Optimization of Micro-Sandblasting Parameters for Enhanced Adhesion and Wear Resistance of AlTiSiN-Coated Tools

Abstract

1. Introduction

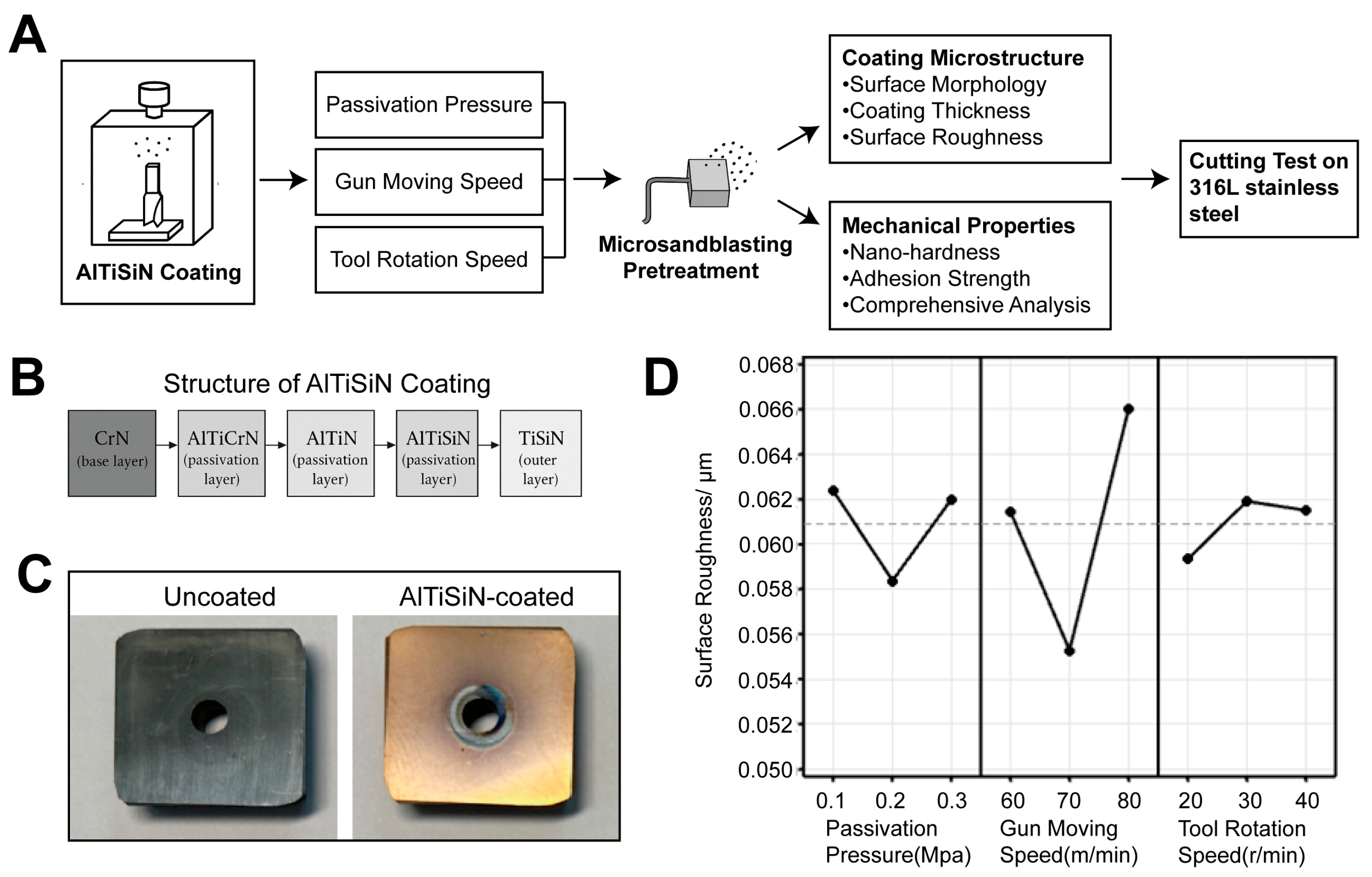

2. Materials and Methods

2.1. Cutting Tools and Sample Preparation

2.2. AlTiSiN Coating Preparation

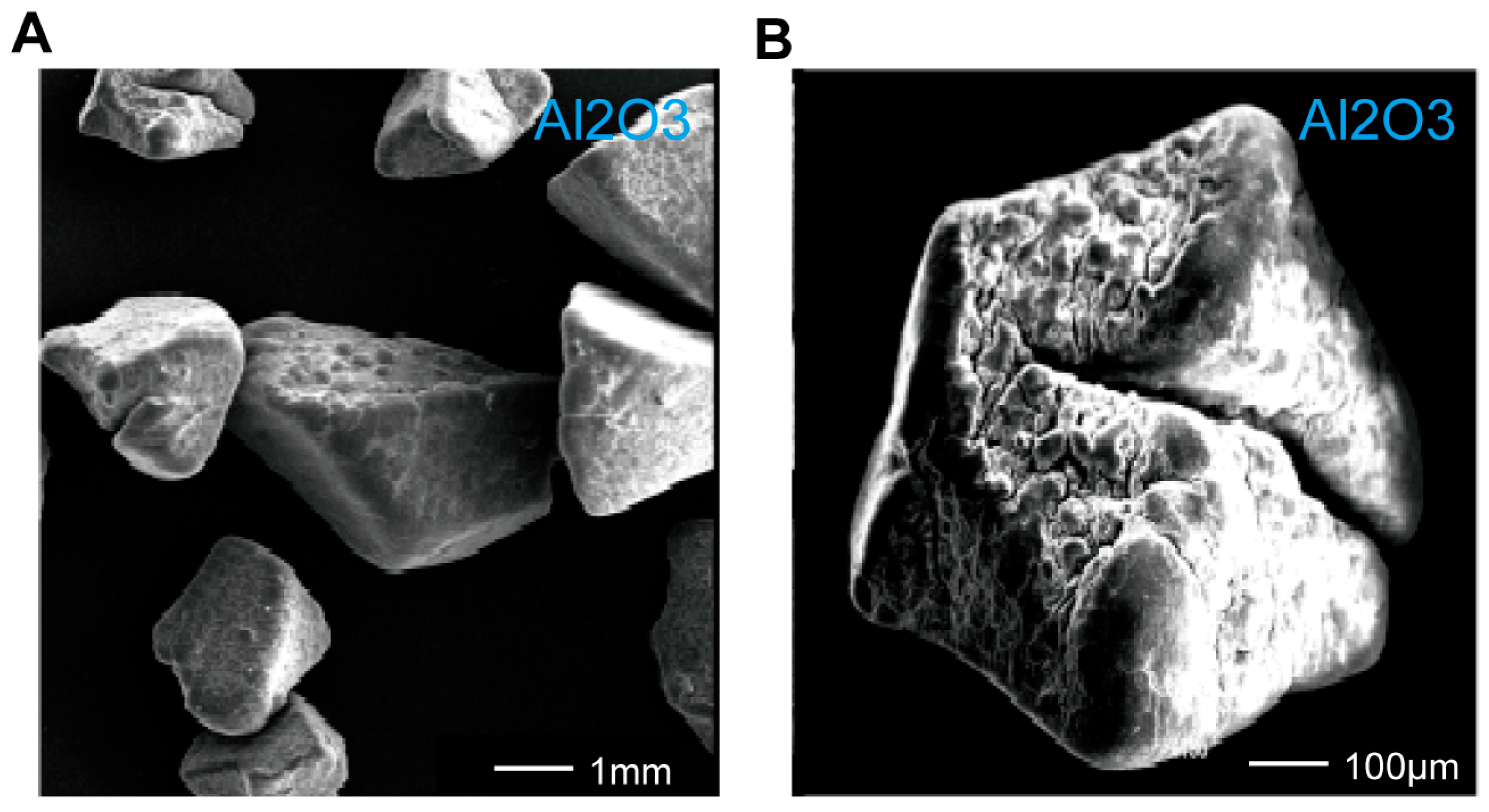

