Numerical Simulation and Modeling of Powder Flow for Rectangular Symmetrical Nozzles in Laser Direct Energy Deposition

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

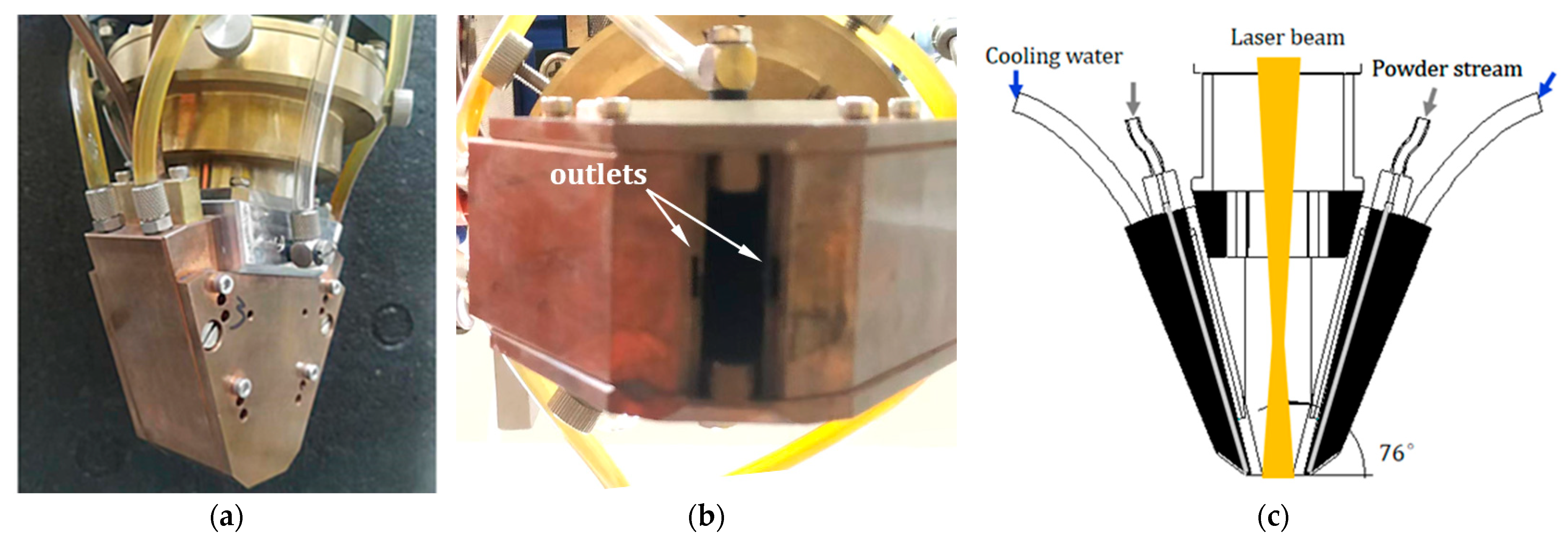

2.2. Experimental Setup

2.3. Methods

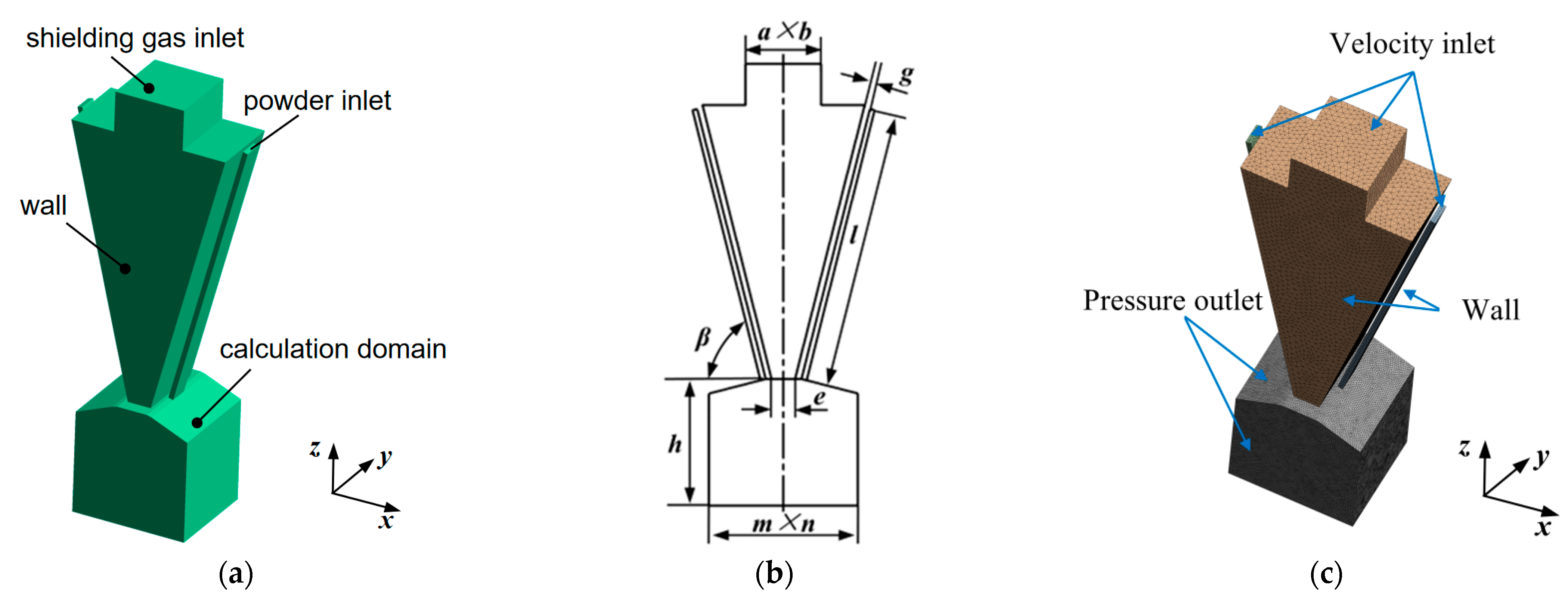

2.3.1. Physical Model of the Rectangular Powder Nozzle

2.3.2. Assumptions

- (1)

- Since the volume fraction of powder particles in the feeding gas is less than 10%, the discrete phase model (DPM) is utilized to simulate the movement of powder particles [3]. The interactions among particles are ignored; the Lagrange method and Euler method are used to calculate the movement of particles and gas, respectively.

- (2)

- The heat transfer between the powder and the laser during flight is negligible; the particle shape and flight track have also not been affected.

- (3)

- The particle size conforms to the Rosin–Rammler distribution [14].

- (4)

- The inertia, gravity, and drag force of powder particles are considered [7].

- (5)

- (6)

- The steady state is adopted to solve the powder flow field.

