Recent Advances in Silver Nanowire-Based Transparent Conductive Films: From Synthesis to Applications

Abstract

1. Introduction

2. Characteristics of Flexible TCFs

2.1. Transparency and Conductivity

2.2. Flexibility and Stability

3. AgNW Synthesis and Film Coating

3.1. Silver Nanowire Synthesis Methods

3.1.1. Liquid-Phase Chemical Reduction (Polyol Method)

3.1.2. Template-Assisted Synthesis

3.1.3. Electrochemical Deposition

3.1.4. Microfluidic and Continuous Flow Synthesis

3.2. Silver Nanowire Film Formation Methods

3.2.1. Mayer Rod Coating Method

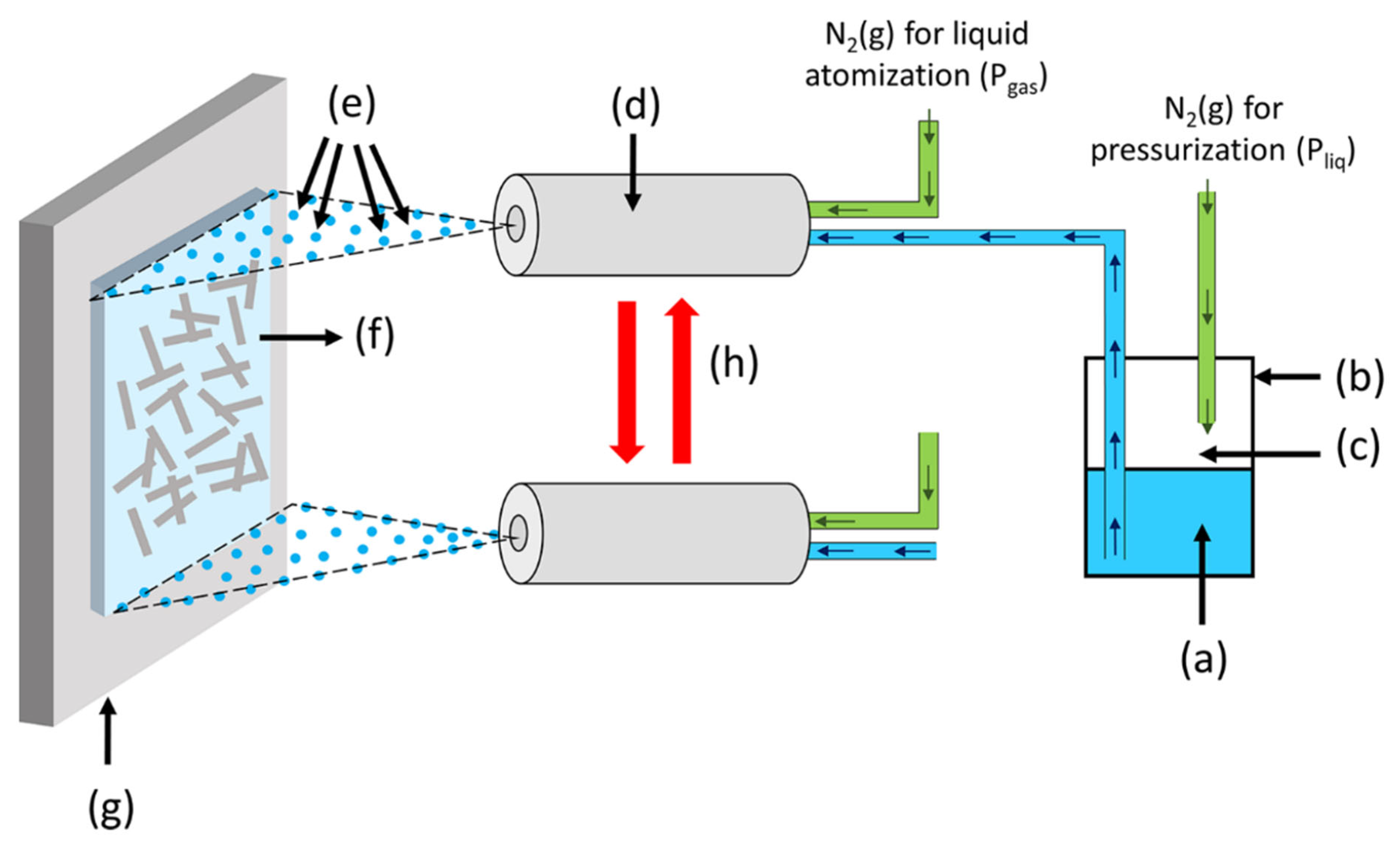

3.2.2. Spraying Method

3.2.3. Spin-Coating Method

3.2.4. Silk-Screen Printing

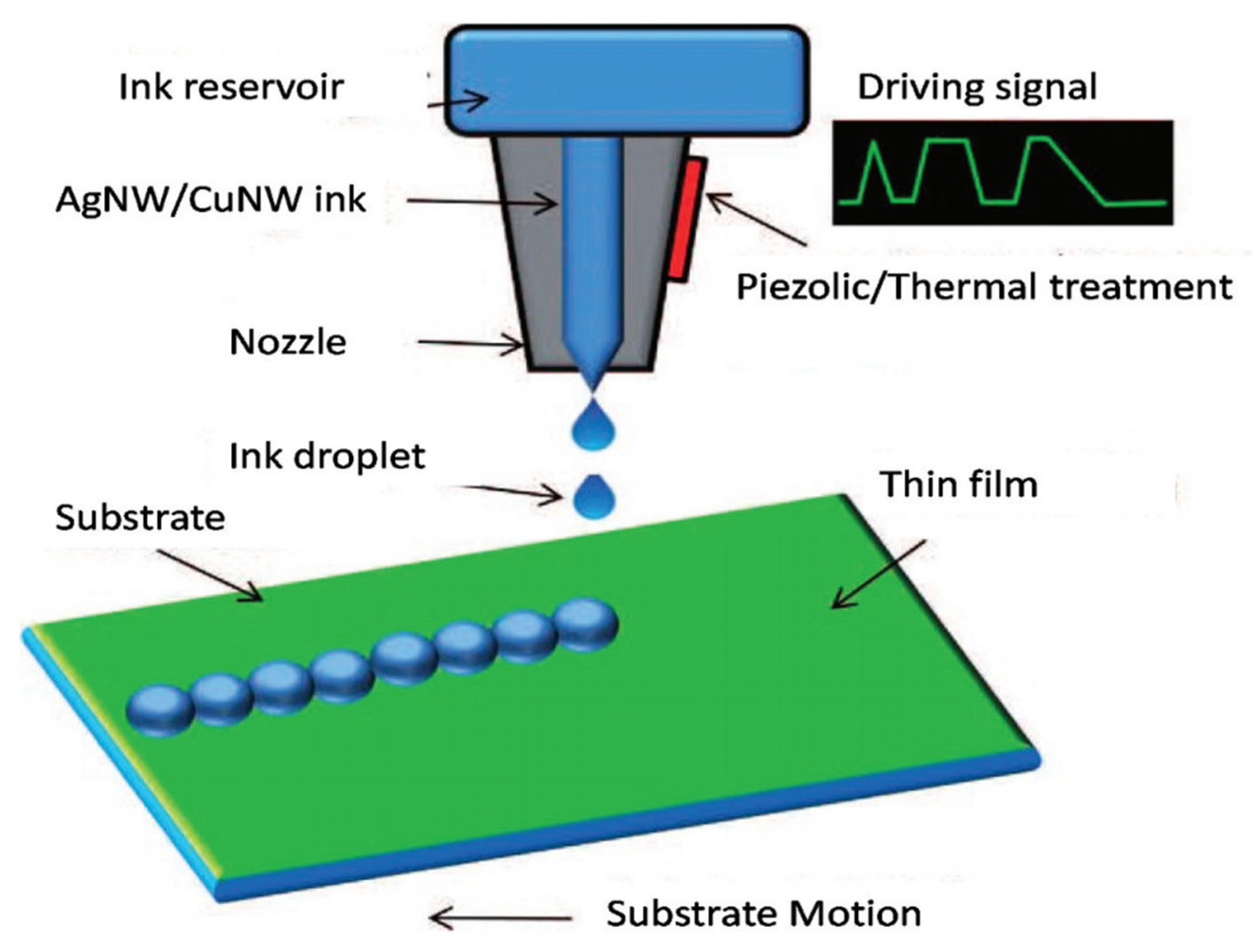

3.2.5. Inkjet Printing Method

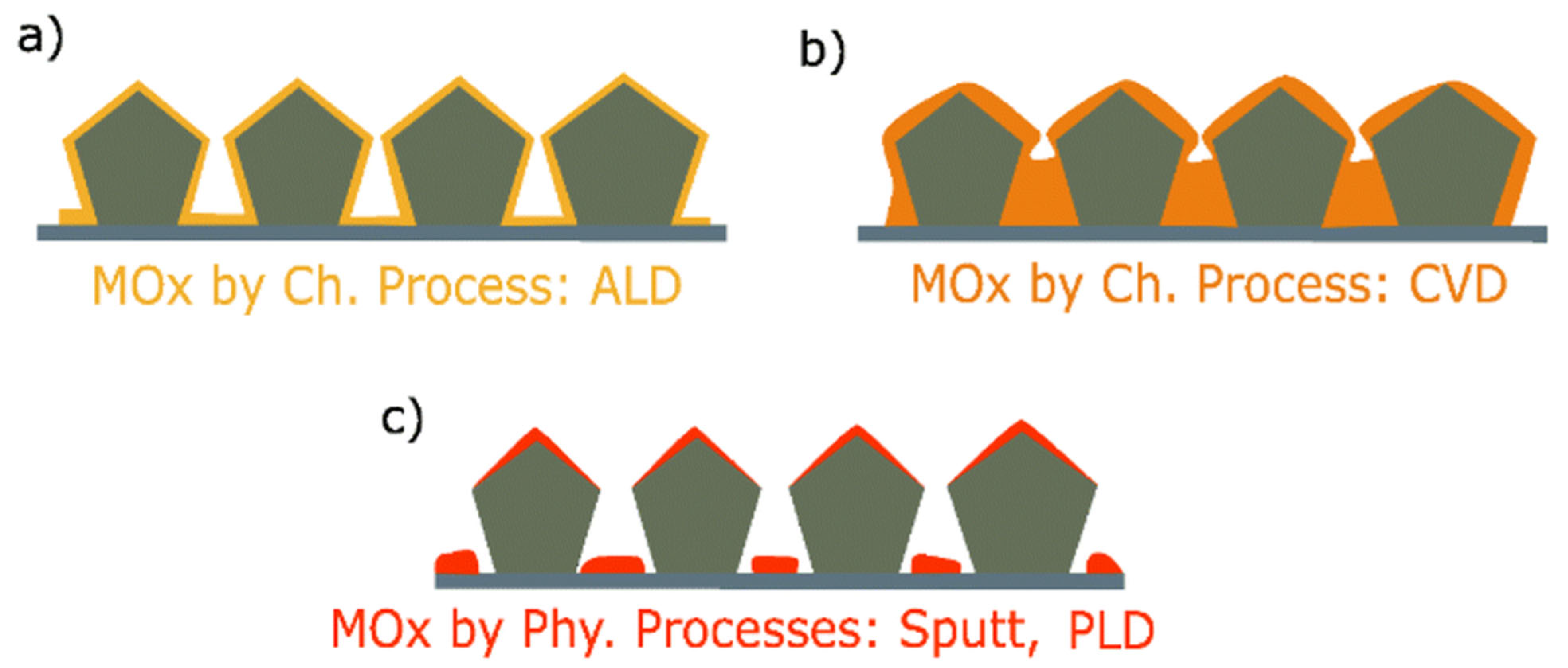

4. Methods for Coating AgNW Networks with Metal Oxides

4.1. Physical Vapor Deposition Methods

4.1.1. Sputtering Deposition

4.1.2. Pulsed Layer Deposition (PLD)

4.2. Chemical Deposition Methods

4.2.1. Chemical Vapor Deposition (CVD)

4.2.2. Atomic Layer Deposition (ALD)

4.2.3. Solution Methods

4.3. Hybrid Approaches

5. Application of AgNW-TCFs

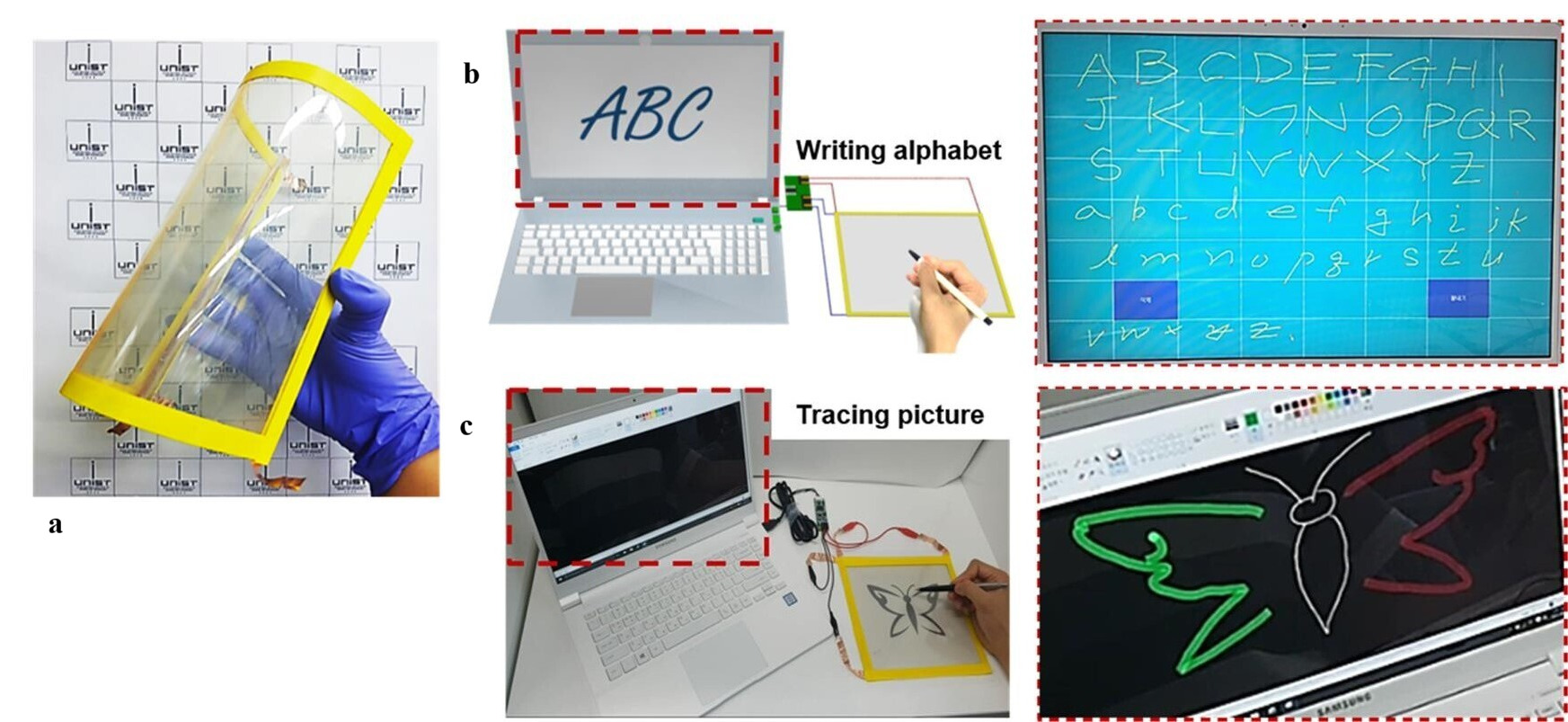

5.1. Displays/Touch Screens

5.2. Lighting and Organic Light-Emitting Diodes (OLEDs)

5.3. Organic Solar Cells (OSCs)

5.4. Flexible Sensors

5.5. Electromagnetic Shielding

5.6. Other Important Applications

6. Stability Challenges and Mitigation in AgNW Networks

6.1. The Degradation Mechanism of AgNWs

6.1.1. Electrical Instability

6.1.2. Thermal Failure

6.1.3. Photodegradation

6.1.4. Chemical Corrosion

- (1)

- Electrical instability: Driven by electromigration and Joule heating under DC bias, this mechanism induces Ag+ ion migration, dendritic growth, and junction failure. AC operation partially mitigates directional ion transport.

