Research Progress on Microstructure, Mechanical Properties, and Strengthening Mechanisms of In Situ-Synthesized Ceramic-Reinforced Titanium Matrix Composite Coatings via Laser Cladding

Abstract

1. Introduction

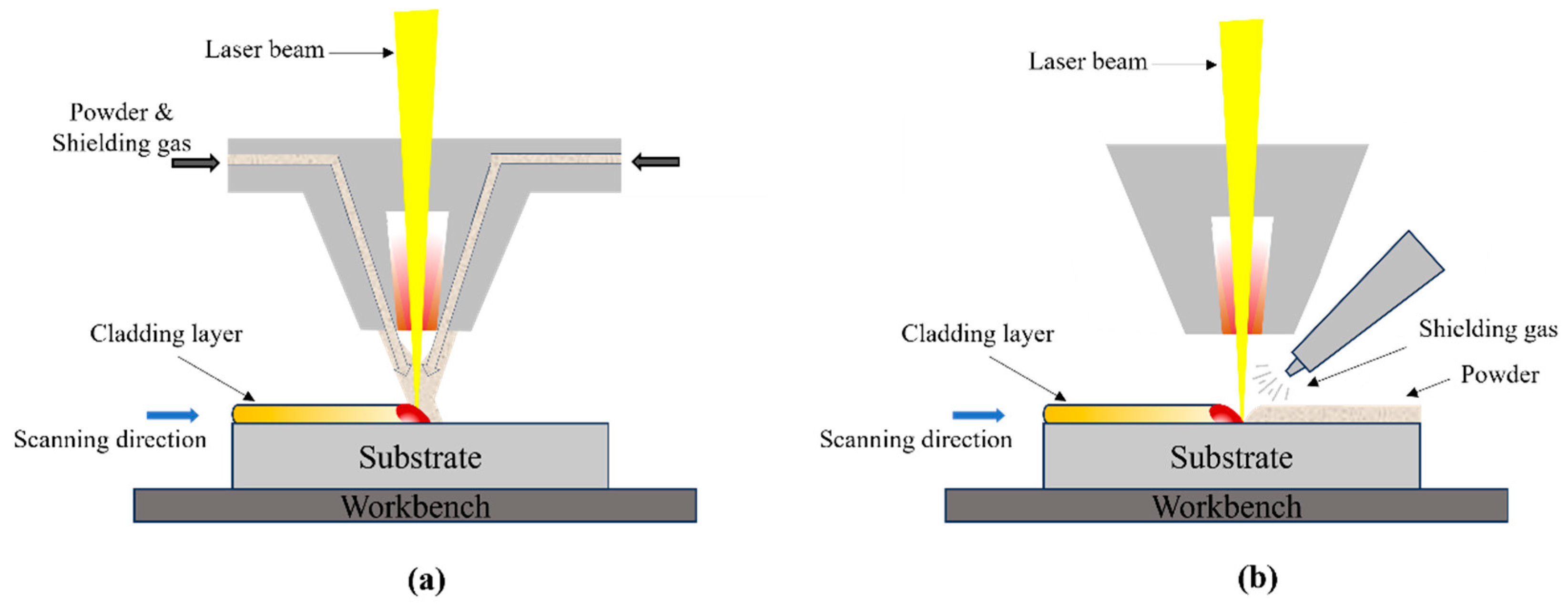

2. Titanium Matrix Composite Coatings

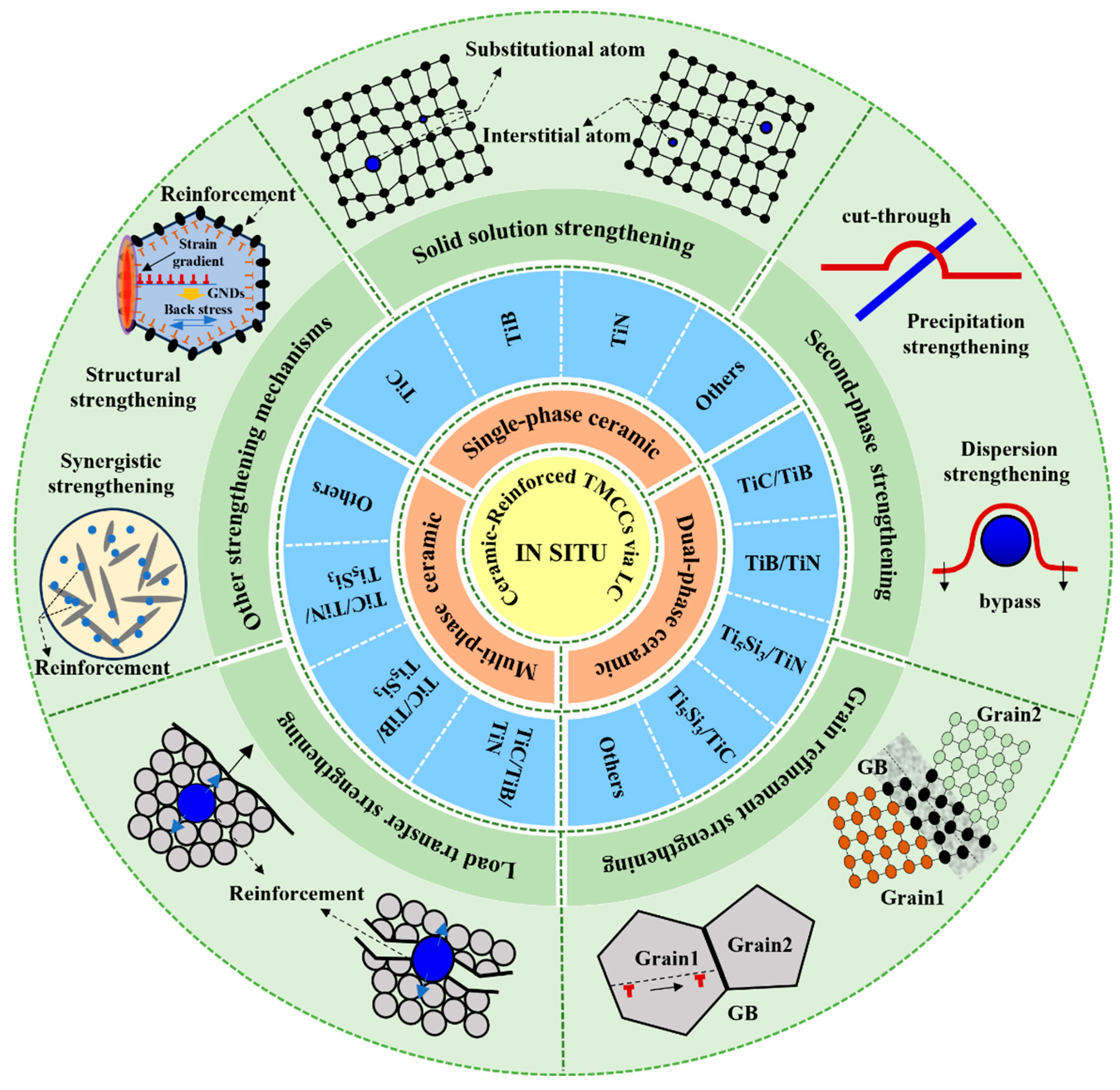

3. Laser Cladding Technology

- (1)

- Laser source and substrate–cladding material pairs

- (2)

- Process parameters

- (3)

