Abstract

Thermoplastic polyurethane (TPU) electrospun fiber membranes possess unique micro-nano structures and excellent properties. Adjusting their wettability enables the directional transportation of lubricants. A conventional method for adjusting porosity and wettability involves inducing membrane shrinkage using absolute ethanol and heat treatment. However, the shrinkage response and the corresponding changes in the tensile properties of TPU fiber membranes after induction remain unclear, limiting their applications. Thus, in this study, after being peeled off, the samples were first left to stand at room temperature (RT) for 24 h to release residual stress and stabilize their dimensions, and then treated with dehydrated ethanol at RT and high temperature, respectively, with their shrinkage behaviors observed and recorded. The results showed that TPU nanofiber membranes shrank significantly in absolute ethanol, and the degree of shrinkage was temperature-dependent. The shrinkage rates were 2% and 4% in dehydrated ethanol at room temperature and high temperature, respectively, and heating increased the shrinkage effect by 200%. These findings prove that absolute ethanol causes TPU fibers to shrink, and high temperatures further promote shrinkage. However, although the strong synergistic effect of heat and solvent accelerates shrinkage, it may induce internal structural defects, resulting in the deterioration of mechanical properties. The contraction response induced by anhydrous ethanol stimulation can be used to directionally adjust the local density and modulus of TPU nanofiber membranes, thereby changing the wettability. This approach provides new opportunities for applications in areas such as medium transportation and interface friction reduction in lubrication systems.

1. Introduction

TPU is a linear multi-block copolymer composed of hard segments (rigid segments formed by the polycondensation of diisocyanates and short-chain diols) and soft segments (flexible segments consisting of polyether polyols or polyesters). Its unique phase-separated structure endows the material with excellent elasticity, the shape memory effect, and adjustable mechanical strength [1,2,3,4]. Compared to polymers such as polylactic acid (PLA) and polycaprolactone (PCL), TPU is more suitable as the research object for shrinkage tests. PLA and PCL have high rigidity, which tends to restrict shrinkage behavior, while TPU can produce stable and controllable shrinkage under stimulation and still maintain good mechanical properties after shrinkage [5,6,7,8]. The TPU nanofiber membrane prepared via electrospinning technology not only provides an ideal model for the study of shrinkage behavior but also shows unique advantages in the field of lubrication: not only can its porous network structure efficiently store lubricants, but the high specific surface area of the fiber membrane can also enhance the interface interaction with lubricating media [9,10,11,12].

Solvent treatment is a key method for regulating the structure and performance of electrospun membranes, among which absolute ethanol has become a preferred stimulant due to its environmental friendliness and ease of use [13,14,15]. In comparison, water exhibits a weak stimulation intensity and a slow shrinkage rate, while strong solvents such as acetone tend to excessively damage the fiber structure. In contrast, absolute ethanol can efficiently activate the shape memory effect of TPU through hydrogen bonding to induce shrinkage [16,17]. Studies have shown that ethanol molecules can penetrate the interior of the fiber membrane, destroy the intermolecular forces of the polymer, and induce fiber rearrangement and contraction. This shrinkage behavior not only changes the porosity and fiber arrangement of the membrane but may also affect the micro-nano structure of the membrane surface, thereby significantly influencing its physical properties and wettability [18,19]. In lubrication applications, changes in membrane structure are directly related to the efficiency of lubricant storage, release, and directional transport. Therefore, revealing the mechanism of solvent-induced shrinkage is of great significance [20,21]. It is worth noting that the local density difference induced by solvents can further trigger a wettability gradient, providing a structural basis for the realization of directional lubricant transport [22,23,24].

In the research on gradient wettability and directional liquid transport, electrospinning technology has become a core research method due to its unique ability to construct micro-nano structures [25,26,27]. In recent years, by regulating the spinning process and material system, researchers have made breakthroughs in the precise design of gradient wettability and the optimization of liquid transport performance. Shen et al. [28] prepared a porous membrane with a bidirectional, gradual transition wettability gradient using PCL and poly (epsilon-caprolactone-co-ethylene glycol) (PCE) as raw materials. Compared to traditional membranes with abrupt gradients or uniform wettability, this membrane achieved efficient unidirectional liquid transport, and the flux increased significantly with the number of gradient layers, showing excellent application potential in oil/water separation and other fields, and opening up a new path for the design of multifunctional membrane materials. Han et al. [29] prepared a functionally graded membrane (GM) with both wettability (superhydrophilic/hydrophobic) and structural (GO spindle) gradients using a one-step electrospinning method. The results showed that the GM achieved efficient emulsion separation under gravity driven by the gradient, demonstrating a higher flux than homogeneous membranes, along with antifouling properties and reusability, providing a new solution for low-energy oil/water separation. To address the impact that condensed droplets in high-humidity environments have on the air filtration performance of nanofiber membranes, Zhu et al. [30] developed a polyacrylonitrile (PAN) nanofiber membrane with gradient wettability, which achieved a filtration efficiency of 99.85% and a significant reduction in pressure drop under high humidity.

These studies indicate the importance of electrospun membranes with gradient wettability in enhancing the efficiency of directional liquid transport. Specifically, external stimuli-induced gradient evolution of membrane microstructures has shown significant potential for precise wettability control. However, further in-depth research is needed on the stimulus–response mechanisms in specific systems, particularly for lubricant transport applications sensitive to mechanical properties. Against this backdrop, this paper investigates the shrinkage mechanism of TPU, as well as the contraction behavior and tensile properties of TPU nanofiber membranes under the combined stimuli of anhydrous ethanol and heat treatment, aiming to lay a foundation for subsequent exploration of their applications in fields such as directional lubricant transport. By leveraging the controllable shrinkage induced by ethanol stimulation, the local density and modulus of the membranes can be directionally tailored, ultimately providing robust support for the precise directional transport of lubricants.

