A Review of Crack Sealing Technologies for Asphalt Pavement: Materials, Failure Mechanisms, and Detection Methods

Abstract

1. Introduction

2. Materials and Performance Evaluation for Asphalt Pavement Crack Sealing

2.1. Development of Asphalt Pavement Cracks

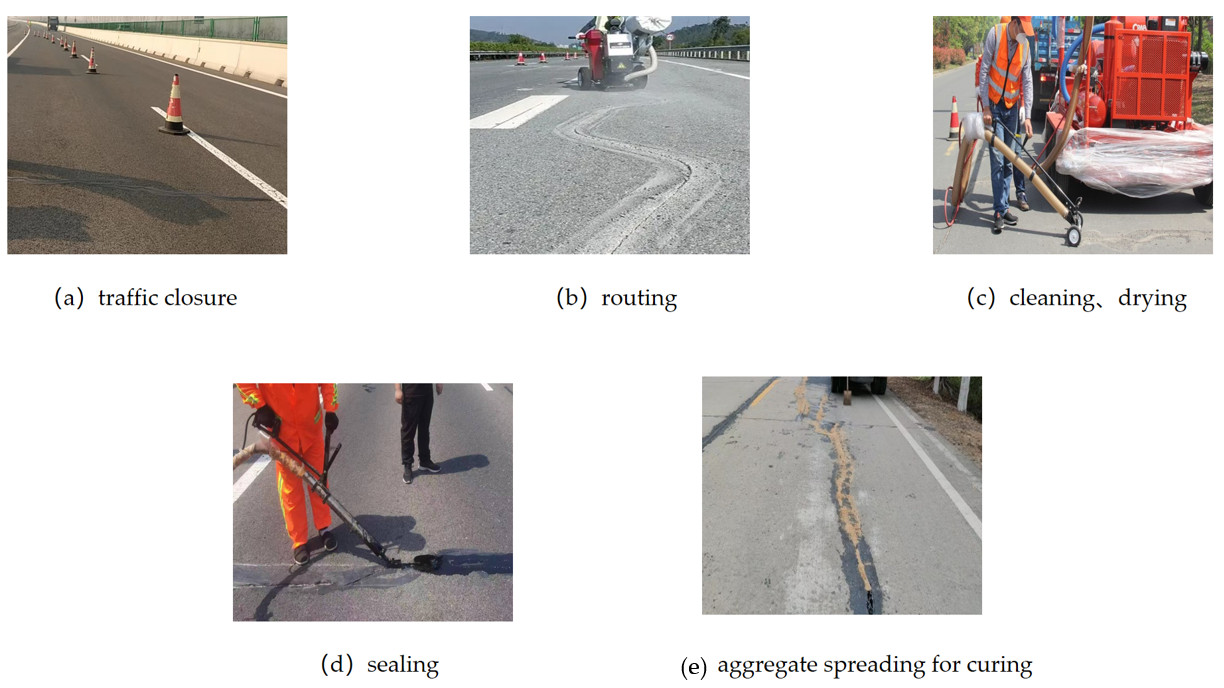

2.2. Crack Repair Methods

- (1)

- Routing is recommended when the measured crack width is ≥3 mm.

- (2)

- For cracks exhibiting a high probability of horizontal movement under thermal variation, field assessment mandates routing prior to sealant application.

- (1)

- When the crack width measures < 3 mm and demonstrates self-healing capability under thermal cycling, routing-free sealing shall be applied.

- (2)

- Cracks exhibiting negligible horizontal displacement may undergo routing-free treatment following a techno-economic assessment.

- (3)

- For cracks 1–3 mm wide, the crack wall conditions dictate the methodology: intact walls without spalling/raveling permit direct sealing; walls with loosening surfaces, oil contamination, or irremovable debris require routed sealing [30].

2.3. Sealing Material Selection

2.3.1. Conventional Sealing Materials

2.3.2. Ambient-Temperature Sealing Materials

2.3.3. Heat-Applied Sealing Materials

2.4. Performance Assessment of Sealing Material

3. Early-Stage Failure Mechanisms in Sealed-Crack

3.1. Interfacial Bond Failure Induced by Construction Defects

- (1)

- Inadequate crack cleaning

- (2)

- Crack wall heating temperature

- (3)

- Sealing Material Application Temperature

- (4)

- Injection volume of the sealing material

- •

- The preparation phase involves precisely measuring crack width and depth and thoroughly removing debris from the crack periphery.

- •

- In the construction phase, nozzles compatible with the crack width are selected, and the heating temperature of the sealing material is strictly controlled.

- •

- In process monitoring, operators should continuously observe the filling status and surface bulging, dynamically adjusting the injection equipment speed to maintain consistent operation.

