Thermal Analysis of Polyurethane Coatings Modified with Graphene and Modification Influence on Mechanical Properties of Hybrid Textile Materials Dedicated to Personal Protective Equipment

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

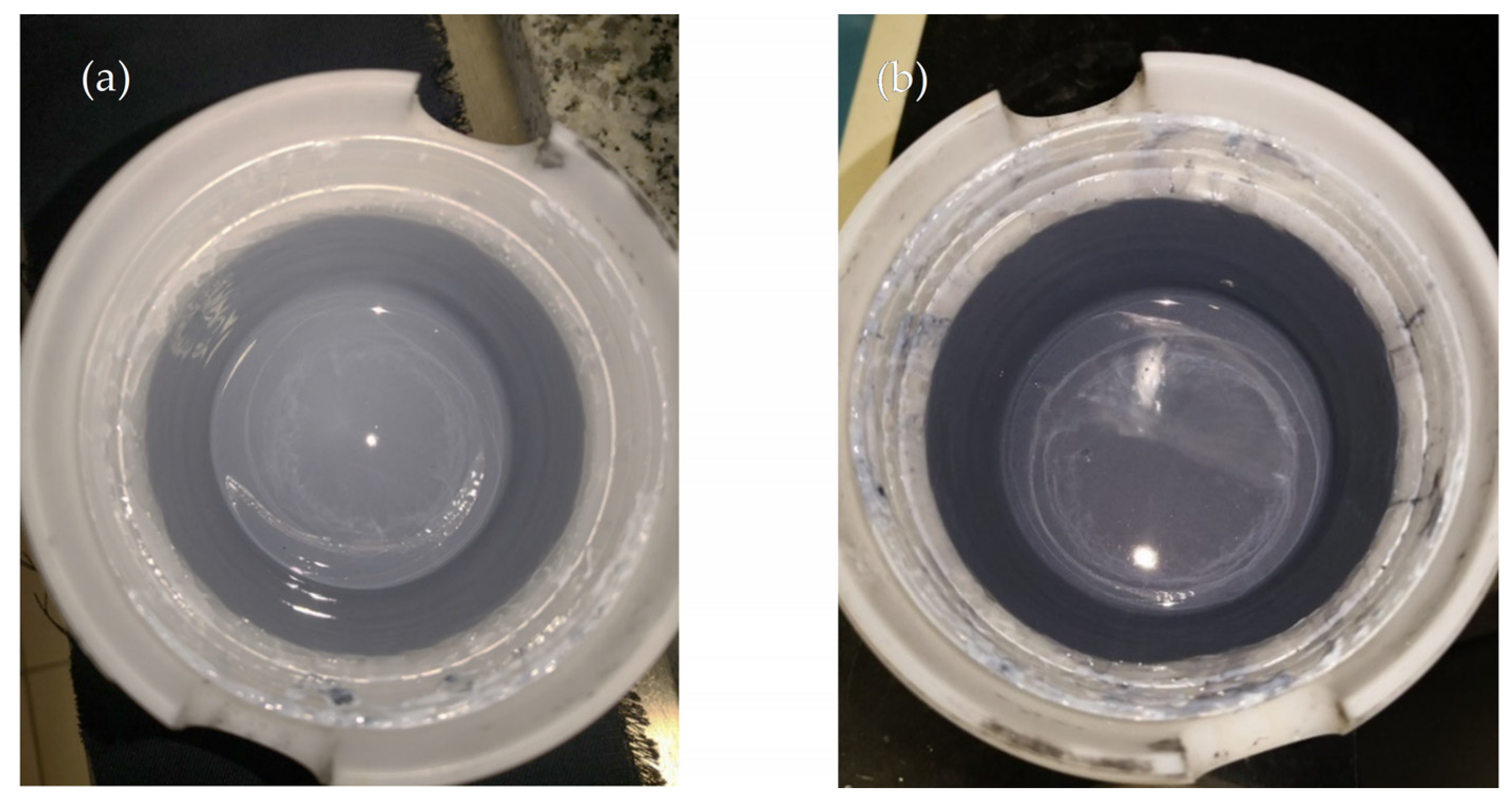

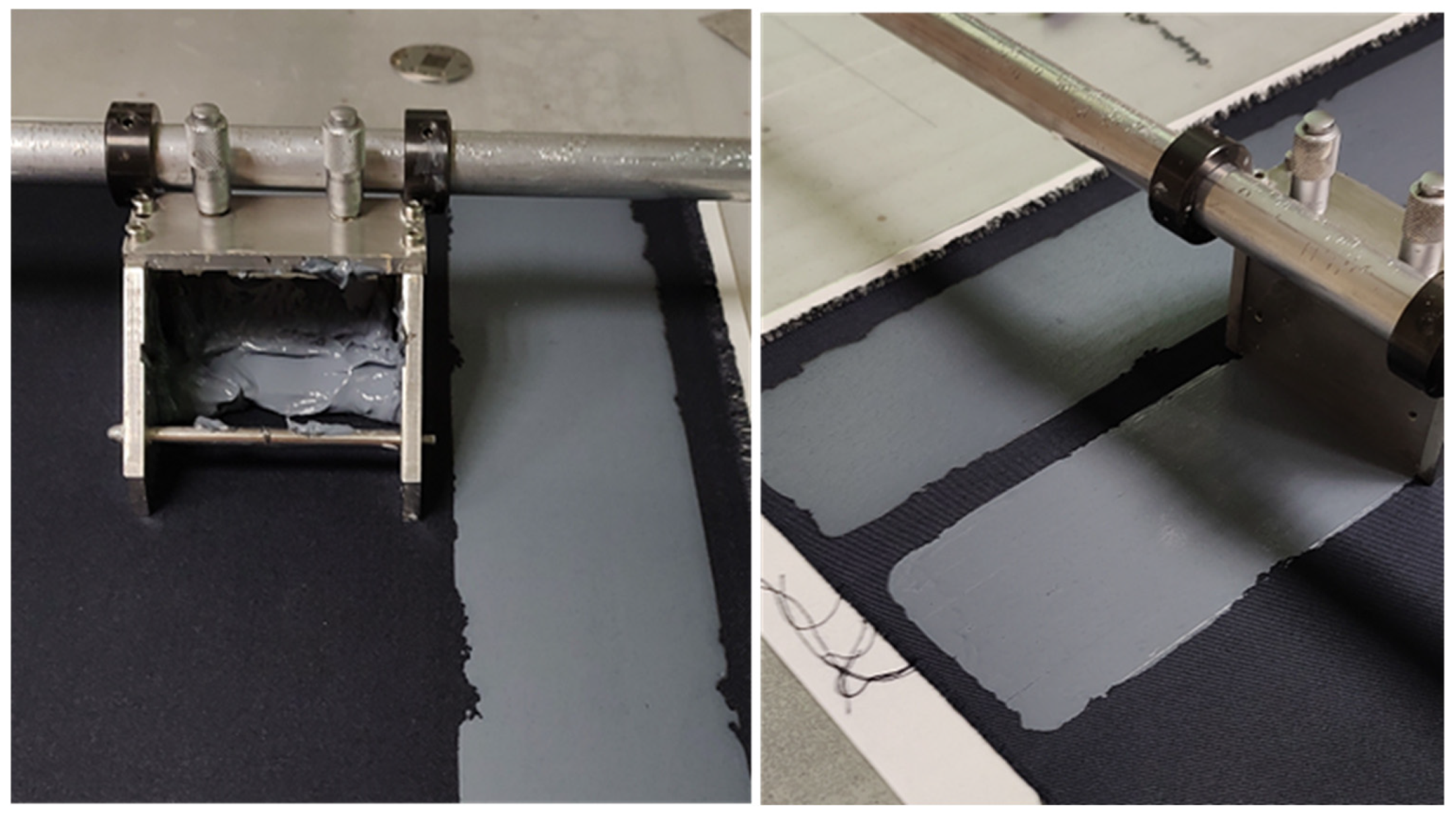

