Abstract

This study enhanced the self-healing performance of cherry wood furniture coatings by incorporating chitosan gum arabic-coated tung oil (CGA-T) microcapsules (types 1 and 2) into UV topcoats at 3%–15% concentrations. Multi-layer coated samples were systematically evaluated for optical, mechanical, and self-healing properties. Results demonstrated that microcapsules conferred self-healing ability, but concentrations >9% reduced reflectance (min 39.20%), increased color difference (max ΔE = 8.35), decreased gloss (max 35.25% loss at 60°), and raised roughness (max 1.79 μm). Mechanically, impact resistance improved (to grade 3), while adhesion declined (to grade 3) and hardness decreased (4H→2H). Self-healing performance peaked at 9% microcapsule 2 content (31.32% healing rate), with optimal overall performance at 6%. The 6% microcapsule 2 formulation (Sample 7) achieved the best overall balance among optical, mechanical, and self-healing properties, demonstrating its suitability for practical applications.

1. Introduction

Cherry wood is favored in furniture manufacturing because of its quicker timbering cycle and moderate physical properties. The combination of good mechanical strength and workability makes cherry an ideal choice for solid wood furniture [1,2,3,4,5,6]. Its unique wood grain characteristics are: wider grain spacing, lower density, and higher brightness. This special grain structure gives the cherry wood products natural elegance, warm and delicate aesthetic qualities, and artistic effect [7,8,9,10]. However, solid wood furniture will suffer unavoidable damage in the process of use, so the surface is usually applied with a transparent coating, in order to retain the natural grain of wood at the same time as the surface of the furniture can also have a higher gloss after finishing [11,12,13,14,15]. The cured coating forms a protective layer on the surface of the substrate, which reduces the damage to the furniture in use and prolongs the service life of the furniture. However, when cracks or scratches appear in the coating, the coating’s ability to protect the substrate is reduced, so coatings with self-healing properties can provide effective protection for furniture for a longer period of time [16,17,18,19,20].

As a typical representative of dry oils, tung oil has an important application value in the coating industry due to its excellent film-forming properties [21,22,23,24,25]. Its molecular structure is rich in conjugated triene structure of tung oil acid glycerol ester. This special unsaturated configuration promotes the tung oil in the air can be quickly oxidized polymerization reaction, resulting of dense and waterproof performance of the smooth coating [26,27,28,29]. Chitosan is the only positively charged polysaccharide in nature, and it possesses multiple excellent characteristics, such as natural origin, safety and non-toxicity, inhibition of bacterial growth, good biocompatibility and environmental degradation [30,31,32]. However, due to the poor interfacial polymerization of chitosan, it is difficult to achieve the desired effect when used alone, so the composite of natural anionic polysaccharide gum arabic and chitosan as wall material can effectively solve the problem of wall polymerization [33,34]. Since gum arabic itself has a good emulsifying effect, core emulsion can be made by dropping the core tung oil directly into the gum arabic solution [35,36,37,38,39]. By dropping acetic acid to change the pH of the solution, the chitosan solution is positively charged and the gum arabic solution is negatively charged, and the two substances coalesce to form microcapsules due to electrical neutralization [40]. Tannins are natural plant polyphenols with the ability to bind to polymers through hydrogen bonding and hydrophobic interactions, and the addition of tannins facilitates the curing of microcapsules [41]. Ma et al. [42] doped self-healing microcapsules into resin to form self-healing composites, characterized the microstructure and micromechanical properties of the composite films using scanning electron microscopy and nanoindentation, and tested the mechanical behavior and self-healing mechanism of the composite films during tensile stretching by using digital scattering spot correlation method. The results showed that the composite film containing 5.0 wt% microcapsules could reach 61.0% self-healing efficiency. Lim et al. [43] prepared microcapsules containing diisocyanate compounds and applied them to self-healing protective coatings. Microcapsules with isophorone diisocyanate in the core and diol compound in the wall were prepared by interfacial polymerization. Self-healing coatings with the addition of this microcapsule resulted in effective healing of scratches [44,45]. Zhang et al. [46] investigated the influence of microcapsule size on morphology, loading properties, dispersibility, and solvent resistance by controlling emulsification method, time, and emulsifier concentration. They found that larger microcapsules exhibited higher yield and coating rate, with solvent resistance also increasing as size increased. When incorporated into the coating matrix to form composite coatings, larger microcapsules demonstrated superior dispersibility. Consequently, coatings containing these larger microcapsules displayed enhanced self-healing properties and corrosion resistance. Chang et al. [47] prepared self-healing microcapsules via emulsion polymerization, using melamine-formaldehyde resin as the wall material and a shellac solution/aqueous coating mixture as the core. They investigated the effects of core-to-wall mass ratio, emulsifier-to-core mass ratio, stirring rate, and the mass ratio of the two core materials on microcapsule yield and encapsulation efficiency. Among these parameters, stirring rate had the most significant impact on the preparation of the melamine formaldehyde resin-coated shellac microcapsules. Liu et al. [48] fabricated acidic pH-responsive microcapsules via layer-by-layer assembly of polyelectrolytes, with chitosan as the wall material. They demonstrated that coatings containing 15 wt% of these microcapsules exhibited a marked response to acidic pH and effectively inhibited corrosion at intact areas. Lv et al. [49] achieved a 70.92% encapsulation efficiency using microcapsules fabricated with phycocyanin as the core material and chitosan/sodium alginate/CaCl2 as the wall material. These microcapsules enhanced the stability and anti-allergic efficacy of the encapsulated alginate.

Chitosan gum Arabic (CGA) microcapsules, as a kind of external self-healing microcapsules, can be added to the coating to obtain a certain self-healing ability. In this paper, two kinds of chitosan gum arabic-coated tung oil (CGA-T) microcapsules were added into the UV topcoat with the contents of 3%, 6%, 9%, 12% and 15%, respectively, and the UV primer and the UV topcoat were coated on the cherry wood substrate with the coating method of two bottoms and two surfaces, to investigate the effect of CGA-T microcapsules on the performance of the surface coating of cherry wood.

2. Test Materials and Methods

2.1. Materials

The various materials used in the preparation of microencapsulated samples are shown in Table 1. A 50 mm × 25 mm × 25 mm silicone mold was used to prepare the paint film. The glass plate size is 75 mm × 25 mm. According to the supplier’s specifications, the coating used is UV top coat, the main components of the top coat are polyurethane acrylic resin, propylene glycol diacrylate, hexylene glycol diacrylate, photoinitiator, functional filler, matting powder, wax powder, defoamer, dispersant, anti-sinking agent, etc., which is provided by Jiangsu Haidian Technology Co., Ltd., Kunshan, China. The cherry wood boards (Linyi Hongchangsheng Wood Factory, Shandong, China) had dimensions of 50 mm × 50 mm × 8 mm. The average air-dry density was 0.62 g/cm3, and moisture content was equilibrated to 12 ± 1% under controlled conditions (25 °C, 60% RH) for 14 days prior to coating. Surface roughness after sanding with 1000-grit paper was Ra = 3.2 μm.

Table 1.

List of materials used in the test.

The solid content of both UV primer and UV top coat is more than 98.0%. According to the supplier’s specifications, the main components of UV primer are epoxy acrylic resin, polyester acrylic resin, trimethylol methacrylate, trimethacrylate, photoinitiator, defoamer, leveling agent and so on. The UV primer and UV topcoat used are from Jiangsu Haidian Company. The equipment used in the test is shown in Table 2.

Table 2.

Test equipment.

2.2. Preparation Method of Microcapsules

The steps for the preparation of microcapsules using sample 1 as an example are as follows. The 3.20 g of gum arabic powder and deionized water were added into a beaker, which was placed in a heat-collecting magnetic stirrer and heated and stirred at 50 °C and 1000 rpm for 1 h, until all the gum arabic powder was dissolved to produce 4% gum arabic solution. Subsequently, 2.00 g of tung oil was weighed according to the core-to-wall ratio of 0.5:1, added to the beaker containing gum arabic solution, and the speed of the magnetic stirrer was adjusted to 2200 rpm, and stirring was continued for 1 h. After stirring, the beaker was put into the ultrasonic emulsification and dispersing apparatus, and ultrasonication was carried out for 10 min under the condition of ultrasonication with a 1 s interval and a 1 s break, and the obtained product was the core material emulsion.

An appropriate amount of acetic acid was measured and added into a beaker together with deionized water to make 1% acetic acid solution. The 0.80 g of chitosan was added to 79.20 mL of 1% acetic acid solution and placed in a magnetic stirrer at 50 °C and 1000 rpm to make 1% chitosan solution. The 1% chitosan solution was added drop by drop to the beaker of core emulsion. The pH of the solution was adjusted to 3 with acetic acid, and the core-wall mixture solution was obtained by heating and stirring for 30 min in a water bath at 50 °C, 800 rpm. The core-wall mixture solution was diluted by deionized water in the ratio of 1:1 and reacted at 25 °C, 800 rpm for 30 min. Tannic acid solution was added dropwise to solidify the microcapsules and stirred continuously for 2 h. The resulting product was a solution of microcapsules. Drying was carried out after standing at room temperature for 24 h. The parameters of the spray dryer were set to a feed rate of 200 mL/h and an inlet temperature of 120 °C. The powdered microencapsulated samples were collected from the collector when the drying of the samples was completed.

The specific breakdown of materials used in sample making is shown in Table 3.

Table 3.

The list of experimental materials.

2.3. Painting Method for Cherry Wood Board

In current wooden furniture manufacturing, hand painting remains a prevalent finishing process, particularly for solid wood furniture. This method allows precise control over coating penetration into wood pores, thereby enhancing substrate-coating adhesion. Consequently, this process was employed. Additionally, coating quality was strictly controlled to ensure consistent material distribution per unit area.

The coating was applied by hand brushing the cherry boards using two bottom and two side coats. Before finishing, 1000 mesh sandpaper was used to sand the substrate surface, surface burrs were removed, so that the paint film can be better adhered to the substrate. The 0.400 g of primer was brushed on the surface of the cherry board, leveling for 10 min and then put into the UV curing machine, curing for 60 s. Subsequently, the sandpaper was used to sand the coating surface, in accordance with the same steps to apply and curing, to complete the second primer coating. CGA-T microcapsules 1 and 2 were added to the UV topcoat at 3%, 6%, 9%, 12%, and 15%, respectively, and the UV topcoat containing different contents of microcapsules was coated on the wood boards in the same steps as the primer was coated. Cherry wood boards with no microcapsules added to the topcoat were also used as blank control samples. The specific materials used in applying the finish are shown in Table 4.

