Surface Property Differences of European Larch Sapwood and Heartwood After Sanding

Abstract

1. Introduction

2. Materials and Methods

2.1. Wood Preparation

2.2. Microscopic Measurements

2.3. Roughness Parameters Determination

2.4. Wettability Measurements

2.5. Wood Colour Determination

2.6. Statistical Analysis

3. Results and Discussion

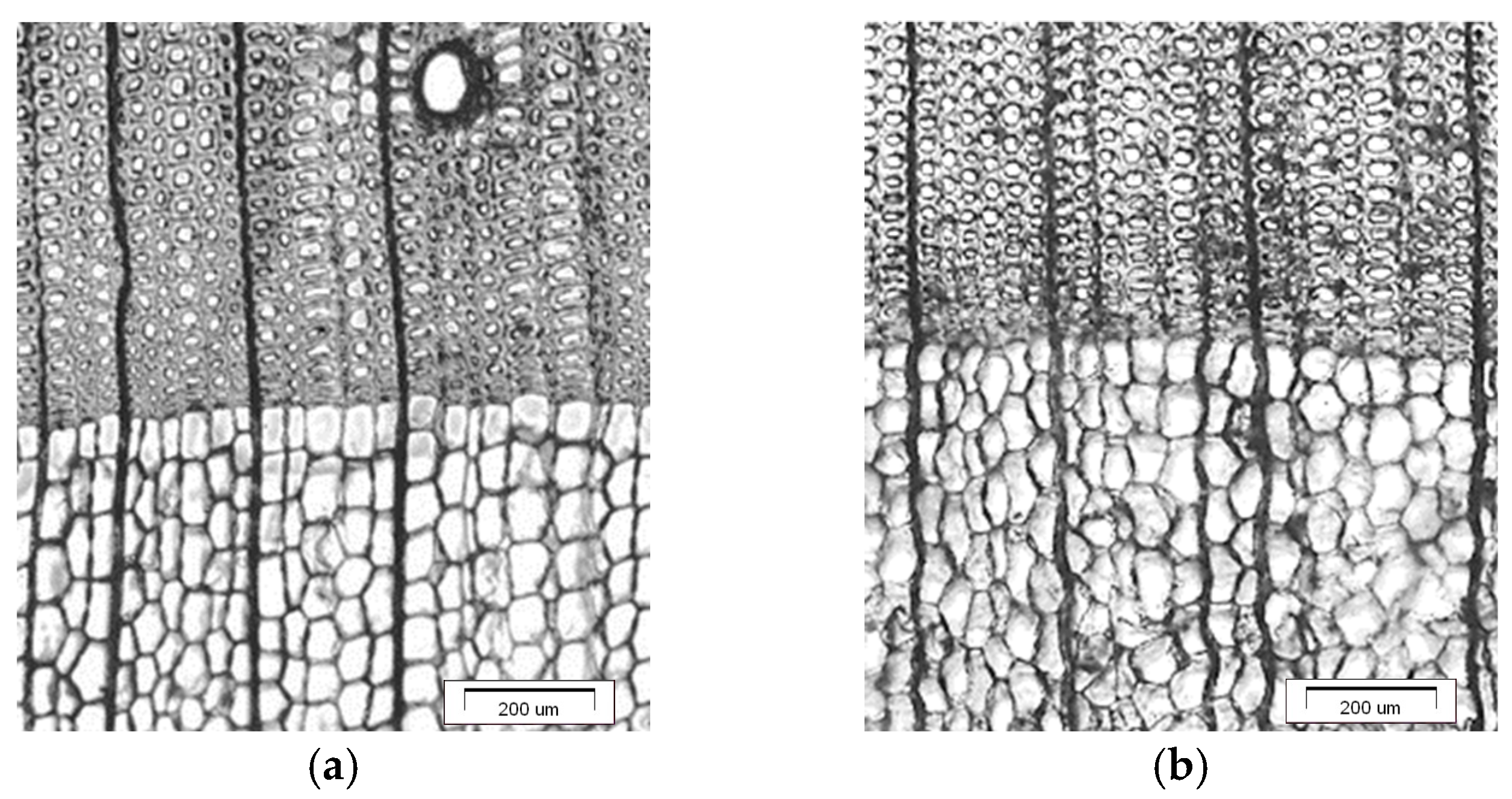

3.1. European Larch Tracheids Dimensions

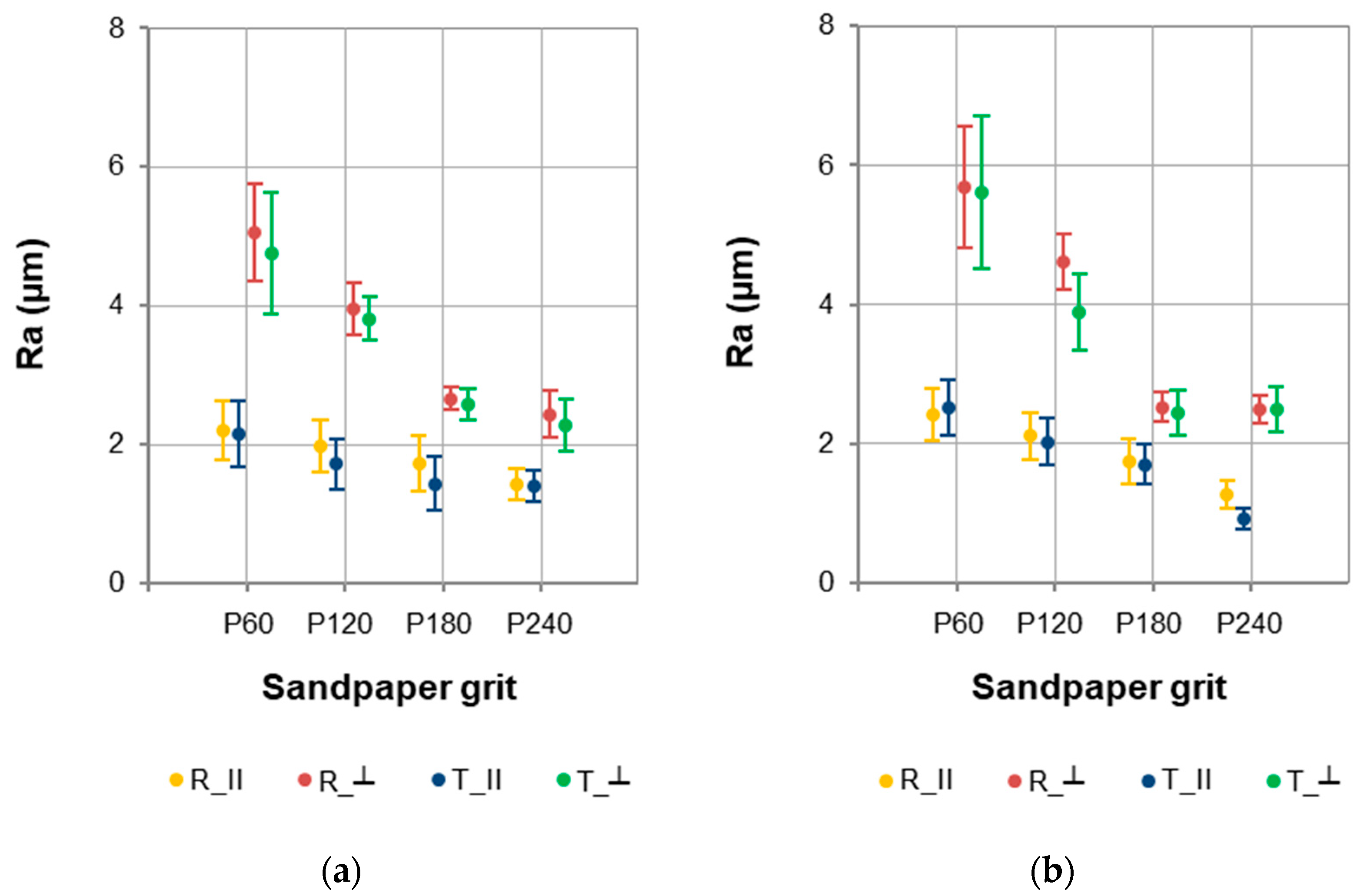

