1. Introduction

Natural lacquer, also known as raw lacquer, is a resinous exudate derived from trees of the Anacardiaceae family [

1], exhibiting exceptional adhesion, chemical resistance, and long-term durability [

2]. Owing to these superior properties, lacquer has been extensively utilized across East Asia since antiquity, serving both as a protective coating and as a decorative medium [

3,

4]. As a natural high-performance coating material, lacquer plays a significant role not only in traditional crafts and artistic expression but also as a reflection of early advances in materials science and technological practice [

5]. Variations in lacquer tree species across different regions result in distinct chemical compositions of lacquer sap, particularly in the types and proportions of phenolic compounds. Notably, Toxicodendron vernicifluum predominantly produces urushiol, T. succedanea secretes laccol, and Gluta usitata yields thitsiol [

6,

7,

8]. Consequently, the characterization of specific lacquer phenols has become a critical method for the identification, technological analysis, and provenance study of historical lacquer artifacts.

Lacquerware, as a quintessential application of lacquer materials, not only exemplifies the functional performance of natural coatings but also embodies rich cultural and historical significance [

9,

10,

11,

12]. The Nanyue Kingdom (204 BCE-111 BCE), located in present-day southern China and northern Vietnam (

Figure 1), served as a critical zone of interaction between the Central Plains culture of the Qin and Han dynasties and the indigenous cultures of Lingnan [

13]. A considerable number of finely crafted lacquer artifacts have been unearthed from this region, reflecting the high level of technical development achieved during the Nanyue period. Among these, the lacquerware recovered from the Luobowan tomb complex in Guigang, Guangxi Zhuang Autonomous Region, China, stands out, demonstrating not only the sophistication of local lacquer production but also the early transmission and localized adaptation of coating technologies originating from the Central Plains [

14]. Archaeological studies suggest that the occupant of Tomb No. 1 at Luobowan was likely the highest-ranking official of Guilin Commandery in the Nanyue Kingdom, who possessed a Central Plains background [

15]. The large-scale tomb and the diversity of grave goods further attest to the individual’s prominent social status during their lifetime.

This study selects a fragment of a lacquered ear cup excavated from the Luobowan tomb complex as the research subject, and systematically investigates its wooden core preparation, lacquer application techniques, and source of raw lacquer through a combination of microscopic structural observations, lacquer layer analysis, and phenolic compound identification. By conducting this case study, the research aims to elucidate the application characteristics of natural lacquer as a functional coating material during the Nanyue Kingdom period, to analyze the relationship between technological processes and material selection in lacquerware production, and to contribute to a broader understanding of the evolution of early natural coating technologies and the mechanisms of their cultural transmission.

2. Materials and Methods

2.1. Analyzed Samples

The experimental sample (

Figure 2) was taken from the side wall of a lacquered ear cup excavated from Tomb No. 1 at the Luobowan site in Guigang Guangxi Zhuang Autonomous Region, China. The ear cup (erbei) is a type of drinking vessel characterized by two small handles resembling ears, from which its name is derived.

2.2. Experimental Methods

2.2.1. Sample Preparation

To facilitate microscopic observation of the lacquer film cross-section, the samples were embedded using a high-transparency cold-mounting resin system (Chuanhe, Shanghai, China). The selected lacquer film fragments were placed into the cold-mounting material and cured to produce standard cross-sectional specimens for subsequent analytical procedures.

2.2.2. Moisture Content Determination

The moisture content of the lacquer film samples was determined according to the standard method outlined in WW/T 0086-2018 [

16]—Determination of Moisture Content for Excavated Bamboo, Wood, and Lacquered Artifacts (Gravimetric Method). The procedure was as follows: the mass of an empty glass vial with its cap was recorded as m₀. Cleaned lacquer film samples were then scraped layer by layer using a stainless steel spatula and placed into the vial, and the combined mass was recorded as m₁. The cap was removed, and the vial containing the samples was dried in an oven at 105 °C for 12 h. After drying, the final mass was recorded as m₂. The moisture content (W) of the lacquer film was calculated using the following formula:

where

m₀ = mass of the empty glass vial with cap (g);

m₁ = mass of the glass vial with cap plus the sample before drying (g);

m₂ = mass of the glass vial with cap plus the sample after drying (g).

2.2.3. Microscopic Observation

Microscopic observation and analysis of the surface and cross-sectional morphology of the lacquer film were conducted using a Smartzoom 5 digital 3D microscope (Carl Zeiss, Oberkochen, Germany). The imaging parameters were set as follows: the sample was magnified to 50×, 100×, 200× and 300×, and illumination was provided by a ring-shaped LED light source. The instrument utilized an automatic focus system, automatic image stitching, and depth of field fusion technology. During the examination, the Z-stack mode was employed to perform multilayer scanning in order to capture the complete microstructural information of the lacquer film.

2.2.4. Scanning Electron Microscopy–Energy-Dispersive Spectroscopy (SEM-EDS) Analysis

The surface and cross-sectional elemental composition of the lacquer film samples were analyzed using an Apreo S scanning electron microscope (Thermo Scientific, Waltham, MA, USA) coupled with an X-MAX20 energy-dispersive spectrometer (Oxfordshire, UK). The testing conditions were as follows: an accelerating voltage of 8 kV, low vacuum mode, and a working distance of 15 mm. Prior to analysis, the sample surfaces were sputter-coated with gold for 40 s. The EDS detector had an effective detection area of 20 mm² and an energy resolution better than 127 eV, covering an elemental detection range from beryllium (Be₄) to uranium (U₉₂).

2.2.5. X-Ray Diffraction (XRD) Analysis

X-ray diffraction (XRD) analysis was performed to determine the mineralogical composition of the lacquer ground layer using a Smart-LAB diffractometer (Rigaku, Tokyo, Japan). The specific testing conditions were as follows: tube current of 150 mA, tube voltage of 40 kV, scanning range from 5° to 90° (2θ), scanning speed of 10 °/min, and step size of 0.01°. The instrument operated at a maximum power of 9 kW, utilizing a copper (Cu) target and a standard Z sample stage for measurements.

2.2.6. Fourier Transform Infrared Spectroscopy (FT-IR) Analysis

Fourier transform infrared (FT-IR) spectroscopy was conducted to analyze the molecular structural characteristics of the lacquer film samples using a LUMOS FT-IR spectrometer (Bruker, Bremen, Germany). Fourier transform infrared spectroscopy was used with the potassium bromide tablet method, scanning in the range of 4000–600 cm−¹, with 24 scans and a resolution of 4 cm−¹ to test the infrared absorption spectra of the samples. The obtained FT-IR spectra were processed using the smoothing function in Origin2023 (Version 10.0), software (OriginLab Corporation, Northampton, MA, USA), with a span of 60 points, to reduce spectral noise and improve the clarity of absorption peaks.