Table 4.

Details of materials used for cherry wood board surface coating.

Laboratory conditions were maintained at 23 ± 2 °C and 50 ± 5% RH throughout coating application, curing, and testing. The dry film thickness was measured by a micrometer. The average thickness of UV primer layers was 100 μm, and the UV topcoat layers was 50 μm, resulting in a total coating thickness of 300 μm. UV curing was performed at 100 mW/cm2 intensity for 60 s per layer under 23 °C and 50% RH.

2.4. Testing and Characterization

- (1)

- Optical performance test

Glossiness test of paint film: Glossiness was measured using a Gloss Tester HG268 in accordance with GB/T 4893.6-2013 [50]. The instrument measures the gloss level of a coating exposed to light at different angles. The surface gloss of the coating after the addition of microcapsules was noted as G1, and the surface gloss of the paint film without the addition of microcapsules was noted as G0, and the formula for the loss of gloss rate G was shown in Equation (1). Gloss loss was interpreted using the ASTM D523-25 standard [51] for coating finishes: Gloss loss <15%: Negligible impact on visual quality; 15%–30% gloss loss: Moderate reduction, acceptable for semi-gloss applications; >30% gloss loss: Severe reduction, unsuitable for high-gloss furniture.

Color Difference Test of Paint Film: The Colorimeter CR7 is used to measure the color difference of paint film surface. During the test, the color value of the UV top coat without microcapsules is measured first, and then the color value of the paint film after microcapsules are added is measured, and the instrument automatically calculates the color difference value ΔE. The L value stands for the degree of lightness and darkness, and the larger the L value is, the brighter the color of the sample is, and vice versa, the darker the color is. a value is used to measure the tendency of the color to be reddish-greenish, if the a value is negative, it means that the color is greenish, and if the a value is positive, it means that the color is reddish. b value is used to indicate the tendency of the color to be yellowish-blue. The b value is used to indicate the yellowish-blue tendency of a color, if the b value is negative, it means the color is bluish, if the b value is positive, it means the color is yellowish. The color difference (ΔE) was evaluated according to the CIE LAB (ISO 11664-4:2019) [52] standard, where ΔE values are classified as follows: ΔE < 1.0: Color difference is imperceptible to the human eye; 1.0 < ΔE < 2.0: Color difference is perceptible only to trained observers; 2.0 < ΔE < 3.5: Color difference is perceptible to untrained observers; ΔE > 3.5: Significant color difference, unacceptable for high-quality finishes.

Visible light transmittance test of paint film: The visible light transmittance (τ) of coatings was measured using a Hitachi U-3900 UV-Vis spectrophotometer according to standard methodologies. Coatings with and without microcapsules were applied to glass substrates (75 mm × 25 mm) and cured identically to the cherry wood samples. Transmittance spectra were recorded over the visible wavelength range (380–780 nm) at 1 nm intervals, with an air reference baseline. The instrument’s integrated software calculated τ automatically using the CIE standard illuminant D65 and the photopic luminosity function, as defined in Equation (2).

- (2)

- Self-healing performance test

The self-healing performance of the paint film was tested using the scratch test. The surface of the coating was scratched with a razor blade, and the width of the scratch was observed and recorded using an optical microscope, at which time the width of the scratch was recorded as W1. The scratch at the location was observed again after 48 h, and the width of the scratch was recorded as W2. The self-healing rate of the paint film was calculated from W2 and W1. The formula for the self-healing rate H is shown in Equation (3).

- (3)

- Microstructure of paint film

A scanning electron microscope QUANTA-200 was used to characterize the microscopic morphology of the microcapsules and paint films. To characterize the morphology of the samples using SEM, the samples were fixed on the sample stage with conductive adhesive. The samples were mounted on the sample tray according to the experimental requirements. Open the SEM sample chamber and mount the sample tray on the sample holder. Close the sample chamber and vacuum the sample chamber. After the vacuum was drawn, the sample was observed and images were taken through the software interface.

- (4)

- Characterization of chemical composition of paint film

The chemical composition of microcapsules and varnish films were tested and characterized using a FTIR spectrometer VERTEX 80V. To test the lacquer film samples, the surface of the ATR crystals was cleaned first. The samples to be tested were prepared to the appropriate size. The parameters are adjusted according to the experimental requirements of the sample. The sample to be measured is placed on the surface of the ATR crystal and the sample is in good contact with the surface and the sample is pressed by rotating the sampling holder. Spectra were collected and data were saved on the software interface. KBr pressing method was used for testing microcapsules and other powdered samples. 1 mg of microcapsule sample was taken with 100 mg of KBr powder in a mortar and pestle for thorough grinding. Subsequently, the powder was poured into a mold for tabletting. Finally, the insert plate containing the mold cover and the sample ingot was inserted directly into the sample holder of the instrument for measurement.

- (5)

- Mechanical property tests

Paint film roughness measurement: Roughness was measured using a Fine Roughness Tester (Model J8-4C). Samples were placed on the stage, the probe position was adjusted via the control knob, and measurements were initiated and recorded upon probe contact with the sample surface.

Hardness test: According to the national standard GB/T 6739-2022 [53] on the surface coating of cherry wood hardness test. The pencil was fixed to the pencil hardness tester, making sure that the pencil was at an angle of 45° to the surface of the coating. A constant pressure of 750 g was applied to the coated surface and the pencil was pushed at a uniform speed across the coated surface for a distance. If the coating was not scratched, the test was repeated with a harder pencil; if the coating was scratched, the hardness rating of the current pencil was recorded. The hardness rating of the coating was the highest hardness pencil rating of the unscratched coating. Higher hardness ratings indicated better scratch resistance of the coating.

Adhesion test: The adhesion test of the coating is based on GB/T 4893.4-2023 [54]. A regular cross grid was cut on the surface of the paint film with a multi-bladed cutter with a blade spacing of 2 mm, and the adhesion between the paint film and the substrate was evaluated by using tape peeling. Use a magnifying glass to observe the peeling of the paint film in the cut area, and judge the adhesion level of the paint film according to GB/T 4893.4-2023 by observing the degree of peeling of the paint film.

Impact resistance test: According to GB/T 4893.9-2013 [55], the sample to be tested was fixed on the test platform of the paint film impactor to ensure that the surface of the sample was flat and perpendicular to the impact block. Whether the surface of the paint film was cracked, peeled or otherwise damaged, and the impact resistance grade of the paint film was evaluated according to the degree of breakage on the surface of the specimen.

All optical, mechanical, and self-healing performance tests were repeated three times, and the results are presented as the mean values.