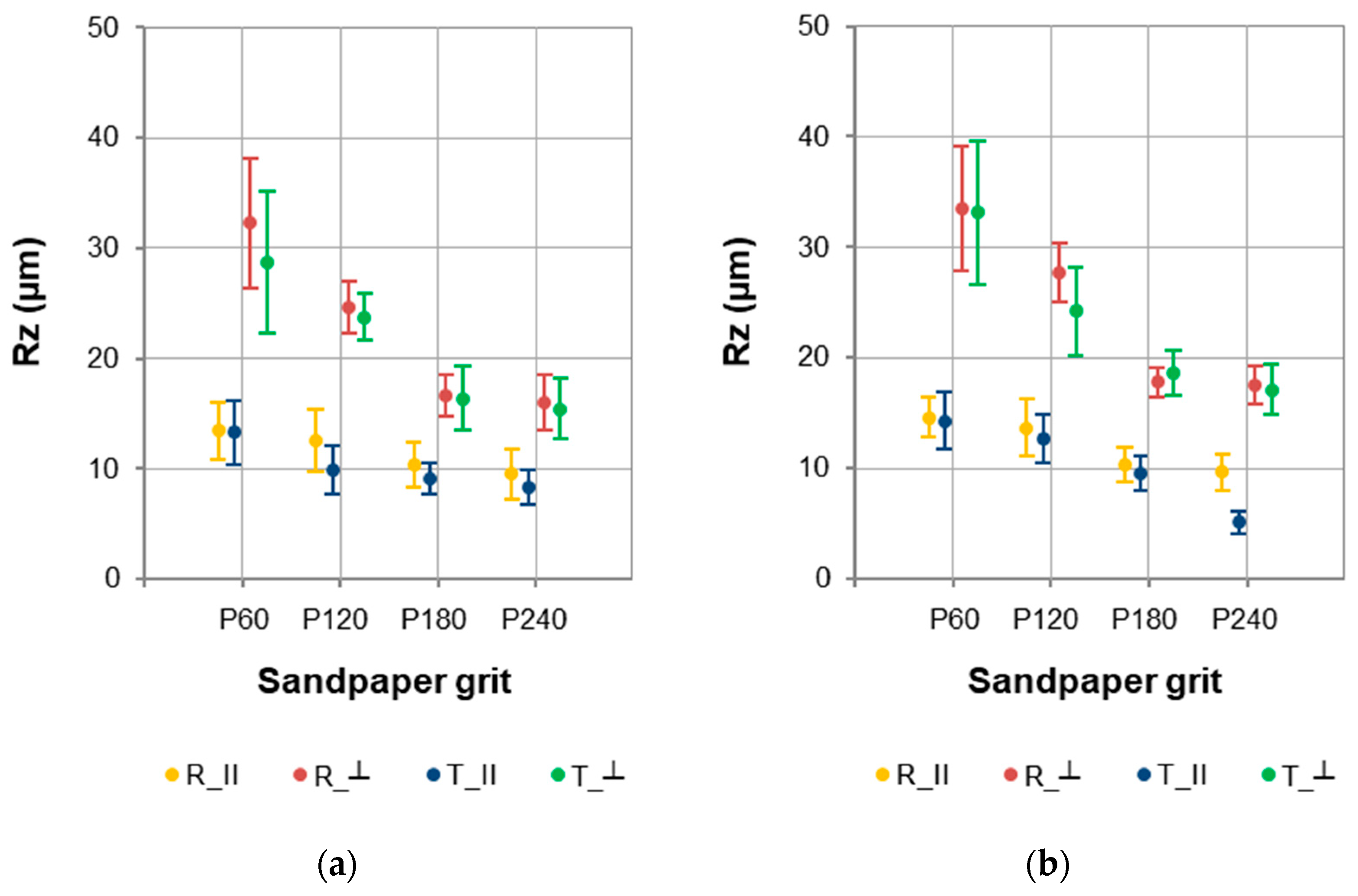

3.2. Roughness of European Larch Wood

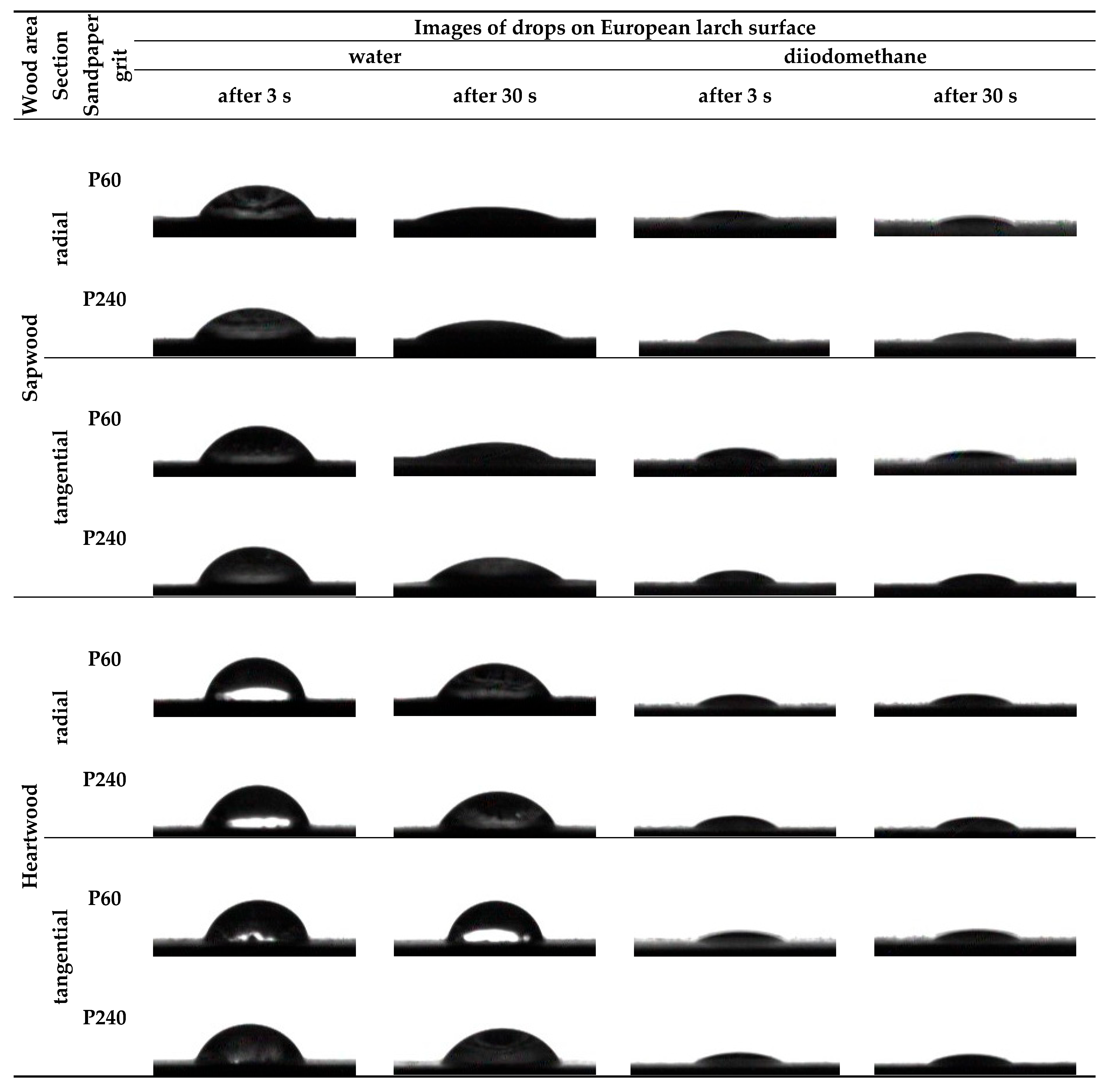

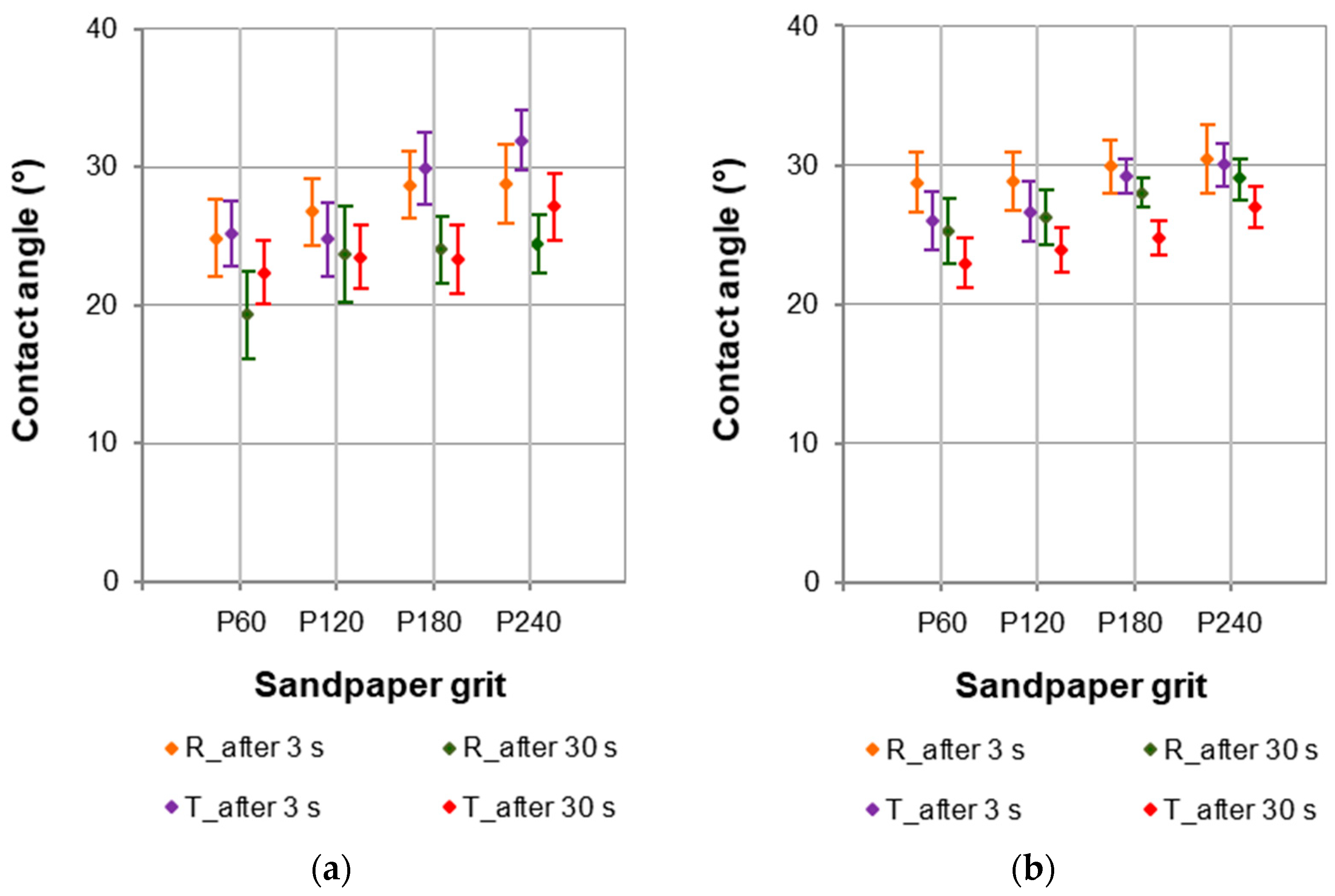

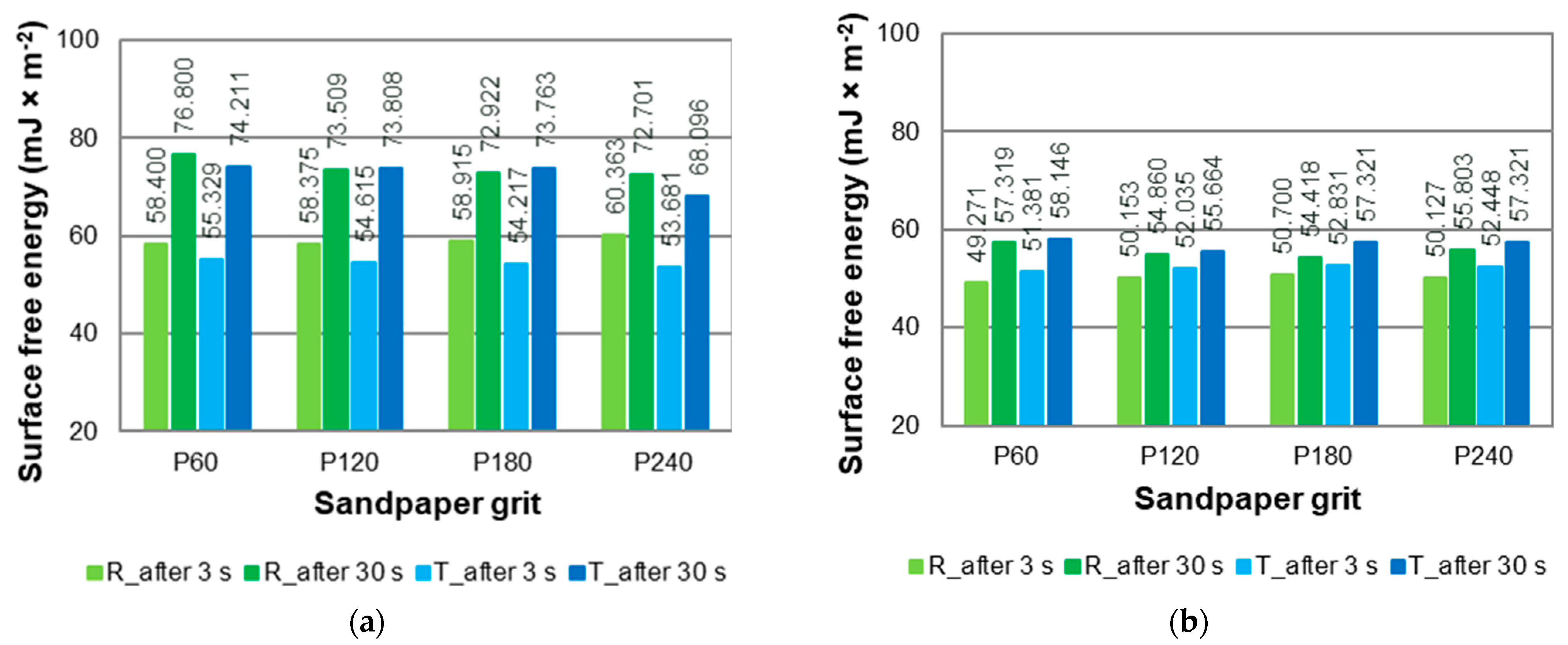

3.3. Wettability of European Larch Wood

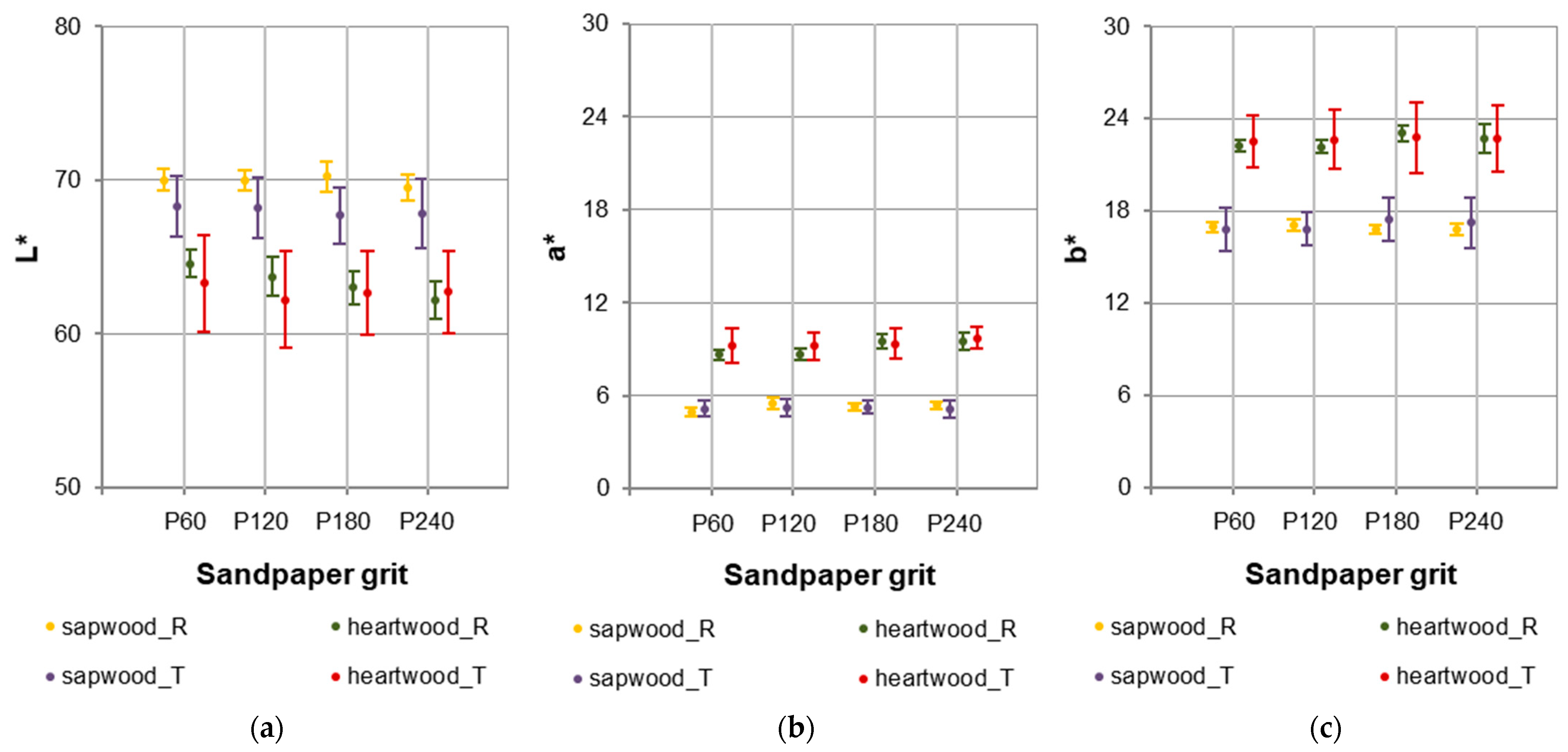

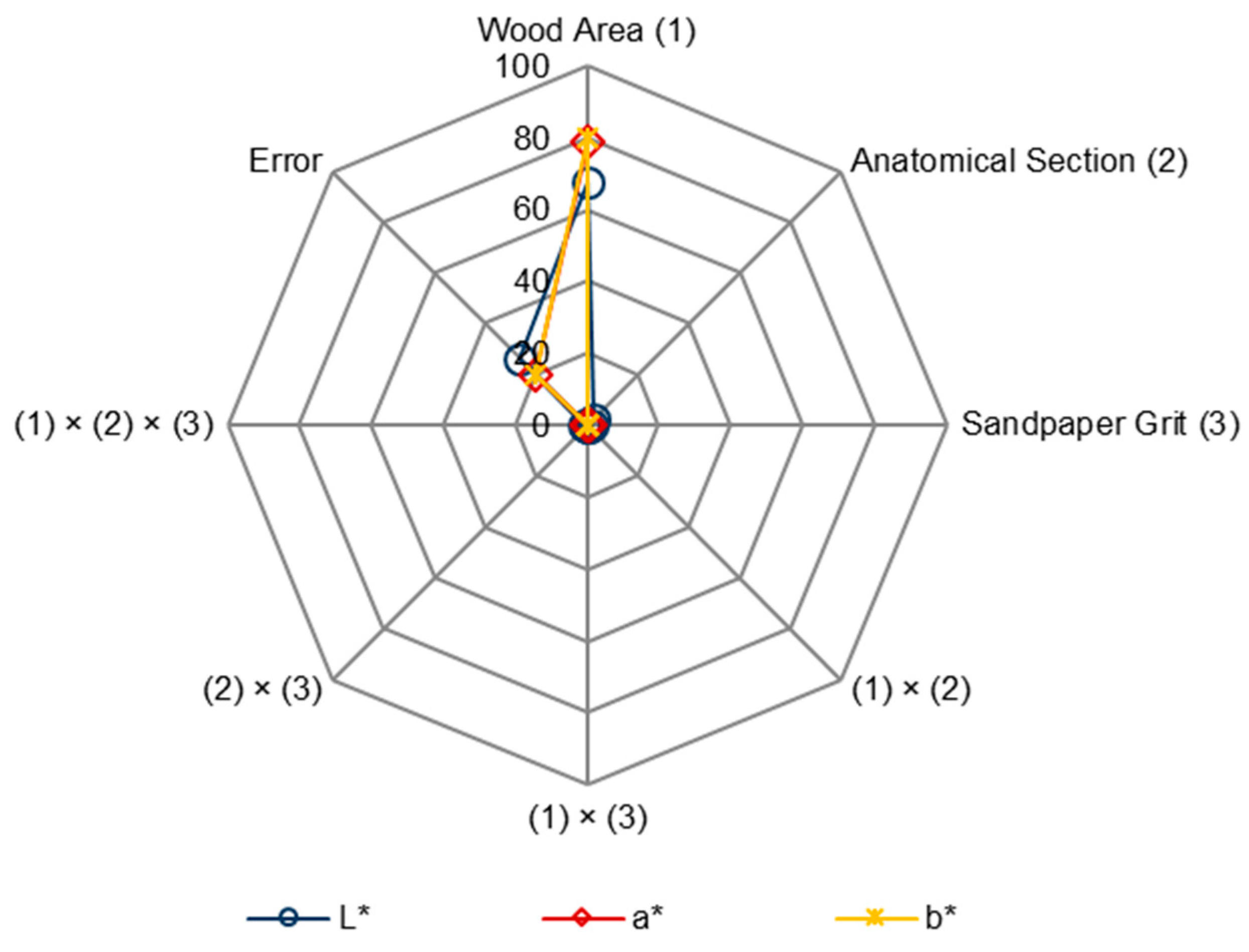

3.4. Colour of European Larch Wood

4. Conclusions

- The sapwood and heartwood of European larch wood on the same anatomical section (radial or tangential) are characterised by similar roughness. The differentiating factors were measurement direction (parallel to the grain or perpendicular to the grain) and sandpaper grit size (in the range P60–P240).

- The measurement direction showed an influence of 47% and sandpaper grit of 30% on Ra value parameter. Similar relationships were found in relation to the Rz parameter. The measurement direction showed an influence of 52% and sandpaper grit of 26%.

- Sapwood was characterised by greater wettability (contact angle with water) than heartwood. Taking into account the section of the wood, sapwood was characterised by the lower wettability on the tangential section, while the heartwood was characterised by the lower wettability on the radial section. This was examined for the contact angle tests performed 3 s after the water droplet had been applied to the wood surface.

- Wood area had the greatest impact on the contact angles at phase boundary wood–water. This influence increased from 55% to 89% when examining the contact angle after 3 s and 30 s.

- Sapwood exhibited generally higher surface free energy values than heartwood. For sapwood, higher surface free energy values were noted for the radial section, and for heartwood these values were noted for the tangential section. These relationships were particularly visible after 3 s from the application of a drop of liquid to the wood surface.

