Lightweight and High-Performance Electromagnetic Wave Absorbers Based on Hollow Glass Microspheres and Carbon-Supported Ni-Co Composites

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

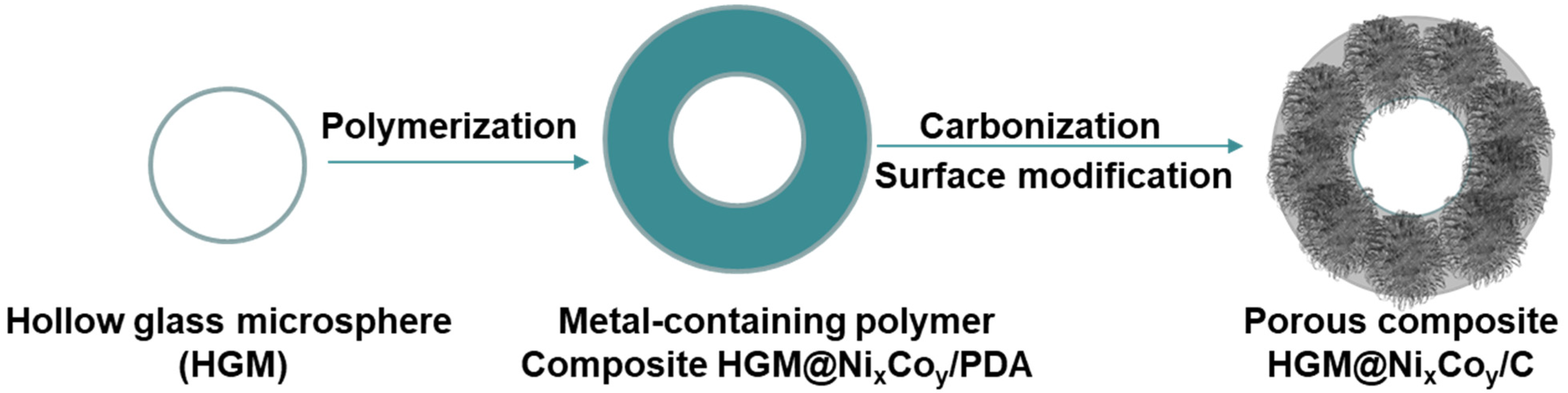

2.2. Preparation of HGM@Ni2Co3/C Composite

2.3. Testing Instruments and Testing Details

