Study on the Damage Evolution Mechanism of FRP-Reinforced Concrete Subjected to Coupled Acid–Freeze Erosion

Abstract

1. Introduction

2. Test Introduction

2.1. Test Block and Erosion Environment

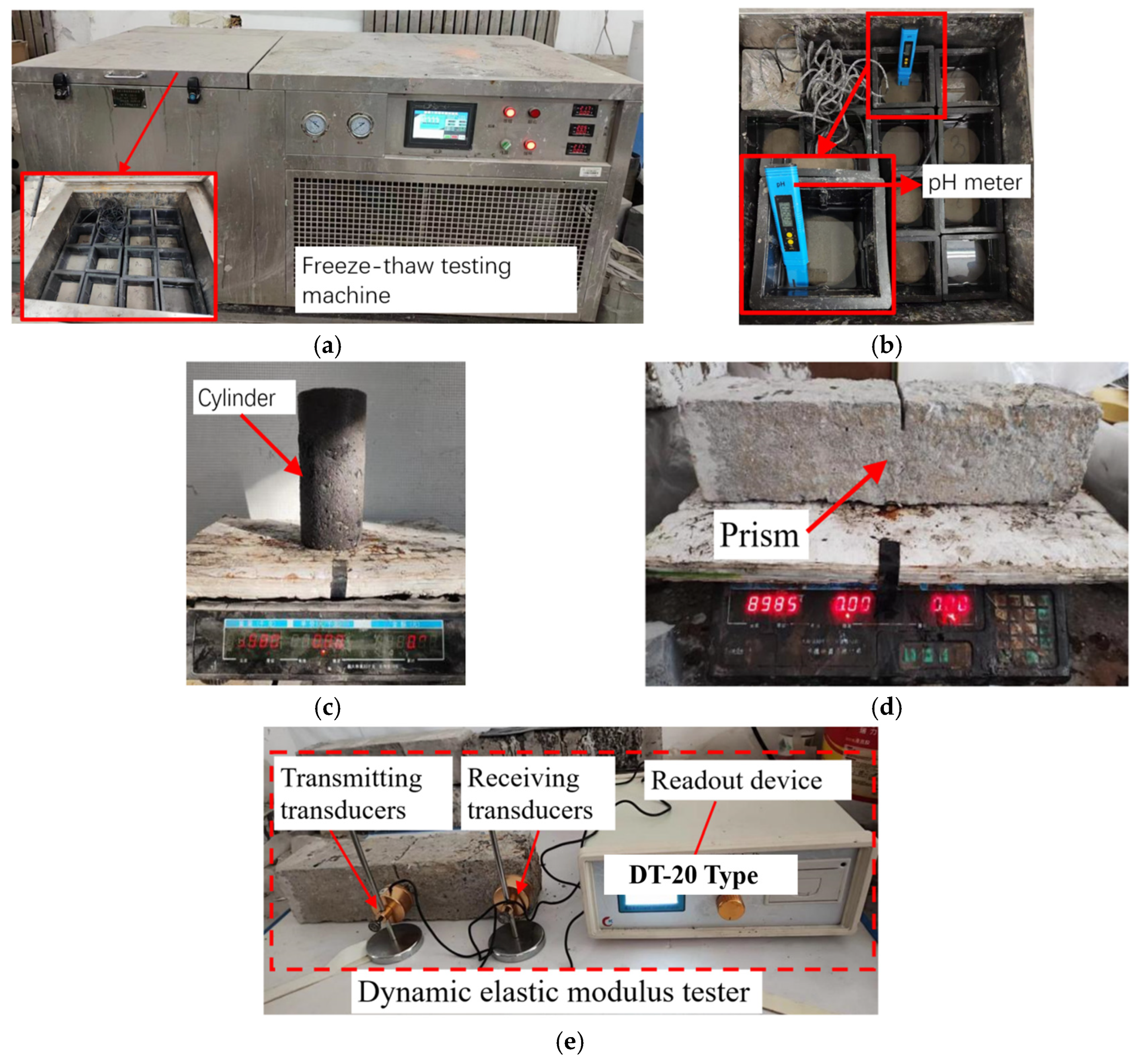

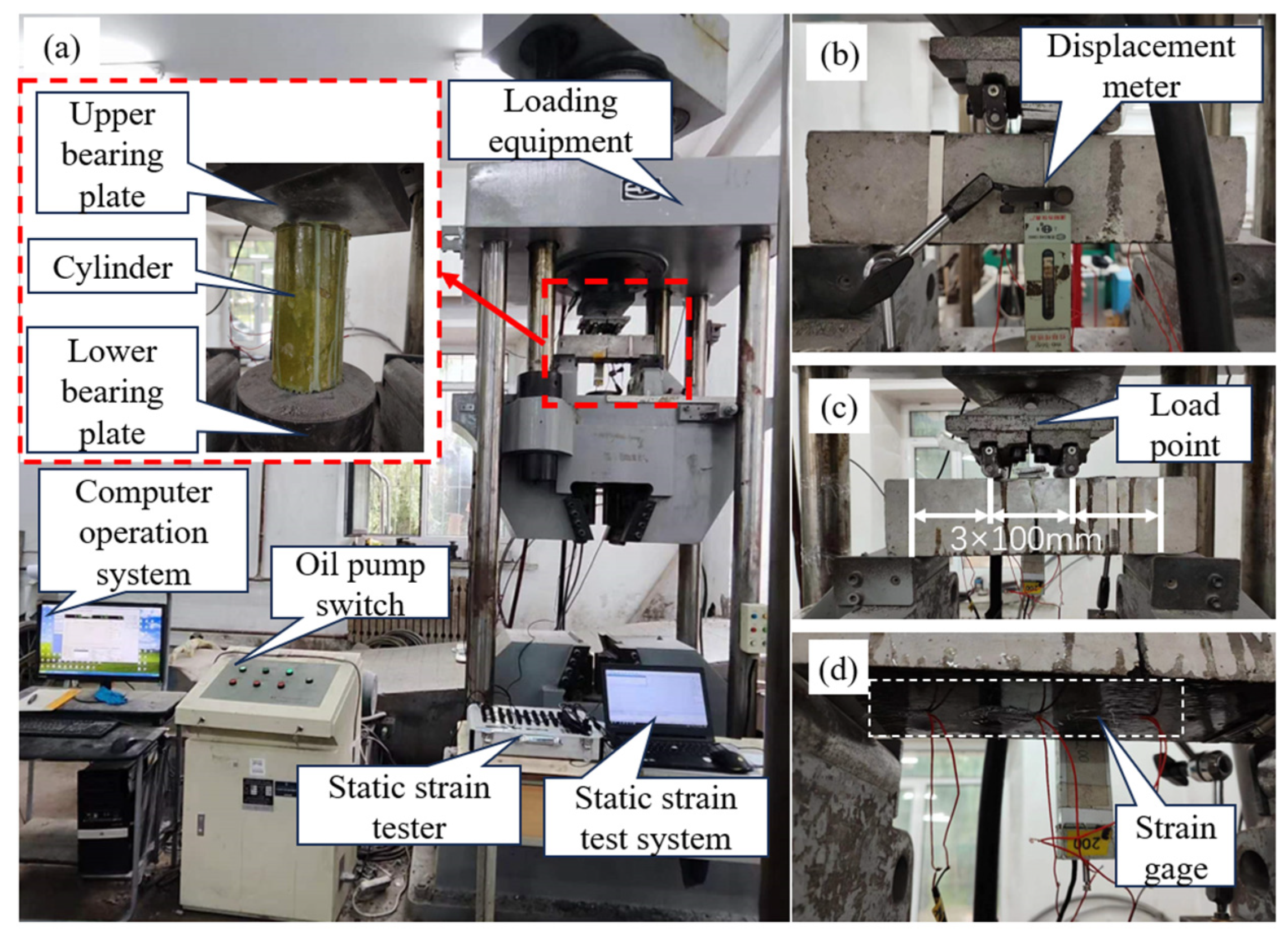