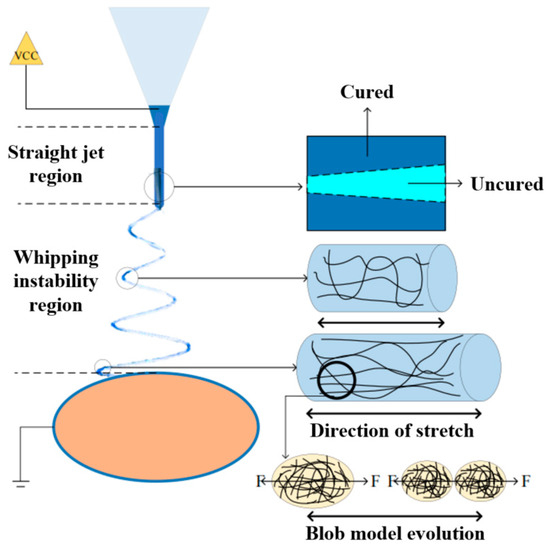

2. Formation Mechanism of Electrospun Nanofiber Membranes

The basic electrospinning process: under the influence of a high-voltage electric field, the charged solution overcomes surface tension and forms a jet [31,32,33]. After passing through a stable linear region and an unstable whipping region, the charged jet undergoes evaporation and cooling, eventually being stretched and collected on a rotating drum to obtain electrospun nanofibers [34,35].

During the spinning process, the system is primarily influenced by the gravitational force, the Coulomb force from the external electric field, and the electrostatic repulsion of the surface charges of the polymer solution, all of which act together:

here, y denotes the surface tension, FE the electrostatic force, FG the gravitational force, y0 the surface tension coefficient, Rd the droplet radius, V the volume of the droplet, σ0 the surface charge density, g the gravitational acceleration, p0 the solution density, and ε0 the vacuum permittivity.

During the electrospinning process, as the electric field intensity increases, the hemispherical droplet gradually overcomes the resistance from surface tension and gravity, becoming elongated to form a Taylor cone. As the electrostatic force continues to stretch the Taylor cone, a jet is ejected from its tip. The critical voltage at which this occurs is given by:

here, L, H, and Rs represent the protruding length of the nozzle beyond the electrode plate, the distance from the nozzle to the collector, and the nozzle diameter, respectively [36].

In this context, σ denotes the electrical conductivity of the solution, β is the dielectric discontinuity parameter, and E, Q, and I correspond to the electric field intensity, solution flow rate, and current, respectively. When the viscoelasticity of the solution dominates, the jet passes through a straight segment known as the stable region. In this region, both viscoelasticity and electrostatic repulsion affect the jet behavior. Therefore, the length L of the straight segment of the stable jet can be analyzed and determined accordingly [37].

The parameters Φ, ε, and rt denote the dimensionless wavelength of the instability, the dielectric constant, and the jet diameter at its terminal point, respectively [38]. In the unstable whipping region, Reneker et al. [39] found that the whipping jet undergoes complex processes such as whipping, bending, and stretching, which help reduce the diameter of the jet. Fridrikh et al. [38] studied this unstable region and established a relationship between the jet diameter and the degree of whipping, as shown in the aforementioned equation. Finally, further stretching occurs on the collector surface, resulting in the formation of nanofiber membranes.

3. Shrinkage Mechanism of TPU Nanofibers

The shape memory effect (SME) is a functional property of materials that solely depends on the molecular structure of polymers and the combination of specific programming and processing methods [40,41]. In contrast, the shape change effect (SCE) differs from the SME in that it does not involve a programming step, and the shape change results from conditions that induce plastic deformation [42,43]. The swelling behavior of hydrogels can be classified as an SCE. In comparison, the contraction of nanofibers can be attributed to the SME, as nanofibers are unable to spontaneously return to their original shape upon external stimulation [44,45]. Furthermore, the electrospinning process, comprising polymer stretching, molecular orientation, and rapid solidification, can be considered a programming stage of the SME. This implies that the processing parameters of electrospinning can be utilized to regulate the programming of shape memory behavior [46,47].

In the mechanism of thermal shrinkage, the thermomechanical model is used to explain the thermodynamic behavior of shape memory polymers (SMPs) [48,49]. In this model, the molecular chains are considered a mixture of small-diameter, long-length springs that are interwoven with one another. Each molecular chain is randomly oriented, resulting in a high entropy state within the polymer. As the temperature increases, the molecular mobility increases, and the polymer exhibits thermoviscoelastic behavior. Therefore, when the molecular chains are oriented or stretched under an external force, the alignment of the chains leads to a decrease in entropy. As the temperature decreases, the polymer loses its viscoelasticity, and molecular motion weakens. As a result, the molecular chains are unable to return to their initial state. However, stress is stored in the molecular chains as elastic potential energy. When the temperature rises again, the polymer regains its viscoelasticity and releases the elastic potential energy.