3. Results and Discussion

3.1. Chemical Composition of UV Coatings on Cherry Wood Panels with Added CGA-T Microcapsules

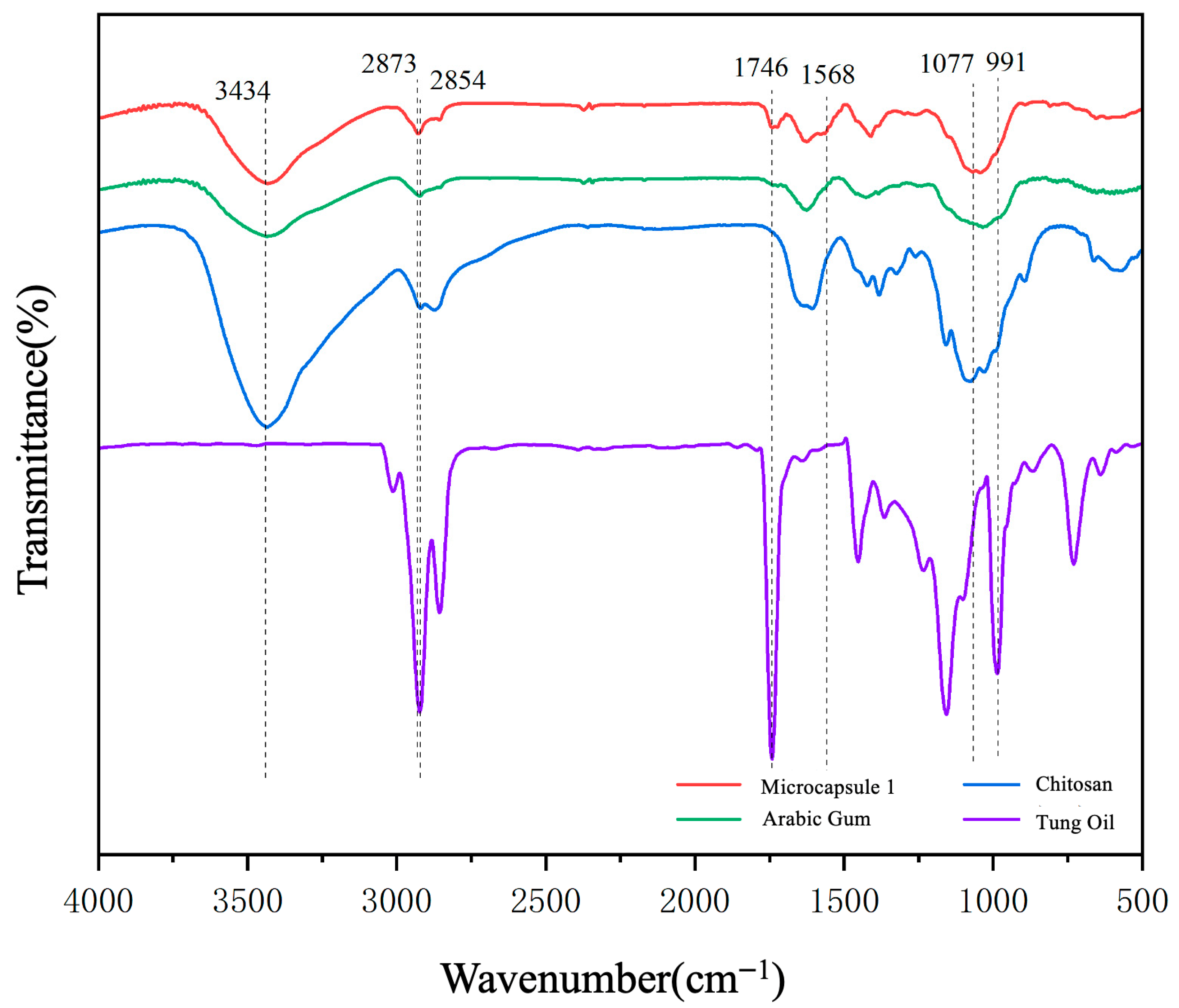

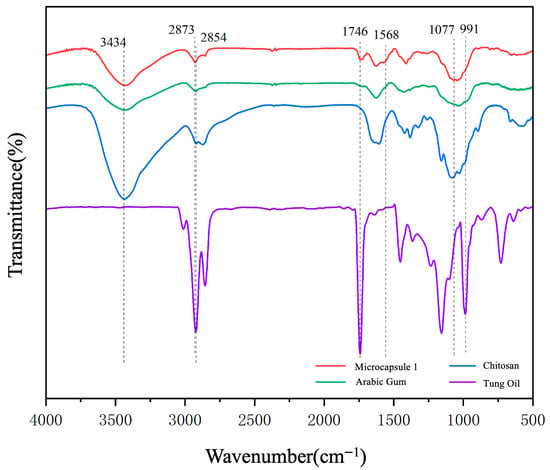

Figure 1 shows the FTIR spectrum of CGA-T microcapsules. The characteristic peaks of tung oil are observed at 2854 cm−1 (C–H stretching vibration), 1746 cm−1 (C=O stretching vibration), and 991 cm−1 (bending vibration of conjugated double bonds) [56], indicating the presence of tung oil in the sample. The absorption peaks at 3434 cm−1 (–OH vibration), 2873 cm−1 (–CH stretching vibration), 1647 cm−1 (amide I band vibration), and 1077 cm−1 (C–O–C stretching vibration) confirm the existence of chitosan [57]. Since arabic gum is a polysaccharide, the peak near 3500 cm−1 corresponds to the –OH stretching vibration. The spectrum exhibits characteristic peaks of both the core and wall materials. The peak at 1568 cm−1 is attributed to the electrostatic interaction between the –COOH groups of arabic gum and the –NH groups of chitosan within the wall material [58]. These results collectively demonstrate that the core material (tung oil) is successfully encapsulated within the wall materials (chitosan and arabic gum), confirming the successful preparation of chitosan/arabic gum-coated tung oil microcapsules.

Figure 1.

Infrared spectra of microcapsules and their raw materials [59].

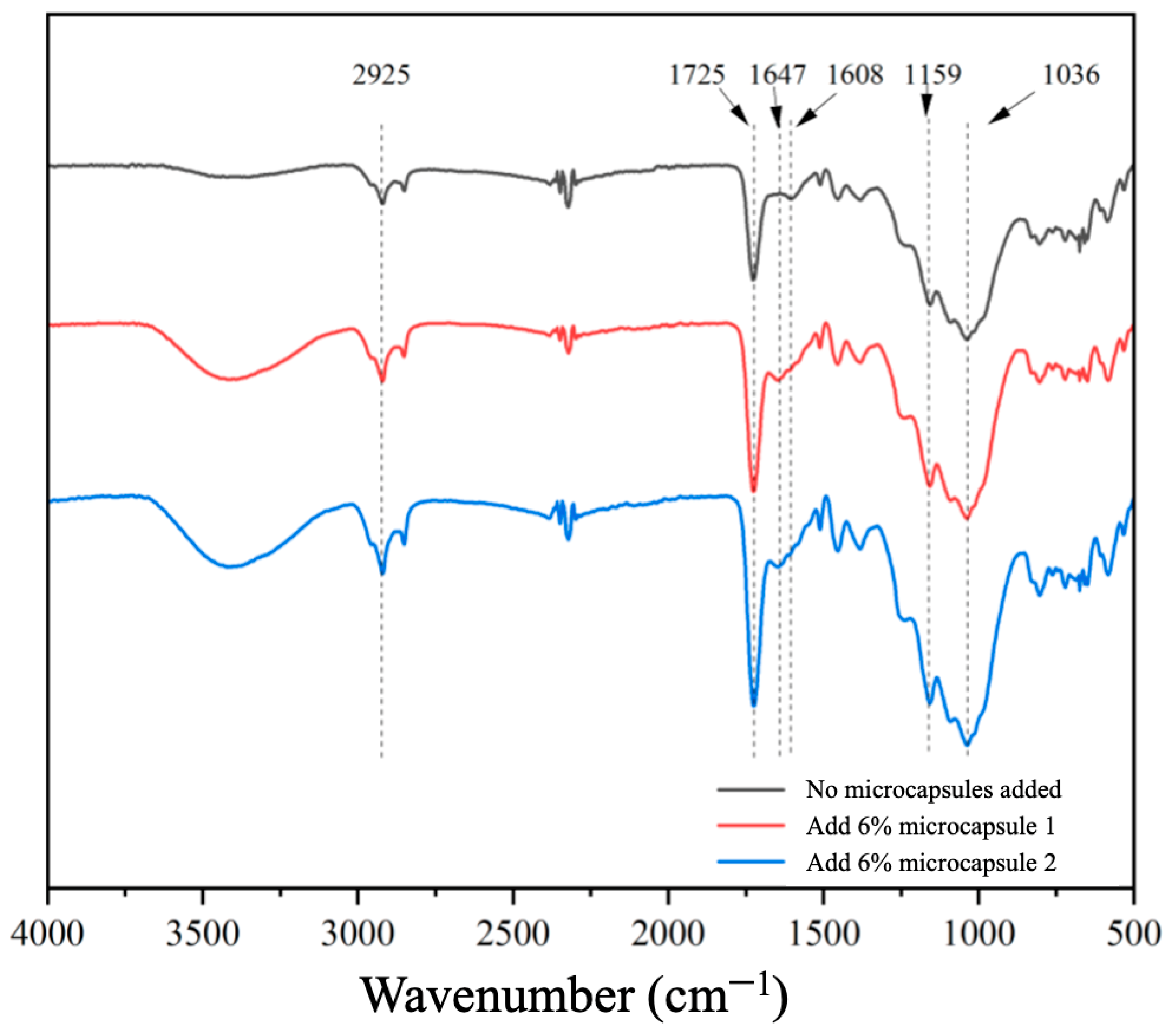

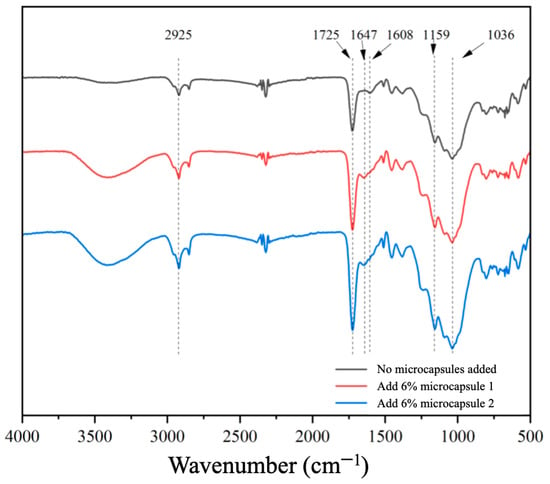

The infrared spectra of different microcapsules added to the surface coating of cherry wood panels are shown in Figure 2. When only UV primer and UV topcoat were included in the surface coating of cherry boards, the C-O and C=O stretching vibration peaks at 1159 cm−1, 1724 cm−1 and 2925 cm−1 and the C-H stretching vibration peaks, these peaks are UV primer in the main components of polyester acrylic resin, trihydroxymethacrylate and trimethacrylate produced by the common characteristics of the peaks [60]. The main ingredients in UV topcoats were polyurethane acrylic resins, propylene glycol diacrylate and hexylene glycol diacrylate. The characteristic peaks of these compositions appear at 1608 cm−1 for the C=C stretching vibration peak, 1725 cm−1 for the C=O vibration peak, and 2925 cm−1 for the C-H stretching vibration peak, respectively [61]. These peaks were similarly observed in coatings with added microcapsules. When microcapsules were added to the UV topcoat in the surface coating of cherry wood panels, the peaks at 3400 cm−1 appeared from the vibrational absorption peaks of -OH of chitosan and gum arabic in the microcapsule wall materials [62]. The vibrational absorption peak of amide group Ι at 1647 cm−1 and the absorption peak of C-O-C at 1077 cm−1 belonging to the microcapsule wall material indicate that there are microcapsules in the UV topcoat with the addition of microcapsules, which proves that the microcapsules do not react chemically in the UV topcoat, and that they can exist independently in the UV topcoat [63].

Figure 2.

Infrared spectrum of cherry wood surface coating.