2.2. pH Value, Mass Loss, Relative Dynamic Modulus of Elasticity

2.3. Mechanical Test

3. Analysis of Test Results

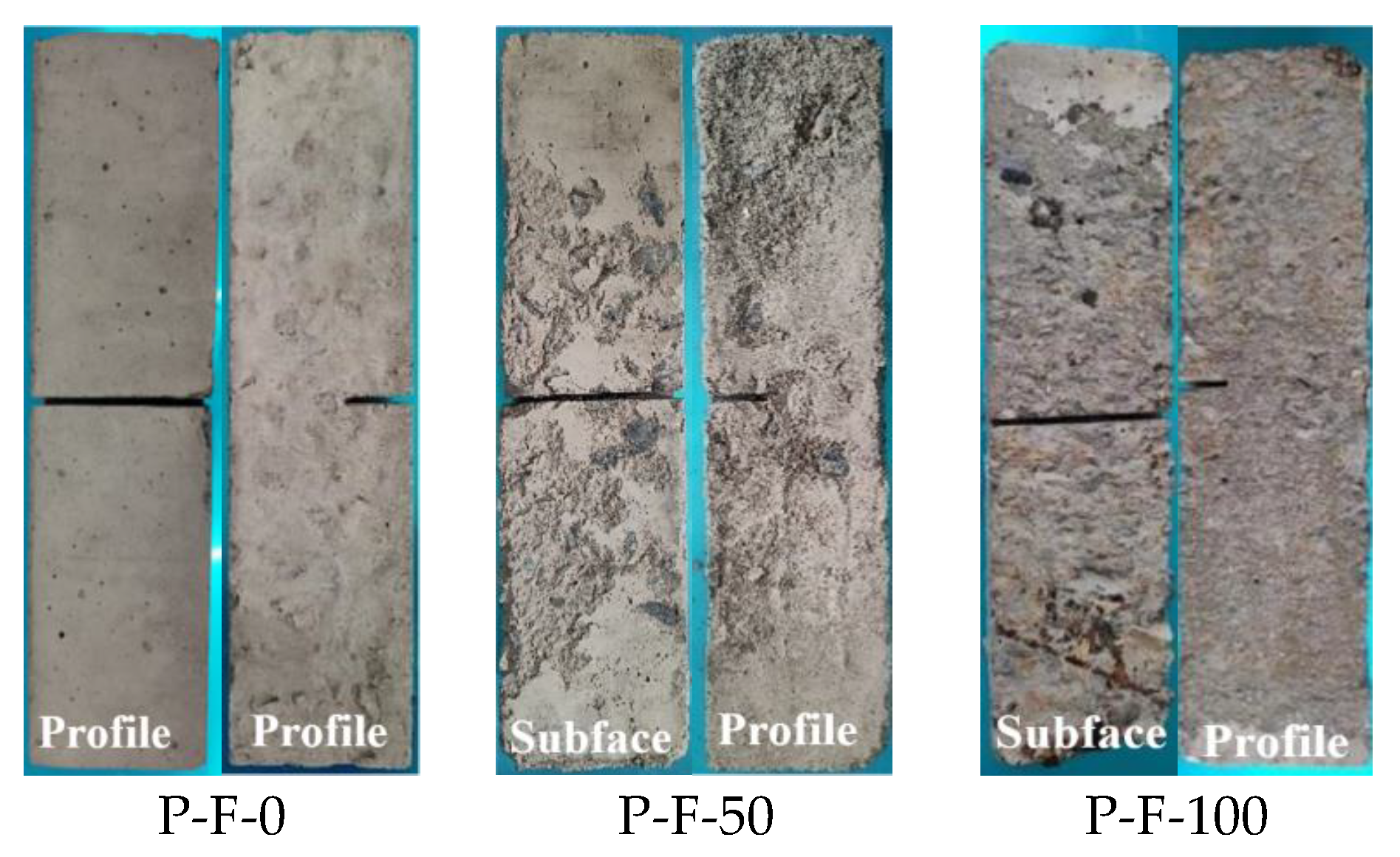

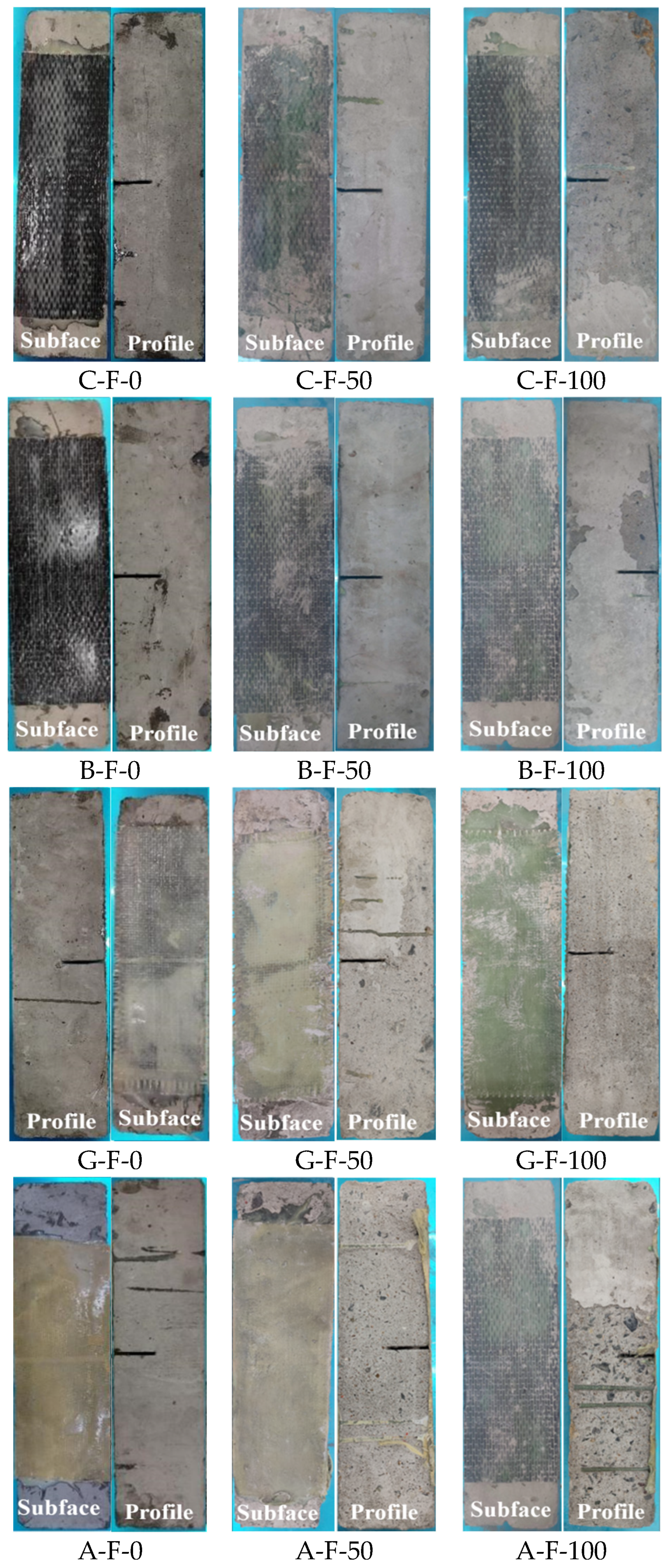

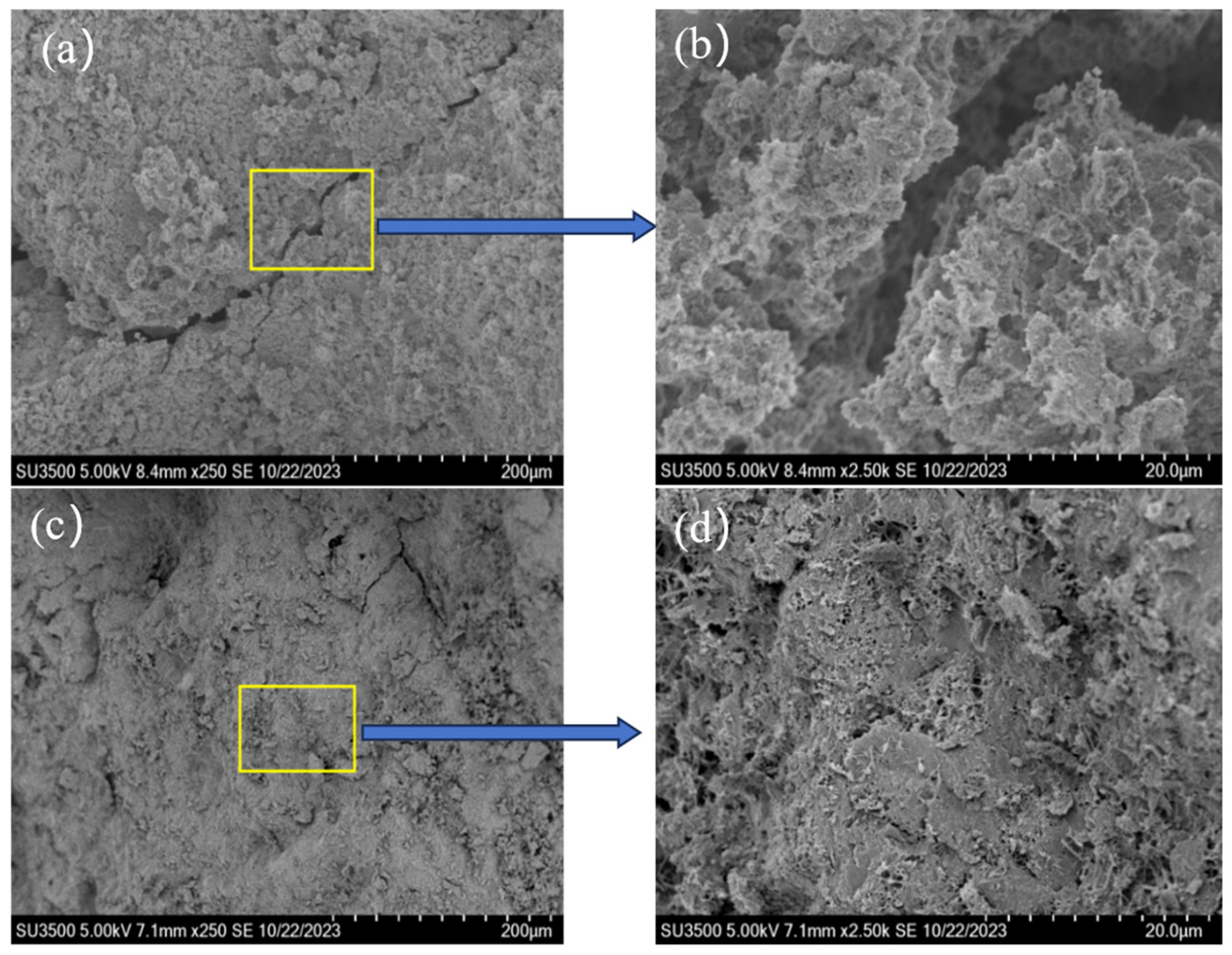

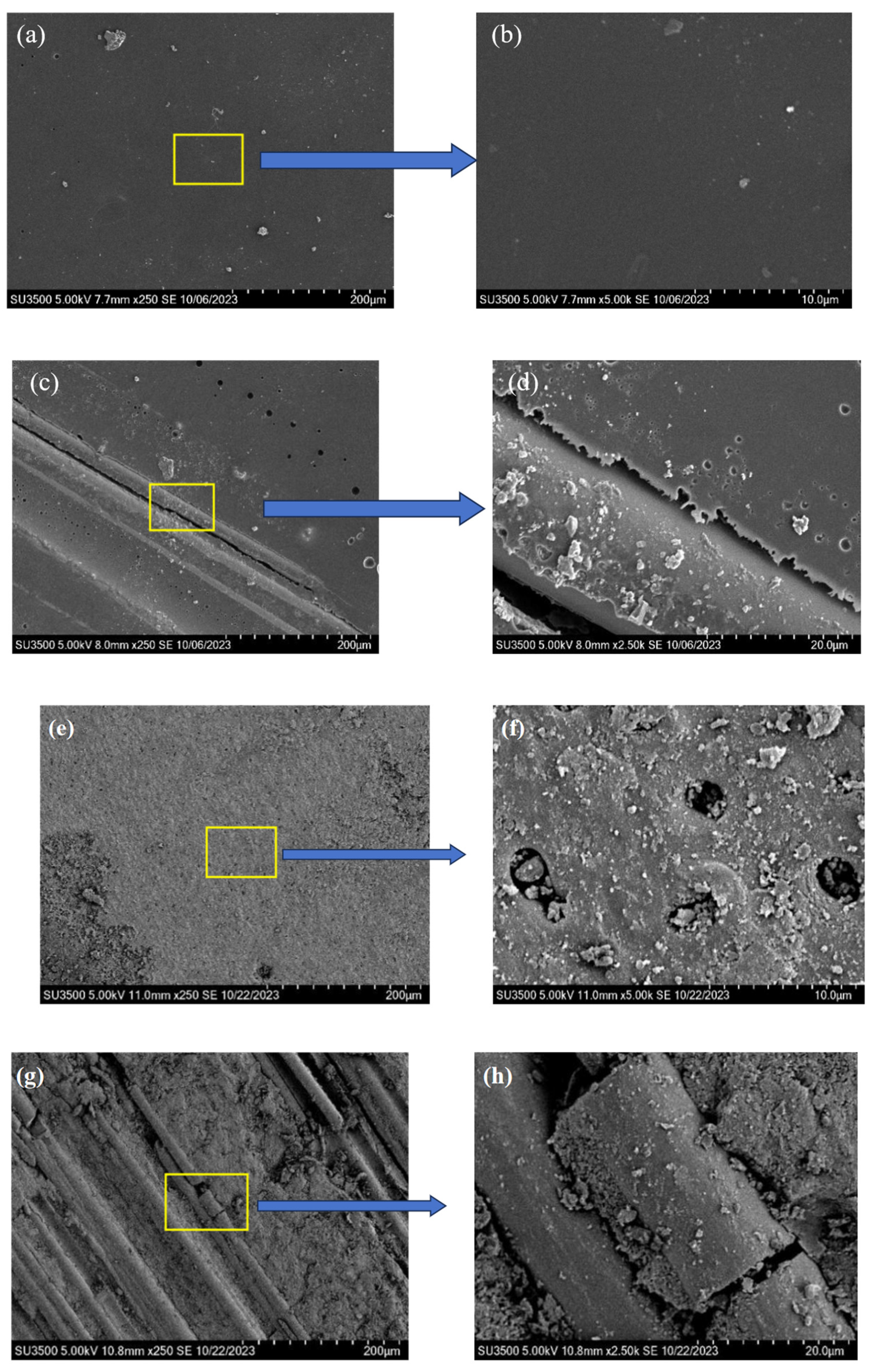

3.1. Surface Condition of Test Block

