shrinkage Response

5.1.2. Analysis of the Effect of Ethanol Treatment on Membrane Tensile Properties

6. Conclusions

- TPU nanofiber membranes exhibit significant shrinkage in dehydrated ethanol, with the extent of shrinkage being temperature-dependent. After immersion in RT ethanol for 1 h, the shrinkage reached approximately 1 mm (2%). When treated with hot ethanol, the contraction increased to 2 mm (4%), indicating a 200% enhancement in the shrinkage effect with an elevated temperature.

- Although the combined effect of heat and solvent accelerates the contraction process, it also leads to simultaneous deterioration in mechanical performance due to the compromise between strength and ductility. Compared to untreated TPU fibers, the nanofiber membranes subjected to hot ethanol treatment showed a marked reduction in mechanical properties. Both tensile strength and elongation at break decreased significantly, with the elongation reduced to approximately 500–600%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| AR | Analytical reagent |

| GM | Graded membrane |

| PCE | Poly (epsilon-caprolactone-co-ethylene glycol) |

| PLA | Polylactic acid |

| SCE | Shape change effect |

| SMP | Shape memory polymer |

| THF | Tetrahydrofuran |

| DMF | N, N-dimethylformamide |

| PAN | Polyacrylonitrile |

| PCL | Poly (epsilon-caprolactone) |

| RT | Room temperature |

| SME | Shape memory effect |

| Tg | Transition temperature |

| TPU | Thermoplastic polyurethane |

References

- Allami, T.; Alamiery, A.; Nassir, M.H.; Kadhum, A.H. Investigating Physio-Thermo-Mechanical Properties of Polyurethane and Thermoplastics Nanocomposite in Various Applications. Polymers 2021, 13, 2467. [Google Scholar] [CrossRef]

- Atiqah, A.; Mastura, M.T.; Ali, B.A.A.; Jawaid, M.; Sapuan, S.M. A Review on Polyurethane and its Polymer Composites. Curr. Org. Synth. 2017, 14, 233–248. [Google Scholar] [CrossRef]

- Kong, M. Structure Design, Preparation and Performance Evaluation of Thermoplastic Polyurethane Flexible Sensor Based on Electrospinning. Master’s Thesis, Qingdao University of Technology, Qingdao, China, 2024. [Google Scholar]

- Yao, Y.; Xiao, M.; Liu, W.G. A Short Review on Self-Healing Thermoplastic Polyurethanes. Macromol. Chem. Phys. 2021, 222, 2100002. [Google Scholar] [CrossRef]

- Guo, Z.W.; Bi, Y.; Wu, Z.M.; Yuan, C.Q. Biomimetic PVA hydrogel and MMT reinforced TPU water-lubricated bearing materials for superior frictional properties and wear resistance. Wear 2025, 571, 205786. [Google Scholar] [CrossRef]

- Khalifa, M.; Anandhan, S.; Wuzella, G.; Lammer, H.; Mahendran, A.R. Thermoplastic polyurethane composites reinforced with renewable and sustainable fillers—A review. Polym.-Plast. Technol. Mater. 2020, 59, 1751–1769. [Google Scholar] [CrossRef]

- Kong, M.; Zhou, R.Y.; Yang, M.; Zhang, J.; Ma, X.; Gao, T.; Zhang, Y.B.; Li, B.K.; Liu, M.Z.; Cui, X.; et al. Mechanism and Performance Evaluation of a Strain Sensor Made from a Composite Hydrogel Containing Conductive Fibers of Thermoplastic Polyurethane and Polyvinyl Alcohol. Acs Omega 2024, 9, 43743–43755. [Google Scholar] [CrossRef]

- Zhang, W.X.; Miao, J.L.; Tian, M.W.; Zhang, X.J.; Fan, T.T.; Qu, L.J. Hierarchically interlocked helical conductive yarn enables ultra-stretchable electronics and smart fabrics. Chem. Eng. J. 2023, 462, 142279. [Google Scholar] [CrossRef]