Moreover, materials with an RT higher than their glass transition temperature still exhibit contraction behavior, which cannot be well explained by the previously discussed theoretical models. To address this, Alhazov et al. [50] proposed the “blob” hypothetical model to explain the thermal shrinkage observed in nanofibers at RT. A comparative study of electrospun TPU nanofiber membranes and conventional TPU films revealed that the supramolecular structure of the TPU polymer significantly influences its contraction characteristics. The hard segments of the polymer macromolecules can form non-crystalline clusters, which consist of molecular connections formed by one or more soft segments from polymer chains. However, due to the low density of these hard segments, they cannot form a percolating structure of hard microphases. Upon heating, some of the hard segment clusters are altered, disrupting the fixed network topology. As a result, the polymer chains decompose into “blob”-like structures. Each blob consists of macromolecular chains between two adjacent hard segment clusters. Heating disrupts the ordered hard segment clusters, leading to an increase in the average diameter and a decrease in the number of blobs along a single chain. This disruption destabilizes the previously balanced and relaxed state maintained at RT. When the material is stretched under external force and then cooled, the restructured blobs within the chains become fixed in a stretched configuration. Eventually, local relaxation occurs within the blobs, allowing the stretched structure of the reconfigured chains to be partially preserved. This sequence of heating, cluster disruption, and blob merging leads to a non-equilibrium state within the fiber matrix, ultimately causing macroscopic shrinkage.

Due to the complexity of the shrinkage mechanism, in practical laboratory settings, factors such as heat transfer methods and cooling processes contribute to fiber behavior. During the electrospinning process, nanofibers undergo cooling and solvent evaporation, causing the outer “shell” of the fiber to solidify first under plastic deformation (e.g., through drum rotation), while the inner “core” remains in an unsolidified, fluid-like state [51]. This differential solidification process leads to the development of pre-strain within the fibers during cooling.

Building on this understanding, Wang et al. [52] proposed that under ethanol stimulation, the release of pre-strain/stress in nanofibers is the direct driving force for deformation, and the fiber diameter has a significant impact on this process. It was observed in the study that there are obvious differences in the deformation responses of polyurethane microfibers/springs with different wire diameters in ethanol: a spring with a wire diameter of approximately 50 μm starts to contract/twist within 2 s in ethanol, while a spring with a wire diameter of about 140 μm requires a longer time to show obvious deformation. This indicates that finer fibers have faster internal stress release and deformation response due to the faster diffusion rate of ethanol. A schematic diagram illustrating the fiber shrinkage mechanism is shown in Figure 1.

Figure 1.

Schematic illustration of the shrinkage mechanism of TPU fibers.

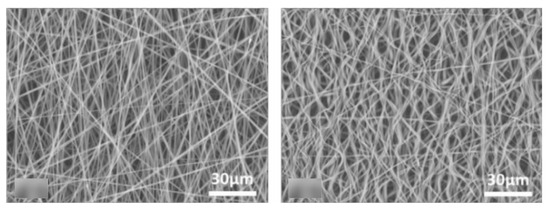

As shown in Figure 2, Fang et al. [16] observed via scanning electron microscopy (SEM) that after ethanol treatment, the fibers in the electrospun TPU nanofiber membrane transformed from their originally relatively straight state to a significantly crimped morphology. In this study, ethanol acts as a stimulant, causing the pre-strained “shell” of the fiber’s outer layer to shrink, while the inner “core” remains relatively stable due to incomplete softening. This gradient stress state ultimately results in the crimped microstructure of the fibers, which is consistent with the conclusion in the aforementioned shrinkage mechanism that deformation is driven by a gradient pre-strain field. Meanwhile, their experiments also demonstrated that adjusting the electrospinning process parameters can affect the distribution of fiber pre-strain and thereby alter the shrinkage behavior.

Figure 2.

Shrinkage of TPU nanofibers under ethanol stimulation [16].

4. Experimental Section

4.1. Materials

TPUs were purchased from Risheng Co., Ltd. (Hangzhou, China). N, N-Dimethylformamide (DMF) and absolute ethanol were obtained from Shanghai Zhanyun Chemical Co., Ltd. (Shanghai, China). Tetrahydrofuran (THF) was sourced from Energy Chemical (Shanghai, China). All chemical reagents and solvents described in this work were of analytical reagent (AR) grade and were used without further purification.

4.2. Preparation of TPU Nanofibers

Firstly, DMF and THF were mixed at a mass ratio of 1:1 to prepare the solvent. Subsequently, a predetermined mass of TPU pellets was accurately weighed and added to the mixed solvent, followed by magnetic stirring at 80 °C for 5 h to obtain a TPU precursor solution with a concentration of 22 wt%. Once the TPU precursor solution became uniform, clear, and transparent, it was allowed to stand and cool to RT.

In the electrospinning process, a 10 mL syringe equipped with a 27G stainless steel needle was used. After loading the prepared precursor solution into the syringe, it was mounted onto a precision syringe pump with a constant feed rate of 18 μL/min. To facilitate the effective collection of nanofibers, high-flatness silicone oil paper was tightly adhered to the surface of a metal drum collector, and the drum rotation speed was set to 300 rpm. The distance between the stainless steel needle and the drum collector was set to 18 cm, while the reciprocating platform operated with a stroke of 10 cm and a movement speed of 10 mm/min. A DC high-voltage power supply was turned on, and the spinning voltage was adjusted to 14.5 kV. Under this specific voltage, the solution overcame its surface tension and was ejected from the tip of the Taylor cone to form a stable jet. The jet underwent continuous thinning and solidification under the combined effects of stretching in the electrostatic field and solvent evaporation, and the formed fibers were deposited on the surface of the drum collector. The rotation of the drum and the reciprocating movement of the platform synergistically promoted the extension of the jet, ultimately forming a structurally uniform, nonwoven nanofiber membrane with a thickness of 120 ± 5 μm on the substrate. It is worth noting that this experiment was conducted under conventional laboratory conditions with a room temperature of (25 ± 2 °C), an ambient humidity of (60 ± 5% RH), and a neutral pH (approximately 7.0).