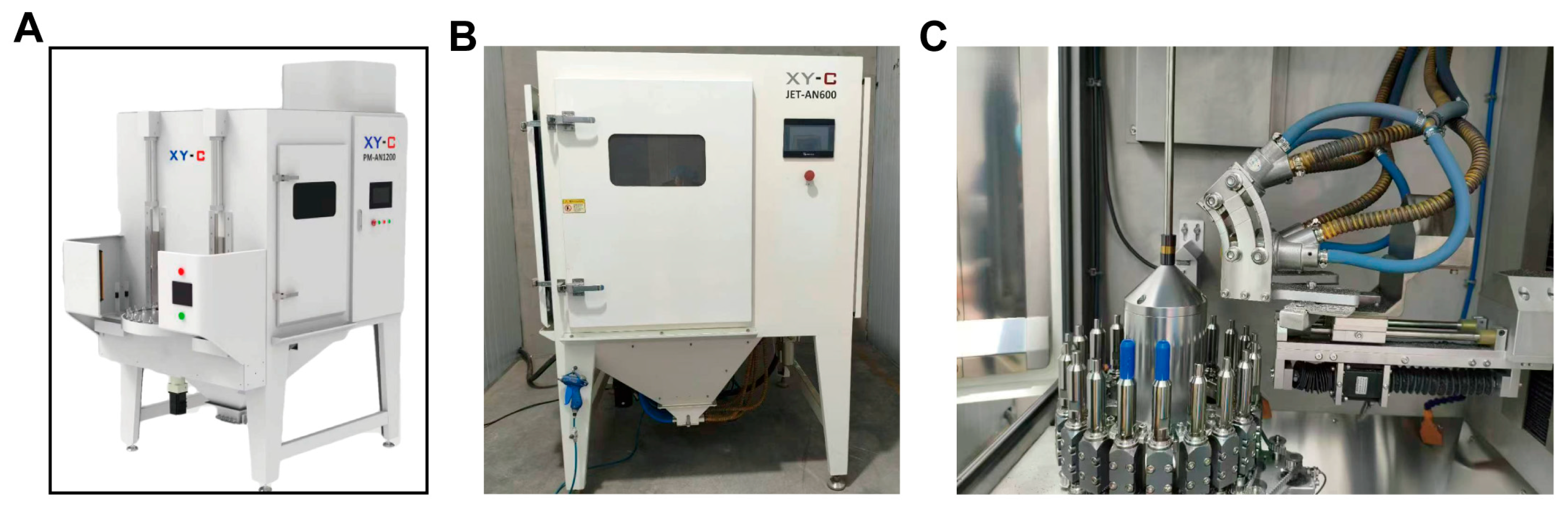

2.3. Materials and Micro-Sandblasting Pretreatment

2.4. Orthogonal Experimental Design Scheme

2.5. Characterization of Coating Microstructure

2.6. Coating Mechanical Property Testing

2.7. Cutting Test on 316 L Stainless Steel

3. Results and Discussion