2.2. Preparation of Coating Pastes and Hybrid Textile Materials

2.3. Measurements

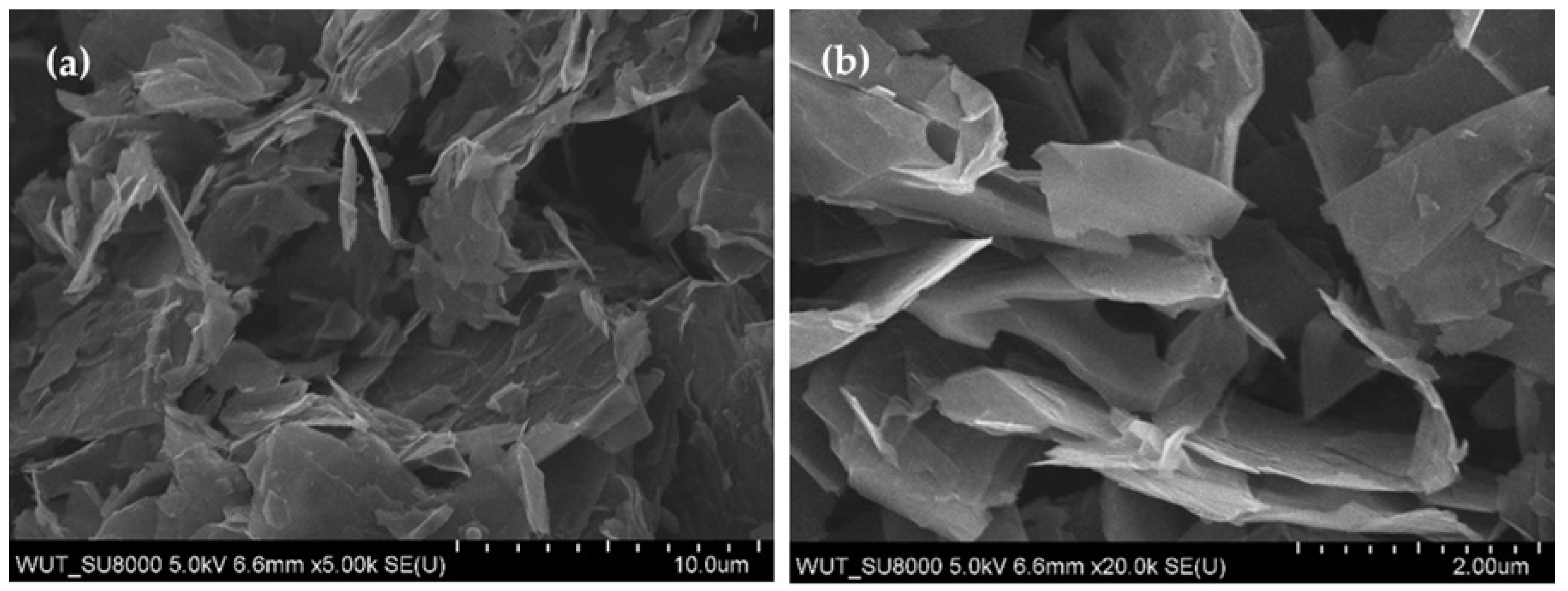

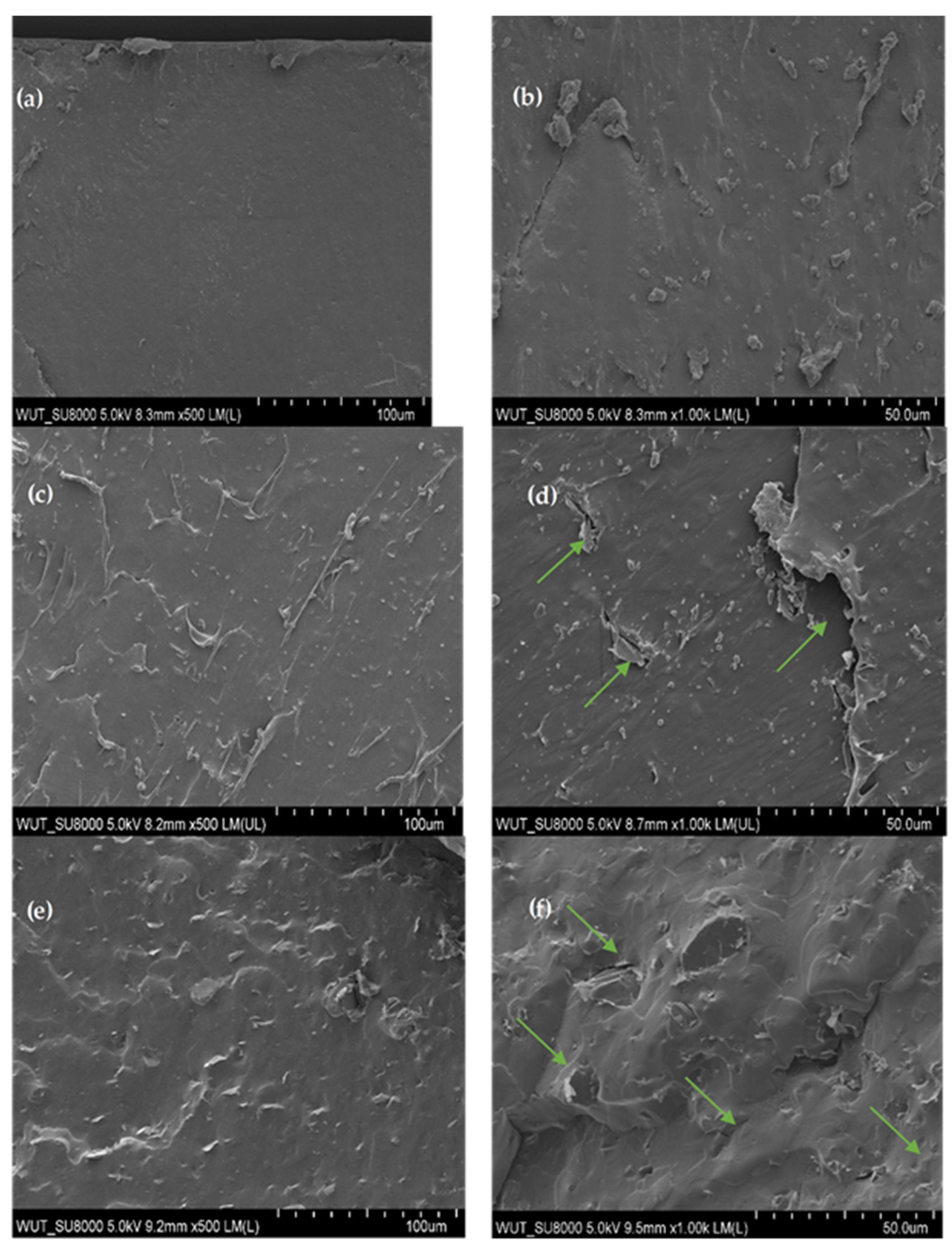

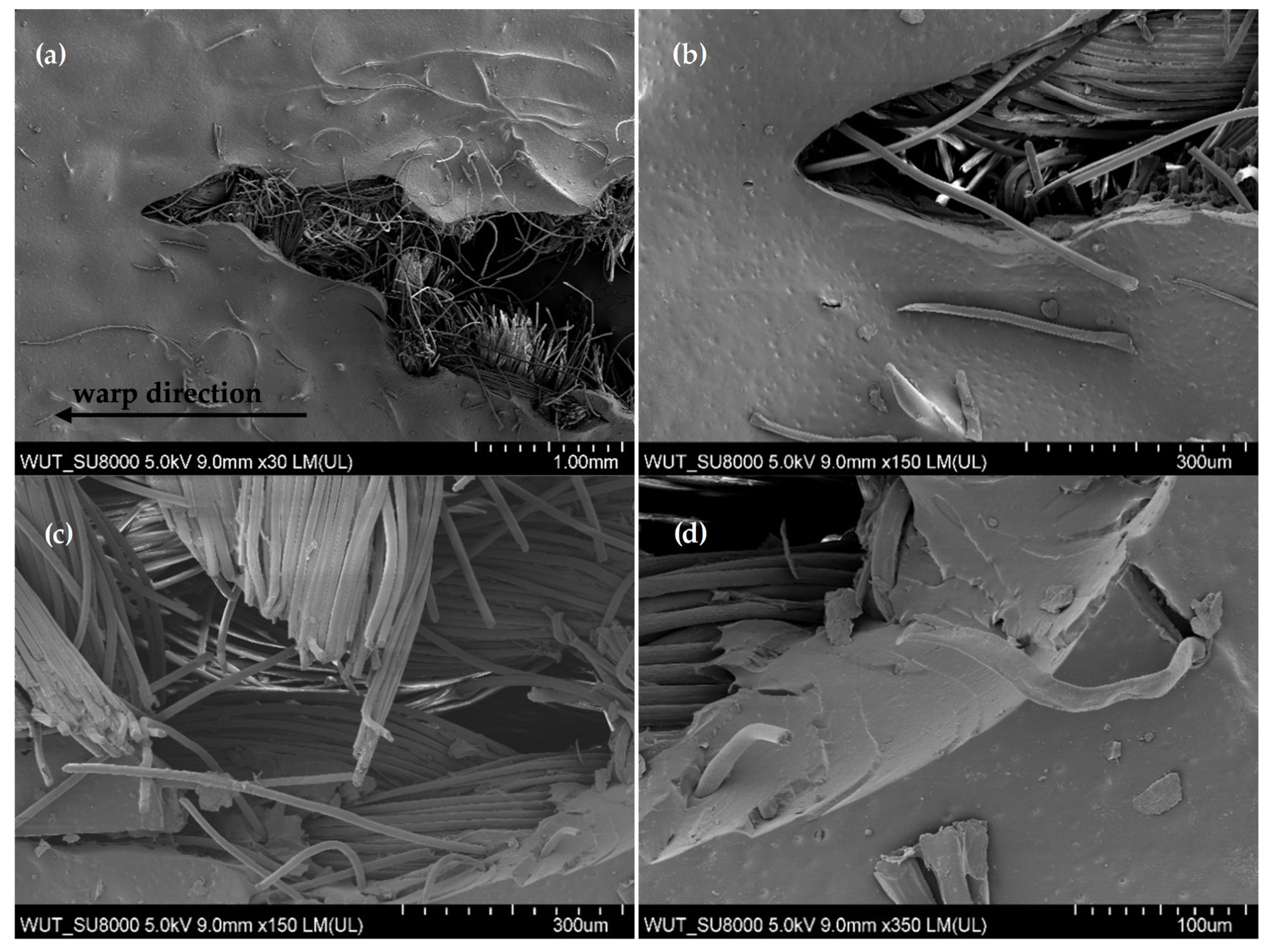

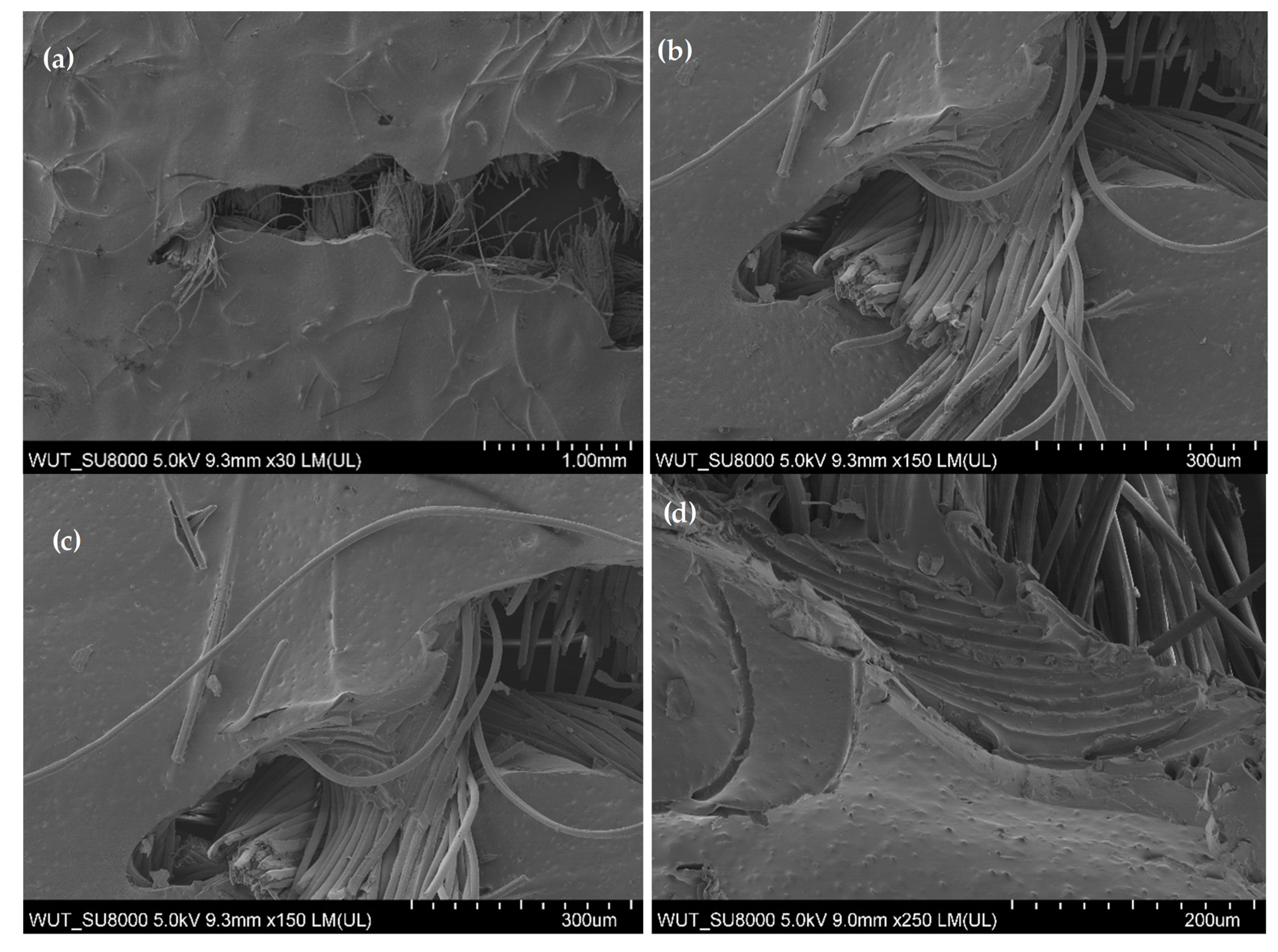

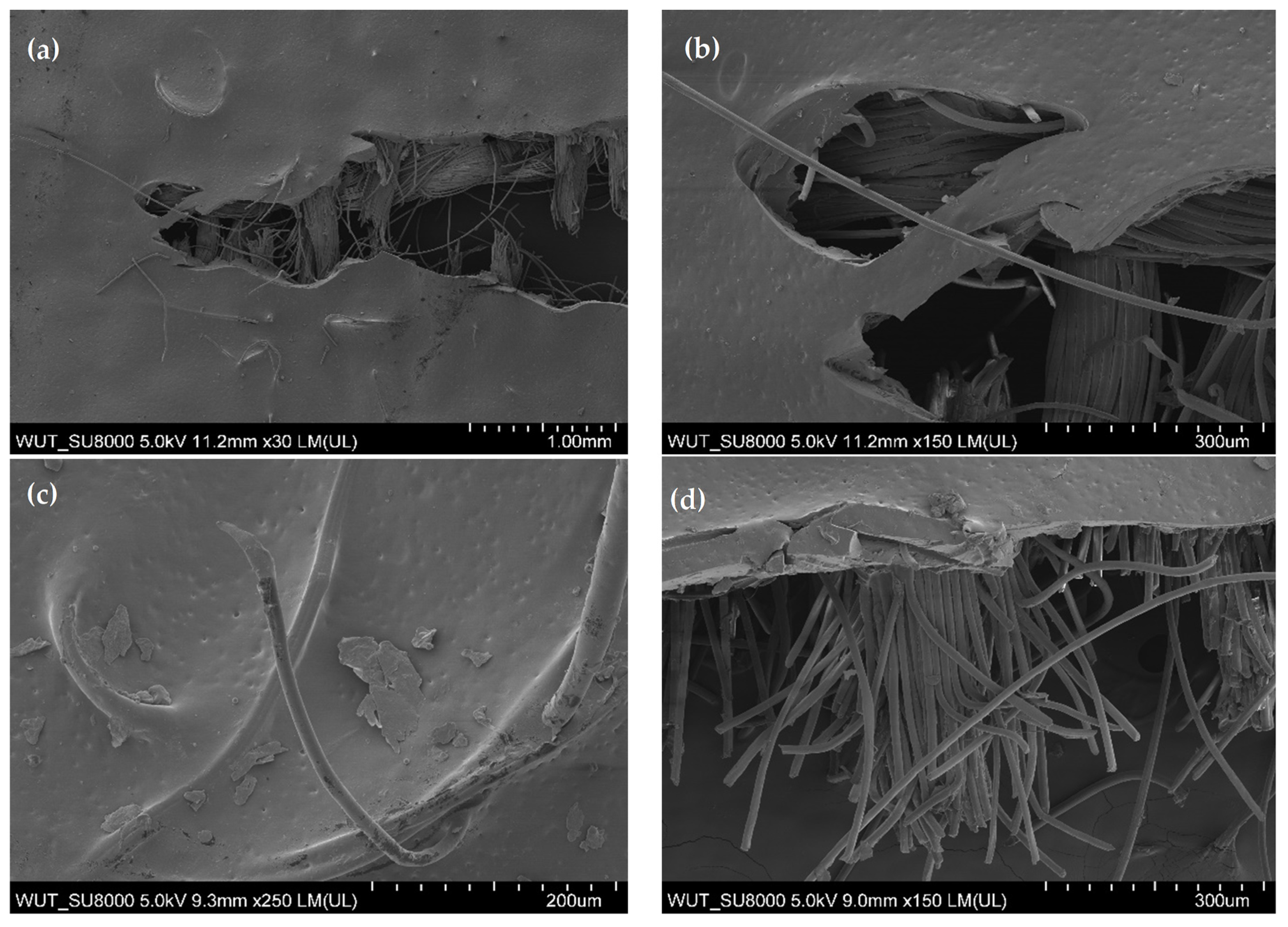

2.3.1. Microstructure Assessment