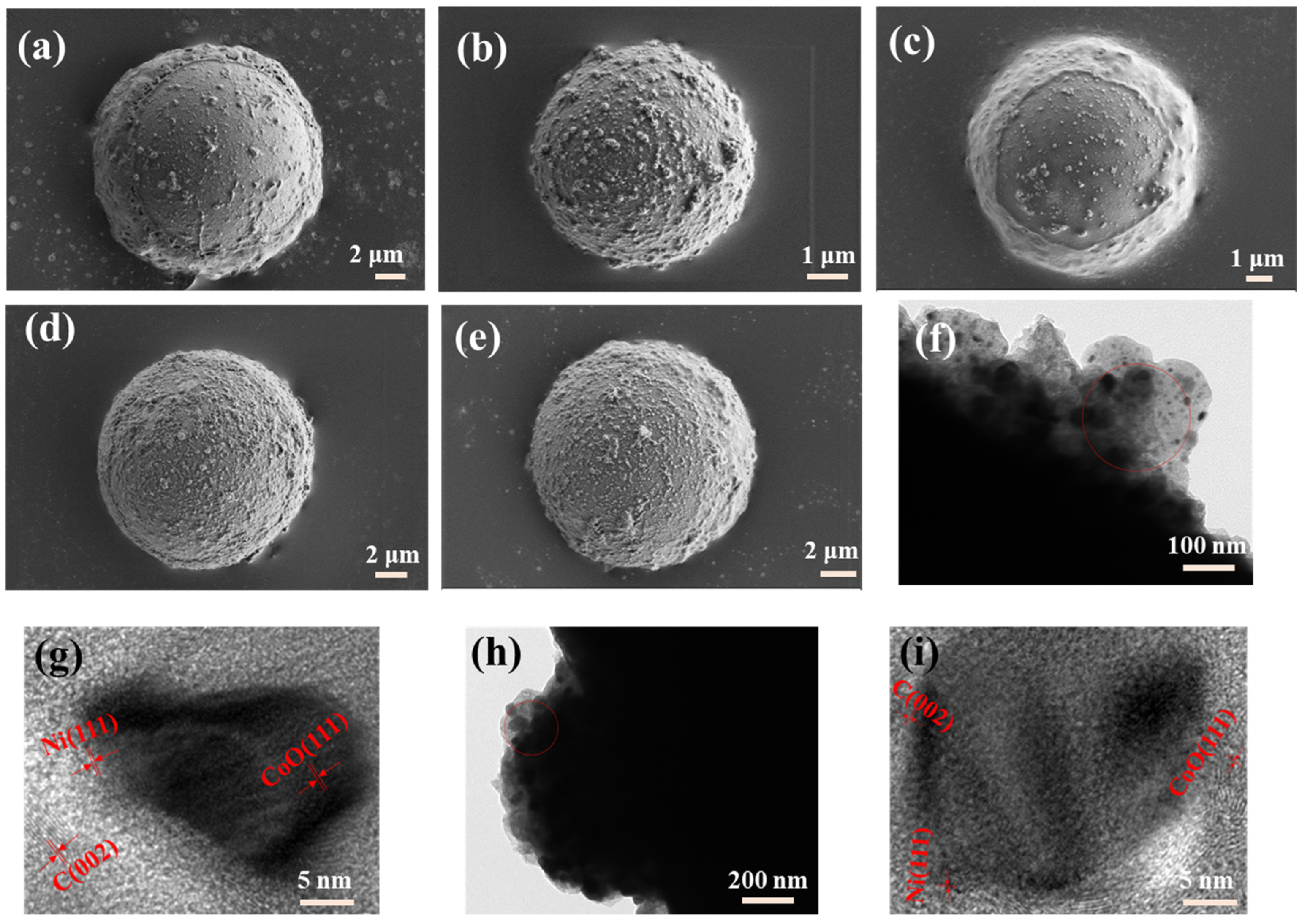

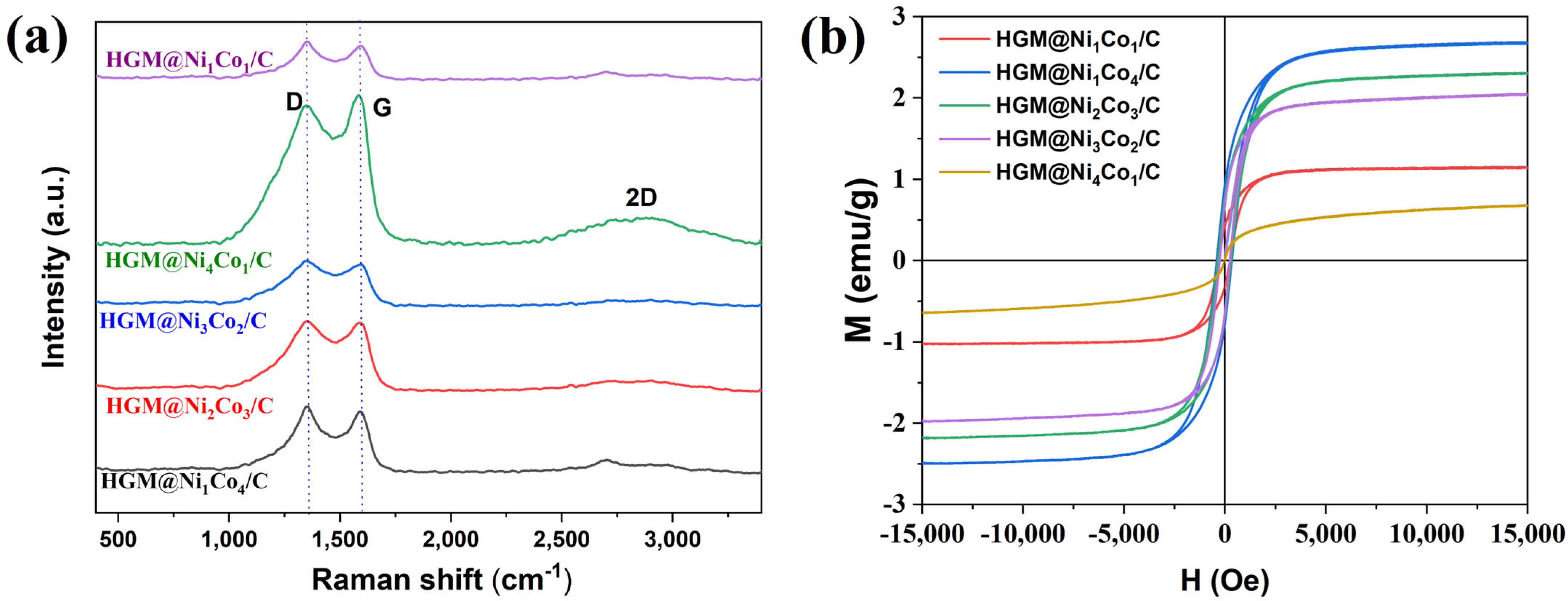

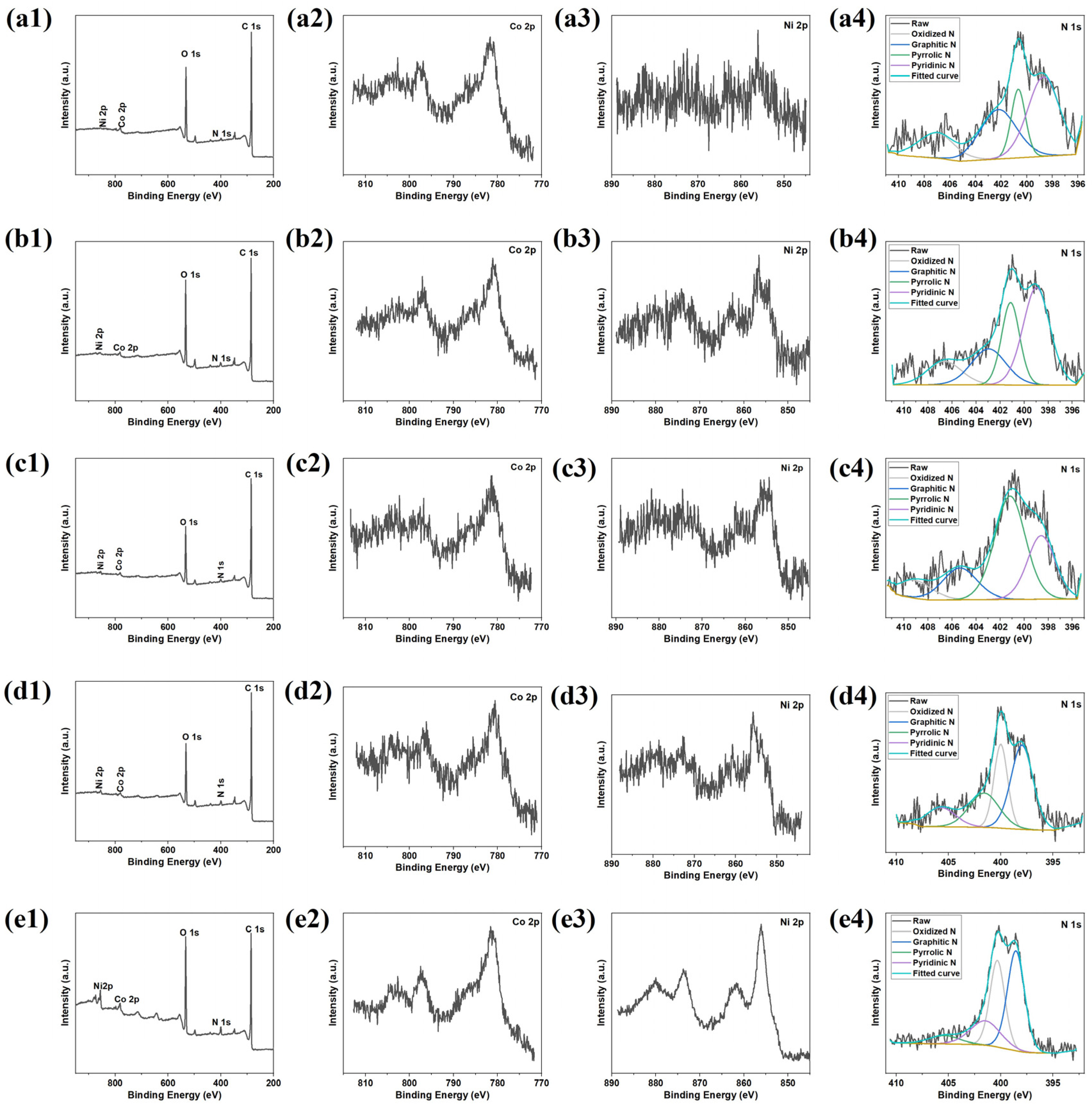

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shin, J.; Oh, J. The microwave absorbing phenomena of ferrite microwave absorbers. IEEE Trans. Magn. 1993, 29, 3437–3439. [Google Scholar] [CrossRef]

- Adam, J.D.; Davis, L.E.; Dionne, G.F.; Schloemann, E.F.; Stitzer, S.N. Ferrite devices and materials. IEEE Trans. Microw. Theory Tech. 2002, 50, 721–737. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, L.; Jian, M.; Liu, Y. Recent research progress of ferrite multielement microwave absorbing composites. Adv. Eng. Mater. 2022, 24, 2200526. [Google Scholar] [CrossRef]

