Numerical Analysis of Impingement Jet Combined Cooling with Film Cooling Holes and Thermal Barrier Coatings Using the Decoupling Method

Abstract

1. Introduction

2. Numerical Methods

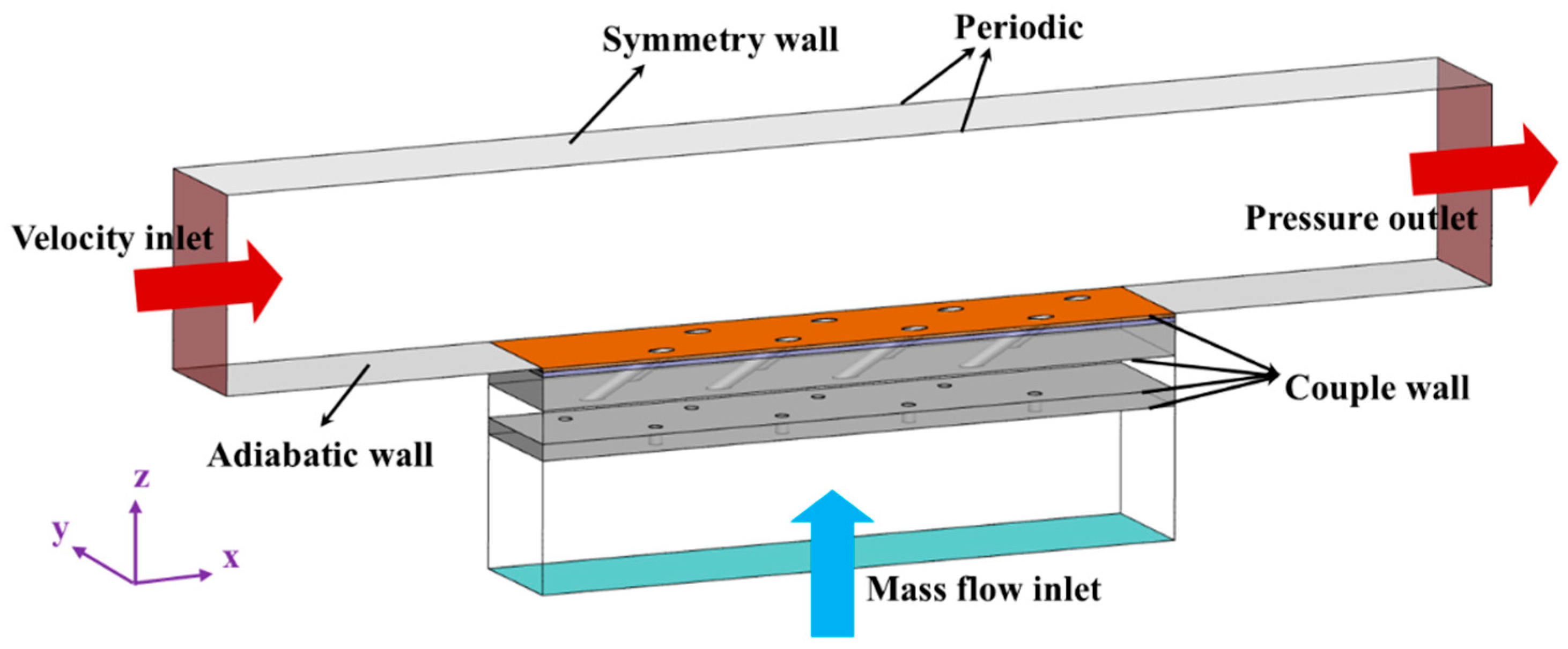