3.1. Effect of Micro-Sandblasting Pretreatment Process Parameters on Microstructure of AlTiSiN Coatings

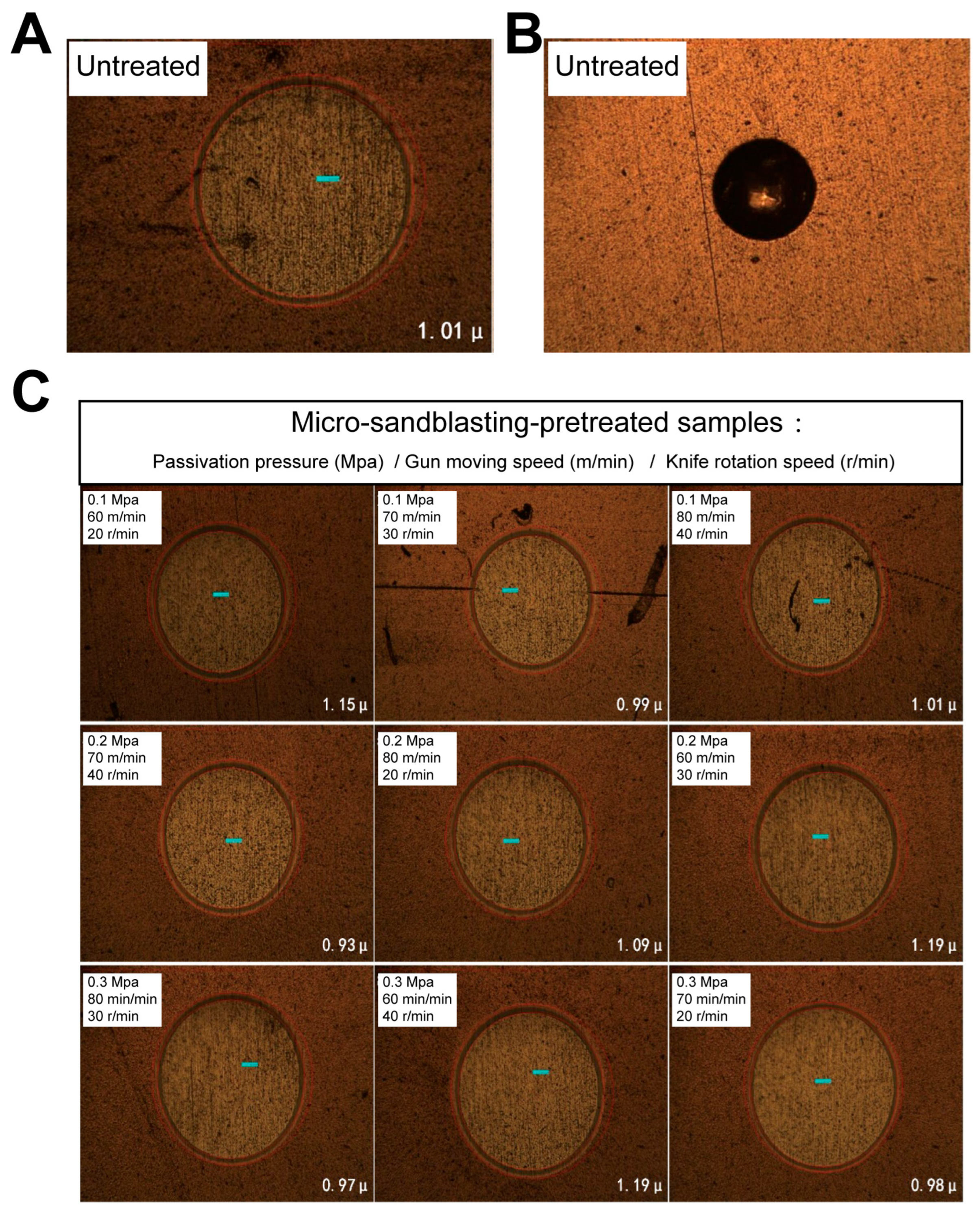

3.1.1. Micro-Sandblasting Pretreatment Has Minimal Effect on Surface Roughness of AlTiSiN Coating

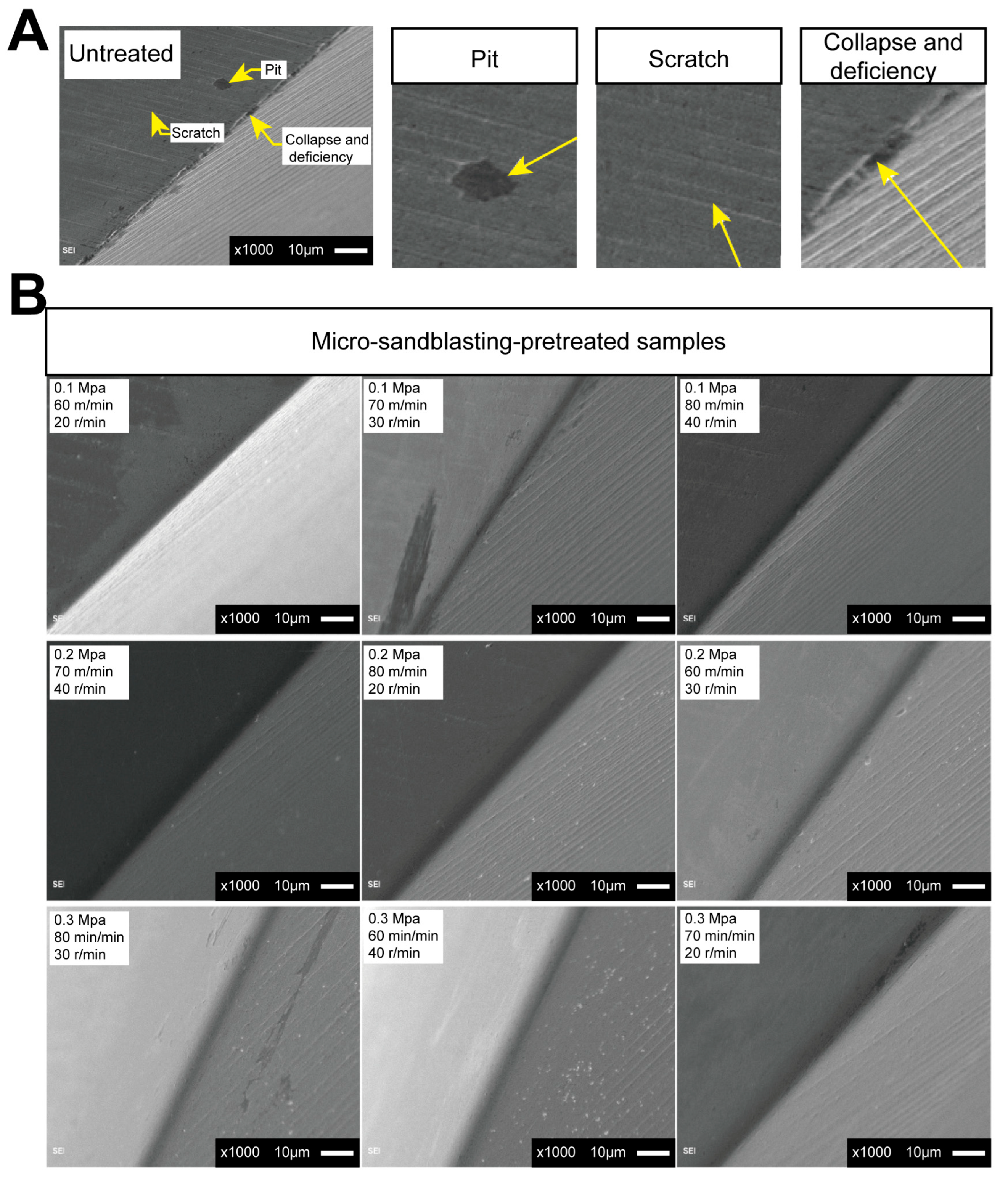

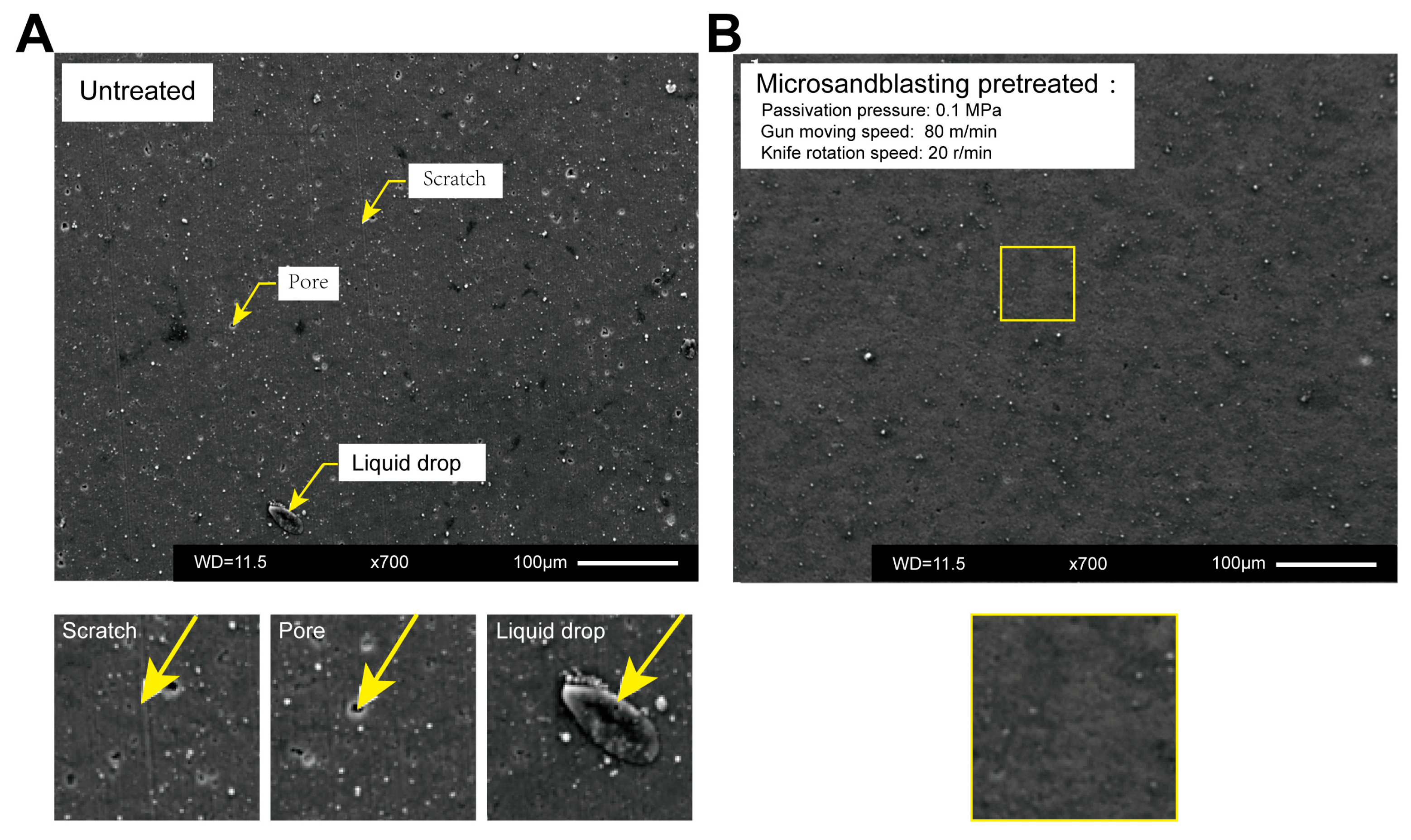