- The content of reinforcement phases

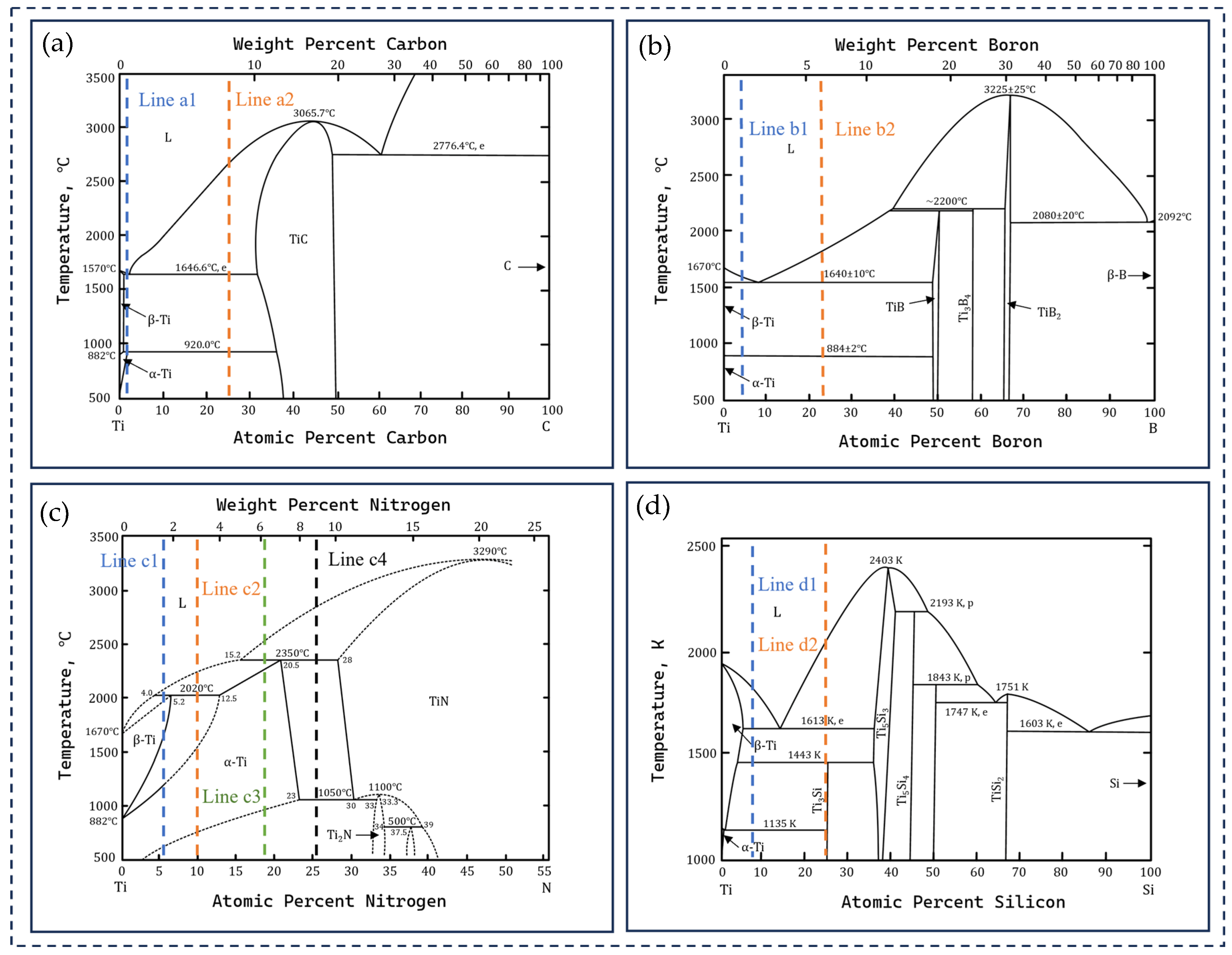

4. In Situ-Synthesized Ceramic-Reinforced TMCCs

4.1. Universal Strengthening Mechanisms

4.1.1. Solid Solution Strengthening

4.1.2. Second-Phase Strengthening

4.1.3. Grain Refinement Strengthening

4.1.4. Load Transfer Strengthening

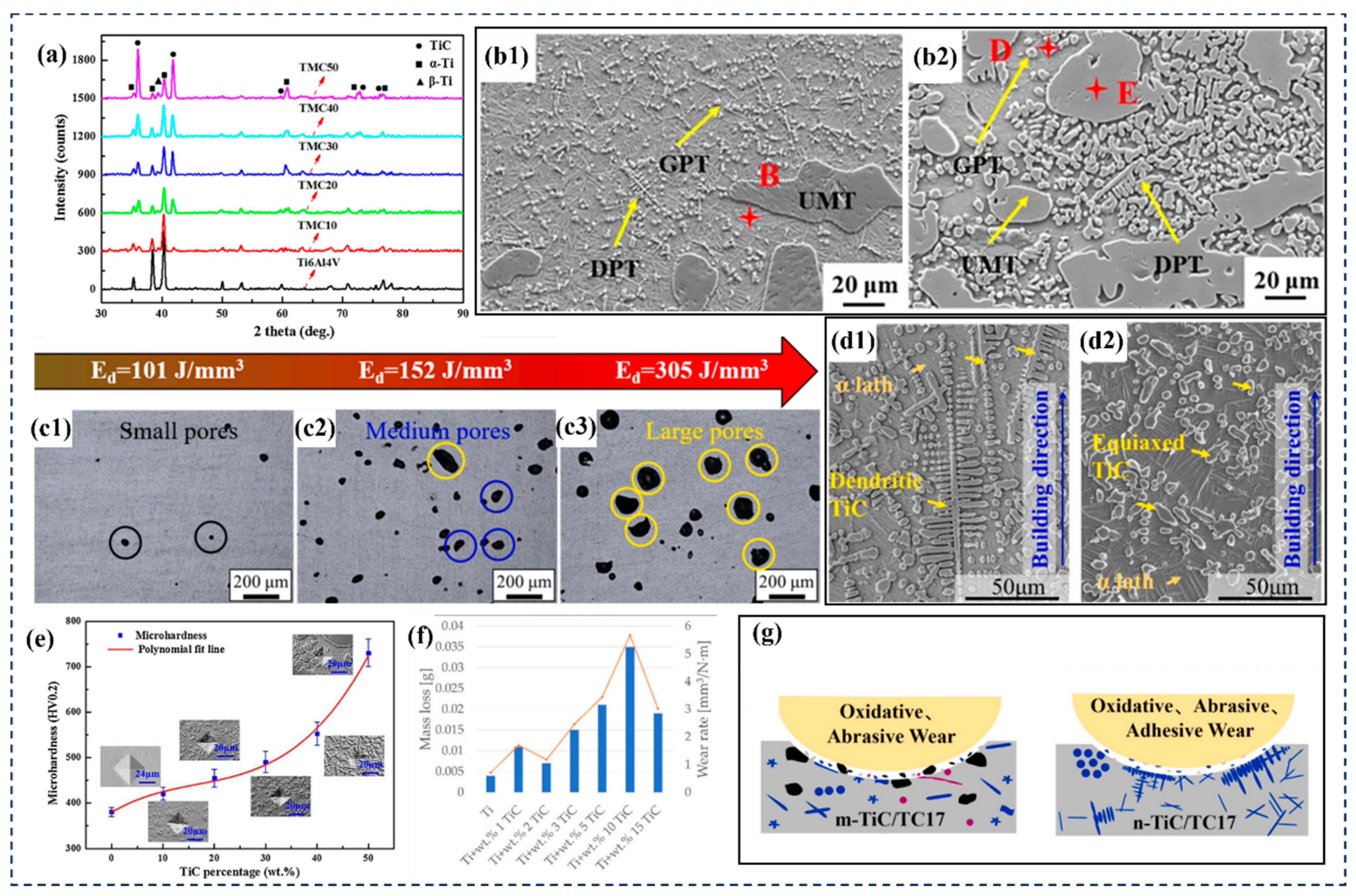

4.2. TiC-Reinforced TMCCs

4.2.1. Phase and Microstructure

4.2.2. Mechanical Properties and Strengthening Mechanisms

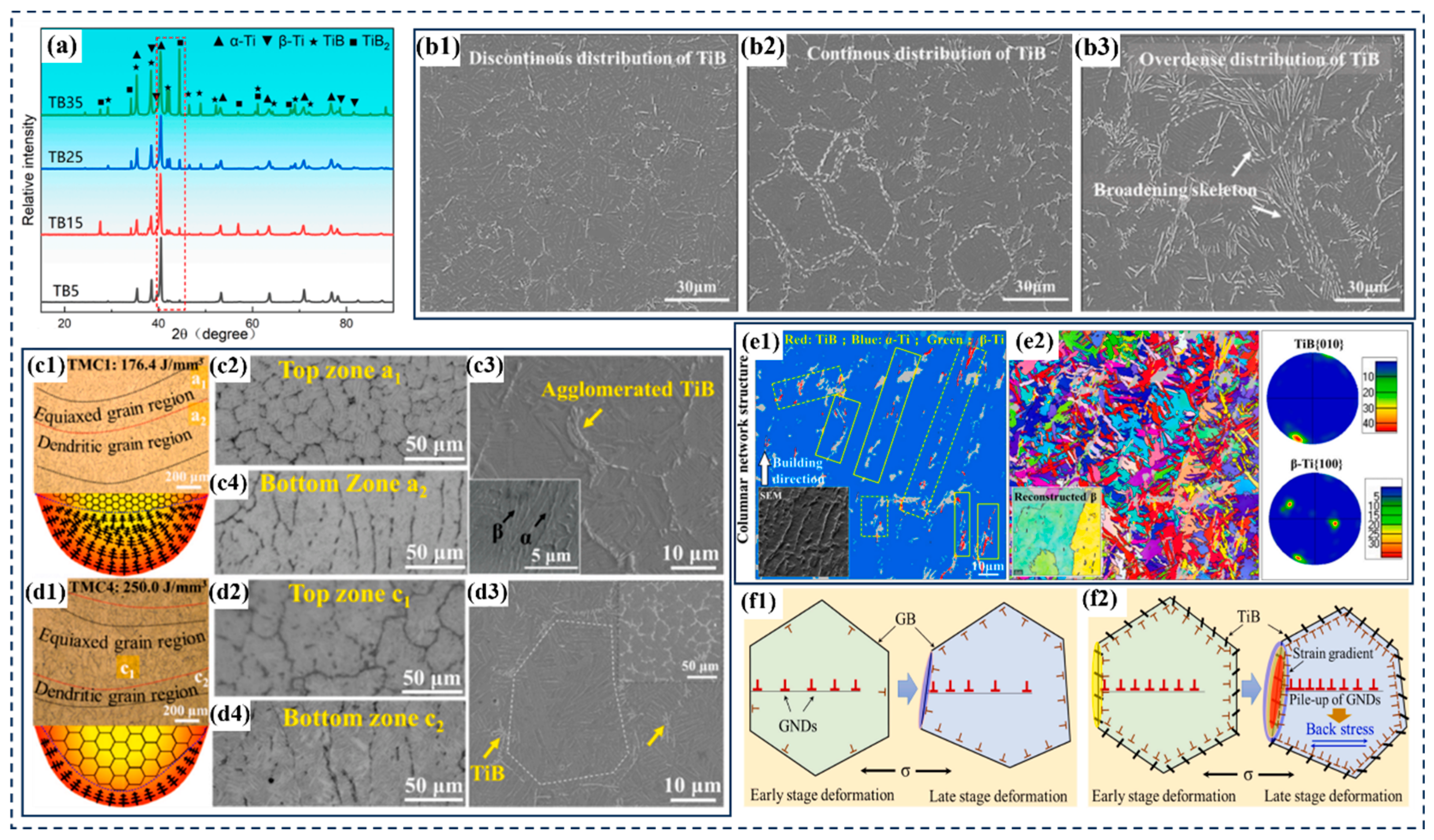

4.3. TiB-Reinforced TMCCs

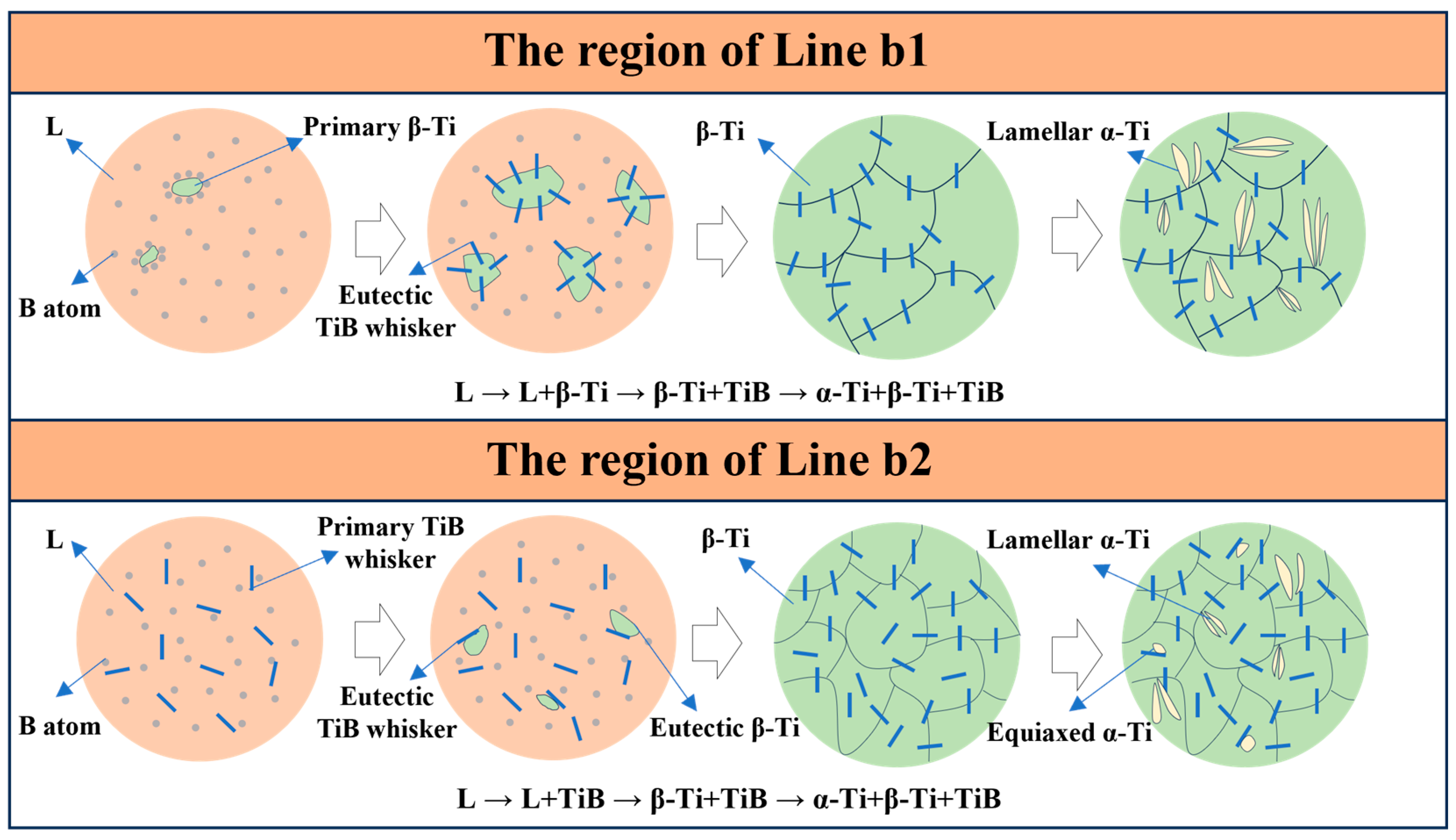

4.3.1. Phase and Microstructure

4.3.2. Mechanical Properties and Strengthening Mechanisms

- (1)

- Different physical properties

- (2)

- Different morphology

- (3)

- Different chemical affinity

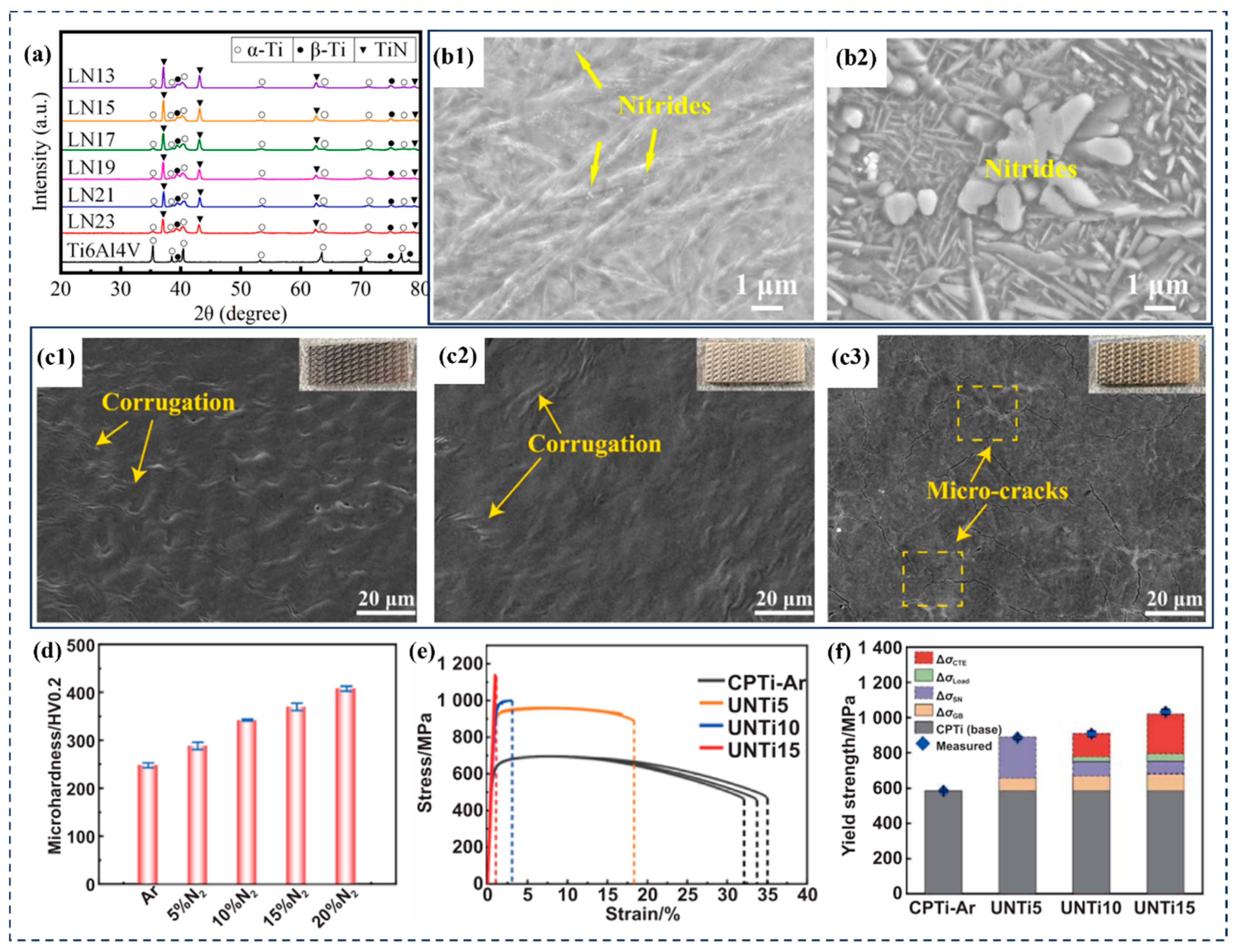

4.4. TiN-Reinforced TMCCs

4.4.1. Phase and Microstructure

| Method | Material | Laser Energy/Power | Scanning Speed (mm/s) | Phase | Hardness | Loss/ Wear Rate | Coefficient of Friction | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Maximum Strain or Elongation (%) | Strengthening Mechanism | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LN | N2 | 100 mJ | 0.6 | (α-Ti) + TiN | 286.62 HV0.1 | 4.01 × 10−4 mm3/Nm | 0.62 | SSS; SPS | [152] | |||

| 200 mJ | 322.83 HV0.1 | 2.89 × 10−4 mm3/Nm | 0.63 | |||||||||

| 250 mJ | 352.19 HV0.1 | 2.00 × 10−4 mm3/Nm | 0.66 | |||||||||

| 300 mJ | 435.55 HV0.1 | 1.44 × 10−4 mm3/Nm | 0.64 | |||||||||

| 400 mJ | 560.90 HV0.1 | 8.01 × 10−4 mm3/Nm | 0.62 | |||||||||

| LN | N2 | 25 W | 40 | Ti + TiN | 1277 HV | SPS; GRS | [151] | |||||

| LN | 100 vol% N2 | 175 W | 100 | (α-Ti) + TiN + TiN0.26 | 7.9 GPa | SSS; SPS; GRS | [153] | |||||

| 100 vol% N2 | 400 | 5.6 GPa | ||||||||||

| 100 vol% N2 | 1600 | 5.3 GPa | ||||||||||

| 75 vol% N2 | 400 | 3.7 GPa | ||||||||||

| 50 vol% N2 | 400 | 3.6 GPa | ||||||||||

| 20 vol% N2 | 400 | 3.4 GPa | ||||||||||

| 0 vol% N2 | 400 | 3.3 GPa | ||||||||||

| LN | N2 | 650 W | 6 | (α-Ti) + (α′-Ti) + (β-Ti) + TiN | 320 HV | SSS; SPS; GRS; DLS | [154,155] | |||||

| LN | TC4 + 1 min N2 | 180 W | 200 | (α-Ti) + (α′-Ti) + TiN + AlN | 395 HV | GRS; DPS; PPS; IFS | [150] | |||||

| TC4 + 2 min N2 | 440 HV | |||||||||||

| TC4 + 5 min N2 | 511 HV | |||||||||||

| LPBF | CP-Ti + 0 vol% N2 | 110–170 W | 400–1200 | (α-Ti) + (α′-Ti) + (β-Ti) + TiN | 235 HV0.2 | 1.51 × 10−3 mm3/Nm | 0.39 | SSS; SPS; GRS | [156] | |||

| CP-Ti + 5 vol% N2 | 286 HV0.2 | 7.1 × 10−4 mm3/Nm | 0.37 | |||||||||

| CP-Ti + 10 vol% N2 | 345 HV0.2 | 6.5 × 10−4 mm3/Nm | 0.35 | |||||||||

| CP-Ti + 15 vol% N2 | 389 HV0.2 | 4.5 × 10−4 mm3/Nm | 0.32 | |||||||||

| LPBF | 0% N2 | 160 W | 1000 | (α-Ti) + (α′-Ti) + (β-Ti) + TiN | 239 HV0.2 | 599.19 | 696.48 | 33.6 | SSS; SPS; GRS; IFS | [55] | ||