2.1. Numerical Model

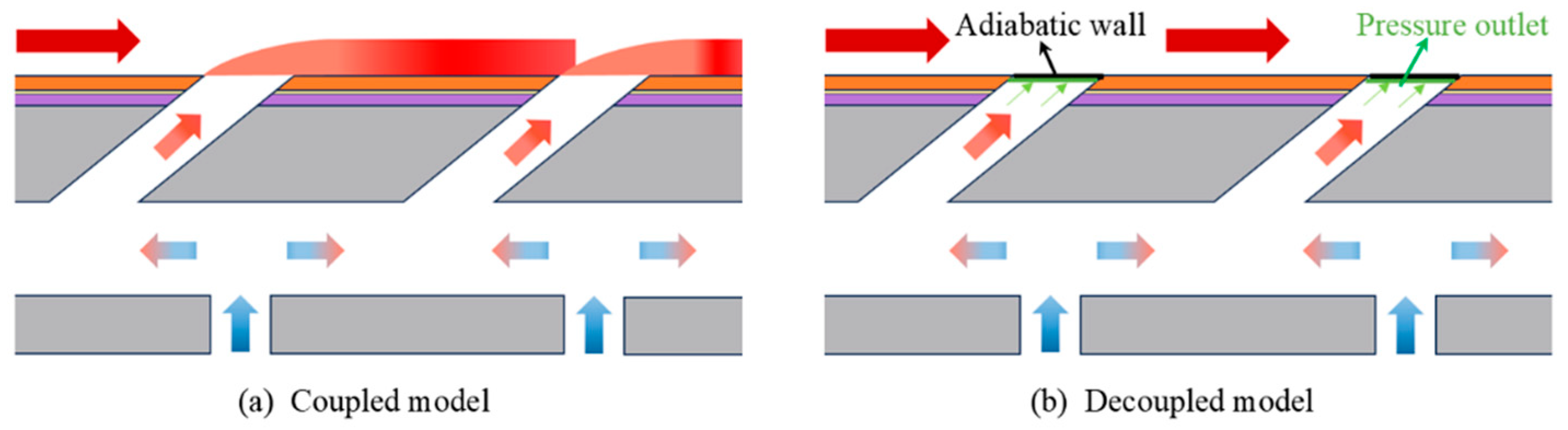

2.2. Boundary Conditions of Coupling Situation and Decoupling Method

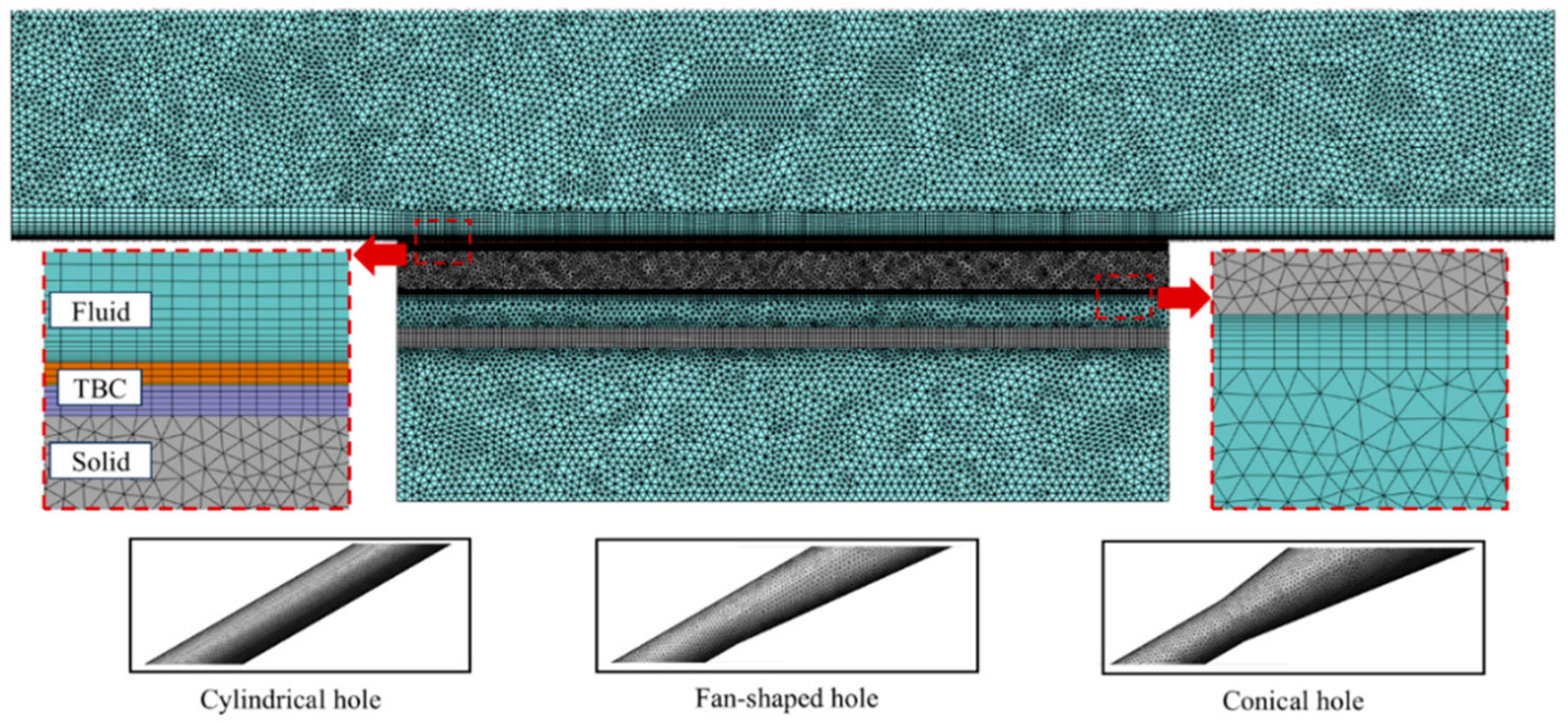

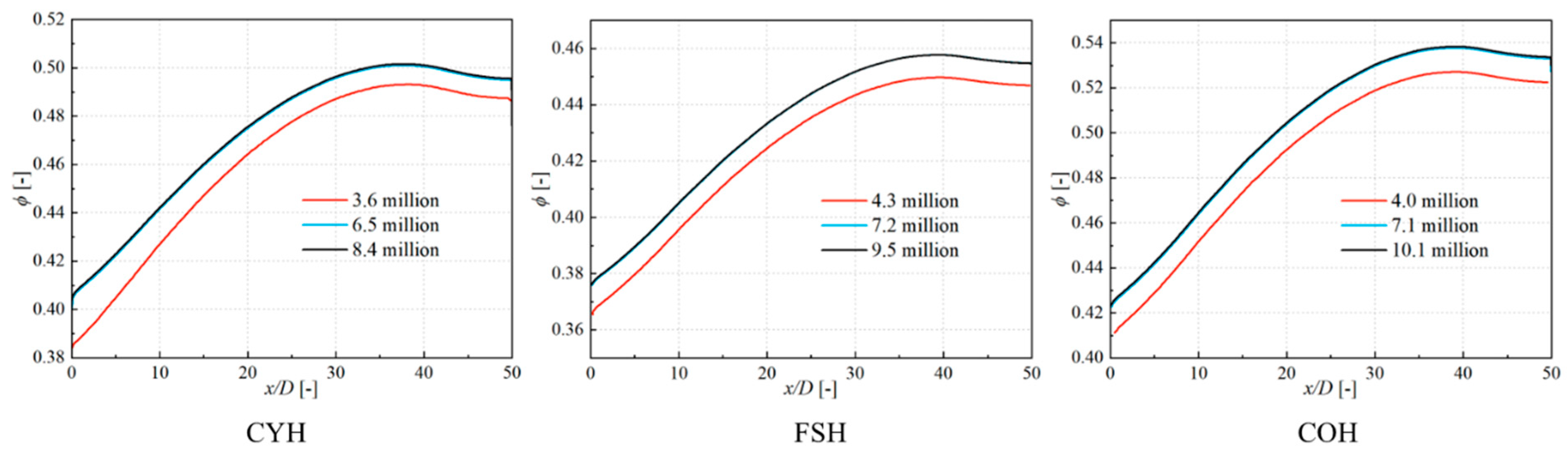

2.3. Grid and Turbulence Model