3.2. Aging Behavior of Sealants

3.3. Hydrodynamic Scouring Effects

3.4. Temperature Effects

4. Advanced Sensing Methodologies for Premature Sealed-Crack Repair Failure

4.1. Passive Sensing Technologies

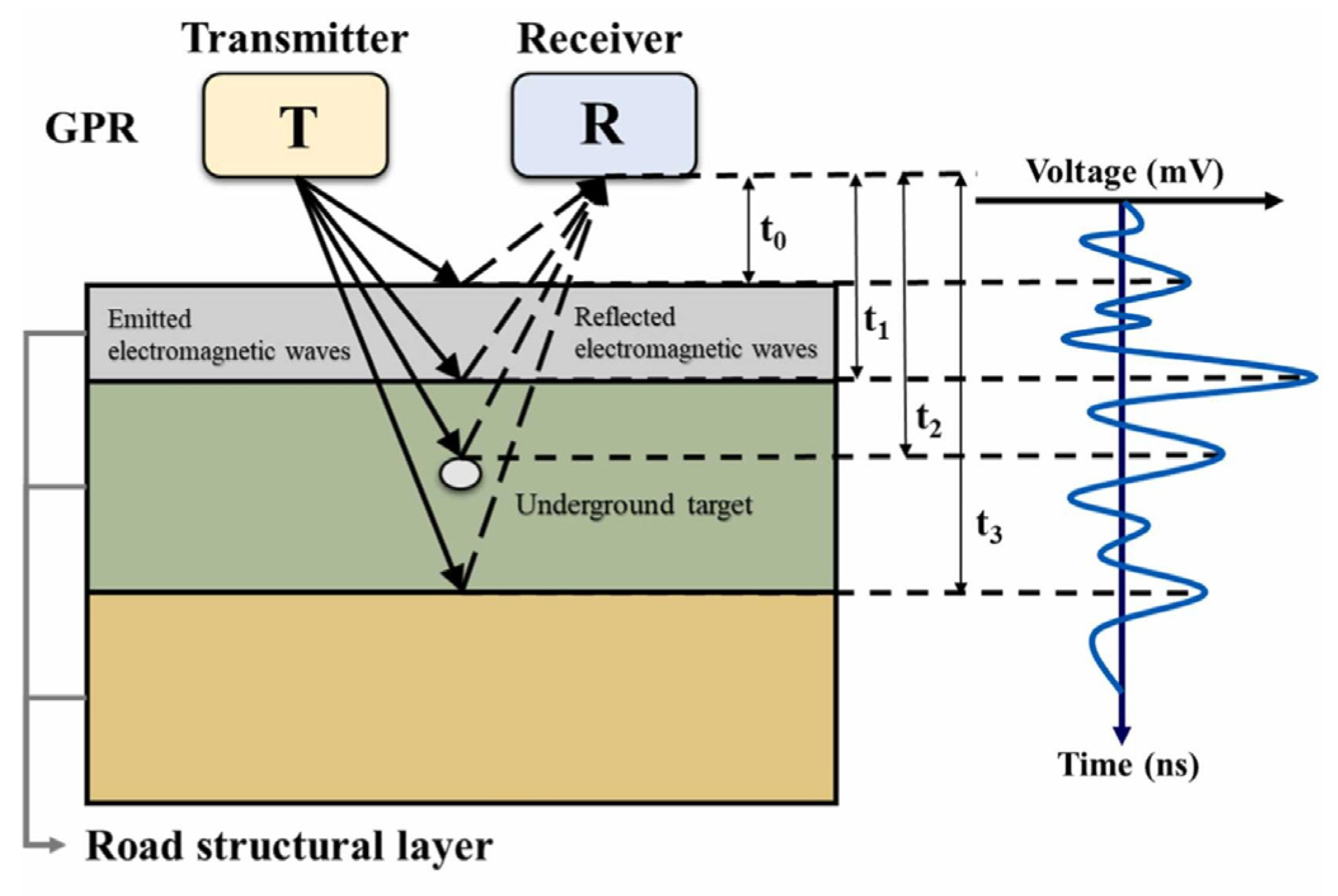

4.1.1. Ground-Penetrating Radar (GPR)

4.1.2. Infrared Thermography (IRT)

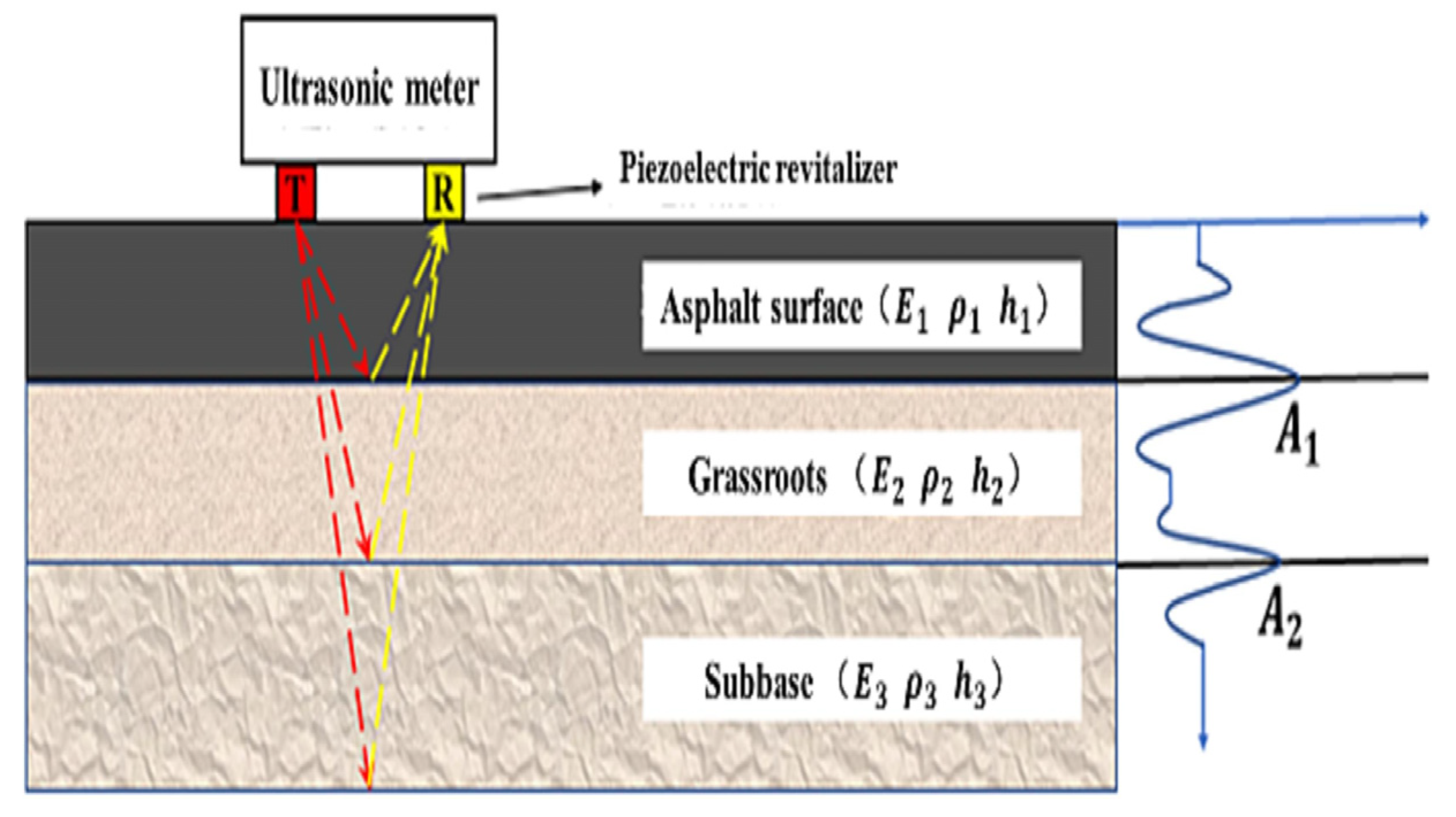

4.1.3. Ultrasonic Testing (UT)

4.2. Active Sensing Technologies for Sealed-Crack Repair Failure Detection

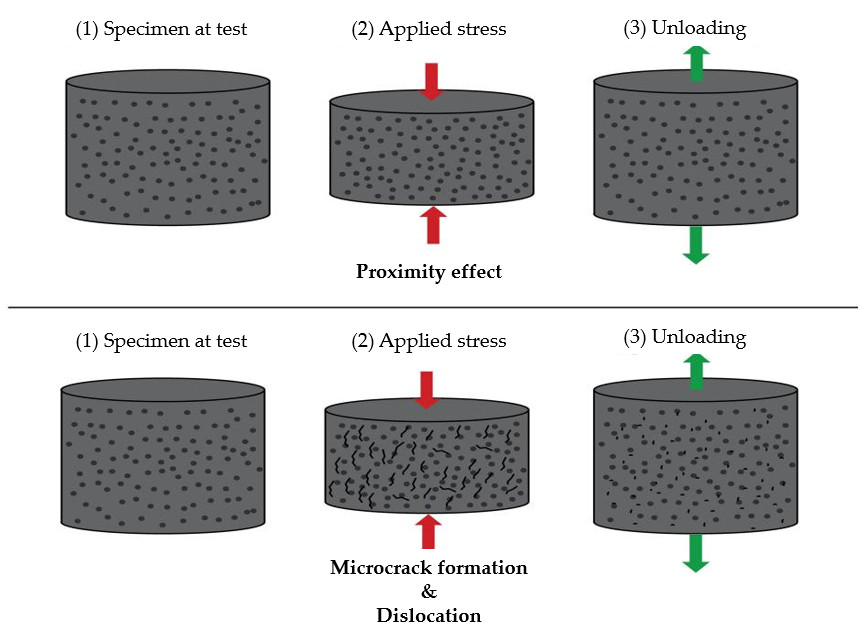

4.2.1. Piezoresistive Materials for Active Failure Detection

- (a)

- Proximity effect, induced by the convergence or separation of conductive particles under compressive/tensile stresses;

- (b)

- Micro-crack effect, caused by the fracture of conductive pathways due to micro-crack formation, elevating electrical resistance;

- (c)

- Conductive path misalignment/restructuring effect, hindered by the viscoelastic behavior of asphalt mixtures, preventing the full restoration of conductive paths to initial states upon unloading.

4.2.2. Piezoelectric Materials for Active Failure Detection

| References | Piezoelectric Materials | Pavement Type | Research Objectives | Result |

|---|---|---|---|---|

| [134] | SWS | Asphalt Concrete | Fatigue cracking at asphalt concrete bottom due to excessive tensile strain. | Both changes in μ and σ of the CDF can locate damage. σ primarily indicates damage severity. |

| [135] | SWS | Asphalt Concrete | Bottom-up cracking caused by excessive strain at asphalt concrete base. | Percentage of voltage/strain droppage is a reliable indicator of damage progression. The gate number and activation effectively reflect damage severity. |

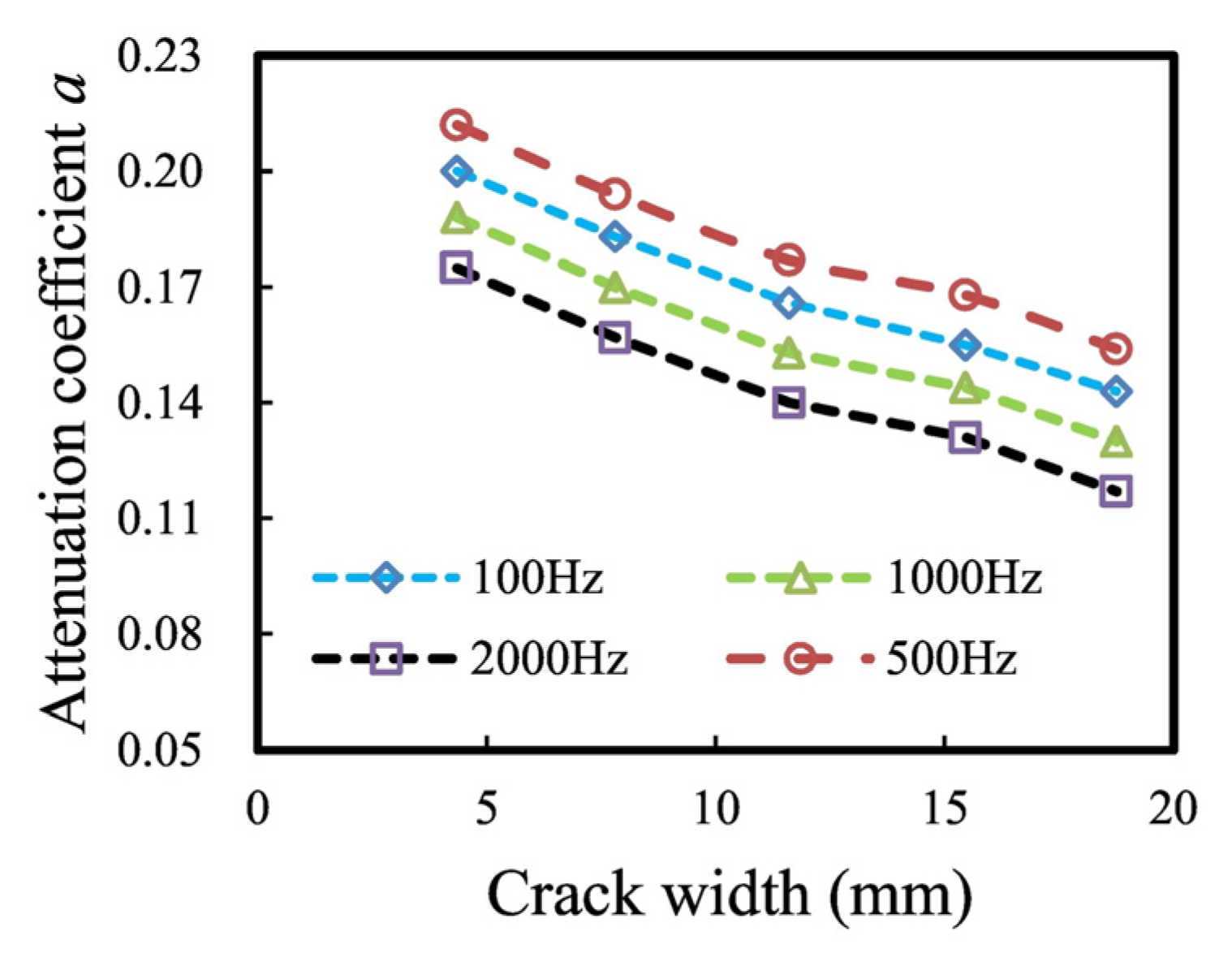

| [136] | PZT + PVDF | Asphalt | Monitoring hidden damage in asphalt pavements (e.g., microcracks). | Acoustic attenuation coefficient obtained from the self-powered damage-detection aggregate (SPA) decreases with increasing crack width in asphalt pavements (Figure 18). |

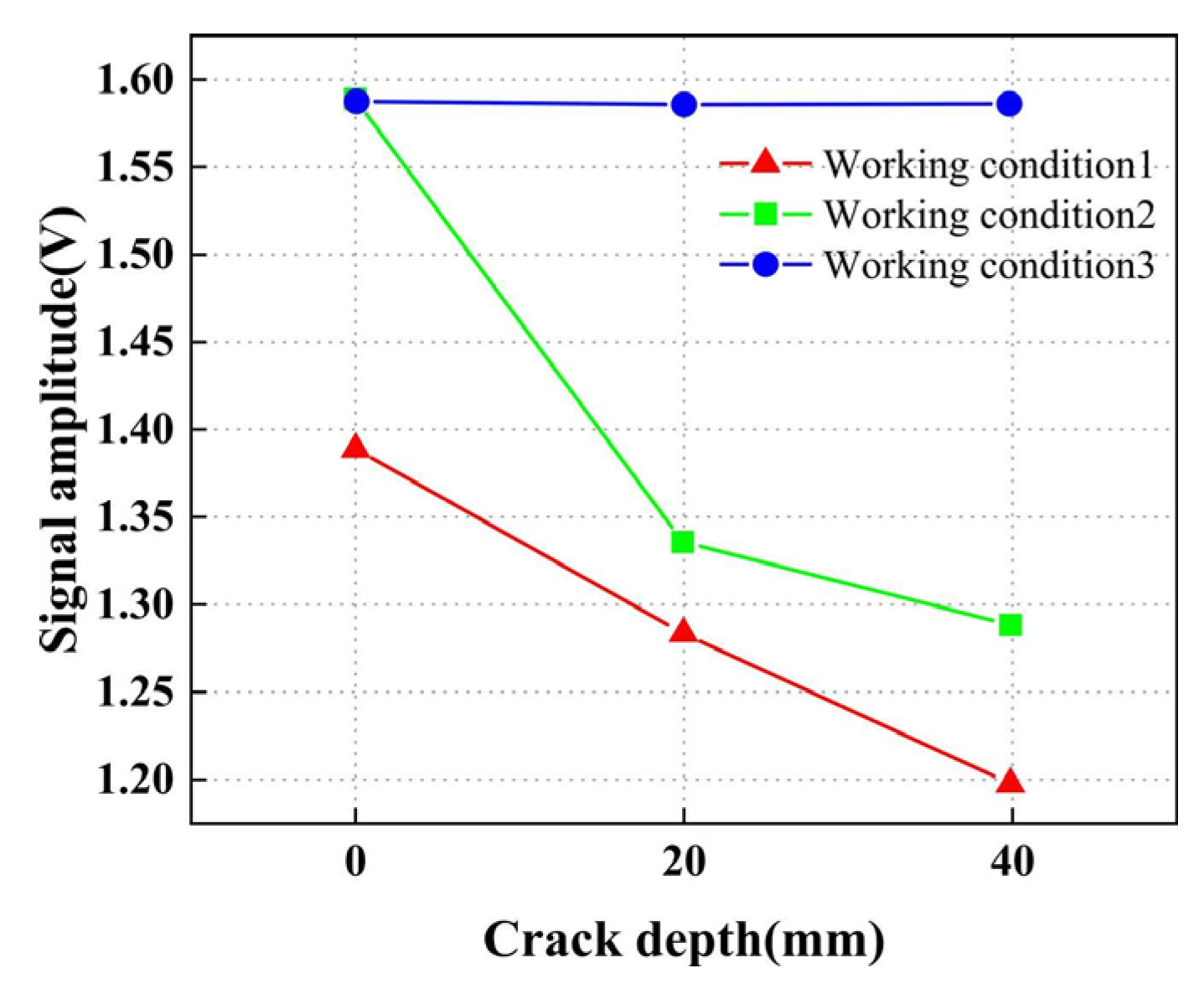

| [137] | PZT + EP | Cement | Depth of crack propagation and localization of crack damage in concrete beams. | The output signal amplitude from piezoelectric sensors effectively determines the development of macroscopic cracks and locates crack positions in concrete (Figure 19). |