| 5% N2 | 500 | 290 HV0.2 | 886.17 | 958.83 | 17.27 | |||||||

| 10% N2 | 330 HV0.2 | 907.64 | 1006.6 | 2.37 | ||||||||

| 15% N2 | 360 HV0.2 | 1032.29 | 1132.39 | 1.03 | ||||||||

| DED | TC4 + 0% N2 | 380 W | 14.16 | (α-Ti) + (β-Ti) + TiN | 350 HV0.3 | 840 | SSS; GRS; DPS; PPS; DLS | [157] | ||||

| TC4 + 2% N2 | 540 HV0.3 | 1050 | ||||||||||

| TC4 + 10% N2 | 550 HV0.3 | 1600 | 15 |

4.4.2. Mechanical Properties and Strengthening Mechanisms

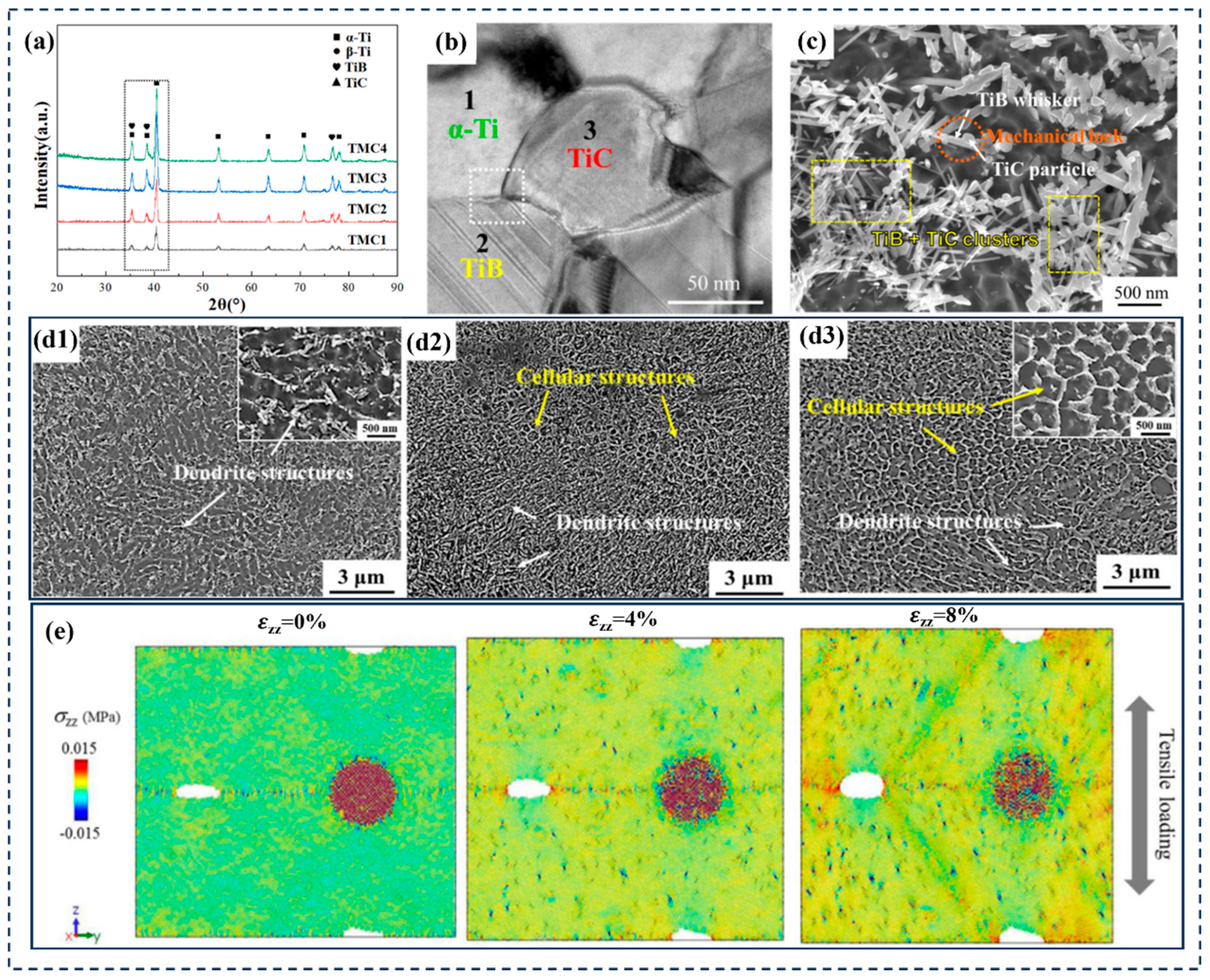

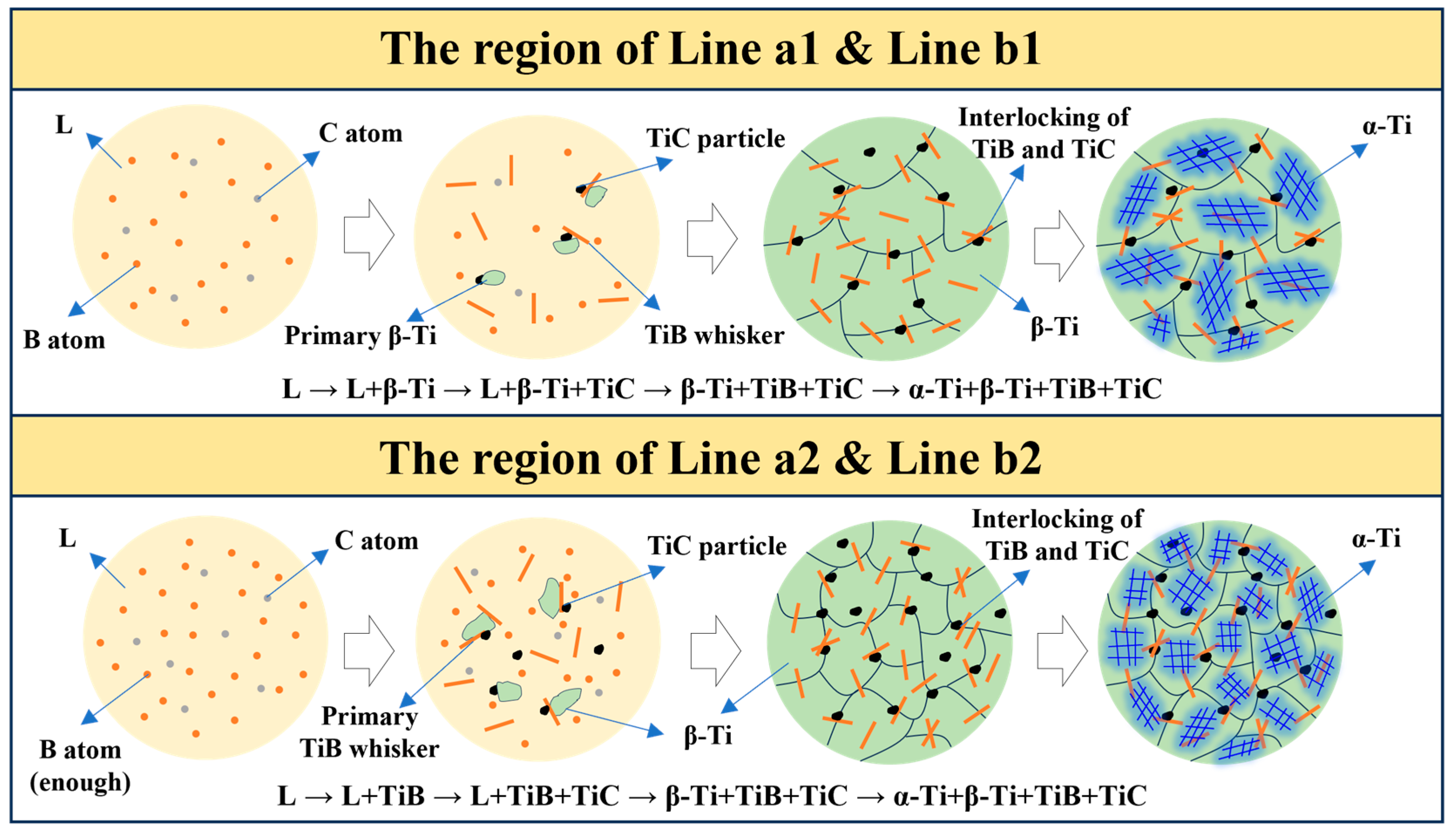

4.5. TiC/TiB-Reinforced TMCCs

4.5.1. Phase and Microstructure

4.5.2. Mechanical Properties and Strengthening Mechanisms

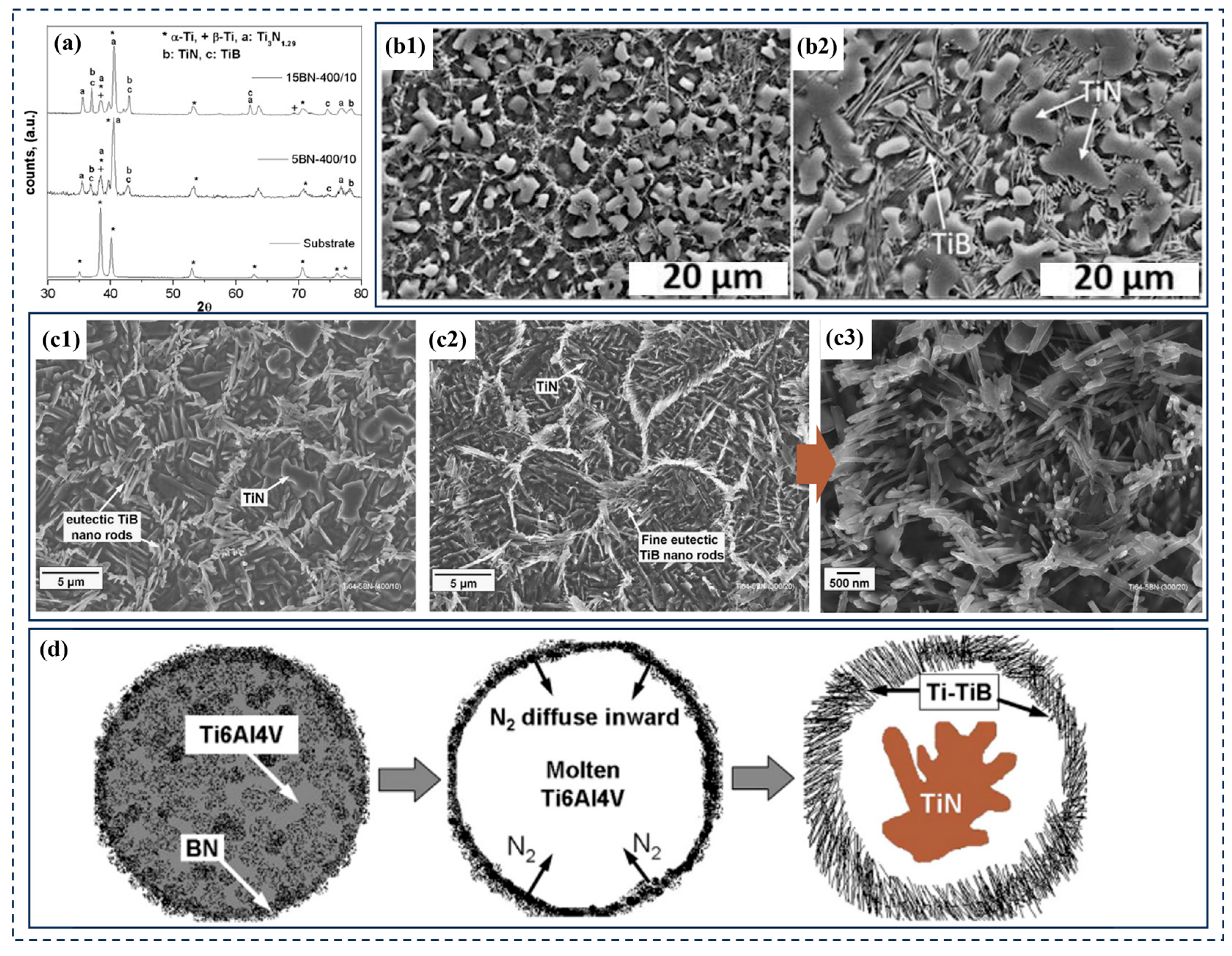

4.6. TiB/TiN-Reinforced TMCCs

4.6.1. Phase and Microstructure

4.6.2. Mechanical Properties and Strengthening Mechanisms

- (1)

- (2)

- (3)

- Load transfer strengthening. TiB and TiN (especially TiB with a large aspect ratio) effectively improve the load transfer efficiency [184].

- (4)

- (5)

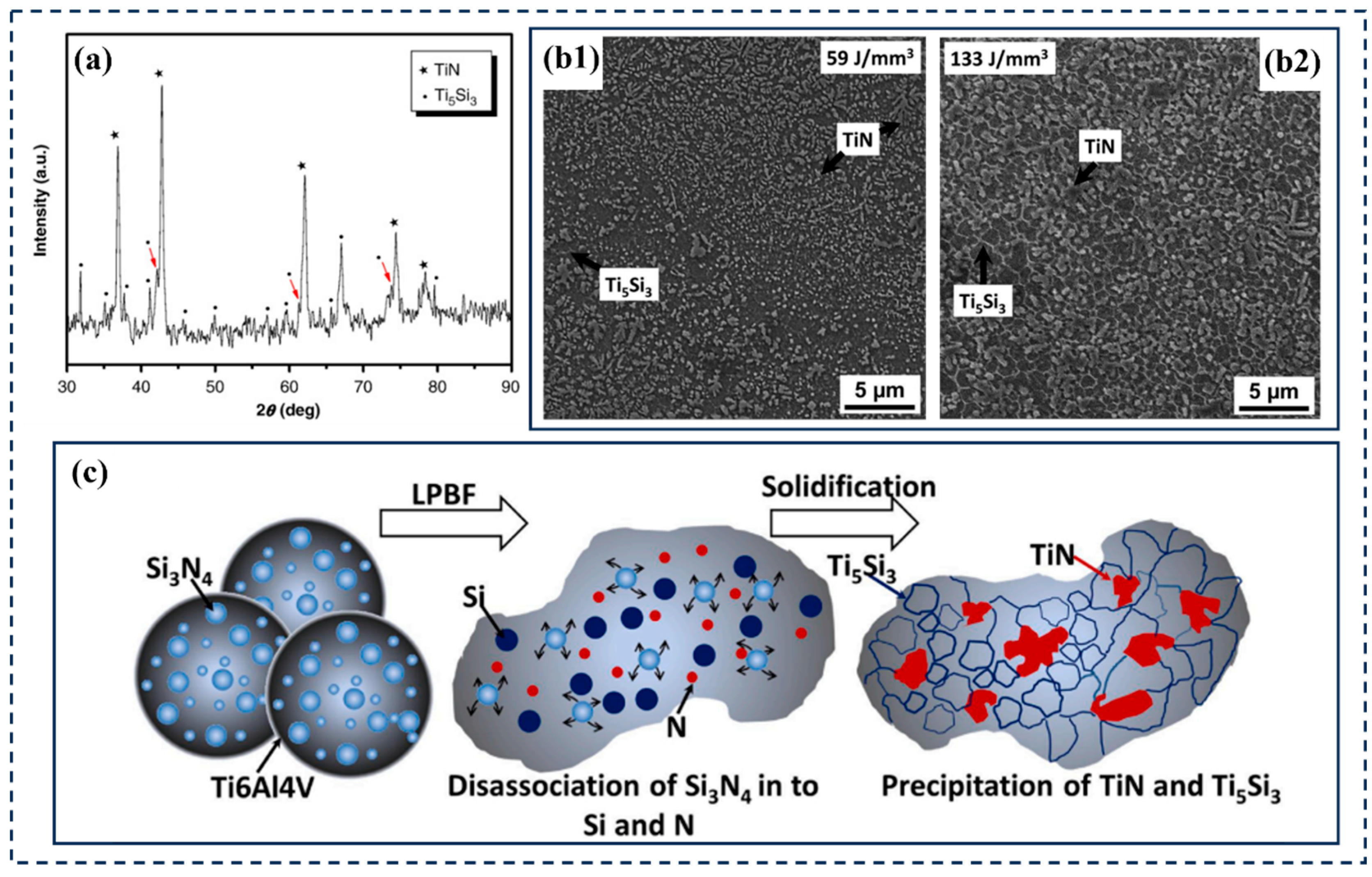

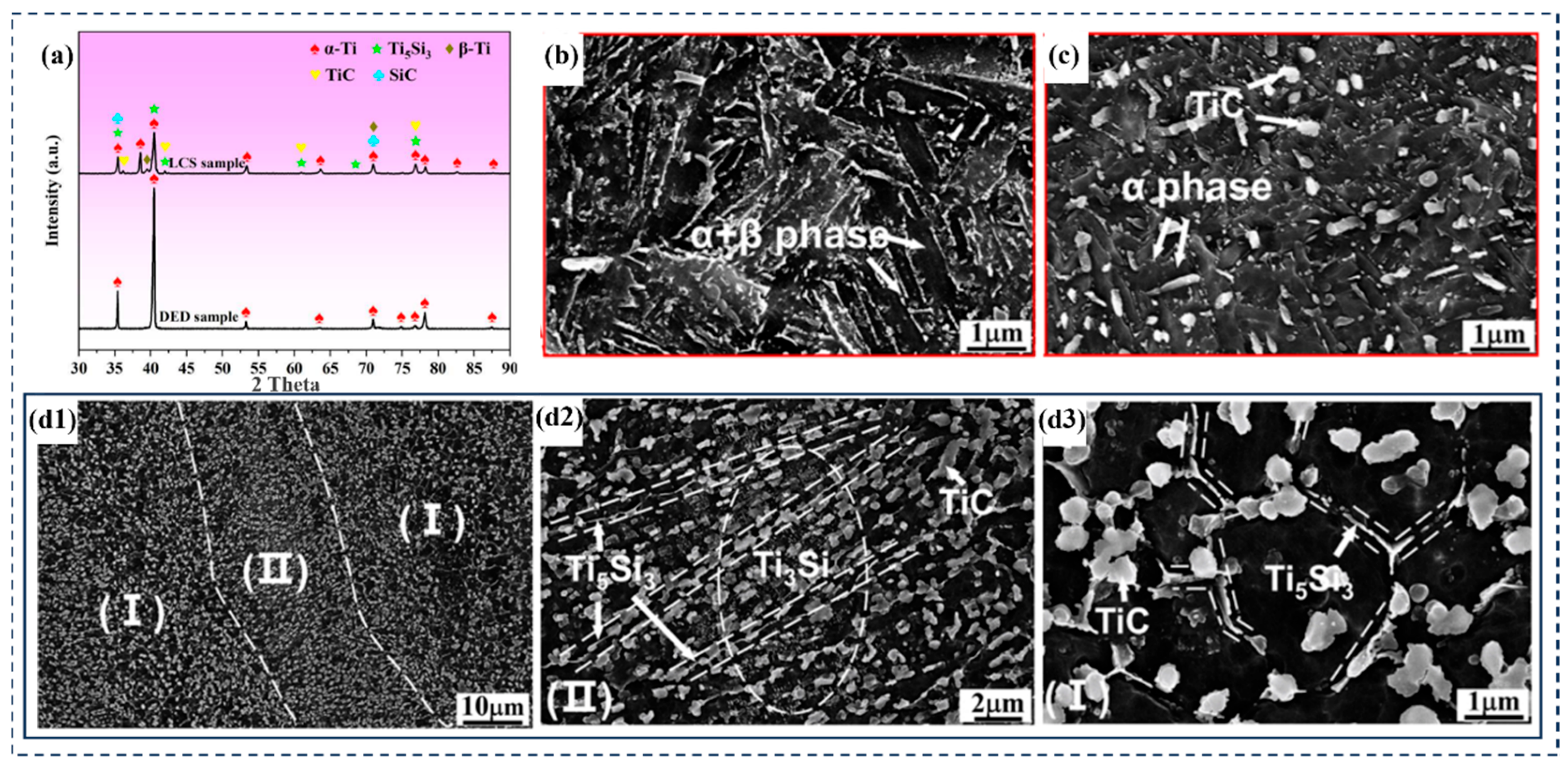

4.7. Ti5Si3/TiN-Reinforced TMCCs

| Method | Material | Laser Power (W) | Scanning Speed (mm/s) | Phase | Hardness | Loss/ Wear Rate | Flexural Strength (MPa) | Flexural Strain (%) | Strengthening Mechanism | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| LC | CP-Ti + 12 wt% Si3N4 | 1400 | 3 | (α-Ti) + TiN + Ti5Si3 + Ti3Al + Ti2N | 721.4 HV0.5 | 0.50 mm3 | SSS; DPS; IFS; GRS | [192] | ||

| CP-Ti + 10 wt% Al + 12 wt% Si3N4 | 757.6 HV0.5 | 0.37 mm3 | ||||||||

| CP-Ti + 20 wt% Al + 12 wt% Si3N4 | 781.2 HV0.5 | 0.29 mm3 | ||||||||

| SPS | CP-Ti + 5 wt% Si3N4 | (α-Ti) + TiN + Ti5Si3 | 632 HV | 880 | 0.0148 | SPS | [193] | |||

| CP-Ti + 10 wt% Si3N4 | 920 HV | 840 | 0.0168 | |||||||

| CP-Ti + 15 wt% Si3N4 | 1126 HV | 710 | 0.0168 | |||||||

| LPBF | TC4 + 5 wt% Si3N4 | 96 | 400 | (α-Ti) + (β-Ti) + TiN + Ti5Si3 | 860 KHN | DPS; SSS; GRS; SGS | [194] | |||

| 600 | 793 KHN | |||||||||

| 900 | 801 KHN | |||||||||

| 1200 | ||||||||||

| SLM | CP-Ti + 24.55 wt% Si3N4 | 900 | 100 | Ti + TiN + Ti5Si3 | DPS; GRS; IFS | [195] | ||||

| SPS | TC4 + 5 wt% Si3N4 | Ti + Si3N4 | 600 HV | SPS; GRS; IFS | [196] | |||||

| TC4 + 10 wt% Si3N4 | 680 HV | |||||||||

| TC4 + 15 wt% Si3N4 | 590 HV | |||||||||

| SPS | CP-Ti + 1 wt% Si3N4 | (α-Ti) + (α-Si3N4) + (β-Si3N4) + Ti5Si3 | 430 HV1 | 0.00030 mm3/Nm | 200 | 0.012 | SSS; SPS | [197] | ||

| CP-Ti + 1.5 wt% Si3N4 | 480 HV1 | 0.00026 mm3/Nm | ||||||||

| CP-Ti + 2 wt% Si3N4 | 610 HV1 | 0.00020 mm3/Nm | ||||||||

| CP-Ti + 2.5 wt% Si3N4 | 650 HV1 | 0.00016 mm3/Nm | 650 | 0.017 | ||||||

| CP-Ti + 5 wt% Si3N4 | 800 HV1 | 0.00010 mm3/Nm | 1280 | 0.023 |

4.7.1. Phase and Microstructure

4.7.2. Mechanical Properties and Strengthening Mechanisms

- (1)

- (2)

- (3)

- (4)

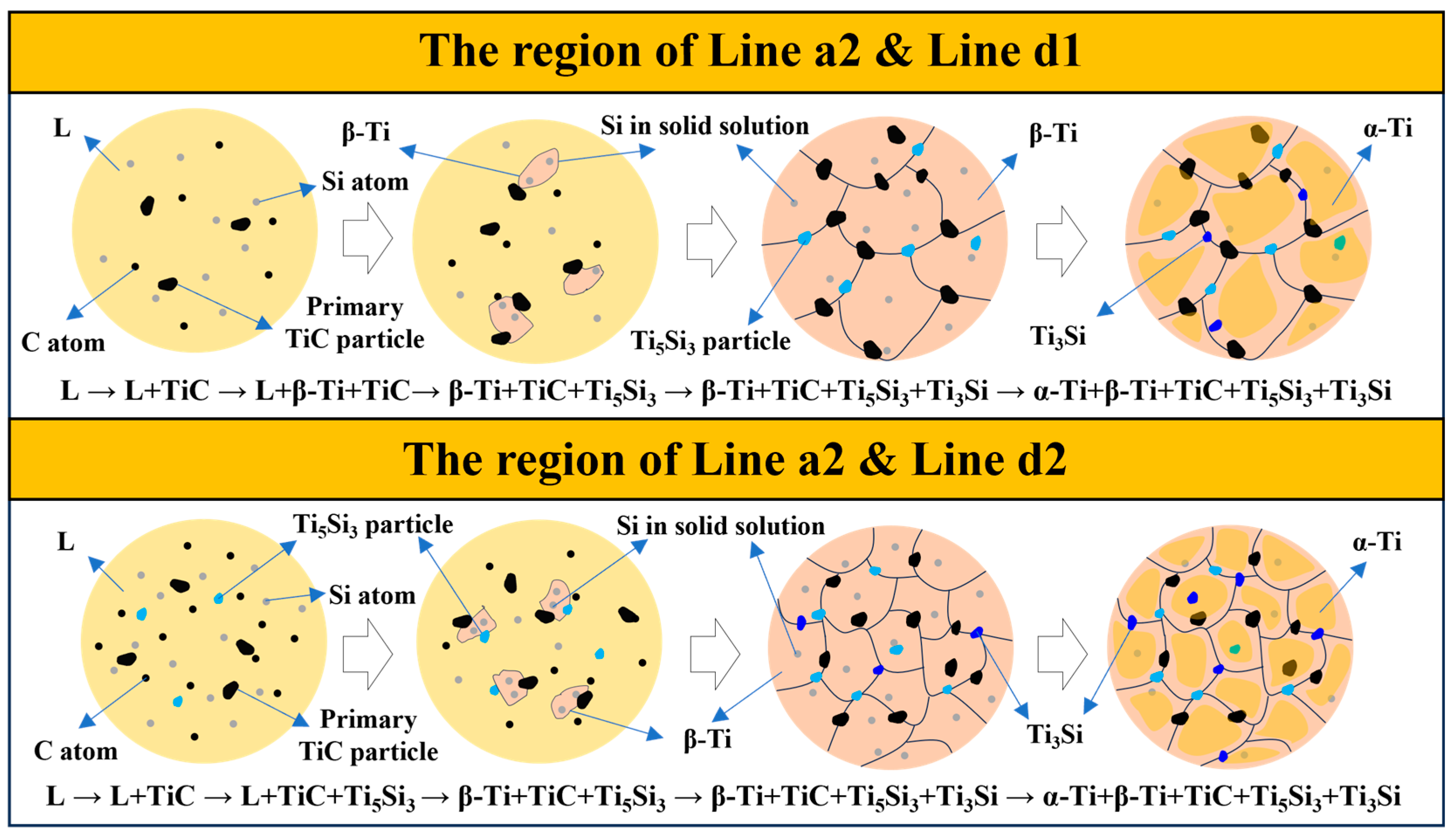

4.8. Ti5Si3/TiC-Reinforced TMCCs

4.8.1. Phase and Microstructure

4.8.2. Mechanical Properties and Strengthening Mechanisms

- (1)

- (2)

- (3)

- (4)

- (5)

- Strong interfacial bonding also minimizes particle pull-out during the service, while the fine particle size reduces third-body wear damage when particles do detach. This combination of factors effectively prevents wear-induced failure mechanisms, contributing to the coating’s excellent wear resistance [79,205,207,208,210].