- (2)

- Thermal failure: At elevated temperatures (>200 °C), Rayleigh instability and surface diffusion are activated, leading to nanowire coalescence, increased junction resistance, and optical haze.

- (3)

- Photodegradation: UV-induced plasmonic heating accelerates oxidation/sulfidation, forming conductive hot spots and structural defects.

- (4)

- Chemical corrosion: Exposure to atmospheric sulfur, moisture, or reactive layers (e.g., MAPbI3) converts AgNWs into insulating Ag2S, degrading conductivity.

6.2. Mitigation Strategies

6.2.1. Surface Encapsulation

6.2.2. Stabilization Additives

6.2.3. Hybrid Nanocomposites

6.2.4. Process Optimization

6.3. Future Challenges and Research Directions

- Dynamic Failure Modeling: Develop multiscale models (nano to macro) simulating real-time failure processes, such as hot-spot diffusion under electrothermal stress. Integrate microscale mechanisms (e.g., Rayleigh instability, electromigration) with macroscale transport behavior to enable predictive analysis of failure propagation.

- Standardized Testing: Establish unified lifetime metrics (e.g., time-to-failure, TTF) under multi-stress conditions (thermal/chemical/mechanical coupling), replacing single extreme tests. Standardize reporting of degradation kinetics (e.g., cyclic resistance changes).

- Process Optimization: Deploy roll-to-roll (R2R) compatible encapsulation technologies (e.g., atomic layer deposition, ALD; GO) to enhance coating uniformity, reduce ALD energy use, and lower GO processing costs for scalable manufacturing. This will ensure cost-effective reliability across flexible electronics and optoelectronic applications.

7. Conclusions and Outlook

7.1. Conclusions

7.2. Outlook and Future Directions