2.2.7. Pyrolysis–Gas Chromatography/Mass Spectrometry (Py-GC/MS) Analysis

Py-GC-MS analysis was performed using a Frontier EGA-PY3030D multifunctional pyrolyzer (Frontier Laboratories Ltd., Koriyama, Fukushima, Japan) coupled with an Agilent 7890B-5977A GC/MS system (Agilent Technologies Inc., Santa Clara, CA, USA), equipped with an HP-5MSUI capillary column (30 m × 0.25 mm × 0.25 μm) and a quadrupole mass spectrometer operating in electron impact (EI) ionization mode at 70 eV. To separately investigate the visually distinguishable red and black lacquer films, micro-samples (approximately 1–2 mm²) were carefully collected from both the interior and exterior surfaces under a stereomicroscope using a sterile scalpel. Contamination from the underlying ground layer or adjacent materials was strictly avoided. Each sample was analyzed independently. An online derivatization technique was applied: less than 1 mg of each sample was mixed with 5 μL of a methylation reagent (10% tetramethylammonium hydroxide in methanol, analytical grade, Aladdin Reagent Co., Shanghai, China) and placed into a sample boat. The sample was then introduced into the pyrolysis tube, where methylation and pyrolysis occurred simultaneously. Pyrolysis was carried out at 500 °C for 0.2 min. The interface temperature between the pyrolyzer and GC was maintained at 300 °C. The GC injector was operated in split mode (50:1) at 300 °C, with helium as the carrier gas at a constant flow rate of 1.0 mL/min. The GC oven was initially held at 50 °C for 2 min, then ramped to 300 °C at 4 °C/min, and held at 300 °C for 5 min. The MS ion source temperature was set to 230 °C and the quadrupole temperature to 150 °C. Full-scan acquisition mode was used across an m/z range of 10–600. Compound identification was performed by comparison with the NIST mass spectral libraries.

3. Results

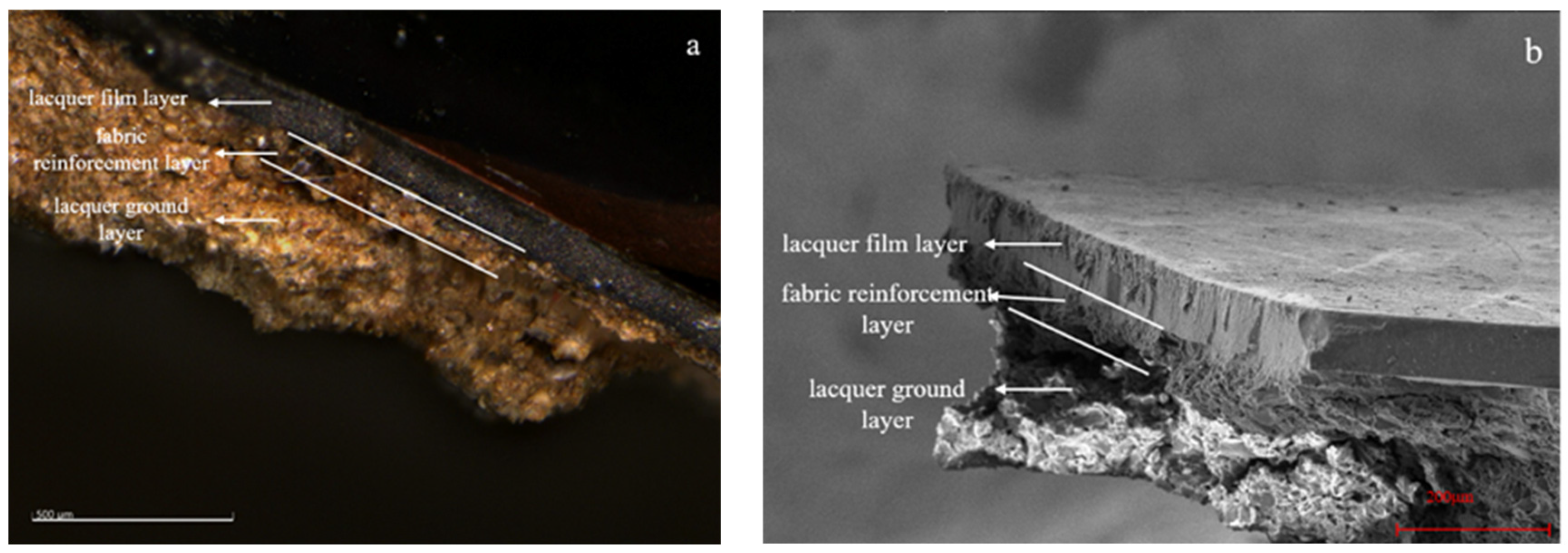

3.1. Structural Organization of Lacquerware

During the Han dynasty, lacquerware was typically constructed through a multilayered composite structure comprising [

17,

18,

19,

20], in sequence, a wooden core, a fabric reinforcement layer, a lacquer ground layer, and a lacquer film layer. This layered arrangement enhanced the mechanical properties and service life of the artifacts. The core material was usually wood or bamboo [

21], locally sourced and skillfully shaped to form the basic framework of the vessel. Due to the inherent porosity and structural instability of natural wood materials, artisans often first applied a layer of plant-based fabric (fabric reinforcement) over the core to increase surface compactness and improve structural resilience [

22]. Subsequently, a lacquer ground layer, composed of raw lacquer mixed with inorganic fillers such as brick powder, tile powder [

23], or bone ash [

24], was applied to fill surface irregularities and achieve a leveled foundation. After curing, the lacquer ground exhibited excellent hardness and compressive strength, although its tensile strength remained relatively low; the fabric layer effectively mitigated cracking caused by substrate deformation or shrinkage. Finally, multiple layers of lacquer were successively applied over the ground layer, each polished smooth after curing, and colored to create a waterproof, corrosion-resistant, and aesthetically refined surface.

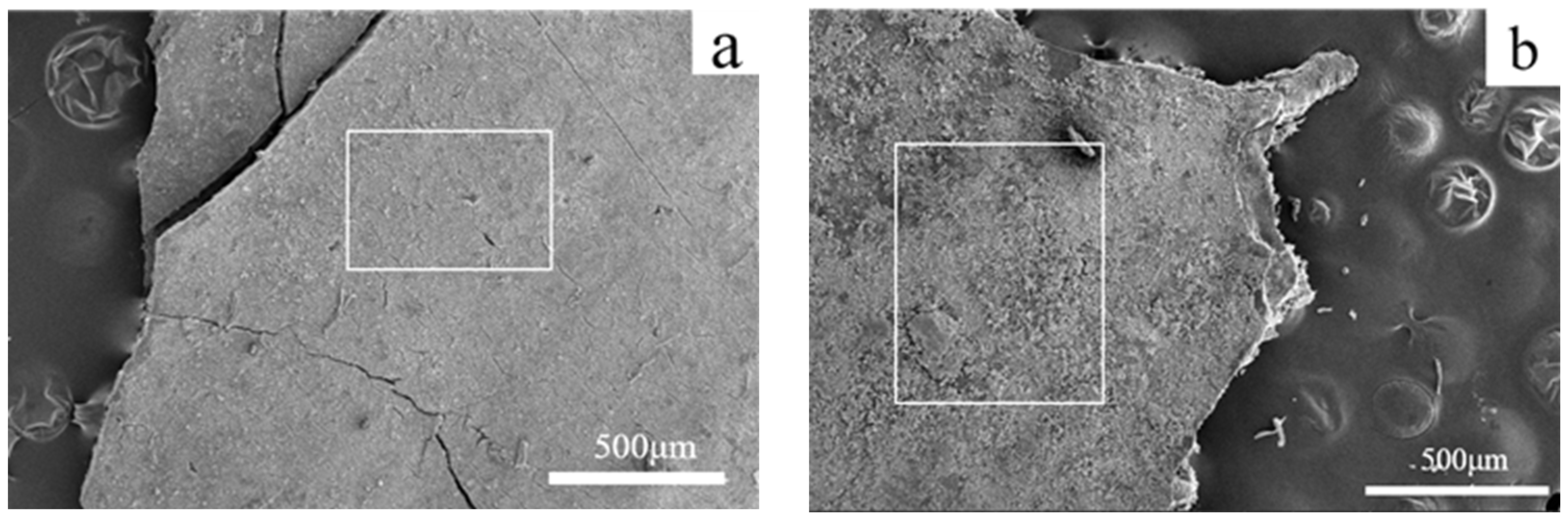

The cross-sectional analysis of the lacquered ear cup excavated from the Luobowan tomb complex in Guigang, Guangxi Zhuang Autonomous Region, China, revealed a stratified structure consisting, from the interior to the exterior, of a wooden core layer, a fabric reinforcement layer, a lacquer ground layer, and a lacquer film layer (