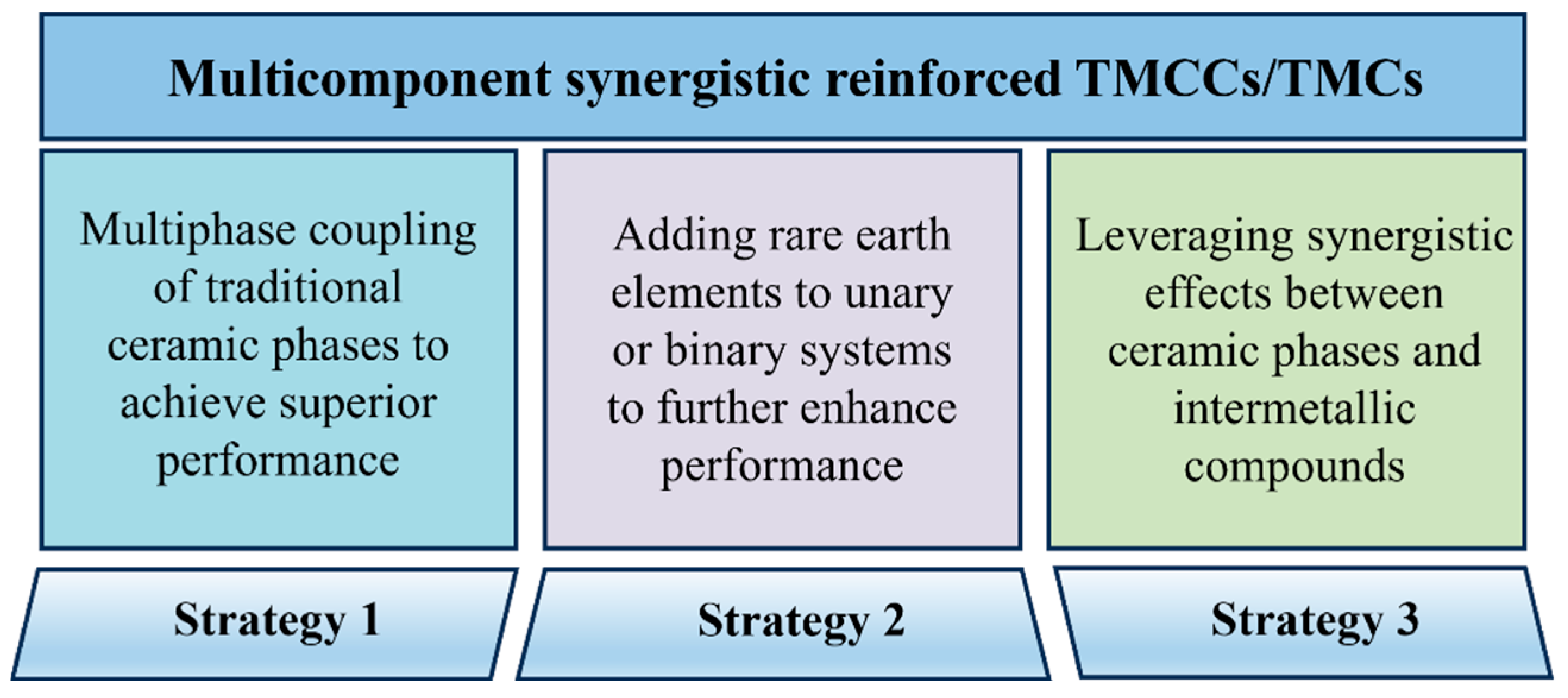

4.9. Other TMCCs

5. Summary, Challenges, and Prospects

Funding

Conflicts of Interest

References

- Zhang, X.; Chen, Y.; Hu, J. Recent Advances in the Development of Aerospace Materials. Prog. Aerosp. Sci. 2018, 97, 22–34. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, S. Research Progress of Laser Cladding Coating on Titanium Alloy Surface. Coatings 2024, 14, 1495. [Google Scholar] [CrossRef]

- Leyens, C.; Peters, M. (Eds.) Titanium and Titanium Alloys: Fundamentals and Applications, 1st ed.; Wiley: Hoboken, NJ, USA, 2003; ISBN 978-3-527-30534-6. [Google Scholar]

- Abd-Elaziem, W.; Darwish, M.A.; Hamada, A.; Daoush, W.M. Titanium-Based Alloys and Composites for Orthopedic Implants Applications: A Comprehensive Review. Mater. Des. 2024, 241, 112850. [Google Scholar] [CrossRef]

- Liu, X.; Chu, P.; Ding, C. Surface Modification of Titanium, Titanium Alloys, and Related Materials for Biomedical Applications. Mater. Sci. Eng. R Rep. 2004, 47, 49–121. [Google Scholar] [CrossRef]

- Cavaliere, P. (Ed.) Laser Cladding of Metals; Springer International Publishing: Cham, Switzerland, 2021; ISBN 978-3-030-53194-2. [Google Scholar]

- Guo, A.X.Y.; Cheng, L.; Zhan, S.; Zhang, S.; Xiong, W.; Wang, Z.; Wang, G.; Cao, S.C. Biomedical Applications of the Powder-based 3D Printed Titanium Alloys: A Review. J. Mater. Sci. Technol. 2022, 125, 252–264. [Google Scholar] [CrossRef]

- Weng, F.; Chen, C.; Yu, H. Research Status of Laser Cladding on Titanium and Its Alloys: A Review. Mater. Des. 2014, 58, 412–425. [Google Scholar] [CrossRef]

- Song, W.W.; Feng, C.; Zhu, L.J.; Zhang, F.F. Progress of Laser Cladding Wear Resistant Coating on Titanium Alloy Surface: A Review. MSF 2021, 1035, 521–527. [Google Scholar] [CrossRef]

- Zhu, L.; Xue, P.; Lan, Q.; Meng, G.; Ren, Y.; Yang, Z.; Xu, P.; Liu, Z. Recent Research and Development Status of Laser Cladding: A Review. Opt. Laser Technol. 2021, 138, 106915. [Google Scholar] [CrossRef]

- Gao, K.; Zhang, Y.; Yi, J.; Dong, F.; Chen, P. Overview of Surface Modification Techniques for Titanium Alloys in Modern Material Science: A Comprehensive Analysis. Coatings 2024, 14, 148. [Google Scholar] [CrossRef]

- Zhao, H.; Zhao, C.; Xie, W.; Wu, D.; Du, B.; Zhang, X.; Wen, M.; Ma, R.; Li, R.; Jiao, J.; et al. Research Progress of Laser Cladding on the Surface of Titanium and Its Alloys. Materials 2023, 16, 3250. [Google Scholar] [CrossRef]

- Mosallanejad, M.H.; Niroumand, B.; Aversa, A.; Saboori, A. In-Situ Alloying in Laser-Based Additive Manufacturing Processes: A Critical Review. J. Alloys Compd. 2021, 872, 159567. [Google Scholar] [CrossRef]

- Sing, S.L.; Huang, S.; Goh, G.D.; Goh, G.L.; Tey, C.F.; Tan, J.H.K.; Yeong, W.Y. Emerging Metallic Systems for Additive Manufacturing: In-Situ Alloying and Multi-Metal Processing in Laser Powder Bed Fusion. Prog. Mater. Sci. 2021, 119, 100795. [Google Scholar] [CrossRef]

- Li, J.; Yu, Z.; Wang, H.; Li, M. Microstructural Characterization of Titanium Matrix Composite Coatings Reinforced by in Situ Synthesized TiB + TiC Fabricated on Ti6Al4V by Laser Cladding. Rare Met. 2010, 29, 465–472. [Google Scholar] [CrossRef]

- An, Q.; Huang, L.; Jiang, S.; Wang, S.; Zhang, R.; Sun, F.; Moridi, A.; Geng, L. Wear Rate of Titanium Matrix Composite Coating at High Temperature Further Increased by Non-Stoichiometric TixC Oxidation. Ceram. Int. 2020, 46, 8068–8074. [Google Scholar] [CrossRef]

- Overview of Coating Technologies. In Surface Modification by Solid State Processing; Elsevier: Amsterdam, The Netherlands, 2014; pp. 1–24. ISBN 978-0-85709-468-1. [CrossRef]

- Munir, K.S.; Kingshott, P.; Wen, C. Carbon Nanotube Reinforced Titanium Metal Matrix Composites Prepared by Powder Metallurgy—A Review. Crit. Rev. Solid State Mater. Sci. 2015, 40, 38–55. [Google Scholar] [CrossRef]

- Zeng, Y.; Wang, J.; Liu, X.; Xue, Y.; Tang, L.; Tong, Y.; Jiang, F. Laser Additive Manufacturing of Ceramic Reinforced Titanium Matrix Composites: A Review of Microstructure, Properties, Auxiliary Processes, and Simulations. Compos. Part A Appl. Sci. Manuf. 2024, 177, 107941. [Google Scholar] [CrossRef]

- Tjong, S. Microstructural and Mechanical Characteristics of in Situ Metal Matrix Composites. Mater. Sci. Eng. R Rep. 2000, 29, 49–113. [Google Scholar] [CrossRef]

- Attar, H.; Ehtemam-Haghighi, S.; Kent, D.; Dargusch, M.S. Recent Developments and Opportunities in Additive Manufacturing of Titanium-Based Matrix Composites: A Review. Int. J. Mach. Tools Manuf. 2018, 133, 85–102. [Google Scholar] [CrossRef]

- Tiley, J.; Searles, T.; Lee, E.; Kar, S.; Banerjee, R.; Russ, J.C.; Fraser, H.L. Quantification of Microstructural Features in α/β Titanium Alloys. Mater. Sci. Eng. A 2004, 372, 191–198. [Google Scholar] [CrossRef]

- Zheng, Z.; Kong, F.; Wang, X.; Chen, Y. Microstructure Evolution, Mechanical Properties and Strengthening Mechanism of Titanium Matrix Composite Sheets. Mater. Sci. Eng. A 2022, 860, 144256. [Google Scholar] [CrossRef]

- Filip, R.; Kubiak, K.; Ziaja, W.; Sieniawski, J. The Effect of Microstructure on the Mechanical Properties of Two-Phase Titanium Alloys. J. Mater. Process. Technol. 2003, 133, 84–89. [Google Scholar] [CrossRef]

- Ankem, S.; Greene, C.A. Recent Developments in Microstructure/Property Relationships of Beta Titanium Alloys. Mater. Sci. Eng. A 1999, 263, 127–131. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, Z.; Xiang, D.; Ju, J. Research and Progress of Laser Cladding: Process, Materials and Applications. Coatings 2022, 12, 1382. [Google Scholar] [CrossRef]

- Qi, Z.; Chen, C.; Wang, C.; Zhou, Z.; Zhou, J.; Long, Y. Effect of Different Laser Wavelengths on Laser Cladding of Pure Copper. Surf. Coat. Technol. 2023, 454, 129181. [Google Scholar] [CrossRef]

- Zhang, H.; Chong, K.; Zhao, W.; Sun, Z. Effects of Pulse Parameters on In-Situ Ti-V Carbides Size and Properties of Fe-Based Laser Cladding Layers. Surf. Coat. Technol. 2018, 344, 163–169. [Google Scholar] [CrossRef]

- Karunaratne, M.S.A.; Kyaw, S.; Jones, A.; Morrell, R.; Thomson, R.C. Modelling the Coefficient of Thermal Expansion in Ni-Based Superalloys and Bond Coatings. J. Mater. Sci. 2016, 51, 4213–4226. [Google Scholar] [CrossRef]

- Liu, D.; Yang, X.; Zhao, A.; Cheng, X.; Zhang, Q. Preparation of Nickel-Based Composite Coatings by Laser Cladding Technology: A Review. Int. J. Adv. Manuf. Technol. 2024, 134, 1–31. [Google Scholar] [CrossRef]

- Hu, Z.; Li, Y.; Lu, B.; Tan, N.; Cai, L.; Yong, Q. Effect of WC Content on Microstructure and Properties of High-Speed Laser Cladding Ni-Based Coating. Opt. Laser Technol. 2022, 155, 108449. [Google Scholar] [CrossRef]

- Liu, L.; Lin, Y.; Peng, L.; Kang, X.; Wang, X. Progress in Microstructure Design and Control of High-Hardness Fe-Based Alloy Coatings via Laser Cladding. Coatings 2024, 14, 1351. [Google Scholar] [CrossRef]

- Yang, L.; Yu, T.; Li, M.; Zhao, Y.; Sun, J. Microstructure and Wear Resistance of In-Situ Synthesized Ti(C, N) Ceramic Reinforced Fe-Based Coating by Laser Cladding. Ceram. Int. 2018, 44, 22538–22548. [Google Scholar] [CrossRef]

- Weng, F.; Yu, H.; Chen, C.; Liu, J.; Zhao, L.; Dai, J.; Zhao, Z. Effect of Process Parameters on the Microstructure Evolution and Wear Property of the Laser Cladding Coatings on Ti-6Al-4V Alloy. J. Alloys Compd. 2017, 692, 989–996. [Google Scholar] [CrossRef]

- Liu, J.; Yu, H.; Chen, C.; Weng, F.; Dai, J. Research and Development Status of Laser Cladding on Magnesium Alloys: A Review. Opt. Lasers Eng. 2017, 93, 195–210. [Google Scholar] [CrossRef]

- Xiang, D.; Liu, Y.; Yu, T.; Wang, D.; Leng, X.; Wang, K.; Liu, L.; Pan, J.; Yao, S.; Chen, Z. Review on Wear Resistance of Laser Cladding High-Entropy Alloy Coatings. J. Mater. Res. Technol. 2024, 28, 911–934. [Google Scholar] [CrossRef]

- Zhao, R.; Chen, C.; Wang, W.; Cao, T.; Shuai, S.; Xu, S.; Hu, T.; Liao, H.; Wang, J.; Ren, Z. On the Role of Volumetric Energy Density in the Microstructure and Mechanical Properties of Laser Powder Bed Fusion Ti-6Al-4V Alloy. Addit. Manuf. 2022, 51, 102605. [Google Scholar] [CrossRef]

- Haubrich, J.; Gussone, J.; Barriobero-Vila, P.; Kürnsteiner, P.; Jägle, E.A.; Raabe, D.; Schell, N.; Requena, G. The Role of Lattice Defects, Element Partitioning and Intrinsic Heat Effects on the Microstructure in Selective Laser Melted Ti-6Al-4V. Acta Mater. 2019, 167, 136–148. [Google Scholar] [CrossRef]

- Guo, Q.; Zhao, C.; Qu, M.; Xiong, L.; Escano, L.I.; Hojjatzadeh, S.M.H.; Parab, N.D.; Fezzaa, K.; Everhart, W.; Sun, T.; et al. In-Situ Characterization and Quantification of Melt Pool Variation under Constant Input Energy Density in Laser Powder Bed Fusion Additive Manufacturing Process. Addit. Manuf. 2019, 28, 600–609. [Google Scholar] [CrossRef]

- Ding, C.; Liu, Y.; Ni, H.; Wang, X.; Wang, H. Effects of Laser Energy Density on Microstructure, Texture and Tribological Property of CoCrFeMnNi High Entropy Alloy Coatings Fabricated by Laser Cladding. Surf. Interfaces 2025, 61, 106107. [Google Scholar] [CrossRef]

- Mahmood, M.A.; Popescu, A.C.; Mihailescu, I.N. Metal Matrix Composites Synthesized by Laser-Melting Deposition: A Review. Materials 2020, 13, 2593. [Google Scholar] [CrossRef]

- Hu, Y.; Cong, W. A Review on Laser Deposition-Additive Manufacturing of Ceramics and Ceramic Reinforced Metal Matrix Composites. Ceram. Int. 2018, 44, 20599–20612. [Google Scholar] [CrossRef]

- Wu, Q.; Long, W.; Zhang, L.; Zhao, H. A Review on Ceramic Coatings Prepared by Laser Cladding Technology. Opt. Laser Technol. 2024, 176, 110993. [Google Scholar] [CrossRef]

- Tan, Q.; Liu, K.; Li, J.; Geng, S.; Sun, L.; Skuratov, V. A Review on Cracking Mechanism and Suppression Strategy of Nickel-Based Superalloys during Laser Cladding. J. Alloys Compd. 2024, 1001, 175164. [Google Scholar] [CrossRef]

- Wei, R.; Mao, M.; Liang, J.; Zhao, C.; Ouyang, C.; Wang, R.; Bai, Q.; Deng, R.; Li, H.; Bian, Q. Study of the Effect of Overlap Rate on the Failure Form, Microstructure and Wear Resistance of Multilayer Laser Cladding on Grey Cast Iron Surfaces. Tribol. Int. 2024, 194, 109568. [Google Scholar] [CrossRef]

- Labusch, R. A Statistical Theory of Solid Solution Hardening. Phys. Status Solidi B 1970, 41, 659–669. [Google Scholar] [CrossRef]

- Shercliff, H.R.; Ashby, M.F. A Process Model for Age Hardening of Aluminium Alloys—I. The Model. Acta Metall. Mater. 1990, 38, 1789–1802. [Google Scholar] [CrossRef]

- Dixit, M.; Mishra, R.S.; Sankaran, K.K. Structure–Property Correlations in Al 7050 and Al 7055 High-Strength Aluminum Alloys. Mater. Sci. Eng. A 2008, 478, 163–172. [Google Scholar] [CrossRef]

- Gao, S.; Zhang, M.; Wang, Z.X.; Wang, Z.; Li, N. Impact-resistant Titanium Alloy with Fine Equiaxed Structure Fabricated by Powder Metallurgy. J. Mater. Sci. Technol. 2025, 221, 129–142. [Google Scholar] [CrossRef]

- Fleischer, R.L. Substitutional Solution Hardening. Acta Metall. 1963, 11, 203–209. [Google Scholar] [CrossRef]

- Scheu, C.; Stergar, E.; Schober, M.; Cha, L.; Clemens, H.; Bartels, A.; Schimansky, F.-P.; Cerezo, A. High Carbon Solubility in a γ-TiAl-Based Ti–45Al–5Nb–0.5C Alloy and Its Effect on Hardening. Acta Mater. 2009, 57, 1504–1511. [Google Scholar] [CrossRef]