3. Discussion

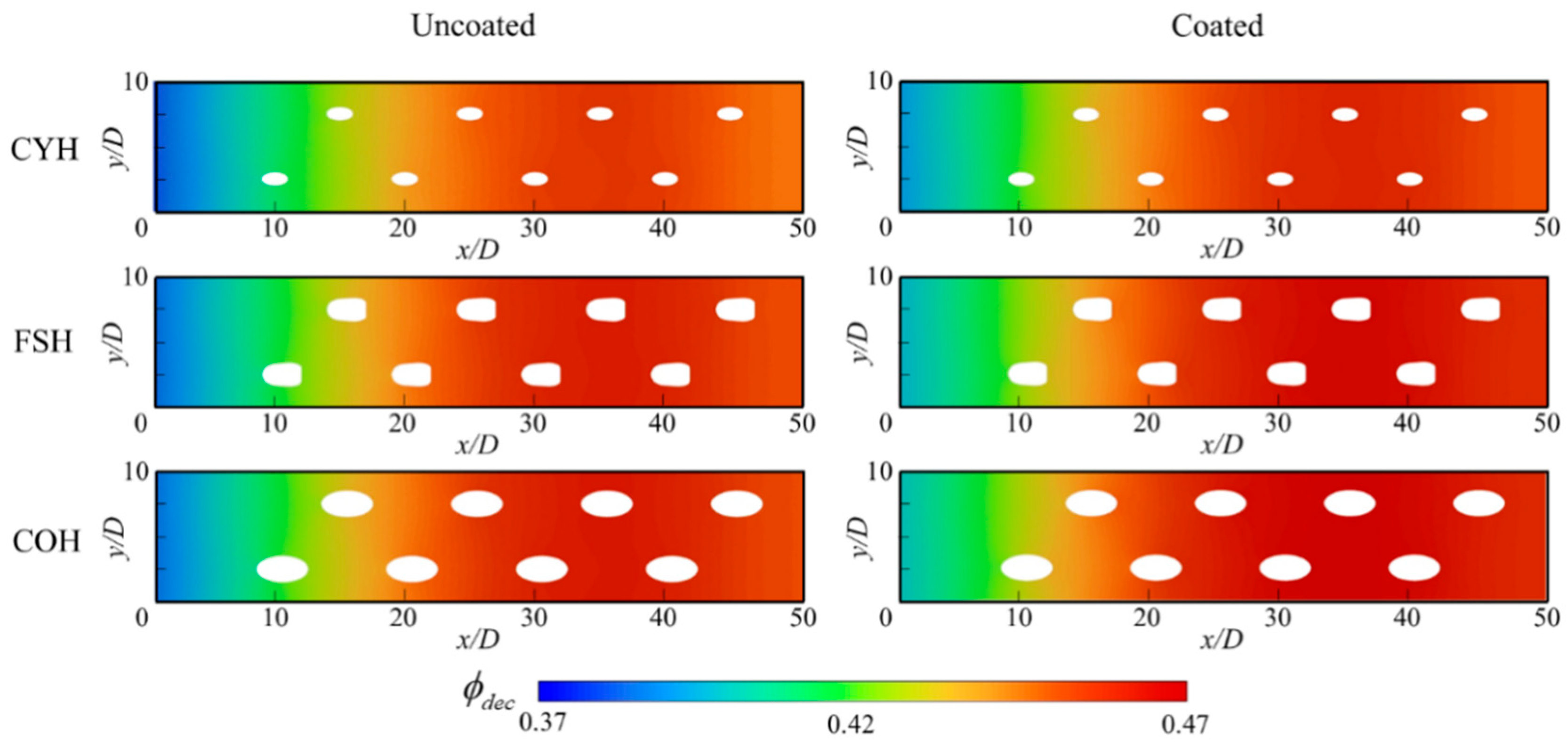

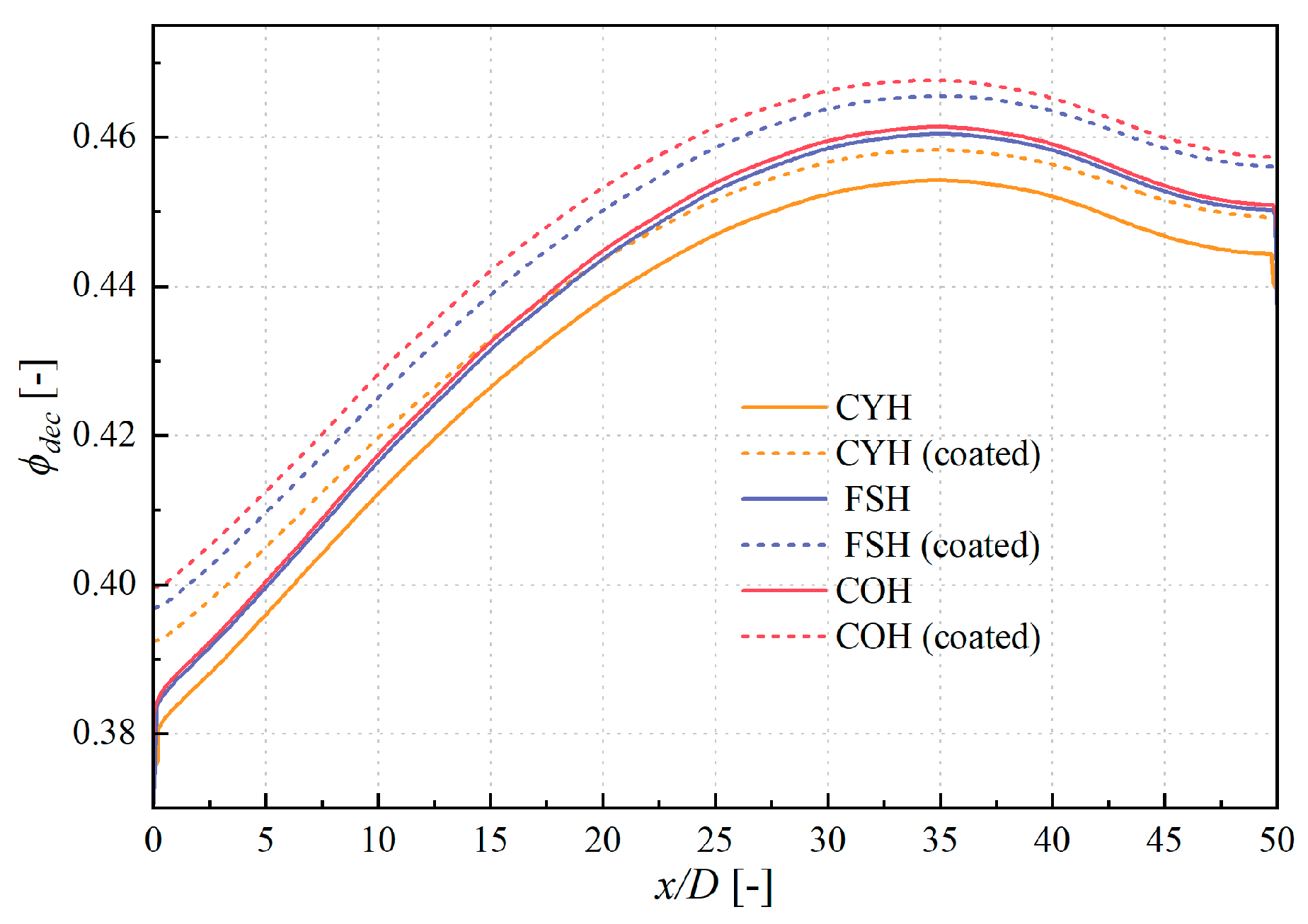

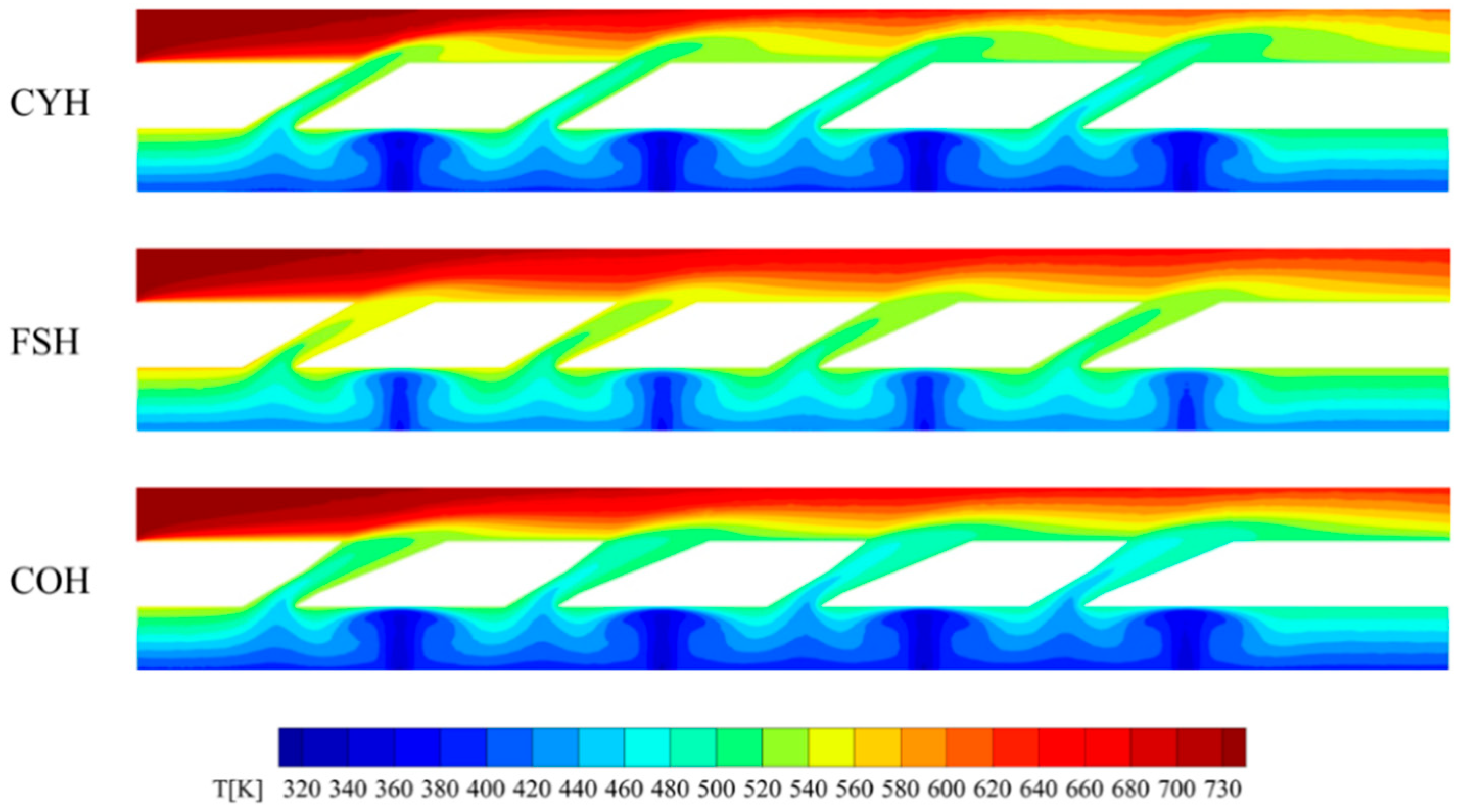

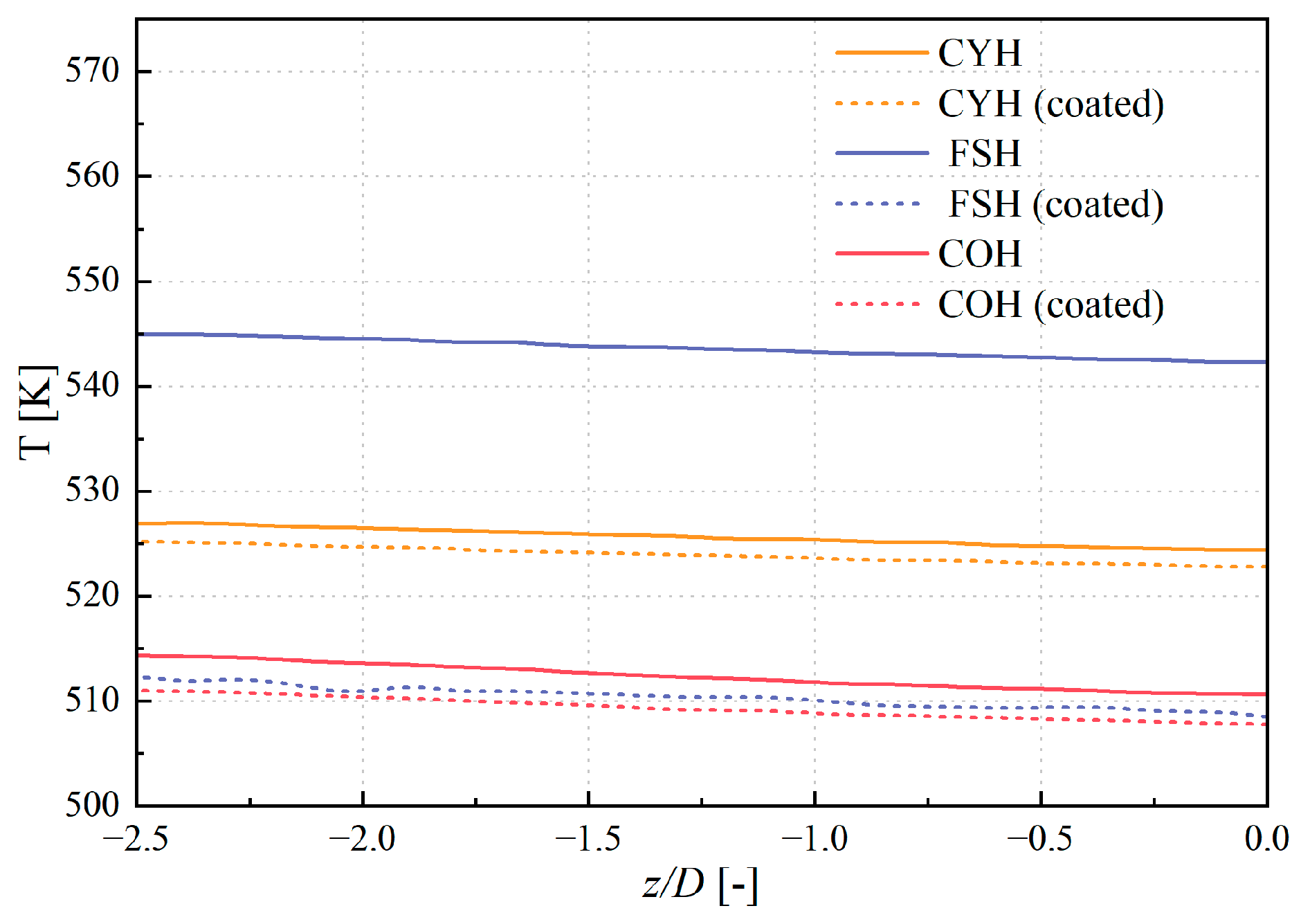

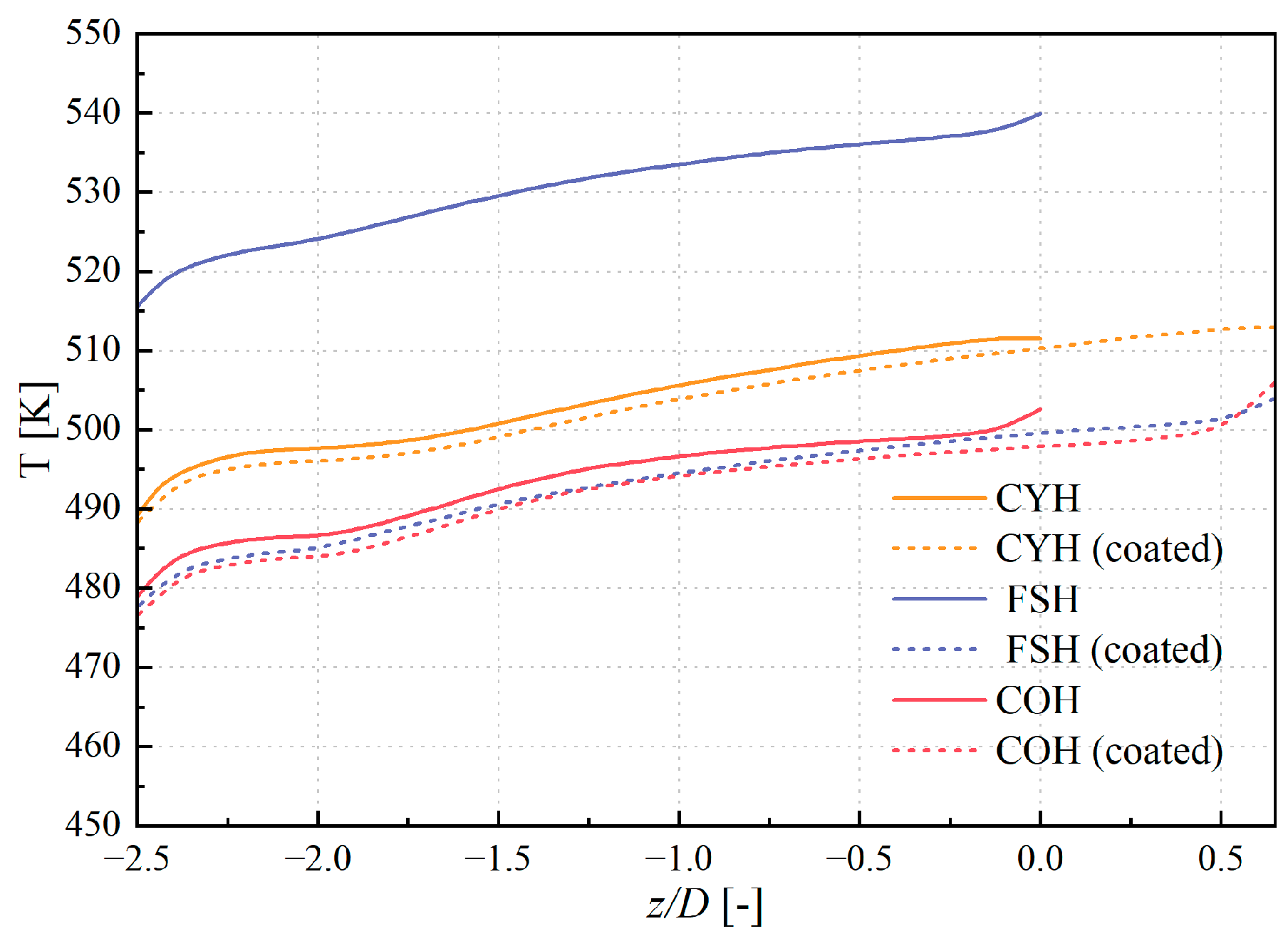