Figure 3), consistent with the typical construction system of Han dynasty lacquerware. The wooden substrate was identified as

Phoebe sp. (Lauraceae), and the fabric reinforcement layer was composed of natural plant fibers, presumed to be hemp. Compositional analysis indicated that the lacquer ground layer was primarily made of natural lacquer mixed with SiO₂ inorganic materials, without the presence of traditional fillers such as bone ash or brick powder, suggesting certain regional characteristics. The ear cup exhibits differential coloration between its interior and exterior surfaces: an inner black lacquer layer and an outer red lacquer layer, both applied as single coats with smooth and well-defined interfaces. The meticulous surface treatment observed reflects a high level of technical refinement. Overall, the structural layout and production techniques of this artifact closely align with the traditional practices of Han dynasty lacquerware from the Central Plains, while the material selection exhibits distinctive regional variations associated with the Nanyue cultural sphere.

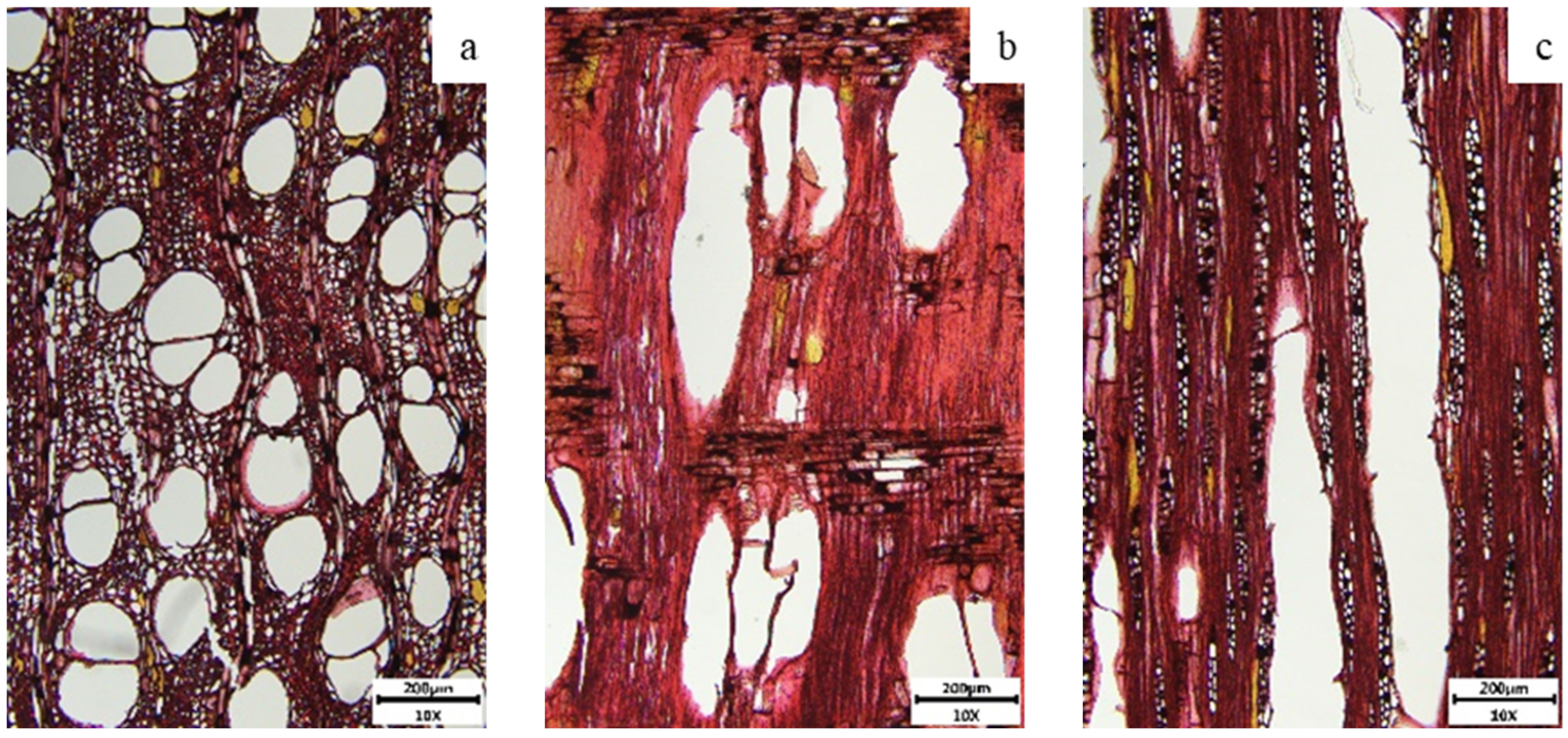

3.2. Analysis of the Wooden Core

Microscopic examination of the wooden core from the lacquered ear cup revealed that it belonged to diffuse–porous wood. In the transverse section, the vessels appeared circular to oval in shape, frequently arranged as solitary pores or short radial multiples, typically consisting of two vessels and occasionally up to three or four. The perforation plates were predominantly simple, with rare occurrences of scalariform perforations. Axial parenchyma was sparse and exhibited a paratracheal distribution, and oil cells were observed. The wood fibers were thin-walled and exhibited septate characteristics. The wood rays were non-storied; uniseriate rays were relatively few and measured 2–7 cells in height, while multiseriate rays were commonly 2–3 cells wide and 10–20 cells high. The ray structure was primarily heterocellular type III and type II, and the ray–vessel pits were characterized by large, rounded outlines with scarred features. No intercellular canals were observed (

Figure 4). Based on these microscopic anatomical characteristics, the wooden core was preliminarily identified as belonging to the genus Phoebe (Lauraceae), commonly known as nanmu.

In Han dynasty lacquerware production, the selection of wooden core materials was critical not only for ensuring the structural stability and functional performance of the artifacts; it also reflected a profound understanding and practical application of material science properties. Nanmu (

Phoebe spp.) is characterized by its fine and uniform texture, moderate air-dry density, excellent mechanical properties, and good workability, making it particularly suitable for carving and forming complex shapes [

25]. These attributes enabled the wooden core to meet the technical demands for surface smoothness and strength required by multilayer lacquer applications. Furthermore, nanmu possesses an attractive natural grain and soft luster, providing favorable adhesion with lacquer layers and enhancing the overall visual and artistic appeal of lacquerware.