- He, Y.F.; Liu, Q.J.; Tian, M.W.; Zhang, X.J.; Qu, L.J.; Fan, T.T.; Miao, J.L. Highly conductive and elastic multi-responsive phase change smart fiber and textile. Compos. Commun. 2023, 44, 101772. [Google Scholar] [CrossRef]

- Ren, M.N.; Wu, Q.S.; Huang, X. Flexible tactile sensors inspired by bio-mechanoreceptors. Biosens. Bioelectron. 2025, 267, 116828. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Cheng, L.; Wen, S.Z.; Zhou, S.B.; Wang, Z.; Deng, L.F.; Mao, H.Q.; Cui, W.G.; Zhang, H.Y. Ice-Inspired Superlubricated Electrospun Nanofibrous Membrane for Preventing Tissue Adhesion. Nano Lett. 2020, 20, 6420–6428. [Google Scholar] [CrossRef]

- Wong, D.; Resendiz, J.; Egberts, P.; Park, S.S. Electrospinning of composite microbeads for tribological improvements. J. Manuf. Process. 2018, 34, 264–273. [Google Scholar] [CrossRef]

- Beniwal, A.; Sunny. Novel TPU/Fe2O3 and TPU/Fe2O3/PPy nanocomposites synthesized using electrospun nanofibers investigated for analyte sensing applications at room temperature. Sens. Actuators B Chem. 2020, 304, 127384. [Google Scholar] [CrossRef]

- Dong, R.H.; Liu, X.Y.; Cheng, S.Y.; Tang, L.X.; Chen, M.; Zhong, L.N.; Chen, Z.; Liu, S.Q.; Jiang, X.Y. Highly Stretchable Metal-Polymer Conductor Electrode Array for Electrophysiology. Adv. Healthc. Mater. 2021, 10, 2000641. [Google Scholar] [CrossRef]

- Kang, L.H.; Ma, J.; Wang, C.; Li, K.C.; Wu, H.Y.; Zhu, M.F. Highly Sensitive and Wide Detection Range Thermoplastic Polyurethane/Graphene Nanoplatelets Multifunctional Strain Sensor with a Porous and Crimped Network Structure. Acs Appl. Mater. Interfaces 2024, 16, 2814–2824. [Google Scholar] [CrossRef]

- Fang, F.Y.; Wang, H.; Wang, H.Q.; Huang, W.M.; Chen, Y.H.; Cai, N.A.; Chen, X.D.; Chen, X. Stimulus-Responsive Shrinkage in Electrospun Membranes: Fundamentals and Control. Micromachines 2021, 12, 920. [Google Scholar] [CrossRef]

- Kong, M.; Yang, M.; Li, R.Z.; Long, Y.Z.; Zhang, J.; Huang, X.; Cui, X.; Zhang, Y.B.; Said, Z.; Li, C.H. Graphene-based flexible wearable sensors: Mechanisms, challenges, and future directions. Int. J. Adv. Manuf. Technol. 2024, 131, 3205–3237. [Google Scholar] [CrossRef]

- Chen, Y.C.; Zhong, W.Y.; Jia, X.Y.; Hu, D.D.; Sun, J.Y.; Peng, Y.; Yu, J.B.; Jiang, X.L.; Wang, H.F.; Zhao, L. Microcellular Thermoplastic Polyurethane (TPU) with Multimodal Cell Structure Fabricated Based on Pressure Swing Strategy and Its Compressive Mechanical Properties. Ind. Eng. Chem. Res. 2024, 63, 8833–8845. [Google Scholar] [CrossRef]

- Lai, S.M.; Lin, T.Y.; Huang, G.L. A novel multi-triggered reversible shape memory thermoplastic polyurethane (TPU)/polycaprolactone (PCL) blend. J. Polym. Res. 2023, 30, 64. [Google Scholar] [CrossRef]