3.2. pH and Mass Loss

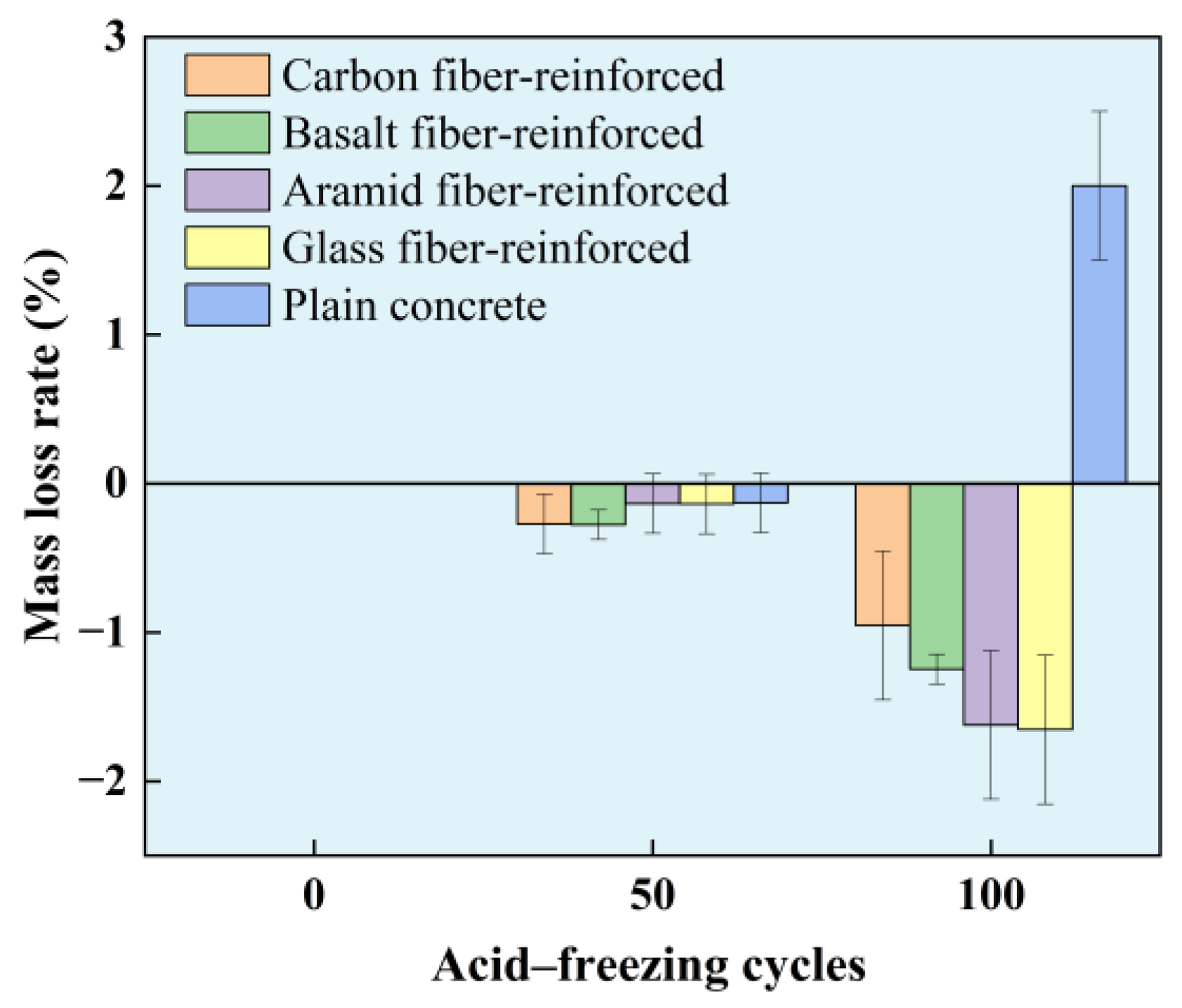

3.2.1. Cylinder Mass Loss Rate

3.2.2. Prism Mass Loss Rate

3.3. Relative Dynamic Modulus of Elasticity

3.4. Mechanical Test Results

3.4.1. Compressive Strength

3.4.2. Flexural Capacity

4. Performance Modeling

5. Conclusions

- (1)