2.3.3. Parameter Configurations for Solution

3. Results and Discussion

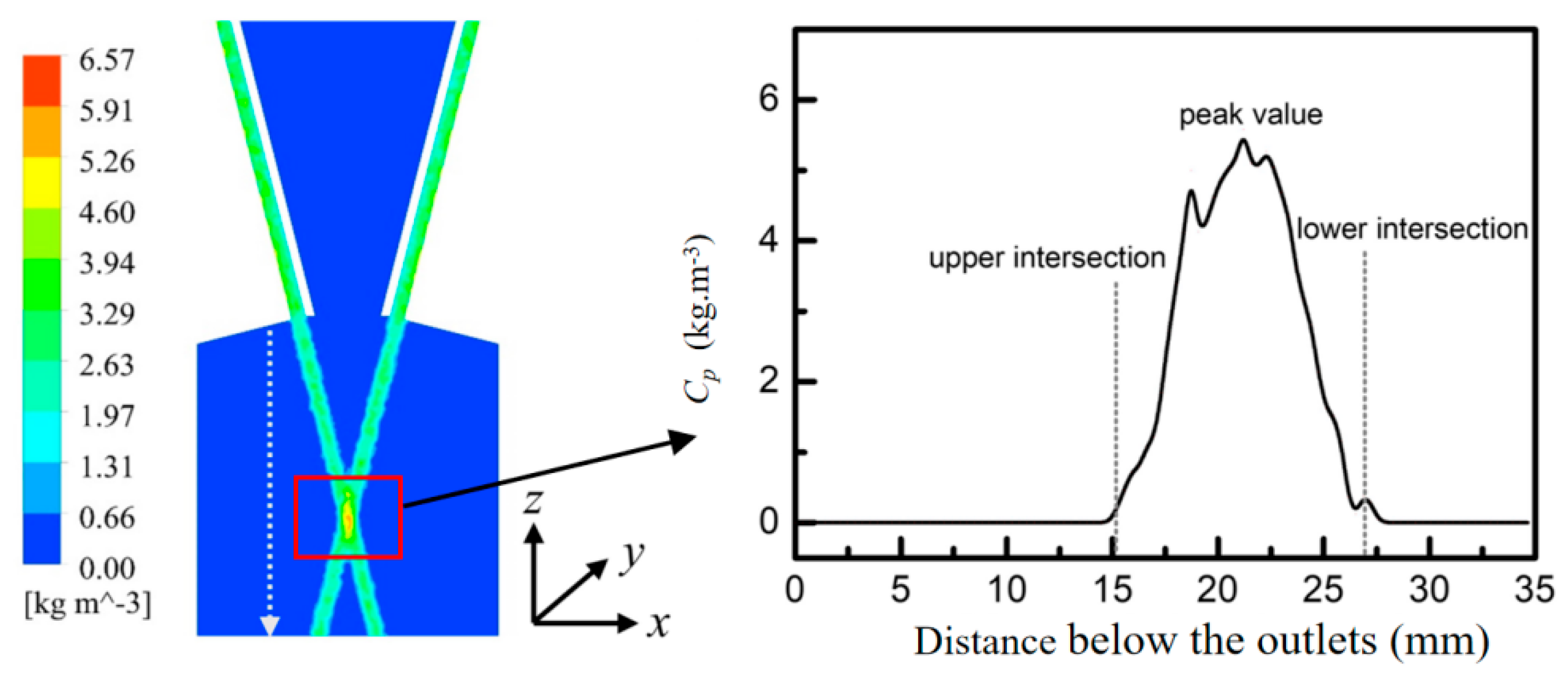

3.1. Dynamic Properties of the Powder Flow Field

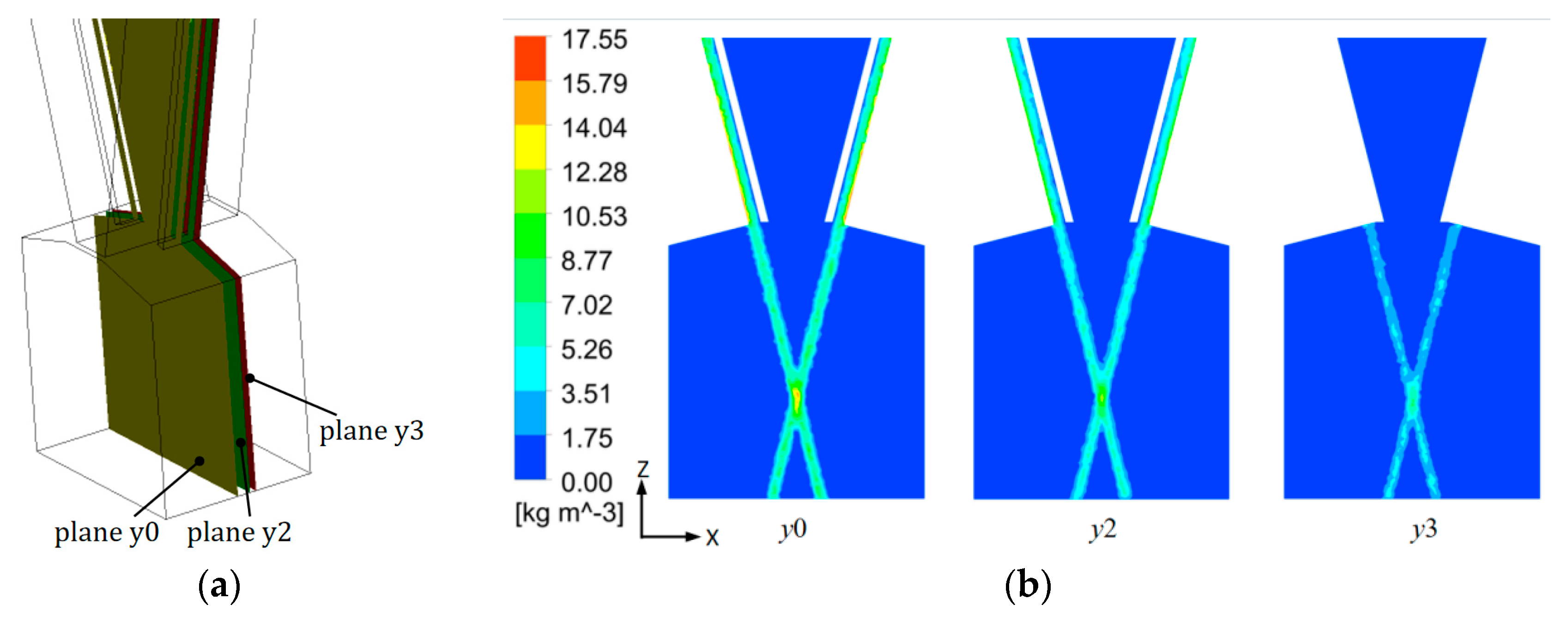

3.2. Powder Concentration Distribution of the Rectangular Nozzle

