The Microstructure Evolution of a Ni-Based Superalloy Turbine Blade at Elevated Temperature

Abstract

1. Introduction

2. Methodology

3. Results and Discussion

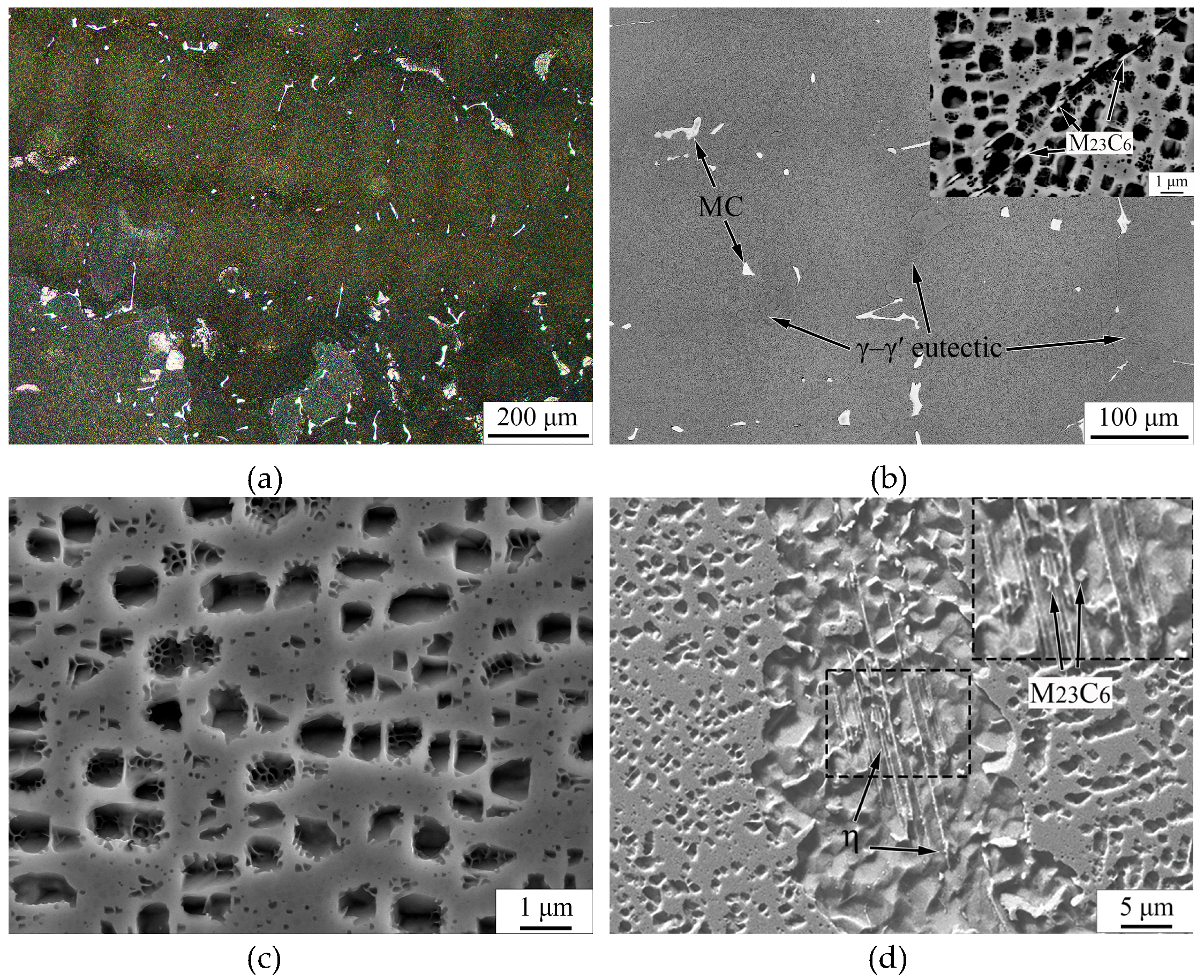

3.1. Microstructural Characteristics Before Exposure

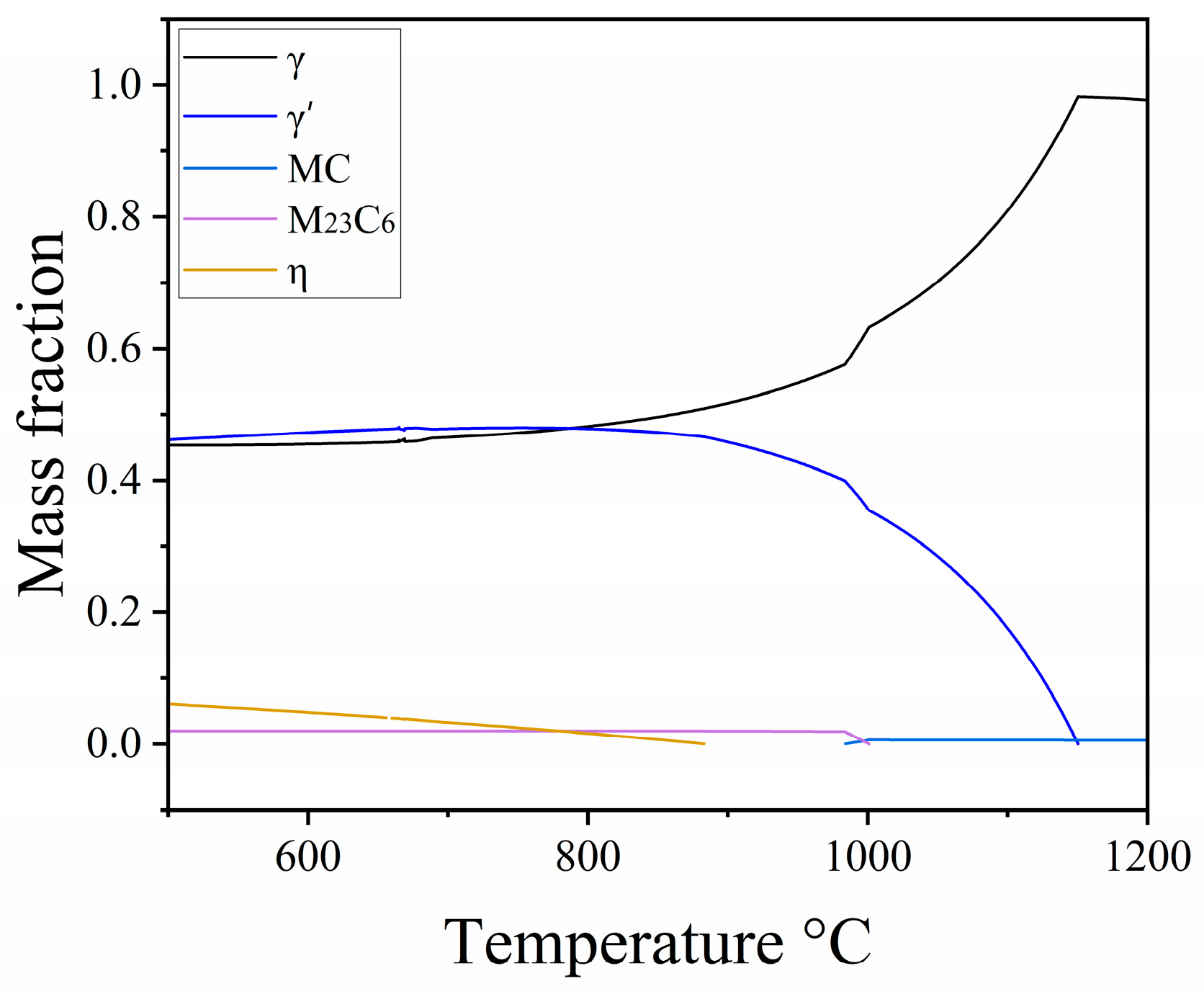

3.2. Phase Composition After Exposure

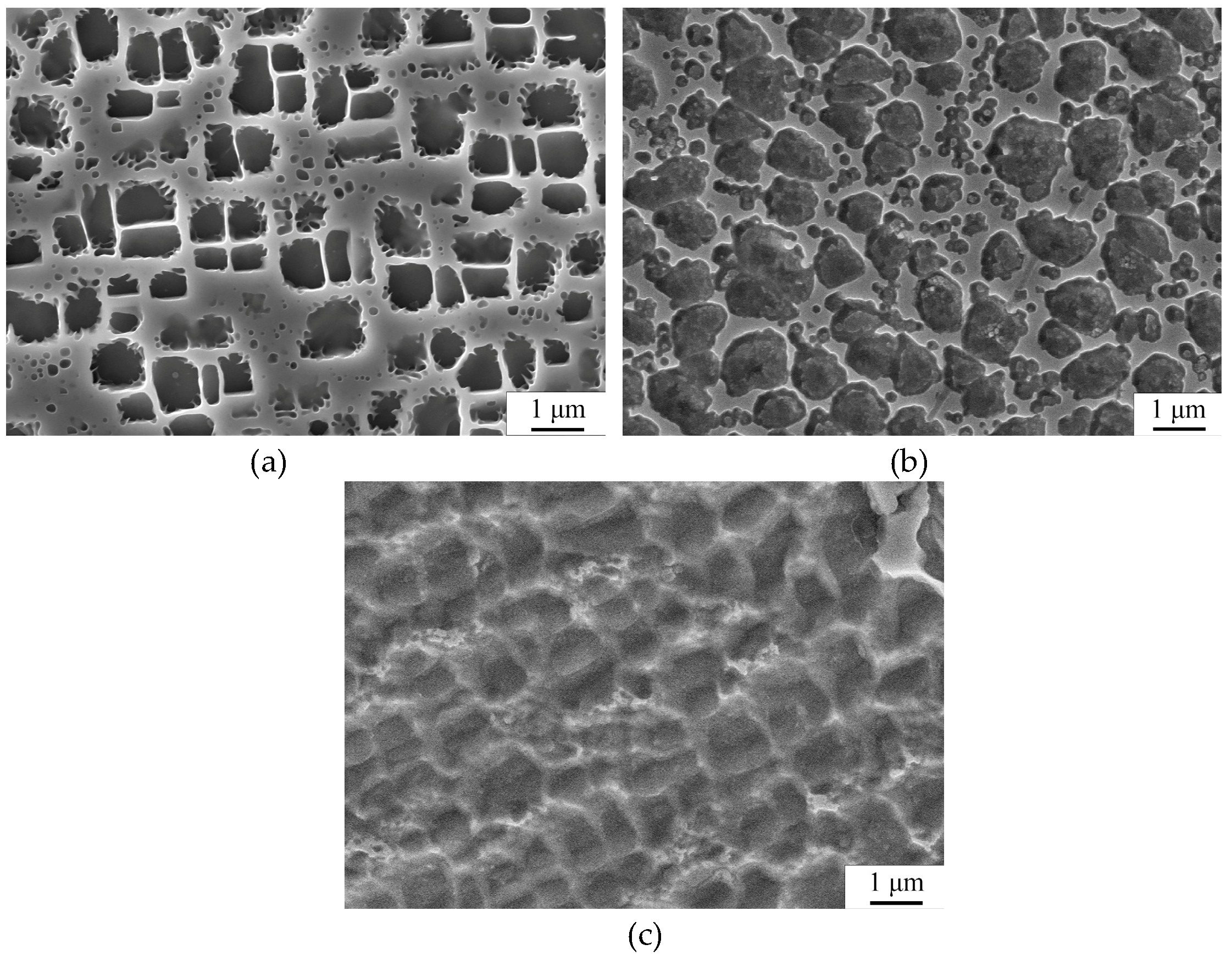

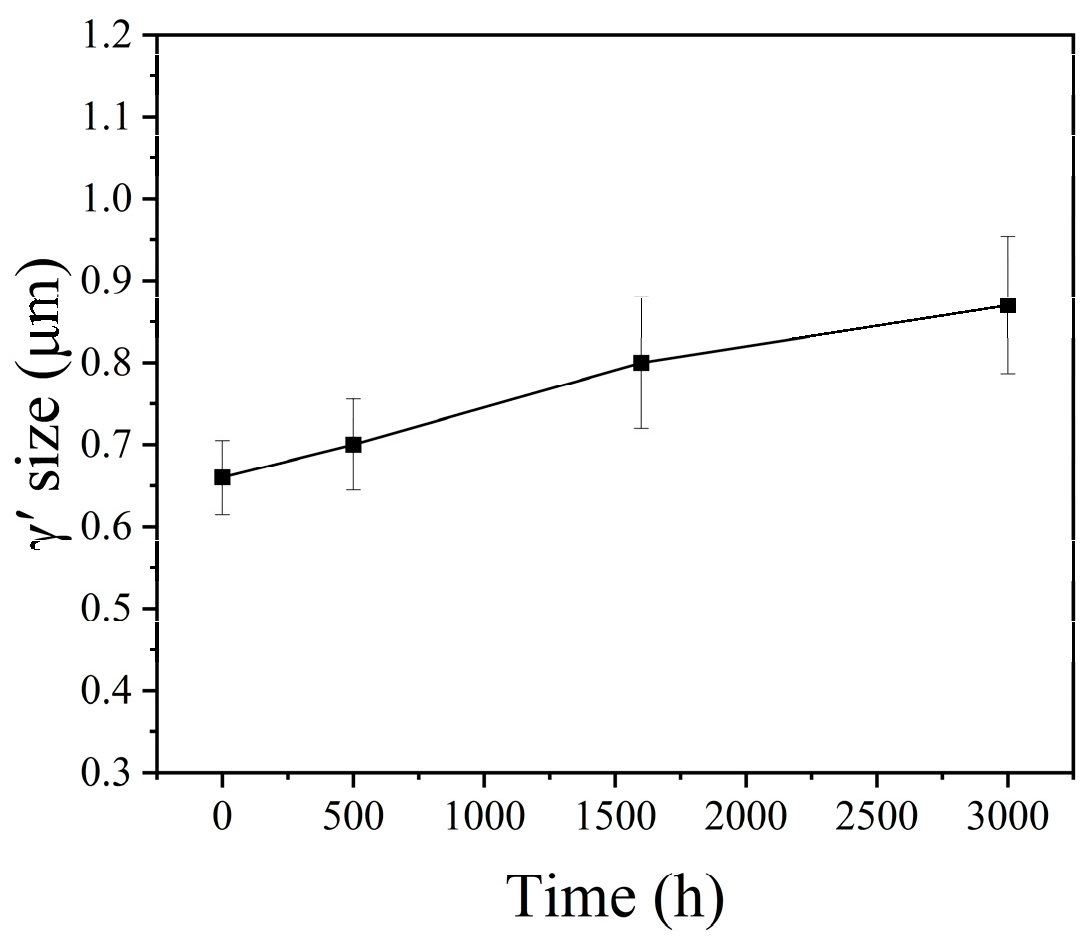