- Liu, T.; Chong, X.-Y.; Yu, W.; Zhou, Y.-X.; Huang, H.-G.; Zhou, R.-F.; Feng, J. Changes of Alloying Elements on Elasticity and Solid Solution Strengthening of α-Ti Alloys: A Comprehensive High-Throughput First-Principles Calculations. Rare Met. 2022, 41, 2719–2731. [Google Scholar] [CrossRef]

- Uesugi, T.; Takigawa, Y.; Higashi, K. Deformation Mechanism of Nanocrystalline Al-Fe Alloys by Analysis from Ab-Initio Calculations. MSF 2006, 503–504, 209–214. [Google Scholar] [CrossRef]

- Wang, J.; Guo, X.; Qin, J.; Zhang, D.; Lu, W. Microstructure and Mechanical Properties of Investment Casted Titanium Matrix Composites with B4C Additions. Mater. Sci. Eng. A 2015, 628, 366–373. [Google Scholar] [CrossRef]

- Xiao, Y.; Song, C.; Liu, Z.; Liu, L.; Zhou, H.; Wang, D.; Yang, Y. In-Situ Additive Manufacturing of High Strength yet Ductility Titanium Composites with Gradient Layered Structure Using N2. Int. J. Extrem. Manuf. 2024, 6, 035001. [Google Scholar] [CrossRef]

- Cottrell, A.H.; Bilby, B.A. Dislocation Theory of Yielding and Strain Aging of Iron. Proc. Phys. Soc. Lond. 1949, 62, 49–62. [Google Scholar] [CrossRef]

- Mishin, Y.; Cahn, J.W. Thermodynamics of Cottrell Atmospheres Tested by Atomistic Simulations. Acta Mater. 2016, 117, 197–206. [Google Scholar] [CrossRef]

- Jiang, F.-X.; Zhang, T.-Y. Stress-Induced Long-Range Ordering Snoek Atmosphere. Scr. Metall. 1988, 22, 773–777. [Google Scholar] [CrossRef]

- Suzuki, M. A New Type of Simple Groups of Finite Order. Proc. Natl. Acad. Sci. USA 1960, 46, 868–870. [Google Scholar] [CrossRef]

- Guo, Z.; Sha, W. Quantification of Precipitation Hardening and Evolution of Precipitates. Mater. Trans. 2002, 43, 1273–1282. [Google Scholar] [CrossRef]

- Dasari, S.; Jagetia, A.; Sharma, A.; Nartu, M.S.K.K.Y.; Soni, V.; Gwalani, B.; Gorsse, S.; Banerjee, R. Tuning the Degree of Chemical Ordering in the Solid Solution of a Complex Concentrated Alloy and Its Impact on Mechanical Properties. Acta Mater. 2021, 212, 116938. [Google Scholar] [CrossRef]

- Gladman, T. Precipitation Hardening in Metals. Mater. Sci. Technol. 1999, 15, 30–36. [Google Scholar] [CrossRef]

- Nartu, M.S.K.K.Y.; Alam, T.; Dasari, S.; Mantri, S.A.; Gorsse, S.; Siller, H.; Dahotre, N.; Banerjee, R. Enhanced Tensile Yield Strength in Laser Additively Manufactured Al0.3CoCrFeNi High Entropy Alloy. Materialia 2020, 9, 100522. [Google Scholar] [CrossRef]

- Seidman, D.N.; Marquis, E.A.; Dunand, D.C. Precipitation Strengthening at Ambient and Elevated Temperatures of Heat-Treatable Al(Sc) Alloys. Acta Mater. 2002, 50, 4021–4035. [Google Scholar] [CrossRef]

- Ardell, A.J. Precipitation Hardening. Met. Trans A 1985, 16, 2131–2165. [Google Scholar] [CrossRef]

- Guo, X.; Wang, L.; Wang, M.; Qin, J.; Zhang, D.; Lu, W. Effects of Degree of Deformation on the Microstructure, Mechanical Properties and Texture of Hybrid-Reinforced Titanium Matrix Composites. Acta Mater. 2012, 60, 2656–2667. [Google Scholar] [CrossRef]

- Dieter, G.E., Jr. Mechanical Metallurgy. J. Frankl. Inst. 1962, 273, 338. [Google Scholar] [CrossRef]

- Wang, C.; Liu, X.; Xing, F.; Xu, G.; Bian, H.; Liu, W. Microstructure and Mechanical Properties of TiC/Ti6Al4V Composite Fabricated by Concurrent Wire-Powder Feeding Laser-Directed Energy Deposition. Opt. Laser Technol. 2025, 181, 111836. [Google Scholar] [CrossRef]

- Wu, L.; Gao, Z.; Fan, Z.; Liu, C.; Liu, Y. Microstructure and Mechanical Properties of In-Situ Hybrid Reinforced (TiB+TiC)/Ti Composites Prepared by Laser Powder Bed Fusion. J. Mater. Res. Technol. 2024, 30, 9258–9273. [Google Scholar] [CrossRef]

- Fereiduni, E.; Ghasemi, A.; Elbestawi, M. Unique Opportunities for Microstructure Engineering via Trace B4C Addition to Ti-6Al-4V through Laser Powder Bed Fusion Process: As-Built and Heat-Treated Scenarios. Addit. Manuf. 2022, 50, 102557. [Google Scholar] [CrossRef]

- Hall, E.O. The Deformation and Ageing of Mild Steel: III Discussion of Results. Proc. Phys. Soc. B 1951, 64, 747–753. [Google Scholar] [CrossRef]

- Li, L.; Ma, P.; Zhang, L.; Tan, H.; Li, M. Fabrication of TiB Whiskers Reinforced Ti6242 Matrix Composites by Direct Laser Deposition: Powder Preparation, Microstructure and Mechanical Property. Compos. Part B Eng. 2024, 268, 111068. [Google Scholar] [CrossRef]

- Liu, H.; Fang, M.; Han, Y.; Huang, G.; Sun, Z.; Zhang, L.; Lu, W. Achieving Strength-Ductility Combination and Anisotropy Elimination in Additively Manufactured TiB/Ti6Al4V by in-Situ Synthesized Network Architecture with Fine Grains. Compos. Part B Eng. 2023, 262, 110822. [Google Scholar] [CrossRef]

- Sanaty-Zadeh, A. Comparison between Current Models for the Strength of Particulate-Reinforced Metal Matrix Nanocomposites with Emphasis on Consideration of Hall–Petch Effect. Mater. Sci. Eng. A 2012, 531, 112–118. [Google Scholar] [CrossRef]

- Li, P.; Li, L.; Tang, L.; Wang, L.; Xu, J.; Dong, L.; Mao, X.; Liu, Y.; Zhang, Y. Micron-Sized SiC Particles Reinforced TC4 Composites: Mechanical Properties and Strengthening Mechanisms. Mater. Today Commun. 2024, 38, 108147. [Google Scholar] [CrossRef]

- Saba, F.; Zhang, F.; Liu, S.; Liu, T. Reinforcement Size Dependence of Mechanical Properties and Strengthening Mechanisms in Diamond Reinforced Titanium Metal Matrix Composites. Compos. Part B Eng. 2019, 167, 7–19. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, Y.; Liu, X.; Zhan, Q.; Wang, K. Microstructure Evolution and Mechanical Properties of In-Situ Ti6Al4V–TiB Composites Manufactured by Selective Laser Melting. Compos. Part B Eng. 2021, 207, 108567. [Google Scholar] [CrossRef]

- Fukuda, H.; Chou, T.-W. A Probabilistic Theory of the Strength of Short-Fibre Composites with Variable Fibre Length and Orientation. J. Mater. Sci. 1982, 17, 1003–1011. [Google Scholar] [CrossRef]

- Zhang, X.; Li, D.; Zheng, Y.; Shojaei, P.; Trabia, M.; O’Toole, B.; Lin, D.; Mushongera, L.; Liao, Y. In-Situ Synthesis of Ti5Si3-Reinforced Titanium Matrix Nanocomposite by Selective Laser Melting: Quasi-Continuous Reinforcement Network and Enhanced Mechanical Performance. J. Mater. Process. Technol. 2022, 309, 117752. [Google Scholar] [CrossRef]

- Brown, L.M.; Stobbs, W.M. The Work-Hardening of Copper-Silica v. Equilibrium Plastic Relaxation by Secondary Dislocations. Philos. Mag. 1976, 34, 351–372. [Google Scholar] [CrossRef]

- Hu, Y.; Cong, W.; Wang, X.; Li, Y.; Ning, F.; Wang, H. Laser Deposition-Additive Manufacturing of TiB-Ti Composites with Novel Three-Dimensional Quasi-Continuous Network Microstructure: Effects on Strengthening and Toughening. Compos. Part B Eng. 2018, 133, 91–100. [Google Scholar] [CrossRef]

- Kumar, N.; Mishra, R.S. Additivity of Strengthening Mechanisms in Ultrafine Grained Al–Mg–Sc Alloy. Mater. Sci. Eng. A 2013, 580, 175–183. [Google Scholar] [CrossRef]

- Rajabi, A.; Ghazali, M.J.; Daud, A.R. Chemical Composition, Microstructure and Sintering Temperature Modifications on Mechanical Properties of TiC-Based Cermet—A Review. Mater. Des. 2015, 67, 95–106. [Google Scholar] [CrossRef]

- Wei, W.; Li, Y.; Wei, B.; Tan, Y.; Lv, P.; Nie, P.; Wang, Y.; Liang, X.; Long, T.; Zhou, J.; et al. The Influence of TiC Nanoparticles Addition on the Microstructure and Mechanical Properties of IN738LC Alloy Prepared by EB-PBF. Mater. Design 2025, 251, 113723. [Google Scholar] [CrossRef]

- Cai, Q.; Li, G.; Wu, B.; Xu, S.; Wang, L.; Guo, Y. Effect of TiC Content on Microstructure and Properties of TiC/Ni60 Coatings on Ti6Al4V Alloy Deposited by Laser Cladding. Opt. Laser Technol. 2024, 168, 109854. [Google Scholar] [CrossRef]

- Awotunde, M.A.; Adegbenjo, A.O.; Ajide, O.O.; Olubambi, P.A. Influence of Ti/TiC Interface and Its Site of Formation on the Properties of Powder Metallurgically Fabricated Ti-Based Composites Reinforced with Carbonaceous Materials: A Review. Crit. Rev. Solid State Mater. Sci. 2023, 48, 643–667. [Google Scholar] [CrossRef]

- Gu, D.; Meng, G.; Li, C.; Meiners, W.; Poprawe, R. Selective Laser Melting of TiC/Ti Bulk Nanocomposites: Influence of Nanoscale Reinforcement. Scr. Mater. 2012, 67, 185–188. [Google Scholar] [CrossRef]

- Li, G.; Munir, K.; Wen, C.; Li, Y.; Ding, S. Machinablility of Titanium Matrix Composites (TMC) Reinforced with Multi-Walled Carbon Nanotubes. J. Manuf. Process. 2020, 56, 131–146. [Google Scholar] [CrossRef]

- Lin, K.; Fang, Y.; Gu, D.; Ge, Q.; Zhuang, J.; Xi, L. Selective Laser Melting of Graphene Reinforced Titanium Matrix Composites: Powder Preparation and Its Formability. Adv. Powder Technol. 2021, 32, 1426–1437. [Google Scholar] [CrossRef]

- Kondoh, K.; Threrujirapapong, T.; Imai, H.; Umeda, J.; Fugetsu, B. Characteristics of Powder Metallurgy Pure Titanium Matrix Composite Reinforced with Multi-Wall Carbon Nanotubes. Compos. Sci. Technol. 2009, 69, 1077–1081. [Google Scholar] [CrossRef]

- Wei, L.; Liu, X.; Gao, Y.; Lv, X.; Hu, N.; Chen, M. Synergistic Strengthening Effect of Titanium Matrix Composites Reinforced by Graphene Oxide and Carbon Nanotubes. Mater. Des. 2021, 197, 109261. [Google Scholar] [CrossRef]

- Feng, K.; Zhang, H.; Cheng, X.; Fan, Q.; Mu, X.; Xiong, N.; Wang, H.; Duan, H. Breaking through the Strength-Ductility Trade-off in Graphene Nanoplatelets Reinforced Titanium Matrix Composites via Two-Scale Laminated Architecture Design. Mater. Charact. 2023, 205, 113290. [Google Scholar] [CrossRef]

- Savalani, M.M.; Ng, C.C.; Li, Q.H.; Man, H.C. In Situ Formation of Titanium Carbide Using Titanium and Carbon-Nanotube Powders by Laser Cladding. Appl. Surf. Sci. 2012, 258, 3173–3177. [Google Scholar] [CrossRef]

- Li, Q.H.; Savalani, M.M.; Zhang, Q.M.; Huo, L. High Temperature Wear Characteristics of TiC Composite Coatings Formed by Laser Cladding with CNT Additives. Surf. Coat. Technol. 2014, 239, 206–211. [Google Scholar] [CrossRef]

- He, B.; Ma, D.; Ma, F.; Xu, K. Microstructures and Wear Properties of TiC Coating Produced by Laser Cladding on Ti-6Al-4V with TiC and Carbon Nanotube Mixed Powders. Ferroelectrics 2019, 547, 217–225. [Google Scholar] [CrossRef]

- Ma, G.; Yu, C.; Tang, B.; Li, Y.; Niu, F.; Wu, D.; Bi, G.; Liu, S. High-Mass-Proportion TiCp/Ti6Al4V Titanium Matrix Composites Prepared by Directed Energy Deposition. Addit. Manuf. 2020, 35, 101323. [Google Scholar] [CrossRef]

- Wang, Y.; Tan, H.; Feng, Z.; Zhang, F.; Shang, W.; Clare, A.T.; Lin, X. Enhanced Mechanical Properties of in Situ Synthesized TiC/Ti Composites by Pulsed Laser Directed Energy Deposition. Mater. Sci. Eng. A 2022, 855, 143935. [Google Scholar] [CrossRef]

- Mihai, S.; Baciu, F.; Radu, R.; Chioibasu, D.; Popescu, A.C. In Situ Fabrication of TiC/Ti–Matrix Composites by Laser Directed Energy Deposition. Materials 2024, 17, 4284. [Google Scholar] [CrossRef]

- Ou, B.; Lu, L.; Wang, Q.; He, Q.; Xie, Y.; Yan, J. Mechanical Properties of TC11 Titanium Alloy and Graphene Nanoplatelets/TC11 Composites Prepared by Selective Laser Melting. Int. J. Mol. Sci. 2022, 23, 6134. [Google Scholar] [CrossRef]

- Jiang, Q.; Li, S.; Guo, S.; Fu, M.; Zhang, B. Comparative Study on Process-Structure-Property Relationships of TiC/Ti6Al4V and Ti6Al4V by Selective Laser Melting. Int. J. Mech. Sci. 2023, 241, 107963. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, J.; Wei, W. Microstructure and Mechanical Properties of TiC/Ti6Al4V Nanocomposites Fabricated by Gas–Liquid Reaction Laser Powder Bed Fusion. Mater. Sci. Eng. A 2023, 869, 144829. [Google Scholar] [CrossRef]

- Designation and Composition of Titanium and Titanium Alloys. Standard’s GB/T 3620.1-2016; Designation and Composition of Titanium and Titanium Alloys. China National Standardization Administration: Beijing, China, 2016.

- Monisha, K.; Shariff, S.M.; Sekar, A.; Raju, R.; Manonmani, J.; Senthilselvan, J. Titanium Boride Coating by High Power Diode Laser Alloying of Amorphous Boron with Titanium and Its Surface Property Investigations. Opt. Laser Technol. 2024, 170, 110159. [Google Scholar] [CrossRef]

- Qiao, G.; Zhang, B.; Bai, Q.; Gao, Y.; Du, W.; Zhang, Y. Machinability of TiC-Reinforced Titanium Matrix Composites Fabricated by Additive Manufacturing. J. Manuf. Process. 2022, 76, 412–418. [Google Scholar] [CrossRef]

- Bernard, G.; Pejchal, V.; Sereda, O.; Logé, R.E. In-Situ Fabrication of Ti-TiCx Metal Matrix Composite by Laser Powder Bed Fusion with Enhanced Elastic Modulus and Superior Ductility. Mater. Des. 2024, 248, 113499. [Google Scholar] [CrossRef]

- Gülenç, İ.T.; Bai, M.; Mitchell, R.L.; Todd, I.; Inkson, B.J. In Situ TiC Reinforced Ti6Al4V Matrix Composites Manufactured via Selective Laser Melting. RPJ 2024, 30, 378–392. [Google Scholar] [CrossRef]

- Okamoto, H. C-Ti (Carbon-Titanium). JPE 1998, 19, 89. [Google Scholar] [CrossRef]

- Murray, J.L.; Liao, P.K.; Spear, K.E. The B−Ti (Boron-Titanium) System. Bull. Alloy Phase Diagr. 1986, 7, 550–555. [Google Scholar] [CrossRef]

- Wriedt, H.A.; Murray, J.L. The N-Ti (Nitrogen-Titanium) System. Bull. Alloy Phase Diagr. 1987, 8, 378–388. [Google Scholar] [CrossRef]

- Seifert, H.J.; Lukas, H.L.; Petzow, G. Thermodynamic Optimization of the Ti-Si System. Z. Met. 1996, 87, 2–13. [Google Scholar]

- Wang, H.; Hu, Y.; Wang, L.; Zhang, Y.; Zhang, H.; Han, H.; Wang, T. Enhancing the Wearing Resistance of TC17 Alloy by Nano/Micro-TiC Ceramic through Directed Energy Deposition. Mater. Today Commun. 2024, 39, 109083. [Google Scholar] [CrossRef]

- Zhang, G.; Chen, J.; Zheng, M.; Yan, Z.; Lu, X.; Lin, X.; Huang, W. Element Vaporization of Ti-6Al-4V Alloy during Selective Laser Melting. Metals 2020, 10, 435. [Google Scholar] [CrossRef]

- Liu, J.; Wen, P. Metal Vaporization and Its Influence during Laser Powder Bed Fusion Process. Mater. Des. 2022, 215, 110505. [Google Scholar] [CrossRef]

- Wang, S.; Wang, W.; Xu, Y.; Zhang, X.; Chen, C.; Geng, P.; Ma, N. Effect of Nanosecond Pulsed Laser Parameters on Texturing Formation of Metallic Surface: Experiment and Modelling. J. Mater. Res. Technol. 2023, 26, 7775–7788. [Google Scholar] [CrossRef]

- Wang, J.; Tang, L.; Xue, Y.; Zhao, Z.; Ye, Z.; Cao, W.; Zhu, J.; Jiang, F. Microstructure and Properties of (Diamond + TiC) Reinforced Ti6Al4V Titanium Matrix Composites Manufactured by Directed Energy Deposition. J. Mater. Res. Technol. 2024, 28, 3110–3120. [Google Scholar] [CrossRef]

- Suh, N.P.; Mosleh, M.; Howard, P.S. Control of Friction. Wear 1994, 175, 151–158. [Google Scholar] [CrossRef]

- Lin, Y.; Yao, J.; Lei, Y.; Fu, H.; Wang, L. Microstructure and Properties of TiB 2 –TiB Reinforced Titanium Matrix Composite Coating by Laser Cladding. Opt. Lasers Eng. 2016, 86, 216–227. [Google Scholar] [CrossRef]