5. Conclusions

- (1)

- Optimization of sealing materials and construction technologies:

- •

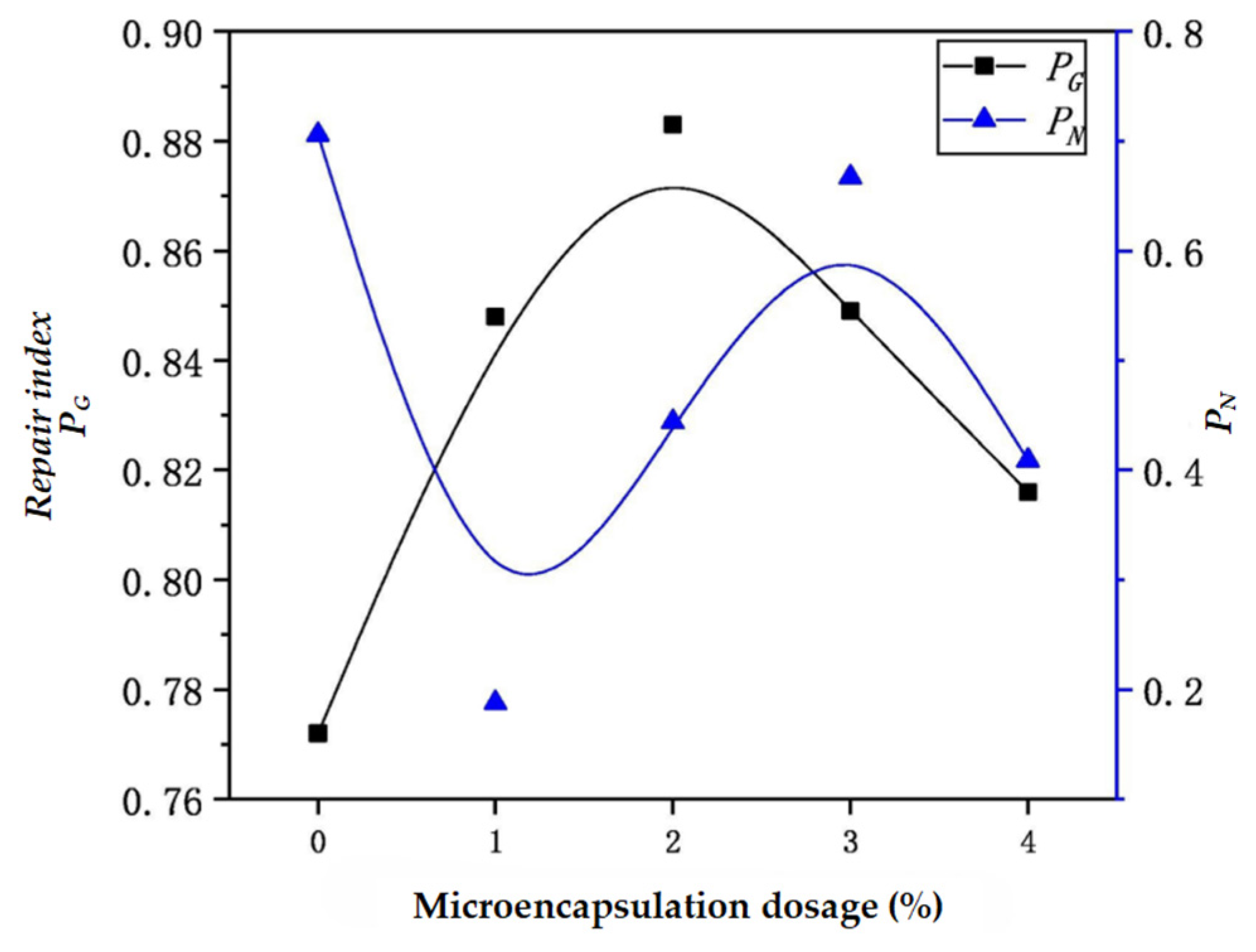

- Development of self-healing microcapsule materials.

- •

- Application of bio-based modified materials.

- •

- Integration of piezoresistive materials into sealants.

- •

- Emphasizing crack pretreatment (cleaning and drying).

- •

- Implementing material preheating and precision temperature control during sealing and grouting.

- (2)

- Interfacial bonding failure mechanisms:

- •

- Molecular dynamics simulations, as used to reveal the failure mechanisms.

- •

- Combined natural exposure testing and laboratory simulations for comprehensive mechanism analysis.

- (3)

- Post-repair detection methods:

- •

- For ground-penetrating radar technology, future research should advance antenna array configurations with multichannel and multi-polarization designs, enhance detection accuracy and pretrained models through deep learning and algorithmic optimization, and optimize antenna selection based on distress characteristics and location—a context where ground-coupled antennas excel at detecting surface cracks and delamination, while air-coupled antennas offer superior precision for internal pavement defects.

- •

- For infrared thermography technology, future trends include the integration of unmanned platforms (e.g., unmanned aerial vehicles), the implementation of AI-powered intelligent distress identification and analysis, and the synergistic processing of multi-source data with complementary 3D information.

- •

- For ultrasonic testing technology, future research should advance toward miniaturization, enhanced efficiency, and real-time monitoring.

- •

- The hybridization of three complementary passive detection techniques can be used to overcome individual limitations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, W.; Wang, L.; Xiong, H.; Luo, R. A review and perspective for research on moisture damage in asphalt pavement induced by dynamic pore water pressure. Constr. Build. Mater. 2019, 204, 631–642. [Google Scholar] [CrossRef]

- Li, X.; Ye, J.; Zhou, Z.; Yang, L.; Wang, S.; Diab, A. Preparation and performance of an asphalt pavement sealant with waterborne epoxy resin. Constr. Build. Mater. 2022, 350, 128827. [Google Scholar] [CrossRef]

- Soliman, H.; Shalaby, A.; Kavanagh, L. Performance evaluation of joint and crack sealants in cold climates using DSR and BBR tests. J. Mater. Civ. Eng. 2008, 20, 470–477. [Google Scholar] [CrossRef]

- Xu, T.; Huang, X. Investigation into causes of in-place rutting in asphalt pavement. Constr. Build. Mater. 2012, 28, 525–530. [Google Scholar] [CrossRef]

- Minhoto, M.J.; Pais, J.C.; Pereira, P.A. The temperature effect on the reflective cracking of asphalt overlays. Road Mater. Pavement Des. 2008, 9, 615–632. [Google Scholar] [CrossRef]

- Wang, S.; Jia, Y.; Li, Z.; Zhou, Z.; Gao, Y.; Huang, X.; Wei, H.; Guan, S. Evaluating the effect of aging on adhesion for hot-poured road sealants through a modified adhesion test. Constr. Build. Mater. 2022, 347, 128576. [Google Scholar] [CrossRef]

- Sawalha, M.; Ozer, H.; Al-Qadi, I.L.; Xue, H. Development of a modified adhesion test for hot-poured asphalt crack sealants. Transp. Res. Rec. 2017, 2612, 85–95. [Google Scholar] [CrossRef]

- Wu, S.; Liu, Q.; Yang, J.; Yang, R.; Zhu, J. Study of adhesion between crack sealant and pavement combining surface free energy measurement with molecular dynamics simulation. Constr. Build. Mater. 2020, 240, 117900. [Google Scholar] [CrossRef]

- Zhi, S.; Gun, W.W.; Hui, L.X.; Bo, T. Evaluation of fatigue crack behavior in asphalt concrete pavements with different polymer modifiers. Constr. Build. Mater. 2012, 27, 117–125. [Google Scholar] [CrossRef]

- Zhang, H.; Sheng, X.; Wang, S.; Xu, T. Effects of different modifiers on thermal stability, constituents and microstructures of asphalt-based sealant. J. Therm. Anal. Calorim. 2020, 142, 1183–1192. [Google Scholar] [CrossRef]

- Li, Q.; Sun, G.; Lu, Y.; Meng, Y.; Luo, S.; Gao, L. Effects of warm-mix asphalt technologies and modifiers on pavement performance of recycled asphalt binders. J. Clean. Prod. 2021, 282, 125435. [Google Scholar] [CrossRef]

- Xu, Z.; Jiang, Y.; Xu, T. Pavement property improvement of graphene modified asphalt and its improving mechanism. J. For. Eng. 2023, 8, 154–160. [Google Scholar] [CrossRef]

- Tao, M.; Xu, T. Development and Properties of Bio-Based Rice Oil Microcapsule and Its Dispersibility in Emulsified Asphalt. J. Ind. Eng. Chem. 2024, 131, 503–513. [Google Scholar] [CrossRef]

- Liu, H.; Yan, G.; Zhang, J.; Gan, X.; Liu, S.; Xu, T. Viscosity and toughness of hydrogenated epoxy emulsified asphalt and the road performance of its cold recycled mixture. J. For. Eng. 2025, 10, 136–143. [Google Scholar] [CrossRef]

- Ji, X.; Hu, H.; Sun, Y.; Ji, X. Healing performance of steel fiber reinforced iron tailings hot mix asphalt heated by microwave. J. Chang. Univ. (Nat. Sci. Ed.) 2025, 45, 1–13. [Google Scholar]

- Wang, H.; Xu, T. Piezoelectric Properties and Microstructural Changes of Smart Asphalt-Based Composites Containing Electroactive Polymer and Carbon Black. Constr. Build. Mater. 2024, 444, 137894. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, X.; Xu, L.; Zhang, H.; Liu, Z. Investigation on the piezoresistive response of carbon fiber-graphite modified asphalt mixtures. Constr. Build. Mater. 2021, 301, 124140. [Google Scholar] [CrossRef]