3.2. Optical Properties of UV Coatings on Cherry Wood Panel Surfaces

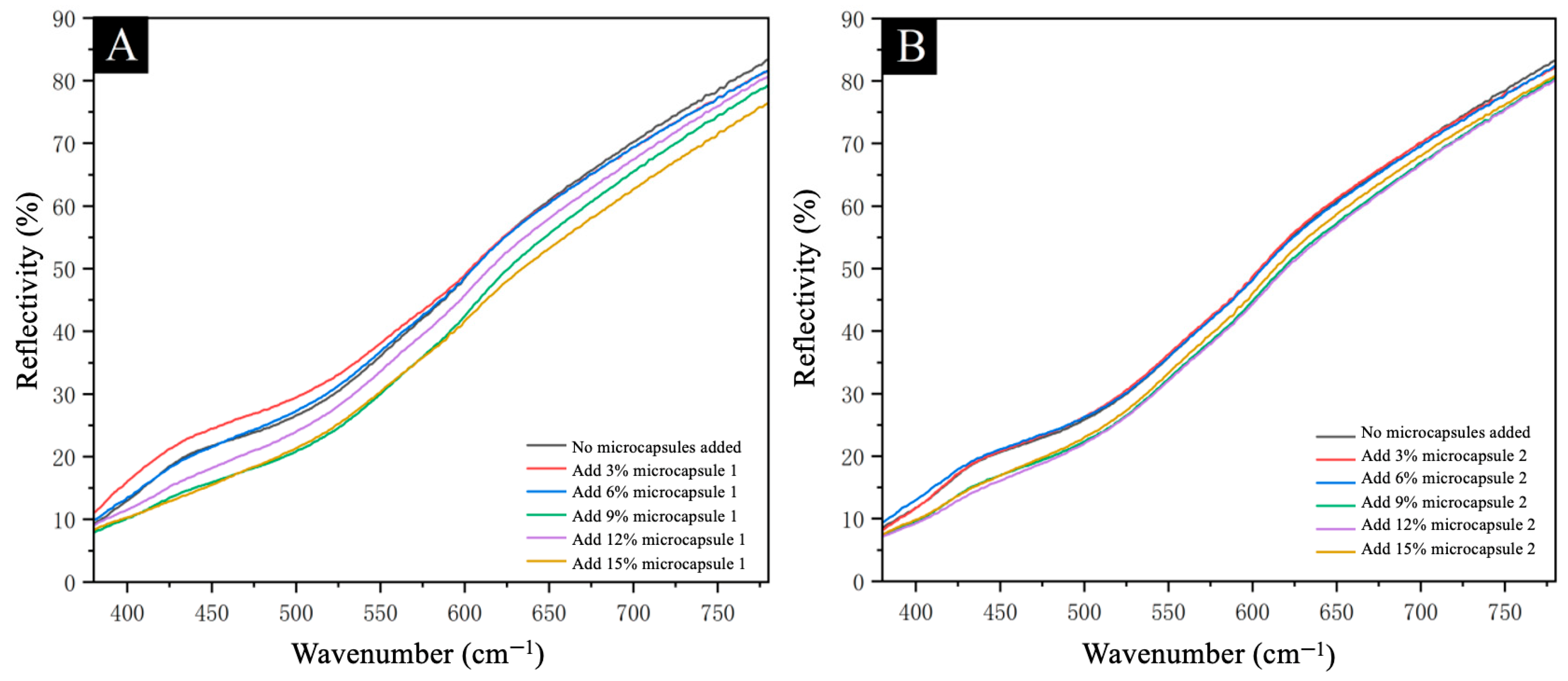

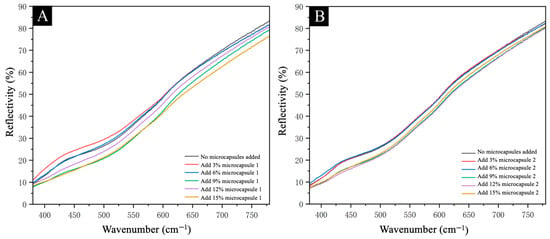

The surface reflectance of the coatings with different contents of microcapsules added is shown in Table 5 and Figure 3. The reflectance of the UV topcoat was 44.96%. The reflectance of the coatings with both microcapsules was maximized at a content of 3%. The reflectance of sample 1 with 3% of microcapsules 1 added to the coating was 45.08%. Sample 6 with 3% of microcapsules 2 added to the coating had a reflectivity of 46.40%. With the increasing content of microcapsules, the reflectivity of the coatings with both microcapsules 1 and microcapsules 2 showed a tendency to increase and then decrease. When the microcapsule 1 addition content was 3% and 6%, the reflectivity appeared to be elevated compared to coating 0. When the microcapsule content in the coating was greater than 6%, the reflectivity of the coating gradually decreased again. The reflectivity of the coating with the addition of microcapsules 2 also decreased with the increase in the content of microcapsules in the coating. This was probably due to the presence of a small number of microcapsules filling the tiny defects in the coating, resulting in a flatter surface, more concentrated light reflection, and increased reflectivity. When the content of microcapsules is high, too many microcapsules agglomerated together to increase the roughness of the coating surface, and the dispersion of light was enhanced, which leads to a decrease in reflectivity. When either 3% or 6% microcapsules are added to the coating, both result in improved reflectivity.

Table 5.

Reflectivity of cherry wood surface coatings.

Figure 3.

Reflectivity of cherry wood surface coating: (A) coatings with microcapsules 1, (B) coatings with microcapsules 2.

The chromaticity values and color difference values of cherry wood surface coatings with different microcapsules added are shown in Table 6. When no microcapsules were added to the surface of cherry boards the brightness value was 62.35, the red-green value was 15.60 and the yellow-blue value was 24.15. When microcapsules1 were added to the coating, the brightness value of the cherry wood surface decreased with increasing microcapsule content in the coating. Among all the coatings with added microcapsules, coating 6 with 3% microcapsules 2 in the coating had the highest lucidity at 61.93 and coating 5 with 15% microcapsules 1 had the lowest lucidity value at 58.20. The red and green values also showed a decreasing trend with the increase of microcapsules content, decreasing from 15.60 when no microcapsules were added to 11.15 (with 15% microcapsules 1) and 11.39 (with 15% microcapsules 2), respectively. The increasing microcapsules content resulted in increasing yellow-blue values for the cherry wood surface coatings, with the highest yellow-blue value of 30.49 for the microcapsules 2 coating 10 with 15% added microcapsules. The surface coating of cherry wood panels with the addition of microcapsules 2 basically showed a similar trend to the addition of microcapsules 1. This is because the UV topcoat itself has a high degree of transparency, so the brightness of the coating is higher after painting, and the microcapsules are opaque powder solids, which decrease the brightness value of the coating after being added to the coating. The cherry boards used as a substrate are reddish in color and therefore have positive a-values in all samples. The prepared CGA-T microcapsules were light yellow in color, thus making the a-value to decrease and b-value to increase after addition of coating. This is due to the addition of microcapsules to the coating of the yellow color, chromaticity principles and color mixing laws show that the yellow contains green components of the red play a neutralizing role, so that the overall color to the direction of the green shift, so the a-value decreases, and as a measure of the color of the yellow and blue values of the b-value is also due to the addition of yellow microcapsules to improve.

Table 6.

Chromaticity and color difference values of cherry wood surface coating.

The color difference between the surface coatings of cherry wood boards with the addition of microcapsules and cherry wood boards without microcapsules was increasing with the microcapsule content. The color difference increased to 8.27 and 8.35 when the content of microcapsules in the coatings increased to 15%, which indicates that the color of the coatings has been significantly changed due to the addition of large amounts of microcapsules. When the content of microcapsules added to the coating was 3% and 6%, the color difference of the coating was less suitable for application, in which the color difference of sample 6 with 3% microcapsules 2 added to the coating was 1.52, and the color difference of sample 7 with 6% microcapsules 2 added to the coating was 1.31, which is more in line with the color of the surface coatings of the cherry wood without microcapsules added.

The gloss and loss of gloss measured by adding different types and contents of microcapsules to the surface coating of cherry wood are shown in Table 7. The highest gloss level was achieved when the microcapsules content in the coating was 0. The gloss levels were 22.10 GU, 57.30 GU, and 58.50 GU at the incidence angles of the three light sources, respectively. The gloss of the coating decreased to varying degrees after the addition of microcapsules to the coating. At 3% and 6% microcapsule content in the coating, the coating still maintained good gloss, and the coating with 6% microcapsule 2 added 7 lost only 13.44% of gloss, with glosses of 16.20 GU, 49.60 GU, and 54.40 GU, respectively. When the content of microcapsules in the coating was 15%, it caused a significant decrease in the gloss of the coating, and the gloss of the coatings with the addition of microcapsules 1 and 2 decreased by 31.59% and 35.25%, respectively, compared with that of the coatings without the addition of microcapsules. This may be due to the addition of a large number of microcapsules to increase the solid content of the UV topcoat, resulting in an increase in the overall viscosity of the coating, so that the leveling of the coating deteriorated, and could not be formed in the curing process of the surface smooth coating. At the same time, the microcapsules added into the coating could not be completely and uniformly dispersed, resulting in a high concentration of microcapsules in the local area, which resulted in an uneven concave and convex structure on the surface of the coating, further reducing the gloss. Gloss data indicate that when ≤6% microcapsules are added, the coating maintains a semi-gloss visual effect (gloss >45 GU at 60° angle), with clear wood grain and no glare interference. When ≥9% microcapsules are added, the coating exhibits a matte texture (gloss <40 GU at 60° angle), where surface diffuse reflection is enhanced, making it suitable for scenarios with lower gloss requirements.

Table 7.

Glossiness and gloss loss rate of cherry wood board surface coating.

3.3. Mechanical Properties of UV Coating on Cherry Wood Board Surfaces

The roughness of the surface coating of cherry wood with different microcapsules added is shown in Table 8. The roughness of the surface without microcapsules in the coating was 0.42 μm. The coatings with both microcapsules showed the same trend as the added content kept changing, i.e., the surface roughness of the coatings with the added microcapsules increased as the microcapsule content kept increasing. When the content of microcapsules in the coating was 3% and 6%, the difference in surface roughness from that without the addition of microcapsules was small, indicating that this level of microcapsule addition is suitable for the application. The lowest roughness was found in coating 1 containing 3% microcapsules, which had a roughness of 0.26 μm, which could be attributed to the fact that the addition of a small amount of microcapsules compensated for the defects produced by the UV topcoat in the process of leveling, which resulted in a reduction of the roughness of the coated surface. Sample 5 with 15% microcapsules added to the coating had the largest surface roughness of 1.79 μm.

Table 8.

Roughness of cherry wood surface coating.

Table 9 shows the results of impact resistance, hardness, and adhesion tests of cherry wood panels with different contents of microcapsules in the coating. The impact rating of the cherry finish without microcapsules was only 5. When 3% of microcapsules were added to the coating, the impact resistance of the coating was already improved, and both types of microcapsules were able to improve the impact resistance of the coatings up to level 4 after being added to the coatings at a level of 3%. As the content of microcapsules in the coating increased, the impact resistance of the coating also increased, and a positive correlation was observed between the amount of microcapsules added and the impact resistance of the coating. This is due to the fact that the addition of microcapsules improves the toughness of the UV coatings, enabling them to undergo a certain amount of plastic deformation when subjected to impact. At the same time, the addition of microcapsules can hinder the crack expansion path and delay the crack propagation, thus improving the impact resistance of the coating. When 9% of microcapsules 1 was added to the coating, it resulted in a level 3 impact resistance, while when the same amount of microcapsules 2 was added to the coating, the impact resistance was level 4. This shows that there is a better enhancement in the impact resistance of the coating when 1 is added to the coating as compared to the addition of microcapsules 2.

Table 9.

Mechanical performance testing results of cherry wood surface coating.

When the cherry wood panel surface coating did not contain microcapsules, the adhesion of the coating was class 1. When microcapsules were added to the coating, the adhesion decreased to different degrees. When the content of microcapsules in the coating reached 12% or more, the adhesion of the coatings with both microcapsules added dropped to level 3. This is due to the fact that as the content of microcapsules in the coating increases, it negatively affects the homogeneity of the coating, which reduces the adhesion. When a small amount of microcapsules were added to both coatings, the adhesion of coating 1 containing 3% microcapsules 1 was level 2, and coating 6 with the addition of 3% microcapsules 2 remained at level 1. This indicates that when 3% of microcapsules 2 are added to the coating, there is no significant effect on the adhesion of the coating.