- Because the increased mass from a portion of H2SO4 infiltrating the solution and the neutralization reaction producing expansive substances is greater than the mass loss from the spalling of the specimen surface, the mass of the plain cylindrical concrete increased by 0.01 kg after 50 cycles of combined acid and freeze–thaw action. After 100 cycles, as more surface concrete spalled, the mass of the plain specimen decreased by 0.082 kg. For the FRP-reinforced specimens, the initial mass loss pattern was consistent with the plain specimens. However, in the later stages, the mass increased because FRP prevented the spalling of the concrete surface. The GFRP-bonded specimens showed the most significant mass increase, reaching 1.653%.

- (2)

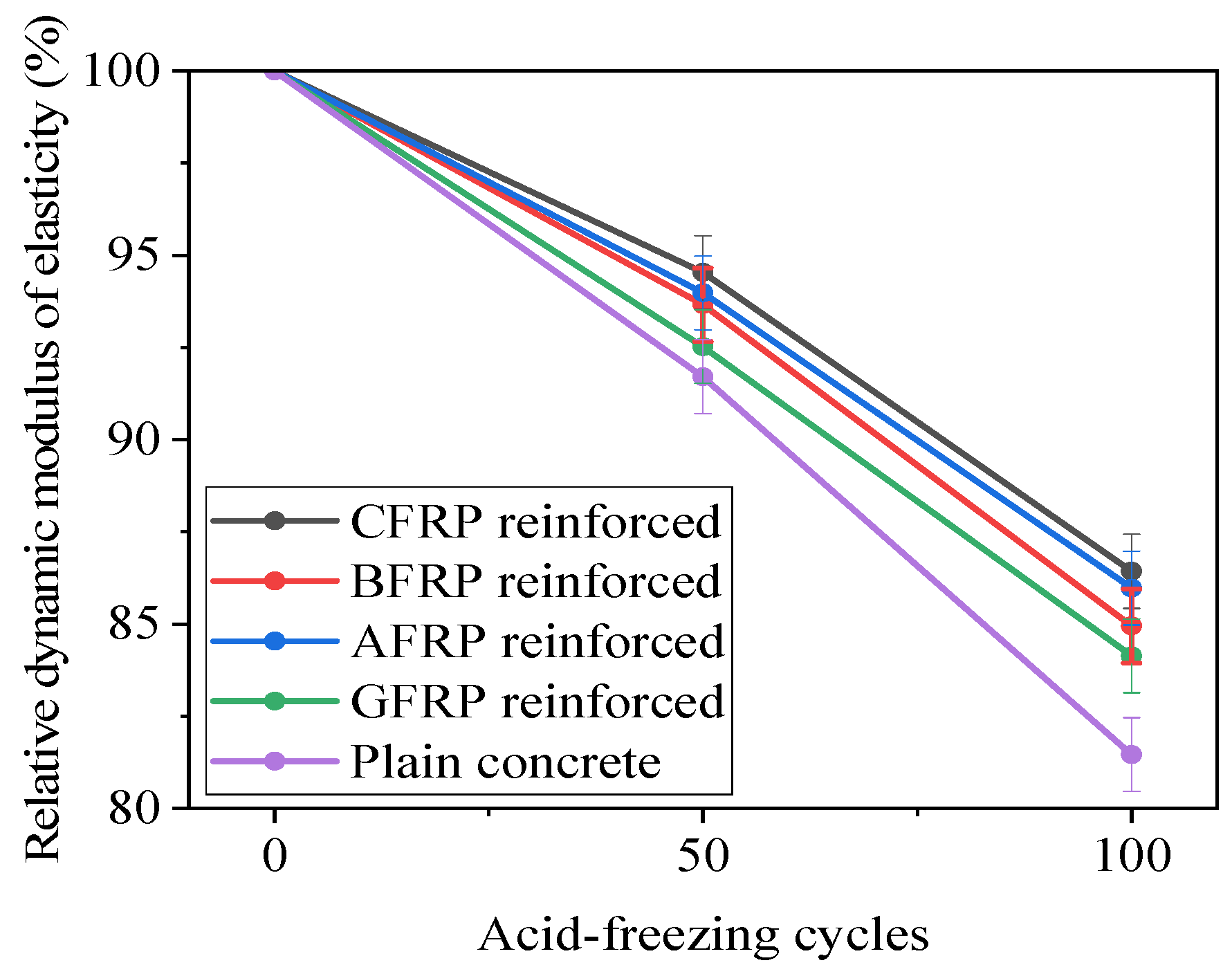

- The mass change patterns of the prismatic and cylindrical specimens were similar in the first 50 cycles of acid and freeze–thaw action. However, in the later stages, the mass of the prismatic specimens still decreased because the FRP sheets increased the volume ratio of the specimens exposed to the acid solution, and their integrity significantly improved. After 50 cycles of acid and freeze–thaw action, the relative dynamic elastic modulus of the plain concrete specimens was 91.7%, and thereafter, the relative dynamic elastic modulus continued to decrease. The relative dynamic elastic modulus of the FRP-bonded specimens was consistent with that of the plain specimens. Because the FRP sheets partially covering the concrete blocks reduced the acid erosion on the concrete, their values were higher than those of the plain specimens. The relative dynamic elastic modulus of the CFRP-bonded, BFRP-bonded, GFRP-bonded, and AFRP-bonded specimens increased by 6.1%, 4.3%, 5.5%, and 3.2%, respectively.

- (3)