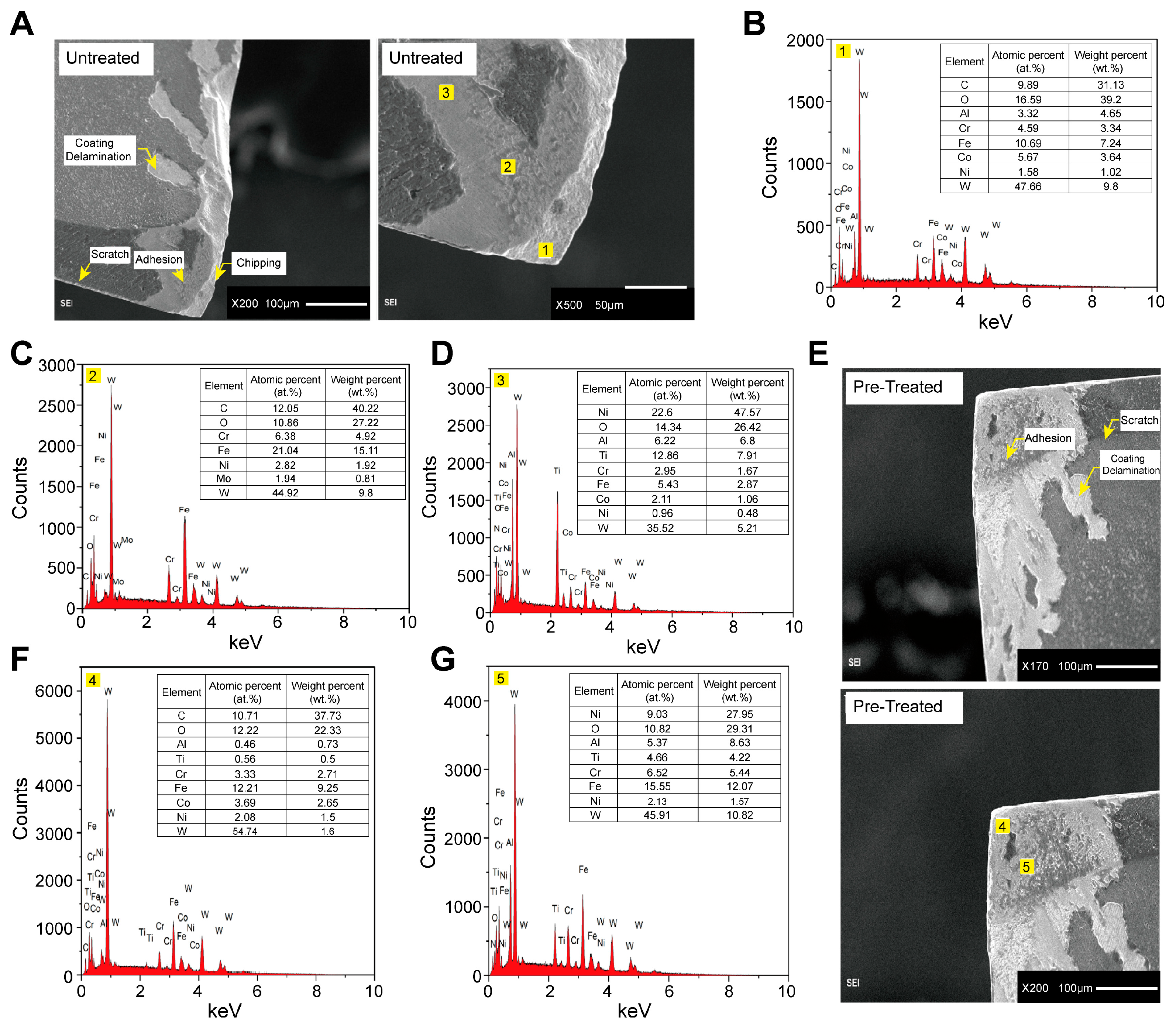

3.1.2. Micro-Sandblasting Treatment Improves Tool Surface Quality and Coating Adhesion

3.1.3. Micro-Sandblasting Has No Effect on Surface Coating Thickness of AlTiSiN

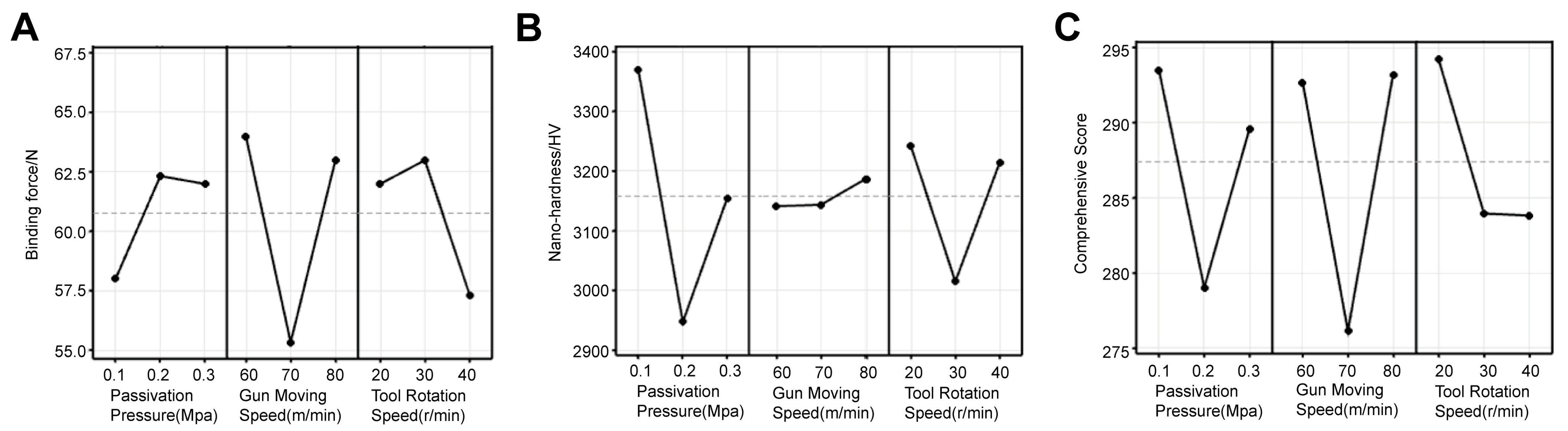

3.2. Influence of Micro-Sandblasting Pretreatment