A Vegetable-Oil-Based Polyurethane Coating for Controlled Nutrient Release: A Review

Abstract

1. Introduction

2. Preparation of Vegetable-Oil-Based PU-Coated Fertilizer

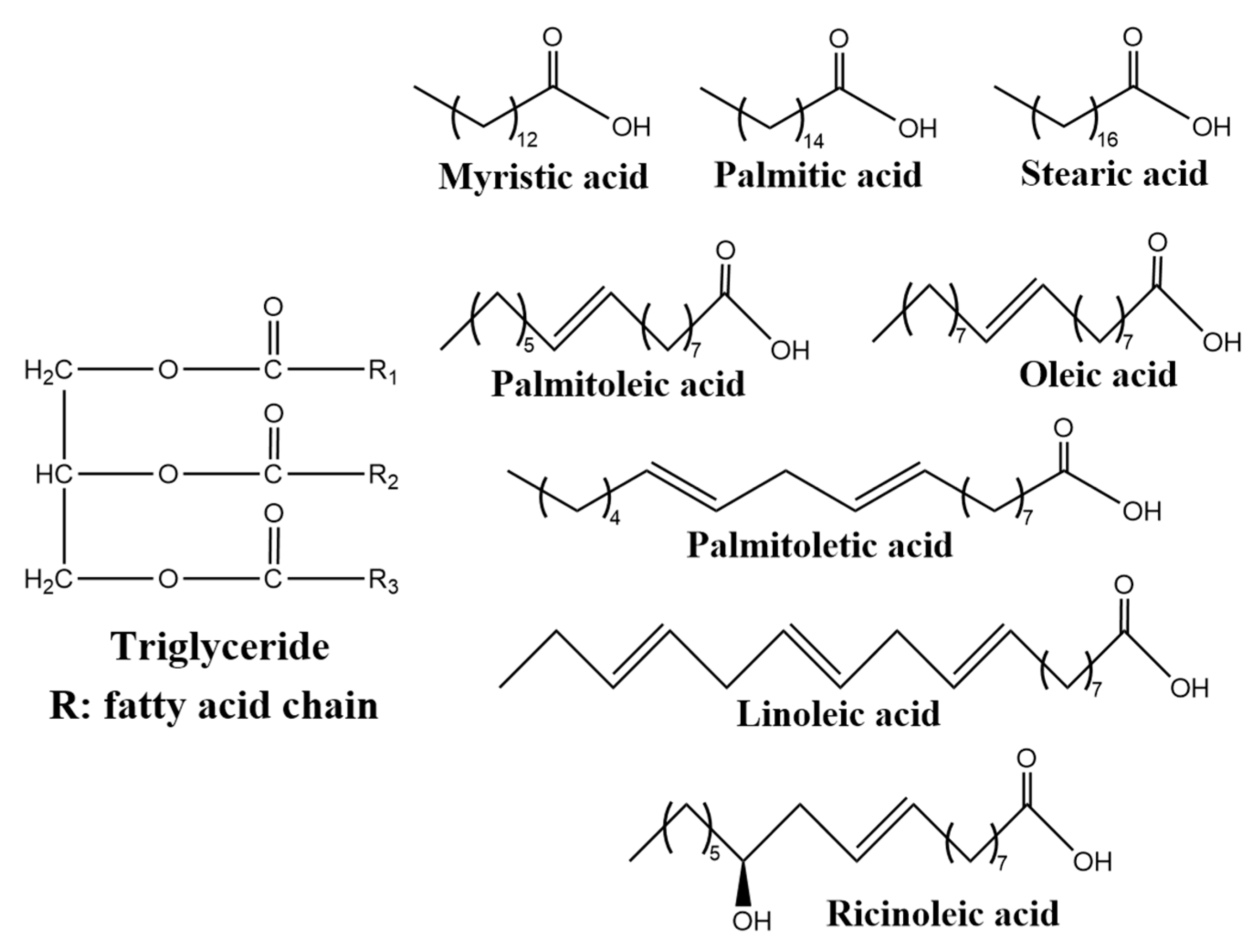

2.1. Bio-Based Polyol from Vegetable Oil