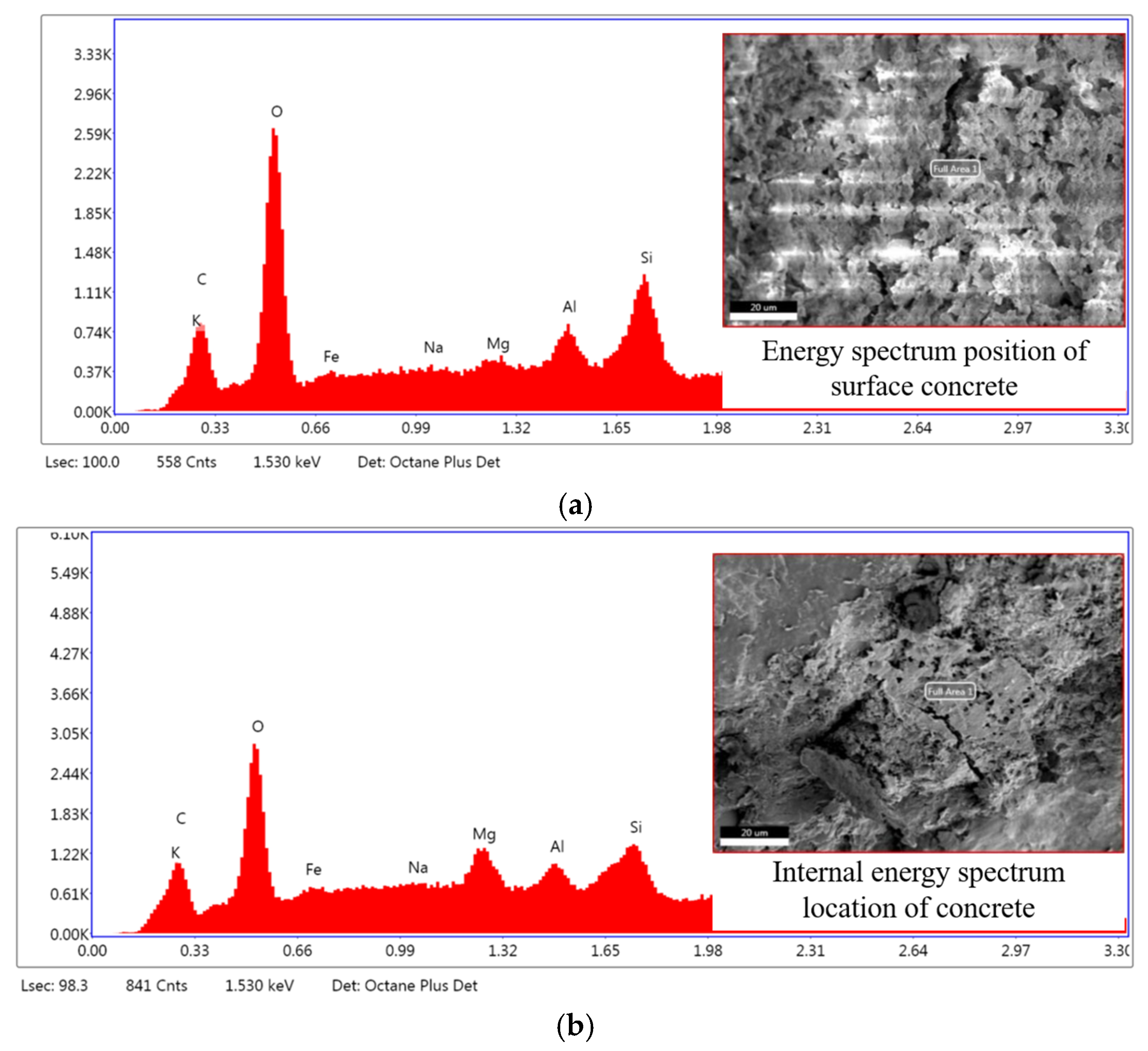

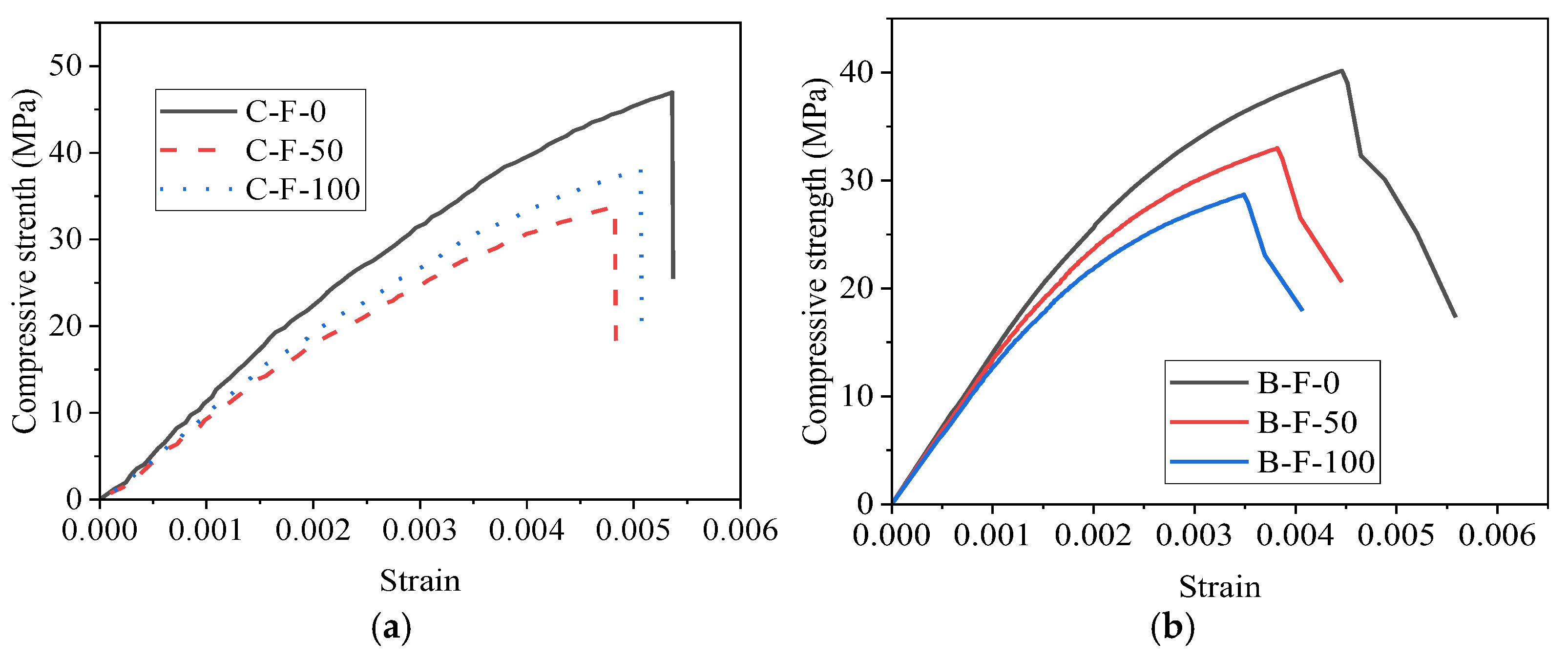

- After 100 cycles of acid and freeze–thaw action, because of the crystallization of water molecules and the neutralization reaction, hydration products dissolved into the pore solution, decreasing the internal compactness. Because of the limited penetration of the sulfuric acid solution into the concrete interior, combined with the concrete surface layer’s thermal insulation effect, the concrete’s internal texture remained dense, and the C-S-H gel was intact.

- (4)