- Wood colour was predominantly influenced by wood area. Sanding the surface of European larch wood with P60–P240 sandpapers changes the texture of the wood, but does not significantly affect the differentiation of the colour parameters, i.e., L*, a*, b*. The greatest colour change ΔE, at level 2.59, was noted for the heartwood on the radial section after sanding with P240 sandpaper. The reference point was the colour parameters determined for heartwood radial section after sanding with P60 sandpaper.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Richter, K.; Feist, W.C.; Knaebe, M.T. The effect of surface roughness on the performance of finishes. Part 1: Roughness characterization and stain performance. For. Prod. J. 1995, 45, 91–96. [Google Scholar]

- Sandak, J.; Negri, M. Wood surface roughness—What is it. In Proceedings of the 17th International Wood Machining Seminar, Rosenheim, Germany, 26–28 September 2005. [Google Scholar]

- Ugulino, B.; Hernández, R.E. Analysis of sanding parameters on surface properties and coating performance of red oak wood. Wood Mater. Sci. Eng. 2016, 13, 64–72. [Google Scholar] [CrossRef]

- Sydor, M.; Mirski, R.; Stuper-Szablewska, K.; Rogoziński, T. Efficiency of machine sanding of wood. Appl. Sci. 2021, 11, 2860. [Google Scholar] [CrossRef]

- Bembenek, M. Researches on influence of wood sanding direction on wood gluing. J. Indian Acad. Wood Sci. 2022, 19, 103–109. [Google Scholar] [CrossRef]

- De Maura, L.F.; Hernández, R.E. Evaluation of varnish coating performance for two surfacing methods on sugar maple wood. Wood Fiber Sci. 2005, 37, 355–366. [Google Scholar]

- De Maura, L.F.; Hernández, R.E. Effects of abrasive mineral, grit size and feed speed on the quality of sanded surfaces of sugar maple wood. Wood Sci. Technol. 2006, 40, 517–530. [Google Scholar] [CrossRef]

- Aguilera, A.; Zamora, R. Surface roughness in sapwood and heartwood of blackwood (Acacia melanoxylon R. Br.) machined in 90-0 direction. Eur. J. Wood Wood Prod. 2009, 67, 297–301. [Google Scholar] [CrossRef]

- Cool, J.; Hernández, R.E. Improving the sanding process of black spruce wood for surface quality and water-based coating adhesion. For. Prod. J. 2011, 61, 372–380. [Google Scholar] [CrossRef]

- Tan, P.L.; Sharif, S.; Sudin, I. Roughness models for sanded wood surfaces. Wood Sci. Technol. 2012, 46, 129–142. [Google Scholar] [CrossRef]

- Luo, B.; Liu, H.; Xu, M.; Xing, F. Analysis of sanding parameters, sanding force, normal force, power consumption, and surface roughness in sanding wood-based panels. Bioresources 2014, 9, 7494–7503. [Google Scholar] [CrossRef]

- Borkowski, J.A. Uses of Abrasives and Abrasive Tools, 1st ed.; Borkowski, J.A., Szymański, A.M., Eds.; Ellis Horwood Series in Mechanical Engineering; Hardcover; Prentice Hall: Upper Saddle River, NJ, USA, 1992; p. 288. ISBN 978-0-13-932518-2. [Google Scholar]

- Taylor, J.B.; Carrano, A.L.; Lemaster, R.L. Quantification of Process Parameters in a Wood Sanding Operation. For. Prod. J. 1999, 49, 41–46. [Google Scholar]

- Očkajová, A.; Sikliena, M. The Influence of Chosen Factors of Wood Sanding upon the Efficiency of Sand Belt. Drev. Vysk./Wood Res. 2000, 45, 33–38. [Google Scholar]

- Carrano, A.L.; Taylor, J.B.; Lemaster, R. Parametric Characterization of Peripheral Sanding. For. Prod. J. 2002, 52, 44–50. [Google Scholar]

- Sinn, G.; Gindl, M.; Reiterer, A.; Stanzl-Tschegg, S. Changes in the Surface Properties of Wood Due to Sanding. Holzforschung 2004, 58, 246–251. [Google Scholar] [CrossRef]

- Gurau, L.; Mansfield-Williams, H.; Irle, M. Processing Roughness of Sanded Wood Surfaces. Eur. J. Wood Wood Prod. 2005, 63, 43–52. [Google Scholar] [CrossRef]

- Kilic, M.; Hiziroglu, S.; Burdurlu, E. Effect of machining on surface roughness of wood. Build. Environ. 2006, 41, 1074–1078. [Google Scholar] [CrossRef]

- De Moura, L.F.; Cool, J.; Hernández, R.E. Anatomical evaluation of wood surfaces produced by oblique cutting and face milling. IAWA J. 2010, 31, 77–88. [Google Scholar] [CrossRef]

- Laina, R.; Sans-Lobera, A.; Villasante, A.; Lopez-Espi, P.; Martinez-Rojas, J.A. Effect of the anatomical structure, wood properties and machining conditions on surface roughness of wood. Maderas-Cienc. Y Tecnol. 2017, 19, 203–212. [Google Scholar] [CrossRef]

- Myles, A.; Wright, A.; Mitton, D. The impact of sanding on the surface properties of wood. Wood Fiber Sci. 2015, 47, 29–36. [Google Scholar][Green Version]

- Jang, S.; Lee, D.; Hwang, T. Influence of sanding on the surface roughness of wood. Wood Sci. Technol. 2017, 51, 573–582. [Google Scholar][Green Version]

- Piao, C.; Winandy, J.E.; Shupe, T.F. From hydrophilicity to hydrophobicity: A critical review: Part I. Wettability and surface behawior. Wood Fiber Sci. 2010, 42, 490–510. [Google Scholar][Green Version]

- Petrić, M.; Primoz, O. Determination of Wettability of Wood and its Significance in Wood Science and Technology. A Cris. Review. Rev. Adhes. Adhes. 2015, 3, 121–187. [Google Scholar] [CrossRef]

- da Silva Siebra, M.B.; de Lima Fernandes, N.C.; Ribeiro, P.G.; Lobão, M.S. Molhabilidade de duas madeiras amazônicas tratadas com produtos de acabamento. Sci. Nat. 2020, 2, 68–71. [Google Scholar]

- Sinderski, L.G.Z. Ângulo de Contato e Rugosidade de Madeiras, uma breve revisão. Braz. J. Wood Sci. 2020, 11, 1–11. [Google Scholar] [CrossRef]