- Lin, Y.; Jiang, C.; Lin, Z.; Chen, Q.; Lei, Y.; Fu, H. Laser In-Situ Synthesis of High Aspect Ratio TiB Fiber Bundle Reinforced Titanium Matrix Composite Coating. Opt. Laser Technol. 2019, 115, 364–373. [Google Scholar] [CrossRef]

- An, Q.; Huang, L.; Jiang, S.; Bao, Y.; Ji, M.; Zhang, R.; Geng, L. Two-Scale TiB/Ti64 Composite Coating Fabricated by Two-Step Process. J. Alloys Compd. 2018, 755, 29–40. [Google Scholar] [CrossRef]

- Zheng, Y.; Xu, L.; Chi, D.; Liang, Z.; Han, S.; Xue, X.; Xiao, S.; Tian, J.; Chen, Y. Tensile and Creep Properties under Different Temperature Conditions of Titanium Matrix Composites Reinforced by TiB and TiC. Mater. Sci. Eng. A 2022, 860, 144279. [Google Scholar] [CrossRef]

- Jiao, Y.; Huang, L.; Geng, L. Progress on Discontinuously Reinforced Titanium Matrix Composites. J. Alloys Compd. 2018, 767, 1196–1215. [Google Scholar] [CrossRef]

- Huang, L.; An, Q.; Geng, L.; Wang, S.; Jiang, S.; Cui, X.; Zhang, R.; Sun, F.; Jiao, Y.; Chen, X.; et al. Multiscale Architecture and Superior High-Temperature Performance of Discontinuously Reinforced Titanium Matrix Composites. Adv. Mater. 2021, 33, 2000688. [Google Scholar] [CrossRef]

- Li, N.; He, D.; Liu, D.; Ma, L.; He, C.; Xu, Y.; Yu, J. In-Situ TiB Reinforced Titanium Matrix Composite Coatings Prepared by Laser Cladding: Effect of TiB2 Content on Microstructure, Hardness and Wear Properties. J. Alloys Compd. 2025, 1010, 178215. [Google Scholar] [CrossRef]

- Lin, Y.; Lei, Y.; Li, X.; Zhi, X.; Fu, H. A Study of TiB2/TiB Gradient Coating by Laser Cladding on Titanium Alloy. Opt. Lasers Eng. 2016, 82, 48–55. [Google Scholar] [CrossRef]

- Lin, Y.; Wang, H.; Zhang, M.; Lin, H.; Yan, D.; Lin, Q.; Kang, X.; Wang, X. Gradient Coating of Laser Cladding TiB2/Ti-Based Alloy on Titanium Alloy Surface. Coatings 2023, 13, 743. [Google Scholar] [CrossRef]

- Li, Y.; Fang, W.; Guo, S.; Duan, M.; Luo, B.; Li, Y.; Liu, J.; Gu, J.; Peng, Y.; Zhou, Q.; et al. In-Situ Reinforced Ti6Al4V-TiB2 Titanium Matrix Composite Fabricated by Selective Laser Melting: Microstructure, Mechanical Properties and Heat Treatment. Mater. Charact. 2024, 212, 113952. [Google Scholar] [CrossRef]

- Zhao, X.; Lu, X.; Zuo, H.; Ma, S.; Wang, C.; Li, M.V. TiBw Reinforced Titanium Matrix Composites Fabricated by Selective Laser Melting: Influence of Energy Density on Microstructure and Tribological Performance. Ceram. Int. 2023, 49, 28920–28933. [Google Scholar] [CrossRef]

- Liu, H.; Han, J.; Han, Y.; Fang, M.; Wang, X.; Huang, G.; Lu, W. Formability, Densification Behavior and Hierarchical Grain Structure of Laser-Directed Energy Deposition of TiB Reinforced Titanium Matrix Composites. Compos. Part B Eng. 2023, 267, 111039. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, G.; Zhang, S.; Zhou, S.; Li, B.; An, D.; He, B.; Li, X.; Xiao, Y.; Lin, P. Microstructure Evolution and Mechanical Properties of In-Situ Ti6Al4V–TiB-Ti2Ni Composites Manufactured by Laser Directed Energy Deposition. Compos. Part B Eng. 2025, 292, 112072. [Google Scholar] [CrossRef]

- Mao, H.; Zhang, Y.; Wang, J.; Cui, K.; Liu, H.; Yang, J. Microstructure, Mechanical Properties, and Reinforcement Mechanism of Second-Phase Reinforced TiC-Based Composites: A Review. Coatings 2022, 12, 801. [Google Scholar] [CrossRef]

- Singh, G.; Ramamurty, U. Reprint: Boron Modified Titanium Alloys. Prog. Mater. Sci. 2021, 120, 100815. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, Y.; Liu, X.; Wu, L. High-Temperature Tensile and Creep Properties of TiB-Reinforced Ti6Al4V Composite Fabricated by Laser Powder Bed Fusion. Mater. Charact. 2023, 200, 112859. [Google Scholar] [CrossRef]

- Li, X.; Qin, C.; An, Y.; Zhang, Y.; Sun, Z.; Zhao, E. Effect of SiC Addition on the Microstructure and Properties of Ti6Al4V by Selective Laser Melting. J. Alloys Compd. 2025, 1010, 177330. [Google Scholar] [CrossRef]

- Hua, Z.; Xiong, L.; Zhang, M.; Wang, C.; Mi, G.; Jiang, P. Microstructure Evolution and Tribological Properties of (TiB+TiC)/Ti–6Al–4V Composites Fabricated via in Situ Laser-Directed Energy Deposition of Wire and Powders in an Underwater Environment. Compos. Part B Eng. 2023, 263, 110817. [Google Scholar] [CrossRef]

- Yumak, N.; Aslantaş, K. A Review on Heat Treatment Efficiency in Metastable β Titanium Alloys: The Role of Treatment Process and Parameters. J. Mater. Res. Technol. 2020, 9, 15360–15380. [Google Scholar] [CrossRef]

- Long, M.; Rack, H.J. Titanium Alloys in Total Joint Replacement—A Materials Science Perspective. Biomaterials 1998, 19, 1621–1639. [Google Scholar] [CrossRef] [PubMed]

- Wang, K. The Use of Titanium for Medical Applications in the USA. Mater. Sci. Eng. A 1996, 213, 134–137. [Google Scholar] [CrossRef]

- Wei, S.; Huang, L.; Li, X.; An, Q.; Geng, L. High-Temperature Cyclic Oxidation Kinetics and Microstructural Transition Mechanisms of Ti-6Al-4V Composites Reinforced with Hybrid (TiC+TiB) Networks. arXiv 2017. [Google Scholar] [CrossRef]

- Qin, Y.; Lu, W.; Qin, J.; Zhang, D. Oxidation Behavior of In Situ Synthesized TiB/Ti Composite in Air Environment. Mater. Trans. 2004, 45, 3241–3246. [Google Scholar] [CrossRef]

- Zhang, E.; Zeng, G.; Zeng, S. Oxidation Behavior of in Situ TiB Short FIbre Reinforced Ti-6Al-1.2B Alloy in Air. J. Mater. Sci. 2002, 37, 4063–4071. [Google Scholar] [CrossRef]

- Sundgren, J.-E. Structure and Properties of TiN Coatings. Thin Solid Film. 1985, 128, 21–44. [Google Scholar] [CrossRef]

- Srinivasan, D.; Kulkarni, T.G.; Anand, K. Thermal Stability and High-Temperature Wear of Ti–TiN and TiN–CrN Nanomultilayer Coatings under Self-Mated Conditions. Tribol. Int. 2007, 40, 266–277. [Google Scholar] [CrossRef]

- Bai, H.; Zhong, L.; Kang, L.; Liu, J.; Zhuang, W.; Lv, Z.; Xu, Y. A Review on Wear-Resistant Coating with High Hardness and High Toughness on the Surface of Titanium Alloy. J. Alloys Compd. 2021, 882, 160645. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, G. Surface Modification of Ti6Al4V Alloy via Advanced Coatings: Mechanical, Tribological, Corrosion, Wetting, and Biocompatibility Studies. J. Alloys Compd. 2024, 989, 174418. [Google Scholar] [CrossRef]

- Subramanian, B.; Muraleedharan, C.V.; Ananthakumar, R.; Jayachandran, M. A Comparative Study of Titanium Nitride (TiN), Titanium Oxy Nitride (TiON) and Titanium Aluminum Nitride (TiAlN), as Surface Coatings for Bio Implants. Surf. Coat. Technol. 2011, 205, 5014–5020. [Google Scholar] [CrossRef]

- Morton, P.A.; Taylor, H.C.; Murr, L.E.; Delgado, O.G.; Terrazas, C.A.; Wicker, R.B. In Situ Selective Laser Gas Nitriding for Composite TiN/Ti-6Al-4V Fabrication via Laser Powder Bed Fusion. J. Mater. Sci. Technol. 2020, 45, 98–107. [Google Scholar] [CrossRef]

- Sahasrabudhe, H.; Soderlind, J.; Bandyopadhyay, A. Laser Processing of in Situ TiN/Ti Composite Coating on Titanium. J. Mech. Behav. Biomed. Mater. 2016, 53, 239–249. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Ren, S.; Li, T.; Chen, P.; Hu, L.; Wu, W.; Li, S.; Liu, H.; Li, R.; Zhang, Y. A Comparison Study on the Microstructure, Mechanical Features, and Tribological Characteristics of TiN Coatings on Ti6Al4V Using Different Deposition Techniques. Coatings 2024, 14, 156. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, C.; Huang, H.; Yan, J.; Zhang, L.; Jiang, M.; Zhang, Z. Achieving Ultra-Low Wear of Ti6Al4V Alloy by Introducing a Sinusoidal Nitriding Layer via Nanosecond Pulsed Laser Irradiation. Tribol. Int. 2024, 200, 110113. [Google Scholar] [CrossRef]

- Wei, W.; Wu, W.; Fan, S.; Duan, X. In-Situ Laser Additive Manufacturing of Ti6Al4V Matrix Composites by Gas–Liquid Reaction in Dilute Nitrogen Gas Atmospheres. Mater. Des. 2021, 202, 109578. [Google Scholar] [CrossRef]

- Xin, Z.; Ren, N.; Ren, Y.; Yue, X.; Han, Q.; Zhou, W.; Tao, Y.; Ye, Y. In-Situ Nitriding on the Textured Titanium Alloy Using Femtosecond Laser. J. Mater. Res. Technol. 2022, 19, 466–471. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, Z.; Liu, J.; Ye, Z.; Hu, Y.; Wu, J.; Liu, K.; Cai, Z. Enhancing the Tribological Properties of TA1 Pure Titanium by Modulating the Energy of Pulsed Laser Nitriding. Opt. Laser Technol. 2024, 169, 110118. [Google Scholar] [CrossRef]

- Zeng, C.; Wen, H.; Hemmasian Ettefagh, A.; Zhang, B.; Gao, J.; Haghshenas, A.; Raush, J.R.; Guo, S.M. Laser Nitriding of Titanium Surfaces for Biomedical Applications. Surf. Coat. Technol. 2020, 385, 125397. [Google Scholar] [CrossRef]

- Zong, X.; Wang, H.; Li, J.; Cheng, X.; Li, Z.; Tang, H. Microstructure Characterization and Evolution Mechanism of Titanium during Laser Surface Nitriding. Mater. Charact. 2022, 190, 112029. [Google Scholar] [CrossRef]

- Zong, X.; Wang, H.; Tang, H.; Cheng, X.; Tian, X.; Ran, X. Microstructure Evolution and Mass Transfer Behavior during Multi-Pass Laser Surface Nitriding Process on Titanium Alloy. Surf. Coat. Technol. 2023, 466, 129565. [Google Scholar] [CrossRef]

- Xiao, Y.; Yang, Y.; Zhang, M.; Liu, Z.; Zhou, H.; Wu, S.; Wang, D.; Song, C. High Wear Resistance of Uniform Nitriding Titanium Composites Fabricated by In-Situ Laser Powder Bed Fusion. Compos. Part A Appl. Sci. Manuf. 2024, 177, 107950. [Google Scholar] [CrossRef]

- Smirnov, S.A.; Filippova, A.V.; Dubinin, O.N.; Shalnova, S.A.; Simonov, A.P.; Sergeichev, I.V.; Qian, G.; Dmitrieva, A.V.; Zherebtsov, S.V.; Narayan, R.L.; et al. In Situ Alloying of Directed Energy Deposition Fabricated Ti6Al4V with Nitrogen. J. Alloys Compd. 2025, 1016, 178872. [Google Scholar] [CrossRef]

- Zhao, Y.; Wu, C.; Zhou, S.; Yang, J.; Li, W.; Zhang, L.-C. Selective Laser Melting of Ti-TiN Composites: Formation Mechanism and Corrosion Behaviour in H2SO4/HCl Mixed Solution. J. Alloys Compd. 2021, 863, 158721. [Google Scholar] [CrossRef]

- Chen, T.; Li, W.; Liu, D.; Xiong, Y.; Zhu, X. Effects of Heat Treatment on Microstructure and Mechanical Properties of TiC/TiB Composite Bioinert Ceramic Coatings in-Situ Synthesized by Laser Cladding on Ti6Al4V. Ceram. Int. 2021, 47, 755–768. [Google Scholar] [CrossRef]

- Xiang, D.; Wang, D.; Wang, S.; Yan, L.; Chen, Y. Analysis and Optimization of Laser Cladding Ti-B4C Composite Coatings Based on the Interaction and GABP-NSGAII Algorithm. Surf. Coat. Technol. 2024, 493, 131186. [Google Scholar] [CrossRef]

- Liang, J.; Yin, X.; Lin, Z.; Chen, S.; Liu, C.; Yan, S.; Dong, S. Effects of LaB6 on Microstructure Evolution and Properties of In-Situ Synthetic TiC+TiBx Reinforced Titanium Matrix Composite Coatings Prepared by Laser Cladding. Surf. Coat. Technol. 2020, 403, 126409. [Google Scholar] [CrossRef]

- Wang, L.; Huang, Y.; Jia, C.; Yang, L.; Yan, S. Laser-Directed Energy Deposition of in-Situ Titanium-Matrix Coatings with a Ti-B4C Cored Wire. Addit. Manuf. 2023, 73, 103682. [Google Scholar] [CrossRef]

- Ogunlana, M.O.; Muchie, M. Microstructure and Mechanical Analyses of Ti6Al4V/B4C Composites on Ti6Al4V Substrate: Effect of Laser Power on Multiple Track Laser Metal Deposition. Procedia CIRP 2023, 120, 1398–1403. [Google Scholar] [CrossRef]

- Mi, H.; Chen, T.; Deng, Z.; Li, S.; Liu, J.; Liu, D. Microstructure and Mechanical Properties of TiC/TiB Composite Ceramic Coatings In-Situ Synthesized by Ultrasonic Vibration-Assisted Laser Cladding. Coatings 2022, 12, 99. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, D.; Cong, W. Feasibility Study of Adding Buffer Layers for the Laser Deposition of High-Ceramic Content (TiB + TiC)–Ti Coatings Using B4C/Ti Powders. Ceram. Int. 2022, 48, 23387–23396. [Google Scholar] [CrossRef]

- Han, C.; Babicheva, R.; Chua, J.D.Q.; Ramamurty, U.; Tor, S.B.; Sun, C.-N.; Zhou, K. Microstructure and Mechanical Properties of (TiB+TiC)/Ti Composites Fabricated in Situ via Selective Laser Melting of Ti and B4C Powders. Addit. Manuf. 2020, 36, 101466. [Google Scholar] [CrossRef]

- Li, R.; Yue, H.; Luo, S.; Zhang, F.; Sun, B. Microstructure and Mechanical Properties of in Situ Synthesized (TiB+TiC)-Reinforced Ti6Al4V Composites Produced by Directed Energy Deposition of Ti and B4C Powders. Mater. Sci. Eng. A 2023, 864, 144466. [Google Scholar] [CrossRef]

- Ma, P.; Li, L.; Liu, J.; Li, M. Microstructure Evolution and Mechanical Property of B4C/Ti65 Composites via Laser Directed Energy Deposition. Mater. Sci. Eng. A 2024, 915, 147273. [Google Scholar] [CrossRef]

- Hua, Z.; Hu, Y.; Mi, G.; Jiang, P.; He, C.; Wang, C. New Insights into the Microstructural Evolution and Properties of (TiB+TiC)/Ti–6Al–4V Composite via Laser Directed Energy Deposition Using B4C Nanoparticles. Vacuum 2024, 220, 112836. [Google Scholar] [CrossRef]

- Nartu, M.S.K.K.Y.; Mantri, S.A.; Pantawane, M.V.; Ho, Y.-H.; McWilliams, B.; Cho, K.; Dahotre, N.B.; Banerjee, R. In Situ Reactions during Direct Laser Deposition of Ti-B4C Composites. Scr. Mater. 2020, 183, 28–32. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, Y. New Insights into the Evolution of TiB Whisker and TiC Particle during Selective Laser Melting of Titanium Matrix Composites. Mater. Sci. Eng. A 2023, 877, 145200. [Google Scholar] [CrossRef]

- Guo, S.; Li, Y.; Gu, J.; Liu, J.; Peng, Y.; Wang, P.; Zhou, Q.; Wang, K. Microstructure and Mechanical Properties of Ti6Al4V/B4C Titanium Matrix Composite Fabricated by Selective Laser Melting (SLM). J. Mater. Res. Technol. 2023, 23, 1934–1946. [Google Scholar] [CrossRef]

- Miao, X.; Wu, M.; Cui, C.; Ma, C.; Wang, Q.; He, R. Effect of Graphene Addition on the Performance of In-Situ (TiC+TiBx)/Ti Composite Coatings by Laser Cladding: Microstructure and Water Droplet Erosion Resistance. Surf. Coat. Technol. 2023, 459, 129381. [Google Scholar] [CrossRef]

- Santecchia, E.; Hamouda, A.M.S.; Musharavati, F.; Zalnezhad, E.; Cabibbo, M.; Spigarelli, S. Wear Resistance Investigation of Titanium Nitride-Based Coatings. Ceram. Int. 2015, 41, 10349–10379. [Google Scholar] [CrossRef]

- Łępicka, M.; Grądzka-Dahlke, M.; Pieniak, D.; Pasierbiewicz, K.; Kryńska, K.; Niewczas, A. Tribological Performance of Titanium Nitride Coatings: A Comparative Study on TiN-Coated Stainless Steel and Titanium Alloy. Wear 2019, 422–423, 68–80. [Google Scholar] [CrossRef]

- Teresa Raimondi, M.; Pietrabissa, R. The In-Vivo Wear Performance of Prosthetic Femoral Heads with Titanium Nitride Coating. Biomaterials 2000, 21, 907–913. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, J.; Pan, W.; Wang, W.; Tang, C. A Review on the Preparation and Application of BN Composite Coatings. Ceram. Int. 2023, 49, 24–39. [Google Scholar] [CrossRef]