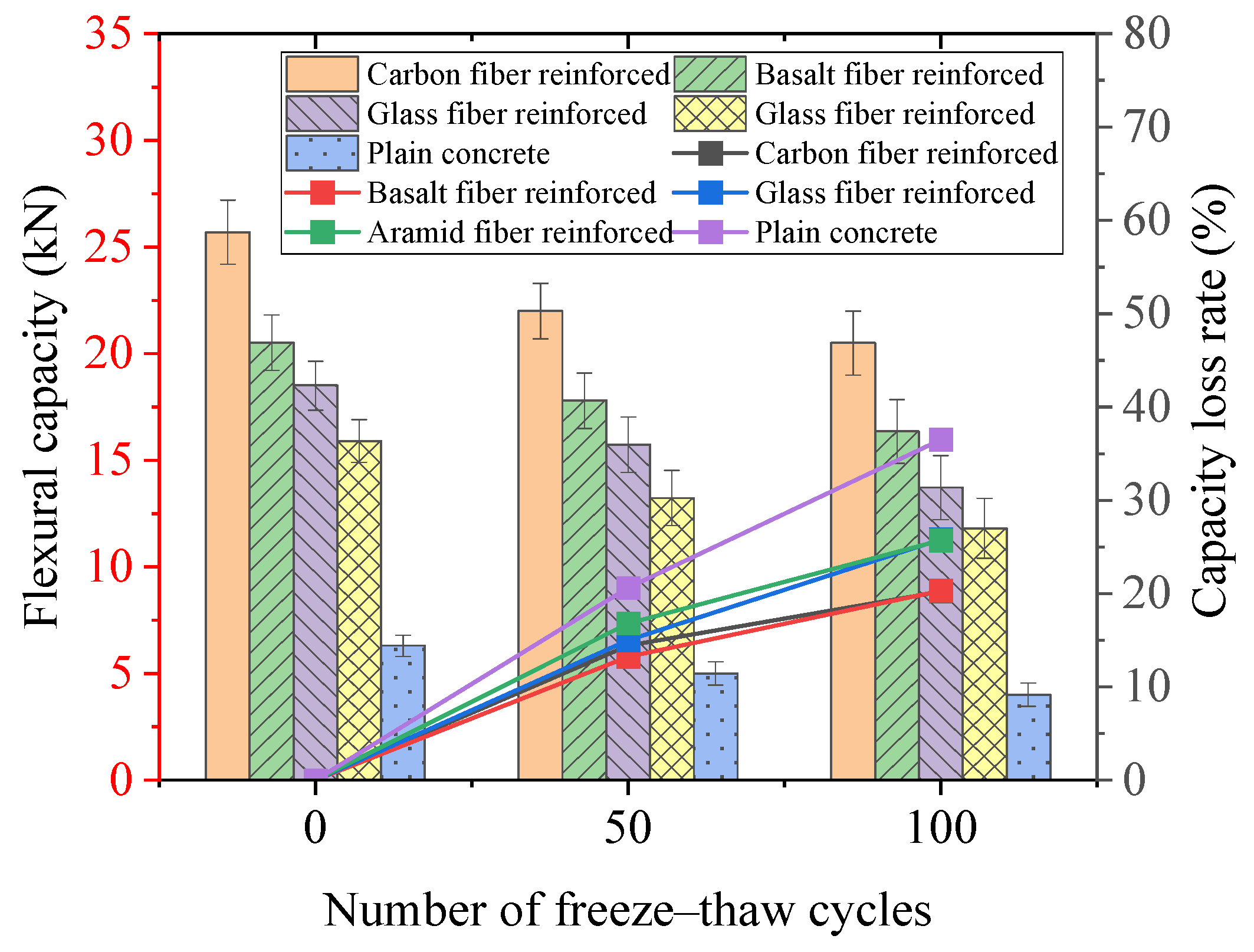

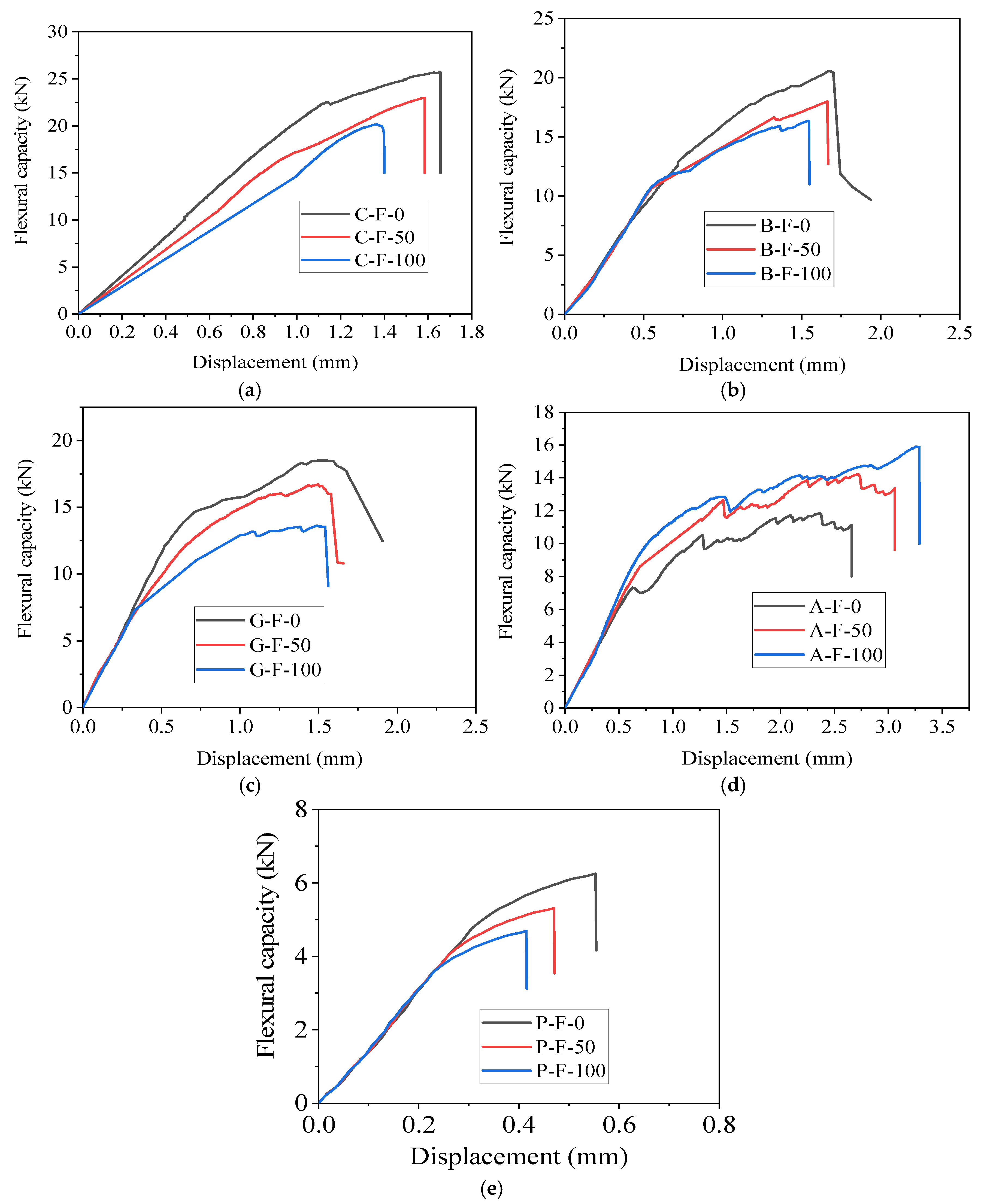

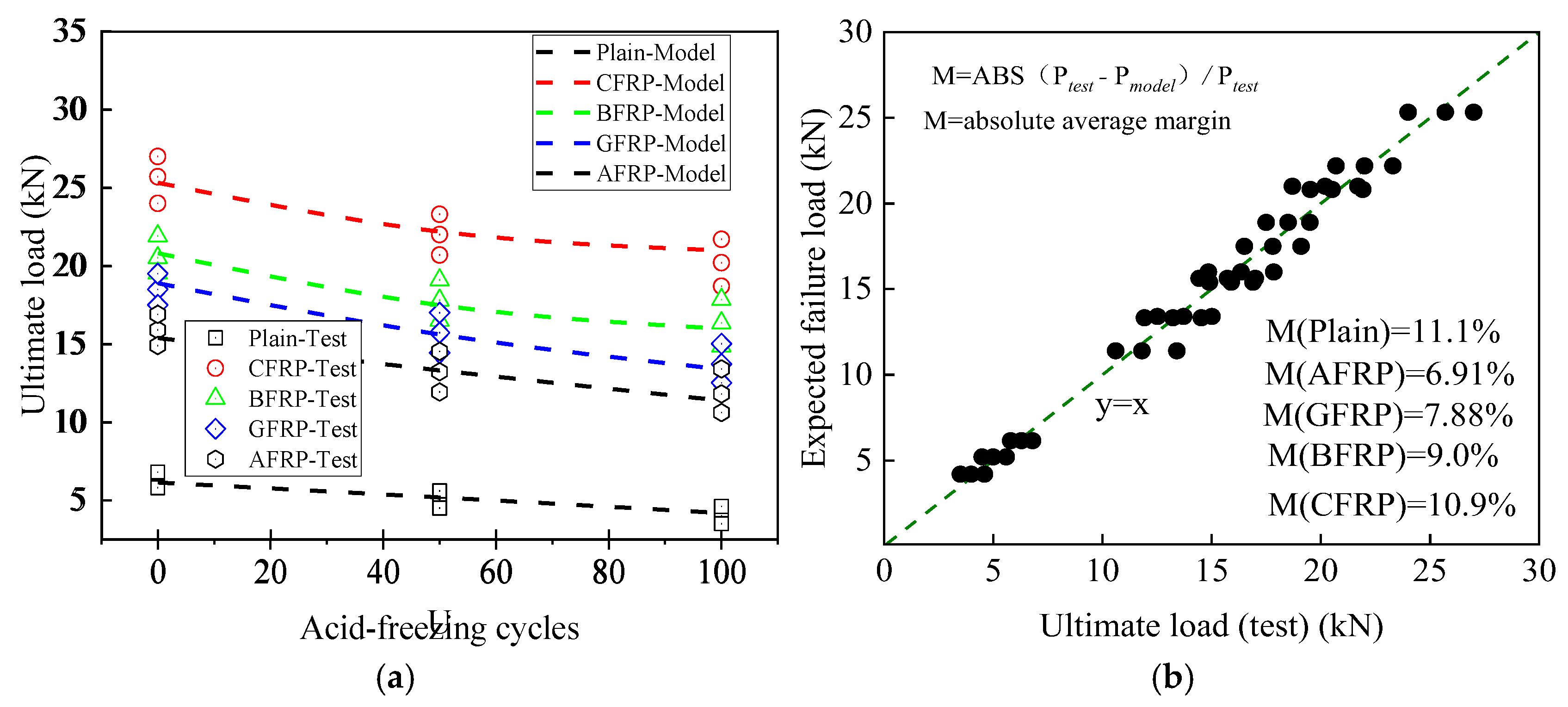

- After 100 cycles of acid and freeze–thaw action, compared to the initial strength at 0 cycles, the strength loss rate, in ascending order, was CFRP-reinforced specimens < BFRP-reinforced specimens < AFRP-reinforced specimens < GFRP-reinforced specimens < plain specimens. The ranking from best to worst regarding compressive strength plasticity was as follows: AFRP-reinforced specimens > GFRP-reinforced specimens > control group > BFRP-reinforced specimens > CFRP-reinforced specimens. After 100 cycles of acid and freeze–thaw action, compared to the initial bearing capacity, the bearing capacity loss of each group, in ascending order, was CFRP-reinforced specimens (20.23%) < BFRP-reinforced specimens (20.3%) < AFRP-reinforced specimens (25.7%) < BFRP-reinforced specimens (25.8%) < plain concrete specimens (36.5%). The compressive strength and bearing capacity of each group increased compared to the control group, indicating that FRP provided good protection for the concrete during the freeze–thaw corrosion process.