- (1)

- Biomedical Electronics: AgNW electrodes with antibacterial properties have been developed and utilized in wearable biosensors and smart bandages.

- (2)

- Energy Systems: AgNW integrated electrodes significantly enhance the charge transfer dynamics in fuel cells and supercapacitors.

- (3)

- Intelligent Environments: A large area of AgNW-TCFs enables energy-saving smart windows to achieve dynamic and adjustable emissivity control.

- (4)

- Neuromorphic Computing: AgNW-based RRAM offers a solution for low-power neuromorphic synaptic devices.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, K.S.; Kim, S.O.; Han, C.J.; Kim, D.U.; Kim, J.S.; Yu, Y.T.; Lee, C.R.; Kim, J.W. Revisiting the thickness reduction approach for near-foldable capacitive touch sensors based on a single layer of Ag nanowire-polymer composite structure. Compos. Sci. Technol. 2018, 165, 58–65. [Google Scholar] [CrossRef]

- Maji, A.; Kuila, C.; Panda, B.; Dhak, D.; Murmu, N.C.; Kuila, T. Tailoring AgNWs-rGO/PVDF advanced composites for flexible strain sensors in wearable electronics with thermal management: Balancing sensitivity and hysteresis. ACS Appl. Electron. Mater. 2025, 7, 1670–1683. [Google Scholar] [CrossRef]

- Wu, Z.; Niu, Z.; Wang, Y.; Xu, Z.; Liu, Y.; Wang, W.; Li, S. Flexible OLED Performance Enhancement: The impact of AgNWs: AgNPs electrode-integrated MoOX QDs hole-injection layer. ACS Appl. Mater. Interfaces 2025, 17, 10898–10906. [Google Scholar] [CrossRef] [PubMed]

- Wan, J.; Chen, Y.; Chen, W.; Xia, J.; Zeng, G.; Cao, J.; Jin, C.; Shen, Y.; Wu, X.; Chen, H.; et al. Enhanced charge collection of AgNWs-based top electrode to realize high-performance, all-solution processed organic solar cells. Sci. China Chem. 2024, 67, 3347–3356. [Google Scholar] [CrossRef]