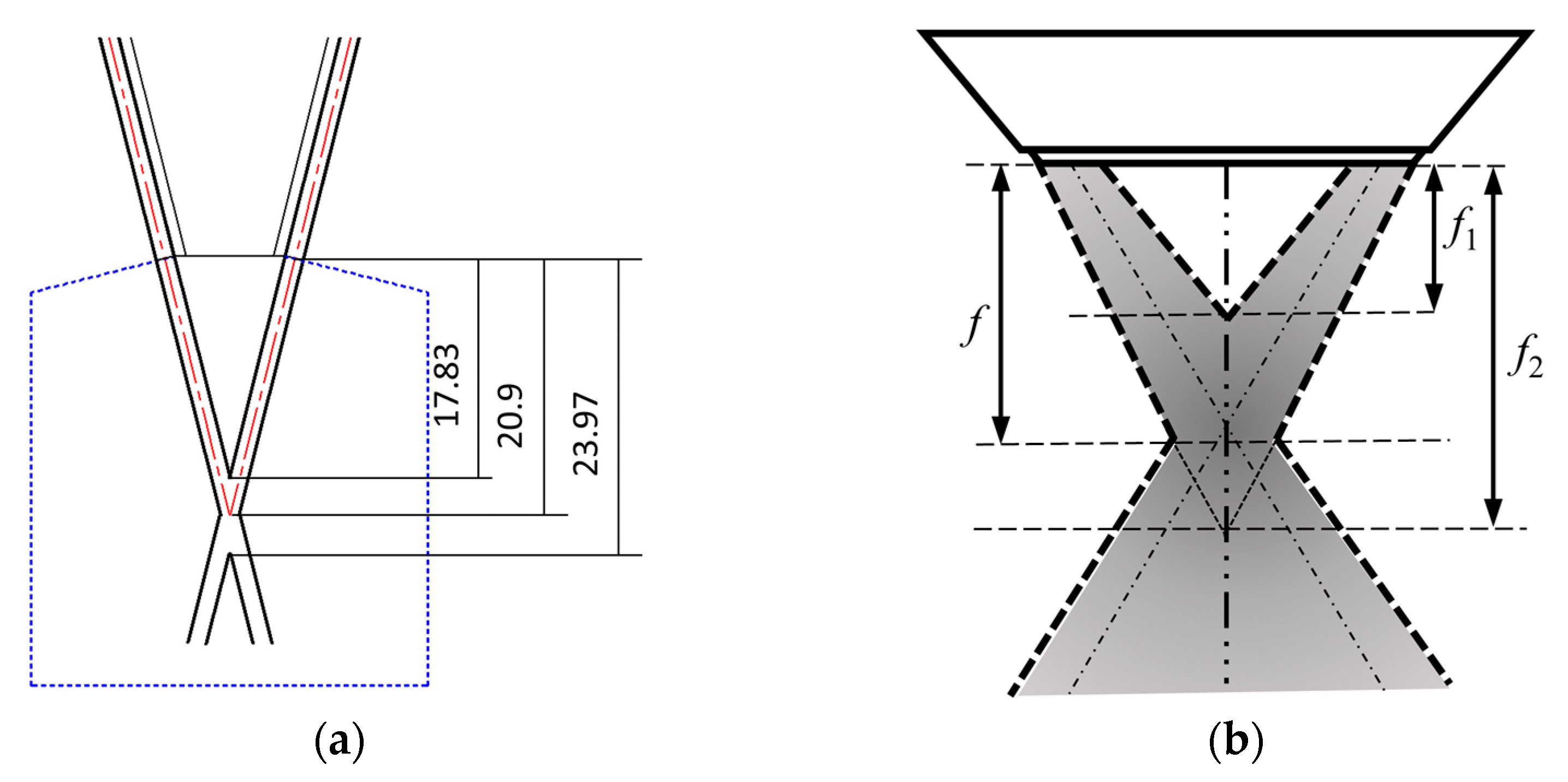

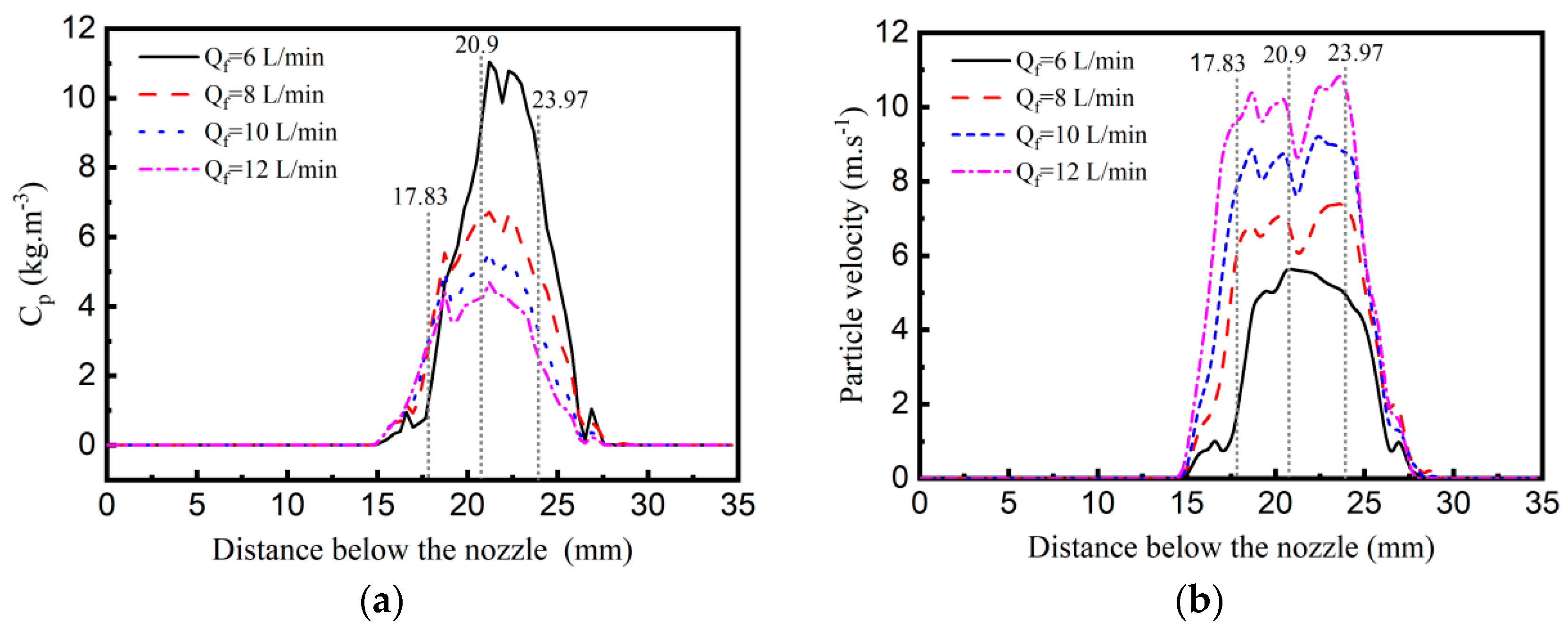

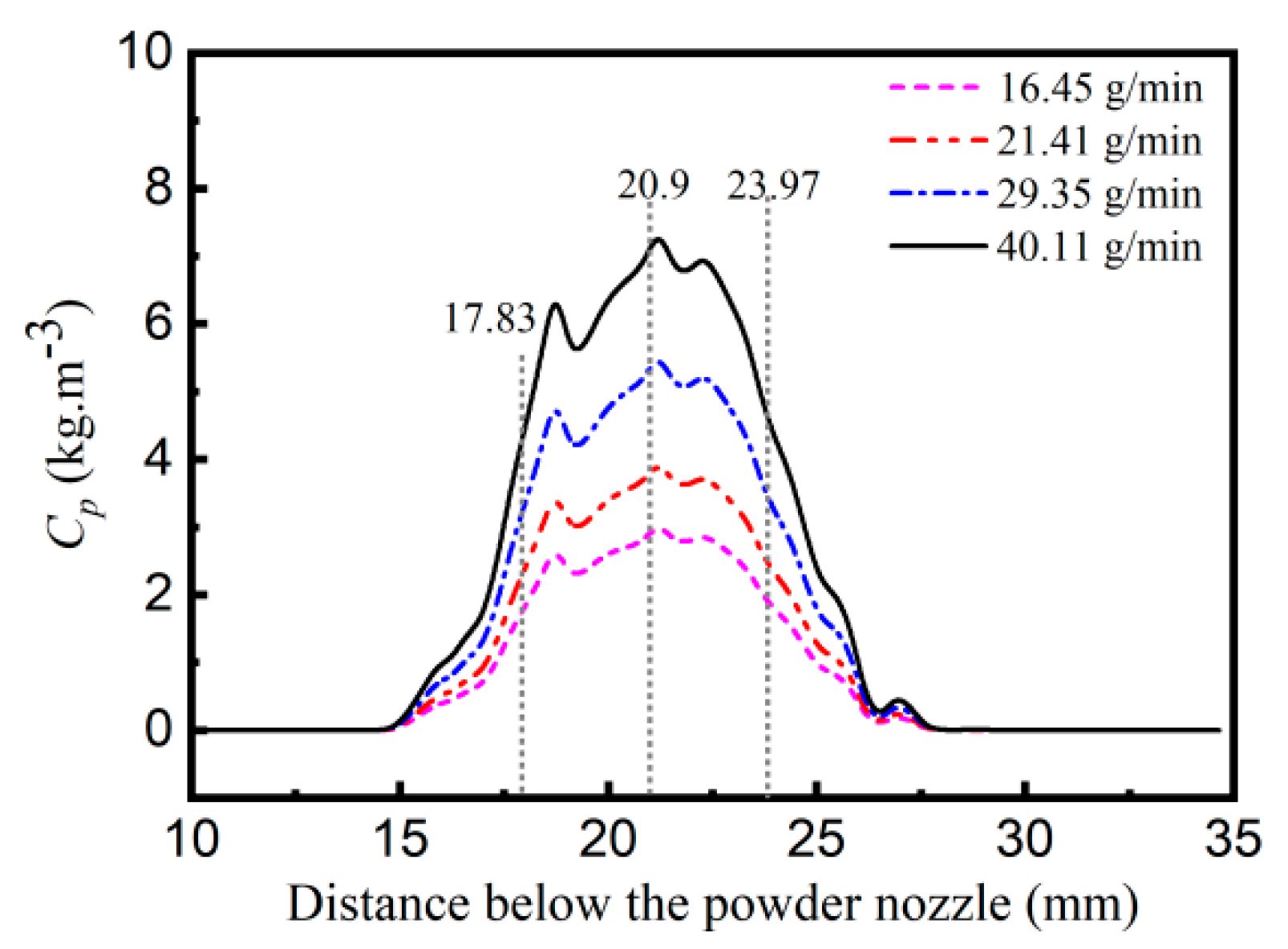

3.2.1. Location of Powder Stream Focal Plane

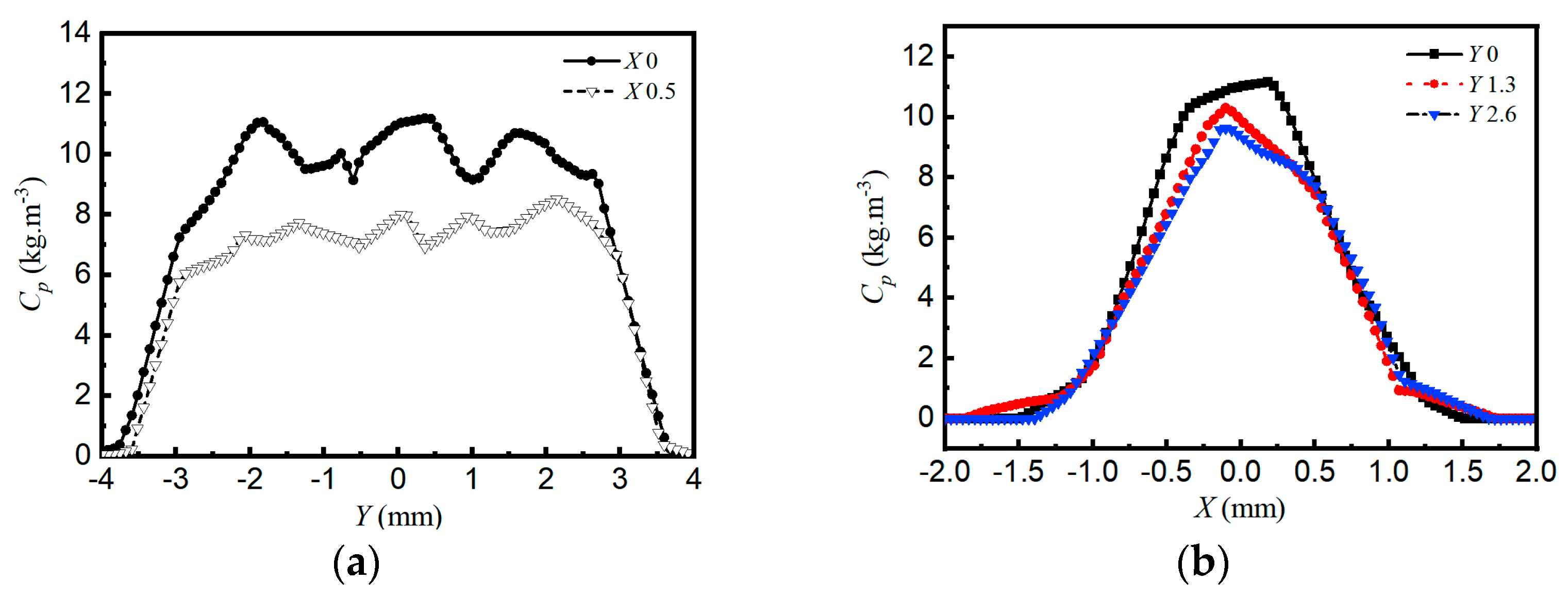

3.2.2. Spatial Powder Concentration Distribution