- Hou, L.L.; Liu, J.C.; Li, D.M.; Gao, Y.; Wang, Y.Q.; Hu, R.J.; Ren, W.; Xie, S.X.; Cui, Z.M.; Wang, N. Electrospinning Janus Nanofibrous Membrane for Unidirectional Liquid Penetration and Its Applications. Chem. Res. Chin. Univ. 2021, 37, 337–354. [Google Scholar] [CrossRef]

- Wang, X.X.; Li, N.; Yang, A.L.; Zhang, N.F.; Qiu, W.; Yang, D.P. Amino oxidized sodium alginate-based humidity-resistant triboelectric nanogenerator for human motion and respiration monitoring. Chem. Eng. J. 2025, 506, 159842. [Google Scholar] [CrossRef]

- Al Haddad, Z.A.; Svinterikos, E.; Zuburtikudis, I. Designing electrospun nanocomposite poly(vinylidene fluoride) mats with tunable wettability. Colloids Surf. A-Physicochem. Eng. Asp. 2017, 523, 81–90. [Google Scholar] [CrossRef]

- Lu, T.D.; Wang, Q.; Gu, S.S.; Sun, S.P. Beyond Symmetry: Exploring Asymmetric Electrospun Nanofiber Membranes for Liquid Separation. Adv. Funct. Mater. 2024, 34, 2310218. [Google Scholar] [CrossRef]

- Zaidouny, L.; Abou-Daher, M.; Tehrani-Bagha, A.R.; Ghali, K.; Ghaddar, N. Electrospun nanofibrous polyvinylidene fluoride-co-hexafluoropropylene membranes for oil-water separation. J. Appl. Polym. Sci. 2020, 137, 49394. [Google Scholar] [CrossRef]

- Bai, T.H.; Wang, Y.Q.; Zhu, K.P.; Zhang, X.F.; Mu, Y.; Liu, J.C.; Yue, G.C.; Cui, Z.M.; Wang, N.; Bai, J.; et al. Multifunctional ultraelastic helical conductive yarn for motion detection and human-machine interaction. Chem. Eng. J. 2024, 498, 155143. [Google Scholar] [CrossRef]

- Guo, R.; Li, T.Y.; Jiang, C.J.; Zong, H.; Li, X.T.; Wan, C.X.; Yu, H.X.; Huang, X. Pressure Regulated Printing of Semiliquid Metal on Electrospinning Film Enables Breathable and Waterproof Wearable Electronics. Adv. Fiber Mater. 2024, 6, 354–366. [Google Scholar] [CrossRef]

- Luo, Y.X.; Li, S.; Xiao, L.; Teng, Y.Q.; Tian, R.; Li, T.; Liu, Y.H.; Li, D.M.; Feng, L.B. A gradient wettability fiber membrane for desalination and wastewater purification by solar-driven interfacial evaporation. Appl. Surf. Sci. 2025, 682, 161624. [Google Scholar] [CrossRef]

- Shen, Q.; Jiang, Y.; Guo, S.Z.; Huang, L.; Xie, H.B.; Li, L. One-step electrospinning membranes with gradual-transition wettability gradient for directional fluid transport. J. Membr. Sci. 2022, 644, 120091. [Google Scholar] [CrossRef]

- Han, H.N.; Shen, Q.; Wu, W.L.; Jiao, J.J.; Li, L.; Shao, J.J.; Zhu, T.; Xu, P. A wettability and structure gradient electrospun membrane for highly efficient emulsion separation. Sep. Purif. Technol. 2024, 342, 127047. [Google Scholar] [CrossRef]

- Zhu, X.; Wu, Y.M.; Feng, S.S.; Zhao, X.Y.; Xue, T.Z.; Zhong, Z.X.; Zhong, J. Design and fabrication of gradient wettability PAN nanofiber membrane for enhanced liquid transport and efficient air purification. Sep. Purif. Technol. 2025, 367, 132938. [Google Scholar] [CrossRef]