- Das, M.; Bhattacharya, K.; Dittrick, S.A.; Mandal, C.; Balla, V.K.; Sampath Kumar, T.S.; Bandyopadhyay, A.; Manna, I. In Situ Synthesized TiB–TiN Reinforced Ti6Al4V Alloy Composite Coatings: Microstructure, Tribological and in-Vitro Biocompatibility. J. Mech. Behav. Biomed. Mater. 2014, 29, 259–271. [Google Scholar] [CrossRef]

- Das, M.; Balla, V.K.; Basu, D.; Manna, I.; Sampath Kumar, T.S.; Bandyopadhyay, A. Laser Processing of in Situ Synthesized TiB–TiN-Reinforced Ti6Al4V Alloy Coatings. Scr. Mater. 2012, 66, 578–581. [Google Scholar] [CrossRef]

- Avila, J.D.; Bandyopadhyay, A. Influence of Boron Nitride on Reinforcement to Improve High Temperature Oxidation Resistance of Titanium. J. Mater. Res. 2019, 34, 1279–1289. [Google Scholar] [CrossRef]

- Zhang, H.; Cui, H.; Man, C.; Liu, F.; Pang, K.; Ma, G.; Chen, H.; Cui, Z. The Tribocorrosion Resistance of TiN+TiB/TC4 Composite Coatings and the Synergistic Strengthening Effects of Multi-Level Reinforcements. Corros. Sci. 2023, 219, 111224. [Google Scholar] [CrossRef]

- Bi, Z.-J.; Liu, K.-C.; Cai, Z.-H.; Chen, T.-H.; Shuai, R.-H.; Zhou, J.; Lou, L.-Y.; Liu, Y.; Wang, H.-D.; Li, C.-X. Influence of Decomposition and Microstructure Evolution of cBN on the Wear Resistance of Ti-Based cBN Composite Coatings Deposited by High-Speed Laser Cladding. J. Therm. Spray Tech. 2025, 34, 1177–1194. [Google Scholar] [CrossRef]

- Zhang, H.; Cui, H.; Liu, F.; Man, C.; Chen, H.; Ma, G.; Cui, Z. Quantitative Study of Corrosion and Wear under Different Constant Tensile Stress of Additively Manufactured Ti-Based Composite Coatings. Corros. Sci. 2024, 239, 112393. [Google Scholar] [CrossRef]

- Sola, A.; Jacob, J.; Kada, S.R.; Wang, J.; Lynch, P.A.; Brodie, E.; Trinchi, A.; Turney, T.W. Grain Refining in Additively Manufactured Titanium Using Boron Nitride Nanosheets. J. Mater. Res. Technol. 2024, 32, 3070–3082. [Google Scholar] [CrossRef]

- Li, B.; Han, C.; Vivegananthan, P.; Kripalani, D.R.; Tian, Y.; Bartolo, P.J.D.S.; Zhou, K. Refined Microstructure and Ultrahigh Mechanical Strength of (TiN + TiB)/Ti Composites in Situ Synthesized via Laser Powder Bed Fusion. Addit. Manuf. Lett. 2022, 3, 100082. [Google Scholar] [CrossRef]

- Li, M.; Huang, J.; Zhu, Y.; Li, Z.; Wu, Y. Growth Morphology and Solidification Behavior of In-Situ Synthesized TiN and TiB. Mater. Trans. 2016, 57, 15–19. [Google Scholar] [CrossRef]

- Liu, N.; Chao, S.; Huang, X. Effects of TiC/TiN Addition on the Microstructure and Mechanical Properties of Ultra-Fine Grade Ti (C, N)–Ni Cermets. J. Eur. Ceram. Soc. 2006, 26, 3861–3870. [Google Scholar] [CrossRef]

- Zhuo, L.; Ji, K.; Lu, J.; Sun, J.; Huo, W.; Shao, H.; Chen, B.; Zhao, Y. Microstructure Characterization and Tensile Performance of a High-Strength Titanium Alloy with in-Situ Precipitates of Ti5Si3. J. Alloys Compd. 2023, 968, 171867. [Google Scholar] [CrossRef]

- Zhang, L.; Wu, J. Ti5Si3 and Ti5Si3-Based Alloys: Alloyingbehavior, Microstructure and Mechanical Property Evaluation. Acta Mater. 1998, 46, 3535–3546. [Google Scholar] [CrossRef]

- Zhang, X.; Peng, C.; Yin, C.; Liu, Y.; Liang, J.; Chen, G.; Chen, R.; Wang, S. Microstructural Evolution and Mechanical Properties in Rapid Sintered Ti5Si3/Ti Matrix Composites with Varying Si Additions. Vacuum 2025, 238, 114240. [Google Scholar] [CrossRef]

- Butz, R.; Rubloff, G.W.; Tan, T.Y.; Ho, P.S. Chemical and Structural Aspects of Reaction at the Ti/Si Interface. Phys. Rev. B 1984, 30, 5421–5429. [Google Scholar] [CrossRef]

- Wang, L.; Huang, Y.; Yuan, Y.; Jia, C.; Yang, L. Microstructure, Wear and Oxidation Resistance of Al-Doped Ti–Si3N4 Coatings by Laser Cladding. Surf. Coat. Technol. 2022, 429, 127942. [Google Scholar] [CrossRef]

- Derakhshandeh, M.R.; Naeini, M.S.; Ghasali, E.; Jam, A.; Fazili, A.; Alizadeh, M.; Kazemzadeh, A.; Ebadzadeh, T. Preparation of In-Situ Formed TiN0.3-Ti5Si3-TiN Composites through Reactive Spark Plasma Sintering of Ti and Si3N4. Ceram. Int. 2019, 45, 6477–6483. [Google Scholar] [CrossRef]

- Akilan, A.A.; Gökçe, A.; Nath, S.D.; Balla, V.K.; Kate, K.H.; Atre, S.V. Laser Powder Bed Fusion of In-Situ Composites Using Dry-Mixed Ti6Al4V and Si3N4 Powder. J. Manuf. Process. 2020, 59, 43–50. [Google Scholar] [CrossRef]

- Gu, D.; Shen, Y.; Lu, Z. Preparation of TiN–Ti5Si3 in-Situ Composites by Selective Laser Melting. Mater. Lett. 2009, 63, 1577–1579. [Google Scholar] [CrossRef]

- Kgoete, F.M.; Popoola, A.P.I.; Fayomi, O.S.I.; Adebiyi, I.D. Influence of Si3N4 on Ti-6Al-4V via Spark Plasma Sintering: Microstructure, Corrosion and Thermal Stability. J. Alloys Compd. 2018, 763, 322–328. [Google Scholar] [CrossRef]

- Singh, H.; Hayat, M.D.; Zhang, H.; Cao, P. The Decomposition of Si3N4 in Titanium and Its Effect on Wear Properties. Wear 2019, 420–421, 87–95. [Google Scholar] [CrossRef]

- Sambasivan, S.; Petuskey, W.T. Phase Chemistry in the Ti-Si-N System: Thermochemical Review with Phase Stability Diagrams. J. Mater. Res. 1994, 9, 2362–2369. [Google Scholar] [CrossRef]

- Ahmad, N.; Sueyoshi, H. Properties of Si3N4–TiN Composites Fabricated by Spark Plasma Sintering by Using a Mixture of Si3N4 and Ti Powders. Ceram. Int. 2010, 36, 491–496. [Google Scholar] [CrossRef]

- Li, J.; Cui, X.; Guan, Y.; Jin, G.; Zheng, W.; Su, W.; Wan, S.; Shi, Z. Analysis of Oxidation Behavior of Laser Cladding SiC-Ti Based Composite Strengthening Coating. Mater. Charact. 2023, 204, 113210. [Google Scholar] [CrossRef]

- Li, J.; Cui, X.; Guan, Y.; Jin, G.; Zheng, W.; Liu, E.; Wan, S.; Shi, Z.; Liu, A. Effect of SiC Content on Microstructural Evolution and Tribology Properties of Laser-Clad TiC-Reinforced Ti-Al-Si Composite Coatings. Mater. Today Commun. 2023, 35, 106019. [Google Scholar] [CrossRef]

- Poletti, C.; Balog, M.; Schubert, T.; Liedtke, V.; Edtmaier, C. Production of Titanium Matrix Composites Reinforced with SiC Particles. Compos. Sci. Technol. 2008, 68, 2171–2177. [Google Scholar] [CrossRef]

- Feng, G.H.; Yang, Y.Q.; Luo, X.; Li, J.; Huang, B.; Chen, Y. Fatigue Properties and Fracture Analysis of a SiC Fiber-Reinforced Titanium Matrix Composite. Compos. Part B Eng. 2015, 68, 336–342. [Google Scholar] [CrossRef]

- Fereiduni, E.; Ghasemi, A.; Elbestawi, M. Selective Laser Melting of Hybrid Ex-Situ/in-Situ Reinforced Titanium Matrix Composites: Laser/Powder Interaction, Reinforcement Formation Mechanism, and Non-Equilibrium Microstructural Evolutions. Mater. Des. 2019, 184, 108185. [Google Scholar] [CrossRef]

- Jiang, T.; Kim, H.S. Simultaneous Improvement in the Hardness and Friction Characteristics of Ti-6Al-4V through Laser Cladding with Nanoscale SiC Particles in an Air Environment. Int. J. Adv. Manuf. Technol. 2021, 116, 1041–1051. [Google Scholar] [CrossRef]

- Chen, C.; Li, W.; Wang, S. Interlayer Laser Cladding SiC Regulates Microstructure and Mechanical Properties of Ti-6Al-4V Arc-Directed Energy Deposited Components. Virtual Phys. Prototyp. 2024, 19, e2399183. [Google Scholar] [CrossRef]

- Wang, H.; Wu, M.; Miao, X.; Jin, X.; Cui, C. TiC In-Situ Strengthening Mechanism and Crack Initiation Mechanism of SiC/TC4 Composite Coatings by Laser Cladding. Ceram. Int. 2024, 50, 52558–52571. [Google Scholar] [CrossRef]

- Li, N.; Xiong, Y.; Xiong, H.; Shi, G.; Blackburn, J.; Liu, W.; Qin, R. Microstructure, Formation Mechanism and Property Characterization of Ti + SiC Laser Cladded Coatings on Ti6Al4V Alloy. Mater. Charact. 2019, 148, 43–51. [Google Scholar] [CrossRef]

- Shalnova, S.A.; Volosevich, D.V.; Sannikov, M.I.; Magidov, I.S.; Mikhaylovskiy, K.V.; Turichin, G.A.; Klimova-Korsmik, O.G. Direct Energy Deposition of SiC Reinforced Ti–6Al–4V Metal Matrix Composites: Structure and Mechanical Properties. Ceram. Int. 2022, 48, 35076–35084. [Google Scholar] [CrossRef]

- Fang, J.; Tan, Y.C.; Yang, Y.; Yi, Y.; Wang, D.; Wei, E.; Zhang, P.; Li, X. Influence of Laser Power on Microstructure and Performance of SiC/Ti Composite Fabricated through Selective Laser Melting. J. Mater. Res. Technol. 2025, 34, 1130–1143. [Google Scholar] [CrossRef]

- Liu, J.; Huo, P.; Bai, P.; Zhao, Z.; Wang, L. High-Temperature Compressive Properties and Microstructural Evolution of in Situ Reacted Nano-SiC Whisker/Ti6Al4V Composites Manufactured by Selective Laser Melting. J. Mater. Res. Technol. 2024, 32, 3161–3168. [Google Scholar] [CrossRef]

- Traxel, K.D.; Bandyopadhyay, A. Selective Laser Melting of Ti6Al4V-B4C-BN in Situ Reactive Composites. J. Mater. Res. Technol. 2022, 18, 2654–2671. [Google Scholar] [CrossRef]

- Feng, Y.; Feng, K.; Yao, C.; Li, Z. Effect of LaB6 Addition on the Microstructure and Properties of (Ti3Al + TiB)/Ti Composites by Laser Cladding. Mater. Des. 2019, 181, 107959. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, L.; Yang, X.; Zhang, T.; Sun, R. Optimization of Microstructure and Properties of Composite Coatings by Laser Cladding on Titanium Alloy. Ceram. Int. 2021, 47, 2230–2243. [Google Scholar] [CrossRef]

- Li, Y.; Su, K.; Bai, P.; Wu, L.; Liu, B.; Su, H.; Du, W. Effect of TiBCN Content on Microstructure and Properties of Laser Cladding Ti/TiBCN Composite Coatings. Met. Mater. Int. 2019, 25, 1366–1377. [Google Scholar] [CrossRef]

- Pu, Y.; Guo, B.; Zhou, J.; Zhang, S.; Zhou, H.; Chen, J. Microstructure and Tribological Properties of in Situ Synthesized TiC, TiN, and SiC Reinforced Ti3Al Intermetallic Matrix Composite Coatings on Pure Ti by Laser Cladding. Appl. Surf. Sci. 2008, 255, 2697–2703. [Google Scholar] [CrossRef]

| Strengthening Mechanism | Formation Reasons | Equation | Reference | ||

|---|---|---|---|---|---|

| Solid Solution Strengthening | Interaction of solute atoms with dislocations. | [46,55] | |||

| [47,48,49,50] | |||||

| [51,52,53,54] | |||||

| Second-phase strengthening | Precipitation Strengthening | Dislocations cut through second-phase particles precipitated from supersaturated solid solutions. | [60,61,62,63] | ||

| [63,64,65] | |||||

| [63,64] | |||||

| Dispersion Strengthening | Dislocations bypass dispersed second-phase particles. | [66,67,68,69,70] | |||

| Grain Refinement Strengthening | Grain refinement and increased number of grain boundaries. | [71,72,73] | |||

| Load Transfer Strengthening | Hard reinforced phase particles for effective load sharing. | [74,75,76] | |||

| [70,77,78,79] | |||||

| Dislocation Strengthening | Mismatch in thermal expansion coefficients and elastic modulus. | [70,80,81,82] | |||

| Method | Material | Laser Power (W) | Scanning Speed (mm/s) | Phase | Hardness | Loss/ Wear Rate | Coefficient of Friction | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Maximum Strain or Elongation (%) | Strengthening Mechanism | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LC | CP-Ti + 5 wt% CNT | 700 | 5 | (α-Ti) + TiC | 382 HV0.5 | 0.50 mm3 | 0.406 | GRS; DPS; LTS | [93,94] | |||

| CP-Ti + 10 wt% CNT | 382 HV0.5 | 0.33 mm3 | 0.313 | |||||||||

| CP-Ti + 15 wt% CNT | 800 HV0.5 | 0.25 mm3 | 0.398 | |||||||||

| CP-Ti + 20 wt% CNT | 1125 HV0.5 | 0.14 mm3 | 0.263 | |||||||||

| LC | TiC + 5 wt% CNT | 2000 | 5–5.83 | Ti + TiC + VC + Al3Ti + Ti3AlC2 | 500–2700 HV0.5 | 0.467 | DDS | [95] | ||||

| DED | TC4 + 10 wt% TiCp | 425 | 5 | (α-Ti) + (β-Ti) + TiC | 420.8 HV0.2 | 0.00786 g | 0.375 | 816.8 | 3.32 | GRS; SSS; LTS; CTE | [96] | |

| TC4 + 20 wt% TiCp | 454.6 HV0.2 | 0.00759 g | 0.367 | 783.5 | 3.06 | |||||||

| TC4 + 30 wt% TiCp | 450 | 490.5 HV0.2 | 0.00689 g | 0.483 | 713.5 | 2.58 | ||||||

| TC4 + 40 wt% TiCp | 552.8 HV0.2 | 0.00600 g | 0.551 | 563.1 | 2.05 | |||||||

| TC4 + 50 wt% TiCp | 730.2 HV0.2 | 0.00461 g | 0.608 | 515.5 | 1.83 | |||||||

| DED | CP-Ti + 0.26 wt% C | 200 | 3 | (α-Ti) + TiC | 222 HV | 0.45 | 420 | 480 | 30 | GRS; SSS; LTS; OWS; CTE | [97] | |

| CP-Ti + 0.43 wt% C | 263 HV | 0.4 | 490 | 510 | 32 | |||||||

| CP-Ti + 0.60 wt% C | 273 HV | 0.26 | 840 | 940 | 19 | |||||||

| CP-Ti + 1.20 wt% C | 285 HV | 0.36 | 610 | 710 | 24 | |||||||

| CP-Ti + 1.60 wt% C | 312 HV | 0.44 | 650 | 760 | 16 | |||||||

| DED | CP-Ti + 1 wt% TiC | 700 | 10 | (α-Ti) + (β-Ti) + TiC | 230 HV0.2 | 1.70 mm3/Nm | 0.51 | 560 | 1.31 | GRS; SSS; LTS | [98] | |

| CP-Ti + 2 wt% TiC | 255 HV0.2 | 1.18 mm3/Nm | 0.50 | 590 | 1.18 | |||||||

| CP-Ti + 3 wt% TiC | 265 HV0.2 | 2.45 mm3/Nm | 0.51 | 616 | 0.79 | |||||||

| CP-Ti + 5 wt% TiC | 250 HV0.2 | 3.43 mm3/Nm | 0.64 | 725 | 0.62 | |||||||

| CP-Ti + 10 wt% TiC | 270 HV0.2 | 5.67 mm3/Nm | 0.62 | 365 | 0.42 | |||||||

| CP-Ti + 15 wt% TiC | 300 HV0.2 | 3.02 mm3/Nm | 0.63 | 355 | 0.25 | |||||||

| DED | TC4 + 2.93 wt% TiC | 1800 | 6 | (α-Ti) + (β-Ti) + TiC | 954 | 1050 | 5.76 | GRS; OWS | [68] | |||

| SLM | TC11 + 0.2 wt% GNP | 280 | 1200 | (α′-Ti) + (β-Ti) + GNP + TiC | 1110 | 1384 | 8.1 | DLS(CET); LTS; GRS; OWS | [99] | |||

| SLM | TC4 + 5.0 vol% TiC | 220 | 600 | (α-Ti) + (α′-Ti) + (β-Ti) + TiC | 1257.40 | 1365.83 | 1.27 | LTS; GRS | [100] | |||

| 900 | 1284.29 | 1424.16 | 1.47 | |||||||||

| 1200 | 1364.42 | 1538.98 | 2.92 | |||||||||

| LPBF | TC4 + 9% volCH4 | 180 | 200 | (α-Ti) + (α′-Ti) + (β-Ti) + TiC + TiAl | 415.76 HV | 2825.43 μm2 | 7.93 | 1176 | 1884 | 23.28 | GRS; DPS, PPS, LTS | [101] |

| TC4 + 19% volCH4 | 200 | 437.09 HV | 2463.51 μm2 | 6.34 | 1251 | 1919 | 21.69 | |||||

| TC4 + 29% volCH4 | 200 | 431.41 HV | 2824.08 μm2 | 8.16 | 1245 | 1718 | 7.71 | |||||