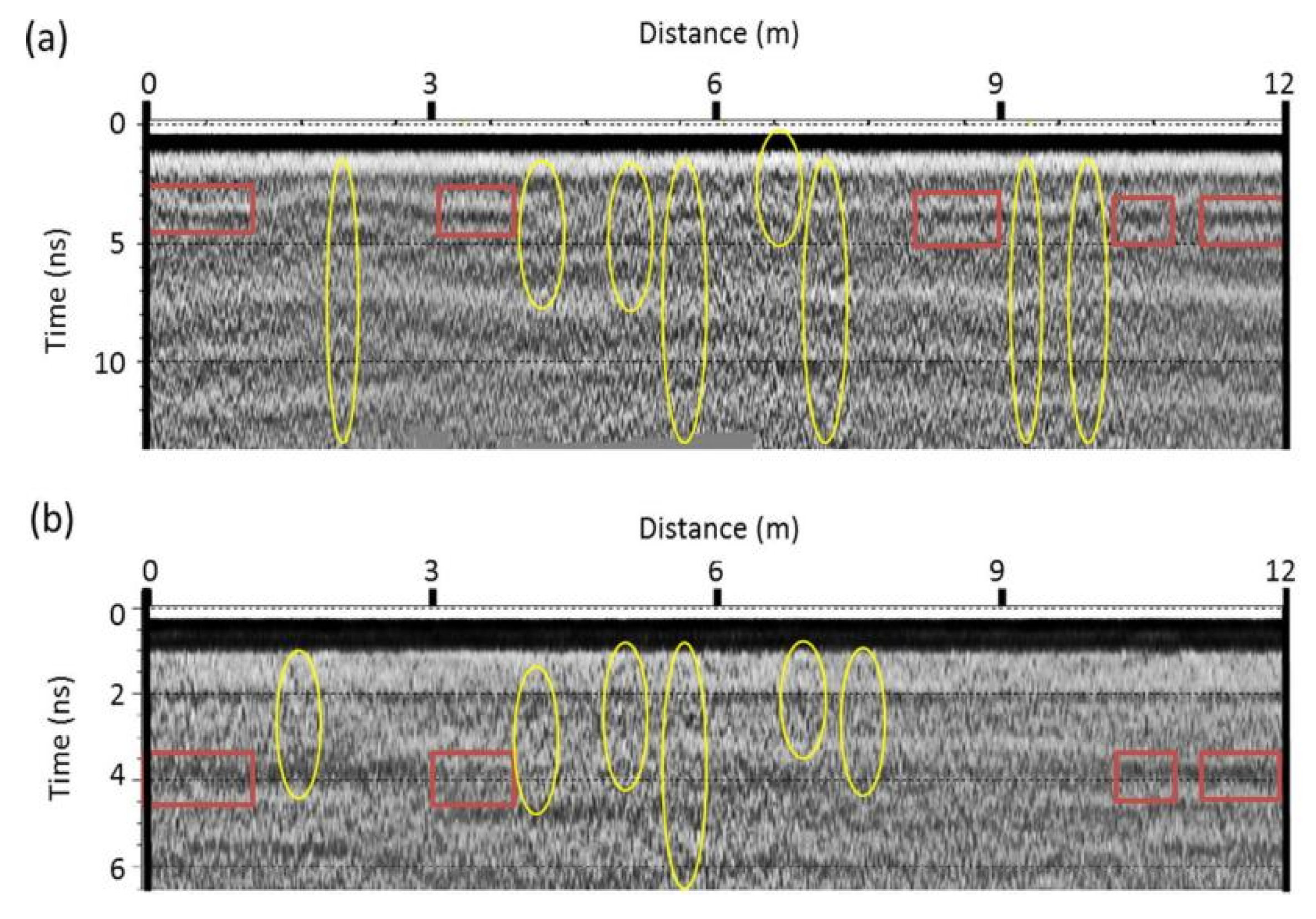

- Guo, S.; Yu, M.; Xu, Z.; Yue, G.; Cai, W.; Tian, P. Study on the Attribute Characteristics of Road Cracks Detected by Ground-Penetrating Radar. Sensors 2025, 25, 595. [Google Scholar] [CrossRef]

- Hashimoto, K.; Shiotani, T. Sonic-IR imaging technique for detection of crack interfaces in cementitious materials. Constr. Build. Mater. 2023, 386, 131549. [Google Scholar] [CrossRef]

- Khazanovich, L.; Velasquez, R.; Nesvijski, E.G. Evaluation of top-down cracks in asphalt pavements by using a self-calibrating ultrasonic technique. Transp. Res. Rec. 2005, 1940, 63–68. [Google Scholar] [CrossRef]

- Zhu, H.; Yang, X. Review of Non-Destructive Testing Technologies for Internal Defects in Asphalt Pavements. Sci. Technol. Eng. 2024, 24, 10588–10604. [Google Scholar] [CrossRef]

- Slabej, M.; Grinč, M.; Kováč, M.; Decký, M.; ŠEDIVÝ, S. Non-invasive diagnostic methods for investigating the quality of Žilina airport’s runway. Contrib. Geophys. Geod. 2015, 45, 237–254. [Google Scholar] [CrossRef]

- Ji, X.; Chen, Y.; Li, Y.; Zhou, H. Intelligent recognition and localization of hidden cracks in asphalt pavement based on smartRock. China J. Highw. Transp. 2024, 37, 408–417. [Google Scholar]

- Tong, J. Mechanism Analysis and Prediction of the Rutting and Surface Crack for Asphalt Pavement. Ph.D. Thesis, Southeast University, Nanjing, China, 2022. [Google Scholar] [CrossRef]

- Editorial Department of China Journal of Highway and Transport. Academic Research Review on Pavement Engineering in China·2020. China J. Highw. Transp. 2020, 33, 1–66. [Google Scholar]

- Wang, H.; Wu, H.; Wu, Q.; Jin, G.; Zhang, Z. Study on Crack Morphological Characteristics and Cracking Mode of Expressway Crack Based on Field Measured Data. J. Highw. Transp. Res. Dev. 2018, 35, 28–34. [Google Scholar] [CrossRef]

- Li, F.; Shi, X.; Xu, J. Performance Evaluation and Technical Requirements of Asphalt Pavement Crack Seal Band. J. Beijing Univ. Technol. 2013, 39, 1855–1860. [Google Scholar] [CrossRef]

- Wang, S.; Xu, Y.; Liu, M.; Gao, Y.; Jia, Y.; Li, Y.; Chen, Z.; Wei, Z. Dynamic behavior of crack sealant bonding interface in the asphalt pavement crack repair structure under moving vehicle load. Case Stud. Constr. Mater. 2023, 18, e01821. [Google Scholar] [CrossRef]

- Standard’s JTG 5142-2019; Asphalt Pavement Maintenance Technical Specifications. Ministry of Transport of the People’s Republic of China: Beijing, China, 2019.

- Yang, D. Research on Repair technology for Asphalt Pavement Cracks in Guizhou Province. Master’s Thesis, Nanjing Forestry University, Nanjing, China, 2023. [Google Scholar] [CrossRef]

- Li, F.; Xu, J.; Shi, X. Asphalt Pavement Crack Sealing and Filling Technic. Highway 2013, 249–253. [Google Scholar] [CrossRef]

- Zhang, M.; Shang, F. Performance Evaluation of Joint Treatment in Gussasphalt Mixtures. Highway 2020, 65, 188–193. [Google Scholar]

- Li, L.; Huang, Y.; Shao, Z.; Ren, D. An experimental investigation on the repairing performance and fatigue life of asphalt pavement potholes with an inclined interface joint. Front. Mater. 2021, 7, 597523. [Google Scholar] [CrossRef]

- Cong, P.; Liu, C.; Zhang, X. Preparation of thermoplastic polyurethane sealant and its adherence properties under various environments. Compos. Part B Eng. 2025, 293, 112125. [Google Scholar] [CrossRef]

- Teng, X.; Wu, P.; Sun, J.; Yang, H.; Zhang, Q. Graphene Oxide-Modified Polysulfide Sealant. Polym. Mater. Sci. Eng. 2013, 29, 54–57. [Google Scholar]

- Ma, B.; Hu, Y.; Liu, F.; Si, W.; Wei, K.; Wang, X.; Kang, X.; Chang, X. Performance of a novel epoxy crack sealant for asphalt pavements. Int. J. Pavement Eng. 2022, 23, 3068–3081. [Google Scholar] [CrossRef]

- Tan, X.; Zhang, J.; Guo, D.; Sun, G.; Zhou, Y.; Zhang, W.; Guan, Y. Preparation, characterization and repeated repair ability evaluation of asphalt-based crack sealant containing microencapsulated epoxy resin and curing agent. Constr. Build. Mater. 2020, 256, 119433. [Google Scholar] [CrossRef]

- Fu, Y.; Wang, S.; Cai, L.; Chen, L. Preparation and Properties of Restructured Polysulfur-Urethane Sealants. Polym. Mater. Sci. Eng. 2011, 27, 136–139. [Google Scholar] [CrossRef]

- Ma, T.; Chen, C.; Zhang, Y.; Zhang, W. Development of Using Crumb Rubber in Asphalt Modification: A Review. China J. Highw. Transp. 2021, 34, 1–16. [Google Scholar] [CrossRef]

- Li, K.; Yan, X.; Ai, T.; Niu, Y.; Jiang, S. Study on properties and application of chloroprene rubber/polyurethane modified asphalt sealant. Constr. Build. Mater. 2023, 406, 133177. [Google Scholar] [CrossRef]

- Gong, Y.; Wu, S.; Zhang, Y.; Pang, Y.; Ma, Y. Investigation of the high-temperature and rheological properties for asphalt sealant modified by SBS and rubber crumb. Polymers 2022, 14, 2558. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Z.; Gao, J.; Xu, X.; Zhou, X.; Jing, H.; Li, J. Property improvement and mechanism of SBS/CR composite modified asphalt sealant with high-polarity EVA modifier. Constr. Build. Mater. 2025, 458, 139594. [Google Scholar] [CrossRef]

- ASTM D6690-12; Standard Specification for Joint and Crack Sealants, Hot-Applied, for Concrete and Asphalt Pavements. ASTM International: West Conshohocken, PA, USA, 2012.