When the coating did not contained microcapsules, the hardness was 4H, which was due to the high hardness of the UV coating due to its dense internal molecular structure and high degree of polymerization. When the content of microcapsules in the coating exceeded 9%, the hardness of the coatings all showed a decrease, and the hardness of both samples 4 and 9 dropped to 2H. The hardness of the coating decreases as the microcapsule content rises. The addition of microcapsules destroys the continuity and densification of the coating, especially at high content, the aggregation or accumulation of microcapsules formed, so that the microcapsules form a stress concentration point at the interface region between the coating and the substrate, resulting in an uneven internal structure of the coating, and the coating is more likely to flake off from the substrate, thus affecting the overall hardness.

3.4. Self-Healing Properties of UV Coatings on Cherry Wood Panel Surfaces

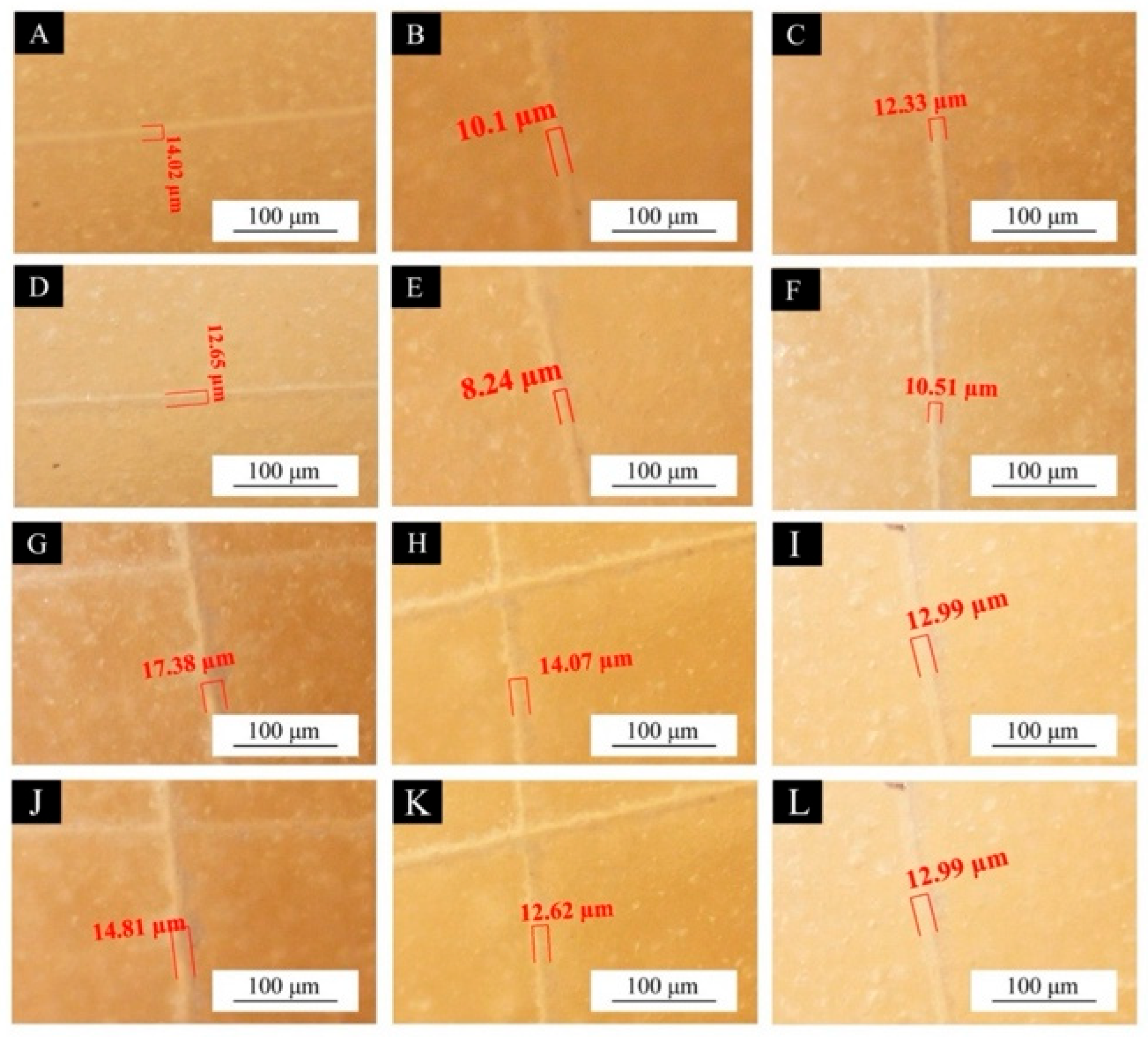

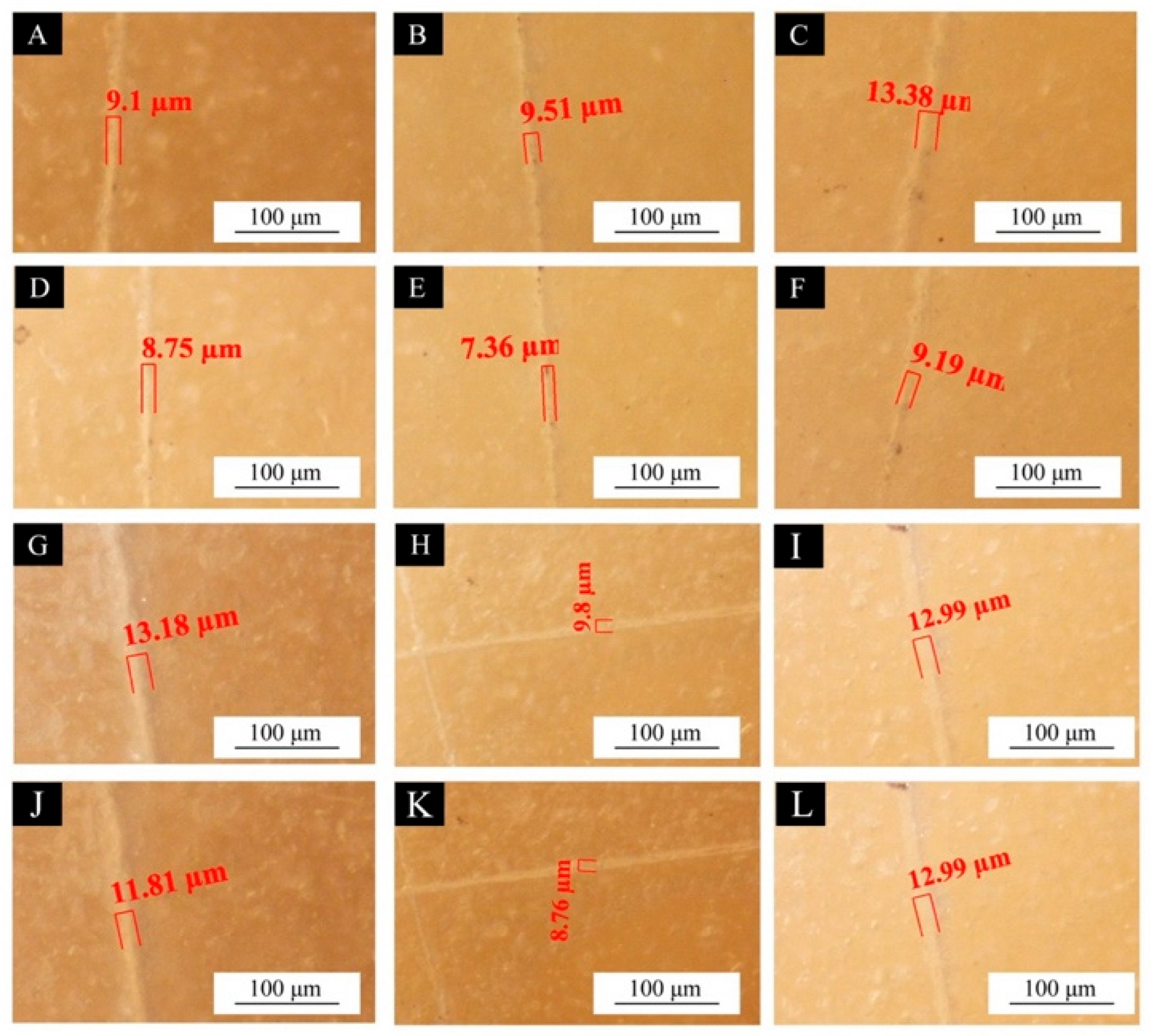

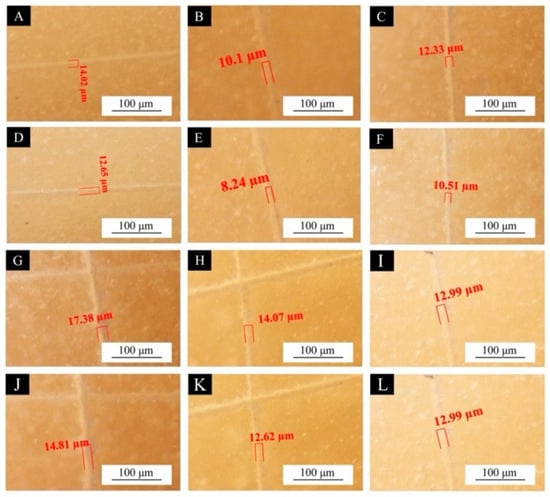

Figure 4 and Table 10 show the results of the scratch repair test with different contents of microcapsules 1 in the surface coating of cherry wood panels. When the coating contained 3% microcapsules, the repair rate was lower at 9.77%. As the content of microcapsules in the coating increased, the self-healing rate of the coating first increased and then decreased, and the self-healing rate of the coating was 18.42% when the microcapsule content was 6%, and the self-healing rate of the coating decreased to 14.76% when the microcapsule content in the coating was 9%. This is due to the fact that when the microcapsule content is low, increasing the amount of microcapsules in the coating results in more restorative agent, which allows more restorative agent to be released when the coating is damaged. When the microcapsule content is too high, the microcapsules undergo aggregation and accumulation in the coating, resulting in an uneven distribution of the repair agent in the coating. Excessive microcapsules in some areas and insufficient microcapsules in other areas affect the release of the repair agent and the repair effect. As the repair agent needs to diffuse in the crack or scratch and fill the damaged area. When the microcapsule content is too high, the diffusion path of the restorative agent may be obstructed, resulting in a decrease in the repair effect. Therefore adding 6% of microcapsules when microcapsules 1 are applied to the coating can result in a better repair rate of the coating.

Figure 4.

Comparison of scratches before and after self-healing of coatings containing microcapsules 1 with different content. Before healing: (A) 3.0%, (B) 6.0%, (C) 9.0%, (G) 12.0%, (H) 15.0%, (I) 0%, after healing: (D) 3.0%, (E) 6.0%, (F) 9.0%, (J) 12.0%, (K) 15.0%, (L) 0%.