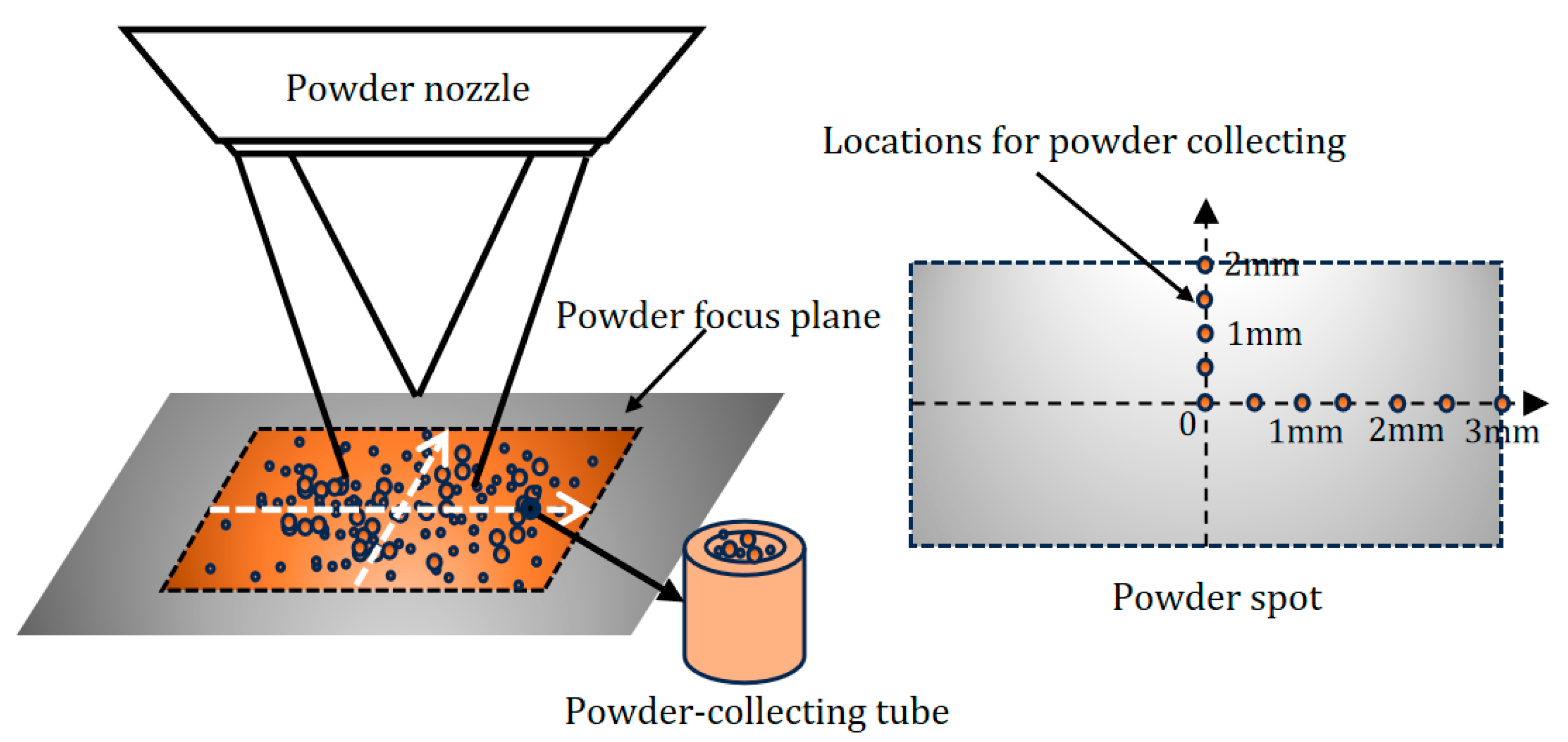

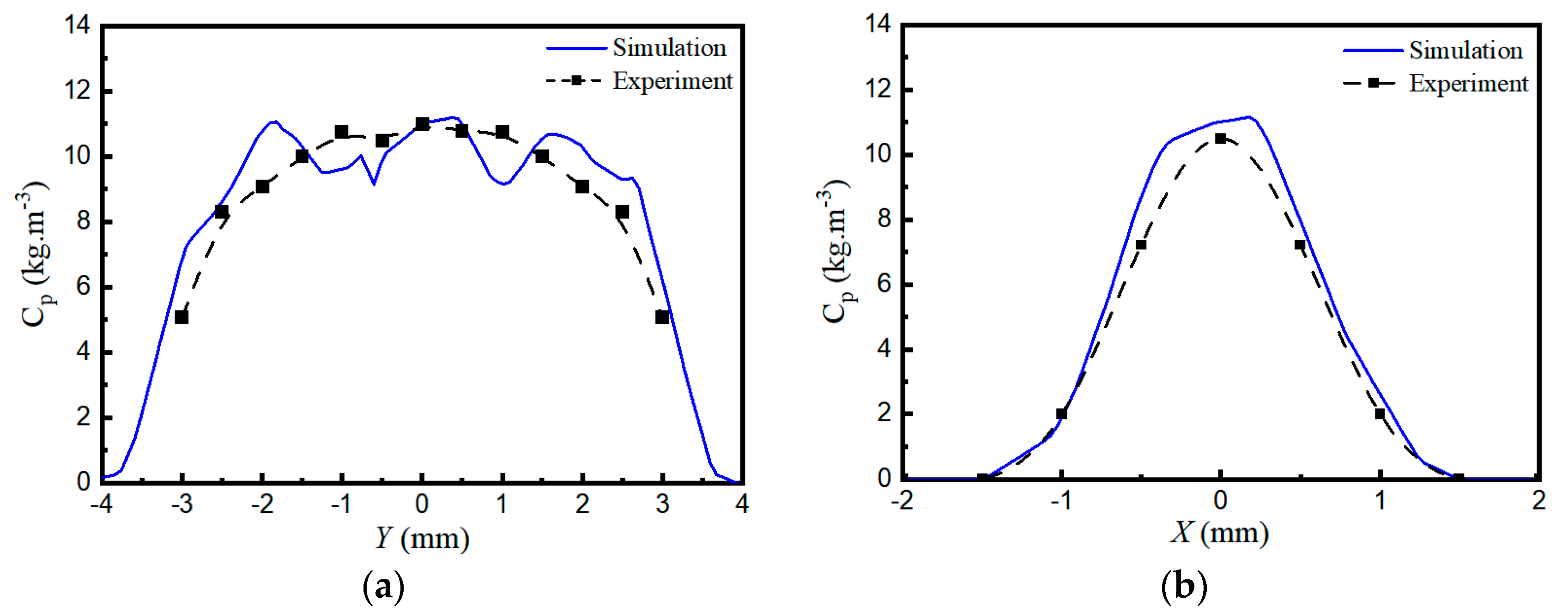

3.2.3. Verification of Powder Concentration Distribution on the Focal Plane

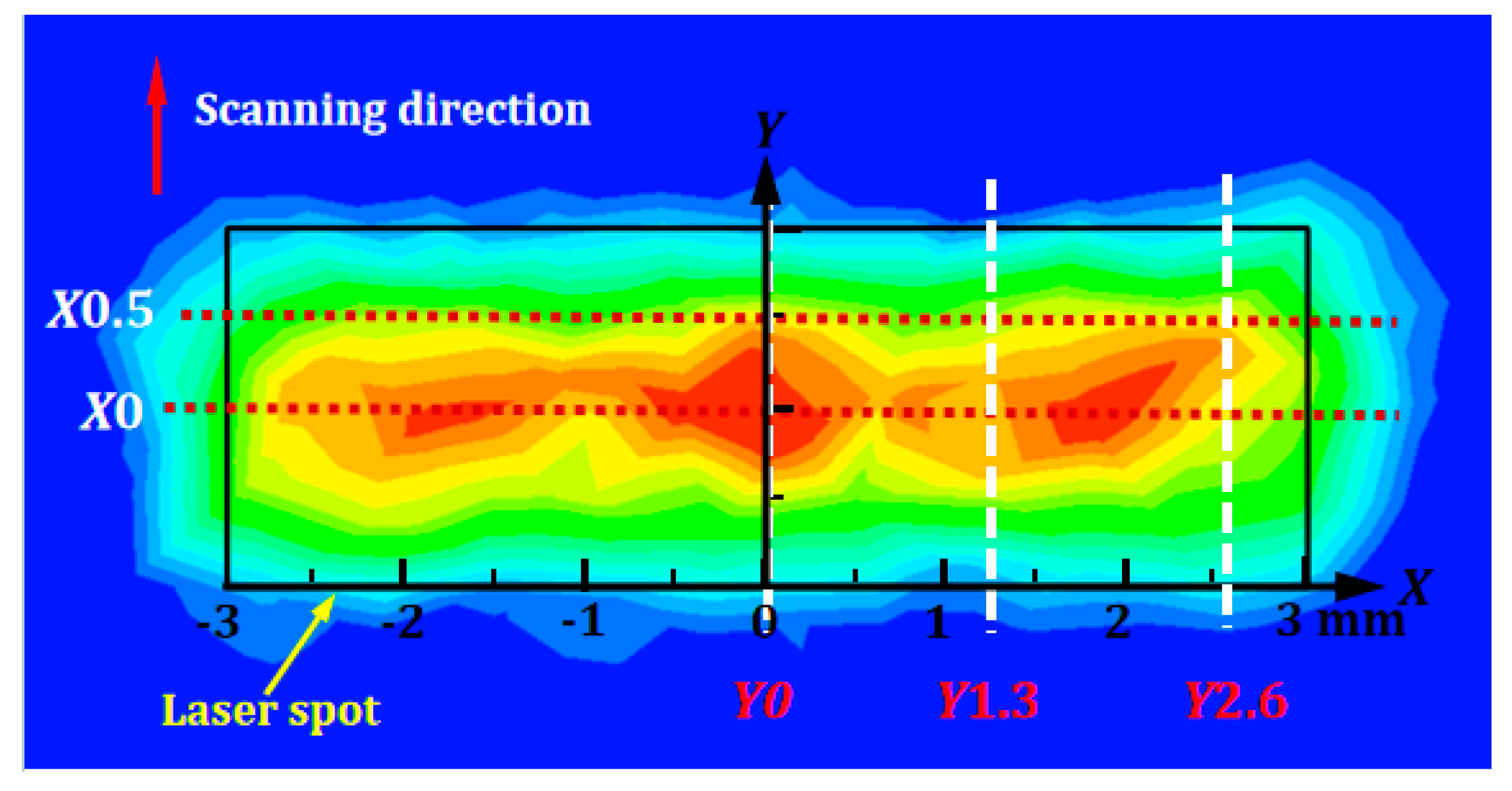

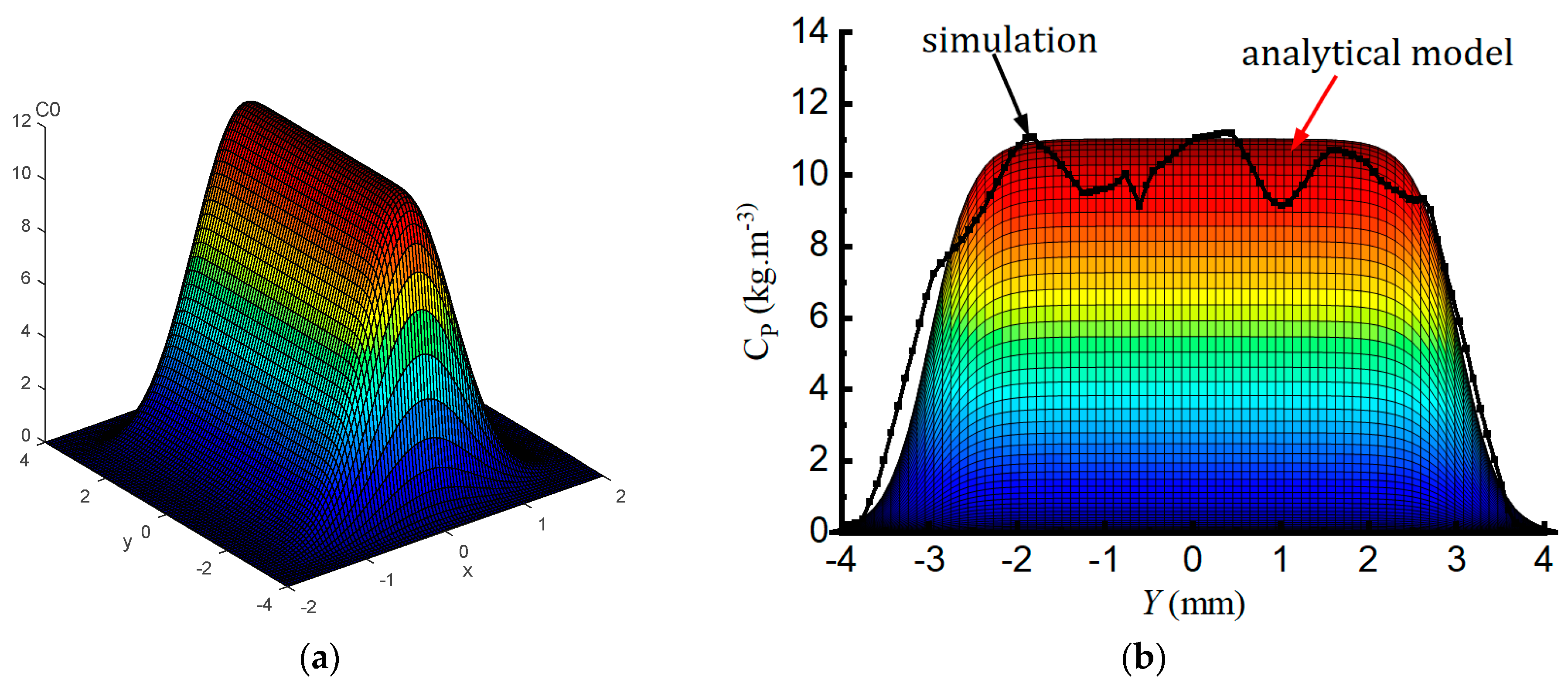

3.3. Powder Spot on the Focal Plane

3.4. Mathematical Model of Powder Flow Field for Rectangular Nozzle

4. Conclusions

- (1)

- The powder focal plane exhibits two characteristic phenomena: peak powder concentration and minimal particle velocity. The locations of the powder flow intersections and the focal plane strongly depend on the nozzle geometry. Powder feeding parameters (carrier gas flow rate, shielding gas flow rate, and powder feeding rate) have negligible effects on the waist position of the powder flow.

- (2)