- Beatrice, C.; Tsakaloudi, V.; Dobák, S.; Zaspalis, V.; Fiorillo, F. Magnetic losses versus sintering treatment in Mn-Zn ferrites. J. Magn. Magn. Mater. 2017, 429, 129–137. [Google Scholar] [CrossRef]

- Phor, L.; Kumar, V. Structural, magnetic and dielectric properties of lanthanum substituted Mn0.5Zn0.5Fe2O4. Ceram. Int. 2019, 45, 22972–22980. [Google Scholar] [CrossRef]

- Zhang, X.-H.; Wei, C.-Y.; Zha, L.-L.; Chen, J.-W.; Wang, J.-W.; Yu, H.-L.; Wu, J.-H. Facile One-Pot Synthesis of Polypyrrole-Coated Magnetic Montmorillonite for Enhanced Microwave Absorption and Sunlight-Induced Heat Generation. J. Alloys Compd. 2024, 971, 172676. [Google Scholar] [CrossRef]

- Murugesan, C.; Md Gazzali, P.; Sathyamoorthy, B.; Chandrasekaran, G. Dielectric properties of Mn0.5Zn0.5Fe2O4 ferrite nanoparticles. In Proceedings of the 57th DAE Solid State Physics Symposium 2012, Mumbai, India, 3–7 December 2012; American Institute of Physics: Melville, NY, USA; pp. 314–315. [Google Scholar]

- Cui, X.; Ruan, Q.; Zhuo, X.; Xia, X.; Hu, J.; Fu, R.; Li, Y.; Wang, J.; Xu, H. Photothermal Nanomaterials: A Powerful Light-to-Heat Converter. Chem. Rev. 2023, 123, 6891–6952. [Google Scholar] [CrossRef]

- Wu, Z.; Yang, Z.; Jin, C.; Zhao, Y.; Che, R. Accurately Engineering 2D/2D/0D Heterojunction In Hierarchical Ti3C2Tx MXene Nanoarchitectures for Electromagnetic Wave Absorption and Shielding. ACS Appl. Mater. Interfaces 2021, 13, 5866–5876. [Google Scholar] [CrossRef]

- Liu, M.; Jiang, W.; Jiang, X.; Yu, L. Nitrogen-doped lychee-like saccharide-based carbon microspheres with high-performance microwave absorption. Diam. Relat. Mater. 2024, 142, 110725. [Google Scholar] [CrossRef]

- Liu, J.T.; Zheng, Y.C.; Hou, X.; Feng, X.-R.; Jiang, K.; Wang, M. Constructing magnetic metal doping carbon micro-particles with columnar structure via carbonization of waste masks for microwave absorption. Polymer 2024, 294, 126739. [Google Scholar] [CrossRef]

- Li, H.; Wei, M.; Song, Y.; Wang, R.; Liu, F.; Liu, F. Design and optimization of double-layer structure for improved electromagnetic wave absorbing characteristic of single-layer foam cement-based materials containing carbon black. J. Build. Eng. 2024, 89, 109319. [Google Scholar] [CrossRef]

- Liu, G.-H.; Wei, C.-Y.; Huang, T.; Wang, F.; Chang, J.-F.; Sun, Q.; Zhang, X.-H. Metal-catalyzed carbon foams synthesized from glucose as highly efficient electromagnetic absorbers. Materials 2024, 17, 3488. [Google Scholar] [CrossRef] [PubMed]

- Ye, C.; Zhang, W.; Liu, Y. Supporting B–TiO2 on iM16K glass bubbles to prepare B–TiO2 (x%)/iM16K hollow spheres for ofloxacin degradation. Ceram. Int. 2020, 46, 10545–10554. [Google Scholar] [CrossRef]

- Hak, A. Weight Reduction Solution by Glass Bubbles. Auto Tech Rev. 2013, 2, 50–53. [Google Scholar] [CrossRef]

- He, Z.; Qi, S.; Zhong, X.; Oiu, H.; Wang, J. Preparation and microwave absorbing properties of hollow glass microspheres/Fe3O4/Ag composites with core-shell structure. J. Mater. Sci. Mater. Electron. 2014, 25, 3455–3460. [Google Scholar] [CrossRef]

- Zhang, X.H.; Liu, J.J.; Zha, L.L.; Chen, J.W.; Chen, B.; Wu, J.H.; Yu, H.L. Graphene-doped high-efficiency absorbing material: C-Mn0.5Zn0.5Fe2O4@PDA. J. Mater. Sci. Mater. Electron. 2021, 32, 26189–26201. [Google Scholar] [CrossRef]