- (5)

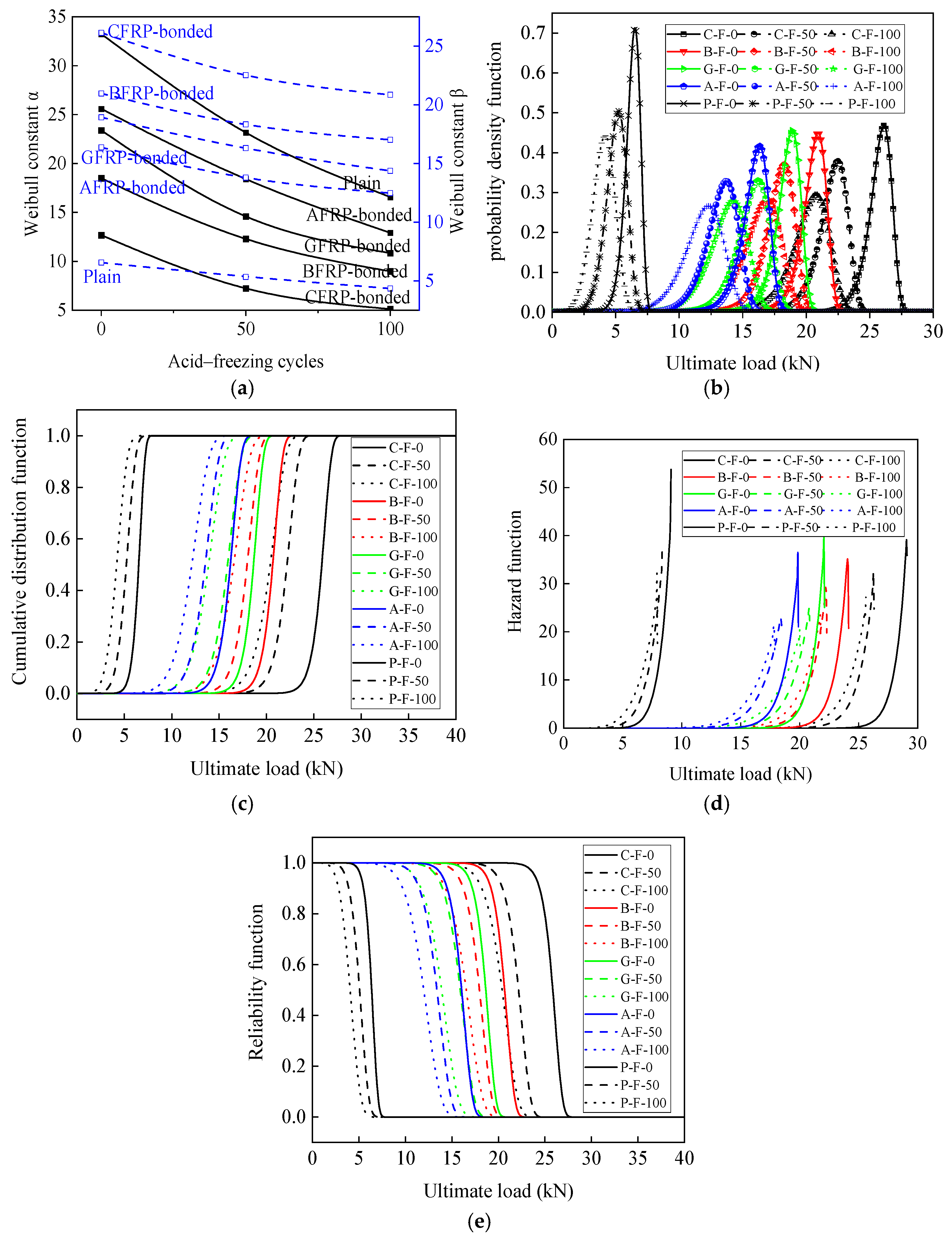

- A probability-based model was developed to study the degradation of the FRP-reinforced and plain concrete under chemical action. As degradation progressed, the probability density of the ultimate load became more concentrated, confirming the weak points in concrete failure. H2SO4 increased the risk of damage, while FRP improved the reliability of concrete’s load-bearing capacity. After 100 acid–freeze–thaw cycles, the unreinforced specimens failed at 4.2 kN, whereas the CFRP-, BFRP-, GFRP-, and AFRP-reinforced specimens had failure loads of 21.0 kN, 16.0 kN, 13.4 kN, and 11.4 kN, respectively, demonstrating FRP’s effectiveness in enhancing durability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, R.; Zhang, Q.; Li, Y. Deterioration of concrete under the coupling effects of freeze–thaw cycles and other actions: A review. Constr. Build. Mater. 2022, 319, 126045. [Google Scholar] [CrossRef]

- Şahin, Y.; Akkaya, Y.; Taşdemir, M.A. Effects of freezing conditions on the frost resistance and microstructure of concrete. Constr. Build. Mater. 2021, 270, 121458. [Google Scholar] [CrossRef]

- Bespalhuk, K.J.; de Oliveira, T.J.C.; Valverde, J.V.P.; Gonçalves, R.A.; Ferreira-Neto, L.; Souto, P.C.S.; Silva, J.R.; de Souza, N.C. Fractal analysis of microstructures in Portland cement pastes—Effect of curing conditions. Constr. Build. Mater. 2023, 363, 129881. [Google Scholar] [CrossRef]

- Zhou, C.; Lan, G.; Cao, P.; Tang, C.; Cao, Q.; Xu, Y.; Feng, D. Impact of freeze-thaw environment on concrete materials in two-lift concrete pavement. Constr. Build. Mater. 2020, 262, 120070. [Google Scholar] [CrossRef]

- Nejad, A.F.; Salim, M.Y.B.; Koloor, S.S.R.; Petrik, S.; Yahya, M.Y.; Hassan, S.A.; Shah, M.K.M. Hybrid and synthetic FRP composites under different strain rates: A review. Polymers 2021, 13, 3400. [Google Scholar] [CrossRef]

- Mugahed Amran, Y.H.; Alyousef, R.; Rashid, R.S.M.; Alabduljabbar, H.; Hung, C.-C. Properties and applications of FRP in strengthening RC structures: A review. Structures 2018, 16, 208–238. [Google Scholar] [CrossRef]

- Qureshi, J. A Review of Recycling Methods for Fibre Reinforced Polymer Composites. Sustainability 2022, 14, 16855. [Google Scholar] [CrossRef]

- Yi, Y.; Guo, S.; Li, S.; Rahman, Z.; Zhou, L.; Shi, C.; Zhu, D. Effect of alkalinity on the shear performance degradation of basalt fiber-reinforced polymer bars in simulated seawater sea sand concrete environment. Constr. Build. Mater. 2021, 299, 123957. [Google Scholar] [CrossRef]

- Kim, H.Y.; Park, Y.H.; You, Y.J.; Moon, C.K. Short-term durability test for GFRP rods under various environmental conditions. Compos. Struct. 2008, 83, 37–47. [Google Scholar] [CrossRef]

- D’Antino, T.; Pisani, M.A.; Poggi, C. Effect of the environment on the performance of GFRP reinforcing bars. Compos. Part B Eng. 2018, 141, 123–136. [Google Scholar] [CrossRef]

- Li, P.D.; Wu, Y.F. Stress-strain behavior of actively and passively confined concreteunder cyclic axial load. Compos. Struct. 2016, 149, 369–384. [Google Scholar] [CrossRef]

- Wu, Y.F.; Cao, Y.G. Effect of load path on behavior of FRP-confined concretel. J. Compos. Constr. 2017, 21, 4017014. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, R.; Liang, Y.; Xu, W.; Liang, Y. Experimental study and finite element analysis on axial compression performance of CFRP-PVC confined coral seawater and sea-sand concrete columns. Eng. Struct. 2024, 302, 117443. [Google Scholar] [CrossRef]

- Wu, Z.; Islam, S.M.; Said, H. A Three-Parameter Bond Strength Model for FRP—Concrete Interface. J. Reinf. Plast. Compos. 2008, 19, 2309–2323. [Google Scholar] [CrossRef]