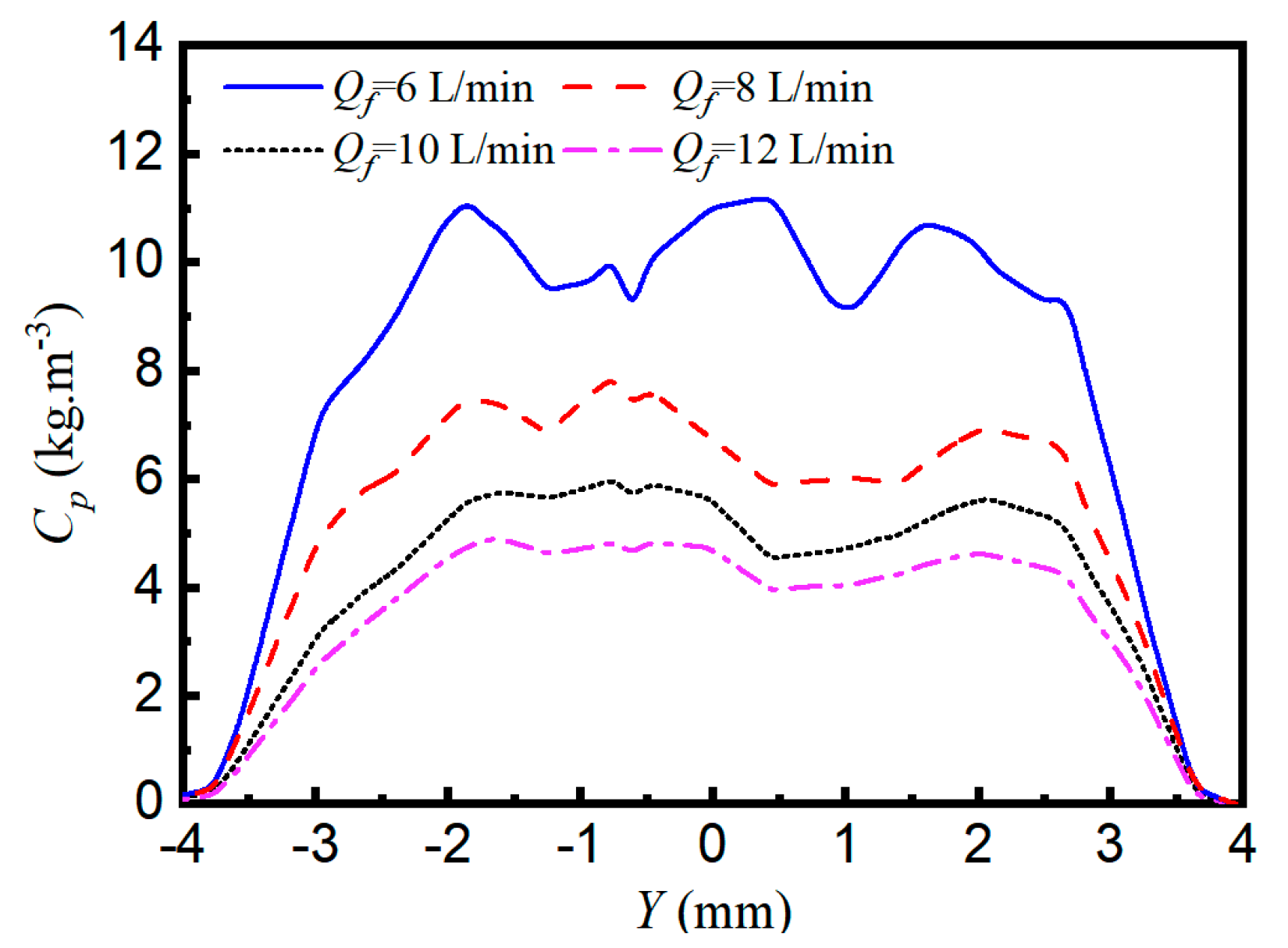

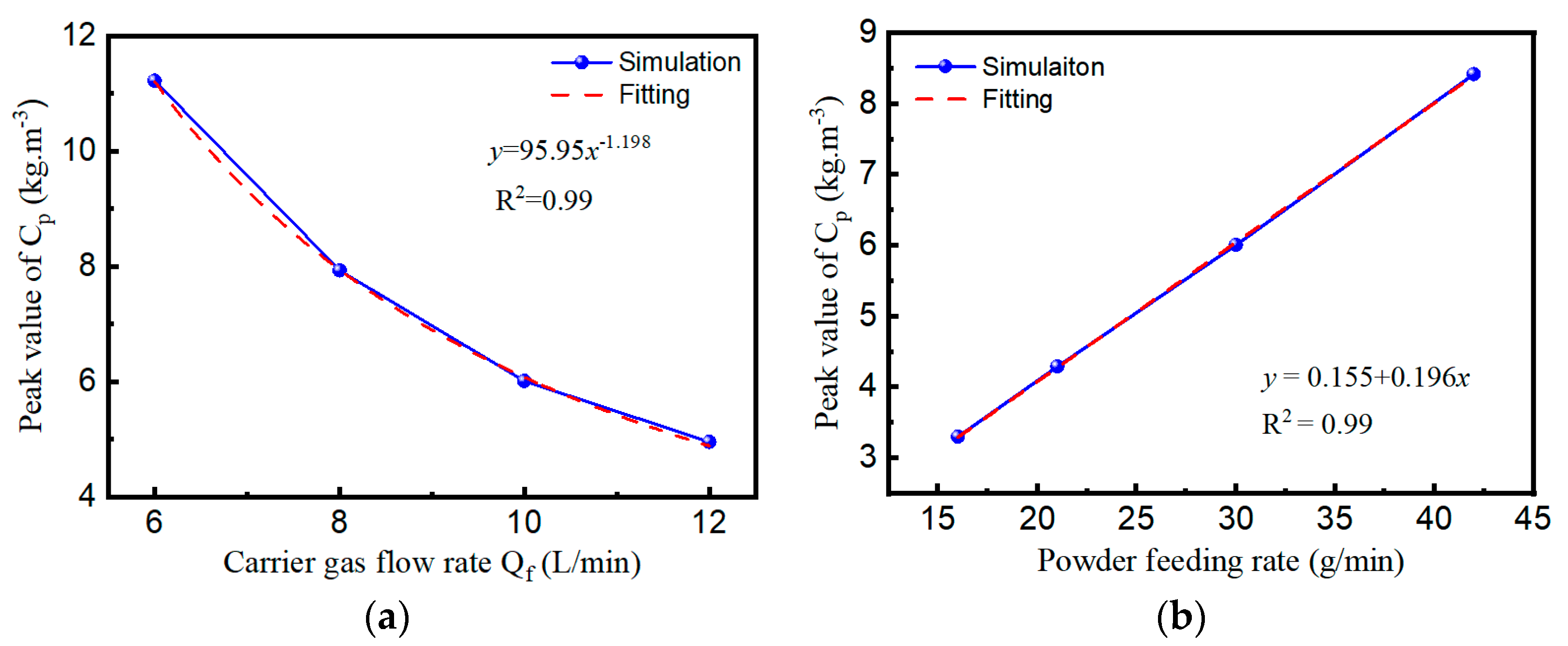

- The maximum powder concentration on the focal plane has a linear positive correlation with the powder feeding rate and decreases exponentially with the increase in the powder gas flow rate. Different from conventional annular nozzles, wide-beam LDED employs rectangular powder delivery profiles to achieve optimal laser-powder coupling.

- (3)

- Round-beam LDED demonstrates a typical Gaussian powder concentration profiles in both the fast axis and slow axis. Wide-beam LDED exhibits hybrid distribution patterns: Gaussian distribution along the scanning direction and quasi-uniform flat-top distribution perpendicular to the scanning direction. This optimized energy-powder spatial coupling configuration improves clad layer homogeneity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Singh, A.; Kapil, S.; Das, M. A comprehensive review of the methods and mechanisms for powder feedstock handling in directed energy deposition. Addit. Manuf. 2020, 35, 101388. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, D.; Wang, P.; Yan, M.; Yang, C.; Chen, Z.; Lu, J.; Lu, Z. Additive manufacturing of metals: Microstructure evolution and multistage control. J. Mater. Sci. Technol. 2022, 100, 224–236. [Google Scholar] [CrossRef]

- Zekovic, S.; Dwivedi, R.; Kovacevic, R. Numerical simulation and experimental investigation of gas–powder flow from radially symmetrical nozzles in laser-based direct metal deposition. Int. J. Mach. Tool Manu. 2007, 47, 112–123. [Google Scholar] [CrossRef]

- Ostolaza, M.; Urresti, A.; Arrizubieta, J.I.; Lamikiz, A.; Ortiz, M. CFD simulation for the modelling of the powder flow on continuous coaxial nozzles in the laser DED process. Procedia CIRP 2022, 111, 282–286. [Google Scholar] [CrossRef]

- Nasiri, M.T.; Movahhedy, M.R. A new design of continuous coaxial nozzle for direct metal deposition process to overcome the gravity effect. Prog. Addit. Manuf. 2022, 7, 173–186. [Google Scholar] [CrossRef]

- Han, B.; Li, R.; Pi, Q.; Shi, Y.; Qi, H.; Bi, K.; Sun, G. Prediction of deposit characteristics based on the discrete coaxial nozzle during laser direct metal deposition. Opt. Laser Technol. 2023, 163, 109385. [Google Scholar] [CrossRef]

- Tabernero, I.; Lamikiz, A.; Ukar, E.; López De Lacalle, L.N.; Angulo, C.; Urbikain, G. Numerical simulation and experimental validation of powder flux distribution in coaxial laser cladding. J. Mater. Process. Technol. 2010, 210, 2125–2134. [Google Scholar] [CrossRef]

- Li, L.; Huang, Y.; Zou, C.; Tao, W. Numerical Study on Powder Stream Characteristics of Coaxial Laser Metal Deposition Nozzle. Crystals 2021, 11, 282. [Google Scholar] [CrossRef]

- Doubenskaia, M.; Kulish, A.; Sova, A.; Petrovskiy, P.; Smurov, I. Experimental and numerical study of gas-powder flux in coaxial laser cladding nozzles of Precitec. Surf. Coat. Technol. 2021, 406, 126672. [Google Scholar] [CrossRef]

- Ni, M.; Qin, X.; Liu, H.; Hu, Z. Analysis and design of coaxial nozzle with rectangular outlet for high power diode laser in laser metal deposition. Int. J. Adv. Manuf. Technol. 2020, 106, 4789–4803. [Google Scholar] [CrossRef]

- Lee, H.-K. Effects of the cladding parameters on the deposition efficiency in pulsed Nd:YAG laser cladding. J. Mater. Process. Technol. 2008, 202, 321–327. [Google Scholar] [CrossRef]

- Lin, J. Laser attenuation of the focused powder streams in coaxial laser cladding. J. Laser Appl. 2000, 12, 17–23. [Google Scholar] [CrossRef]

- Gao, X.; Yao, X.X.; Niu, F.Y.; Zhang, Z. The influence of nozzle geometry on powder flow behaviors in directed energy deposition additive manufacturing. Adv. Powder Technol. 2022, 33, 103487. [Google Scholar] [CrossRef]

- Wang, K.; Tong, Y.; Chen, Y.; Kong, L.; Lu, K.; Wang, J.; Liang, X. Powder stream performance of a novel annular laser direct metal deposition with inside-laser coaxial powder feeding nozzle: Simulation and experimental perspectives. Opt. Laser Technol. 2024, 175, 110723. [Google Scholar] [CrossRef]

- Guner, A.; Bidare, P.; Jiménez, A.; Dimov, S.; Essa, K. Nozzle Designs in Powder-Based Direct Laser Deposition: A Review. Int. J. Precis. Eng. Manuf. 2022, 23, 1077–1094. [Google Scholar] [CrossRef]