- Zha, L.-L.; Zhang, X.-H.; Wu, J.-H.; Liu, J.-J.; Lan, J.-F.; Yang, Y.; Wu, B. Enhanced electromagnetic wave absorption based on Ti3C2Tx loaded nickel nanoparticles via polydopamine connection. Ceram. Int. 2023, 49, 20672–20681. [Google Scholar] [CrossRef]

- Jiao, L.; Zhu, J.; Zhang, Y.; Yang, W.; Zhou, S.; Li, A.; Xie, C.; Zheng, X.; Zhou, W.; Yu, S.-H.; et al. Non-Bonding Interaction of Neighboring Fe and Ni Single-Atom Pairs on MOF-Derived N-Doped Carbon for Enhanced CO2 Electroreduction. J. Am. Chem. Soc. 2021, 143, 19417–19424. [Google Scholar] [CrossRef]

- Duan, Y.; Wang, L.; Zhang, J.; Sun, C.; Wen, R.; Dou, M. Surface Engineering Route to Non-pyrolysis MOFs with High-Density Co–Nx Sites and 3D Conductive Networks for Efficient Oxygen Reduction. ACS Appl. Energy Mater. 2023, 6, 3244–3250. [Google Scholar] [CrossRef]

- Kim, T.K.; Lee, K.J.; Cheon, J.Y.; Lee, J.H.; Joo, S.H.; Moon, H.R. Nanoporous Metal Oxides with Tunable and Nanocrystalline Frameworks via Conversion of Metal–Organic Frameworks. J. Am. Chem. Soc. 2013, 135, 8940–8946. [Google Scholar] [CrossRef]

- Tan, P.; Li, G.; Fang, R.; Chen, L.; Luque, R.; Li, Y. Controlled Growth of Monodisperse Ferrite Octahedral Nanocrystals for Biomass-Derived Catalytic Applications. ACS Catal. 2017, 7, 2948–2955. [Google Scholar] [CrossRef]

- Zhang, Z.-Q.; Tsai, C.-C.; Li, B.-H.; Lin, C.-H.; Lee, S. Impact of hydrofluoric acid treatment on the composition, electrical conductivity, and structure of carbonized metal–organic frameworks. J. Chin. Chem. Soc. 2022, 69, 66–72. [Google Scholar] [CrossRef]

- Liu, T.; Zhang, L.Y.; You, W.; Yu, J.G. Core-Shell Nitrogen-Doped Carbon Hollow Spheres/Co3O4 Nanosheets as Advanced Electrode for High-Performance Supercapacitor. Small 2018, 14, 1702407. [Google Scholar] [CrossRef] [PubMed]

- Qin, M.; Zhang, L.M.; Zhao, X.R.; Wu, H.J. Defect Induced Polarization Loss in Multi-Shelled Spinel Hollow Spheres for Electromagnetic Wave Absorption Application. Adv. Sci. 2021, 8, 2004640. [Google Scholar] [CrossRef] [PubMed]

- Gong, W.; Li, H.; Zhao, Z.; Chen, J. Ultrafine particles of Fe, Co, and Ni ferromagnetic metals. J. Appl. Phys. 1991, 69, 5119–5121. [Google Scholar] [CrossRef]

- Si, W.; Liao, Q.; Hou, W.; Chen, L.; Li, X.; Zhang, Z.; Sun, M.; Song, Y.; Qin, L. Low-Frequency Broadband Absorbing Coatings Based on MOFs: Design, Fabrication, Microstructure and Properties. Coatings 2022, 12, 766. [Google Scholar] [CrossRef]

- Liu, N.; Dou, Y.; Zhang, X.; Yu, L.; Yan, X. Design of porous FeNi-carbon nanosheets by a double-effect synergistic strategy for electromagnetic wave absorption. Carbon 2022, 190, 125–135. [Google Scholar] [CrossRef]

- Shu, R.; Wu, Y.; Zhang, J.; Wan, Z.; Li, X. Facile synthesis of nitrogen-doped cobalt/cobalt oxide/carbon/reduced graphene oxide nanocomposites for electromagnetic wave absorption. Compos. Part B Eng. 2020, 193, 108027. [Google Scholar] [CrossRef]

- Li, C.; Sui, J.; Zhang, Z.; Jiang, X.; Zhang, Z.; Yu, L. Microwave-assisted synthesis of tremella-like NiCo/C composites for efficient broadband electromagnetic wave absorption at 2–40 GHz. Chem. Eng. J. 2019, 375, 122017. [Google Scholar] [CrossRef]