- Zhang, X.; Dai, H.; Ji, M.; Han, Y.; Jiang, B.; Cheng, C.; Song, X.; Song, Y.; Wu, G. A flexible piezoresistive strain sensor based on AgNWs/MXene/PDMS sponge. J. Mater. Sci. Mater. Electron. 2025, 36, 452. [Google Scholar] [CrossRef]

- Wu, B.; Yu, Y.; Wu, P.; Wu, Y.; Huang, J.; Song, X. SiC whisker/AgNWs/TPU composite film with asymmetric structure for low-reflection electromagnetic interference shielding. J. Appl. Polym. Sci. 2024, 141, e56019. [Google Scholar] [CrossRef]

- Sharma, V.; Arora, E.K.; Jaison, M.; Vashist, T.; Jagtap, S.; Adhikari, A.; Kumar, P.; Dash, J.K.; Patel, R. Tuning the work function and properties of the conducting polymer PEDOT:PSS for enhancing optoelectronic device performance of solar cells and organic light emitting diodes. Polym. Plast. Technol. Mater. 2025, 64, 1019–1045. [Google Scholar] [CrossRef]

- Azadmehr, S.; Alamdari, S.; Tafreshi, M.J. Flexible and transparent highly luminescent sensor based on doped zinc tungstate/graphene oxide nanocomposite. Eur. Phys. J. Plus 2025, 140, 284. [Google Scholar] [CrossRef]

- Achagri, G.; Ismail, R.; Kadier, A.; Ma, P.C. A solar-powered electrocoagulation process with a novel CNT/silver nanowire coated basalt fabric cathode for effective oil/water separation: From fundamentals to application. J. Environ. Manag. 2025, 375, 124289. [Google Scholar] [CrossRef] [PubMed]

- He, W.; Ye, C. Flexible Transparent Conductive Films on the Basis of Ag Nanowires: Design and Applications: A Review. J. Mater. Sci. Technol. 2015, 31, 581–588. [Google Scholar] [CrossRef]

- Hou, S.; Liu, J.; Shi, F.; Zhao, G.X.; Tan, J.W.; Wang, G. Recent Advances in Silver Nanowires Electrodes for Flexible Organic/Perovskite Light-Emitting Diodes. Front. Chem. 2022, 10, 864186. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Li, X.; Li, N.; Liu, X.; Li, H.; Li, X.; Wang, Y.; Liang, J.; Chen, Z. Multilayer directionally arranged silver nanowire networks for flexible transparent conductive films. Phys. Chem. Chem. Phys. 2023, 25, 14778. [Google Scholar] [CrossRef] [PubMed]

- Tao, J.; Liu, N.; Li, S.; Shi, J.; Ji, S. Structural manipulation of silver nanowire transparent conductive films for optoelectrical property optimization in different application fields. Thin Solid Film. 2021, 729, 138679. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, Y.; Ma, C.; Liu, H. Large-area, stretchable, ordered silver nanowires electrode by superwetting-induced transfer of ionic liquid@silver nanowires complex. Chem. Eng. J. 2023, 476, 146505. [Google Scholar] [CrossRef]

- Zhang, P.; Tong, X.; Gao, Y.; Qian, Z.; Ren, R.; Bian, C.; Wang, J.; Cai, G. A sensing and stretchable polymer-dispersed liquid crystal device based on spiderweb-inspired silver nanowires-micromesh transparent electrode. Adv. Funct. Mater. 2023, 33, 2303270. [Google Scholar] [CrossRef]

- Tang, Q.; Zou, M.; Chang, L.; Guo, W. A super-flexible and transparent wood film/silver nanowire electrode for optical and capacitive dual-mode sensing wood-based electronic skin. Chem. Eng. J. 2022, 430, 132152. [Google Scholar] [CrossRef]

- Hao, T.; Zhang, L.; Ji, H.; Zhou, Q.; Feng, T.; Song, S.; Wang, B.; Liu, D.; Ren, Z.; Liu, W.; et al. A stretchable, transparent, and mechanically robust silver nanowire-polydimethylsiloxane electrode for electrochromic devices. Polymers 2023, 15, 2640. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Song, C.; Wang, Y.; Feng, S.; Xu, D.; Hao, T.; Xu, H. Flexible transparent films of oriented silver nanowires for a stretchable strain sensor. Materials 2024, 17, 4059. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.H.; Yu, K.C.; Kim, Y.; Kim, J.W. Highly stretchable and mechanically stable transparent electrode based on composite of silver nanowires and polyurethane-urea. ACS Appl. Mater. Interfaces 2015, 7, 15214–15222. [Google Scholar] [CrossRef] [PubMed]

- Thomas, N.; Sharma, N.; Swaminathan, P. Optimizing silver nanowire dimensions by the modification of polyol synthesis for the fabrication of transparent conducting films. Nanotechnology 2023, 35, 055602. [Google Scholar] [CrossRef] [PubMed]

- Ge, Y.; Liu, J.; Liu, X.; Hu, J.; Duan, X.; Duan, X. Rapid electrochemical cleaning silver nanowire thin films for high-performance transparent conductors. J. Am. Chem. Soc. 2019, 141, 12251–12257. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Li, C.; Si, X.; He, Z.; Qi, J.; Feng, J.; Cao, J. Single-crystalline silver nanowire arrays directly synthesized onto substrates by template-assisted chemical wetting. Materialia 2020, 9, 100529. [Google Scholar] [CrossRef]

- Song, M.; Zhou, X.; He, X.; Cao, H.; Liu, J.; Qiu, H.; Jin, Z. Distance dependent fluorescence enhancement of silver nanowires deposited on AAO. Opt. Mater. 2018, 83, 241–244. [Google Scholar] [CrossRef]

- Bleiji, Y.; Cordaro, A.; Tabernig, S.W.; Alarcón-Lladó, E. High Aspect Ratio Silver Nanogrids by Bottom-Up Electrochemical Growth as Transparent Electrode. ACS Appl. Opt. Mater. 2024, 2, 508–516. [Google Scholar] [CrossRef] [PubMed]

- Sekhar, S.C.; Nagaraju, G.; Yu, J.S. Conductive silver nanowires-fenced carbon cloth fibers-supported layered double hydroxide nanosheets as a flexible and binder-free electrode for high-performance asymmetric supercapacitors. Nano Energy 2017, 36, 3658–3667. [Google Scholar] [CrossRef]

- Wang, L.; Kong, Y.; Zhang, Z.; Luo, G.; Hou, X.; Su, A.; Yang, X.; Wu, K.J. Streamlined Synthesis of Silver Nanowires Using Multi-Objective Optimization for Electrically Conductive Composite Filaments. Adv. Funct. Mater. 2024, 34, 2407999. [Google Scholar] [CrossRef]

- Kaabipour, S.; Hemmati, S. Continuous, green, and room-temperature synthesis of silver nanowires in a helically-coiled millifluidic reactor. Colloids Surf. A Physicochem. Eng. Asp. 2023, 659, 130806. [Google Scholar] [CrossRef]