2.3.2. Thermogravimetric Analysis (TGA)

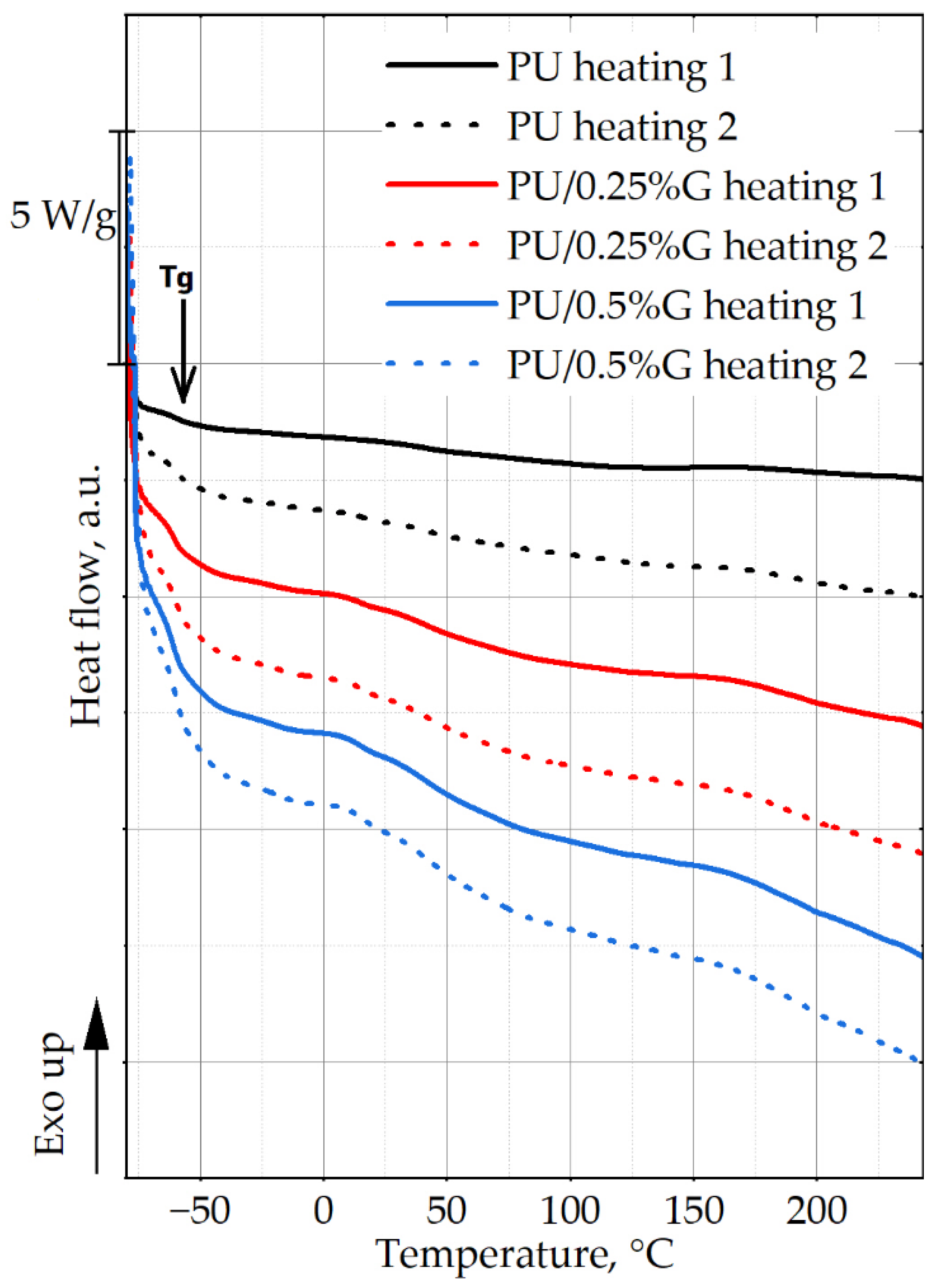

2.3.3. Differential Scanning Calorimetry (DSC)

2.3.4. Fourier-Transform Infrared Spectroscopy (FT-IR) Absorbance Spectrum Analysis

2.3.5. Tear Resistance of Hybrid Textile Materials

3. Results and Discussion

3.1. Foil Sample Analysis

3.2. Hybrid Textile Material Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Honda, H.; Iwata, K. Personal Protective Equipment and Improving Compliance among Healthcare Workers in High-Risk Settings. Curr. Opin. Infect Dis. 2016, 29, 400–406. [Google Scholar] [CrossRef]

- Lee, Y.A.; Salahuddin, M.; Gibson-Young, L.; Oliver, G.D. Assessing Personal Protective Equipment Needs for Healthcare Workers. Health Sci. Rep. 2021, 4, e370. [Google Scholar] [CrossRef]

- Saran, S.; Gurjar, M.; Baronia, A.K.; Lohiya, A.; Azim, A.; Poddar, B.; Rao, N.S. Personal Protective Equipment during COVID-19 Pandemic: A Narrative Review on Technical Aspects. Expert Rev. Med. Devices 2020, 17, 1265–1276. [Google Scholar] [CrossRef] [PubMed]

- PN-EN ISO 13937-2:2002; Textiles—Tear Properties of Fabrics—Part 2: Determination of Tear Force of Trouser—Shaped Test Specimens (Single Tear Method). Polish Committee for Standardization: Warsaw, Poland, 2002.