| TC4 + 19% volCH4 | 125 | 415.98 HV | 2928.55 μm2 | 7.82 | 1227 | 1709 | 10.3 | |||||

| 150 | 421.26 HV | 2728.36 μm2 | 5.27 | 1236 | 1834 | 14.86 | ||||||

| 300 | 432.43 HV | 2690.47 μm2 | 7.82 | 1221 | 1843 | 20.63 | ||||||

| 135 | 150 | 421.35 HV | 2875.79 μm2 | 6.14 | 1237 | 1847 | 17.34 | |||||

| 99 | 110 | 415.07 HV | 3030.50 μm2 | 8.15 | 1181 | 1649 | 10.78 |

| Method | Material | Laser Power (W) | Scanning Speed (mm/s) | Phase | Hardness | Loss/ Wear Rate | Coefficient of Friction | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Maximum Strain or Elongation (%) | Strengthening Mechanism | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LC | TC4 + 5 wt% TiB2 | 2400 | 8–10 | (α-Ti) + (β-Ti) + TiB2 + TiB | 500.3 HV0.2 | 0.2949 g/min | LTS; GRS; PPS; SSS | [123] | ||||

| TC4 + 15 wt% TiB2 | 555.3 HV0.2 | 0.1146 g/min | ||||||||||

| TC4 + 25 wt% TiB2 | 635.9 HV0.2 | 0.1078 g/min | ||||||||||

| TC4 + 35 wt% TiB2 | 747.1 HV0.2 | 0.0216 g/min | ||||||||||

| LC | TiB2 | 2950 | 6 | (α-Ti) + (β-Ti) + TiB2 + TiB | 667 HV0.3 | IFS | [124] | |||||

| LC | CP-Ti + 30 vol% TiB2 | 2600 | 7 | (α-Ti) + TiB2 + TiB | 650 HV0.2 | 0.17 mm3 | 0.46 | DDS; DPS; GRS | [125] | |||

| LB | Amorphous B | 1000 | 5 | (α-Ti) + (β-Ti) + TiB2 + TiB + TiB25 + TiO2 | 650 HV0.2 | SPS; DLS; SS | [103] | |||||

| 2500 | 1500 HV0.2 | 0.393 | ||||||||||

| 3000 | 950 HV0.2 | 2.216 mm3/Nm | 0.413 | |||||||||

| DLD | Ti6242 + 2 wt% TiB2 | 2500 | 5 | (α-Ti) + (β-Ti) + TiB | 1024.9 | 1100 | 6.2 | LTS; GRS; IFS; SS | [72] | |||

| Ti6242 + 5 wt% TiB2 | 1285.5 | 1376 | 3.7 | |||||||||

| DED | TC4 + 1.25 vol% TiB | 1500 | 10 | (α-Ti) + (β-Ti) + TiB | 1010 | 1075 | 7.1 | GRS; LTS; DLS; OWS; CTE; SS | [73] | |||

| TC4 + 2.50 vol% TiB | 1095 | 1153 | 6.2 | |||||||||

| TC4 + 5.00 vol% TiB | 1085 | 1174 | 3.5 | |||||||||

| SLM | TC4 + 0.01 wt% TiB2 | 160 | 800 | (α-Ti) + (β-Ti) + TiB | 351.8 HV | GRS; DPS; IFS; DLS; SS | [126] | |||||

| TC4 + 1.0 wt% TiB2 | 372.6 HV | |||||||||||

| TC4 + 3.4 wt% TiB2 | 410.1 HV | |||||||||||

| TC4 + 4.8 wt% TiB2 | 430.8 HV | |||||||||||

| SLM | TC4 + 5 wt% TiB2 | 350 | 972 | (α-Ti) + (β-Ti) + TiB2 + TiB | 580 HV | 45.5 μm | 0.44 | GRS; SPS; SS | [127] | |||

| 530 | 573 HV | 57.3 μm | 0.51 | |||||||||

| 364 | 565 HV | 78.5 μm | 0.64 |

| Method | Material | Laser Power (W) | Scanning Speed (mm/s) | Phase | Hardness | Loss/ Wear Rate | Coefficient of Friction | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Maximum Strain or Elongation (%) | Strengthening Mechanism | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DED | CP-Ti + 12.61 wt% B4C | 1500 | 2 | (α-Ti) + TiB + TiC + TiB2 + B4C | 981.2 HV0.5 | 3.73 × 10−5 mm3/Nm | 0.1685 | SPS; GRS; DLS; SGS | [162] | |||

| LMD | TC4 + 20 wt% B4C | 1000 | 16.67 | (α-Ti) + (β-Ti) + TiB + TiC + TiB2 | 470 HV0.3 | GRS; DPS; DLS; SGS | [163] | |||||

| 1200 | 548 HV0.3 | |||||||||||

| 1400 | 461 HV0.3 | |||||||||||

| LC | CP-Ti + 30 wt% B4C | 450 | 3 | (α-Ti) + (β-Ti) + TiB + TiC + AlTi3 + TiVC2 | 758.0 HV0.2 | 2.31 × 10−1 mm3 | 0.32 | SPS; GRS; SGS | [164] | |||

| 836.4 HV0.2 | 1.44 × 10−1 mm3 | 0.28 | ||||||||||

| 896.1 HV0.2 | 1.02 × 10−1 mm3 | 0.16 | ||||||||||

| 785.9 HV0.2 | 1.61 × 10−1 mm3 | 0.48 | ||||||||||

| DED | CP-Ti + 10 wt% B4C | 350 | 4.23 | Ti + TiB + TiC + TiB2 + B4C + B25C | 300 HV0.2 | 4.4 × 10−4 mm3/Nm | GRS; DPS | [165] | ||||

| CP-Ti + 15 wt% B4C | 500 HV0.2 | 3.9 × 10−4 mm3/Nm | ||||||||||

| CP-Ti + 20 wt% B4C | 1000 HV0.2 | 1.2 × 10−4 mm3/Nm | ||||||||||

| SLM | CP-Ti + 0 wt% B4C | 250 | 1500 | (α-Ti) + TiB + TiC | 205.07 HV0.1 | 499.05 | 582.39 | 26.37 | GRS; DPS; SGS | [166] | ||

| CP-Ti + 1 wt% B4C | 275.06 HV0.1 | 761.77 | 945.99 | 4.75 | ||||||||

| CP-Ti + 2 wt% B4C | 320.18 HV0.1 | 744.66 | 834.14 | 1.19 | ||||||||

| CP-Ti + 3 wt% B4C | 343.08 HV0.1 | 627.96 | 0.56 | |||||||||

| CP-Ti + 5 wt% B4C | 424.83 HV0.1 | |||||||||||

| LPBF | CP-Ti + 0 wt% TiB/TiC | 160 | 1200 | (α-Ti) + (β-Ti) + TiB + TiC | 173.1 HV | 489.1 | 540.7 | 20.9 | GRS; SSS; DPS; LTS; SGS | [69] | ||

| CP-Ti + 2.5 wt% TiB/TiC | 228.4 HV | 668.1 | 803.1 | 11.0 | ||||||||

| CP-Ti + 5 wt% TiB/TiC | 275.9 HV | 777.1 | 940.3 | 6.1 | ||||||||

| CP-Ti + 7.5 wt% TiB/TiC | 298.5 HV | 828.8 | 999.2 | 3.7 | ||||||||

| CP-Ti + 10 wt% TiB/TiC | 309.9 HV | 869.7 | 1059.2 | 2.9 | ||||||||

| DED | TC4 + 0%B4C | 3200 | 12 | (α-Ti) + (β-Ti) + TiB + TiC | 375.7 HV | 0.00044 mm3/Nm | 0.42 | 920 | 1020 | 4.61 | GRS; DPS; SSS; LTS | [134] |

| TC4 + 16.7%B4C | 440.2 HV | 0.00038 mm3/Nm | 0.36 | 1140 | 1200 | 2.27 | ||||||

| TC4 + 25%B4C | 455.2 HV | 0.00036 mm3/Nm | 0.33 | 1160 | 1230 | 2.09 | ||||||

| TC4 + 14.3%B4C + 42.9%C | 478.1 HV | 0.00041 mm3/Nm | 0.37 | 1100 | 1160 | 1.89 | ||||||

| DED | TC4 + 0 wt% B4C | 3300 | 3.33 | (α-Ti) + (β-Ti) + TiB + TiC | 344.0 HV0.5 | 983.3 | 8.2 | LTS; OWS; GRS; SGS | [167] | |||

| TC4 + 5 wt% B4C | 414.0 HV0.5 | 1126.1 | 4.2 | |||||||||

| LPBF | TC4 + 0 wt% B4C | 200 | 1000 | (α-Ti) + (α′-Ti) + (β-Ti) + TiB + TiC | 380 HV | GRS; LTS; OWS; DLS; SSS; SGS | [70] | |||||

| TC4 + 0.2 wt% B4C | 250 | 1000 | 395 HV | |||||||||

| DED | Ti65 + 0.1 wt% B4C | 2000 | 4 | (α-Ti) + (β-Ti) + TiB + TiC | 1024 | 1135 | 11.40 | GRS; LTS; SSS | [168] | |||

| Ti65 + 0.2 wt% B4C | 1048 | 1142 | 10.19 | |||||||||

| Ti65 + 0.3 wt% B4C | 1085 | 1201 | 5.54 | |||||||||

| Ti65 + 0.5 wt% B4C | 1138 | 1155 | 1.28 |

| Method | Material | Laser Power (W) | Scanning Speed (mm/s) | Phase | Hardness | Loss/ Wear Rate | Coefficient of Friction | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Maximum Strain or Elongation (%) | Strengthening Mechanism | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LENS | TC4 + 5 wt% BN | 400 | 10 | (α-Ti) + (β-Ti) + TiB + TiN + BN | 604 HV1.0 | 4.26 × 10−5 mm3/Nm | 0.47 | DPS; SS; GRS; IFS | [178,179] | |||

| 300 | 570 HV1.0 | 8.50 × 10−5 mm3/Nm | 0.48 | |||||||||

| 400 | 20 | 568 HV1.0 | 7.50 × 10−5 mm3/Nm | 0.46 | ||||||||

| 300 | 543 HV1.0 | 1.51 × 10−4 mm3/Nm | 0.44 | |||||||||

| TC4 + 15 wt% BN | 400 | 10 | 877 HV1.0 | 1.90 × 10−6 mm3/Nm | 0.49 | |||||||

| 300 | 765 HV1.0 | 4.50 × 10−6 mm3/Nm | 0.45 | |||||||||

| 400 | 20 | 816 HV1.0 | 6.20 × 10−6 mm3/Nm | 0.49 | ||||||||

| 300 | 733 HV1.0 | 4.80 × 10−6 mm3/Nm | 0.46 | |||||||||

| LENS | CP-Ti + 0 wt% BN | 427 | 12.7 | (α-Ti) + (α′-Ti) + TiB + TiN + TiN0.176 + BN | 256.9 HV0.2 | SSS; SPS; GRS | [180] | |||||

| CP-Ti + 3 wt% BN | 475 | 10.6 | 538.1 HV0.2 | |||||||||

| CP-Ti + 6 wt% BN | 500 | 10.6 | 584.7 HV0.2 | |||||||||

| LC | TC4 + 2 wt% BN | 1600 | 16.7 | (α-Ti) + (β-Ti) + TiB + TiN | 650 HV0.2 | 0.55 | SPS; SSS; PPS; GRS; SGS | [181] | ||||

| TC4 + 4 wt% BN | 850 HV0.2 | 0.65 | ||||||||||

| TC4 + 6 wt% BN | 920 HV0.2 | 0.75 | ||||||||||

| LC | Ti60 + 25 wt% BN | 1500 | 150 | (α-Ti) + (β-Ti) + TiB + TiN + BN | 700 HV0.3 | 6.5 × 10−5 mm2 | 0.55 | SSS; SPS; SGS | [182] | |||

| 200 | 650 HV0.3 | 7.5 × 10−5 mm2 | 0.52 | |||||||||

| 250 | 610 HV0.3 | 7.9 × 10−5 mm2 | 0.54 | |||||||||

| 2000 | 150 | 1100 HV0.3 | 4.4 × 10−5 mm2 | 0.61 | ||||||||

| 200 | 950 HV0.3 | 6.0 × 10−5 mm2 | 0.55 | |||||||||

| 250 | 1000 HV0.3 | 6.1 × 10−5 mm2 | 0.53 | |||||||||

| 2500 | 150 | 1200 HV0.3 | 3.5 × 10−5 mm2 | 0.68 | ||||||||

| 200 | 1100 HV0.3 | 4.1 × 10−5 mm2 | 0.68 | |||||||||

| 250 | 1000 HV0.3 | 6.4 × 10−5 mm2 | 0.66 | |||||||||

| DED | TC4 + 2 wt% BN | 1600 | 10 | (α-Ti) + (β-Ti) + TiB + TiN | 530 HV0.2 | 1.61 × 10−4 mm3/Nm | 0.44 | 888.51 | 4.45 | SPS; SSS; DLS; GRS; SGS | [183] | |

| 2400 | 480 HV0.2 | 1.06 × 10−4 mm3/Nm | 0.41 | 892.16 | 5.81 | |||||||

| LPBF | CP-Ti + 0 vol% BN | (α-Ti) + TiB + TiN | 203.19 HV | 519.8 | GRS; LTS; SSS; SPS; SGS | [184] | ||||||

| CP-Ti + 1.5 vol% BN | 369.45 HV | 508.7 | ||||||||||

| LPBF | CP-Ti + 0.5 wt% BN | 250 | 1500 | (α-Ti) + TiB + TiN + BN | 1020 | 1040 | 3.2 | GRS; DPS; SSS | [185] |

| Method | Material | Laser Power (W) | Scanning Speed (mm/s) | Phase | Hardness | Loss/ Wear Rate | Coefficient of Friction | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Maximum Strain or Elongation (%) | Strengthening Mechanism | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LC | SiC | 60 | 1 | Ti + TiC + Ti5Si3 + TiO2 + SiO2 + SiC | 950 HV | 550 μm | 0.05 | GRS; SPS | [205] | |||

| 3 | 740 HV | 400 μm | 0.09 | |||||||||

| 5 | 600 HV | 200 μm | 0.13 | |||||||||

| DED | TC4 + 17.6 wt% SiC | 500 | 5 | (α-Ti) + (β-Ti) + TiC + Ti5Si3 + SiC | 393.7 HV | 1241.1 | 15.01 | GRS; PPS; SSS; IFS | [206] | |||

| DED + LC | 476.8 HV | 1099.4 | 12.90 | |||||||||

| LC | TC4 + 4 wt% SiC | 1000 | 10 | (α-Ti) + (β-Ti) + TiC + SiC | 648.5 HV0.2 | 3.18 × 10−4 mm3/Nm | 0.585 | SPS; GRS; SS | [207] | |||

| 1300 | 715.5 HV0.2 | 1.99 × 10−4 mm3/Nm | 0.511 | |||||||||

| 1600 | 730.1 HV0.2 | 1.57 × 10−4 mm3/Nm | 0.491 | |||||||||

| 1900 | 691.3 HV0.2 | 2.61 × 10−4 mm3/Nm | 0.538 | |||||||||

| LC | CP-Ti + 10 vol% SiC | 600 | 10 | Ti + TiC + Ti5Si3 | 527.3 HV | 7.5 μm | 0.45 | DPS; IFS; GRS; | [208] | |||

| CP-Ti + 20 vol% SiC | 932.2 HV | 0.35 μm | 0.10 | |||||||||

| SLM | TC4 + 0 wt% SiC | 350 | 1000 | (α-Ti) + (β-Ti) + TiC + Ti5Si3 + Ti3Si | 332 HV | GRS; LTS; SSS; OWS; CTE; DLS; SGS | [133] | |||||

| TC4 + 1.1 wt% SiC | 403 HV | |||||||||||

| TC4 + 2.2 wt% SiC | 429 HV | |||||||||||

| TC4 + 3.3 wt% SiC | 576 HV | |||||||||||

| DED | TC4 + 1 vol% SiC | 1200 | 20 | (α-Ti) + (β-Ti) + TiC + Ti5Si3 + SiC | 450 HV0.3 | 1110 | 1300 | 2.1 | GRS; SPS; IFS | [209] | ||

| TC4 + 3 vol% SiC | 490 HV0.3 | 1030 | 1310 | 0.5 | ||||||||

| TC4 + 5 vol% SiC | 500 HV0.3 | 1010 | 0.2 | |||||||||

| TC4 + 7 vol% SiC | 510 HV0.3 | |||||||||||

| SLM | CP-Ti + 1 wt% SiC | 120 | 1000 | (α-Ti) + TiC + TiSi2 + Ti3Si2 + SiC | 303 HV | 3.19 × 10−11 mm3/Nm | 0.635 | 814 | 955 | 4.4 | PPS; DPS; GRS; DLS; IFS; LTS; SGS | [210] |

| 140 | 344 HV | 3.07 × 10−11 mm3/Nm | 0.615 | 939 | 1097 | 11.5 | ||||||

| 160 | 289 HV | 3.50 × 10−11 mm3/Nm | 0.629 | 915 | 1062 | 12.9 | ||||||

| SLM | CP-Ti + 0 wt% SiC | 150 | 20 | (α-Ti) + Ti5Si3 | 466 VHN | 3 × 10−4 mm3/Nm | OWS; DLS; CTE; LTS; GRS; SSS; SS; SGS | [79] | ||||

| CP-Ti + 1 wt% SiC | 588 VHN | |||||||||||

| CP-Ti + 2.5 wt% SiC | 617 VHN | |||||||||||

| CP-Ti + 5 wt% SiC | 706 VHN | 9 × 10−5 mm3/Nm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, M.; Jiang, B.; Duan, X.; Xiang, D. Research Progress on Microstructure, Mechanical Properties, and Strengthening Mechanisms of In Situ-Synthesized Ceramic-Reinforced Titanium Matrix Composite Coatings via Laser Cladding. Coatings 2025, 15, 815. https://doi.org/10.3390/coatings15070815

Wen M, Jiang B, Duan X, Xiang D. Research Progress on Microstructure, Mechanical Properties, and Strengthening Mechanisms of In Situ-Synthesized Ceramic-Reinforced Titanium Matrix Composite Coatings via Laser Cladding. Coatings. 2025; 15(7):815. https://doi.org/10.3390/coatings15070815

Chicago/Turabian StyleWen, Min, Boqiang Jiang, Xianyin Duan, and Dingding Xiang. 2025. "Research Progress on Microstructure, Mechanical Properties, and Strengthening Mechanisms of In Situ-Synthesized Ceramic-Reinforced Titanium Matrix Composite Coatings via Laser Cladding" Coatings 15, no. 7: 815. https://doi.org/10.3390/coatings15070815

APA StyleWen, M., Jiang, B., Duan, X., & Xiang, D. (2025). Research Progress on Microstructure, Mechanical Properties, and Strengthening Mechanisms of In Situ-Synthesized Ceramic-Reinforced Titanium Matrix Composite Coatings via Laser Cladding. Coatings, 15(7), 815. https://doi.org/10.3390/coatings15070815