4.3. Shrinkage Test

The shrinkage behavior of TPU nanofiber membranes was tested using anhydrous ethanol at room temperature and hot anhydrous ethanol (i.e., heated to 90 °C in a constant-temperature water bath under a sealed environment). After peeling the TPU nanofiber membranes from the drum collector, they were first allowed to stand at room temperature for 24 h to ensure the complete release of residual stress generated by curing or stretching during the collection process and to stabilize their dimensions.

In the experiment, all specimens were selected from the middle area of TPU nanofiber membranes prepared in the same batch, with avoidance of membrane edges and areas with obvious defects. A template of uniform specifications was used for sample cutting to ensure that the dimensional deviation of each specimen was controlled within ±0.5 mm. Meanwhile, the same operational procedures and environmental conditions (such as room temperature and humidity) were applied to all samples during the processes of peeling, standing, and treatment to reduce accidental errors in the preparation process. Subsequently, the membranes were cut into rectangular specimens with a length of 50 mm. In the test, the samples were immersed in anhydrous ethanol at room temperature and at high temperature for 1 h, respectively, and then taken out. After the residual solvent on the surface was gently blotted dry with filter paper, their lengths were measured again.

4.4. Tensile Test

The mechanical properties of pure TPU and TPU nanofiber membranes treated with hot anhydrous ethanol (i.e., heated to 90 °C in a constant-temperature water bath under a sealed environment) were tested using an electronic universal testing machine. The TPU nanofiber membranes were peeled from the drum collector and cut into rectangular specimens with a length of 50 mm. The tests were conducted at room temperature with a loading rate of 50 mm/min until the samples fractured. The stress–strain curve was recorded via the data analysis system of the testing machine.

It is worth noting that in the study by Alhazov et al. [50], 90 °C was selected as a key experimental temperature when conducting thermomechanical programming and thermal response tests on the TPU material system. Given that these measurement results confirmed that 90 °C can effectively induce the destruction of ordered clusters of hard segments in TPU and the relaxation of the stretched polymer matrix, which is highly relevant to the shrinkage behavior and changes in mechanical properties of TPU nanofiber membranes in a thermal environment focused on in this study, the temperature of hot anhydrous ethanol in this paper is thus set to 90 °C.

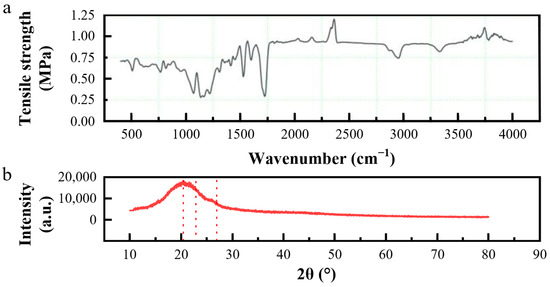

4.5. Material Characterization

Figure 3 presents the Fourier transform infrared spectroscopy (FTIR) analysis and X-ray diffraction (XRD) patterns of the prepared TPU electrospun nanofiber membranes. The FTIR analysis confirms the typical chemical structure of TPU, with its characteristic absorption peaks attributed to functional groups such as N-H stretching vibration (~3300 cm−1) and C=O stretching vibration (~1730 cm−1), clearly indicating the presence of urethane bonds (-NHCOO-). The XRD pattern shows a broad and diffuse diffraction peak at ~20°, suggesting that the pure TPU sample is mainly composed of an amorphous structure with low crystallinity.

Figure 3.

Material characterization of TPU fiber membrane: (a) FTIR analysis; (b) XRD patterns.

5. Results and Discussion

5.1. Effect of Absolute Ethanol Immersion at Room and Elevated Temperatures on Macroscopic Shrinkage Behavior and Tensile Mechanical Properties of Nanofiber Membranes

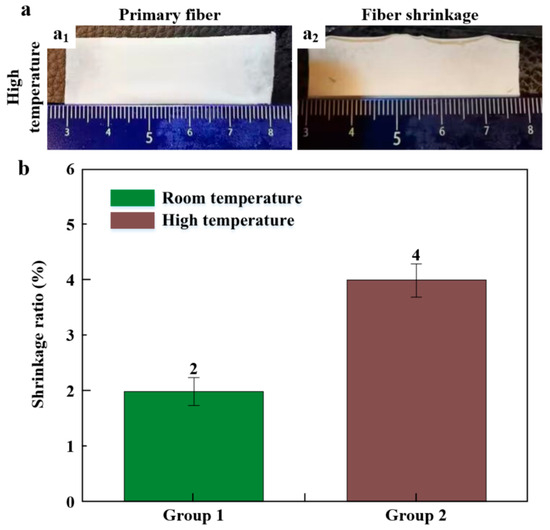

5.1.1. Analysis of Macroscopic Shrinkage Response

This study verifies the ethanol-responsive behavior of TPU nanofiber membranes by comparing the nanofiber shrinkage behavior in two composite material systems. The underlying mechanism is as follows: Ethanol molecules, acting as a plasticizer, infiltrate the fiber network and selectively disrupt the hydrogen-bond associations between TPU hard segments, significantly enhancing the mobility of the molecular chains and causing a reduction in the glass transition temperature (Tg). This plasticizing effect induces the inherent shape memory properties of TPU, ultimately driving the fibers to undergo macroscopic contraction.

The results (Figure 4a,b) show that the fiber membranes underwent significant shrinkage upon wetting with anhydrous ethanol, exhibiting anisotropic shrinkage characteristics both longitudinally and laterally. The TPU nanofiber membranes experienced notable contraction, with the extent of shrinkage controlled by temperature. After treatment at room temperature for 1 h, the shrinkage rate is about 1 mm, and the corresponding shrinkage rate is 2%. Under high-temperature treatment, the shrinkage increased to 2 mm, and the corresponding shrinkage rate was 4%, indicating that the shrinkage effect was enhanced by 200% with heating. This demonstrates that anhydrous ethanol causes TPU fiber shrinkage, and high temperatures further promote contraction. The essence of this behavior stems from ethanol molecules infiltrating the microdomain of the TPU hard segments, inducing swelling and reconstruction. High temperatures accelerate the dissociation of the hydrogen-bond network through enhanced molecular thermal motion, thereby facilitating polymer chain rearrangement and densification, which in turn intensifies the shrinkage phenomenon.