- Jiang, G.J.; Johnson, L.; Xie, S. Investigations into the mechanisms of electrohydrodynamic instability in free surface electrospinning. Open Phys. 2019, 17, 313–319. [Google Scholar] [CrossRef]

- Ma, Y.Q.; Zhou, R.Y.; Yang, M.; Zhang, J.; Song, W.; Ma, X.; Liu, M.Z.; Cui, X.; Li, B.K.; Zhang, Y.B.; et al. Electrospinning-based bone tissue scaffold construction: Progress and trends. Mater. Des. 2025, 252, 113792. [Google Scholar] [CrossRef]

- Zheng, C.H.; Chen, J.; Zhang, Y.Z.; Zhou, S.; Wang, L.X.; Zhou, J.; Chen, X.F.; Yang, D.P.; Hong, Y.M. Sandwich-type electrochemical immunosensing of hypopharyngeal carcinoma biomarker carcinoembryonic antigen based on N-doped hollow mesoporous nanocarbon spheres/gold hybrids as sensing platform and gold/ferrocene as signal amplifier. Anal. Sci. 2023, 39, 5–11. [Google Scholar] [CrossRef]

- Yu, M.; Dong, R.H.; Yan, X.; Yu, G.F.; You, M.H.; Ning, X.; Long, Y.Z. Recent Advances in Needleless Electrospinning of Ultrathin Fibers: From Academia to Industrial Production. Macromol. Mater. Eng. 2017, 302, 1700002. [Google Scholar] [CrossRef]

- Zhou, R.Y.; Ma, Y.Q.; Yang, M.; Cheng, Y.X.; Ma, X.; Li, B.K.; Zhang, Y.B.; Cui, X.; Liu, M.Z.; Long, Y.Z.; et al. Wound dressings using electrospun nanofibers: Mechanisms, applications, and future directions. Eur. Polym. J. 2025, 231, 113900. [Google Scholar] [CrossRef]

- Taylor, G.I. Electrically driven jets. Proc. R. Soc. London A Math. Phys. Sci. 1969, 313, 453–475. [Google Scholar] [CrossRef]

- Rutledge, G.C.; Fridrikh, S.V. Formation of fibers by electrospinning. Adv. Drug Deliv. Rev. 2007, 59, 1384–1391. [Google Scholar] [CrossRef] [PubMed]

- Fridrikh, S.V.; Yu, J.H.; Brenner, M.P.; Rutledge, G.C. Controlling the fiber diameter during electrospinning. Phys. Rev. Lett. 2003, 90, 144502. [Google Scholar] [CrossRef]

- Reneker, D.H.; Yarin, A.L. Electrospinning jets and polymer nanofibers. Polymer 2008, 49, 2387–2425. [Google Scholar] [CrossRef]

- Liu, X.X.; Hu, J.L.; Babu, K.M.; Wang, S.Y. Elasticity and Shape Memory Effect of Shape Memory Fabrics. Text. Res. J. 2008, 78, 1048–1056. [Google Scholar] [CrossRef]

- Wu, X.L.; Huang, W.M.; Lu, H.B.; Wang, C.C.; Cui, H.P. Characterization of polymeric shape memory materials. J. Polym. Eng. 2017, 37, 1–20. [Google Scholar] [CrossRef]

- Zhang, J.L.; Huang, W.M.; Gao, G.R.; Fu, J.; Zhou, Y.; Salvekar, A.V.; Venkatraman, S.S.; Wong, Y.S.; Tay, K.H.; Birch, W.R. Shape memory/change effect in a double network nanocomposite tough hydrogel. Eur. Polym. J. 2014, 58, 41–51. [Google Scholar] [CrossRef]

- Zhang, J.L.; Huang, W.M.; Lu, H.B.; Sun, L. Thermo-/chemo-responsive shape memory/change effect in a hydrogel and its composites. Mater. Des. 2014, 53, 1077–1088. [Google Scholar] [CrossRef]