Parameters on Mechanical Properties of AlTiSiN Coatings

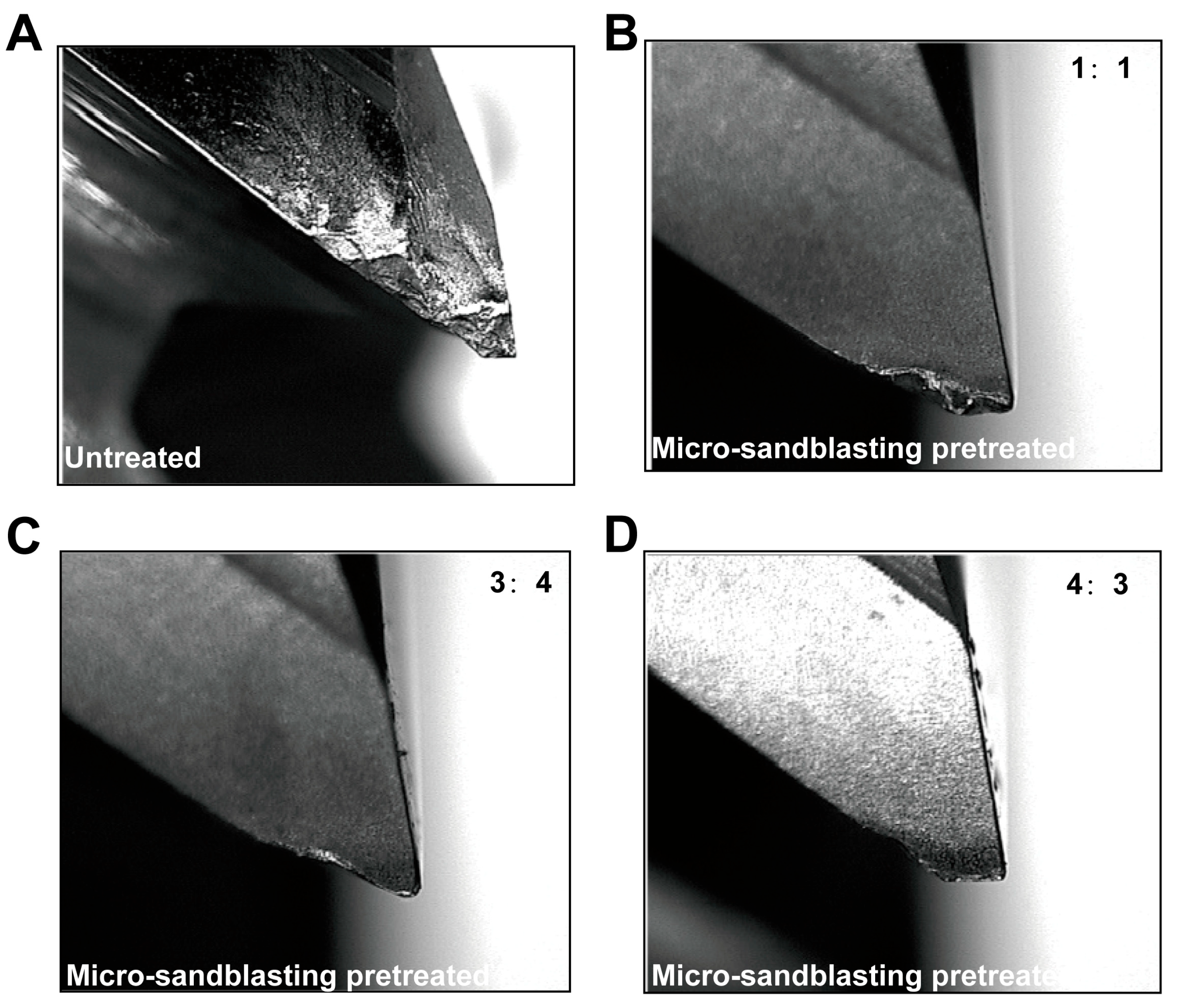

3.3. Effect of Forward-to-Reverse Rotation Time Ratio on Cutting Life of Coated Tools

3.4. Optimized Micro-Sandblasting Pretreatment Enhances Wear Resistance of AlTiSiN-Coated Tools During 316 L Stainless Steel Milling