- Zhou, L.; Yu, M.; Yao, L.; Lai, W.Y. Mayer rod-coated organic light-emitting devices: Binary solvent inks, film topography optimization, and large-area fabrication. Adv. Eng. Mater. 2022, 24, 2101558. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, X.; Lin, T.; He, P. A method to fabricate uniform silver nanowires transparent electrode using meyer rod coating and dynamic heating. J. Mater. Sci. Mater. Electron. 2019, 30, 18702–18709. [Google Scholar] [CrossRef]

- Sannicolo, T.; Charvin, N.; Flandin, L.; Kraus, S.; Papanastasiou, D.T.; Celle, C.; Simonato, J.P.; Munoz-Rojas, D.; Jiménez, C.; Bellet, D. Electrical mapping of silver nanowire networks: A versatile tool for imaging network homogeneity and degradation dynamics during failure. ACS Nano 2018, 12, 4648–4659. [Google Scholar] [CrossRef] [PubMed]

- Crepelliere, J.; Menguelti, K.; Wack, S.; Bouton, O.; Gerard, M.; Popa, P.L.; Pistillo, B.R.; Leturcq, R.; Michel, M. Spray deposition of silver nanowires on large area substrates for transparent electrodes. ACS Appl. Nano Mater. 2021, 4, 1126–1135. [Google Scholar] [CrossRef]

- Gholami, M.; Tajabadi, F.; Taghavinia, N.; Moshfegh, A. Chemically-stable flexible transparent electrode: Gold-electrodeposited on embedded silver nanowires. Sci. Rep. 2023, 13, 17511. [Google Scholar] [CrossRef] [PubMed]

- Zheng, J.; Zhao, Y.; Chen, L.; Zheng, Y.; Wang, X.; Xu, G.; Xiao, X. Unveiling the function and mechanism of the ordered alignment silver nanowires on boosting the electrochromic performance. Chem. Eng. J. 2023, 463, 142524. [Google Scholar] [CrossRef]

- Song, L.; Qu, S.; Ma, L.; Yu, S. All solution prepared WOx/AgNW composite transparent conductive films with enhanced adhesion and stability. Mater. Lett. 2023, 336, 133918. [Google Scholar] [CrossRef]

- Shi, L. Flexible transparent silver nanowires conductive films fabricated with spin-coating method. Micro Nano Lett. 2022, 18, e12151. [Google Scholar] [CrossRef]

- Wang, P.; Jian, M.; Wu, M.; Zhang, C.; Zhou, C.; Ling, X.; Zhang, J.; Yang, L. Highly sandwich-structured silver nanowire hybrid transparent conductive films for flexible transparent heater applications. Compos. Part A Appl. Sci. Manuf. 2022, 159, 106998. [Google Scholar] [CrossRef]

- Correia, V.; Mitra, K.Y.; Castro, H.; Rocha, J.G.; Sowade, E.; Baumann, R.R.; Lanceros-Méndez, S. Design and fabrication of multilayer inkjet-printed passive components for printed electronics circuit development. J. Manuf. Process. 2018, 31, 364–371. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, X.; Shan, J.; Liu, C.; Guo, X.; Zhao, X.; Yang, H. Facile fabrication of large-scale silver nanowire transparent conductive films by screen printing. Mater. Res. Express 2022, 9, 066401. [Google Scholar] [CrossRef]

- Xu, X.; Liu, Z.; He, P.; Yang, J. Screen-printed silver nanowire and graphene oxide hybrid transparent electrodes for long-term electrocardiography monitoring. J. Phys. D Appl. Phys. 2019, 52, 455401. [Google Scholar] [CrossRef]

- Li, W.; Yarali, E.; Bakytbekov, A.; Anthopoulos, T.D.; Shamim, A. Highly transparent and conductive electrodes enabled by scalable printing. Nanotechnology 2020, 31, 395201. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.; Ali, S.; Bermak, A. Smart manufacturing technologies for printed electronics. In Hybrid Nanomaterials; IntechOpen: Rijeka, Croatia, 2020; p. 148. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, X.; Wang, K.; Lin, K.; Xie, H.; Zhang, X.; Li, J. Novel insights into inkjet printed silver nanowires flexible transparent Conductive Films. Int. J. Mol. Sci. 2021, 22, 7719. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Wang, S.; Luo, Z.; Lu, J.; Lin, K.; Xie, H.; Wang, Y.; Li, J.Z. Inkjet printing of flexible transparent conductive films with silver nanowires ink. Nanomaterials 2021, 11, 1571. [Google Scholar] [CrossRef] [PubMed]

- Al-Milaji, K.N.; Huang, Q.; Li, Z.; Ng, T.N.; Zhao, H. Direct Embedment and alignment of silver nanowires by Inkjet printing for stretchable conductors. ACS Appl. Electron. Mater. 2020, 2, 3289–3298. [Google Scholar] [CrossRef]

- Jia, L.C.; Yan, D.X.; Liu, X.; Ma, R.; Wu, H.Y.; Li, Z.M. Highly efficient and reliable transparent electromagnetic interference shielding film. ACS Appl. Mater. Interfaces 2018, 10, 11941–11949. [Google Scholar] [CrossRef] [PubMed]

- Sekkat, A.; Sanchez-Velasquez, C.; Bardet, L.; Weber, M.; Jiménez, C.; Bellet, D.; Muñoz-Rojas, D.; Nguyen, V.H. Towards enhanced transparent conductive nanocomposites based on metallic nanowire networks coated with metal oxides: A brief review. J. Mater. Chem. A 2024, 12, 25600–25621. [Google Scholar] [CrossRef]

- Qiu, R.; Zheng, H.; Zhao, X.; Yang, P.; Yu, S. The high transmittance silver nanowire conductive films with excellent electromagnetic shielding efficiency prepared by electrospinning and magnetron sputtering. Opt. Mater. 2024, 157, 116219. [Google Scholar] [CrossRef]

- Wu, C.T.; Ho, Y.R.; Huang, D.Z.; Huang, J.J. AZO/silver nanowire stacked films deposited by RF magnetron sputtering for transparent antenna. Surf. Coat. Technol. 2019, 360, 95–102. [Google Scholar] [CrossRef]

- Zhao, X.; Deng, Z.; Long, Y.; Feng, B.; Jiang, X.; Liu, X.; Zhong, Y.; Zou, S.; Zhen, Z.; Lin, S.; et al. Multifunctional sensing platform with pulsed-laser-deposited silver nanoporous structures. Sens. Actuators A. Phys. 2019, 293, 136–144. [Google Scholar] [CrossRef]

- Vikulova, E.S.; Dorovskikh, S.I.; Basova, T.V.; Zheravin, A.A.; Morozova, N.B. Silver CVD and ALD Precursors: Synthesis, Properties, and Application in Deposition Processes. Molecules 2024, 29, 5705. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Li, Z.; Shi, Z.; Zhu, P.; Wang, Z.; Zhang, J.; Li, Y.; He, P.; Zhang, S. ALD prepared silver nanowire/ZnO thin film for ultraviolet detectors. Mater. Today Commun. 2023, 37, 106974. [Google Scholar] [CrossRef]