- Feng, X.; Huang, Y.; Li, C.; Chen, X.; Zhou, S.; Gao, X.; Chen, C. Controllable synthesis of porous NiCo2O4/NiO/Co3O4 nanoflowers for asymmetric all-solid-state supercapacitors. Chem. Eng. J. 2019, 368, 51–60. [Google Scholar] [CrossRef]

- Li, S.; Duan, Y.; Teng, Y.; Fan, N.; Huo, Y. MOF-derived tremelliform Co3O4/NiO/Mn2O3 with excellent capacitive performance. Appl. Surf. Sci. 2019, 478, 247–254. [Google Scholar] [CrossRef]

- Wang, F.; Wang, N.; Han, X.; Liu, D.; Wang, Y.; Cui, L.; Xu, P.; Du, Y. Core-shell FeCo@carbon nanoparticles encapsulated in polydopamine-derived carbon nanocages for efficient microwave absorption. Carbon 2019, 145, 701–711. [Google Scholar] [CrossRef]

- Ze, Q.; Kuang, X.; Wu, S.; Wong, J.; Montgomery, S.M.; Zhang, R.; Kovitz, J.M.; Yang, F.; Qi, H.J.; Zhao, R. Magnetic Shape Memory Polymers with Integrated Multifunctional Shape Manipulation. Adv. Mater. 2020, 32, e1906657. [Google Scholar] [CrossRef]

- Yu, K.; Zeng, M.; Yin, Y.; Zeng, X.; Liu, J.; Li, Y.; Tang, W.; Wang, Y.; An, J.; He, J.; et al. MWCNTs as conductive network for monodispersed Fe3O4 nanoparticles to enhance the wave absorption performances. Adv. Eng. Mater. 2018, 20, 1700543. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Y.; Qin, G. Break Snoek limit via superparamagnetic coupling in Fe3O4/silica multiple-core/shell nanoparticles. Appl. Phys. Lett. 2015, 106, 033105. [Google Scholar] [CrossRef]

- Wang, J.; Cui, Y.; Wu, F.; Shah, T.; Ahmad, M.; Zhang, A.; Zhang, Q.; Zhang, B. Core-shell structured Fe/Fe3O4@TCNFs@TiO2 magnetic hybrid nanofibers: Preparation and electromagnetic parameters regulation for enhanced microwave absorption. Carbon 2020, 165, 275–285. [Google Scholar] [CrossRef]

- Zhao, L.; Guo, Y.; Xie, Y.; Cheng, T.; Meng, A.; Yuan, L.; Zhao, W.; Sun, C.; Li, Z.; Zhang, M. Construction of SiCNWS@NiCo2O4@PANI 1D hierarchical nanocomposites toward high-efficiency microwave absorption. Appl. Surf. Sci. 2022, 592, 153324. [Google Scholar] [CrossRef]

- Cheng, S.; Zhang, C.; Wang, H.; Ye, J.; Li, Y.; Zhuang, Q.; Dong, W.; Xie, A. Carbon nanofilm stabilized twisty V2O3 nanorods with enhanced multiple polarization behavior for electromagnetic wave absorption application. J. Mater. Sci. Technol. 2022, 119, 37–44. [Google Scholar] [CrossRef]

- Cheng, S.; Xie, A.; Pan, X.; Zhang, K.; Zhang, C.; Lin, X.; Dong, W. Modulating surficial oxygen vacancy of the VO2 nanostructure to boost its electromagnetic absorption performance. J. Mater. Chem. C 2021, 9, 9158–9168. [Google Scholar] [CrossRef]

- Shu, R.; Zhang, G.; Zhang, J.; Wang, X.; Wang, M.; Gan, Y.; Shi, J.; He, J. Synthesis and high-performance microwave absorption of reduced graphene oxide/zinc ferrite hybrid nanocomposite. Mater. Lett. 2018, 215, 229–232. [Google Scholar] [CrossRef]

- Guo, R.D.; Su, D.; Chen, F.; Cheng, Y.Z.; Wang, X.; Gong, R.Z.; Luo, H. Hollow Beaded Fe3C/N-Doped Carbon Fibers toward Broadband Microwave Absorption. ACS Appl. Mater. Interfaces 2022, 14, 3084–3094. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W.J.; Liu, N.; Li, C.P.; Yu, L.M.; Zhang, Z.M.; Li, C.C.; Yan, X.F. Electromagnetic wave absorption of inexpensive C/ZnO composites derived from zinc-based acrylate resins. Ceram. Int. 2021, 47, 27002–27011. [Google Scholar] [CrossRef]