3.4.1. Flank Wear Behavior of AlTiSiN-Coated Tools During 316 L Stainless Steel Milling

3.4.2. Wear Morphology of Rake Face of AlTiSiN-Coated Tools During Milling of 316 L Stainless Steel

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AlTiSiN | titanium aluminum silicon nitride |

| AlCrN | aluminum chromium nitride |

| TiAlN | titanium aluminum nitride |

| AlTiN | aluminum titanium nitride |

| AlCr | aluminum chromium |

| TiN | titanium nitride |

| HSS | high-speed steel |

| MPa | Megapascal |

| r/min | Revolutions per Minute |

| ANOVA | Analysis of Variance |

| SEM | scanning electron microscopy |

| PVD | physical vapor deposition |

| BUE | built-up edges |

| EDS | energy-dispersive spectroscopy |

| VBₘₐₓ | maximum flank wear width |

| SLM | spindle load monitoring |

| WC | tungsten carbide |

References

- Zeng, K.; Wu, X.; Jiang, F.; Shen, J.Y.; Zhu, L.F.; Li, L. A comprehensive review on the cutting and abrasive machining of cemented carbide materials. J. Manuf. Process. 2023, 108, 335–358. [Google Scholar] [CrossRef]

- García, J.; Ciprés, V.C.; Blomqvist, A.; Kaplan, B. Cemented carbide microstructures: A review. Int. J. Refract. Met. Hard Mater. 2019, 80, 40–68. [Google Scholar] [CrossRef]

- Xian, L.J.; Fan, H.Y.; Xian, G.; Li, L.; Luo, Y.Z.; Zhao, H.B. Comparison study of the microstructure, mechanical and tribological properties of TiAlN, AlCrBN and TiAlN/AlCrBN coatings by cathodic arc evaporation. Int. J. Refract. Met. Hard Mater. 2025, 128, 107017. [Google Scholar] [CrossRef]

- Chang, Y.Y.; Cai, M.C. Mechanical property and tribological performance of AlTiSiN and AlTiBN hard coatings using ternary alloy targets. Surf. Coat. Technol. 2019, 374, 1120–1127. [Google Scholar] [CrossRef]

- Xu, S.P.; Zhan, F.Q.; Wan, L.; Zheng, Y.H.; La, P. Enhancing high-temperature chloride molten salts corrosion resistance of 310S steel with Si-added Ni-Al coating. J. Mater. Res. Technol. 2024, 33, 4557–4568. [Google Scholar] [CrossRef]

- Yu, D.H.; Wang, C.Y.; Cheng, X.L.; Zhang, F.L. Microstructure and properties of TiAlSiN coatings prepared by hybrid PVD technology. Thin Solid Films 2009, 517, 4950–4955. [Google Scholar] [CrossRef]

- Chang, Y.Y.; Yang, M.X.; Chang, C.E.; Chang, B.Y. Cyclic thermal shock resistance and tribological properties of AlCrSiN, AlTiSiN and AlCrSiN/AlTiSiN multilayer hard coatings. Surf. Coat. Technol. 2025, 496, 131650. [Google Scholar] [CrossRef]

- Yu, Z.; Dong, Y.J.; Zheng, G.M.; Jiang, X.L.; Cheng, X.; Yang, X.H.; Chang, K.S.; Li, X.W. Influence of micro sandblasting on the surface integrity of the AlTiN-coated tools. Int. J. Adv. Manuf. Technol. 2022, 120, 1359–1372. [Google Scholar] [CrossRef]

- Bouzakis, K.D.; Skordaris, G.; Bouzakis, E.; Tsouknidas, A.; Makrimallakis, S.; Gerardis, S.; Katirtzoglou, G. Optimization of wet micro-blasting on PVD films with various grain materials for improving the coated tools’ cutting performance. CIRP Ann.-Manuf. Technol. 2011, 60, 587–590. [Google Scholar] [CrossRef]

- Puneet, C.; Valleti, K.; Gopal, A.V. Influence of surface preparation on the tool life of cathodic arc PVD coated twist drills. J. Manuf. Process. 2017, 27, 233–240. [Google Scholar] [CrossRef]

- Liu, C.Y.; Liu, Z.Q.; Wang, B. Modification of surface morphology to enhance tribological properties for CVD coated cutting tools through wet micro-blasting post-process. Ceram. Int. 2018, 44, 3430–3439. [Google Scholar] [CrossRef]

- Rudawska, A.; Danczak, I.; Müller, M.; Valasek, P. The effect of sandblasting on surface properties for adhesion. Int. J. Adhes. Adhes. 2016, 70, 176–190. [Google Scholar] [CrossRef]

- Muslimin, M.; Muhamad, A.M.; Triawan, F.; Nandiyanto, A.B.D. Surface characteristics of low carbon steel JISG3101SS400 after sandblasting process by steel grit G25. J. Eng. Res. 2022, 10, 193–204. [Google Scholar] [CrossRef]

- Bouzakis, K.D.; Tsouknidas, A.; Skordaris, G.; Bouzakis, E.; Makrimallakis, S.; Gerardis, S.; Katirtzoglou, G. Optimization of Wet or Dry Micro-blasting on PVD Films by Various Al2O3 Grain Sizes for Improving the Coated Tools’ Cutting Performance. Tribol. Ind. 2011, 33, 49–56. [Google Scholar]

- Wang, S.L.; Chen, S.; Liu, M.; Huang, Q.H.; Liu, Z.M.; Li, X.; Xu, S.F. The Effect of Plasma Spray Parameters on the Quality of Al-Ni Coatings. Coatings 2023, 13, 2063. [Google Scholar] [CrossRef]

- Begg, H.; Riley, M.; Lovelock, H.D. Mechanization of the Grit Blasting Process for Thermal Spray Coating Applications: A Parameter Study. J. Therm. Spray Technol. 2016, 25, 12–20. [Google Scholar] [CrossRef]

- Kacker, R.N.; Lagergren, E.S.; Filliben, J.J. Taguchi’s Orthogonal Arrays Are Classical Designs of Experiments. J. Res. Natl. Inst. Stand. Technol. 1991, 96, 577. [Google Scholar] [CrossRef]

- Yu, C.F.; Zhao, C.C.; Zhang, Z.F.; Liu, W. Tensile Properties of Selective Laser Melted 316L Stainless Steel. Acta Metall. Sin. 2020, 56, 683–692. [Google Scholar] [CrossRef]