- Weng, Y.; Chen, G.; Zhou, X.; Zhang, Y.; Yan, Q.; Guo, T. Stability enhancement and patterning of silver nanowire networks by conformal TiO2 coating for flexible transparent conductive electrodes. J. Mater. Sci. 2023, 58, 17816–17828. [Google Scholar] [CrossRef]

- Kang, J.; Han, K.; Sun, X.; Zhang, L.; Huang, R.; Ismail, I.; Wang, Z.; Ding, C.; Zha, W.; Li, F.; et al. Suppression of Ag migration by low-temperature sol-gel zinc oxide in the Ag nanowires transparent electrode-based flexible perovskite solar cells. Org. Electron. 2020, 82, 105714. [Google Scholar] [CrossRef]

- Jang, S.; Lee, J.; Nam, S.; Ko, H.; Chang, S.T. Large-Area, Highly Sensitive SERS Substrates with Silver Nanowire Thin Films Coated by Microliter-Scale Solution Process. Nanoscale Res. Lett. 2017, 12, 581. [Google Scholar] [CrossRef] [PubMed]

- Galle, L.; Ehrling, S.; Lochmann, S.; Kaskel, S.; Bischoff, L.; Grothe, J. Conductive ITO Interfaces for Optoelectronic Applications Based on Highly Ordered Inverse Opal Thin Films. ChemNanoMat 2020, 6, 560–566. [Google Scholar] [CrossRef]

- Kumar, A.; Shaikh, M.O.; Chuang, C.H. Silver Nanowire Synthesis and Strategies for Fabricating Transparent Conducting Electrodes. Nanomaterials 2021, 11, 693. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.Y.; Lee, E.S.; Oh, Y.J.; Kang, H.W. A silver nanowire mesh overcoated protection layer with graphene oxide as a transparent electrode for flexible organic solar cells. RSC Adv. 2017, 7, 52914–52922. [Google Scholar] [CrossRef]

- Jang, J.; Choi, J.Y.; Jeon, J.; Lee, J.; Im, J.; Lee, J.; Jin, S.W.; Park, H.J.; Lee, S.H.; Kim, D.B.; et al. Flexible Transparent Electrode Characteristics of Graphene Oxide/Cysteamine/AgNP/AgNW Structure. Nanomaterials 2020, 10, 2352. [Google Scholar] [CrossRef] [PubMed]

- Cho, S.; Kang, S.; Pandya, A.; Shanker, R.; Khan, Z.; Lee, Y.; Park, J.; Craig, S.L.; Ko, H. Large-area cross-aligned silver nanowire electrodes for flexible, transparent, and force-sensitive mechanochromic touch screens. ACS Nano 2017, 11, 4346–4357. [Google Scholar] [CrossRef] [PubMed]

- Hwang, B.; Qaiser, N.; Lee, C.; Matteini, P.; Yoo, S.J.; Kim, H. Effect of Al2O3/Alucone nanolayered composite overcoating on reliability of Ag nanowire electrodes under bending fatigue. J. Alloys Compd. 2020, 846, 156420. [Google Scholar] [CrossRef]

- Wang, P.; Jian, M.; Zhang, C.; Wu, M.; Ling, X.; Zhang, J.; Wei, B.; Yang, L. Highly Stable Graphene-Based Flexible Hybrid Transparent Conductive Electrodes for Organic Solar Cells. Adv. Mater. Interfaces 2021, 9, 2101442. [Google Scholar] [CrossRef]

- Jia, Y.; Chen, C.; Jia, D.; Li, S.; Ji, S.; Ye, C. Silver Nanowire Transparent Conductive Films with High Uniformity Fabricated via a Dynamic Heating Method. ACS Appl. Mater. Interfaces 2016, 8, 9865–9871. [Google Scholar] [CrossRef] [PubMed]

- Yoo, J.H.; Kim, Y.; Han, M.K.; Choi, S.; Song, K.Y.; Chung, K.C.; Kim, J.M.; Kwak, J. Silver Nanowire–Conducting Polymer–ITO Hybrids for Flexible and Transparent Conductive Electrodes with Excellent Durability. ACS Appl. Mater. Interfaces 2015, 7, 15928–15934. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Tian, Y.; Dirican, M.; Fang, D.; Yan, C.; Xie, J.; Jia, D.; Liu, Y.; Li, C.; Cui, M.; et al. Flexible, transparent and tough silver nanowire/nanocellulose electrodes for flexible touch screen panels. Carbohydr. Polym. 2021, 273, 118539. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Wang, Y.; Gui, J.; Wang, X.; Li, R.; Liu, W.; Sun, C.; Zhao, X.; Guo, S. Efficient Welding of Silver Nanowires embedded in a Poly (vinylidene fluoride) Film for Robust Wearable Electronics. Adv. Mater. Technol. 2019, 4, 1800438. [Google Scholar] [CrossRef]

- Du, M.; Yang, Z.; Miao, Y.; Wang, C.; Dong, P.; Wang, H.; Guo, K. Facile nanowelding process for silver nanowire electrodes toward high-performance large-area flexible organic light-emitting diodes. Adv. Funct. Mater. 2024, 34, 2404567. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Y.; Wang, T.; Liu, S.; Chen, Z.; Duan, S. Low-temperature nanowelding silver nanowire hybrid flexible transparent conductive film for green light OLED devices. Nanotechnology 2022, 33, 455201. [Google Scholar] [CrossRef] [PubMed]

- Qian, P.F.; Geng, W.H.; Bao, Z.L.; Jing, L.C.; Zhang, D.; Geng, H.Z. Eco-friendly transparent conductive films formed by silver nanowires embedded with conductive polymers in HPMC for flexible OLEDs. Surf. Interfaces 2025, 56, 105583. [Google Scholar] [CrossRef]

- Kim, D.W.; Han, J.W.; Lim, K.T.; Kim, Y.H. Highly enhanced light-outcoupling efficiency in ITO-free organic light emitting diodes using surface nanostructure embedded high-refractive index polymers. ACS Appl. Mater. Interfaces 2018, 10, 985–991. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Kim, J.; Kim, D.; Kim, B.; Chae, H.; Yi, H.; Hwang, B. High-performance transparent quantum dot light-emitting diode with patchable transparent electrodes. ACS Appl. Mater. Interfaces 2019, 11, 26333–26338. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Liu, Y.; Su, A.; Wang, J.; Duan, Y. Promising hybrid graphene-silver nanowire composite electrode for flexible organic light-emitting diodes. Sci. Rep. 2019, 9, 17998. [Google Scholar] [CrossRef] [PubMed]