- Hasan, O.; Pranshoo, S.; Seyed, S.Y. Field Validation of Laboratory-Predicted Low-Temperature Performance of Hot-Poured Crack Sealants. Transp. Res. Rec. 2014, 2431, 57–66. [Google Scholar]

- Liu, C.; Wang, H.; Liu, S.; Yang, D.; Xiong, Y. Performance Evaluation of Asphalt-Pavement Crack-Repair Materials. Materials 2025, 18, 1611. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Nl, F.; Wang, W. Performance comparison of cracking repairing materials for asphalt pavements. Highw. Eng. 2013, 38, 33–37. [Google Scholar]

- Chen, H.; Ao, F.; He, Q.; Yan, C. Preparation and Performance of Warm Mix Crack Filling Material for Bituminous Pavement in Alpine Region. J. Civ. Eng. Manag. 2021, 38, 95–100. [Google Scholar] [CrossRef]

- Song, L.; Xue, Y.; Xia, H.; Niu, Y. Preparation and properties of SBS/LNBR/CR composite modified asphalt sealant. Appl. Chem. Ind. 2023, 52, 1630–1636. [Google Scholar] [CrossRef]

- Sun, Z.; Li, S.; Zhang, J.; Zeng, Y. Adhesion property of bituminous crack sealants to different asphalt mixtures based on surface energy theory. Constr. Build. Mater. 2020, 261, 120006. [Google Scholar] [CrossRef]

- Wang, W.; He, R.; Chen, Z.; Shi, J.; Xu, L.; Sun, Y. Performance evaluation indicators for asphalt pavement sealants in seasonal frozen region: An experimental study. Case Stud. Constr. Mater. 2025, 22, e04421. [Google Scholar] [CrossRef]

- Li, F.; Zhou, S.; Cai, W.; Du, Y.; Li, L. Laboratory evaluation of short and long term performance of hot-poured sealants. Constr. Build. Mater. 2017, 148, 30–37. [Google Scholar] [CrossRef]

- Lin, C. Research on Sealing Technology and Cracks Investigation for Transverse Cracks of Asphalt Pavement in Large Temperature Difference Region. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2011. [Google Scholar] [CrossRef]

- Lai, M. Research on Preparation and Properties of High Performance of Asphalt Pavement Filling Materials. Master’s Thesis, Jilin University, Changchun, China, 2016. [Google Scholar]

- Standard’s JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- Feng, X.; Liang, H.; Peng, C. Preparation and performance of high performance grouting sealant for asphalt pavement in humid and hot areas. J. Chang. Univ. (Nat. Sci. Ed.) 2023, 43, 11–20. [Google Scholar] [CrossRef]

- Li, Y.; Mei, P.; Yuan, H.; Li, F. Viscosity-emperature Characteristics of Asphalt Pavement Hot-applied Sealant. J. Highw. Transp. Res. Dev. 2015, 8–12. [Google Scholar] [CrossRef]

- Naskar, M.; Reddy, K.S.; Chaki, T.K.; Divya, M.K.; Deshpande, A.P. Effect of ageing on different modified bituminous binders: Comparison between RTFOT and radiation ageing. Mater. Struct. 2013, 46, 1227–1241. [Google Scholar] [CrossRef]

- Jamal, M.; Giustozzi, F. Enhancing the asphalt binder’s performance against oxidative ageing and solar radiations by incorporating rubber from waste tyres. Constr. Build. Mater. 2022, 350, 128803. [Google Scholar] [CrossRef]

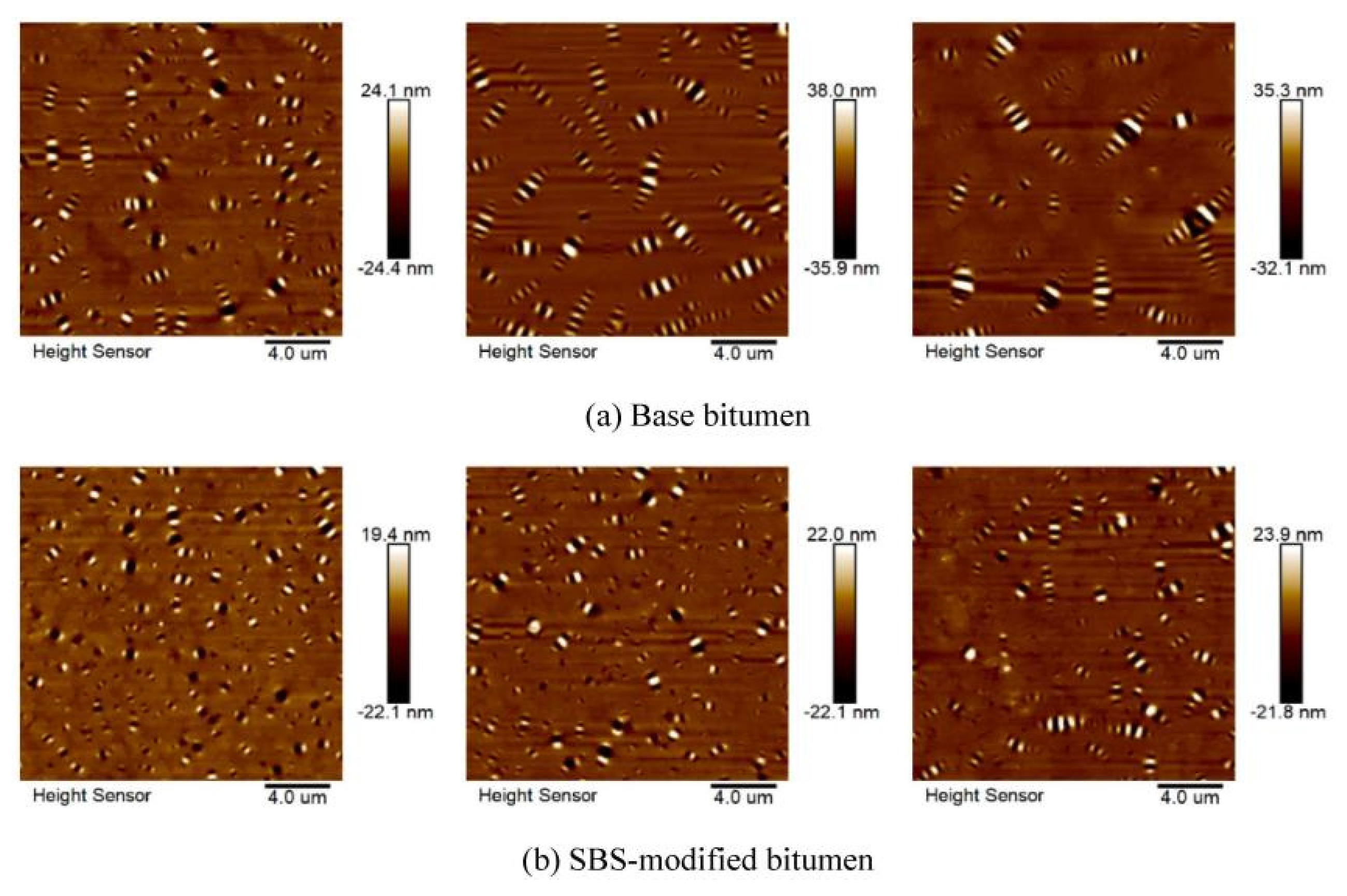

- Zhou, Y.; Du, L.; Liu, X.; Zhang, K.; Xu, P.; Zhang, Y. Microscopic performance of modified asphalt based on aging. Constr. Build. Mater. 2021, 279, 122429. [Google Scholar] [CrossRef]

- Li, C.; Xie, X.; Wang, L.; Guo, Y.; Zhang, L.; Xue, Z. Evaluation of the effect of thermal oxygen aging on base and SBS-modified bitumen at micro and macroscales. Constr. Build. Mater. 2022, 324, 126623. [Google Scholar] [CrossRef]

- Camargo, I.G.D.N.; Hofko, B.; Mirwald, J.; Grothe, H. Effect of thermal and oxidative aging on asphalt binders rheology and chemical composition. Materials 2020, 13, 4438. [Google Scholar] [CrossRef]

- Hung, A.M.; Kazembeyki, M.; Hoover, C.G.; Fini, E.H. Evolution of morphological and nanomechanical properties of bitumen thin films as a result of compositional changes due to ultraviolet radiation. ACS Sustain. Chem. Eng. 2019, 7, 18005–18014. [Google Scholar] [CrossRef]

- Hung, A.; Fini, E.H. Surface morphology and chemical mapping of UV-aged thin films of bitumen. ACS Sustain. Chem. Eng. 2020, 8, 11764–11771. [Google Scholar] [CrossRef]

- Enfrin, M.; Giustozzi, F. Chemo-rheological deterioration of bitumen due to UV ageing: Correlations between accelerated UV ageing tests and 1-year outdoor exposure. Constr. Build. Mater. 2024, 449, 138425. [Google Scholar] [CrossRef]

- Li, Y.; Wu, S.; Liu, Q.; Dai, Y.; Li, C.; Li, H.; Nie, S.; Song, W. Aging degradation of asphalt binder by narrow-band UV radiations with a range of dominant wavelengths. Constr. Build. Mater. 2019, 220, 637–650. [Google Scholar] [CrossRef]

- Yang, C.; Cao, L.; Ullah, S.; Dong, Z.; Zhang, X.; Wei, D. Performance evolution and mechanism of asphalt crack sealant under UV aging: A continuity study. Constr. Build. Mater. 2024, 431, 136539. [Google Scholar] [CrossRef]

- Cao, L.; Yang, C.; Dong, Z.; Wang, W.; Yin, H. Aging mechanism of hot-poured sealants for asphalt pavement under natural environmental exposure. Int. J. Pavement Eng. 2022, 23, 197–206. [Google Scholar] [CrossRef]

- Dong, P.; Cao, X.; Tang, B. Research on dynamic stress and excess pore water pressure of asphalt pavement under hydraulic-mechanical coupling. Heliyon 2024, 10, e26011. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Zou, X.; Zhang, T. Review on Damage Mechanism of Asphalt Pavement under Dynamic Water Pressure Effects. J. China Foreign Highw. 2018, 38, 59–64. [Google Scholar] [CrossRef]

- Dong, Z.; Tan, Y.; Cao, L.; Zhong, Y. Research on pore pressure with in asphalt pavement under the coupled moisture-loading action. J. Harbin Inst. Technol. 2007, 39, 1614–1617. [Google Scholar] [CrossRef]

- Chen, W.; Wang, Z.; Guo, W.; Dai, W. Measurement and evaluation for interbedded pore water pressure of saturated asphalt pavement under vehicle loading. Appl. Sci. 2020, 10, 1416. [Google Scholar] [CrossRef]

- Dong, Q.; Li, Y.; Shi, X.; Li, Z. Calculation and Analysis of Dynamic Water Pressure on Road Surfaces. J. Chang. Univ. (Nat. Sci. Ed.) 2013, 33, 17–22. [Google Scholar]

- Zhang, Y.; Gu, X.; Xing, S.; Wang, X.; Cui, B. Study on Dynamic Water Pressure of Asphalt Pavement Structure Based on COMSOL Fluid-Solid Coupling. Munic. Eng. Technol. 2020, 38, 48–52+64. [Google Scholar] [CrossRef]

- Yi, J.; Feng, D.; Yang, S.H.; Yu, F. A Preliminary Analysis on Determination of Optimum Crack Sealing Time for Asphalt Pavement (No. 13-1336). In Proceedings of the Transportation Research Board, Washington, DC, USA, 13–17 January 2013. [Google Scholar] [CrossRef]