Figure 4.

Shrinkage experiment of TPU nanofiber membranes: (a). photographs of shrinkage experiment; (a1). untreated TPU nanofiber membrane; (a2). TPU nanofiber membranes treated with hot anhydrous ethanol; (b). Shrinkage ratio of TPU nanofiber membranes (error is standard deviation, n = 6).

5.1.2. Analysis of the Effect of Ethanol Treatment on Membrane Tensile Properties

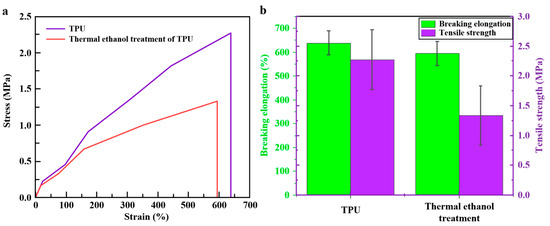

In order to assess the mechanical properties of the materials, tensile strength tests were performed on the samples. The stress–strain curves of the original TPU nanofiber membrane and the TPU nanofiber membrane treated with hot ethanol are shown in Figure 5a. Both curves exhibit the typical stages of “elastic deformation-plastic deformation-fracture.” In the elastic stage (low-strain region), the stress increases approximately linearly with strain, resulting from small elastic extensions of the molecular chains. In the plastic deformation stage (medium- to high-strain region), the slope of the curve decreases, with the molecular chains gradually sliding and rearranging. Specifically, for the original TPU, the stress continues to rise more noticeably due to the strengthening of molecular orientation; whereas, after hot ethanol treatment, the molecular interactions are disrupted, leading to a more gradual increase in stress. In the fracture stage, the stress sharply drops after reaching the peak value, as the material fails due to the rupture of molecular chains/chemical bonds. The hot ethanol-treated samples fractured earlier due to internal structural damage, with both the fracture strain and strength being lower. As shown in the figure, the tensile strength range of the original TPU nanofiber membrane is 1 to 3 MPa. It is worth noting that this relatively low strength range is mainly due to the small thickness of the nanofiber membrane. As shown in Figure 5b, compared to the untreated TPU nanofiber membrane, the load-bearing properties of the TPU nanofiber membrane treated with hot ethanol significantly decrease, with both the tensile strength and the elongation at break being noticeably reduced, dropping to about 500% to 600%.

Figure 5.

Tensile testing of TPU nanofiber membranes: (a). Stress–strain curves of TPU nanofiber membranes with and without hot ethanol treatment; (b). Comparison of tensile strength and elongation at break of TPU nanofiber membranes before and after hot ethanol treatment (error is standard deviation, n = 3).

As described in Section 3, heat treatment disrupts the physically cross-linked network that is stable at room temperature by destroying the ordered hard segment clusters in TPU. Meanwhile, the penetration of anhydrous ethanol not only induces the dissociation of hydrogen bonds between molecular chains and enhances the mobility of soft segments but also causes fiber swelling, resulting in a decrease in the material’s resistance to external loads. In addition, the densification shrinkage caused by the release of residual stress in TPU nanofibers under the stimulation of heating and ethanol optimizes the pore distribution of the membrane layer, which helps to improve the lubricant retention capacity.

6. Conclusions

In this study, the thermally induced shrinkage and tensile behavior of TPU nanofiber membranes were investigated under absolute ethanol treatment at different temperatures. The following conclusions were drawn:

- TPU nanofiber membranes exhibit significant shrinkage in dehydrated ethanol, with the extent of shrinkage being temperature-dependent. After immersion in RT ethanol for 1 h, the shrinkage reached approximately 1 mm (2%). When treated with hot ethanol, the contraction increased to 2 mm (4%), indicating a 200% enhancement in the shrinkage effect with an elevated temperature.

- Although the combined effect of heat and solvent accelerates the contraction process, it also leads to simultaneous deterioration in mechanical performance due to the compromise between strength and ductility. Compared to untreated TPU fibers, the nanofiber membranes subjected to hot ethanol treatment showed a marked reduction in mechanical properties. Both tensile strength and elongation at break decreased significantly, with the elongation reduced to approximately 500–600%.

Author Contributions

Formal analysis, S.W.; investigation, C.L.; data curation, M.K.; Writing—original draft, L.W.; Writing—review & editing, M.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This study was financially supported by the Support plan for Outstanding Youth Innovation Team in Universities of Shandong Province [2023KJ114], Young Talent of Lifting engineering for Science and Technology in Shandong, China [SDAST2024QTA043].

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

We sincerely thank all those who contributed to this work.