- Zhou, W.J.; Liu, F.B.; Ge, Y.Q.; Yu, L.M.; Zhang, Z.M.; Li, C.C.; Yan, X.F. Lightweight N-doped C/ZnO composites prepared from zinc-based acrylate resin precursors for electromagnetic wave absorption at 2–18 GHz. J. Alloys Compd. 2022, 896, 162810. [Google Scholar] [CrossRef]

- Sun, Q.; Ji, Y.; He, L.; Long, X. In situ formation of Fe3O4/N-doped carbon coating on the surface of carbon fiber with improved electromagnetic wave-absorption property. RSC Adv. 2020, 10, 30443–30450. [Google Scholar] [CrossRef]

- Zhang, X.H.; Zha, L.L.; Chen, J.W.; Wei, C.Y.; Wu, B.; Wang, J.W.; Yu, H.L.; Wu, J.H.; Yan, X.F. N-doped composites prepared from ferro-based acrylate resin precursors for electromagnetic wave absorption. Mater. Today Commun. 2022, 33, 104678. [Google Scholar] [CrossRef]

| Sample | HGM | 10.5 mmol/L NiCl2 | 10.5 mmol/L CoCl2 |

|---|---|---|---|

| HGM@Ni1Co1/PDA | 0.5 g | 20 mL | 20 mL |

| HGM@Ni1Co4/PDA | 0.5 g | 8 mL | 32 mL |

| HGM@Ni2Co3/PDA | 0.5 g | 16 mL | 24 mL |

| HGM@Ni3Co2/PDA | 0.5 g | 24 mL | 16 mL |

| HGM@Ni4Co1/PDA | 0.5 g | 32 mL | 8 mL |

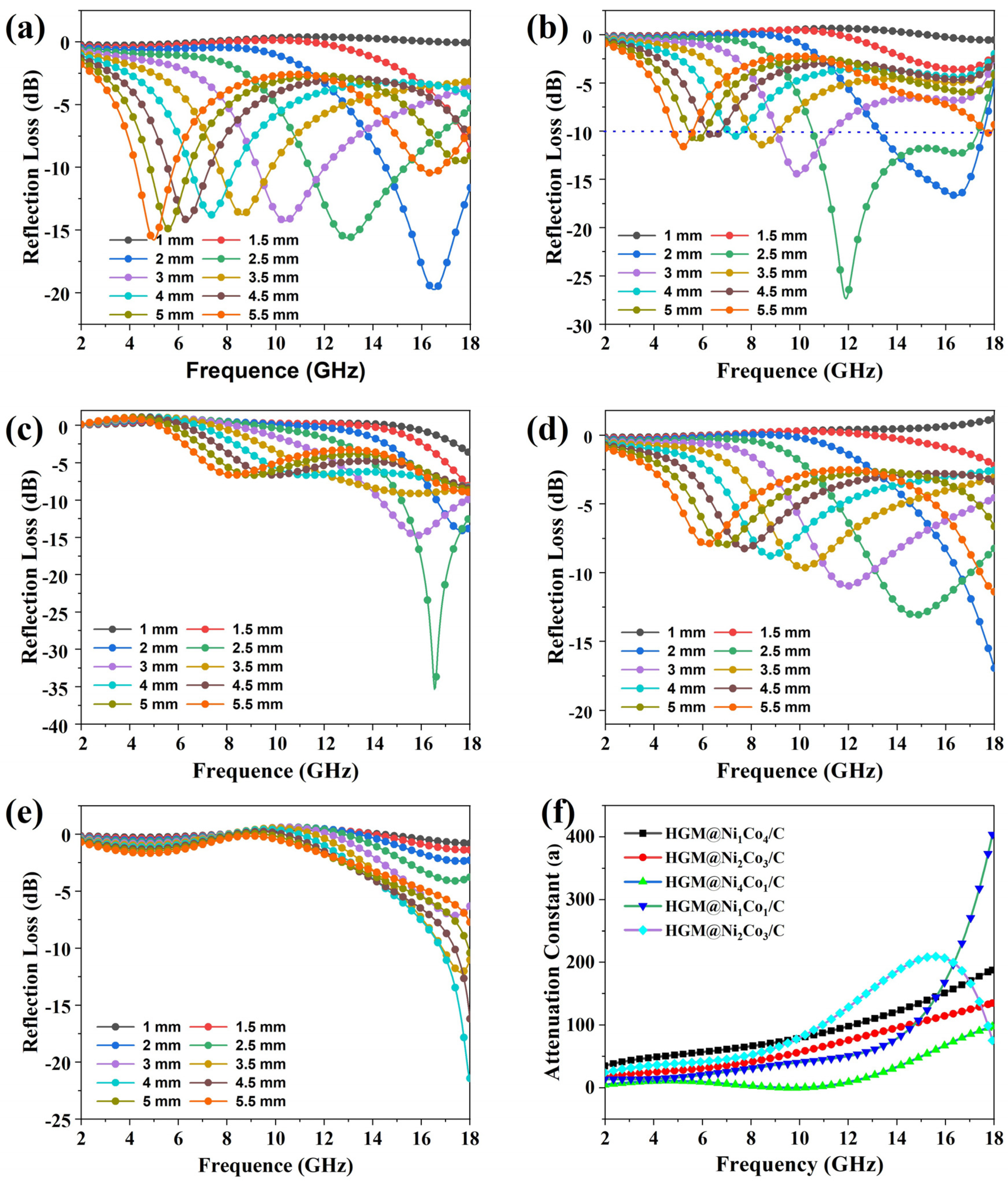

| Samples | Thickness/mm | EAB/GHz | RLmin/−dB |

|---|---|---|---|

| HGM@Ni4Co1/C | 4.0 | 2.00 (16.00–18.00) | −21.47 (18.00) |

| HGM@Ni3Co2/C | 2.5 | 3.85 (13.16–17.01) | −13.16 (14.73) |

| HGM@Ni1Co1/C | 2.5 | 2.84 (15.16–18.00) | −35.22 (16.56) |

| HGM@Ni2Co3/C | 2.5 | 6.83 (10.53–17.36) | −27.26 (11.90) |

| HGM@Ni1Co4/C | 2.0 | 3.45 (14.55–18.00) | −19.73 (16.51) |

| Samples | Thickness mm | /-dB (Corresponding Frequency GHz) | Frequency Range/GHz | EAB/GHz | Ref. |

|---|---|---|---|---|---|

| MMT/Fe3O4/PPy | 3.5 | 41.35 (11.52) | 6.47–15.39 | 8.92 | [6] |

| Mn0.5Zn0.5Fe2O4 | 3.0 | 32.46 (15.72) | 14.81–17.39 | 2.59 | [17] |