Table 10.

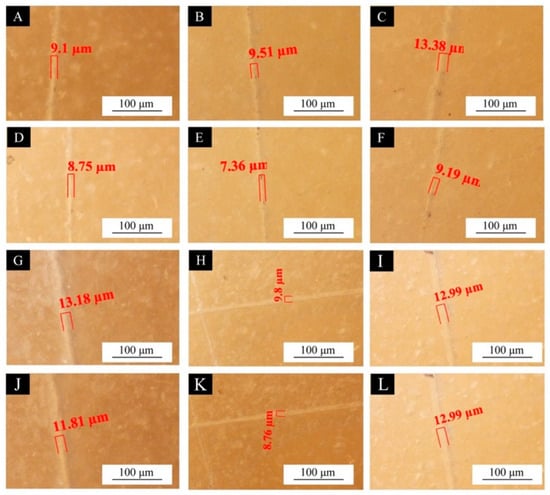

Self-healing results of cherry wood board surface coating.

As shown in Figure 5, the results of the scratch repair test with different contents of microcapsules 2 in the surface coating of cherry wood panels are shown. When the coating contained 3% of microcapsules, the self-healing rate of the coating was low at 3.85%, and when the microcapsule content in the coating increased to 6%, the coating could obtain a healing rate of 22.61%; when the microcapsule content in the coating increased to 9%, the self-healing rate of the coating reached the highest value at 31.32%. When the microcapsule content in the coating continued to increase to 12%, the self-healing rate of the coating showed a decrease to 10.39%. With the increase of the content of the two groups of microcapsules in the coating, the self-healing effect of the coating showed a consistent trend, i.e., increasing and then decreasing, and reached the maximum value of self-healing when the content of microcapsules in the coating was 6% and 9%, respectively.

Figure 5.

Comparison of scratches before and after self-healing of coatings containing microcapsules 2 with different content. Before healing: (A) 3.0%, (B) 6.0%, (C) 9.0%, (G) 12.0%, (H) 15.0%, (I) 0%, after healing: (D) 3.0%, (E) 6.0%, (F) 9.0%, (J) 12.0%, (K) 15.0%, (L) 0%.

3.5. Microscopic Morphology of UV Coating on the Surface of Cherry Wood Boards

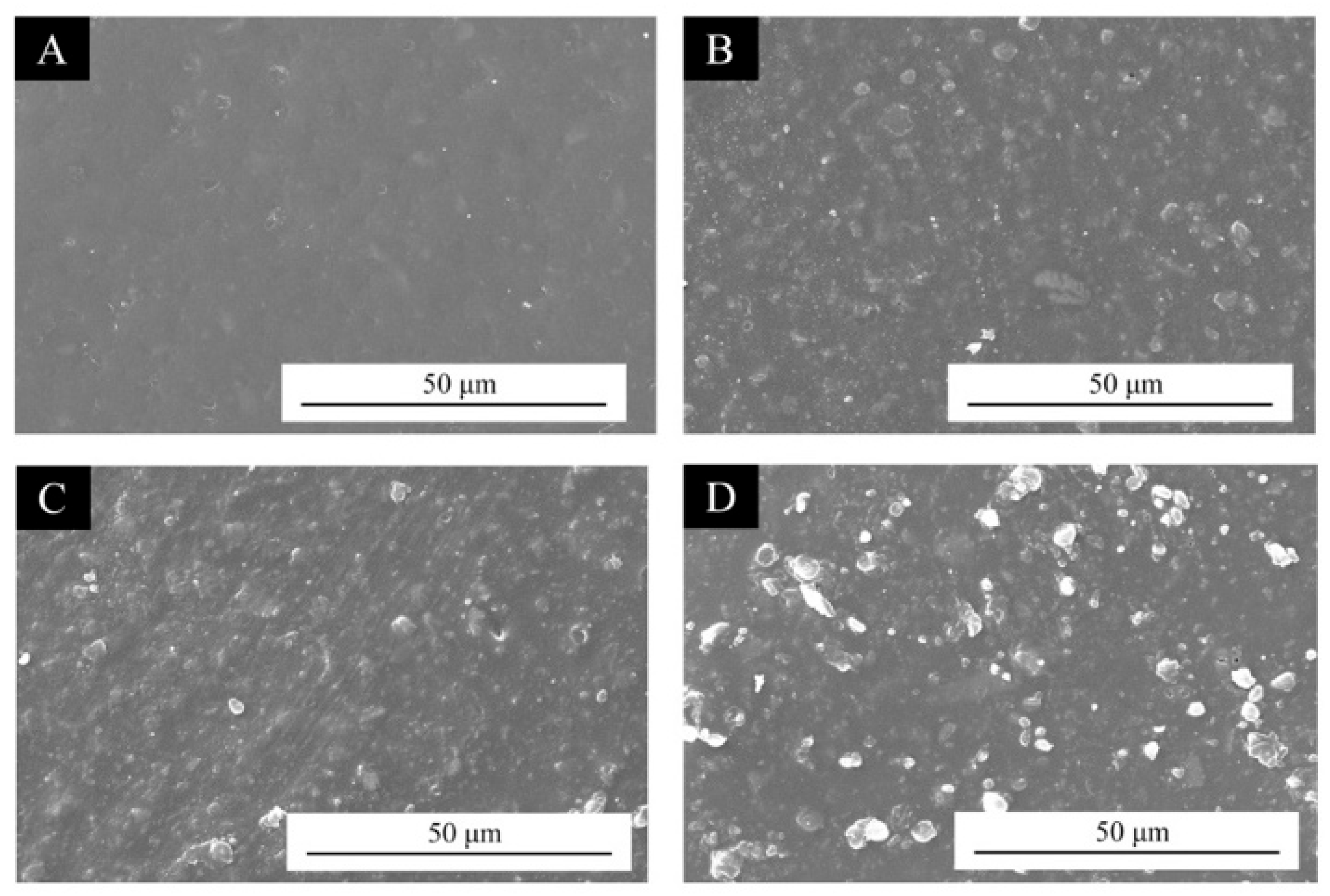

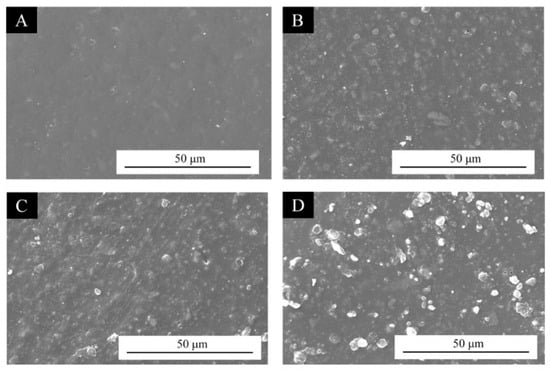

Figure 6 is a microscopic topography of the surface coating of cherry wood panels when different contents of microcapsules 2 were added to the coating, and it can be observed that there were smaller depressions on the surface of the coating without the addition of microcapsules. When 3% of microcapsules were added to the coating, the surface of the coating was relatively flat but microcapsule particles could be observed, when the content of microcapsules in the coating was 6%, the coating had more obvious granular bumps than when the content was 3%, and when the content of microcapsules was increased to 15%, a large number of white dots were visible in the field of view, which was due to the aggregation caused by uneven distribution of the microcapsules so that the density of the microcapsules was high in this region, and the electron beam had stronger interactions with the sample interacts more strongly, resulting in a localized increase in brightness. Although the microcapsules were unevenly distributed after being added to the UV topcoat, the coating did not show any microscopic defects caused by poor leveling, such as orange peel and ripples, indicating that the microcapsules were more compatible with the coating substrate.

Figure 6.

SEM images of the UV coating with different contents microcapsules on the surface of cherry wood board 2: (A) 0%, (B) 3%, (C) 6%, (D) 15%.

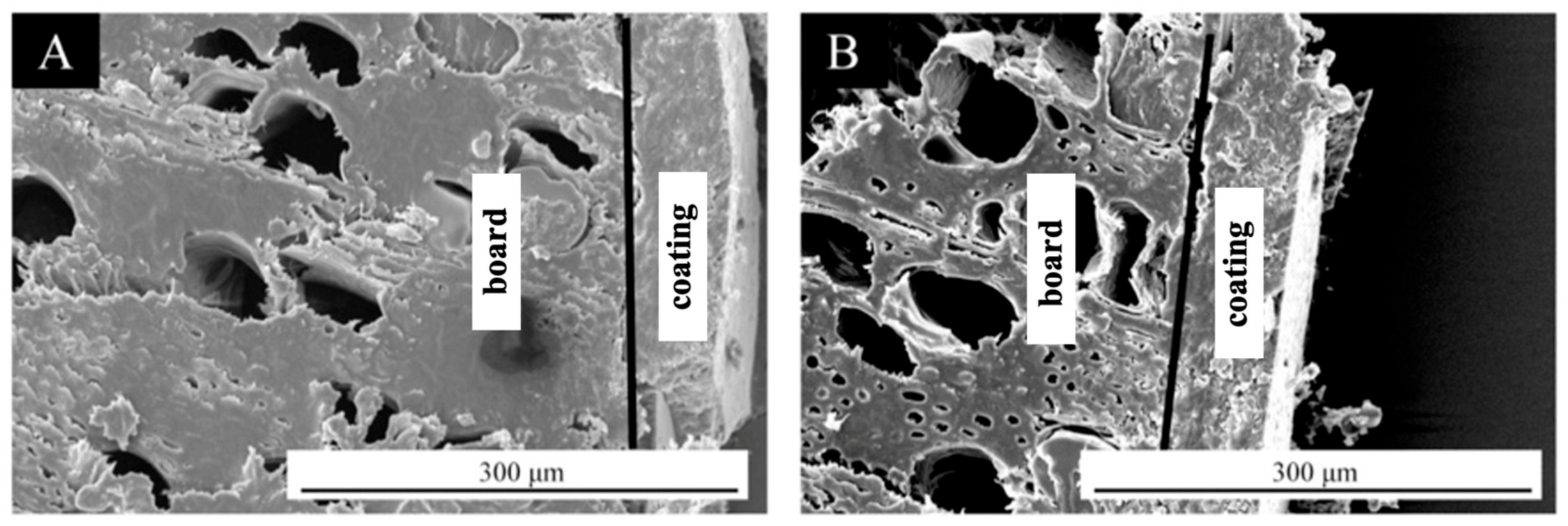

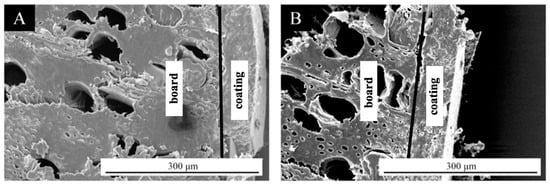

Figure 7 shows a cross-section of a cherry wood panel under SEM. It was possible to observe that the coating was able to cover the surface of the cherry wood more evenly. The interface between the paint film and the substrate was tightly bonded and there was paint penetration into the wood conduit pores, which improved the bonding between the coating and the substrate, and made the wood surface neat and smooth due to the excellent filling of the pores on the surface of the substrate after coating with UV paint. From the morphology of the inside of the coating in the cut section, there were no bubbles, cracks or other defects in the inside of the coating, and the cut section of the coating without microcapsules was neater and smoother compared to the coating with the addition of microcapsules 2.