- Mousa, M.; Elseifi, M.A.; Bashar, M.; Zhang, Z.; Gaspard, K. Field evaluation and cost effectiveness of crack sealing in flexible and composite pavements. Transp. Res. Rec. 2018, 2672, 51–61. [Google Scholar] [CrossRef]

- Mousa, M.R.; Elseifi, M.A.; Bashar, M.Z.; Zhang, Z.; Gaspard, K.; Free, K. Cost effectiveness and optimal timing of crack sealing in asphalt concrete overlays. J. Transp. Eng. Part B Pavements 2019, 145, 04019029. [Google Scholar] [CrossRef]

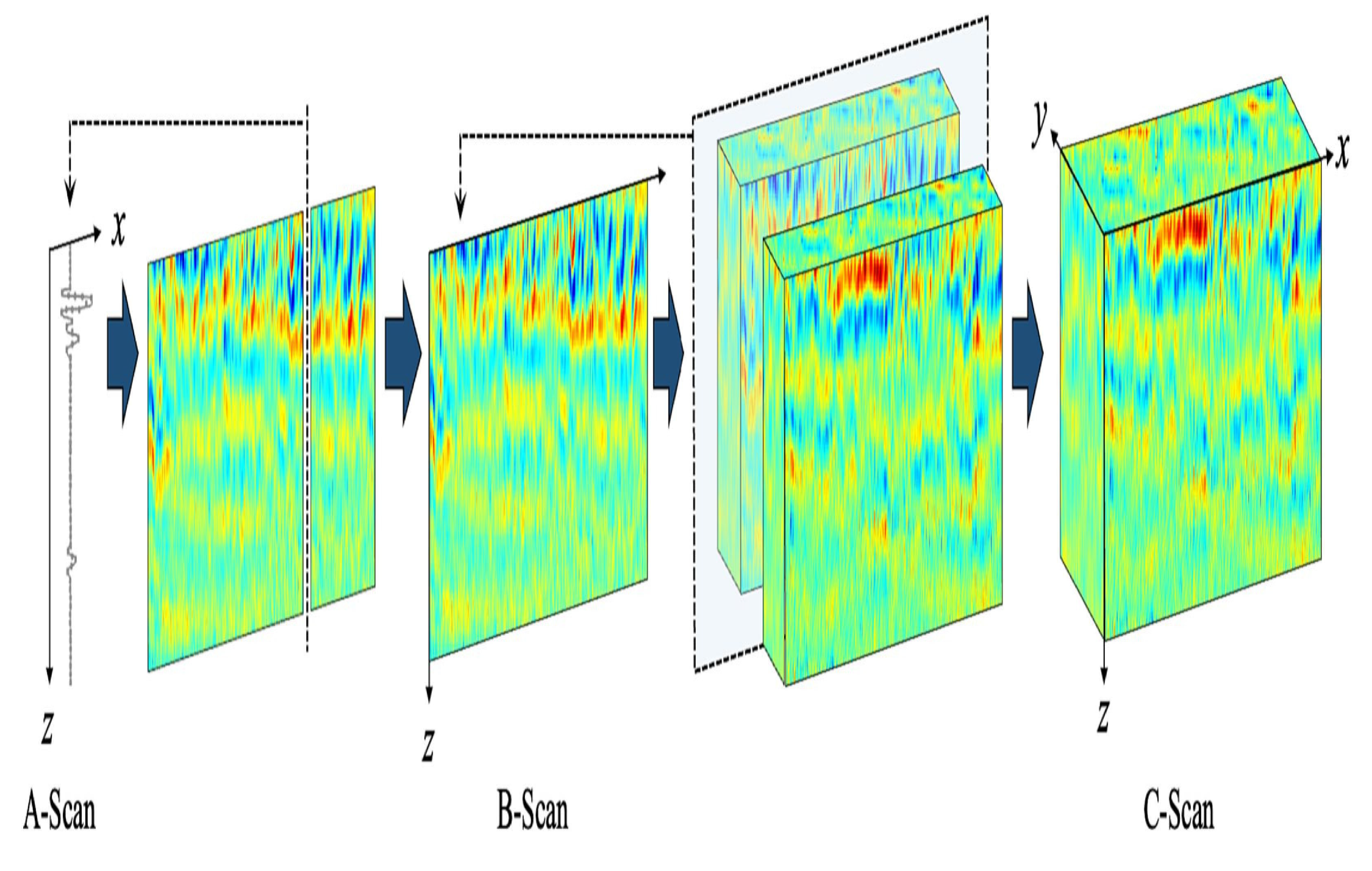

- Yue, G.; Du, Y.; Liu, C.; Guo, S.; Li, Y.; Gao, Q. Road subsurface distress recognition method using multiattribute feature fusion with ground penetrating radar. Int. J. Pavement Eng. 2023, 24, 2037591. [Google Scholar] [CrossRef]

- Zhao, W.; Yang, Q. Evaluation of Fatigue Performance of Old Cement Concrete Pavement Based Three-Dimensional Ground On Penetrating Radar and Falling Weight Deflectometer. J. Tongji Univ. (Nat. Sci.) 2025, 53, 732–740. [Google Scholar] [CrossRef]

- Wang, D.W.; Lyu, H.T.; Tang, F.J.; Ye, C.S.; Zhang, F.; Wang, S.Q.; Ni, Y.W.; Leng, Z.; Lu, G.Y.; Liu, P.F. Review on Detection Analysis and Digital Technology for Road Hidden Diseases Using 3D Ground Penetrating Radar. Zhongguo Gonglu Xuebao/China J. Highw. Transp. 2023, 36, 1–19. [Google Scholar]

- Liu, W.; Luo, R.; Xiao, M.; Chen, Y. Intelligent detection of hidden distresses in asphalt pavement based on GPR and deep learning algorithm. Constr. Build. Mater. 2024, 416, 135089. [Google Scholar] [CrossRef]

- Liu, C.; Du, Y.; Yue, G.; Li, Y.; Wu, D.; Li, F. Advances in automatic identification of road subsurface distress using ground penetrating radar: State of the art and future trends. Autom. Constr. 2024, 158, 105185. [Google Scholar] [CrossRef]

- Dou, Q.; Wei, L.; Magee, D.R.; Cohn, A.G. Real-time hyperbola recognition and fitting in GPR data. IEEE Trans. Geosci. Remote Sens. 2016, 55, 51–62. [Google Scholar] [CrossRef]

- Liu, C.; Yao, Y.; Li, J.; Qian, J.; Liu, L. Research on lightweight GPR road surface disease image recognition and data expansion algorithm based on YOLO and GAN. Case Stud. Constr. Mater. 2024, 20, e02779. [Google Scholar] [CrossRef]

- Harkat, H.; Bennani, H.D. Ground penetrating radar imaging for buried cavities in a dispersive medium: Profile reconstruction using a modified hough transform approach and a time-frequency analysis. Int. J. Commun. Antenna Propag. (IRECAP) 2015, 5, 78–92. [Google Scholar] [CrossRef]

- Solla, M.; Lagüela, S.; González-Jorge, H.; Arias, P. Approach to identify cracking in asphalt pavement using GPR and infrared thermographic methods: Preliminary findings. NDT E Int. 2014, 62, 55–65. [Google Scholar] [CrossRef]

- Guo, S.; Xu, Z.; Li, X.; Zhu, P. Detection and characterization of cracks in highway pavement with the amplitude variation of GPR Diffracted waves: Insights from forward modeling and field data. Remote Sens. 2022, 14, 976. [Google Scholar] [CrossRef]

- Yang, J.; Yang, S.; Yao, Y.; Gao, J.; Wang, S. Three-dimensional orthorectified simulation and ground penetrating radar detection of interlayer bonding condition in asphalt pavements. Meas. Sci. Technol. 2024, 35, 095017. [Google Scholar] [CrossRef]

- Marecos, V.; Solla, M.; Fontul, S.; Antunes, V. Assessing the pavement subgrade by combining different non-destructive methods. Constr. Build. Mater. 2017, 135, 76–85. [Google Scholar] [CrossRef]

- Wang, S.; Leng, Z.; Sui, X. Detectability of concealed cracks in the asphalt pavement layer using air-coupled ground-penetrating radar. Measurement 2023, 208, 112427. [Google Scholar] [CrossRef]

- Su, J.; Shi, J.; Wang, W. Experimental Study of Infrared Thermal lmagers about Influence of Distance for Temperature Measurement Accuracy and Method of lmproving Accuracy. Infrared Technol. 2013, 35, 587–590. [Google Scholar]

- Chen, W.; Wei, K.; Wei, J.; Han, W.; Zhang, X.; Hu, G.; Wei, S.; Niu, L.; Chen, K.; Fu, Z.; et al. Research on the road performance of asphalt mixtures based on infrared thermography. Materials 2022, 15, 4309. [Google Scholar] [CrossRef]

- Vyas, V.; Patil, V.J.; Singh, A.P.; Srivastava, A. Application of infrared thermography for debonding detection in asphalt pavements. J. Civ. Struct. Health Monit. 2019, 9, 325–337. [Google Scholar] [CrossRef]

- Singla, R.; Sharma, S.; Siddique, R. Monitoring of chemical-assisted healing of fine cracks in concrete using ultrasonics and infrared thermographic techniques. J. Build. Eng. 2025, 104, 112279. [Google Scholar] [CrossRef]

- Liu, F.; Liu, J.; Wang, L. Deep learning and infrared thermography for asphalt pavement crack severity classification. Autom. Constr. 2022, 140, 104383. [Google Scholar] [CrossRef]

- Du, Y.; Zhang, X.; Li, F.; Sun, L. Detection of crack growth in asphalt pavement through use of infrared imaging. Transp. Res. Rec. 2017, 2645, 24–31. [Google Scholar] [CrossRef]

- Golrokh, A.J.; Gu, X.; Lu, Y. Real-time thermal imaging-based system for asphalt pavement surface distress inspection and 3D crack profiling. J. Perform. Constr. Facil. 2021, 35, 04020143. [Google Scholar] [CrossRef]

- Liu, F.; Liu, J.; Wang, L.; Al-Qadi, I.L. Multiple-type distress detection in asphalt concrete pavement using infrared thermography and deep learning. Autom. Constr. 2024, 161, 105355. [Google Scholar] [CrossRef]

- Yang, X.; Huang, R.; Meng, Y.; Liang, J.; Rong, H.; Liu, Y.; Tan, S.; He, X.; Feng, Y. Overview of the application of Ground-Penetrating Radar, Laser, infrared thermal Imaging, and ultrasonic in nondestructive testing of road surface. Measurement 2024, 224, 113927. [Google Scholar] [CrossRef]

- Tang, N.; Guo, S.; Yang, Y.; Sun, W. Ultrasonic waves generated by smart aggregates for concealed crack detection in asphalt mixture. Constr. Build. Mater. 2024, 438, 137183. [Google Scholar] [CrossRef]

- Pan, W.H.; Sun, X.D.; Wu, L.M.; Yang, K.K.; Tang, N. Damage detection of asphalt concrete using piezo-ultrasonic wave technology. Materials 2019, 12, 443. [Google Scholar] [CrossRef]