In addition, nanmu is rich in aromatic volatile compounds and natural antimicrobial and insect-resistant chemicals, conferring excellent durability and environmental adaptability, thereby contributing to the extended preservation of lacquered artifacts [

26]. The widespread use of nanmu as a core material—especially in ritual vessels, burial objects, and high-end daily wares—reflects its important role within the social hierarchy and cultural ideologies of the Han dynasty.

Thus, the selection of nanmu as the wooden core material for the lacquered ear cup examined in this study demonstrates not only a rational technological exploitation of superior material properties but also the Nanyue Kingdom’s comprehensive considerations of functionality, aesthetics, and cultural symbolism in material choice.

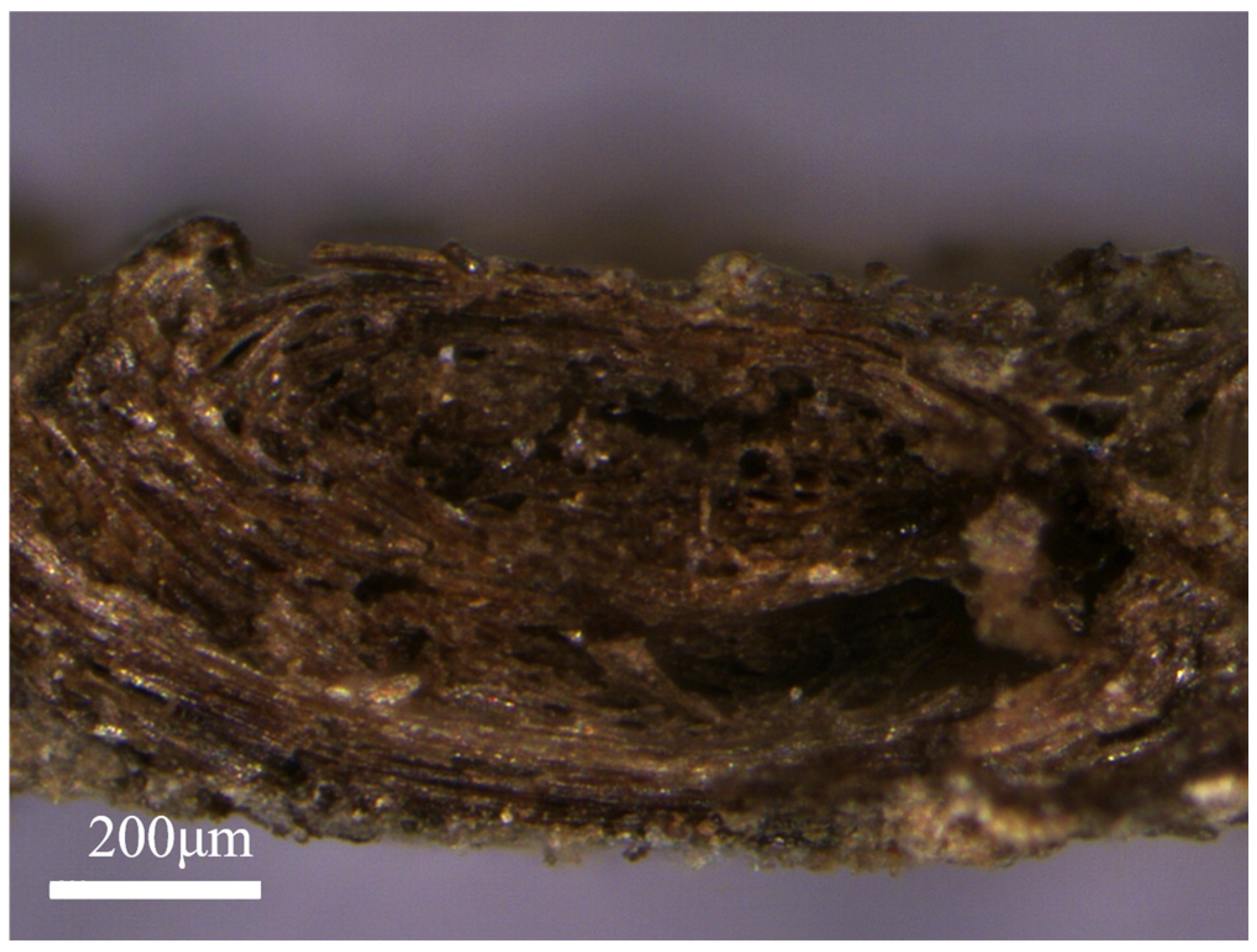

3.3. Analysis of the Fabric Reinforcement Layer

In the cross-sectional analysis of the lacquered ear cup, a residual layer of fibrous fabric was identified between the lacquer ground layer and the wooden core, confirming the presence of a fabric reinforcement layer (

Figure 5). Observation of the cross-section of a single yarn reveals that the fiber cross-sections exhibited a porous and irregular morphology, with prominent fine surface textures and a layered or scaly structure, characterized by a rough surface and numerous microvoids (

Figure 6 and

Figure 7). Such structural features are commonly observed in natural plant fibers, particularly those derived from bast plants such as hemp.

In traditional Han dynasty lacquerware production, fabric reinforcement layers were typically applied to enhance the structural integrity of the wooden core and to strengthen the adhesion between the wooden core and the lacquer ground, effectively preventing cracking and lacquer film detachment caused by stress variations during use. Based on the observed fiber morphology and historical technological practices, the material of the fabric reinforcement layer in this artifact is presumed to have originated from hemp or related plant fibers [

27]. However, due to severe degradation resulting from long-term burial conditions, the fiber tissues exhibited blurred cellular structures and loose arrangements, rendering precise botanical identification impossible under the current observational conditions. Nevertheless, the presence of the fabric reinforcement layer and its structural characteristics provide important physical evidence for understanding the techniques employed during the Nanyue Kingdom period to control the stability and durability of lacquerware bodies.