- PN-EN 469:2020-01; Protective Clothing for Firefighters—Performance Requirements for Protective Clothing for Firefighting Activities. Polish Committee for Standardization: Warsaw, Poland, 2020.

- PN-EN ISO 11611:2015-11; Protective Clothing Used for Welding and Related Processes. Polish Committee for Standardization: Warsaw, Poland, 2015.

- PN-EN ISO 11612:2015-11; Protective Clothing—Clothing to Protect Against Heat and Flame—Minimum Performance Requirements. Polish Committee for Standardization: Warsaw, Poland, 2015.

- De Luca, P.; B.Nagy, J.; Macario, A. Nanomaterials Used in the Preparation of Personal Protective Equipment (PPE) in the Fight against SARS-CoV-2. Inorganics 2023, 11, 294. [Google Scholar] [CrossRef]

- Basodan, R.A.M.; Park, B.; Chung, H.J. Smart Personal Protective Equipment (PPE): Current PPE Needs, Opportunities for Nanotechnology and e-Textiles. Flex. Print. Electron. 2021, 6, 043004. [Google Scholar] [CrossRef]

- Syduzzaman, M.; Hassan, A.; Anik, H.R.; Akter, M.; Islam, M.R. Nanotechnology for High-Performance Textiles: A Promising Frontier for Innovation. ChemNanoMat 2023, 9, e202300205. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Joshi, R.; Chughtai, A.A.; Macintyre, C.R. Graphene Modified Multifunctional Personal Protective Clothing. Adv. Mater. Interfaces 2019, 6, 1900622. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Ji, Y. Graphene as Advanced Applied Material in Flexible Display Applications. Appl. Comput. Eng. 2023, 23, 152–156. [Google Scholar] [CrossRef]

- He, S.; Ma, Y.; Maulik, G.; Jellicoe, M.; Nag, A.; Powell, W.; Deng, S.; Fang, J.; Wu, Y. A review on graphene-based sensors for tactile applications. Sens. Actuators A Phys. 2024, 372. [Google Scholar] [CrossRef]

- Abbas, Q.; Shinde, P.A.; Abdelkareem, M.A.; Alami, A.H.; Mirzaeian, M.; Yadav, A.; Olabi, A.G. Graphene Synthesis Techniques and Environmental Applications. Materials 2022, 15, 7804. [Google Scholar] [CrossRef]

- Dhinakaran, V.; Lavanya, M.; Vigneswari, K.; Ravichandran, M.; Vijayakumar, M.D. Review on Exploration of Graphene in Diverse Applications and Its Future Horizon. Mater. Today Proc. 2020, 27, 824–828. [Google Scholar] [CrossRef]

- Ge, Q.; Chu, J.; Cao, W.; Yi, F.; Ran, Z.; Jin, Z.; Mao, B.; Li, Z.; Novoselov, K.S. Graphene-Based Textiles for Thermal Management and Flame Retardancy. Adv Funct Mater 2022, 32. [Google Scholar] [CrossRef]

- Lavorato, C.; Fontananova, E. An Overview on Exploitation of Graphene-Based Membranes: From Water Treatment to Medical Industry, Including Recent Fighting against COVID-19. Microorganisms 2023, 11, 310. [Google Scholar] [CrossRef]

- Musico, Y.L.F.; Santos, C.M.; Dalida, M.L.P.; Rodrigues, D.F. Surface Modification of Membrane Filters Using Graphene and Graphene Oxide-Based Nanomaterials for Bacterial Inactivation and Removal. ACS Sustain. Chem. Eng. 2014, 2, 1559–1565. [Google Scholar] [CrossRef]

- Zhang, X.; Kong, H.; Yang, G.; Zhu, D.; Luan, X.; He, P.; Wei, G. Graphene-Based Functional Hybrid Membranes for Antimicrobial Applications: A Review. Appl. Sci. 2022, 12, 4834. [Google Scholar] [CrossRef]

- Ali, I.; Kim, N.K.; Bhattacharyya, D. Effects of Graphene Nanoplatelets on Mechanical and Fire Performance of Flax Polypropylene Composites with Intumescent Flame Retardant. Molecules 2021, 26, 4094. [Google Scholar] [CrossRef] [PubMed]

- Erdoǧdu, Y.E.; Korkmaz, E.E.; Temiz, Ş. Effect of Graphene Nanoplatelet Filling on Mechanical Properties of Natural Fiber Reinforced Polymer Composites. Mater. Test. 2021, 63, 322–328. [Google Scholar] [CrossRef]

- Chattopadhyay, D.K.; Webster, D.C. Thermal Stability and Flame Retardancy of Polyurethanes. Prog. Polym. Sci. 2009, 34, 1068–1133. [Google Scholar] [CrossRef]

- Sałasińska, K.; Leszczyńska, M.; Celiński, M.; Kozikowski, P.; Kowiorski, K.; Lipińska, L. Burning Behaviour of Rigid Polyurethane Foams with Histidine and Modified Graphene Oxide. Materials 2021, 14, 1184. [Google Scholar] [CrossRef]