- Očkajová, A.; Kučerka, M.; Krišťák, L.; Ružiak, I.; Gaff, M. Efficiency of sanding belts for beech and oak sanding. BioResources 2016, 11, 5242–5254. [Google Scholar] [CrossRef]

- Thoma, H.; Peri, L.; Lato, E. Evaluation of wood surface roughness depending on species characteristics. Maderas. Cienc. Y Tecnol. 2015, 17, 285–292. [Google Scholar] [CrossRef]

- Chun-Won, K.; Kazuharu, H.; Eunsuk, J.; Haradhan, K. Relationship between wood anatomical features and surface roughness characteristics. Wood Res. 2023, 68, 455–464. [Google Scholar] [CrossRef]

- Aslan, S.; Coşkun, H.; Kiliç, M. The Effect of the Cutting Direction, Number of Blades and Grain Size of the Abrasives on Surface Roughness of Taurus Cedar (Cedrus libani A. Rich.). Woods. Build. Environ. 2008, 43, 696–701. [Google Scholar] [CrossRef]

- Jankowska, A. Understanding of surface roughness of wood based on analysis its structure and density. Ann. WULS—SGGW. For. Wood Technol. 2020, 111, 27–31. [Google Scholar] [CrossRef]

- Hiziroglu, S.; Anwar, U.M.K.; Hamdan, H.; Paridah, M.T. Evaluation of surface quality of some Malaysian species as function of outdoor exposure. J. Mater. Process. Technol. 2008, 199, 156–162. [Google Scholar] [CrossRef]

- Amorim, M.R.S.; Ribeiro, P.G.; Martins, S.A.; Del Menezzi, C.H.S.; De Souza, M.R. Surface wettability and roughness of 11 Amazonian tropical hardwoods. Floresta E Ambiente 2013, 20, 99–109. [Google Scholar] [CrossRef]

- Alia-Syahirah, Y.; Paridah, M.T.; Hamdan, H.; Anwar, U.M.K.; Nordhalia, A.S.; Lee, S.H. Effects of anatomical characteristics and wood density on surface roughness and their relation to surface wettability of hardwood. J. Trop. For. Sci. 2019, 31, 269–277. [Google Scholar] [CrossRef]

- Suwała, M. Drewno w meblarstwie. Leśne Pr. Badaw. 2004, 1, 144–149. [Google Scholar]

- Kopeć, K. Drewno. Właściwości i Zastosowanie. [Wood. Properties and Uses]; Karol Kopeć: Starachowice, Poland, 2017; Volume I, p. 207. ISBN 978-83-946932-1-3. [Google Scholar]

- Gierlinger, N.; Jacques, D.; Schwanninger, M.; Wimmer, R.; Pâques, L.E. Heartwood extractives and lignin content of different larch species (Larix sp.) and relationships to brown-rot decay-resistance. Trees 2004, 18, 230–236. [Google Scholar] [CrossRef]

- Grabner, M.; Müller, U.; Gierlinger, N.; Wimmer, R. Effects of Heartwood Extractives on Mechanical Properties of Larch. IAWA J. 2005, 26, 211–220. [Google Scholar] [CrossRef]

- Wang, Z.J.; DeGroot, R. Treatability and Durability of Heartwood. In National Conference on Wood Transportation Structures; Ritter, M.A., Duwadi, S.R., Lee, P.D.H., Eds.; Gen. Tech. Rep. FPL-GTR-94; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1996. [Google Scholar]

- Vek, V.; Balzano, A.; Poljanšek, I.; Humar, M.; Oven, P. Improving Fungal Decay Resistance of Less Durable Sapwood by Impregnation with Scots Pine Knotwood and Black Locust Heartwood Hydrophilic Extractives with Antifungal or Antioxidant Properties. Forests 2020, 11, 1024. [Google Scholar] [CrossRef]

- Masuda, M. Influence of Colour and Glossiness on Image of Wood. J. Soc. Mater. Sci. 1985, 34, 972–978. [Google Scholar] [CrossRef]

- Lindberg, S.; Roos, A.; Kihlstedt, A.; Lindström, M. A product semantic study of the influence of the sense of touch on the evaluation of wood-based materials. Mater. Des. 2013, 52, 300–307. [Google Scholar] [CrossRef]

- Rowell, R.M. (Ed.) Handbook of Wood Chemistry and Wood Composites, 2nd ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2012; p. 703. [Google Scholar] [CrossRef]

- Kamke, F.A.; Lee, J.N. Adhesive penetration in wood—A review. Wood Fiber Sci. 2007, 39, 205–220. [Google Scholar]

- Bardak, S.; Nemli, G.; Bardak, T. The quality comparison of particleboards produced from heartwood and sapwood of European larch. Maderas. Cienc. Y Tecnol. 2019, 21, 511–520. [Google Scholar] [CrossRef]

- ISO 13061-1; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 1: Determination of Moisture Content for Physical and Mechanical Tests. International Organization for Standardization: Geneva, Switzerland, 2014.

- ISO 13061-2; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 2: Determination of Density for Physical and Mechanical Tests. International Organization for Standardization: Geneva, Switzerland, 2014.

- ISO 21920-2; Geometrical Product Specifications (GPS)—Surface Texture: Profile Part 2: Terms, definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 2021.

- Gindl, M.; Sinn, G.; Gindl, W.; Reiterer, A.; Tschegg, S. A comparison of different methods to calculate the surface free energy of wood using contact angle measurements. Colloids Surf. A—Physicochem. Eng. Asp. 2001, 181, 279–287. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- EN ISO/CIE 11664-2; Colorimetry—Part 2: CIE standard illuminants. International Organization for Standardization: Geneva, Switzerland, 2022.

- ISO 7724-3; Paints and Varnishes—Colorimetry—Part 3: Calculation of Colour Differences. International Organization for Standardization: Geneva, Switzerland, 1984.