3.1. Comparison of the Overall Cooling Performance

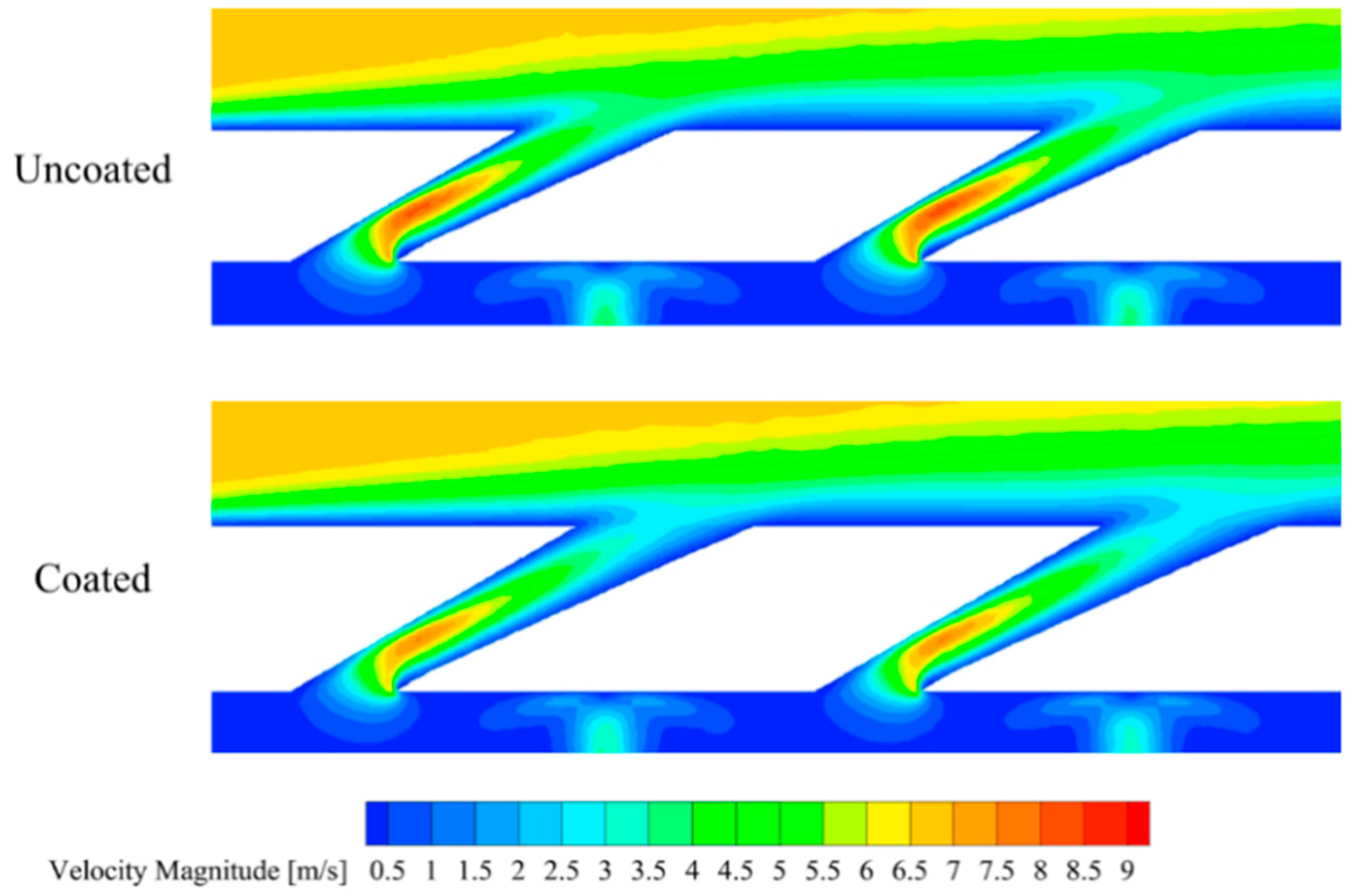

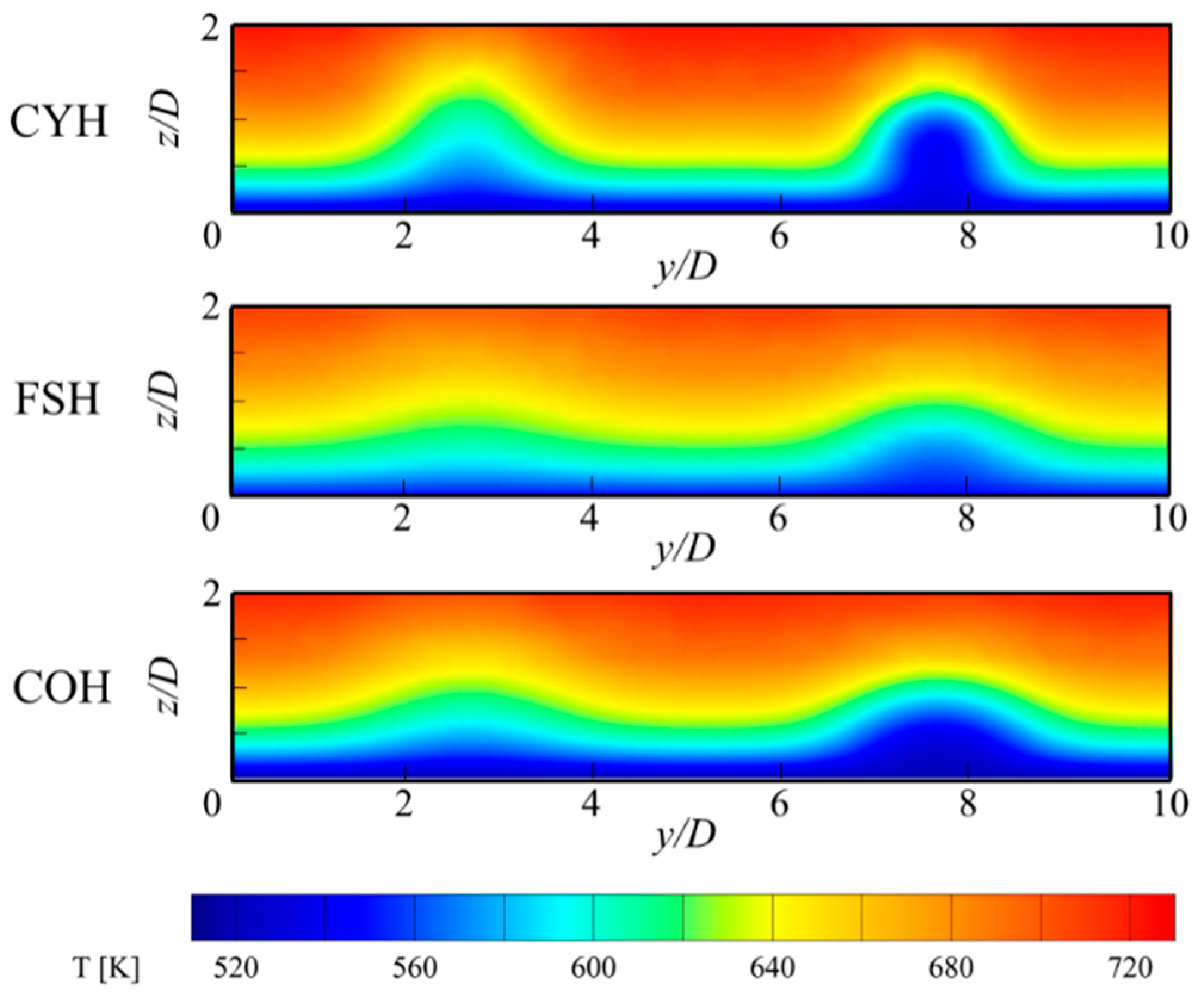

3.2. Influence on the Inner and Outer Cooling Performance

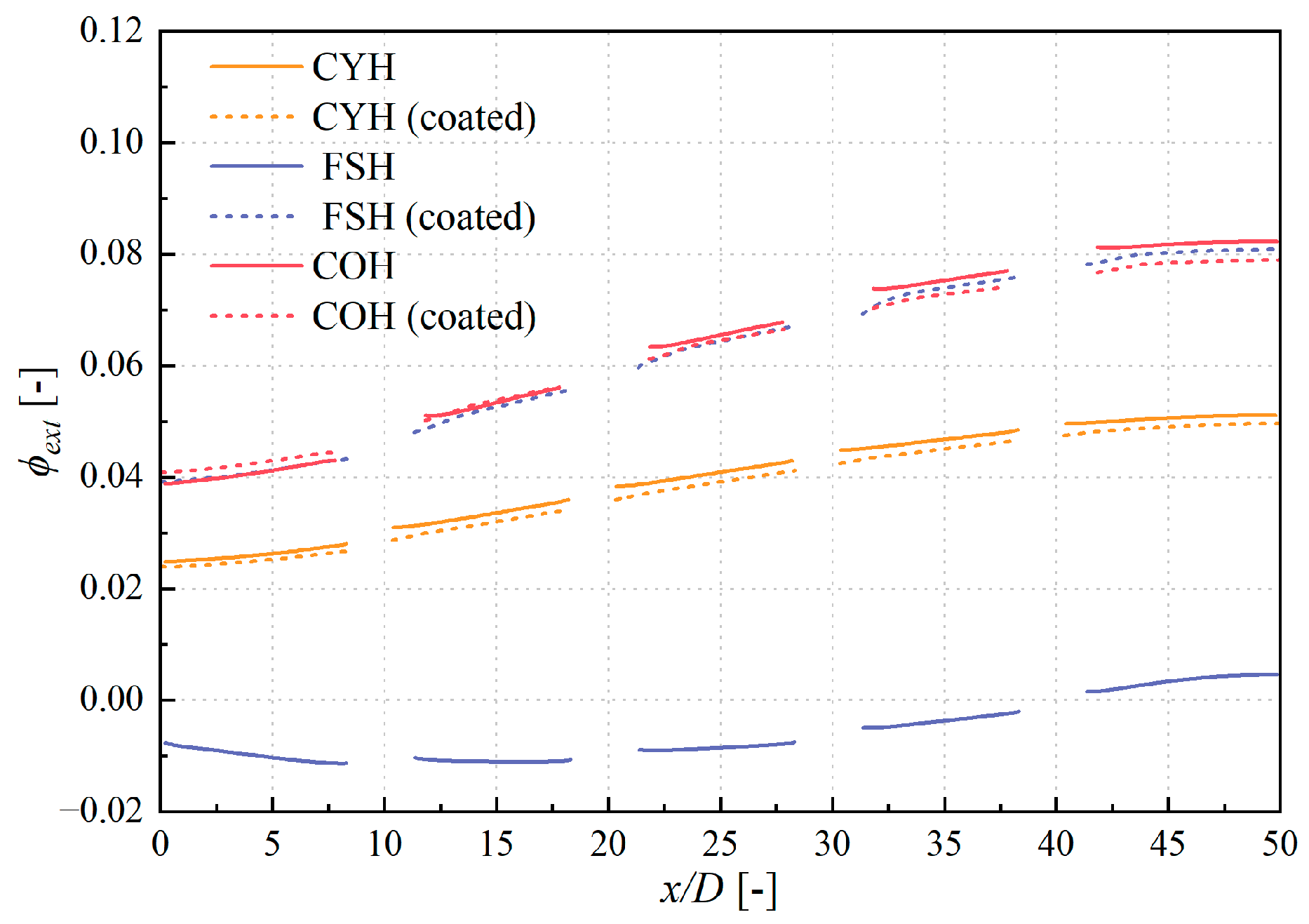

3.3. Influence on the Contributions of the Three Cooling Components

4. Conclusions

- Without TBCs, the conical hole provides the best cooling performance on the film-cooled flat plate, while the fan-shaped hole performs the worst. After applying the TBCs, the cooling effectiveness of the cylindrical and conical holes changes little, but the fan-shaped hole shows a significant improvement, with its cooling performance becoming comparable to that of the conical hole.