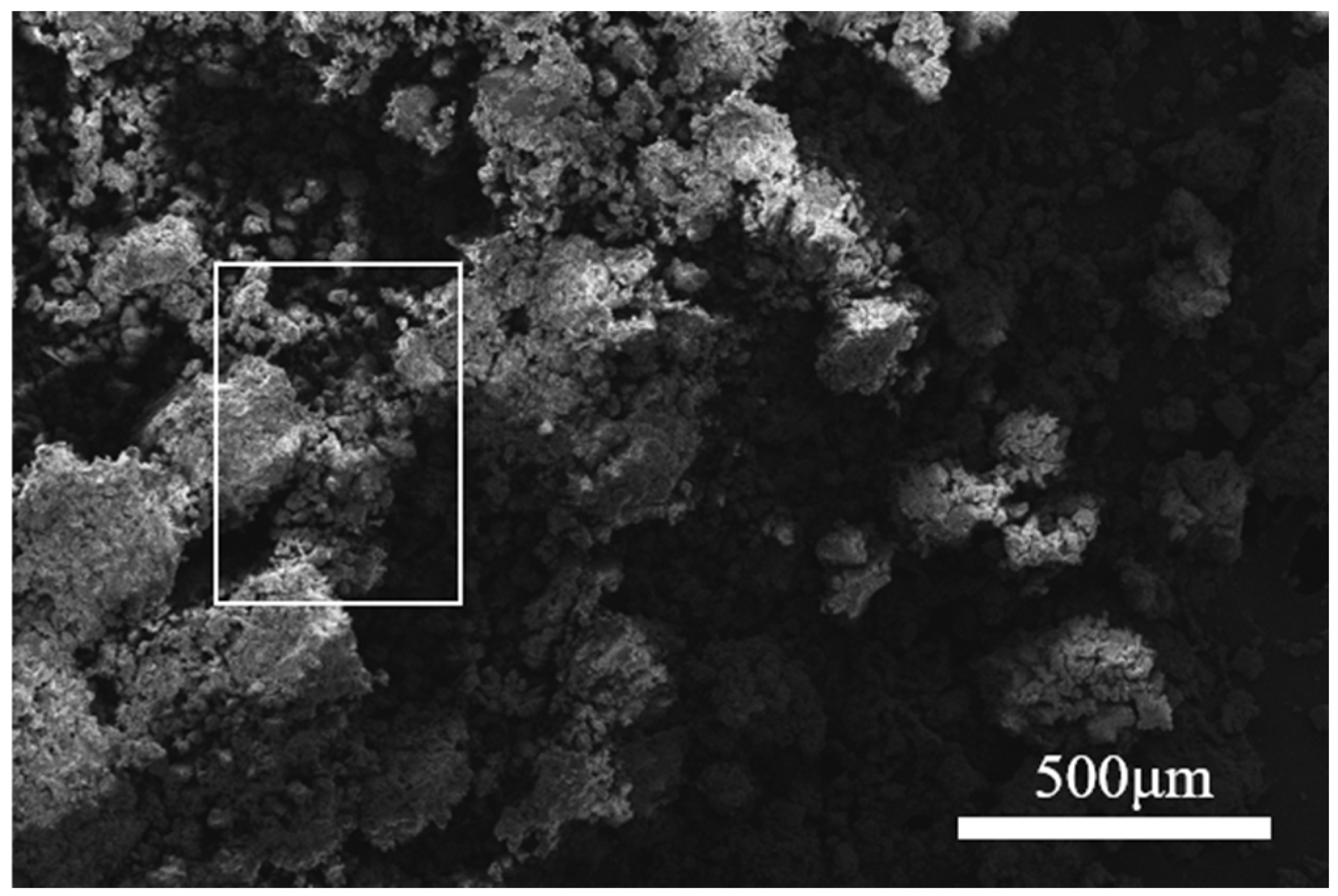

3.4. Analysis of the Lacquer Ground Layer

In traditional Han dynasty lacquerware production, the lacquer ground layer served as a critical transitional layer between the wooden core and the lacquer film. Its primary functions included leveling the surface of the wooden core, sealing the inherent pores of the wood, and enhancing the overall structural stability of the artifact [

28]. Typically, lacquer ground layers were composed of natural lacquer mixed with various inorganic fillers, such as brick powder, tile powder, or bone ash, in order to increase hardness, compressive strength, and to improve the adhesion conditions for subsequent lacquer applications.

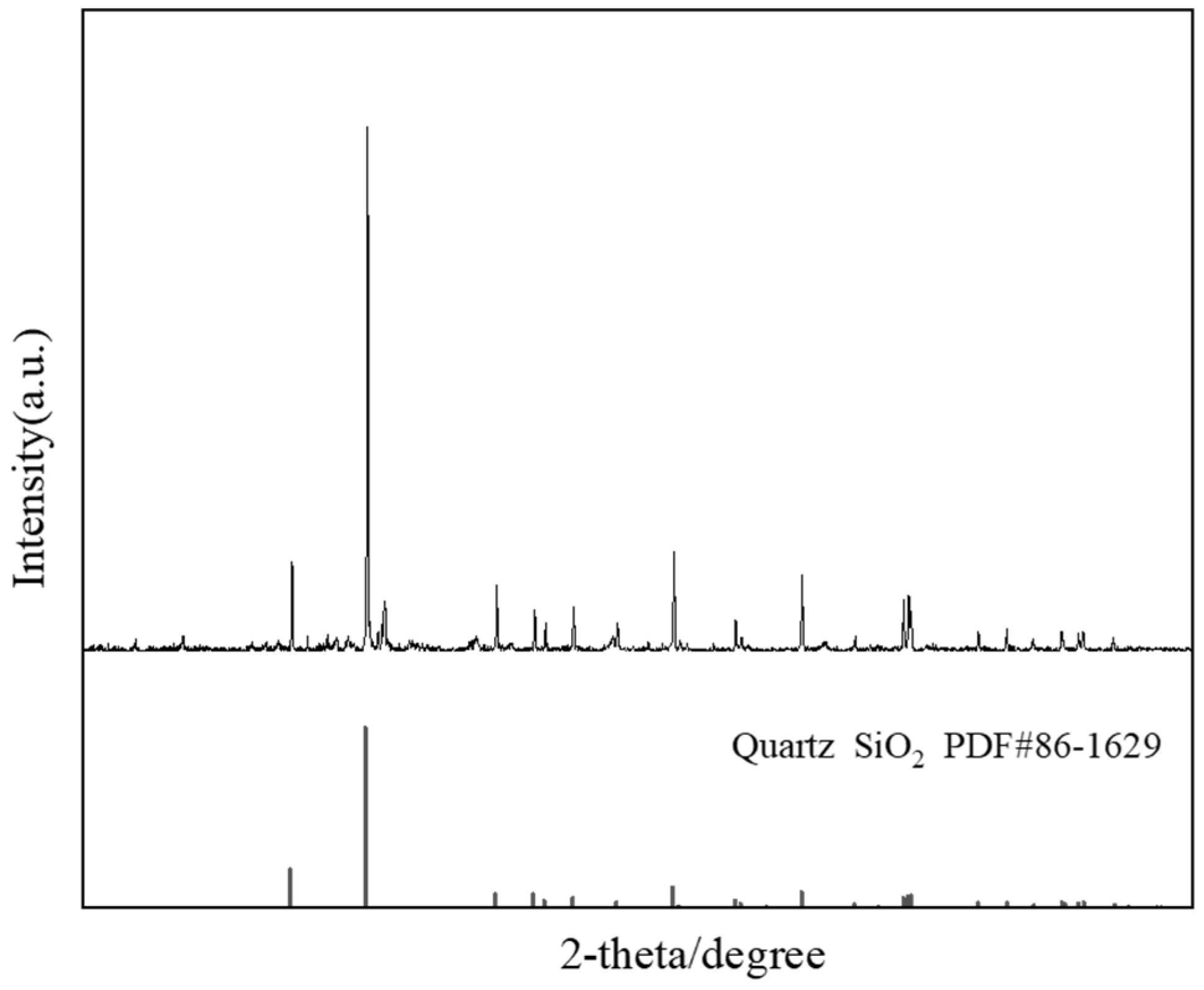

In this study, detailed analysis was conducted on a lacquered ear cup sample excavated from the Luobowan tomb complex in Guigang, Guangxi Zhuang Autonomous Region. The results revealed notable compositional particularities in the lacquer ground layer of this artifact. Combined scanning electron microscopy–energy-dispersive spectroscopy (SEM-EDS) and X-ray diffraction (XRD) analyses confirmed that the lacquer ground was primarily composed of natural lacquer mixed with SiO₂, with no detectable traces of bone ash or other conventional inorganic fillers (

Figure 8 and

Table 1). The EDS spectra and XRD diffraction patterns clearly indicated that SiO₂ was the major inorganic constituent (

Figure 9), and the lacquer ground exhibited relatively high compositional purity.