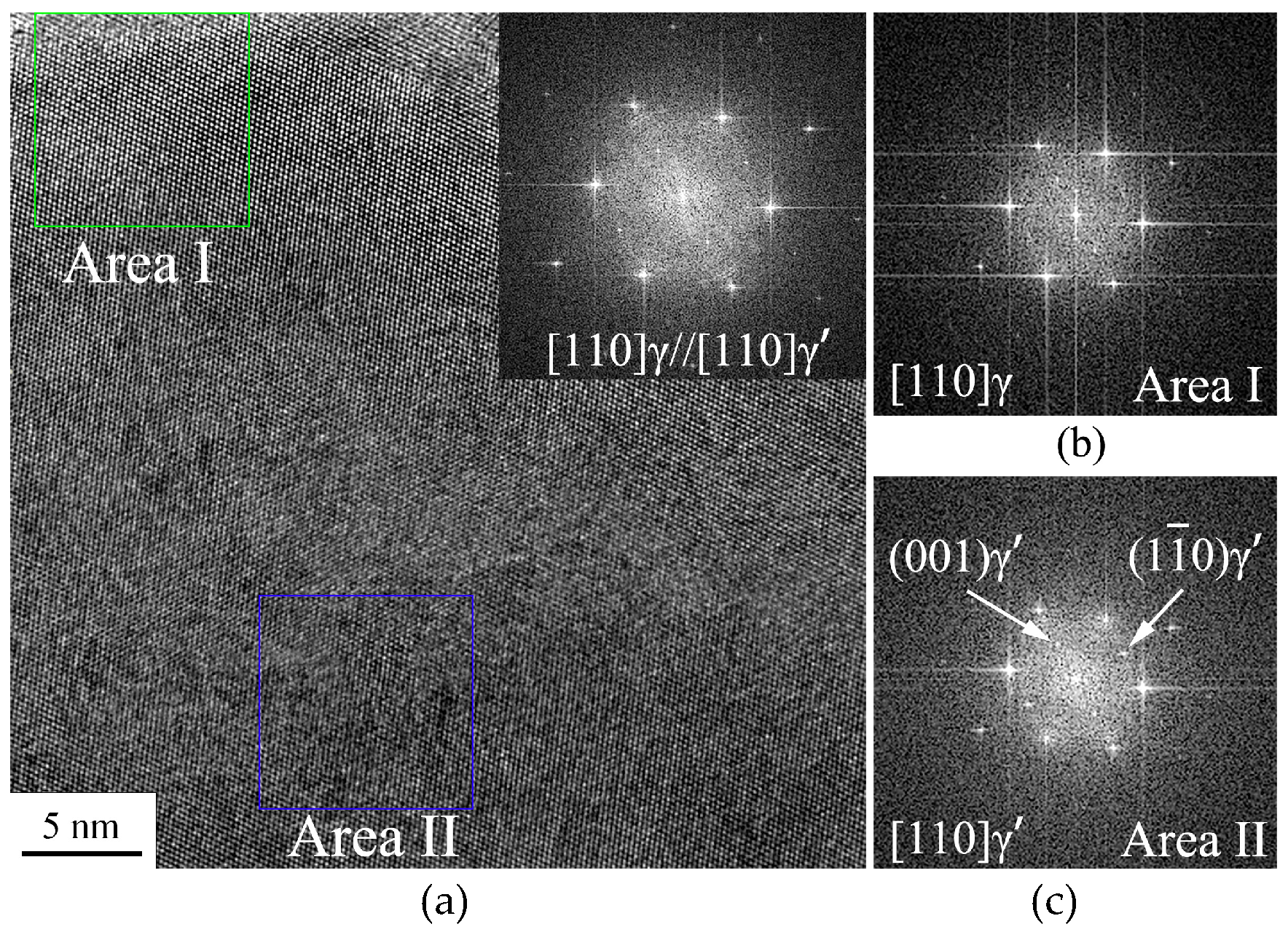

3.3. Evolution of γ′ Precipitates

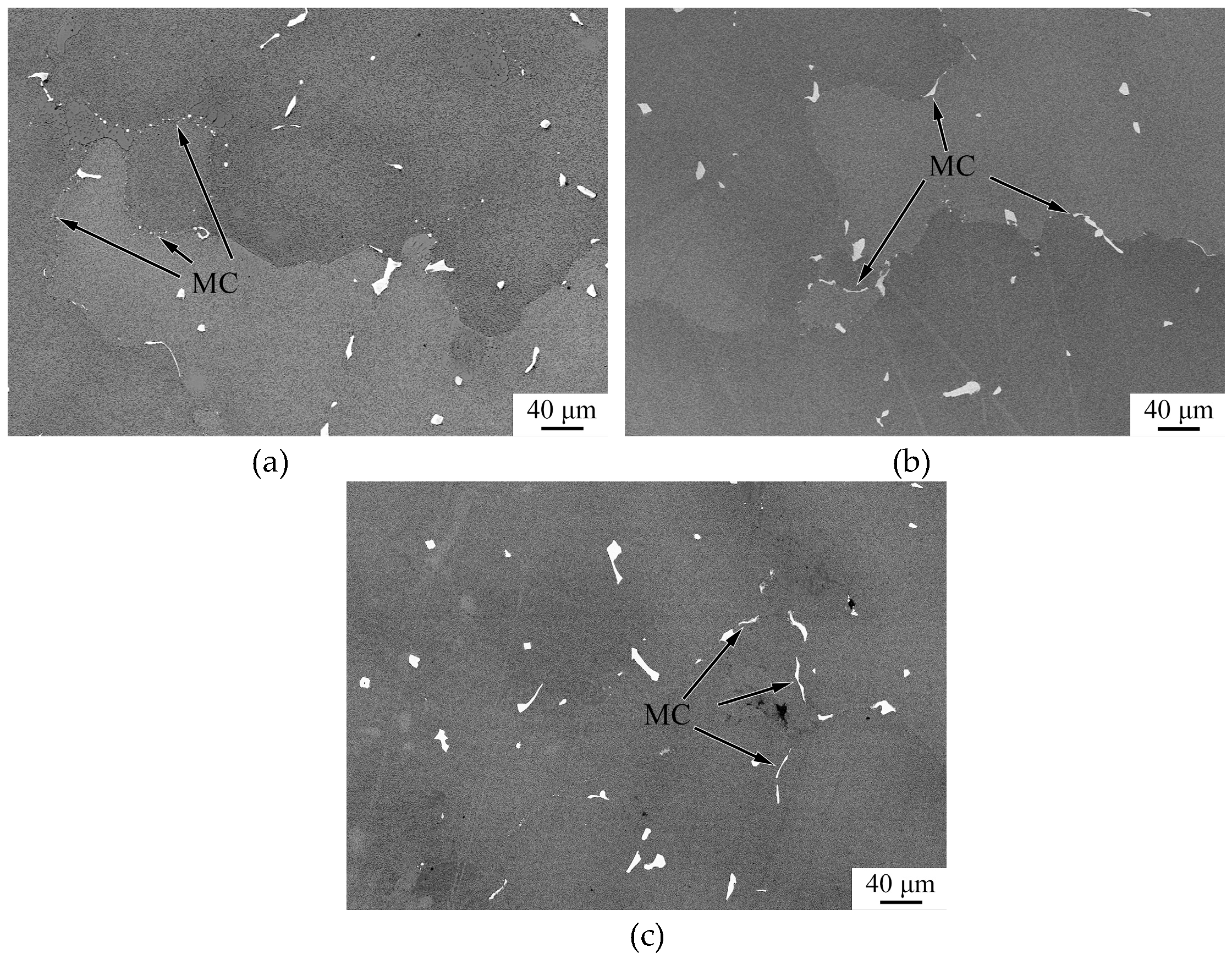

3.4. Evolution of MC Carbide During Exposure

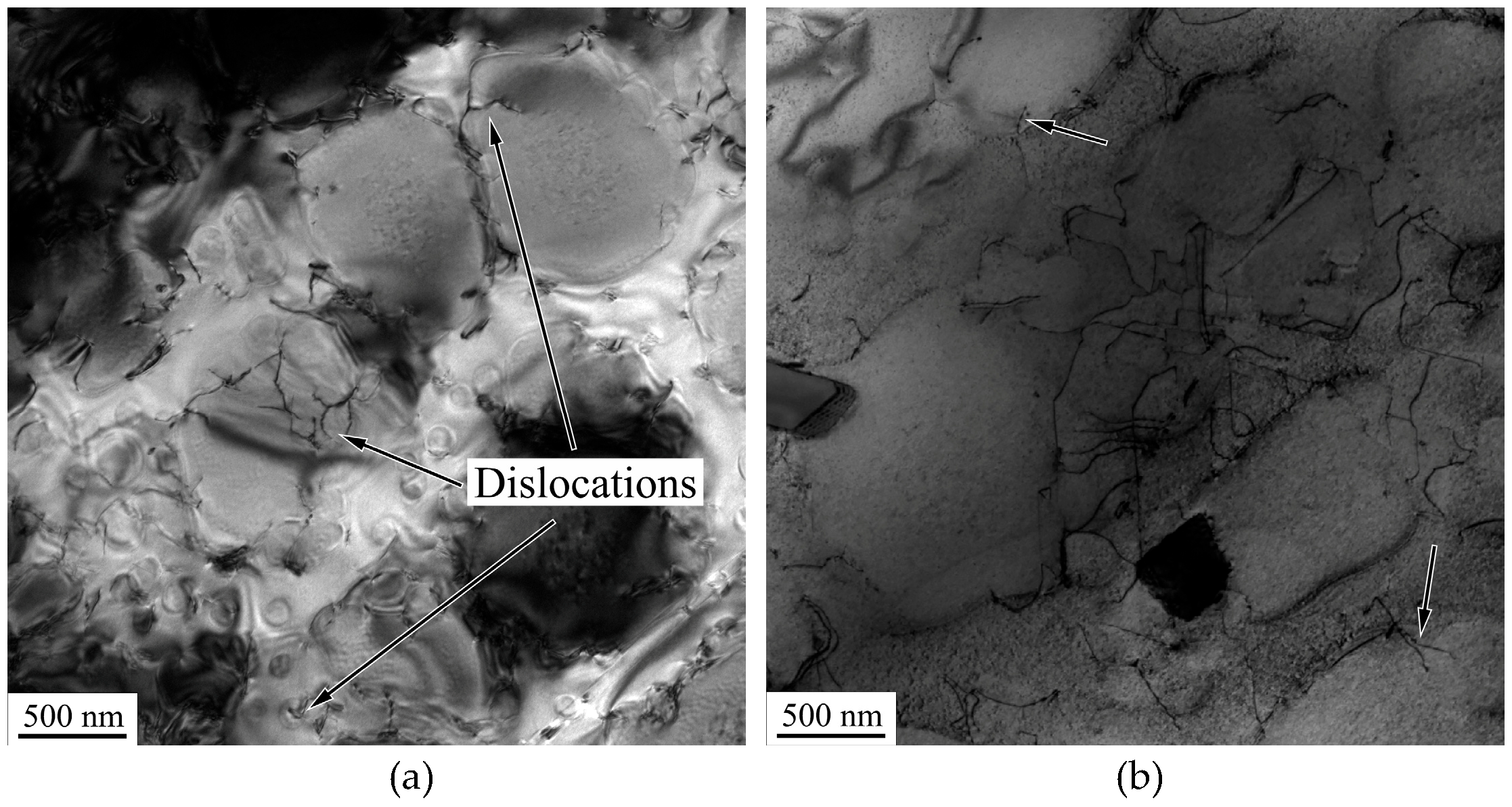

3.5. Dislocation Distribution

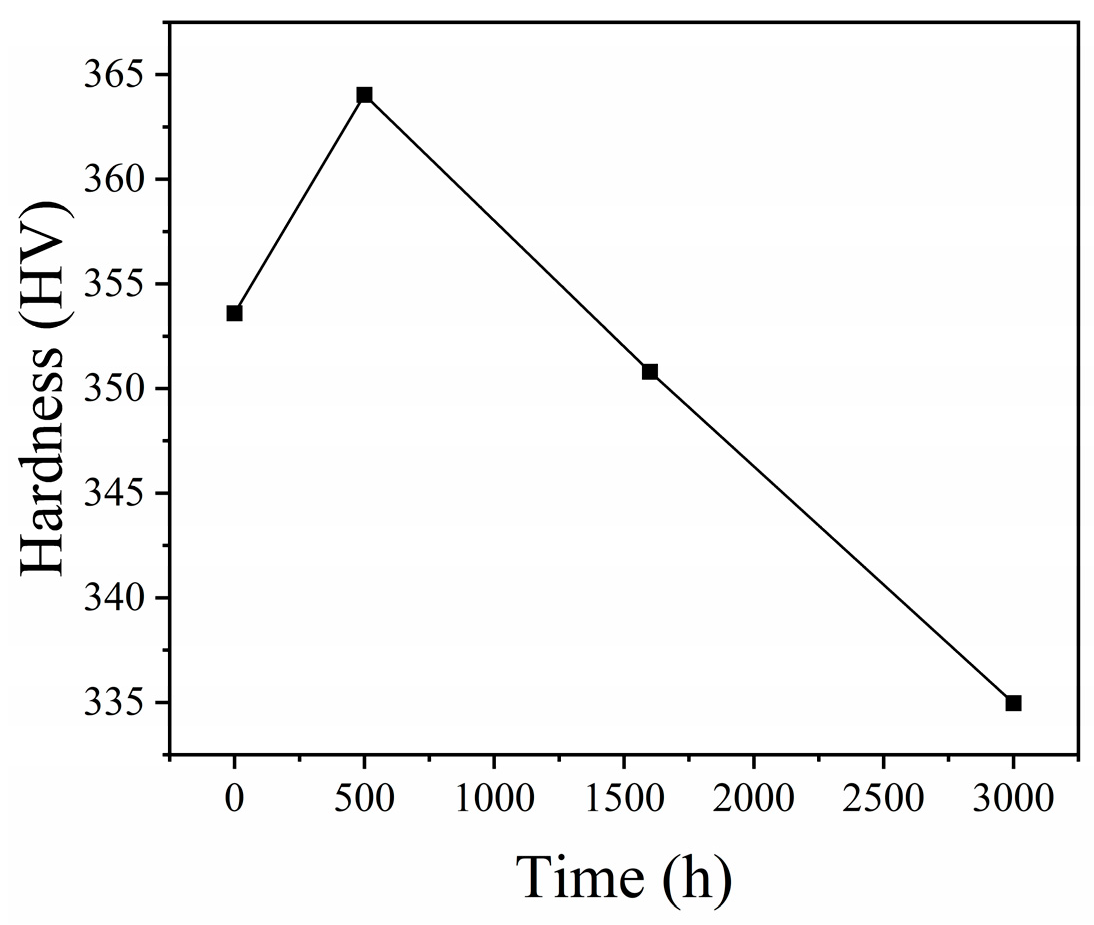

3.6. Hardness

4. Conclusions

- (1)

- As exposure time increases, cubic γ′ precipitates changes become spherical in shape, and their size increases from the initial 0.63 μm to 0.89 μm after 3000 h.