- Wagenführ, R. Holzatlas, 6th ed.; Neu Bearbeitete und Erweiteste Auflage; Fachbuchverlag: Leipzig, Germany, 2007. [Google Scholar]

- Mańkowski, P.; Laskowska, A. Compressive strength parallel to grain of earlywood and latewood of yellow pine. Maderas-Cienc. Y Tecnol. 2021, 23, 1–12. [Google Scholar] [CrossRef]

- Pazdrowski, W.; Jelonek, T.; Tomczak, A.; Stypuła, I.; Spława-Neyman, S. Proportion of sapwood and heartwood and selected biometric features in larch trees (Larix decidua Mill.). Wood Res. 2007, 52, 1–16. [Google Scholar]

- Bektaş, İ.; Tutuş, A.; Gültekin, G. The Effect of Sapwood and Heartwood Differences on Mechanical Properties of Fast-Growing Tree Species. Drv. Ind. 2020, 71, 261–269. [Google Scholar] [CrossRef]

- Kozakiewicz, P.; Życzkowski, W. Physical and mechanical properties and anatomy of common juniper (Juniperus communis L.). wood. Sylwan 2015, 159, 151–159. [Google Scholar] [CrossRef]

- Sinn, G.; Myesterday, H.; Stanzl-Tschegg, S. Surface properties of wood and MDF after ultrasonic-assisted cutting. J. Mater. Sci. 2005, 40, 4325–4332. [Google Scholar] [CrossRef]

- Hendarto, B.; Shayan, E.; Ozarska, B.; Carr, R. Analysis of roughness of a sanded wood surface. Int. J. Adv. Manuf. Technol. 2006, 28, 775–780. [Google Scholar] [CrossRef]

- Liptáková, E.; Kúdela, J. Analysis of the Wood-Wetting Process. Holzforschung 1994, 48, 139–144. [Google Scholar] [CrossRef]

- Słupianek, A.; Dolzblasz, A.; Sokołowska, K. Xylem Parenchyma—Role and Relevance in Wood Functioning in Trees. Plants 2021, 10, 1247. [Google Scholar] [CrossRef] [PubMed]

- Ugrenović, A. Wood Technology; Croatian Publishing: House, Zagreb, 1950. [Google Scholar]

- Horvat, I.; Krpan, J. Drvnoindustrijski Priručnik; Croatian Publishing: House, Zagreb, 1967. [Google Scholar]

- Mokrzycki, W.S.; Tatol, M. Colour difference ∆E—A survey. Mach. Graph. Vis. 2011, 20, 383–411. [Google Scholar]

| Area | Tracheids | Diameter (µm) | |

|---|---|---|---|

| Radial Direction | Tangential Direction | ||

| Sapwood | Earlywood | 50.25 (7.07) | 34.61 (7.26) |

| Latewood | 9.58 (2.34) | 21.12 (5.10) | |

| Heartwood | Earlywood | 42.29 (8.61) | 26.65 (4.12) |

| Latewood | 5.61 (1.43) | 19.34 (4.47) | |

| Roughness Parameters | Factor | Fisher’s F-Test | Significance Level | Factor Influence (%) |

|---|---|---|---|---|

| F | p | |||

| Ra | Wood Area (1) | 12.287 | 0.000539 | 1 |

| Anatomical Section (2) | 5.610 | 0.018611 | 1 | |

| Direction (3) | 935.035 | 0.000000 | 47 | |

| Sandpaper Grit (4) | 205.481 | 0.000000 | 30 | |

| (1) × (2) | 0.690 | 0.406879 | 0 | |

| (1) × (3) | 5.357 | 0.021441 | 1 | |

| (1) × (4) | 3.856 | 0.010055 | 1 | |

| (2) × (3) | 0.760 | 0.384144 | 0 | |

| (2) × (4) | 1.203 | 0.309147 | 0 | |

| (3) × (4) | 58.923 | 0.000000 | 9 | |

| (1) × (2) × (3) | 0.341 | 0.559770 | 0 | |

| (1) × (2) × (4) | 1.456 | 0.227145 | 0 | |

| (1) × (3) × (4) | 1.609 | 0.187847 | 0 | |

| (2) × (3) × (4) | 2.579 | 0.054184 | 0 | |

| (1) × (2) × (3) × (4) | 2.202 | 0.088295 | 0 | |

| Error | 10 | |||

| Rz | Wood Area (1) | 9.171 | 0.002719 | 1 |

| Anatomical Section (2) | 10.687 | 0.001232 | 1 | |

| Direction (3) | 885.044 | 0.000000 | 52 | |

| Sandpaper Grit (4) | 152.530 | 0.000000 | 26 | |

| (1) × (2) | 0.008 | 0.930706 | 0 | |

| (1) × (3) | 4.006 | 0.046435 | 1 | |

| (1) × (4) | 1.320 | 0.268294 | 0 | |

| (2) × (3) | 0.247 | 0.619288 | 0 | |

| (2) × (4) | 0.847 | 0.469196 | 0 | |

| (3) × (4) | 36.569 | 0.000000 | 6 | |

| (1) × (2) × (3) | 0.295 | 0.587791 | 0 | |

| (1) × (2) × (4) | 0.722 | 0.539497 | 0 | |

| (1) × (3) × (4) | 0.802 | 0.493887 | 0 | |

| (2) × (3) × (4) | 1.329 | 0.265495 | 0 | |

| (1) × (2) × (3) × (4) | 1.498 | 0.215772 | 0 | |

| Error | 13 |

| Wood Area | Sandpaper Grit | ΔE | |

|---|---|---|---|

| Section | |||

| Radial | Tangential | ||

| Sapwood | 120 | 1.22 | 0.11 |

| 180 | 0.47 | 0.89 | |

| 240 | 0.69 | 0.66 | |

| Heartwood | 120 | 0.85 | 1.08 |

| 180 | 1.98 | 0.66 | |

| 240 | 2.59 | 0.78 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Laskowska, A.; Lipska, K.; Kłosińska, T.; Piwek, A.; Boruszewski, P. Surface Property Differences of European Larch Sapwood and Heartwood After Sanding. Coatings 2025, 15, 860. https://doi.org/10.3390/coatings15070860

Laskowska A, Lipska K, Kłosińska T, Piwek A, Boruszewski P. Surface Property Differences of European Larch Sapwood and Heartwood After Sanding. Coatings. 2025; 15(7):860. https://doi.org/10.3390/coatings15070860

Chicago/Turabian StyleLaskowska, Agnieszka, Karolina Lipska, Teresa Kłosińska, Anna Piwek, and Piotr Boruszewski. 2025. "Surface Property Differences of European Larch Sapwood and Heartwood After Sanding" Coatings 15, no. 7: 860. https://doi.org/10.3390/coatings15070860

APA StyleLaskowska, A., Lipska, K., Kłosińska, T., Piwek, A., & Boruszewski, P. (2025). Surface Property Differences of European Larch Sapwood and Heartwood After Sanding. Coatings, 15(7), 860. https://doi.org/10.3390/coatings15070860