- Franesqui, M.A.; Yepes, J.; García-González, C. Ultrasound data for laboratory calibration of an analytical model to calculate crack depth on asphalt pavements. Data Brief 2017, 13, 723–730. [Google Scholar] [CrossRef] [PubMed]

- Franesqui, M.A.; Gallego, J. Inspection and depth sizing of surface-initiated cracking for preventive maintenance of asphalt pavements. Int. J. Pavement Eng. 2023, 24, 2083617. [Google Scholar] [CrossRef]

- Zhang, W.; Akber, M.A.; Hou, S.; Bian, J.; Zhang, D.; Le, Q. Detection of dynamic modulus and crack properties of asphalt pavement using a non-destructive ultrasonic wave method. Appl. Sci. 2019, 9, 2946. [Google Scholar] [CrossRef]

- Li, S. Study on Nondestructive Testing Technology Based on Ground Penetrating Radar and Ultrasonic Testing in Pavements. Master’s Thesis, Southeast University, Nanjing, China, 2021. [Google Scholar]

- Liu, Z.; Gu, X.; Wu, C.; Ren, H.; Zhou, Z.; Tang, S. Studies on the validity of strain sensors for pavement monitoring: A case study for a fiber Bragg grating sensor and resistive sensor. Constr. Build. Mater. 2022, 321, 126085. [Google Scholar] [CrossRef]

- Liu, Z.; Zhu, G.; Liu, L.; Li, W.; Fu, S. Integrated Design Method for Built-in Sensing Devices and Asphalt Pavement Considering Cooperative Deformation Enhancement. J. Chang. Univ. Sci. Technol. (Nat. Sci. Ed.) 2023, 19, 131–142. [Google Scholar]

- Chen, Z.; Wang, Z.; Li, X.; Lin, Y.; Luo, N.; Long, M.; Zhao, N.; Xu, J.-B. Flexible piezoelectric-induced pressure sensors for static measurements based on nanowires/graphene heterostructures. ACS Nano 2017, 11, 4507–4513. [Google Scholar] [CrossRef]

- Shi, J.; Wang, L.; Dai, Z.; Zhao, L.; Du, M.; Li, H.; Fang, Y. Multiscale hierarchical design of a flexible piezoresistive pressure sensor with high sensitivity and wide linearity range. Small 2018, 14, 1800819. [Google Scholar] [CrossRef]

- Weng, S.; Zhang, Z.; Gao, K.; Zhu, H. Research progress of flexible piezoresistive strain sensing technology in structural health monitoring. J. Build. Struct. 2024, 45, 242–261. [Google Scholar] [CrossRef]

- Yi, H.; Wang, S.; Mei, S.; Li, Z. Conductive polymer composites for resistive flexible strain sensors. Polymer 2024, 307, 127286. [Google Scholar] [CrossRef]

- Huang, P.; Wang, T.; Zhou, Y.; Fan, Y.; Wu, Y.; Wang, H.; Yang, J.; Huang, W. Piezoresistive response of MWCNTs/Epoxy mixtures with load-sensing capability. Constr. Build. Mater. 2024, 438, 137203. [Google Scholar] [CrossRef]

- Xin, X.; Qiu, Z.; Luan, X.; Ding, X.; Liang, M.; Yao, Z.; Li, Y. Novel conductive polymer composites for asphalt pavement structure in situ strain monitoring: Influence of CB/CNT and GNP/CNT nano/micro hybrid fillers on strain sensing behavior. IEEE Sens. J. 2022, 22, 3945–3956. [Google Scholar] [CrossRef]

- Gulisano, F.; Buasiri, T.; Apaza, F.R.A.; Cwirzen, A.; Gallego, J. Piezoresistive behavior of electric arc furnace slag and graphene nanoplatelets asphalt mixtures for self-sensing pavements. Autom. Constr. 2022, 142, 104534. [Google Scholar] [CrossRef]

- Rizvi, H.R.; Khattak, M.J.; Madani, M.; Khattab, A. Piezoresistive response of conductive Hot Mix Asphalt mixtures modified with carbon nanofibers. Constr. Build. Mater. 2016, 106, 618–631. [Google Scholar] [CrossRef]

- Liu, X.M.; Wu, S.P. Study on the piezoresistivity character of electrically conductive asphalt concrete. Adv. Mater. Res. 2011, 233, 1756–1761. [Google Scholar] [CrossRef]

- Ruschau, G.R.; Yoshikawa, S.; Newnham, R.E. Resistivities of conductive composites. J. Appl. Phys. 1992, 72, 953–959. [Google Scholar] [CrossRef]

- Garcia, J.R.; O’Suilleabhain, D.; Kaur, H.; Coleman, J.N. A simple model relating gauge factor to filler loading in nanocomposite strain sensors. ACS Appl. Nano Mater. 2021, 4, 2876–2886. [Google Scholar] [CrossRef]

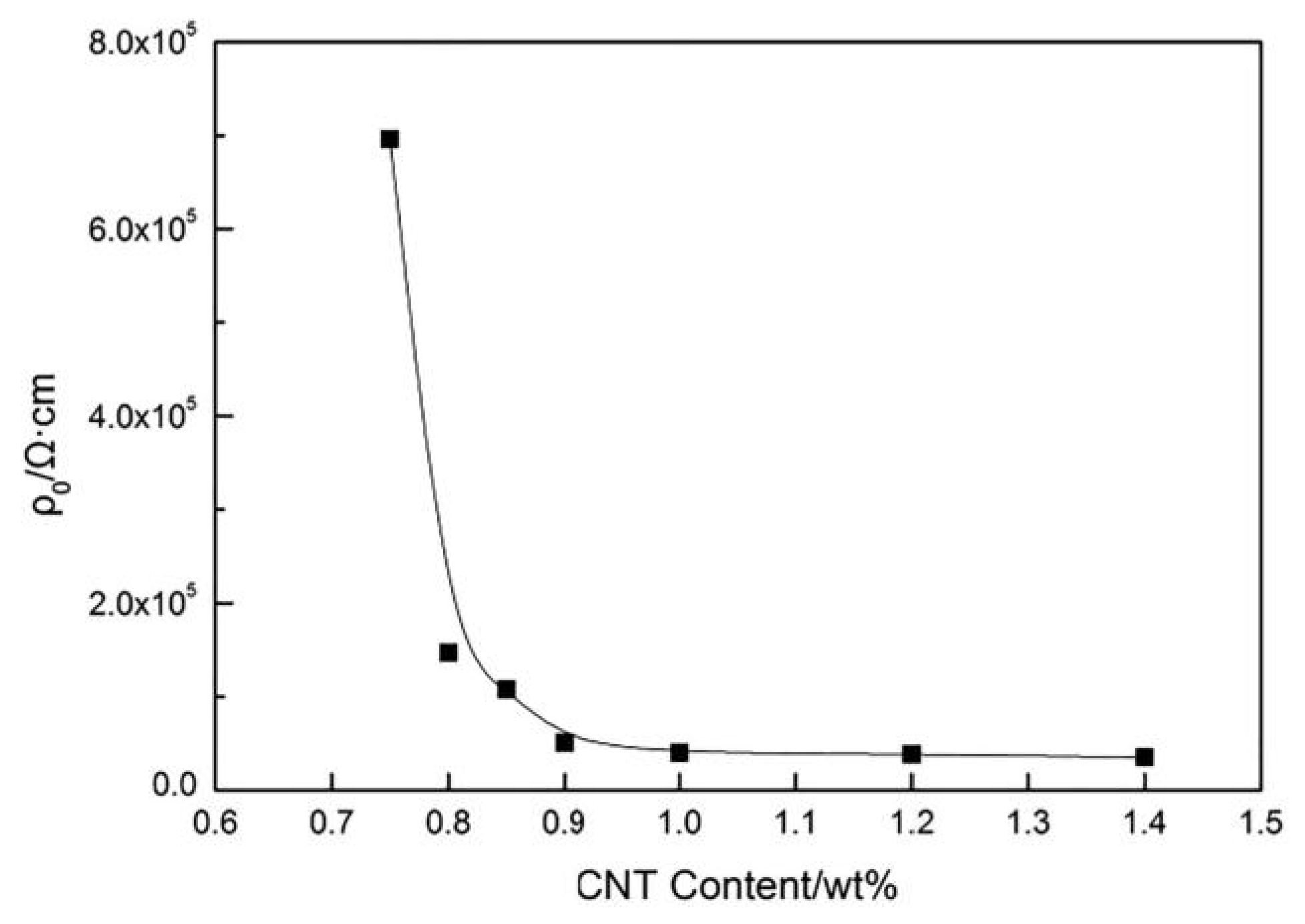

- Xin, X.; Liang, M.; Yao, Z.; Su, L.; Zhang, J.; Li, P.; Sun, C.; Jiang, H. Self-sensing behavior and mechanical properties of carbon nanotubes/epoxy resin composite for asphalt pavement strain monitoring. Constr. Build. Mater. 2020, 257, 119404. [Google Scholar] [CrossRef]

- Xin, X.; Luan, X.; Su, L.; Ma, C.; Liang, M.; Ding, X.; Yao, Z. The innovative self-sensing strain sensor for asphalt pavement structure: Substitutability and synergy effects of graphene platelets with carbon nanotubes in epoxy composites. Front. Mater. 2022, 9, 824364. [Google Scholar] [CrossRef]

- Wang, Z.; Feng, Z.G.; Cui, Q.; Guang, G.; Li, X. Evaluation of piezoresistive response and mechanical performance of self-sensing asphalt concrete mixed with different lengths of carbon fiber. Constr. Build. Mater. 2025, 462, 139942. [Google Scholar] [CrossRef]

- Li, D. Cement-Based Piezoresistive Sensors and Fatigue Properties of Embedded Components. Mater’s Thesis, Tsinghua University, Beijing, China, 2021. [Google Scholar] [CrossRef]

- Xu, X. Mechanical properties and sensing properties of embedded ngraphene cement-based sensor. Mater’s Thesis, Chang’an University, Xian, China, 2024. [Google Scholar] [CrossRef]

- Gao, L.; Ding, S.; She, J.; Zhang, J.; He, R. Research Status of Piezoelectric Technology Application in Intelligent Road. Sci. Technol. Eng. 2023, 23, 11486–11495. [Google Scholar] [CrossRef]

- Zhao, H.; Qin, L.; Ling, J. Synergistic performance of piezoelectric transducers and asphalt pavement. Int. J. Pavement Res. Technol. 2018, 11, 381–387. [Google Scholar] [CrossRef]

- Cain, M.G.; Stewart, M. Standards for piezoelectric and ferroelectric ceramics. In Characterisation of Ferroelectric Bulk Materials and Thin Films; Springer: Dordrecht, The Netherlands, 2014; pp. 267–275. [Google Scholar]

- Jiang, W.; Li, P.; Sha, A.; Li, Y.; Yuan, D.; Xiao, J.; Xing, C. Research on pavement traffic load state perception based on the piezoelectric effect. IEEE Trans. Intell. Transp. Syst. 2023, 24, 8264–8278. [Google Scholar] [CrossRef]