- Ara, I.; Bajwa, D.; Raeisi, A. A review on the wear performance of additively manufactured 316L stainless steel: Process, structure, and performance. J. Mater. Sci. 2025, 60, 5686–5720. [Google Scholar] [CrossRef]

- Hoier, P.; Malakizadi, A.; Klement, U.; Krajnik, P. Characterization of abrasion- and dissolution-induced tool wear in machining. Wear 2019, 426, 1548–1562. [Google Scholar] [CrossRef]

- Kameneva, A.; Kichigin, V.; Bublik, N. Structure and Electrochemical Behavior of AlN, AlTiN, and AlTiSiN Physical Vapor Deposition Coatings in 3% NaCl Solution. J. Mater. Eng. Perform. 2022, 31, 10402–10411. [Google Scholar] [CrossRef]

- Bouzakis, K.D.; Klocke, F.; Skordaris, G.; Bouzakis, E.; Gerardis, S.; Katirtzoglou, G.; Makrimallakis, S. Influence of dry micro-blasting grain quality on wear behaviour of TiAlN coated tools. Wear 2011, 271, 783–791. [Google Scholar] [CrossRef]

- Kang, J.J.; Xu, B.S.; Wang, H.D.; Wang, C.B. Influence of Spraying Parameters on the Microstructure and Properties of Plasma-sprayed Al2O3/40%TiO2 Coating. Phys. Procedia 2013, 50, 169–176. [Google Scholar] [CrossRef]

- Bouzakis, K.D.; Hadjiyiannis, S.; Skordaris, G.; Mirisidis, I.; Michailidis, N.; Efstathiou, K.; Pavlidou, E.; Erkens, G.; Cremer, R.; Rambadt, S.; et al. The effect of coating thickness, mechanical strength and hardness properties on the milling performance of PVD coated cemented carbides inserts. Surf. Coat. Technol. 2004, 177, 657–664. [Google Scholar] [CrossRef]

- Surya, M.S. Optimization of machining parameters while turning AISI316 stainless steel using response surface methodology. Sci. Rep. 2024, 14, 30083. [Google Scholar] [CrossRef]

- Takikawa, H.; Tanoue, H. Review of cathodic arc deposition for preparing droplet-free thin films. IEEE Trans. Plasma Sci. 2007, 35, 992–999. [Google Scholar] [CrossRef]

- Sonawane, G.D.; Bachhav, R.; Barnwal, A. Correlating the Characterization and Machining Performance of Advanced PVD Coatings for Dry Turning. JOM 2024, 76, 313–326. [Google Scholar] [CrossRef]

- Chowdhury, M.S.I.; Bose, B.; Akter, S.; Veldhuis, S.C. Effect of Deposition Parameters on Micromechanical Properties and Machining Performance of CrN Coating for Wet Finish Turning of Ti6Al4V Alloy. Materials 2024, 17, 4328. [Google Scholar] [CrossRef]

- Mubarak, A.; Akhter, P.; Hamzah, E.; Toff, M.R.H.J.M.; Qazi, I.A. Effect of coating thickness on the properties of TiN coatings deposited on tool steels using cathodic arc PVD technique. Surf. Rev. Lett. 2008, 15, 401–410. [Google Scholar] [CrossRef]

- Walczak, M.; Pasierbiewicz, K.; Szala, M. Adhesion and Mechanical Properties of TiAlN and AlTiN Magnetron Sputtered Coatings Deposited on the DMSL Titanium Alloy Substrate. Acta Phys. Pol. A 2019, 136, 294–298. [Google Scholar] [CrossRef]

- Panjan, P.; Drnovsek, A.; Mahne, N.; Cekada, M.; Panjan, M. Surface Topography of PVD Hard Coatings. Coatings 2021, 11, 1387. [Google Scholar] [CrossRef]

- Fu, H.; Yang, X.; Mei, M.; Yang, J.; Zhang, Y.H.; Ji, J.H.; Fu, Y.H. Experimental Study and Mechanism Analysis of the Influence of Micro-Dimple Geometry on the Adhesion Strength of Textured Coatings. Coatings 2024, 14, 973. [Google Scholar] [CrossRef]

- Singh, A.; Ghosh, S.; Aravindan, S. Influence of dry micro abrasive blasting on the physical and mechanical characteristics of hybrid PVD-AlTiN coated tools. J. Manuf. Process. 2019, 37, 446–456. [Google Scholar] [CrossRef]

- Jacob, A.; Gangopadhyay, S.; Satapathy, A.; Mantry, S.; Jha, B.B. Influences of micro-blasting as surface treatment technique on properties and performance of AlTiN coated tools. J. Manuf. Process. 2017, 29, 407–418. [Google Scholar] [CrossRef]

- Bouzakis, K.D.; Bouzakis, E.; Skordaris, G.; Makrimallakis, S.; Tsouknidas, A.; Katirtzoglou, G.; Gerardis, S. Effect of PVD films wet micro-blasting by various Al2O3 grain sizes on the wear behaviour of coated tools. Surf. Coat. Technol. 2011, 205, S128–S132. [Google Scholar] [CrossRef]

- Zhuang, K.J.; Fu, C.N.; Weng, J.; Hu, C. Cutting edge microgeometries in metal cutting: A review. Int. J. Adv. Manuf. Technol. 2021, 116, 2045–2092. [Google Scholar] [CrossRef]

- Yanan, L.; Bin, Z.; Shuai, Z. Study on Edge Preparation of Cemented Carbide Inserts Based on Micro-blasting Jet Technology. Tool Eng. 2017, 51, 16–20. [Google Scholar]

- Zheng, W.; Huang, B.; Zhao, X.; Zhou, Y. Finite Element Analysis on Influence of Rounded Cutting Edge Radius of Milling Cutter to Cutting Property. Coal Mine Mach. 2014, 35, 125–127. [Google Scholar]

- Tymczyszyn, J.; Szajna, A.; Mrówka-Nowotnik, G. Influence of Nanocomposite PVD Coating on Cutting Tool Wear During Milling of 316L Stainless Steel Under Air Cooling Conditions. Materials 2025, 18, 1959. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, H.D.; Wan, Q.; Cai, Y.; Chen, H.; Chen, Y.M.; Guo, J.L.; Yang, B. High-temperature oxidation behaviour of AlTiSiN and AlCrSiN coatings. Surf. Eng. 2019, 35, 652–660. [Google Scholar] [CrossRef]

- Jäger, N.; Meindlhumer, M.; Zitek, M.; Spor, S.; Hruby, H.; Nahif, F.; Julin, J.; Rosenthal, M.; Keckes, J.; Mitterer, C.; et al. Impact of Si on the high-temperature oxidation of AlCr(Si)N coatings. J. Mater. Sci. Technol. 2022, 100, 91–100. [Google Scholar] [CrossRef]