- (2)

- During thermal exposure, MC particles formed and coarsened along the grain boundaries, and primary MC carbide decomposed into M23C6 and the η phase. MC located at the grain boundaries is not as stable as that within the grains.

- (3)

- The orientation of the γ′ precipitate was altered during the coarsening process. The GTD 111 alloy can be deformed through dislocation shearing at 800 °C.

- (4)

- The hardness value initially increases as exposure time increases, then continuously decreases with further exposure, which is related to the reduced precipitation strengthening by γ′ precipitates and the reduction in the hardness of the γ matrix.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| HRTEM | High-resolution electron microscopy |

| SEM | Scanning electron microscopy |

| BSE | Back-scattered electron |

| EDS | Energy-dispersive spectroscopy |

| XRD | X-ray diffraction |

| TEM | Transmission electron microscopy |

| LSW | Lifshitz–Slyozov–Wagner |

| FFT | Fast Fourier transform |

References

- Pan, Y.M.; Zhang, L.F.; Huang, Z.W.; Jiang, L. Coarsening behavior of γ′ precipitates of single crystal Ni-based superalloys during long-term exposure. Mater. Lett. 2019, 241, 210–213. [Google Scholar] [CrossRef]

- Choi, B.G.; Kim, I.S.; Kim, D.H.; Jo, C.Y. Temperature dependence of MC decomposition behavior in Ni-base superalloy GTD 111. Mat. Sci. Eng. A 2008, 478, 329–335. [Google Scholar] [CrossRef]

- Sun, W.; Qin, X.Z.; Guo, J.T.; Lou, L.H.; Zhou, L.Z. Microstructure stability and mechanical properties of a new low cost hot-corrosion resistant Ni–Fe–Cr based superalloy during long-term thermal exposure. Mater. Des. 2015, 69, 70–80. [Google Scholar] [CrossRef]