The absence of additional filler materials suggests that ancient craftsmen demonstrated a high degree of precision and control in selecting and formulating lacquer ground materials. Despite the lack of traditional reinforcing fillers, the lacquer ground layer showed excellent physical properties, providing a solid, smooth substrate that supported the subsequent application of multiple lacquer film layers and ensured the surface smoothness and structural stability of the finished artifact.

Moreover, the distinctive formulation of the lacquer ground observed in this study implies that in the Nanyue Kingdom region, lacquerware production may have followed technological routes or material selection traditions distinct from those of the Central Plains. These findings provide new material evidence and perspectives for further exploration of regional technological diversity and cultural exchange patterns in Han dynasty lacquerware production.

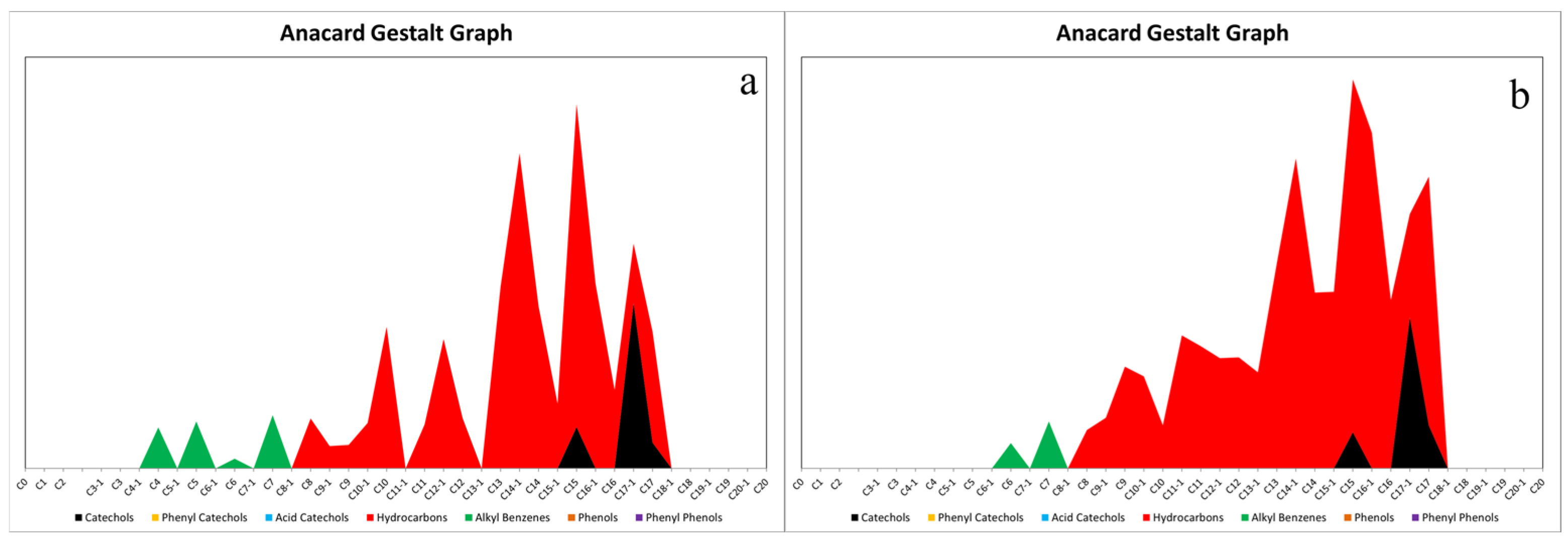

3.5. Analysis of the Lacquer Film Composition

Pyrolysis–gas chromatography–mass spectrometry (Py-GC-MS) was employed to analyze the compositions of the red and black lacquer films from the lacquered ear cup. The results indicated that both layers consisted of a mixture of Chinese lacquer (Toxicodendron vernicifluum, mainly containing C₁₇-structured phenolic compounds, urushiol) and Vietnamese lacquer (T. succedanea, mainly containing C₁₅-structured phenolic compounds, laccol) (

Figure 10). Urushiol-based lacquer sap was predominantly distributed in mainland China, whereas laccol-based lacquer sap sourced from Vietnam and Southeast Asia was more abundant but exhibited relatively lower physical properties. The coexistence of both types of lacquer phenols within a single artifact reflects the frequent material exchanges and the integrative material strategies characteristic of lacquerware production during the Nanyue Kingdom period.

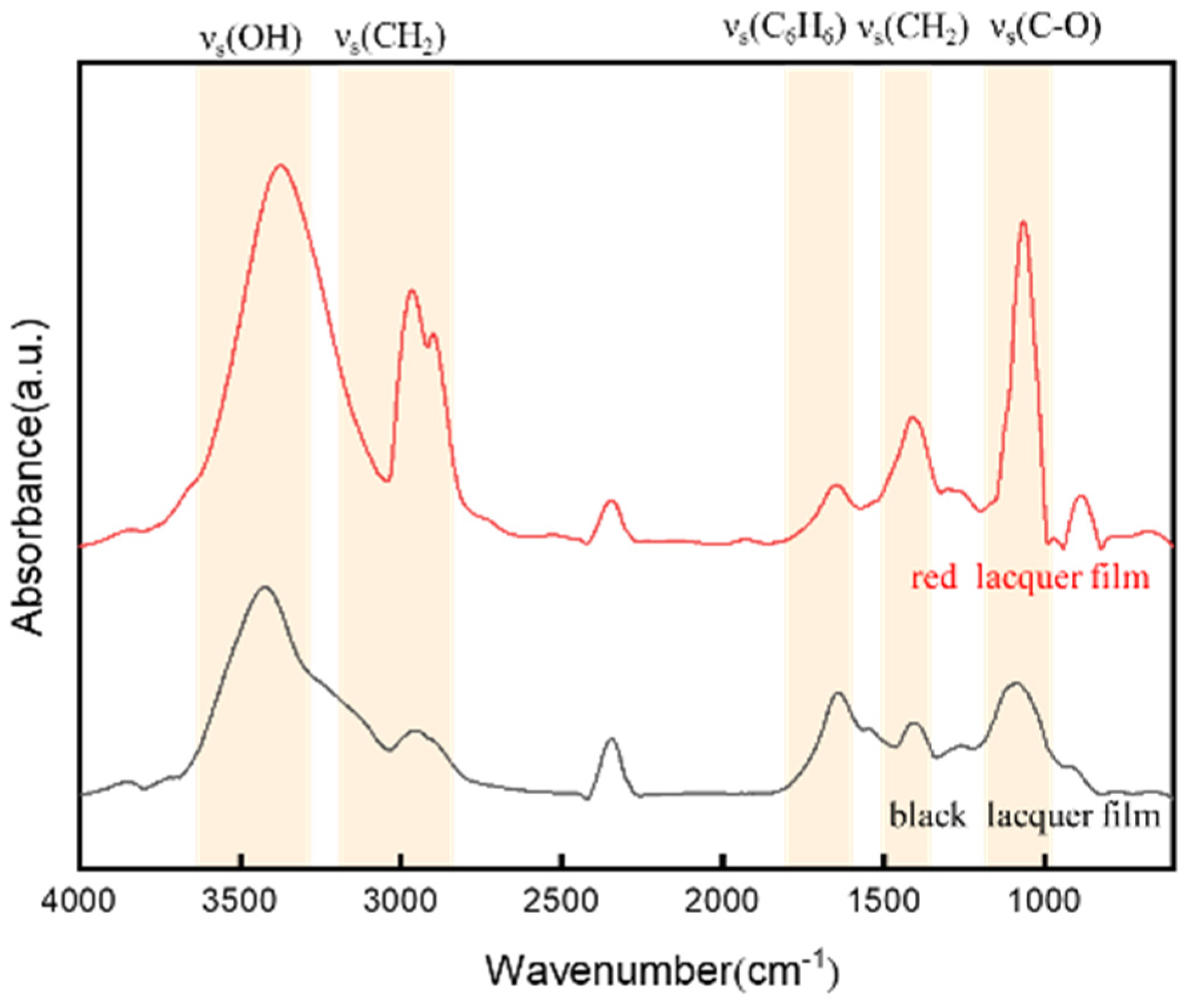

Fourier transform infrared spectroscopy (FT-IR) further revealed differences in the organic structures between the red and black lacquer films (