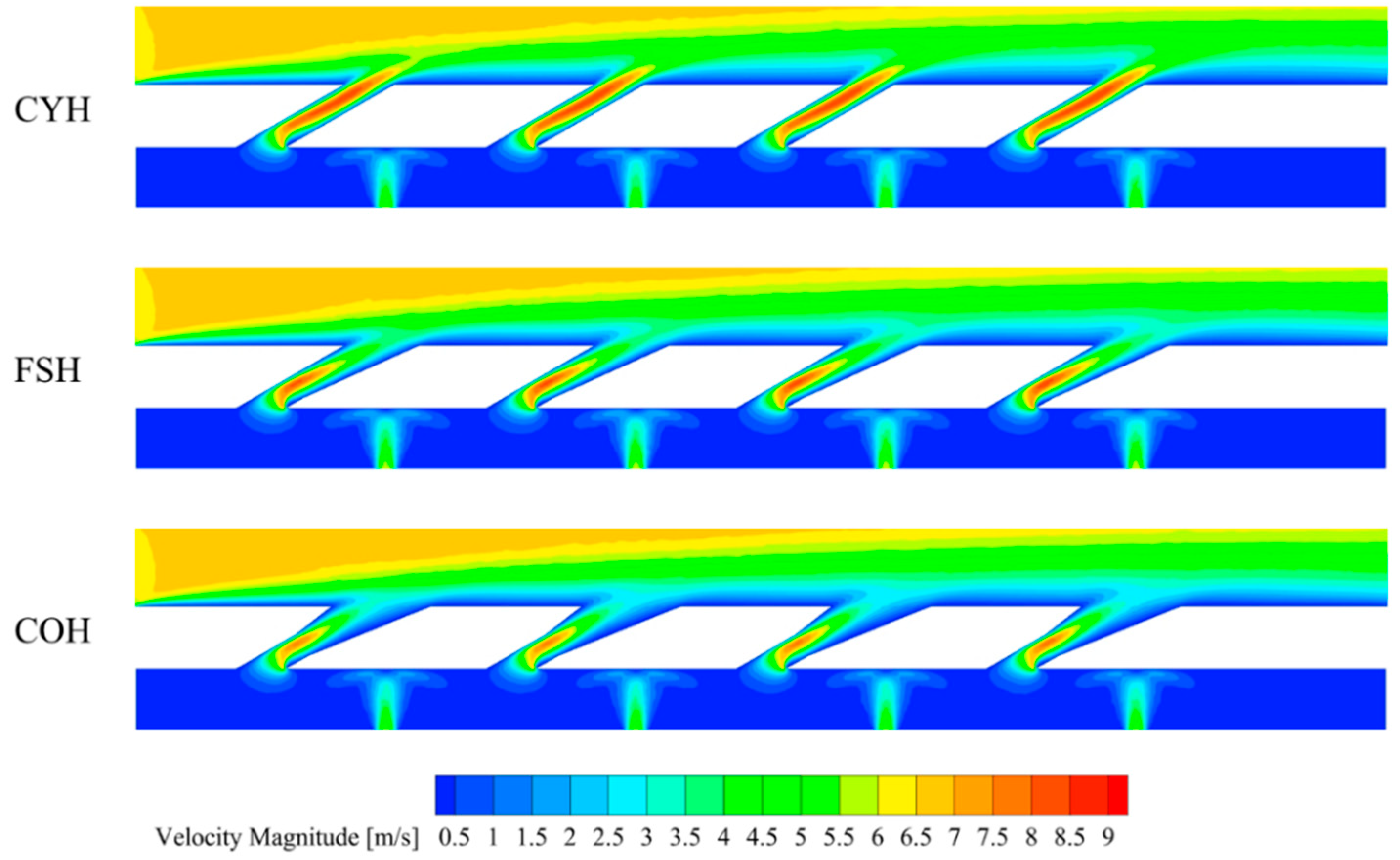

- The cylindrical hole has a constant cross-sectional area, resulting in the highest flow velocity at the hole exit, which is unfavorable for forming a stable coolant film. In contrast, the fan-shaped and conical holes feature expanding flow passages, leading to a gradual decrease in flow velocity. This helps to form a stable film near the wall, providing effective thermal protection.

- The contribution of impingement cooling accounts for more than 75% of the overall cooling effectiveness across all three hole types. For the cylindrical and conical holes, the improvement in cooling effectiveness due to the TBCs is primarily attributed to in-hole cooling. For the fan-shaped hole, the impingement cooling effectiveness decreases, while the in-hole cooling and film cooling effectiveness increase, leading to a significant rise in its contribution.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| D | Diameter of the cylindrical hole [mm] |

| L | Length of film hole [mm] |

| Lf | Expansion section length film hole [mm] |

| R | Corner radius [mm] |

| k | Thermal conductivity [W/(m·K)] |

| Tg | Mainstream inlet temperature [K] |

| Tw | Temperature of the coupling surface [K] |

| Tw,dec | Temperature of the decoupling surface [K] |

| Tc | Coolant inlet temperature [K] |

| M | Blowing ratio [-] |

| ϕ | Overall cooling effectiveness [-] |

| ϕdec | Decoupled internal cooling effectiveness [-] |

| ϕext | External film cooling effectiveness [-] |

| ϕimp | Impingement cooling effectiveness [-] |

| ϕinhole | In-hole cooling effectiveness [-] |

| β | Lateral divergence angle [°] |

| Abbreviations | |

| BC | Bond coat |

| CHT | Conjugate heat transfer |

| COH | Conical holes |

| CYH | Cylindrical holes |

| FSH | Fan-shaped holes |

| TBC | Thermal barrier coating |

| TC | Top coat |

| TGO | Thermally grown oxide |

| Superscripts | |

| − | Lateral averaged value |

| = | Area averaged value |

References

- Van Treuren, K.W.; McClain, S.T. The Challenges of High Altitude Gas Turbine Engine Cycles. In Proceedings of the ASME Turbo Expo 2010: Power for Land, Sea, and Air, Glasgow, UK, 14–18 June 2010; pp. 367–378. [Google Scholar]

- Romeo, G.; Frulla, G. Heliplat®: High altitude very-long endurance solar powered UAV for telecommunication and Earth observation applications. Aeronaut. J. 2004, 108, 277–293. [Google Scholar] [CrossRef]

- Ji, Z.; Rokni, M.M.; Qin, J.; Zhang, S.; Dong, P. Energy and configuration management strategy for battery/fuel cell/jet engine hybrid propulsion and power systems on aircraft. Energy Convers. Manag. 2020, 225, 113393. [Google Scholar] [CrossRef]

- Mu, C.; Zhang, W.; Wang, J.; Huang, D.; Jiang, C. Low-Reynolds-Number effect on film cooling in Turbines: Jet-induced vortex structures on cooling effectiveness and aerodynamic loss. Appl. Therm. Eng. 2025, 274, 126325. [Google Scholar] [CrossRef]

- Jia, Z.; Tang, H.; Jin, D.; Chen, M.; Li, S.; Liu, X. Multifidelity Simulation Research on the Low Reynolds Number Effect on the Engine Performance at Different Altitudes. J. Eng. Gas Turb. Power 2022, 144, 101011. [Google Scholar] [CrossRef]

- Chokhar, I.A.; Dyachenko, A.Y.; Pakhomov, M.A.; Philippov, M.V.; Terekhov, V.I. Experimental study of the effect of a transverse trench depth on film cooling effectiveness. Case Stud. Therm. Eng. 2021, 25, 100934. [Google Scholar] [CrossRef]

- Wu, H.; Yang, X.; Liu, Z.; Feng, Z. Comparisons between forward- and backward-inclined film injection over an effusion wall with internal jet-array impingement: Cooling effectiveness, heat transfer, and analytical model. Appl. Therm. Eng. 2025, 262, 125280. [Google Scholar] [CrossRef]

- Youn, J.-S.; Choi, W.-W.; Kim, S.-M. Numerical investigation of jet array impingement cooling with effusion holes. Appl. Therm. Eng. 2021, 197, 117347. [Google Scholar] [CrossRef]

- Mensch, A.; Thole, K.A. Overall Effectiveness of a Blade Endwall with Jet Impingement and Film Cooling. In Proceedings of the ASME Turbo Expo 2013: Turbine Technical Conference and Exposition, San Antonio, TX, USA, 3–7 June 2013. [Google Scholar]