- Ruan, J.J.; Ueshima, N.; Oikwa, K. Phase transformations and grain growth behaviors in superalloy 718. J. Alloys Compd. 2018, 737, 83–91. [Google Scholar] [CrossRef]

- Shingledecker, J.P.; Evans, N.D.; Pharr, G.M. Influences of composition and grain size on creep–rupture behavior of Inconel® alloy 740. Mat. Sci. Eng. A 2013, 578, 277–286. [Google Scholar] [CrossRef]

- Evans, N.D.; Maziasz, P.J.; Swindeman, R.W.; Smith, G.D. Microstructure and phase stability in INCONEL alloy 740 during creep. Scr. Mater. 2004, 51, 503–507. [Google Scholar] [CrossRef]

- Ferreri, C.N.; Vogel, C.S.; Knezevic, M. Determining volume fractions of γ, γ′, γ″, δ, and MC-carbide phases in Inconel 718 as a function of its processing history using an advanced neutron diffraction procedure. Mat. Sci. Eng. A 2020, 781, 139228. [Google Scholar] [CrossRef]

- Zhao, S.Q.; Xie, X.S.; Smith, G.D.; Patel, S.J. Research and Improvement on structure stability and corrosion resistance of nickel-base superalloy INCONEL alloy 740. Mater. Des. 2006, 27, 1120–1127. [Google Scholar] [CrossRef]

- Song, X.Q.; Wang, Y.X.; Zhao, X.X.; Zhang, J.; Li, Y.; Wang, Y.F.; Chen, Z. Analysis of carbide transformation in MC-M23C6 and its effect on mechanical properties of Ni-based superalloy. J. Alloys Compd. 2022, 91, 164959. [Google Scholar] [CrossRef]

- Gao, S.; Hou, J.S.; Guo, Y.A.; Zhou, L.Z. Phase precipitation behavior and tensile properties of as-cast Ni-based superalloy during heat treatment. Trans. Nonferrous Met. Soc. China 2018, 28, 1735–1744. [Google Scholar] [CrossRef]

- Hou, K.L.; Wang, M.; Ou, M.Q.; Li, H.Z.; Hao, X.C.; Ma, Y.C.; Liu, K. Effects of microstructure evolution on the deformation mechanisms and tensile properties of a new Ni-base superalloy during aging at 800 °C. J. Mater. Sci. Technol. 2021, 68, 40–52. [Google Scholar] [CrossRef]

- Jahangiri, M.R.; Arabi, H.; Boutorabi, S.M.A. Investigation on the dissolution of η phase in a cast Ni-based superalloy. Int. J. Min. Met. Mater. 2013, 20, 42–48. [Google Scholar] [CrossRef]

- Özgün, Ö.; Yılmaz, R.; Gülsoy, Ö.H.; Fındık, F. The effect of aging treatment on the fracture toughness and impact strength of injection molded Ni-625 superalloy parts. Mater. Charact. 2015, 108, 8–15. [Google Scholar] [CrossRef]

- Gao, L.; Song, C.Q.; Zhu, H.; Zheng, B.Y.; Liu, X.L.; Wu, Y.D.; Hui, X.D. Microstructural Stability and Mechanical Properties of a Novel Weldable Ni-based Superalloy during Thermal Exposure at 800 °C. J. Mater. Eng. Perform. 2025. [Google Scholar] [CrossRef]

- Wu, Y.S.; Qin, X.Z.; Wang, C.S.; Zhou, L.Z. Microstructural evolution and its influence on the impact toughness of GH984G alloy during long-term thermal exposure. J. Mater. Sci. Technol. 2021, 60, 61–69. [Google Scholar] [CrossRef]

- Chen, J.J.; Wang, S.L.; Lai, K.W.; Sang, P.; Qin, Q.Q.; Li, Y.S. Rafting and redissolution of γʹ phase in Ni–Al alloy under external stress. Heliyon 2023, 9, e23093. [Google Scholar] [CrossRef]

- Jiang, H.; Xiang, X.M.; Dong, J.X. The morphology and characteristics evolution of MC carbide during homogenization in hard-to-deform superalloy GH4975. J. Alloys Compd. 2022, 929, 167086. [Google Scholar] [CrossRef]

- Hu, R.; Bai, G.H.; Li, J.S.; Zhang, J.Q.; Zhang, T.B.; Fu, H.Z. Precipitation behavior of grain boundary M23C6 and its effect on tensileproperties of Ni–Cr–W based superalloy properties of Ni–Cr–W based superalloy. Mater. Sci. Eng. A 2012, 548, 83–88. [Google Scholar] [CrossRef]

- Hu, X.B.; Guo, X.W.; Wang, Y.J.; Hou, J.S.; Qin, X.Z.; Zhou, L.Z.; Liu, J.F.; Ma, X.L. Microstructural characterization of the η-Ni3(Ti, Al) phase in a long-term-aged Ni-based superalloy. Philos. Mag. Lett. 2017, 97, 442–449. [Google Scholar] [CrossRef]

- Hou, K.; Ou, M.; Xing, W.; Ma, G.; Hao, X.; Wang, M.; Ma, Y. The formation of η-Ni3Ti phase microstructure in a cast nickel-based superalloy with high Ti/Al ratio. J. Mater. Res. Technol. 2024, 29, 764–778. [Google Scholar] [CrossRef]