- Mostefa, H.; Farid Bi Bensaid, B.; Tahar, H.D.; Selma, C.; Abderahim, L.; Sofiane, A. Experimental and numerical investigation on the deflection behavior of pre-cracked and repaired reinforced concrete beams with fiber-reinforced polymer. Constr. Build. Mater. 2020, 249, 118745. [Google Scholar]

- Umberto, D.M.; Daniele, G.; Fabrizio, G.; Paolo, L.; Andrea, P. The damage effect on the dynamic characteristics of FRP-strengthened reinforced concrete structures. Compos. Struct. 2023, 309, 116731. [Google Scholar]

- Song, M.; Wu, W.; Zhou, H. Experimental study on the mechanical properties of concrete confined by carbon fiber cloth under uniaxial compression at different strain rates. Compos. Sci. Eng. 2023, 80–87. [Google Scholar] [CrossRef]

- Golham, M.A.; Al-Ahmed, A.H.A. Behavior of GFRP reinforced concrete slabs with openings strengthened by CFRP strips. Results Eng. 2023, 18, 101033. [Google Scholar] [CrossRef]

- ELWakkad, N.Y.; Heiza, K.M.; Mansour, W. Experimental study and finite element modelling of the torsional behavior of self-compacting reinforced concrete (SCRC) beams strengthened by GFRP. Case Stud. Constr. Mater. 2023, 18, e02123. [Google Scholar] [CrossRef]

- Wang, H.; Wang, B.; Yang, X. Effect of acid, alkaline, and chlorine salt on the flexural behavior of reinforced concrete beams strengthened by basalt fiber cloth. Build. Struct. 2015, 45, 81–85+55. [Google Scholar] [CrossRef]

- Sena-Cruz, J.; Michels, J.; Correia, L.L.G.; Harmanci, Y.; Silva, P.M.; Gallego, J.; Fernandes, P.M.G.; Czaderski, C.; França, P. Recent contributions from UMinho and Empa on durability issues of flexural strengthening of RC slab with EB CFRP laminates. In Proceedings of the Fourth Conference on Smart Monitoring, Assessment and Rehabilitation of Structures (SMAR 2017), Zurich, Switzerland, 13–15 September 2017. [Google Scholar]

- Green, M.F.; Bisby, L.A.; Beaudoin, Y.; Labossière, P. Effect of freeze-thaw cycles on the bond durability between fibre reinforced polymer plate reinforcement and concrete. Can. J. Civ. Eng. 2000, 27, 949–959. [Google Scholar] [CrossRef]

- Harmanci, Y.E.; Michels, J.; Chatzi, E. Behaviour of Prestressed CFRP Anchorages during and after Freeze-Thaw Cycle Exposure. Polymers 2018, 10, 565. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Xie, J.; Lu, Z. Durability of interface between CFRP and damaged RC members under chloride environment. Ind. Constr. 2019, 49, 124–129. [Google Scholar] [CrossRef]

- Li, W.; Wang, D.; Xu, W.; Ji, Y. Investigation on damage evolution mechanism of various FRP strengthened concrete subjected to chemical-freeze-thaw coupling erosion. PLoS ONE 2024, 19, e0303645. [Google Scholar] [CrossRef]

- GB/T 50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. China Standard Press: Beijing, China, 2009.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Poperties. China Standard Press: Beijing, China, 2019.

- Bensted, J.; Rbrough, A.; Page, M.M. Chemical degradation of concrete. In Durability of Concrete and Cement Composites; CRC Press: Boca Raton, FL, USA, 2007; pp. 86–135. [Google Scholar]

- Kumar, R.; Dev, N. Effect of acids and freeze–thaw on the durability of modified rubberized concrete with optimum rubber crumb content. J. Appl. Polym. Sci. 2022, 139, 52191. [Google Scholar] [CrossRef]

- Wang, C.; Li, Z.; Ge, G.; Li, X.; Rong, Z.; Xue, S. Experimental study on salt corrosion resistance of polypropylene fiber concrete under the linked action of composite salt erosion-drying-wetting. Concrete 2023, 4, 29–35+39. [Google Scholar]

- He, J.; Ding, X.; Yang, W.; Yang, H.; Liu, L. Predicting the Effect of the Loading Rate on the Fracture Toughness of Hydraulic Asphalt Concrete Based on the Weibull Distribution. Materials 2024, 17, 803. [Google Scholar] [CrossRef]

- Sakin, R.; Ay, I. Statistical analysis of bending fatigue life data using Weibull distribution in glass-fiber reinforced polyester composites. Mater. Des. 2008, 29, 1170–1181. [Google Scholar] [CrossRef]

- Wang, M.; Bian, W.; Jiang, Z. Effects of diameter itself on Weibull modulus and fracture toughness of panbased carbon fiber. Glass Fiber Reinf. Plast./Compos. Mater. 2017, 287, 19–24. [Google Scholar]

- Huang, B.T.; Li, Q.H.; Xu, S.L. Fatigue deformation model of plain and fiber-reinforced concrete based on Weibull function. J. Struct. Eng. 2019, 145, 04018234. [Google Scholar] [CrossRef]

| Materials | Water | Cement | Medium Sand | Nature Aggregate (5–10 mm) | Nature Aggregate (10–20 mm) |

|---|---|---|---|---|---|

| Content | 209.0 | 387.0 | 635.0 | 350.7 | 818.3 |

| Materials | Strength/MPa | Elastic Modulus/GPa | Elongation at Break/% |

|---|---|---|---|

| CFRP | 3520 | 267 | 1.78 |

| BFRP | 3000 | 120 | 1.60 |

| GFRP | 2500 | 80 | 2.3 |

| AFRP | 2106 | 117.8 | 1.75 |

| Epoxy resin adhesive | 54.3 | 2.7 | 2.25 |

| Freeze–Thaw Cycles | Mass Change of Test Block (kg) | ||||

|---|---|---|---|---|---|

| CFRP-Reinforced | BFRP-Reinforced | AFRP-Reinforced | GFRP-Reinforced | Plain | |

| 0 | 3.67 | 3.61 | 3.7 | 3.63 | 3.58 |

| 50 | 3.68 | 3.62 | 3.705 | 3.635 | 3.59 |

| 100 | 3.705 | 3.655 | 3.76 | 3.69 | 3.58 |

| Freeze–Thaw Cycles | Transverse Fundamental Frequency of Specimens (Hz) | ||||

|---|---|---|---|---|---|

| CFRP-Reinforced | BFRP-Reinforced | AFRP-Reinforced | GFRP-Reinforced | Plain | |

| 0 | 1730 | 1820 | 1732 | 1867 | 1888 |

| 50 | 1669 | 1774 | 1685 | 1811 | 1828 |

| 100 | 1601 | 1659 | 1607 | 1700 | 1754 |

| Specimen | Constant | Acid–Freezing 0 Times | Acid–Freezing 50 Times | Acid–Freezing 100 Times |

|---|---|---|---|---|

| Plain | α | 33.239 | 23.158 | 16.570 |

| β | 26.131 | 22.521 | 20.855 | |

| CFRP | α | 25.582 | 18.410 | 12.913 |

| β | 20.962 | 18.324 | 17.016 | |

| BFRP | α | 23.389 | 14.589 | 10.847 |

| β | 18.934 | 16.304 | 14.373 | |

| GFRP | α | 18.499 | 12.293 | 8.981 |

| β | 16.366 | 13.794 | 12.473 | |

| AFRP | α | 12.679 | 7.237 | 5.131 |

| β | 6.561 | 5.336 | 4.350 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, F.; Li, W.; Jin, S.; Wang, D.; Cheng, P.; Piao, M. Study on the Damage Evolution Mechanism of FRP-Reinforced Concrete Subjected to Coupled Acid–Freeze Erosion. Coatings 2025, 15, 759. https://doi.org/10.3390/coatings15070759

Li F, Li W, Jin S, Wang D, Cheng P, Piao M. Study on the Damage Evolution Mechanism of FRP-Reinforced Concrete Subjected to Coupled Acid–Freeze Erosion. Coatings. 2025; 15(7):759. https://doi.org/10.3390/coatings15070759

Chicago/Turabian StyleLi, Fei, Wei Li, Shenghao Jin, Dayang Wang, Peifeng Cheng, and Meitong Piao. 2025. "Study on the Damage Evolution Mechanism of FRP-Reinforced Concrete Subjected to Coupled Acid–Freeze Erosion" Coatings 15, no. 7: 759. https://doi.org/10.3390/coatings15070759

APA StyleLi, F., Li, W., Jin, S., Wang, D., Cheng, P., & Piao, M. (2025). Study on the Damage Evolution Mechanism of FRP-Reinforced Concrete Subjected to Coupled Acid–Freeze Erosion. Coatings, 15(7), 759. https://doi.org/10.3390/coatings15070759