| C-Mn0.5Zn0.5Fe2O4@PDA | 2.0 | 17.57 (13.17) | 11.70–17.06 | 5.36 | [17] |

| Ni/NC@Ti3C2Tx-2 | 1.5 | 20.60 (15.20) | 13.20–17.85 | 4.65 | [18] |

| RGO/ZnFe2O4 | 2.0 | ~35.0 (12.0) | 10.80–14.00 | 3.20 | [41] |

| Fe3C/N-Doped Carbon Fibers | 2.16 | ~18.0 (14.8) | 12.72–18.00 | 5.28 | [42] |

| C/ZnO composites | 1.5 | 24.83 (16.72) | 14.39–18.00 | 3.61 | [43] |

| N/ZnO0.064-900 | 3.0 | 43.15 (9.68) | 8.61–11.40 | 3.51 | [44] |

| Fe3O4/N-doped carbon/carbon fiber | 3.0 | 31.38 (15.50) | 9.36–18.00 | 8.64 | [45] |

| Fe-3SM-9AN | 2.0 | 36.70 (11.41) | 9.93–18.00 | 8.07 | [46] |

| HGM@Ni2Co3/C | 2.5 | 27.26 (11.90) | 10.53–17.36 | 6.83 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Q.; Li, S.; Jin, L.; Xiao, J.; Wulin, T.; Hou, X.; Zhang, X. Lightweight and High-Performance Electromagnetic Wave Absorbers Based on Hollow Glass Microspheres and Carbon-Supported Ni-Co Composites. Coatings 2025, 15, 775. https://doi.org/10.3390/coatings15070775

Sun Q, Li S, Jin L, Xiao J, Wulin T, Hou X, Zhang X. Lightweight and High-Performance Electromagnetic Wave Absorbers Based on Hollow Glass Microspheres and Carbon-Supported Ni-Co Composites. Coatings. 2025; 15(7):775. https://doi.org/10.3390/coatings15070775

Chicago/Turabian StyleSun, Qian, Song Li, Longlong Jin, Jingyao Xiao, Tuoya Wulin, Xianbin Hou, and Xianhui Zhang. 2025. "Lightweight and High-Performance Electromagnetic Wave Absorbers Based on Hollow Glass Microspheres and Carbon-Supported Ni-Co Composites" Coatings 15, no. 7: 775. https://doi.org/10.3390/coatings15070775

APA StyleSun, Q., Li, S., Jin, L., Xiao, J., Wulin, T., Hou, X., & Zhang, X. (2025). Lightweight and High-Performance Electromagnetic Wave Absorbers Based on Hollow Glass Microspheres and Carbon-Supported Ni-Co Composites. Coatings, 15(7), 775. https://doi.org/10.3390/coatings15070775