- Puszka, A.; Sikora, J.W. Synthesis and Characterization of New Polycarbonate-Based Poly(Thiourethane-Urethane)s. Polymers 2022, 14, 2933. [Google Scholar] [CrossRef]

- Hebda, E.; Bukowczan, A.; Michałowski, S.; Pielichowski, K. Flexible Polyurethane Foams Reinforced by Functionalized Polyhedral Oligomeric Silsesquioxanes: Structural Characteristics and Evaluation of Thermal/Flammability Properties. Polymers 2022, 14, 4743. [Google Scholar] [CrossRef] [PubMed]

- Mishra, A.K.; Chattopadhyay, D.K.; Sreedhar, B.; Raju, K.V.S.N. FT-IR and XPS Studies of Polyurethane-Urea-Imide Coatings. Prog. Org. Coat. 2006, 55, 231–243. [Google Scholar] [CrossRef]

- Eltahan, E. Structural parameters affecting tear strength of the fabrics tents. Alex. Eng. J. 2018, 57, 97–105. [Google Scholar] [CrossRef]

| Sample | Material Description |

|---|---|

| PU | polyurethane foil |

| PU/0.25%G | polyurethane foil containing 0.25 wt.% graphene nanofiller |

| PU/0.5%G | polyurethane foil containing 0.5 wt.% graphene nanofiller |

| Sample | Material Description |

|---|---|

| textile | meta-aramid textile carrier with the addition of 2% antistatic fibers |

| textile/PU | meta-aramid textile carrier with the addition of 2% antistatic fibers coated with polyurethane |

| textile/PU/0.25%G | meta-aramid textile carrier with the addition of 2% antistatic fibers coated with polyurethane containing 0.25 wt.% of graphene |

| textile/PU/0.5%G | meta-aramid textile carrier with the addition of 2% antistatic fibers coated with polyurethane containing 0.5 wt.% of graphene |

| The Average Tearing Force Obtained During the Test Based on the PN-EN ISO 13937-2:2002 Standard [4] | |

|---|---|

| The minimum value required based on the EN 469:2020 (PN-EN 469:2020-01) standard (protective clothing for firefighters) [5] | 30 N |

| The minimum value required based on the EN ISO 11611:2015 (PN-EN ISO 11611:2015-11) standard (protective clothing used during welding and related processes) [6] | 15 N—level 1 of performance 20 N—level 2 of performance |

| The minimum value required based on the EN ISO 11612:2015 (PN-EN ISO 11612:2015-11) standard (clothing for protection against heat and flame) [7] | 10 N |

| Samples | T5% | DTG1 | DTG2 | DTG3 | Residue at 575 °C (Nitrogen Atmosphere) | Residue at 575 °C (Air Atmosphere) |

|---|---|---|---|---|---|---|

| [°C] | [°C]; [%/°C] | [%] | [%] | |||

| PU | 292 | 292; 0.18 | 357; 0.99 | 402; 0.92 | 7.0 | 28.3 |

| PU/0.25%G | 297 | 299; 0.19 | 360; 0.80 | 406; 0.71 | 27.4 | 27.8 |

| PU/0.5%G | 297 | 311; 0.26 | 359; 0.75 | 403; 0.71 | 27.9 | 28.1 |

| Sample | First Heating | Second Heating | ||

|---|---|---|---|---|

| TIg1, [°C] | Tm, [°C] | ΔH [J/g] | TIg2, [°C] | |

| PU | −60.8 | 86.2 | 5.1 | −60.1 |

| PU/0.25%G | −59.2 | 80.3 | 13.1 | −61.2 |

| PU/0.5%G | −60.8 | 79.2 | 16.9 | −61.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Irzmańska, E.; Jurczyk-Kowalska, M.; Boczkowska, A.; Sałasińska, K.; Strycharz, K.; Olejnik, O.; Sygocki, W. Thermal Analysis of Polyurethane Coatings Modified with Graphene and Modification Influence on Mechanical Properties of Hybrid Textile Materials Dedicated to Personal Protective Equipment. Coatings 2025, 15, 705. https://doi.org/10.3390/coatings15060705

Irzmańska E, Jurczyk-Kowalska M, Boczkowska A, Sałasińska K, Strycharz K, Olejnik O, Sygocki W. Thermal Analysis of Polyurethane Coatings Modified with Graphene and Modification Influence on Mechanical Properties of Hybrid Textile Materials Dedicated to Personal Protective Equipment. Coatings. 2025; 15(6):705. https://doi.org/10.3390/coatings15060705

Chicago/Turabian StyleIrzmańska, Emilia, Magdalena Jurczyk-Kowalska, Anna Boczkowska, Kamila Sałasińska, Kamila Strycharz, Olga Olejnik, and Witold Sygocki. 2025. "Thermal Analysis of Polyurethane Coatings Modified with Graphene and Modification Influence on Mechanical Properties of Hybrid Textile Materials Dedicated to Personal Protective Equipment" Coatings 15, no. 6: 705. https://doi.org/10.3390/coatings15060705

APA StyleIrzmańska, E., Jurczyk-Kowalska, M., Boczkowska, A., Sałasińska, K., Strycharz, K., Olejnik, O., & Sygocki, W. (2025). Thermal Analysis of Polyurethane Coatings Modified with Graphene and Modification Influence on Mechanical Properties of Hybrid Textile Materials Dedicated to Personal Protective Equipment. Coatings, 15(6), 705. https://doi.org/10.3390/coatings15060705