- Pant, P.; Chatterjee, D.; Samanta, S.K.; Lohar, A.K. Experimental and Numerical Analysis of the Powder Flow in a Multi-Channel Coaxial Nozzle of a Direct Metal Deposition System. J. Manuf. Sci. Eng. 2021, 143, 071003. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, K.; Yang, L.; Zhang, J.; Ding, H.; Pan, Z. Coupling Characteristics of Powder and Laser of Coaxial Cone Nozzle for Laser Direct Metal Deposition: Numerical Simulation and Experimental Study. Materials 2023, 16, 3403. [Google Scholar] [CrossRef] [PubMed]

- Pinkerton, A.J.; Li, L. Modelling powder concentration distribution from a coaxial deposition nozzle for laser-based rapid tooling. J. Manuf. Sci. Eng. 2004, 126, 33–41. [Google Scholar] [CrossRef]

- Liu, Q.; Li, W.; Yang, K.; Gao, Y.; Wang, L.; Chu, X. Analytical investigation into the powder distribution and laser beam-powder flow interaction in laser direct energy deposition with a continuous coaxial nozzle. Adv. Powder Technol. 2023, 34, 104058. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, L.; Zhang, W.; Qiu, J.; Xiao, H.; Liu, Y. Numerical simulation and experimental study for aerodynamic characteristics and powder transport behavior of novel nozzle. Opt. Laser. Eng. 2020, 126, 105873. [Google Scholar] [CrossRef]

- Chu, M.; Lian, G.; Yao, M.; Feng, M.; Chen, C.; Huang, X. Numerical simulation and experimental investigation of gas-powder flow feed behavior in laser cladding with coaxial nozzle. Int. J. Adv. Manuf. Technol. 2022, 122, 881–894. [Google Scholar] [CrossRef]

- Liu, H.; He, X.; Yu, G.; Wang, Z.; Li, S.; Zheng, C.; Ning, W. Numerical simulation of powder transport behavior in laser cladding with coaxial powder feeding. Sci. China Phys. Mech. Astron. 2015, 58, 104701. [Google Scholar] [CrossRef]

- DeWitte, L.; Saldana, C.; Kurfess, T.; Fu, K. Effect of coaxial nozzle wear on catchment efficiency in direct energy deposition built components. J. Manuf. Syst. 2022, 63, 524–538. [Google Scholar] [CrossRef]

- Lei, K.; Qin, X.; Liu, H.; Ni, M. Analysis and modeling of melt pool morphology for high power diode laser cladding with a rectangle beam spot. Opt. Laser. Eng. 2018, 110, 89–99. [Google Scholar] [CrossRef]

- Zhu, H.; Lin, X.; Xue, X.; Zhang, Y.; Wang, L.; Ning, Y.; Dong, Y.; Fang, X. Laser cladding of stainless-steel ball valves by a high-power diode laser source with a rectangular beam spot. Opt. Laser Technol. 2024, 169, 110123. [Google Scholar] [CrossRef]

- Hu, B.; Han, J.; Li, X.; Wang, J. Modeling of melt pool and thermal field simulation for wide-band laser cladding. Opt. Eng. 2023, 62, 116103. [Google Scholar] [CrossRef]

- Lu, L.; Shi, T.; Li, G.; Wei, C.; Fu, G. Design and Numerical Analysis of an Inside-Beam Powder Feeding Nozzle for Wide-Band Laser Cladding. Materials 2024, 17, 12. [Google Scholar] [CrossRef]

- Nogdhe, Y.; Rai, A.K.; Manjaiah, M. Numerical study of powder flow characteristics of coaxial nozzle direct energy deposition at different operating and design conditions. Prog. Addit. Manuf. 2024, 10, 701–723. [Google Scholar] [CrossRef]

- Alya, S.; Singh, R. Discrete Phase Modeling of the Powder Flow Dynamics and the Catchment Efficiency in Laser Directed Energy Deposition with Inclined Coaxial Nozzles. J. Manuf. Sci. Eng. 2021, 143, 081004. [Google Scholar] [CrossRef]

- Liu, S.; Farahmand, P.; Kovacevic, R. Optical monitoring of high power direct diode laser cladding. Opt. Laser Technol. 2014, 64, 363–376. [Google Scholar] [CrossRef]

- Lin, J. Concentration mode of the powder stream in coaxial laser cladding. Opt. Laser Technol. 1999, 31, 251–257. [Google Scholar] [CrossRef]

- Liu, J.; Li, L. Study on cross-section clad profile in coaxial single-pass cladding with a low-power laser. Opt. Laser Technol. 2005, 37, 478–482. [Google Scholar] [CrossRef]

- Mazzarisi, M.; Errico, V.; Angelastro, A.; Campanelli, S.L. Influence of standoff distance and laser defocusing distance on direct laser metal deposition of a nickel-based superalloy. Int. J. Adv. Manuf. Technol. 2022, 120, 2407–2428. [Google Scholar] [CrossRef]

| Cr | Ni | Mn | Mo | Si | P | C | Fe | S |

|---|---|---|---|---|---|---|---|---|

| 16.2 | 12.6 | 0.62 | 2.48 | 0.85 | 0.011 | 0.006 | Bal. | 0.006 |

| Size Distribution (μm) | Flow Rate (s/50 g) | Degree of Spherical | |||

|---|---|---|---|---|---|

| D10 | D50 | D90 | D97 | ||

| 66.71 | 108.8 | 177.6 | 219.6 | 15.19 | 0.835 |

| Para. | a/mm | b/mm | g/mm | l/mm | β/° | e/mm | h/mm | m/mm | n/mm |

|---|---|---|---|---|---|---|---|---|---|

| Value | 22 | 21 | 1 | 82 | 76 | 7 | 35 | 34 | 26 |

| Phase | Parameter | Value |

|---|---|---|

| Continuous phase (argon) | Density | 1.613 kg/m3 |

| Viscosity | 2.262 × 10−5 Pa.s | |

| Discrete phase (powder) | Density | 7800 kg/m3 |

| Minimum size | 67.3 μm | |

| Maximum size | 219.8 μm | |

| Average size | 110 μm | |

| Coefficient of rebound | 0.95 |

| Qf (L/min) | (g/min) | Powder Spot Size (mm) |

|---|---|---|

| 6 | 30 | 7.20 × 2.33 |

| 8 | 30 | 7.15 × 2.28 |

| 10 | 30 | 7.10 × 2.33 |

| 12 | 30 | 7.10 × 2.37 |

| 10 | 16.45 | 7.15 × 2.36 |

| 10 | 21.41 | 7.18 × 2.35 |

| 10 | 29.35 | 7.10 × 2.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, B.; Wang, J.; Zhang, L. Numerical Simulation and Modeling of Powder Flow for Rectangular Symmetrical Nozzles in Laser Direct Energy Deposition. Coatings 2025, 15, 744. https://doi.org/10.3390/coatings15070744

Hu B, Wang J, Zhang L. Numerical Simulation and Modeling of Powder Flow for Rectangular Symmetrical Nozzles in Laser Direct Energy Deposition. Coatings. 2025; 15(7):744. https://doi.org/10.3390/coatings15070744

Chicago/Turabian StyleHu, Bin, Junhua Wang, and Li Zhang. 2025. "Numerical Simulation and Modeling of Powder Flow for Rectangular Symmetrical Nozzles in Laser Direct Energy Deposition" Coatings 15, no. 7: 744. https://doi.org/10.3390/coatings15070744

APA StyleHu, B., Wang, J., & Zhang, L. (2025). Numerical Simulation and Modeling of Powder Flow for Rectangular Symmetrical Nozzles in Laser Direct Energy Deposition. Coatings, 15(7), 744. https://doi.org/10.3390/coatings15070744