- Zhou, Y.; Xie, F.; Cheng, L.F.; Xu, H.; Wang, X.Y.; Yu, D.Q. Optimize Design and Manufacture of 130MW Gas Turbine First Stage Blade. In Proceedings of the 2022 IEEE 6th Conference on Energy Internet and Energy System Integration, Chengdu, China, 11–13 November 2022; pp. 2749–2754. [Google Scholar]

- Jiang, H.; Dong, J.X.; Zhang, M.C. The phase decomposition with related element interaction and redistribution during long term aging of 740H superalloy. J. Alloys Compd. 2019, 782, 323–333. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, X.B.; Yuan, Y.; Dang, Y.Y.; Li, W.Q.; Xu, J.C.; Cheng, Y.; Yue, Q.Z.; Gu, Y.F.; Zhang, Z. Influence of thermal exposure on microstructural stability and tensile properties of a new Ni-base superalloy. J. Mater. Res. Technol. 2022, 21, 4462–4472. [Google Scholar] [CrossRef]

- Liu, L.R.; Jin, T.; Zhao, N.R.; Sun, X.F.; Guan, H.R.; Hu, Z.Q. Formation of carbides and their effects on stress rupture of a Ni-base single crystal superalloy. Mat. Sci. Eng. A 2003, 361, 191–197. [Google Scholar] [CrossRef]

- He, L.Z.; Zheng, Q.; Sun, X.F.; Hou, G.C.; Guan, H.R.; Hu, Z.Q. M23C6 precipitation behavior in a Ni-base superalloy M963. J. Mater. Sci. 2005, 40, 2959–2964. [Google Scholar] [CrossRef]

- Yin, H.F.; Gao, Y.M.; Gu, Y.F. Effects of long term thermal exposure on microstructure and mechanical property evolution of a new wrought Ni–Fe based superalloy. Mater. Des. 2016, 105, 66–74. [Google Scholar] [CrossRef]

- Connor, L.D.; Stone, H.J.; Collins, D.M.; Preuss, M.; Hardy, M.C.; Rae, C.M.F. The Effect of Cooling Rate from Solution on the Lattice Misfit During Isothermal Aging of a Ni-Base Superalloy. Metall. Mater. Trans. A 2014, 45, 2436–2444. [Google Scholar] [CrossRef]

- Qin, X.Z.; Guo, J.T.; Yuan, C.; Chen, C.L.; Hou, J.S.; Ye, H.Q. Decomposition of primary MC carbide and its effects on the fracture behaviors of a cast Ni-base superalloy. Mat. Sci. Eng. A 2008, 485, 74–79. [Google Scholar] [CrossRef]

- Chu, C.H.; Guo, Q.Y.; Guan, Y.; Qiao, Z.X.; Liu, Y.C. Deformation mechanisms of a γʹ phase strengthened CoNi-based superalloy at high temperatures. Mat. Sci. Eng. A 2002, 833, 142587. [Google Scholar] [CrossRef]

- Oh, J.H.; Choi, I.C.; Kim, Y.J.; Yoo, B.G.; Jang, J.I. Variations in overall- and phase-hardness of a new Ni-based superalloy during isothermal aging. Mat. Sci. Eng. A 2011, 528, 6121–6127. [Google Scholar] [CrossRef]

| Cr | Co | Al | Ti | Ta | W | Mo | C | S | Si | Mg | V |

| 13.76 | 9.03 | 3.06 | 4.70 | 2.84 | 3.93 | 1.61 | 0.10 | 0.0014 | 0.012 | 0.0024 | 0.067 |

| As | O | B | Ni | ||||||||

| 0.00018 | 0.0011 | 0.018 | Balance |

| Ti | Cr | Co | Ni | Mo | Ta | W | Al | |

|---|---|---|---|---|---|---|---|---|

| MC | 26.43 | 0.72 | 0.43 | 2.39 | 2.25 | 58.78 | 9.00 | - |

| M23C6 | 1.64 | 66.37 | 2.99 | 12.71 | 6.73 | 0.24 | 8.83 | 0.48 |

| Ti | Cr | Co | Ni | Mo | Ta | W | Al | |

|---|---|---|---|---|---|---|---|---|

| η | 10.31 | 1.59 | 5.48 | 64.56 | 0.54 | 11.49 | 3.68 | 2.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Cui, Y.; Zhou, Y.; Li, Z.; Zhao, Y.; Wang, J. The Microstructure Evolution of a Ni-Based Superalloy Turbine Blade at Elevated Temperature. Coatings 2025, 15, 835. https://doi.org/10.3390/coatings15070835

Wang X, Cui Y, Zhou Y, Li Z, Zhao Y, Wang J. The Microstructure Evolution of a Ni-Based Superalloy Turbine Blade at Elevated Temperature. Coatings. 2025; 15(7):835. https://doi.org/10.3390/coatings15070835

Chicago/Turabian StyleWang, Xuyang, Yanna Cui, Yang Zhou, Ze Li, Yuzhu Zhao, and Jun Wang. 2025. "The Microstructure Evolution of a Ni-Based Superalloy Turbine Blade at Elevated Temperature" Coatings 15, no. 7: 835. https://doi.org/10.3390/coatings15070835

APA StyleWang, X., Cui, Y., Zhou, Y., Li, Z., Zhao, Y., & Wang, J. (2025). The Microstructure Evolution of a Ni-Based Superalloy Turbine Blade at Elevated Temperature. Coatings, 15(7), 835. https://doi.org/10.3390/coatings15070835