- Triambulo, R.E.; Kim, J.H.; Park, J.W. Highly flexible organic light-emitting diodes on patterned Ag nanowire network transparent electrodes. Org. Electron. 2019, 71, 220–226. [Google Scholar] [CrossRef]

- Lian, L.; Dong, D.; Feng, D.; He, G. Low roughness silver nanowire flexible transparent electrode by low temperature solution-processing for organic light emitting diodes. Org. Electron. 2017, 49, 9–18. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Q.; Zhang, G.; Xiao, C.; Wei, Y.; Li, W. Ultrathin flexible transparent composite electrode via semi-embedding silver nanowires in a colorless polyimide for high performance ultraflexible organic solar cells. ACS Appl. Mater. Interfaces 2022, 14, 5699–5708. [Google Scholar] [CrossRef] [PubMed]

- Lei, T.; Peng, R.; Song, W.; Hong, L.; Huang, J.; Fei, N.; Ge, Z. Bendable and foldable flexible organic solar cells based on Ag nanowire films with 10.30% efficiency. J. Mater. Chem. A 2019, 7, 3737–3744. [Google Scholar] [CrossRef]

- Song, W.; Yu, K.; Zhou, E.; Xie, L.; Hong, L.; Ge, J.; Zhang, J.; Zhang, X.; Peng, R.; Ge, Z. Crumple durable ultra flexible organic solar cells with an excellent ower-per-weight performance. Adv. Funct. Mater. 2021, 31, 2102694. [Google Scholar] [CrossRef]

- Qi, J.; Chen, S.; Lan, C.; Wang, A.C.; Cui, X.; You, Z.; Zhang, Q.; Li, Y.; Wang, Z.L.; Wang, H.; et al. Large-grained perovskite films enabled by one-step meniscus-assisted solution printing of cross-aligned conductive nanowires for biodegradable flexible solar cells. Adv. Energy Mater. 2020, 10, 2001185. [Google Scholar] [CrossRef]

- Qin, W.; Xue, Y.; Li, G.; Peng, H.; Gong, G.; Yan, R.; Zhao, X.; Pang, J. Highly-sensitive wearable pressure sensor based on AgNWs/MXene/non-woven fabric. Org. Electron. 2024, 125, 106958. [Google Scholar] [CrossRef]

- Chen, X.; Jin, J.; Liu, B.; Li, S.; Guo, T.; Sheng, Z.; Wu, H. Flexible and transparent leaf-vein electrodes fabricated by liquid film rupture self-assembly AgNWs for application of heaters and pressure sensors. Chem. Eng. J. 2024, 499, 156500. [Google Scholar] [CrossRef]

- Castillo-López, D.N.; Gómez-Pavón, L.D.C.; Gutíerrez-Nava, A.; Zaca-Morán, P.; Arriaga-Arriaga, C.A.; Muñoz-Pacheco, J.M.; Luis-Ramos, A. Flexible force sensor based on a PVA/AgNWs nanocomposite and cellulose acetate. Sensors 2024, 24, 2819. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Cai, G.; Song, J.; Zhang, Y.; Yu, B.; Zhai, S.; Chen, K.; Zhang, H.; Yu, Y.; Qi, D. Large-scale fabrication of tunable sandwich-structured silver nanowires and aramid nanofiber films for exceptional electromagnetic interference (EMI) shielding. Polymers 2023, 16, 61. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Zhao, Y.; Luo, P.; Chen, Z.; Song, P.; Jin, Y.; Pei, L.; Ren, F.; Ren, P. Durable and sustainable CoFe2O4@MXene-silver nanowires/cellulose nanofibers composite films with controllable electric–magnetic gradient towards high-efficiency electromagnetic interference shielding and Joule heating capacity. Chem. Eng. J. 2024, 485, 149691. [Google Scholar] [CrossRef]

- Nguyen, D.K.; Pham, T.N.; Pham, A.L.H.; Nguyen, V.C.; Tran, M.S.; Bui, V.Q.; Vu, M.C. Multilayered silver nanowires and graphene fluoride-based aramid nanofibers for excellent thermosconductive electromagnetic interference shielding materials with low-reflection. Colloids Surf. A Physicochem. Eng. Asp. 2024, 688, 133553. [Google Scholar] [CrossRef]

- Hanauer, S.; Celle, C.; Crivello, C.; Szambolics, H.; Muñoz-Rojas, D.; Bellet, D.; Simonato, J.P. Transparent and Mechanically Resistant Silver-Nanowire-Based Low-Emissivity Coatings. ACS Appl. Mater. Interfaces 2021, 13, 21971–21978. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.B.; Meena, J.S.; Joo, J.; Kim, J.W. Autonomous self-healing wearable flexible heaters enabled by innovative MXene/polycaprolactone composite fibrous networks and silver nanowires. Adv. Compos. Hybrid Mater. 2023, 6, 227. [Google Scholar] [CrossRef]

- Milano, G.; Pedretti, G.; Montano, K.; Ricci, S.; Hashemkhani, S.; Boarino, L.; Ielmini, D.; Ricciardi, C. In materia reservoir computing with a fully memristive architecture based on self-organizing nanowire networks. Nat. Mater. 2021, 21, 195–202. [Google Scholar] [CrossRef] [PubMed]

- Charvin, N.; Resende, J.; Papanastasiou, D.T.; Munoz-Rojas, D.; Jiménez, C.; Nourdine, A.; Bellet, D.; Flandin, L. Dynamic degradation of metallic nanowire networks under electrical stress: A comparison between experiments and simulations. Nanoscale Adv. 2021, 3, 675–681. [Google Scholar] [CrossRef] [PubMed]

- Grazioli, D.; Gangi, G.; Nicola, L.; Simone, A. Predicting mechanical and electrical failure of nanowire networks in flexible transparent electrodes. Compos. Sci. Technol. 2024, 245, 110304. [Google Scholar] [CrossRef]

- Oh, H.; Lee, J.; Lee, M. Transformation of silver nanowires into nanoparticles by rayleigh instability: Comparison between laser irradiation and heat treatment. Appl. Surf. Sci. 2018, 427, 65–73. [Google Scholar] [CrossRef]

- Hwang, B.; An, Y.; Lee, H.; Lee, E.; Becker, S.; Kim, Y.H.; Kim, H. Highly flexible and transparent Ag nanowire electrode encapsulated with Ultra-Thin Al2O3: Thermal, ambient, and mechanical stabilities. Sci. Rep. 2017, 7, 41336. [Google Scholar] [CrossRef] [PubMed]

- Jeong, Y.C.; Nam, J.; Kim, J.; Kim, C.S.; Jo, S. Enhancing thermal oxidation stability of silver nanowire transparent electrodes by using a cesium carbonate-incorporated overcoating layer. Materials 2019, 12, 1140. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.C.; Lin, D.X.; Lin, S.H. Degradation problem in silver nanowire transparent electrodes caused by ultraviolet exposure. Nanotechnology 2020, 31, 215705. [Google Scholar] [CrossRef] [PubMed]