Figure 11). The red lacquer film exhibited strong absorption bands in the 3000–2800 cm⁻¹ region, corresponding to C–H stretching vibrations, and prominent carbonyl (C=O) absorption in the 1700–1600 cm⁻¹ region. Additionally, characteristic signals of aromatic structures (C=C) were observed between 1600 and 1500 cm⁻¹, and ether linkages (C–O–C) were detected in the 1200–1000 cm⁻¹ range [

29].

To further clarify the pigment compositions, analysis was conducted. The results identified characteristic Raman bands of carbon black in the black lacquer film and cinnabar (HgS) in the red lacquer film, confirming the use of cinnabar as a red pigment. Energy-dispersive spectroscopy (EDS) analysis further supported these findings by detecting mercury (Hg) signals in the red lacquer film (

Figure 12 and

Table 2), consistent with the application of cinnabar, while no iron elements were detected in either the red or black lacquer films, ruling out the use of iron-based compounds as pigments.

Integrating the results from the Py-GC-MS, FT-IR, and EDS analyses, it is evident that the lacquered ear cup demonstrated not only the sophisticated utilization of different natural lacquer resources but also the refined selection and application of inorganic pigments. These findings highlight the technical maturity and detailed craftsmanship in lacquerware production during the Nanyue Kingdom period, as well as the broader patterns of cross-regional material exchange and cultural interaction.

3.6. Preservation State of the Lacquer Film

As a natural polymer coating material, lacquer possesses excellent waterproofing and corrosion-resistant properties. However, archaeological excavations frequently reveal that excavated lacquer artifacts exhibit significant deterioration in waterproofing ability and physical performance. In this study, the moisture content of the red and black lacquer films from the lacquered ear cup was measured using the gravimetric method. The calculated moisture content indicated that the black lacquer film had a significantly higher moisture content than the red lacquer film within the same sample (

Table 3).

This difference may be attributed to two factors. First, in terms of surface structure, the black lacquer film may have developed more microvoids or rougher surface areas due to aging or the influence of pigment particle size distribution, leading to greater water retention. In contrast, the surface of the red lacquer film may be denser or smoother, reducing its water adsorption capacity. Second, in terms of pigment hygroscopicity, the black lacquer film employed carbon black, which has a high specific surface area and porosity, inherently favoring moisture absorption. Meanwhile, the red lacquer film used cinnabar (HgS), a dense inorganic mineral pigment with low hygroscopicity, resulting in a lower overall moisture content.

This observation is particularly interesting, as it differs from the commonly observed phenomenon in archaeological lacquerware, where extensive surface weathering typically leads to a uniformly elevated moisture content. In the present sample, although the outer surface exhibited relatively low moisture absorption, rapid moisture loss from the outer layers caused surface shrinkage. Meanwhile, slower moisture migration and retention within the deeper layers led to internal swelling. This imbalance between surface contraction and internal expansion ultimately manifested macroscopically as cracking, warping, and even outward curling of the lacquer film. These results underscore the profound impact of post-burial environmental changes on the microstructural integrity and mechanical performance of lacquer artifacts.

4. Conclusions

This study provides a comprehensive analysis of a lacquered ear cup from the Luobowan tomb complex, offering new insights into the material composition, structural layering, and preservation state of early Han dynasty lacquerware associated with the Nanyue Kingdom.

The lacquered ear cup is composed of four distinct layers, from interior to exterior, of a wooden core, a fabric reinforcement layer, a lacquer ground layer, and a lacquer film layer—demonstrating technological consistency with Han period lacquer traditions. The structural arrangement is standardized and technologically consistent with Han dynasty lacquerware traditions.

Material identification revealed the use of Phoebe sp. wood, presumed hemp fabric, and a lacquer ground made from raw lacquer mixed with brick or tile powder (SiO₂). Significantly, the lacquer films were found to contain a blend of Chinese urushi and Vietnamese laccol, with cinnabar and carbon black used as red and black pigments, respectively. These findings highlight the dynamic utilization of natural lacquer resources and inorganic pigments, providing rare material evidence of cross-regional raw material exchange and technological interaction in early southern China.

Preservation analysis revealed that the black lacquer film exhibited a higher moisture content than the red lacquer film, likely due to differences in surface microstructure and pigment hygroscopicity. Based on these findings, this study recommends that lacquerware storage environments maintain a temperature of 19–24 °C with daily fluctuations within ±3 °C, and a relative humidity around 55%, with daily variation not exceeding 5% and a maximum RH below 75%.

In sum, this research not only advances our understanding of early cross-cultural lacquer technologies in the Han dynasty but also contributes valuable data for evidence-based conservation planning of archaeological lacquerware.

Author Contributions

Formal analysis, writing—original draft, L.Z.; Writing—review and editing, X.L. (Xia Li); Data curation and funding acquisition, Z.Z.; Investigation, S.T.; Resources and supervision, J.T.; Writing—review and editing, S.L. and X.L. (Xiaocen Li); Methodology, N.W.; Conceptualization, T.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (52203126); the Key Research and Development Plan of Shaanxi Province (2022SF321); the Projects of the Social Science Foundation of Shaanxi Province (2021G001); and the Shaanxi Province Youth Science and Technology Rising Star Project (2024ZC-KJXX-033).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets used and/or analyzed during the current study are available from the first author on reasonable request.