- Idumah, C.I.; Odera, R.S.; Ezeani, E.O.; Low, J.H.; Tanjung, F.A.; Damiri, F.; Luing, W.S. Construction, characterization, properties and multifunctional applications of stimuli-responsive shape memory polymeric nanoarchitectures: A review. Polym.-Plast. Technol. Mater. 2023, 62, 1247–1272. [Google Scholar] [CrossRef]

- Pisani, S.; Genta, I.; Modena, T.; Dorati, R.; Benazzo, M.; Conti, B. Shape-Memory Polymers Hallmarks and Their Biomedical Applications in the Form of Nanofibers. Int. J. Mol. Sci. 2022, 23, 1290. [Google Scholar] [CrossRef]

- Salaris, V.; Leonés, A.; Lopez, D.; Kenny, J.M.; Peponi, L. Shape-Memory Materials via Electrospinning: A Review. Polymers 2022, 14, 995. [Google Scholar] [CrossRef]

- Zhuo, H.T.; Hu, J.L.; Chen, S.J. Electrospun polyurethane nanofibres having shape memory effect. Mater. Lett. 2008, 62, 2074–2076. [Google Scholar] [CrossRef]

- Coccia, M.; Farotti, E.; Chiappini, G.; Bellezze, T.; Sasso, M. Effects of temperature, strain and strain rate on shape memory thermoplastic polyurethane processed by injection molding. J. Intell. Mater. Syst. Struct. 2023, 34, 751–765. [Google Scholar] [CrossRef]

- Xia, Y.L.; He, Y.; Zhang, F.H.; Liu, Y.J.; Leng, J.S. A Review of Shape Memory Polymers and Composites: Mechanisms, Materials, and Applications. Adv. Mater. 2021, 33, 2000713. [Google Scholar] [CrossRef]

- Alhazov, D.; Burman, M.; Arinstein, A.; Zussman, E. Relaxation Suppression in a Stretched Copolymer Matrix Above Tg. J. Polym. Sci. Part B-Polym. Phys. 2015, 53, 1254–1259. [Google Scholar] [CrossRef]

- Li, D.M.; Yue, G.C.; Li, S.; Liu, J.; Li, H.K.; Gao, Y.; Liu, J.C.; Hou, L.L.; Liu, X.F.; Cui, Z.M.; et al. Fabrication and Applications of Multi-Fluidic Electrospinning Multi-Structure Hollow and Core-Shell Nanofibers. Engineering 2022, 13, 116–127. [Google Scholar] [CrossRef]

- Wang, C.C.; Zhao, Y.; Purnawali, H.; Huang, W.M.; Sun, L. Chemically induced morphing in polyurethane shape memory polymer micro fibers/springs. React. Funct. Polym. 2012, 72, 757–764. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Kong, M.; Wang, S.; Li, C.; Yang, M. Effect of Absolute Ethanol and Thermal Treatment on Shrinkage and Mechanical Properties of TPU Electrospun Nanofiber Membranes. Coatings 2025, 15, 897. https://doi.org/10.3390/coatings15080897

Wang L, Kong M, Wang S, Li C, Yang M. Effect of Absolute Ethanol and Thermal Treatment on Shrinkage and Mechanical Properties of TPU Electrospun Nanofiber Membranes. Coatings. 2025; 15(8):897. https://doi.org/10.3390/coatings15080897

Chicago/Turabian StyleWang, Lei, Ming Kong, Shengchun Wang, Chunsheng Li, and Min Yang. 2025. "Effect of Absolute Ethanol and Thermal Treatment on Shrinkage and Mechanical Properties of TPU Electrospun Nanofiber Membranes" Coatings 15, no. 8: 897. https://doi.org/10.3390/coatings15080897

APA StyleWang, L., Kong, M., Wang, S., Li, C., & Yang, M. (2025). Effect of Absolute Ethanol and Thermal Treatment on Shrinkage and Mechanical Properties of TPU Electrospun Nanofiber Membranes. Coatings, 15(8), 897. https://doi.org/10.3390/coatings15080897