- Yan, Z.; Chen, H.; Li, M.; Wen, X.; Yang, Y.; Choy, W.C.; Lu, H. Observing and understanding the corrosion of silver nanowire electrode by precursor reagents and MAPbI3 film in different environmental conditions. Adv. Mater. Interfaces 2021, 8, 2001669. [Google Scholar] [CrossRef]

- Yeh, M.H.; Chen, P.H.; Yang, Y.C.; Chen, G.H.; Chen, H.S. Investigation of Ag-TiO2 interfacial reaction of highly stable Ag nanowire transparent conductive film with conformal TiO2 coating by atomic layer deposition. ACS Appl. Mater. Interfaces 2017, 9, 10788–10797. [Google Scholar] [CrossRef] [PubMed]

- Entifar, S.A.N.; Han, J.W.; Lee, D.J.; Ramadhan, Z.R.; Hong, J.; Kang, M.H.; Kim, S.; Lim, D.; Yun, C.; Kim, Y.H. Simultaneously enhanced optical, electrical, and mechanical properties of highly stretchable transparent silver nanowire electrodes using organic surface modifier. Sci. Technol. Adv. Mater. 2019, 20, 116–123. [Google Scholar] [CrossRef] [PubMed]

- Pillai, S.K.R.; Wang, J.; Wang, Y.; Sk, M.M.; Prakoso, A.B.; Rusli Chan-Park, M.B. Totally embedded hybrid thin films of carbon nanotubes and silver nanowires as flat homogenous flexible transparent conductors. Sci. Rep. 2016, 6, 38453. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Ruan, H.; Liu, H.; Zhang, J.; Shi, D.; Han, T.; Yang, L. Low-temperature solution processed flexible silver nanowires/ZnO composite electrode with enhanced performance and stability. J. Alloys Compd. 2018, 747, 659–665. [Google Scholar] [CrossRef]

- Choo, D.C.; Kim, T.W. Degradation mechanisms of silver nanowire electrodes under ultraviolet irradiation and heat treatment. Sci. Rep. 2017, 7, 1696. [Google Scholar] [CrossRef] [PubMed]

- Patil, J.J.; Chae, W.H.; Trebach, A.; Carter, K.J.; Lee, E.; Sannicolo, T.; Grossman, J.C. Failing Forward: Stability of Transparent Electrodes Based on Metal Nanowire Networks. Adv. Mater. 2020, 33, e2004356. [Google Scholar] [CrossRef] [PubMed]

| Method of Film Deposition | Tav % | Rs Ω/sq | FOM | Reference |

|---|---|---|---|---|

| Mayer Rod Coating | 92.2 | 12.9 | 352.33 | [12] |

| Mayer Rod Coating | 91 | 10 | 390.08 | [29] |

| Spraying | 91.7 | 9 | 709 | [31] |

| Spraying | 86.6 | 18.3 | 138 | [33] |

| Spin Coating | 82.6 | 9.4 | 199.78 | [34] |

| Spin Coating | 87.5 | 14.4 | 189.44 | [36] |

| Silk-screen printing | 95.3 | 13.6 | 568.47 | [38] |

| Inkjet Printing | 81.9 | 13 | 138 | [42] |

| Inkjet Printing | 83.1 | 34 | 57.12 | [43] |

| Preparation Method | Film Uniformity | Equipment Cost | Production Efficiency | Applicable Scenarios |

|---|---|---|---|---|

| Mayer Rod Coating | good | low | slow | small scale in the laboratory |

| Spin Coating | excellent (small area) | moderate (except high-precision) | fast (small area) | electronic, optical devices |

| Spraying | moderate (dependent on spray control) | moderate | fast | architectural glass, solar cells |

| Silk-screen printing | moderate (except for edges and corners) | low (except high-precision) | fast | electronic circuits, sensors |

| Inkjet Printing | excellent (sprinkler head) | high (spray head and ink) | low (large area) fast (small area) | microelectronics, flexible electronics, biosensors |

| Preparation Method | Film Uniformity | Equipment Cost | Production Efficiency | Applicable Scenarios |

|---|---|---|---|---|

| Sputtering Deposition | excellent (dense, regular-structured) | high | medium | TCEs (e.g., displays, solar cells) |

| Pulsed layer deposition (PLD) | excellent (precise patterning) | very high | low (small area) | high-performance electronic devices (e.g., gas sensors, high-frequency electronic components) |

| Chemical vapor deposition (CVD) | excellent (large area, high quality) | very high | high (large area) | flexible electronic devices (e.g., flexible display screens, wearable devices) |

| Atomic layer deposition (ALD) | extremely high (atomic level) | very high | low (layer-by-layer deposition) | high-stability electrodes (e.g., lithium battery electrodes, UV photodetectors) |

| Solution methods | poor (porous structure) | low | relatively high | flexible wearable devices (e.g., flexible circuits, biosensors), low-cost optoelectronic devices |

| Material | Substrate | Area (cm2) | Turn-On Voltage (V) | Maximum Current Efficiency (cd/A) | Maximum Luminance (cd/m2) | Reference |

|---|---|---|---|---|---|---|

| LPMN-processed AgNWs | PET | 2.5 × 2.5 | 3 | 78.0 | 5118 | [66] |

| Ti3C2Tx/ AgNWs | PEDOT: PSS | 4 × 4 | 7 | 3.7 | 10,040 | [67] |

| HRLOC/ AgNWs | PI | 20 × 20 | 18.37 | 20,000 | [69] | |

| AgNWs | GLASS | 4 × 4 | 5.5 | 45.99 | 27,310 | [70] |

| Graphene/AgNWs | PET | 9 | 15,000 | [71] | ||

| AgNWs/ITO | PI | 1 × 1 | 7.7 | 5000 | [72] | |

| PVA/AgNWs | PEN | 10 | 35.3 | 18,540 | [73] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Luo, J.; Liu, Y. Recent Advances in Silver Nanowire-Based Transparent Conductive Films: From Synthesis to Applications. Coatings 2025, 15, 858. https://doi.org/10.3390/coatings15070858

Li J, Luo J, Liu Y. Recent Advances in Silver Nanowire-Based Transparent Conductive Films: From Synthesis to Applications. Coatings. 2025; 15(7):858. https://doi.org/10.3390/coatings15070858

Chicago/Turabian StyleLi, Ji, Jun Luo, and Yang Liu. 2025. "Recent Advances in Silver Nanowire-Based Transparent Conductive Films: From Synthesis to Applications" Coatings 15, no. 7: 858. https://doi.org/10.3390/coatings15070858

APA StyleLi, J., Luo, J., & Liu, Y. (2025). Recent Advances in Silver Nanowire-Based Transparent Conductive Films: From Synthesis to Applications. Coatings, 15(7), 858. https://doi.org/10.3390/coatings15070858