- Guo, L.; Liang, Z.Q.; Du, Y.C.; Sun, Y.H.; Shi, J.L.; Zhang, R.; Su, Z.P. Study on the cutting performance of AlTiN/AlTiSiN composite coating tool in deep-hole pull boring tool of GH4169. Tribol. Int. 2025, 202, 110236. [Google Scholar] [CrossRef]

| Milling Cutter Model | Front Angle | Back Corner | Spiral Angle | Tip Radius | Number of Cutting Edges |

|---|---|---|---|---|---|

| Baoke 58° knife | 6.5° | 11° | 40° | 3 mm | 4 |

| Spindle Speed (r/min) | vc (m/min) | vf (mm/min) | fz (mm) | ap (mm) | ae (mm) | Overhang Length (mm) |

|---|---|---|---|---|---|---|

| 4500 | 85 | 1500 | 0.09 | 0.3 | 2.5 | 30 |

| Elements | Cr | Ni | Mo | Mn | Si | C | P | Fe |

|---|---|---|---|---|---|---|---|---|

| Composition Ingredients | 16 to 18 | 10–14 | 2–3 | 2 or less | 1 or less | 0.03 or less | 0.045 or less | Other |

| Density (g/cm3) | HRC | Melting Point (°C) | Heat Conductivity (20–100 °C) (W/(m·K)) | Deformation Temperature (°C) | Tensile Strength (MPa) | Elongation (%) | Reduction in Section (%) |

|---|---|---|---|---|---|---|---|

| 7.98 | 28 | 1400 | 15 | 800 | 530 | 40 | 60 |

| Group | Factor 1 | Factor 2 | Factor 3 | Surface Roughness (μm) |

|---|---|---|---|---|

| Pressure (MPa) | Movement Speed (m/min) | Tool Rotation Speed (r/min) | ||

| 1 | 0.1 | 60 | 20 | 0.0652 |

| 2 | 0.1 | 70 | 30 | 0.0638 |

| 3 | 0.1 | 80 | 40 | 0.0581 |

| 4 | 0.2 | 70 | 40 | 0.0572 |

| 5 | 0.2 | 80 | 20 | 0.0680 |

| 6 | 0.2 | 60 | 30 | 0.0499 |

| 7 | 0.3 | 80 | 30 | 0.0720 |

| 8 | 0.3 | 60 | 40 | 0.0692 |

| 9 | 0.3 | 70 | 20 | 0.0448 |

| R Value | 0.00400 | 0.01077 | 0.00257 | - |

| Groups | Factor 1 | Factor 2 | Factor 3 | Coating Mechanical Properties | ||

|---|---|---|---|---|---|---|

| Pressure (MPa) | Movement Speed (m/min) | Tool Rotation Speed (r/min) | Binding Force (N) | Nano-Hardness (HV) | Comprehensive Weighted Scoring | |

| 1 | 0.1 | 60 | 20 | 57 | 3525 | 299.961 |

| 2 | 0.1 | 70 | 30 | 54 | 3314 | 282.798 |

| 3 | 0.1 | 80 | 40 | 63 | 3268 | 297.621 |

| 4 | 0.2 | 70 | 40 | 48 | 3079 | 258.570 |

| 5 | 0.2 | 80 | 20 | 65 | 3162 | 295.743 |

| 6 | 0.2 | 60 | 30 | 74 | 2602 | 282.810 |

| 7 | 0.3 | 80 | 30 | 61 | 3130 | 286.323 |

| 8 | 0.3 | 60 | 40 | 61 | 3297 | 295.341 |

| 9 | 0.3 | 70 | 20 | 64 | 3038 | 287.124 |

| Coating Properties | Factors | SS | DF | MS | F-Value | p-Value |

|---|---|---|---|---|---|---|

| Binding Power, N | Passivation pressure (A) | 34.889 | 2 | 17.444 | 0.169 | 0.856 |

| Gun movement speed (B) | 134.889 | 2 | 67.444 | 0.625 | 0.605 | |

| Tool rotation speed (C) | 54.889 | 2 | 27.444 | 0.265 | 0.790 | |

| Error | 206.889 | 2 | 103.444 | |||

| Nano-hardness, HV | Passivation pressure (A) | 266,304.889 | 2 | 133,152.444 | 1.674 | 0.374 |

| Gun move speed (B) | 3909.556 | 2 | 1954.778 | 0.025 | 0.976 | |

| Tool rotation speed (C) | 91,689.556 | 2 | 45,844.778 | 0.576 | 0.634 | |

| error | 159,113.556 | 2 | 79,556.778 | |||

| Overall rating | Passivation pressure (A) | 334.246 | 2 | 167.123 | 2.152 | 0.317 |

| Gun movement speed (B) | 565.061 | 2 | 282.531 | 3.638 | 0.216 | |

| Tool rotation speed (C) | 214.914 | 2 | 107.457 | 1.384 | 0.420 | |

| Error | 155.332 | 2 | 77.666 |

| Mechanical Properties | Pressure | Movement Speed | Tool Rotation Speed | Optimal Process Parameter Combination |

|---|---|---|---|---|

| Binding force | 4.33 | 8.67 | 5.67 | Passivation pressure: 0.1 MPa Gun moving speed: 80 m/min Knife rotation speed: 20 r/min |

| Nano-hardness | 421 | 45 | 226 | |

| Comprehensive Score | 14.4 | 17.1 | 10.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Du, J.; Liu, Z.; Qian, H.; Wang, Q. Optimization of Micro-Sandblasting Parameters for Enhanced Adhesion and Wear Resistance of AlTiSiN-Coated Tools. Coatings 2025, 15, 757. https://doi.org/10.3390/coatings15070757

Wang J, Du J, Liu Z, Qian H, Wang Q. Optimization of Micro-Sandblasting Parameters for Enhanced Adhesion and Wear Resistance of AlTiSiN-Coated Tools. Coatings. 2025; 15(7):757. https://doi.org/10.3390/coatings15070757

Chicago/Turabian StyleWang, Junlong, Jiaxuan Du, Zhipeng Liu, Hongliang Qian, and Qi Wang. 2025. "Optimization of Micro-Sandblasting Parameters for Enhanced Adhesion and Wear Resistance of AlTiSiN-Coated Tools" Coatings 15, no. 7: 757. https://doi.org/10.3390/coatings15070757

APA StyleWang, J., Du, J., Liu, Z., Qian, H., & Wang, Q. (2025). Optimization of Micro-Sandblasting Parameters for Enhanced Adhesion and Wear Resistance of AlTiSiN-Coated Tools. Coatings, 15(7), 757. https://doi.org/10.3390/coatings15070757