Conflicts of Interest

Authors Lei Wang, Shengchun Wang and Chunsheng Li were employed by the company CNPC Jichai Power Company Limited. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Nomenclature

| AR | Analytical reagent |

| GM | Graded membrane |

| PCE | Poly (epsilon-caprolactone-co-ethylene glycol) |

| PLA | Polylactic acid |

| SCE | Shape change effect |

| SMP | Shape memory polymer |

| THF | Tetrahydrofuran |

| DMF | N, N-dimethylformamide |

| PAN | Polyacrylonitrile |

| PCL | Poly (epsilon-caprolactone) |

| RT | Room temperature |

| SME | Shape memory effect |

| Tg | Transition temperature |

| TPU | Thermoplastic polyurethane |

References

- Allami, T.; Alamiery, A.; Nassir, M.H.; Kadhum, A.H. Investigating Physio-Thermo-Mechanical Properties of Polyurethane and Thermoplastics Nanocomposite in Various Applications. Polymers 2021, 13, 2467. [Google Scholar] [CrossRef]

- Atiqah, A.; Mastura, M.T.; Ali, B.A.A.; Jawaid, M.; Sapuan, S.M. A Review on Polyurethane and its Polymer Composites. Curr. Org. Synth. 2017, 14, 233–248. [Google Scholar] [CrossRef]

- Kong, M. Structure Design, Preparation and Performance Evaluation of Thermoplastic Polyurethane Flexible Sensor Based on Electrospinning. Master’s Thesis, Qingdao University of Technology, Qingdao, China, 2024. [Google Scholar]

- Yao, Y.; Xiao, M.; Liu, W.G. A Short Review on Self-Healing Thermoplastic Polyurethanes. Macromol. Chem. Phys. 2021, 222, 2100002. [Google Scholar] [CrossRef]

- Guo, Z.W.; Bi, Y.; Wu, Z.M.; Yuan, C.Q. Biomimetic PVA hydrogel and MMT reinforced TPU water-lubricated bearing materials for superior frictional properties and wear resistance. Wear 2025, 571, 205786. [Google Scholar] [CrossRef]

- Khalifa, M.; Anandhan, S.; Wuzella, G.; Lammer, H.; Mahendran, A.R. Thermoplastic polyurethane composites reinforced with renewable and sustainable fillers—A review. Polym.-Plast. Technol. Mater. 2020, 59, 1751–1769. [Google Scholar] [CrossRef]

- Kong, M.; Zhou, R.Y.; Yang, M.; Zhang, J.; Ma, X.; Gao, T.; Zhang, Y.B.; Li, B.K.; Liu, M.Z.; Cui, X.; et al. Mechanism and Performance Evaluation of a Strain Sensor Made from a Composite Hydrogel Containing Conductive Fibers of Thermoplastic Polyurethane and Polyvinyl Alcohol. Acs Omega 2024, 9, 43743–43755. [Google Scholar] [CrossRef]

- Zhang, W.X.; Miao, J.L.; Tian, M.W.; Zhang, X.J.; Fan, T.T.; Qu, L.J. Hierarchically interlocked helical conductive yarn enables ultra-stretchable electronics and smart fabrics. Chem. Eng. J. 2023, 462, 142279. [Google Scholar] [CrossRef]

- He, Y.F.; Liu, Q.J.; Tian, M.W.; Zhang, X.J.; Qu, L.J.; Fan, T.T.; Miao, J.L. Highly conductive and elastic multi-responsive phase change smart fiber and textile. Compos. Commun. 2023, 44, 101772. [Google Scholar] [CrossRef]

- Ren, M.N.; Wu, Q.S.; Huang, X. Flexible tactile sensors inspired by bio-mechanoreceptors. Biosens. Bioelectron. 2025, 267, 116828. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Cheng, L.; Wen, S.Z.; Zhou, S.B.; Wang, Z.; Deng, L.F.; Mao, H.Q.; Cui, W.G.; Zhang, H.Y. Ice-Inspired Superlubricated Electrospun Nanofibrous Membrane for Preventing Tissue Adhesion. Nano Lett. 2020, 20, 6420–6428. [Google Scholar] [CrossRef]

- Wong, D.; Resendiz, J.; Egberts, P.; Park, S.S. Electrospinning of composite microbeads for tribological improvements. J. Manuf. Process. 2018, 34, 264–273. [Google Scholar] [CrossRef]

- Beniwal, A.; Sunny. Novel TPU/Fe2O3 and TPU/Fe2O3/PPy nanocomposites synthesized using electrospun nanofibers investigated for analyte sensing applications at room temperature. Sens. Actuators B Chem. 2020, 304, 127384. [Google Scholar] [CrossRef]

- Dong, R.H.; Liu, X.Y.; Cheng, S.Y.; Tang, L.X.; Chen, M.; Zhong, L.N.; Chen, Z.; Liu, S.Q.; Jiang, X.Y. Highly Stretchable Metal-Polymer Conductor Electrode Array for Electrophysiology. Adv. Healthc. Mater. 2021, 10, 2000641. [Google Scholar] [CrossRef]

- Kang, L.H.; Ma, J.; Wang, C.; Li, K.C.; Wu, H.Y.; Zhu, M.F. Highly Sensitive and Wide Detection Range Thermoplastic Polyurethane/Graphene Nanoplatelets Multifunctional Strain Sensor with a Porous and Crimped Network Structure. Acs Appl. Mater. Interfaces 2024, 16, 2814–2824. [Google Scholar] [CrossRef]

- Fang, F.Y.; Wang, H.; Wang, H.Q.; Huang, W.M.; Chen, Y.H.; Cai, N.A.; Chen, X.D.; Chen, X. Stimulus-Responsive Shrinkage in Electrospun Membranes: Fundamentals and Control. Micromachines 2021, 12, 920. [Google Scholar] [CrossRef]

- Kong, M.; Yang, M.; Li, R.Z.; Long, Y.Z.; Zhang, J.; Huang, X.; Cui, X.; Zhang, Y.B.; Said, Z.; Li, C.H. Graphene-based flexible wearable sensors: Mechanisms, challenges, and future directions. Int. J. Adv. Manuf. Technol. 2024, 131, 3205–3237. [Google Scholar] [CrossRef]