Figure 7.

Cherry wood board cross-section: (A) UV coating on the surface of the cherry wood board did not contain microcapsules, (B) UV coating on the surface of the cherry wood board contained microcapsules 2.

By comparing the test results of each performance, it can be found that the self-healing effect of UV coatings 8 (with 9% of microcapsules 2 added), 7 (with 6% of microcapsules 2 added), and 2 (with 6% of microcapsules 1 added) is better, and the self-healing rate can be up to 31.32%, 22.61%, and 18.42%, respectively. The roughness of coating 8 with the addition of 9% microcapsules 2 was higher at 1.20 μm, and the roughness of coatings 2 and 7 was lower at 0.56 μm and 0.71 μm, respectively. In the optical test, the loss of light in coating 2 with the addition of 6% microcapsules 1 at the angle of incidence of the light source of 60° was 20.42%, and the chromatic aberration was 2.86, and the loss of light in coating 7 with the addition of UV coating of 6% microcapsules 2 at the angle of incidence of the light source of 60° was 20.42% and the chromatic aberration was 2.86, respectively. The light loss rate of UV coating 7 with 6% microcapsules 2 at an incident angle of 60° was 13.44%, and the color aberration was 1.31, which indicated that the UV coating 7 on the surface of cherry wood had superior optical properties compared with UV coating 2. When comparing all the properties, the coating sample 7 containing 6% of microcapsules 2 has a better overall performance.

4. Conclusions

CGA-T microcapsules 1 and 2 were selected to be added to the UV topcoat on the surface of cherry wood panels. The reflectance of the coatings with the addition of microcapsules 1 and 2 both showed a tendency to increase and then decrease as the microcapsule content continued to increase. The brightness of the coatings was constantly decreasing and the color difference was constantly increasing. The gloss of the coatings with the addition of microcapsules 1 was higher than that of the coating with the addition of microcapsules 2 when the content of microcapsules was the same. Roughness also increased with the increase in microcapsule content. The inclusion of microcapsules improved the impact resistance of the coatings, but as the microcapsule content increased it negatively affected both the adhesion and hardness of the coatings. The 3% CGA-T microcapsules were incorporated into the coatings to give the coatings self-healing ability. As the content of microcapsules in the coatings increased, the self-healing performance of the coatings increased and then decreased. The best self-healing performance of the coatings was achieved by adding 9% of microcapsules 2 to the coatings up to 31.32%. Combining the results of all the tests, the surface coating of cherry wood 7 to which 6% of CGA-T microcapsules 2 were added in the surface coatings had better performance. The UV-visible reflectance of the coatings was 45.25%, the brightness value was 61.62, the red-green value was 15.20, the yellow-blue value was 25.16, the color difference value was 1.31, and the loss of light at the angle of incidence of the light source of 60° was 13.44%. The roughness of the coating was 0.71 μm, the impact resistance grade was 4, the adhesion grade was 2, the hardness was 4H, and the self-healing rate for scratches was 22.61%. In conclusion, this study successfully demonstrates the feasibility of conferring self-healing properties to UV-cured cherry wood coatings using CGA-T microcapsules. The comprehensive performance evaluation reveals a critical interplay between microcapsule concentration, self-healing efficiency, and the optical/mechanical properties defining coating quality. The key analytical insight is that while self-healing performance increases with microcapsule loading, a threshold exists (approximately 6%–9%) beyond which the degradation in optical quality and key mechanical properties (adhesion, hardness) becomes unacceptable for high-end furniture applications. Therefore, the optimal formulation (6% Microcapsules 2—Sample 7) represents a technologically viable and industrially relevant solution, offering a significant self-healing capability (22.61%) while preserving the essential aesthetic and protective functions expected of a premium wood finish. This balanced approach paves the way for the development of more durable and maintenance-friendly wood furniture coatings.

Author Contributions

Conceptualization and methodology, writing—review and editing, Y.D., validation, resources, data management, J.D., formal analysis, investigation, and supervision X.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This project was partly supported by the Postgraduate Research and Practice Innovation Program of Jiangsu Province (SJCX25_0453).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare that there is no conflicts of interest.

References

- Mai, C.; Schmitt, U.; Niemz, P. A brief overview on the development of wood research. Holzforschung 2022, 76, 102–119. [Google Scholar] [CrossRef]

- Zhang, N.; Xu, W.; Tan, Y. Multi-attribute hierarchical clustering for product family division of customized wooden doors. Bioresources 2023, 18, 7889–7904. [Google Scholar] [CrossRef]

- Hu, W.G.; Liu, N.; Xu, L.; Guan, H.Y. Study on cold/warm sensation of materials used in desktop of furniture. Wood Res. 2020, 65, 497–506. [Google Scholar] [CrossRef]

- Hu, W.; Yang, Z.; Shi, N.; Yu, X. Experimental study on effects of the selected load parameters on fatigue life of the mortise-and-tenon furniture joint. Wood Mater. Sci. Eng. 2025, 19, 1–7. [Google Scholar] [CrossRef]

- Hu, W.; Yang, P.; Wang, Y.; Zhang, J. Damage zone analysis and its effect on the elastic constants of beech blocks with different grain orientations under compression. Wood Sci. Technol. 2025, 59, 62. [Google Scholar] [CrossRef]

- Hu, W.; Yu, R.; Luo, M.; Konukcu, A.C. Study on tensile strength of single dovetail joint: Experimental, numerical, and analytical analysis. Wood Mater. Sci. Eng. 2023, 18, 1478–1486. [Google Scholar] [CrossRef]

- Qi, Y.Q.; Sun, Y.; Zhou, Z.W.; Huang, Y.; Li, J.X.; Liu, G.Y. Response surface optimization based on freeze-thaw cycle pretreatment of poplar wood dyeing effect. Wood Res. 2023, 68, 293–305. [Google Scholar] [CrossRef]

- Hu, W.G.; Liu, N.; Guan, H.Y. Experimental and numerical study on methods of testing withdrawal resistance of mortise-and-tenon joint for wood products. Forests 2020, 11, 280. [Google Scholar] [CrossRef]

- Hu, W.G.; Li, S.; Liu, Y. Vibrational characteristics of four wood species commonly used in wood products. Bioresources 2021, 16, 7101. [Google Scholar] [CrossRef]

- Gu, Y.T.; Zhang, J.L. Tensile properties of natural and synthetic rattan strips used as furniture woven materials. Forests 2020, 11, 1299. [Google Scholar] [CrossRef]

- Hu, J.; Liu, Y.; Xu, W. Influence of cell characteristics on the construction of structural color layers on wood surfaces. Forests 2024, 15, 676. [Google Scholar] [CrossRef]

- Brito, A.F.; Calonego, F.W.; Bond, B.H.; Severo, E.T.D. Color changes, EMC and biological resistance of thermally modified yellow poplar. Wood Fiber Sci. 2018, 50, 439–446. [Google Scholar] [CrossRef]

- Hu, W.; Zhao, Y.; Xu, W.; Liu, Y. The influences of selected factors on bending moment capacity of case furniture joints. Appl. Sci. 2024, 14, 10044. [Google Scholar] [CrossRef]

- Yu, R.; Liu, Y.; Konukcu, C.A.; Hu, W. A method of simulating seat load for numerical analysis of wood chair structure. Wood Res-Slovakia. 2024, 69, 432–444. [Google Scholar] [CrossRef]

- Hu, W.; Yu, R.; Yang, P. Characterizing roughness of wooden mortise and tenon considering effects of measured position and assembly condition. Forests 2024, 15, 1584. [Google Scholar] [CrossRef]

- Althaqafi, K.A.; Satterthwaite, J.; AlShabib, A.; Silikas, N. Synthesis and characterisation of microcapsules for self-healing dental resin composites. BMC Oral Health 2024, 24, 109. [Google Scholar] [CrossRef] [PubMed]

- Chang, Y.J.; Yan, X.X.; Wu, Z.H. Application and prospect of self-healing microcapsules in surface coating of wood. Colloids Interface Sci. Commun. 2023, 56, 100736. [Google Scholar] [CrossRef]

- Aguirresarobe, R.H.; Nevejans, S.; Reck, B.; Irusta, L.; Sardon, H.; Asua, J.M.; Ballard, N. Healable and self-healing polyurethanes using dynamic chemistry. Prog. Polym. Sci. 2021, 114, 101362. [Google Scholar] [CrossRef]

- Hu, W.; Luo, M.; Yu, R.; Zhao, Y. Effects of the selected factors on cyclic load performance of T-shaped mortise-and-tenon furniture joints. Wood Mater. Sci. Eng. 2024, 18, 1–10. [Google Scholar] [CrossRef]

- Hu, W.; Yu, R. Study on the strength mechanism of the wooden round-end mortise-and-tenon joint using the digital image correlation method. Holzforschung 2024, 78, 519–530. [Google Scholar] [CrossRef]

- Hu, W.; Fu, W.; Zhao, Y. Optimal design of the traditional Chinese wood furniture joint based on experimental and numerical method. Wood Res.-Slovakia. 2024, 69, 50–59. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, W.; Kasal, A.; Erdil, Y.Z. The state of the art of biomechanics applied in ergonomic furniture design. Appl. Sci. 2023, 13, 12120. [Google Scholar] [CrossRef]

- Zhou, J.C.; Xu, W. Optimizing the interface compatibility of transparent wood for green phase-change thermal storage. Wood Sci. Technol. 2025, 59, 45. [Google Scholar] [CrossRef]

- Wang, G.K.; Li, X.L.; Xiong, X.Q.; Wang, S.Q. Optimization of drilling processes in panel furniture manufacturing: A case study. PLoS ONE 2025, 20, e0318667. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Li, J.Y.; Wang, T.Y.; Chu, Q.; Wang, X.W. Fused deposition 3D printing of bonsai tree guiding mold based on acrylonitrile-butadiene-styrene copolymer. Bioresources 2024, 19, 5839. [Google Scholar] [CrossRef]