- Zhu, X.; Zhou, X.; Ye, F.; Wu, H.; Du, Z. Development and evaluation of cement/emulsified-asphalt based piezoelectric sensors for road weigh-in-motion system. Smart Mater. Struct. 2021, 30, 125013. [Google Scholar] [CrossRef]

- He, H.; Huang, J.; Zhao, Q.; Tan, Q.; Zang, X. Self-powered asphalt-based sensors for smart roads. Nano Energy 2025, 134, 110525. [Google Scholar] [CrossRef]

- Sebaaly, P.E.; Tabatabaee, N.; Kulakowski, B. Evaluation of the hall effect sensor for pavement instrumentation. J. Test. Eval. 1995, 23, 189–195. [Google Scholar] [CrossRef]

- Wang, J.; Han, Y.; Cao, Z.; Xu, X.; Zhang, J.; Xiao, F. Applications of optical fiber sensor in pavement Engineering: A review. Constr. Build. Mater. 2023, 400, 132713. [Google Scholar] [CrossRef]

- Kashaganova, G.; Kozbakova, A.; Kartbayev, T.; Balbayev, G.; Togzhanova, K.; Alimseitova, Z.; Orazaliyeva, S. Research of a fiber sensor based on fiber Bragg grating for road surface monitoring. Electronics 2023, 12, 2491. [Google Scholar] [CrossRef]

- Sundaram, B.A.; Ravisankar, K.; Senthil, R.; Parivallal, S. Wireless sensors for structural health monitoring and damage detection techniques. Curr. Sci. 2013, 104, 1496–1505. [Google Scholar]

- Xiao, J.; Zou, X.; Xu, W. ePave: A self-powered wireless sensor for smart and autonomous pavement. Sensors 2017, 17, 2207. [Google Scholar] [CrossRef] [PubMed]

- Alavi, A.H.; Hasni, H.; Lajnef, N.; Chatti, K. Continuous health monitoring of pavement systems using smart sensing technology. Constr. Build. Mater. 2016, 114, 719–736. [Google Scholar] [CrossRef]

- Hasni, H.; Alavi, A.H.; Jiao, P.; Lajnef, N.; Chatti, K.; Aono, K.; Chakrabartty, S. A new approach for damage detection in asphalt concrete pavements using battery-free wireless sensors with non-constant injection rates. Measurement 2017, 110, 217–229. [Google Scholar] [CrossRef]

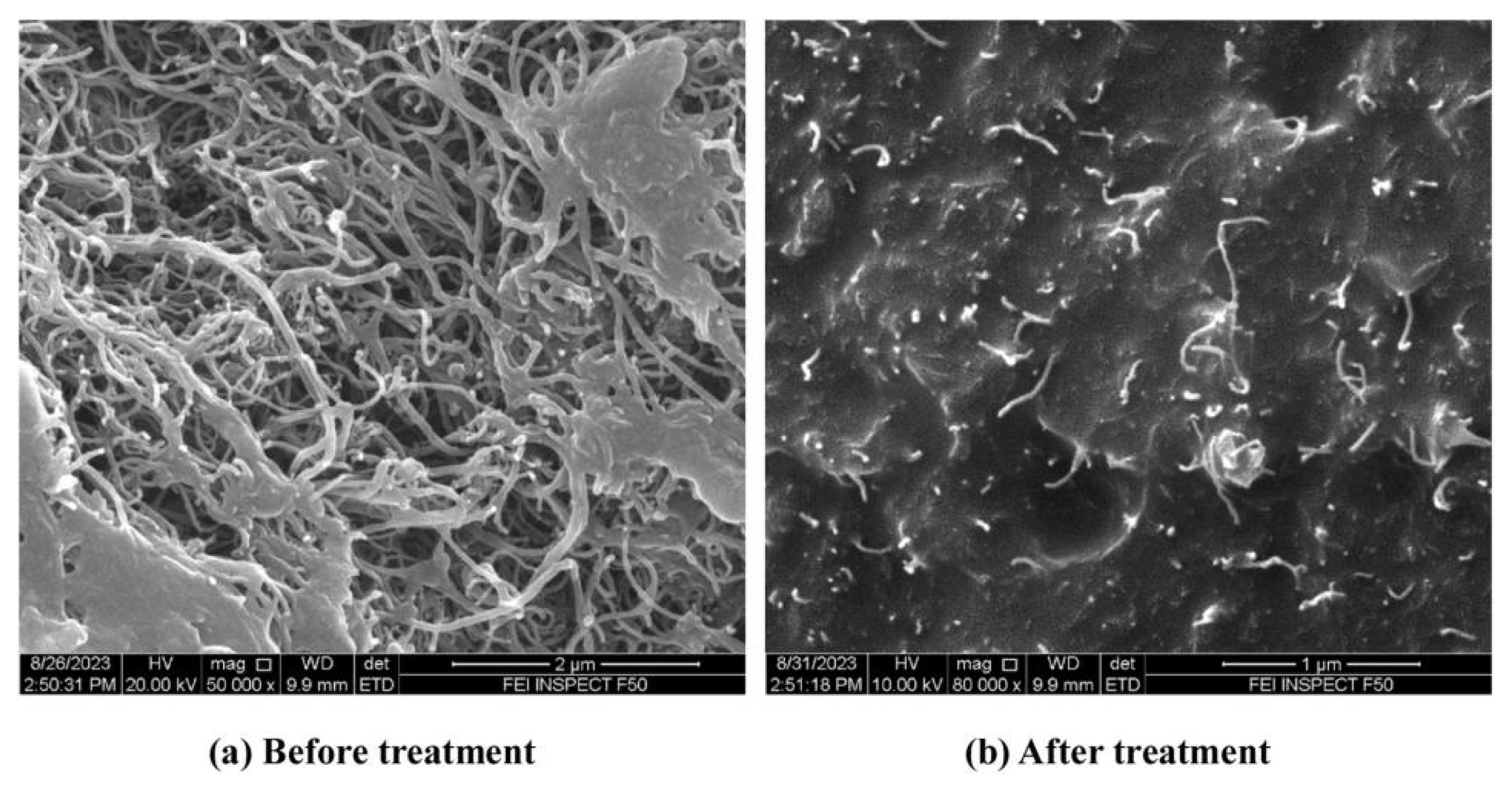

- Ji, X.; Hou, Y.; Chen, Y.; Zhen, Y. Fabrication and performance of a self-powered damage-detection aggregate for asphalt pavement. Mater. Des. 2019, 179, 107890. [Google Scholar] [CrossRef]

- Fu, B.; Li, P.; Zhang, Y.; Zheng, S.; Wang, Y. Research on damage recognition of concrete beams based on embedded piezoelectric sensors. Case Stud. Constr. Mater. 2025, 22, e04769. [Google Scholar] [CrossRef]

- Xiong, H.; Wang, L. Piezoelectric energy harvester for public roadway: On-site installation and evaluation. Appl. Energy 2016, 174, 101–107. [Google Scholar]

| Crack Type | Severity Level | Pavement Manifestation | Crack Width (mm) |

|---|---|---|---|

| Alligator Cracking | Slight | Fine shallow patterns, non-networked, no spalling | ≤2 |

| Moderate | Deepened cracks, localized networking with debris | 2~5 | |

| Severe | Dense networked cracking, fragmentation settlement, and base layer exposure | ≥5 | |

| Longitudinal and transverse crack | Slight | Minor raveling adjacent to the crack/no loose material, few secondary cracks | ≤3 |

| Severe | Significant raveling adjacent to the crack, numerous secondary cracks | ≥3 |

| Problem Type | Specific Manifestations | Consequences |

|---|---|---|

| Inadequate Injection | Incomplete filling, presence of voids | Water infiltration exacerbation, bond failure, crack propagation. |

| Excessive Injection | Material overflow, surface bulging | Unnecessary material waste, extrusion deformation under traffic loading, compromised skid resistance. |

| Nondestructive Testing Technique | Detection Principle | Detection Targets | Detection Depth | Technical Advantages |

|---|---|---|---|---|

| GPR technology [82,83,84,85,86,87,88] | Dielectric Constant | Density, thickness, void content, and subsurface hidden defects | 3–4 m | High accuracy and speed for density/thickness/hidden defect detection, yet it is model-dependent. |

| Infrared thermal imaging technology [92,93,94,95,96,97] | Infrared Radiation | Temperature segregation, compaction uniformity, pavement water seepage, surface cracks, etc. | 2–3 m | Enables intuitive and precise long-term pavement condition monitoring, with particular advantage in detecting incipient micro-cracks within surface layers. |

| Ultrasonic testing technology [101,102,103,104,105] | Elastic Wave Reflection | Hidden cracks, interlayer bonding, moisture content, etc. | 0.8–1.2 m | Effective internal damage inspection with low environmental constraints, suitable for complex pavement structures. |

| Literature | Conductive Filler | Matrix | Optimum Dosage | Percolation Threshold/Region | Sensitivity Evaluation Metric | Sensor Durability Validation | |

|---|---|---|---|---|---|---|---|

| GF | FCR | ||||||

| [118] | CNT/EP | Asphalt | 0.8 wt.% CNTs | Graphene percolation region: 2%–6%. CNT percolation region: 2%–5%. Steel fiber percolation threshold: 1.2%. Carbon fiber percolation threshold: 1%–6%. | 26.04 | - | fatigue tensile test |

| [119] | CNTs-GNP/EP | Asphalt | 0.5 wt% CNTs + 0.3 wt.% GNP/Ep | 13.42 | - | Bending strain test | |

| [120] | CF | Asphalt Concrete | CF mixture ratio (3 mm:6 mm:9 mm): 2:6:2, 5.5 wt.% CF | 40.40 | 51% | Piezoresistive response under vehicle loading | |

| [121] | SF/CF/CNT | Cement | 0.5 wt.% CNTs | 33.40 | 7.81% | Bending fatigue life test | |

| [122] | Graphene/Cement | Cement | 0.5 wt.% Graphene | 149.5 | 14.2% | Cyclic compression test | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Min, W.; Lu, P.; Liu, S.; Wang, H. A Review of Crack Sealing Technologies for Asphalt Pavement: Materials, Failure Mechanisms, and Detection Methods. Coatings 2025, 15, 836. https://doi.org/10.3390/coatings15070836

Min W, Lu P, Liu S, Wang H. A Review of Crack Sealing Technologies for Asphalt Pavement: Materials, Failure Mechanisms, and Detection Methods. Coatings. 2025; 15(7):836. https://doi.org/10.3390/coatings15070836

Chicago/Turabian StyleMin, Weihao, Peng Lu, Song Liu, and Hongchang Wang. 2025. "A Review of Crack Sealing Technologies for Asphalt Pavement: Materials, Failure Mechanisms, and Detection Methods" Coatings 15, no. 7: 836. https://doi.org/10.3390/coatings15070836

APA StyleMin, W., Lu, P., Liu, S., & Wang, H. (2025). A Review of Crack Sealing Technologies for Asphalt Pavement: Materials, Failure Mechanisms, and Detection Methods. Coatings, 15(7), 836. https://doi.org/10.3390/coatings15070836