- Chen, Y.C.; Zhong, W.Y.; Jia, X.Y.; Hu, D.D.; Sun, J.Y.; Peng, Y.; Yu, J.B.; Jiang, X.L.; Wang, H.F.; Zhao, L. Microcellular Thermoplastic Polyurethane (TPU) with Multimodal Cell Structure Fabricated Based on Pressure Swing Strategy and Its Compressive Mechanical Properties. Ind. Eng. Chem. Res. 2024, 63, 8833–8845. [Google Scholar] [CrossRef]

- Lai, S.M.; Lin, T.Y.; Huang, G.L. A novel multi-triggered reversible shape memory thermoplastic polyurethane (TPU)/polycaprolactone (PCL) blend. J. Polym. Res. 2023, 30, 64. [Google Scholar] [CrossRef]

- Hou, L.L.; Liu, J.C.; Li, D.M.; Gao, Y.; Wang, Y.Q.; Hu, R.J.; Ren, W.; Xie, S.X.; Cui, Z.M.; Wang, N. Electrospinning Janus Nanofibrous Membrane for Unidirectional Liquid Penetration and Its Applications. Chem. Res. Chin. Univ. 2021, 37, 337–354. [Google Scholar] [CrossRef]

- Wang, X.X.; Li, N.; Yang, A.L.; Zhang, N.F.; Qiu, W.; Yang, D.P. Amino oxidized sodium alginate-based humidity-resistant triboelectric nanogenerator for human motion and respiration monitoring. Chem. Eng. J. 2025, 506, 159842. [Google Scholar] [CrossRef]

- Al Haddad, Z.A.; Svinterikos, E.; Zuburtikudis, I. Designing electrospun nanocomposite poly(vinylidene fluoride) mats with tunable wettability. Colloids Surf. A-Physicochem. Eng. Asp. 2017, 523, 81–90. [Google Scholar] [CrossRef]

- Lu, T.D.; Wang, Q.; Gu, S.S.; Sun, S.P. Beyond Symmetry: Exploring Asymmetric Electrospun Nanofiber Membranes for Liquid Separation. Adv. Funct. Mater. 2024, 34, 2310218. [Google Scholar] [CrossRef]

- Zaidouny, L.; Abou-Daher, M.; Tehrani-Bagha, A.R.; Ghali, K.; Ghaddar, N. Electrospun nanofibrous polyvinylidene fluoride-co-hexafluoropropylene membranes for oil-water separation. J. Appl. Polym. Sci. 2020, 137, 49394. [Google Scholar] [CrossRef]

- Bai, T.H.; Wang, Y.Q.; Zhu, K.P.; Zhang, X.F.; Mu, Y.; Liu, J.C.; Yue, G.C.; Cui, Z.M.; Wang, N.; Bai, J.; et al. Multifunctional ultraelastic helical conductive yarn for motion detection and human-machine interaction. Chem. Eng. J. 2024, 498, 155143. [Google Scholar] [CrossRef]

- Guo, R.; Li, T.Y.; Jiang, C.J.; Zong, H.; Li, X.T.; Wan, C.X.; Yu, H.X.; Huang, X. Pressure Regulated Printing of Semiliquid Metal on Electrospinning Film Enables Breathable and Waterproof Wearable Electronics. Adv. Fiber Mater. 2024, 6, 354–366. [Google Scholar] [CrossRef]

- Luo, Y.X.; Li, S.; Xiao, L.; Teng, Y.Q.; Tian, R.; Li, T.; Liu, Y.H.; Li, D.M.; Feng, L.B. A gradient wettability fiber membrane for desalination and wastewater purification by solar-driven interfacial evaporation. Appl. Surf. Sci. 2025, 682, 161624. [Google Scholar] [CrossRef]

- Shen, Q.; Jiang, Y.; Guo, S.Z.; Huang, L.; Xie, H.B.; Li, L. One-step electrospinning membranes with gradual-transition wettability gradient for directional fluid transport. J. Membr. Sci. 2022, 644, 120091. [Google Scholar] [CrossRef]

- Han, H.N.; Shen, Q.; Wu, W.L.; Jiao, J.J.; Li, L.; Shao, J.J.; Zhu, T.; Xu, P. A wettability and structure gradient electrospun membrane for highly efficient emulsion separation. Sep. Purif. Technol. 2024, 342, 127047. [Google Scholar] [CrossRef]

- Zhu, X.; Wu, Y.M.; Feng, S.S.; Zhao, X.Y.; Xue, T.Z.; Zhong, Z.X.; Zhong, J. Design and fabrication of gradient wettability PAN nanofiber membrane for enhanced liquid transport and efficient air purification. Sep. Purif. Technol. 2025, 367, 132938. [Google Scholar] [CrossRef]

- Jiang, G.J.; Johnson, L.; Xie, S. Investigations into the mechanisms of electrohydrodynamic instability in free surface electrospinning. Open Phys. 2019, 17, 313–319. [Google Scholar] [CrossRef]

- Ma, Y.Q.; Zhou, R.Y.; Yang, M.; Zhang, J.; Song, W.; Ma, X.; Liu, M.Z.; Cui, X.; Li, B.K.; Zhang, Y.B.; et al. Electrospinning-based bone tissue scaffold construction: Progress and trends. Mater. Des. 2025, 252, 113792. [Google Scholar] [CrossRef]

- Zheng, C.H.; Chen, J.; Zhang, Y.Z.; Zhou, S.; Wang, L.X.; Zhou, J.; Chen, X.F.; Yang, D.P.; Hong, Y.M. Sandwich-type electrochemical immunosensing of hypopharyngeal carcinoma biomarker carcinoembryonic antigen based on N-doped hollow mesoporous nanocarbon spheres/gold hybrids as sensing platform and gold/ferrocene as signal amplifier. Anal. Sci. 2023, 39, 5–11. [Google Scholar] [CrossRef]