- Zhang, A.Q.; Li, J.; Fan, H.J.; Xiang, J.; Wang, L.; Yan, J. Effect of mechanical properties on the self-healing behavior of waterborne polyurethane coatings. J. Appl. Polym. Sci. 2022, 139, 52364. [Google Scholar] [CrossRef]

- Samadzadeh, M.; Boura, S.H.; Peikari, M.; Ashrafi, A.; Kasiriha, M. Tung oil: An autonomous repairing agent for self-healing epoxy coatings. Prog. Org. Coat. 2011, 70, 383–387. [Google Scholar] [CrossRef]

- Wang, C.; Li, J.Y.; Zhang, C.Y. Effect of Corrected Extrusion Flow Rate on Wall Thickness Error of MEAM Thin-walled Model. Mater. Plast. 2025, 62, 78–85. [Google Scholar] [CrossRef]

- Wang, C.; Li, J.Y.; Wang, T.Y.; Wang, X.W.; Chu, Q. Effect of Optimised Infill Parameters on the Tensile Properties of MEX Co-polyester Models. Mater. Plast. 2024, 61, 129–136. [Google Scholar] [CrossRef]

- Wang, C.; Li, J.Y.; Wang, T.Y.; Wang, X.W. Additive Manufacturing of Furniture Corner Guards Based on Thermoplastic Polyurethane Filament. Bioresources 2025, 20, 5398–5406. [Google Scholar] [CrossRef]

- Liu, Q.Q.; Gao, D.; Xu, W. Effect of paint process on the performance of modified poplar wood antique. Coatings 2021, 11, 1174. [Google Scholar] [CrossRef]

- Liu, Q.Q.; Gao, D.; Xu, W. Influence of the bottom color modification and material color modification process on the performance of modified poplar. Coatings 2021, 11, 660. [Google Scholar] [CrossRef]

- Xu, W.; Fang, X.Y.; Han, J.T.; Wu, Z.H.; Zhang, J.L. Effect of coating thickness on sound absorption property of four wood species commonly used for piano soundboards. Wood Fiber Sci. 2020, 52, 28–43. [Google Scholar] [CrossRef]

- Liu, Q.Q.; Gao, D.; Xu, W. Effect of sanding processes on the surface properties of modified poplar coated by primer compared with mahogany. Coatings 2020, 10, 856. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, L.M.; Shehzad, H.; Farooqi, Z.H.; Sharif, A.; Ahmed, E.; Habiba, U.; Qaisar, F.; Noor-E-Fatima; Begum, R.; et al. Innovative free radical induced synthesis of WO3-doped diethyl malonate grafted chitosan encapsulated with phosphorylated alginate matrix for UO22+ adsorption: Parameters optimisation through response surface methodology. Separation Purif. Technol. 2025, 353, 128455. [Google Scholar] [CrossRef]

- Baiocco, D.; Preece, J.A.; Zhang, Z.B. Encapsulation of hexylsalicylate in an animal-free chitosan-gum Arabic shell by complex coacervation. Colloid Surf. Physicochem. Eng. Asp. 2021, 625, 126861. [Google Scholar] [CrossRef]

- Qi, L.F.; Xu, Z.R.; Jiang, X.; Hu, C.H.; Zou, X.F. Preparation and antibacterial activity of chitosan nanoparticles. Carbohydr. Res. 2004, 339, 2693–2700. [Google Scholar] [CrossRef] [PubMed]

- Qian, J.Q.; Chen, Y.; Wang, Q.; Zhao, X.H.; Yang, H.Y.; Gong, F.; Guo, H. Preparation and antimicrobial activity of pectin-chitosan embedding nisin microcapsules. Eur. Polym. J. 2021, 157, 110676. [Google Scholar] [CrossRef]

- Cots, A.; Camacho, N.M.; Palma, S.D.; Alustiza, F.; Pedraza, L.; Bonino, F.; Carreño, J.; Bracamonte, C.F.; Acevedo, D.; Bozzo, A.; et al. Chitosan-alginate microcapsules: A strategy for improving stability and antibacterial potential of bovine Lactoferrin. Int. J. Biol. Macromol. 2025, 307, 141870. [Google Scholar] [CrossRef] [PubMed]

- Beach, M.; Davey, T.; Subramanian, P.; Such, G. Self-healing organic coatings–Fundamental chemistry to commercial application. Prog. Org. Coat. 2023, 183, 107759. [Google Scholar] [CrossRef]

- Zeng, X.T.; Guo, H.; Liu, H.L.; Liu, C.; Fang, B.; Li, Y.Z.; Jiang, Z.L.; Liu, J. Self-healing performance and anti-corrosion mechanism of microcapsule-containing epoxy coatings under deep-sea environment. Prog. Org. Coat. 2025, 203, 109176. [Google Scholar] [CrossRef]

- Ma, Y.X.; Liu, J.T.; Zhang, Y.R.; Ge, Y.; Wu, R.; Song, X.H.; Zhang, P.; Wu, J. Mechanical behavior and self-healing mechanism of polyurea-based double-walled microcapsule/epoxy composite films. Prog. Org. Coat. 2021, 157, 106283. [Google Scholar] [CrossRef]

- Lim, Y.J.; Song, Y.K.; Kim, D.M.; Chung, C.M. Preparation of isophorone diisocyanate-loaded microcapsules and their application to self-healing protective coating. Polymers 2015, 39, 56–63. [Google Scholar]

- Liu, W.; Zou, S.Q.; Pan, J.Y.; Zhang, Z.Q.; Chen, J.K.; Liu, B.W.; Yue, Z.W. Carbon nanotubes/carbon black reinforced epoxy resin microcapsule-based cement composites with combined self-healing and self-sensing capacities. J. Build. Eng. 2025, 103, 112171. [Google Scholar] [CrossRef]

- Ding, F.Y.; Li, H.B.; Du, Y.M.; Shi, X.W. Recent advances in chitosan-based self-healing materials. Res. Chem. Intermed. 2018, 44, 4827–4840. [Google Scholar] [CrossRef]

- Zhang, L.C.; Wu, K.Y.; Sun, G.Q.; Liu, R.; Luo, J. Investigation of particle size effect on the performance of micro/nano capsules and composite coatings. Colloid Surf. Physicochem. Eng. Asp. 2023, 675, 132020. [Google Scholar] [CrossRef]

- Chang, Y.J.; Yan, X.X. Preparation and self-repairing properties of MF-coated shellac water-based microcapsules. Coatings 2020, 10, 778. [Google Scholar] [CrossRef]

- Liu, J.G.; Chen, F.Y.; Zhang, Q.S.; Xing, X.; Cui, G. Study on preparation and performance of acid pH-responsive intelligent self-healing coating. Polymers 2024, 16, 2473. [Google Scholar] [CrossRef] [PubMed]

- Lv, L.T.; Wang, Y.T.; Dai, J.; Yang, Z.Y.; Yang, Q.L. The study on preparation, stability and anti-allergic efficacy of phycocyanin microcapsules. Food Res. Int. 2025, 201, 115530. [Google Scholar] [CrossRef] [PubMed]

- GB/T 4893.6-2013; Physical and chemical property test of furniture surface paint film Part 6 Gloss determination method. Standardization Administration of the People’s Republic of China: Beijing, China, 2013.

- ASTM D523-25; Standard Test Method for Specular Gloss. ASTM International: West Conshohocken, PA, USA, 2025.

- ISO 11664-4:2019; * Colorimetry—Part 4: CIE 1976 L*a*b* Colour Space*. International Organization for Standardization: Geneva, Switzerland, 2019.

- GB/T 6739-2022; Determination of paint film hardness by the pencil method for color paints and varnishes. Standardization Administration of the People’s Republic of China: Beijing, China, 2022.

- GB/T 4893.4-2023; Physical and chemical property test of furniture surface paint film Part 4: Adhesion cross-cutting method. Standardization Administration of the People’s Republic of China: Beijing, China, 2023.

- GB/T 4893.9-2013; Physical and chemical property test of furniture surface paint film Part 9: Impact resistance method. Standardization Administration of the People’s Republic of China: Beijing, China, 2013.

- Fayyad, E.M.; Almaadeed, M.A.; Jones, A. Encapsulation of tung oil for self-healing coatings in corrosion applications. Sci. Adv. Mater. 2015, 7, 2628–2638. [Google Scholar] [CrossRef]

- Li, H.Y.; Cui, Y.X.; Li, Z.K.; Zhu, Y.J.; Wang, H.Y. Fabrication of microcapsules containing dual-functional tung oil and properties suitable for self-healing and self-lubricating coatings. Prog. Org. Coat. 2018, 115, 164–171. [Google Scholar] [CrossRef]

- Paolini, N.A.; Neto, A.G.C.; Pellanda, A.C.; Jorge, A.R.D.C.; Soares, B.D.; Floriano, J.B.; Berton, M.A.C.; Vijayan, P.P.; Thomas, S. Evaluation of Corrosion Protection of Self-Healing Coatings Containing Tung and Copaiba Oil Microcapsules. Int. J. Polym. Sci. 2021, 2021, 6650499. [Google Scholar] [CrossRef]

- Deng, J.Z.; Yan, X.X. Preparation of Tung Oil Microcapsules Coated with Chitosan–Arabic Gum and Its Effect on the Properties of UV Coating. Polymers 2025, 17, 1985. [Google Scholar] [CrossRef]

- Veeramani, N.; Samikannu, R.; Deshpande, A.P.; Varghese, S.; Moses, V. Effects of polymeric microcapsules on self-healing composites reinforced with carbon fibers: A comparative study. Int. Polym. Process. 2023, 38, 483–495. [Google Scholar] [CrossRef]

- Yan, X.X.; Zhao, W.T.; Wang, L. Mechanism of thermochromic and self-repairing of waterborne wood coatings by synergistic action of waterborne acrylic microcapsules and fluorane microcapsules. Polymers 2021, 14, 56. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.G.; Zhou, Y.H.; Hu, L.H. Novel biobased materials from tung oil-based monomer and tung oil-modified unsaturated polyester. Adv. Mater. Res. 2012, 581, 121–124. [Google Scholar] [CrossRef]

- Zhang, T.; Deng, J.; Zhang, L.Z. A photothermal self-healing superhydrophobic coating with anti-frosting and anti-corrosion properties. Prog. Org. Coat. 2023, 180, 107569. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).