Acknowledgments

We would like to express our gratitude to Xing Zhao from Northwest University for his guidance in this research.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| OM | Optical microscopy |

| SEM-EDS | Scanning electron microscopy with energy-dispersive X-ray spectroscopy |

| XRD | X-ray diffraction |

| FT-IR | Fourier transform infrared spectroscopy |

| Py-GC-MS | Pyrolysis–gas chromatography–mass spectrometry |

References

- Veenhoven, J.; van Keulen, H.; Saverwyns, S.; Lynen, F.; van Bommel, M. Optimising the analysis of Anacardiaceae (Asian lacquer) polymers using pyrolysis-gas chromatography-mass spectrometry. J. Anal. Appl. Pyrolysis. 2023, 170, 105845. [Google Scholar] [CrossRef]

- Lu, R.; Honda, T.; Kamiya, Y.; Yoshida, K.; Miyakoshi, T. Analysis of Japanese Jōmon lacquer-ware by pyrolysis-gas chromatography/mass spectrometry. J. Anal. Appl. 2013, 103, 68–72. [Google Scholar] [CrossRef]

- Jaewan, C.H.O.I.; Soochul, K.I.M. Lacquer techniques in the late Joseon dynasty. J. Korean Wood Sci. Technol. 2023, 51, 69–80. [Google Scholar]

- Norman, J. Lacquer: Technology and conservation: A comprehensive guide to the technology and conservation of Asian and European lacquer. Stud. Conserv. 2006, 51, 157–158. [Google Scholar] [CrossRef]

- Snyder, D.M. An overview of oriental lacquer: Art and chemistry of the original high-tech coating. J. Chem. Educ. 1989, 66, 977. [Google Scholar] [CrossRef]

- Lee, J.; Jung, S.B.; Terlier, T.; Lee, K.B.; Lee, Y. Molecular identification of Asian lacquers from different trees using Py-GC/MS and ToF-SIMS. Surf. Interface Anal. 2018, 50, 696–704. [Google Scholar] [CrossRef]

- Han, B.; Fan, X.; Chen, Y.; Gao, J.; Sablier, M. The lacquer crafting of Ba state: Insights from a Warring States lacquer scabbard excavated from Lijiaba site (Chongqing, southwest China). J. Archaeol. Sci.: Rep. 2022, 42, 103416. [Google Scholar] [CrossRef]

- Niimura, N.; Miyakoshi, T.; Onodera, J.; Higuchi, T. Characterization of Rhus vernicifera and Rhus succedanea lacquer films and their pyrolysis mechanisms studied using two-stage pyrolysis-gas chromatography/mass spectrometry. J. Anal. Appl. Pyrolysis 1996, 37, 199–209. [Google Scholar] [CrossRef]

- Zhai, K.; Sun, G.; Zheng, Y.; Wu, M.; Zhang, B.; Zhu, L.; Hu, Q. The earliest lacquerwares of China were discovered at Jingtoushan site in the Yangtze River Delta. Archaeometry 2022, 64, 218–226. [Google Scholar] [CrossRef]

- Frade, J.C.; Ribeiro, M.I.; Graça, J.; Rodrigues, J. Applying pyrolysis-gas chromatography/mass spectrometry to the identification of oriental lacquers: Study of two lacquered shields. Anal. Bioanal. Chem. 2009, 395, 2167–2174. [Google Scholar] [CrossRef]

- Zhu, Z.; Qin, Y.; Guo, Z.; Cai, S.; Lin, P.; Wang, X.; Yang, J. Shedding new light on lacquering crafts from the Northern Wei Dynasty (386–534 CE) by revisiting the lacquer screen from Sima Jinlong’s Tomb. J. Cult. Herit. 2025, 71, 309–319. [Google Scholar] [CrossRef]

- Shi, S.; Xiao, Y.; Ma, C.; Fu, Y.; Chen, Z.; Shi, D.; Wei, S. Identification of laccol as a paint binder in Neolithic pottery from China. J. Archaeol. Sci. 2025, 173, 106119. [Google Scholar] [CrossRef]

- Zhang, Q.L. On high-ranking tombs during the Nanyue Kingdom period of the Western Han Dynasty. Acta Archaeol. Sin. 2021, 183, 475–500. [Google Scholar]

- Huang, W.; Lai, L.F.; Ren, X.L.; Huang, X.Y. Conservation and restoration of the coffin unearthed from No.1 Han tomb at Luobowan, Guigang, Guangxi. Stud. Chin. Cult. Relics. 2024, 2024, 89–96. [Google Scholar]

- Ren, X.L.; Huang, H.W.; Li, Y.C. Conservation and restoration of Han dynasty lacquerware in the Guangxi Zhuang Autonomous Region Museum. China Raw Lacq. 2018, 37, 40–46. [Google Scholar]

- WW/T 0086-2018; Determination of the Moisture Content of Unearthed (Bamboo, Wood and Lacquer) Artifacts—Drying–Degravimetric Method. Cultural Relics Press: Beijing, China, 2018.

- Wang, Z.Y. Restoration and refurbishment of lacquerware from the Western Han Dynasty—A case study of lacquerware from Han Guangling Kingdom. Jianghan Archaeol. 2024, S1, 192–196. [Google Scholar]

- Wei, S.; Ma, Q.; Schreiner, M. Scientific investigation of the paint and adhesive materials used in the Western Han dynasty polychromy terracotta army, Qingzhou, China. J. Archaeol. Sci. 2012, 39, 1628–1633. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, Y.; Zhang, K.; Du, K.Z.; Yang, K.Y. Study of the lacquer technique of lacquered boxes unearthed from Xie Jia Qiao No.1 Han tomb, Jingzhou. China Raw Lacquer. 2023, 42, 56–60. [Google Scholar]

- Wu, S.C.; Cheng, P.; Li, T.T.; Yang, Y.; Tie, F.D.; Jin, P.J. Study of lacquerwares from between the mid-Warring States period and the mid-Western Han Dynasty excavated in the Changsha region. Archaeometry 2022, 59, 547–565. [Google Scholar]

- Wang, C.; Chen, H.; Zhou, H.; Li, W.; Lu, L.; Phuc, B.T. Investigation and development on processing of Vietnamese lacquer. Adv. Biol. Chem. 2014, 4, 79–85. [Google Scholar] [CrossRef]

- Gao, Z. Flexible material forming method in the Jiazhu process of lacquerware. J. Nanjing Univ. Arts (Fine Arts Des. Ed.) 2015, 4, 132–135. [Google Scholar]

- He, Q.J.; Zhao, R.T. Study on the lacquering process of lacquered fragments unearthed from Laoshan Han tomb in Beijing. Cult. Relics 2013, 10, 85–91. [Google Scholar]

- Li, X.Y.; Wu, X.J.; Wen, Q.Y.; Xie, Z.B.; Shen, X.Y.; Tong, H. Component structure and process analysis of six Song dynasty Wenzhou lacquerwares. Cult. Relics Conserv. Archaeol. 2018, 30, 44–52. [Google Scholar]

- Jiao, L.; Lu, Y.; Zhang, M.; Chen, Y.; Wang, Z.; Guo, Y.; Yin, Y. Ancient plastid genomes solve the tree species mystery of the imperial wood “Nanmu” in the Forbidden City, the largest existing wooden palace complex in the world. Plants People Planet 2022, 4, 696–709. [Google Scholar] [CrossRef]

- Yang, H.; Wang, F.; An, W.; Gu, Y.; Jiang, Y.; Guo, H.; Zhu, P. Comparative metabolomics and transcriptome analysis reveal the fragrance-related metabolite formation in Phoebe zhennan wood. Molecules 2023, 28, 7047. [Google Scholar] [CrossRef]

- Li, H.L. An archaeological and historical account of cannabis in China. Econ. Bot. 1974, 28, 437–448. [Google Scholar] [CrossRef]

- Hu, F.D.; Zhang, Y.C.; Du, J.; Li, N.S. Component structure analysis of lacquer fragments unearthed from Nanhai I. Cult. Relics Conserv. Archaeol. 2023, 35, 43–52. [Google Scholar]

- Wang, R.; Nie, F.; Chen, J.M.; Zhu, Y. Studies on lacquerwares from between the mid-Warring States period and the mid-Western Han dynasty excavated in the Changsha region. Archaeometry 2017, 59, 547–565. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).