- Liu, R.; Li, H.; You, R.; Tao, Z.; Huang, Y. Numerical decoupling of the effect of internal cooling and external film cooling on overall cooling effectiveness. Appl. Therm. Eng. 2023, 222, 119905. [Google Scholar] [CrossRef]

- Terrell, E.J.; Mouzon, B.D.; Bogard, D.G. Convective Heat Transfer Through Film Cooling Holes of a Gas Turbine Blade Leading Edge. In Proceedings of the ASME Turbo Expo 2005: Power for Land, Sea, and Air, Reno-Tahoe, NV, USA, 6–9 June 2005; pp. 833–844. [Google Scholar]

- Bryant, C.E.; Rutledge, J.L. A Computational Technique to Evaluate the Relative Influence of Internal and External Cooling on Overall Effectiveness. J. Turbomach. 2020, 142, 051008. [Google Scholar] [CrossRef]

- Chen, P.; Zhang, D.; Liu, H.; Mao, J. Conjugate heat transfer analysis on composite cooling structure with low Reynolds number using the decoupling method. Case Stud. Therm. Eng. 2024, 61, 105051. [Google Scholar] [CrossRef]

- Wang, J.; Ke, T.; Jing, L.; Sundén, B. Effect of hole configurations on film cooling performance. Nume. Heat Transf. A-Appl. 2019, 75, 725–738. [Google Scholar] [CrossRef]

- Goldstein, R.J.; Eckert, E.R.G.; Burggraf, F. Effects of hole geometry and density on three-dimensional film cooling. Int. J. Heat Mass Tran. 1974, 17, 595–607. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, Z.; Tian, L.; Ren, X.; Sundén, B. Effects of hole configuration on film cooling effectiveness and particle deposition on curved surfaces in gas turbines. Appl. Therm. Eng. 2021, 190, 116861. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, H.; Liu, R.; Tao, Z.; Zhou, Z. Film cooling comparison of shaped holes among the pressure surface, the suction surface and the leading edge of turbine vane. Appl. Therm. Eng. 2023, 219, 119343. [Google Scholar] [CrossRef]

- Padture, N.P.; Gell, M.; Jordan, E.H. Thermal Barrier Coatings for Gas-Turbine Engine Applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef] [PubMed]

- Evans, A.G.; Mumm, D.R.; Hutchinson, J.W.; Meier, G.H.; Pettit, F.S. Mechanisms controlling the durability of thermal barrier coatings. Prog. Mater. Sci. 2001, 46, 505–553. [Google Scholar] [CrossRef]

- Miller, R.A. Oxidation-Based Model for Thermal Barrier Coating Life. J. Am. Ceram. Soc. 1984, 67, 517–521. [Google Scholar] [CrossRef]

- Wright, P.K.; Evans, A.G. Mechanisms governing the performance of thermal barrier coatings. Curr. Opin. Solid State Mater. Sci. 1999, 4, 255–265. [Google Scholar] [CrossRef]

- Meng, Z.; Liu, Y.; Li, Y.; He, X. The performance evaluation for thermal protection of turbine vane with film cooling and thermal barrier coating. Appl. Therm. Eng. 2022, 210, 118405. [Google Scholar] [CrossRef]

- Vo, D.-T.; Mai, T.D.; Kim, B.; Ryu, J. Numerical study on the influence of coolant temperature, pressure, and thermal barrier coating thickness on heat transfer in high-pressure blades. Int. J. Heat Mass Transf. 2022, 189, 122715. [Google Scholar] [CrossRef]

- Pi, Y.H.; Park, J.S. Effect of the thermal barrier coating set up and modeling in numerical analysis for prediction gas turbine blade temperature and film cooling effectiveness. Int. Commun. Heat Mass Transf. 2025, 164, 108860. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, H.; Chen, P.; Mao, J. Numerical analysis on multiple parameters for overall cooling effectiveness of impingement effusion cooling with low Reynolds number. Int. Commun. Heat Mass Transf. 2024, 153, 107366. [Google Scholar] [CrossRef]

- Liu, J.H.; Liu, Y.B.; He, X.; Liu, L. Study on TBCs insulation characteristics of a turbine blade under serving conditions. Case Stud. Therm. Eng. 2016, 8, 250–259. [Google Scholar] [CrossRef]

- Zhou, W.; Deng, Q.; He, W.; He, J.; Feng, Z. Conjugate heat transfer analysis for composite cooling structure using a decoupled method. Int. J. Heat Mass Transf. 2020, 149, 119200. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Y.; Su, X.; Yuan, X. Experimental and numerical investigations of shaped hole film cooling with the influence of endwall cross flow. Int. J. Heat Mass Transf. 2018, 120, 42–55. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Diameter of the cylindrical hole D (mm) | 0.4 |

| Length of film hole L/D (-) | 5 |

| Shaped length ratio Lf/L (-) | 2/3 |

| Lateral divergence angle β (°) | 8 |

| Corner radius R (mm) | 0.2 |

| Material | Density (kg/m3) | Temperature T (°C) | Thermal Conductivity K (W/m∙K) |

|---|---|---|---|

| TC | 5650 | - | 1.05 |

| TGO | 3978 | - | 25.20 |

| BC | 7320 | 25 | 4.30 |

| 400 | 6.40 | ||

| 800 | 10.20 | ||

| 1000 | 16.10 |

| CYH | 0.473 | 0.388 | 0.046 | 0.039 |

| CYH (coated) | 0.477 | 0.388 | 0.052 | 0.037 |

| FSH | 0.432 | 0.393 | 0.046 | −0.007 |

| FSH (coated) | 0.507 | 0.387 | 0.059 | 0.061 |

| COH | 0.502 | 0.388 | 0.051 | 0.063 |

| COH (coated) | 0.510 | 0.383 | 0.065 | 0.062 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, S.; Shi, L.; Tan, X.; Wang, C.; Luo, Y.; Deng, R.; Zhang, H.; Zheng, C.; Peng, J. Numerical Analysis of Impingement Jet Combined Cooling with Film Cooling Holes and Thermal Barrier Coatings Using the Decoupling Method. Coatings 2025, 15, 832. https://doi.org/10.3390/coatings15070832

Liao S, Shi L, Tan X, Wang C, Luo Y, Deng R, Zhang H, Zheng C, Peng J. Numerical Analysis of Impingement Jet Combined Cooling with Film Cooling Holes and Thermal Barrier Coatings Using the Decoupling Method. Coatings. 2025; 15(7):832. https://doi.org/10.3390/coatings15070832

Chicago/Turabian StyleLiao, Siqi, Li Shi, Xiao Tan, Changce Wang, Yue Luo, Rongli Deng, Haoyu Zhang, Chenwei Zheng, and Jinfeng Peng. 2025. "Numerical Analysis of Impingement Jet Combined Cooling with Film Cooling Holes and Thermal Barrier Coatings Using the Decoupling Method" Coatings 15, no. 7: 832. https://doi.org/10.3390/coatings15070832

APA StyleLiao, S., Shi, L., Tan, X., Wang, C., Luo, Y., Deng, R., Zhang, H., Zheng, C., & Peng, J. (2025). Numerical Analysis of Impingement Jet Combined Cooling with Film Cooling Holes and Thermal Barrier Coatings Using the Decoupling Method. Coatings, 15(7), 832. https://doi.org/10.3390/coatings15070832