- Yu, M.; Dong, R.H.; Yan, X.; Yu, G.F.; You, M.H.; Ning, X.; Long, Y.Z. Recent Advances in Needleless Electrospinning of Ultrathin Fibers: From Academia to Industrial Production. Macromol. Mater. Eng. 2017, 302, 1700002. [Google Scholar] [CrossRef]

- Zhou, R.Y.; Ma, Y.Q.; Yang, M.; Cheng, Y.X.; Ma, X.; Li, B.K.; Zhang, Y.B.; Cui, X.; Liu, M.Z.; Long, Y.Z.; et al. Wound dressings using electrospun nanofibers: Mechanisms, applications, and future directions. Eur. Polym. J. 2025, 231, 113900. [Google Scholar] [CrossRef]

- Taylor, G.I. Electrically driven jets. Proc. R. Soc. London A Math. Phys. Sci. 1969, 313, 453–475. [Google Scholar] [CrossRef]

- Rutledge, G.C.; Fridrikh, S.V. Formation of fibers by electrospinning. Adv. Drug Deliv. Rev. 2007, 59, 1384–1391. [Google Scholar] [CrossRef] [PubMed]

- Fridrikh, S.V.; Yu, J.H.; Brenner, M.P.; Rutledge, G.C. Controlling the fiber diameter during electrospinning. Phys. Rev. Lett. 2003, 90, 144502. [Google Scholar] [CrossRef]

- Reneker, D.H.; Yarin, A.L. Electrospinning jets and polymer nanofibers. Polymer 2008, 49, 2387–2425. [Google Scholar] [CrossRef]

- Liu, X.X.; Hu, J.L.; Babu, K.M.; Wang, S.Y. Elasticity and Shape Memory Effect of Shape Memory Fabrics. Text. Res. J. 2008, 78, 1048–1056. [Google Scholar] [CrossRef]

- Wu, X.L.; Huang, W.M.; Lu, H.B.; Wang, C.C.; Cui, H.P. Characterization of polymeric shape memory materials. J. Polym. Eng. 2017, 37, 1–20. [Google Scholar] [CrossRef]

- Zhang, J.L.; Huang, W.M.; Gao, G.R.; Fu, J.; Zhou, Y.; Salvekar, A.V.; Venkatraman, S.S.; Wong, Y.S.; Tay, K.H.; Birch, W.R. Shape memory/change effect in a double network nanocomposite tough hydrogel. Eur. Polym. J. 2014, 58, 41–51. [Google Scholar] [CrossRef]

- Zhang, J.L.; Huang, W.M.; Lu, H.B.; Sun, L. Thermo-/chemo-responsive shape memory/change effect in a hydrogel and its composites. Mater. Des. 2014, 53, 1077–1088. [Google Scholar] [CrossRef]

- Idumah, C.I.; Odera, R.S.; Ezeani, E.O.; Low, J.H.; Tanjung, F.A.; Damiri, F.; Luing, W.S. Construction, characterization, properties and multifunctional applications of stimuli-responsive shape memory polymeric nanoarchitectures: A review. Polym.-Plast. Technol. Mater. 2023, 62, 1247–1272. [Google Scholar] [CrossRef]

- Pisani, S.; Genta, I.; Modena, T.; Dorati, R.; Benazzo, M.; Conti, B. Shape-Memory Polymers Hallmarks and Their Biomedical Applications in the Form of Nanofibers. Int. J. Mol. Sci. 2022, 23, 1290. [Google Scholar] [CrossRef]

- Salaris, V.; Leonés, A.; Lopez, D.; Kenny, J.M.; Peponi, L. Shape-Memory Materials via Electrospinning: A Review. Polymers 2022, 14, 995. [Google Scholar] [CrossRef]

- Zhuo, H.T.; Hu, J.L.; Chen, S.J. Electrospun polyurethane nanofibres having shape memory effect. Mater. Lett. 2008, 62, 2074–2076. [Google Scholar] [CrossRef]

- Coccia, M.; Farotti, E.; Chiappini, G.; Bellezze, T.; Sasso, M. Effects of temperature, strain and strain rate on shape memory thermoplastic polyurethane processed by injection molding. J. Intell. Mater. Syst. Struct. 2023, 34, 751–765. [Google Scholar] [CrossRef]

- Xia, Y.L.; He, Y.; Zhang, F.H.; Liu, Y.J.; Leng, J.S. A Review of Shape Memory Polymers and Composites: Mechanisms, Materials, and Applications. Adv. Mater. 2021, 33, 2000713. [Google Scholar] [CrossRef]

- Alhazov, D.; Burman, M.; Arinstein, A.; Zussman, E. Relaxation Suppression in a Stretched Copolymer Matrix Above Tg. J. Polym. Sci. Part B-Polym. Phys. 2015, 53, 1254–1259. [Google Scholar] [CrossRef]

- Li, D.M.; Yue, G.C.; Li, S.; Liu, J.; Li, H.K.; Gao, Y.; Liu, J.C.; Hou, L.L.; Liu, X.F.; Cui, Z.M.; et al. Fabrication and Applications of Multi-Fluidic Electrospinning Multi-Structure Hollow and Core-Shell Nanofibers. Engineering 2022, 13, 116–127. [Google Scholar] [CrossRef]

- Wang, C.C.; Zhao, Y.; Purnawali, H.; Huang, W.M.; Sun, L. Chemically induced morphing in polyurethane shape memory polymer micro fibers/springs. React. Funct. Polym. 2012, 72, 757–764. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).