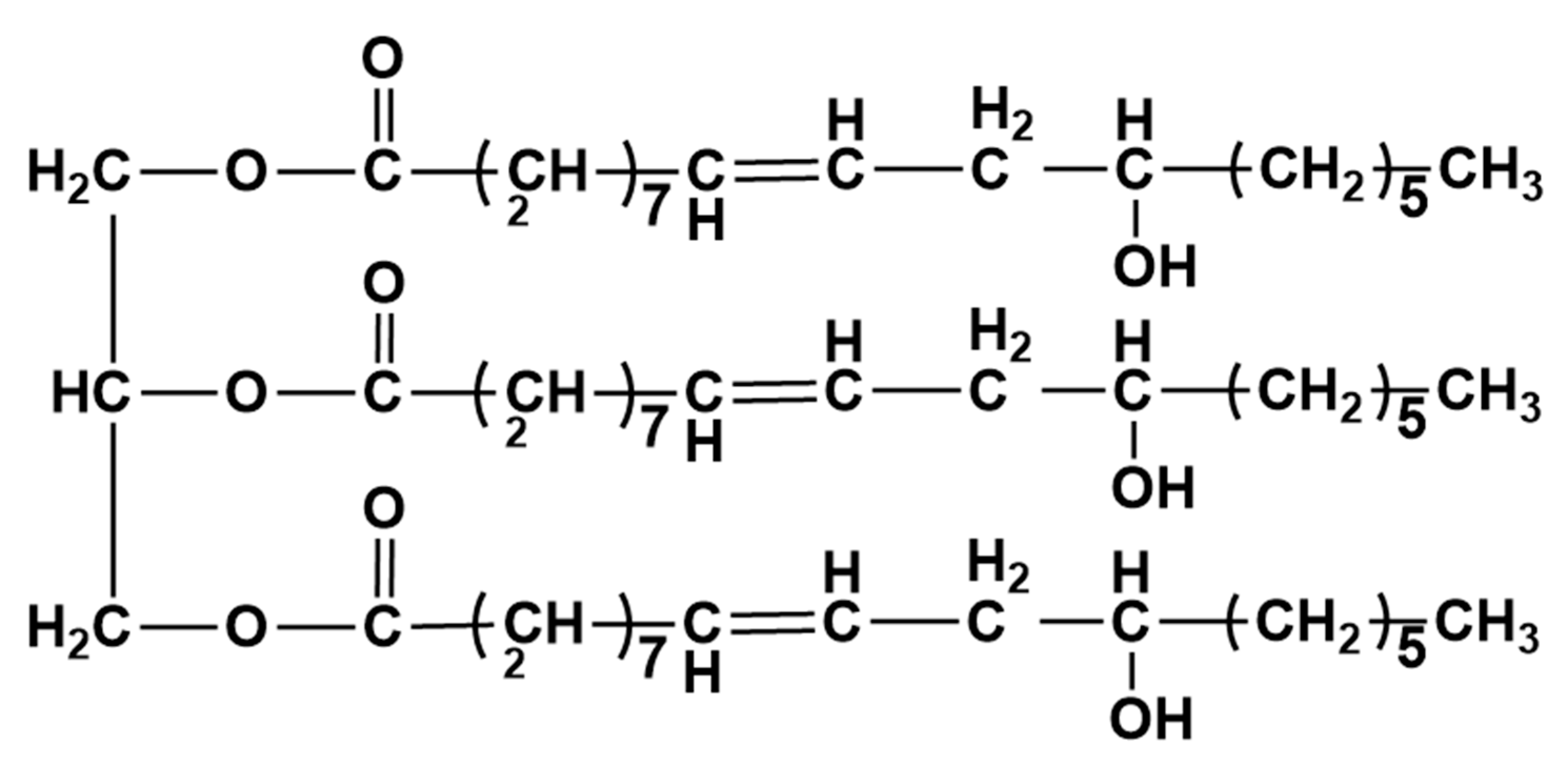

2.1.1. Cater-Oil-Based Polyols

2.1.2. Other Vegetable-Oil-Based Polyols

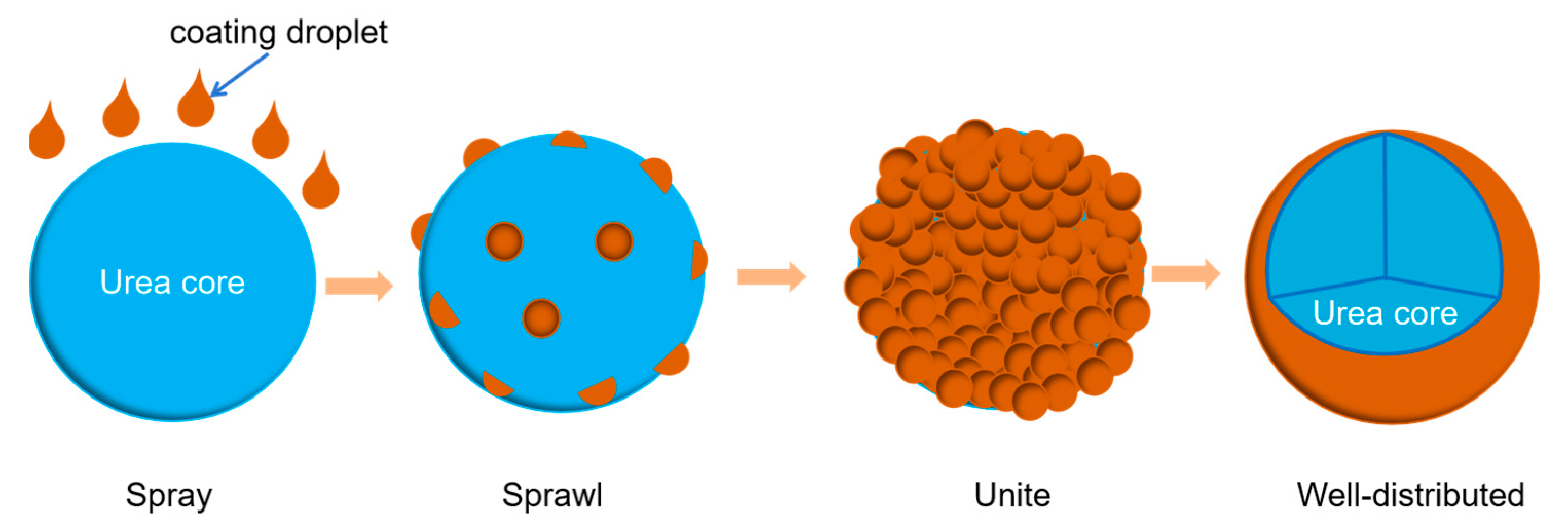

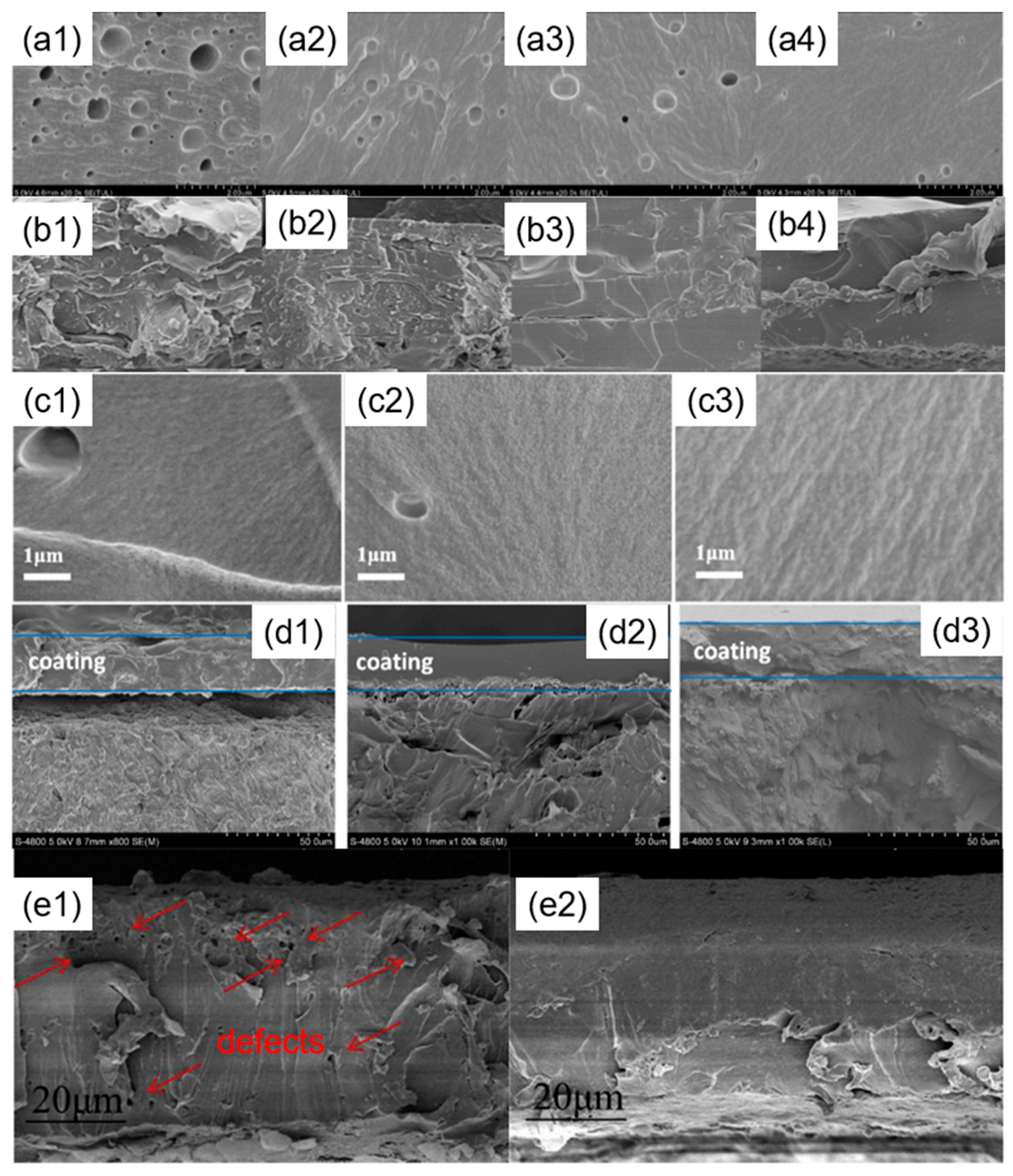

2.2. Coating Process of Vegetable-Oil-Based PU-Coated CRFs

2.3. Modification of Vegetable-Oil-Based PU Coating for CRFs

2.3.1. Co-Polymerization

2.3.2. Composite Modification

2.3.3. Surface Modification

2.3.4. A Summary of the Modification Methods

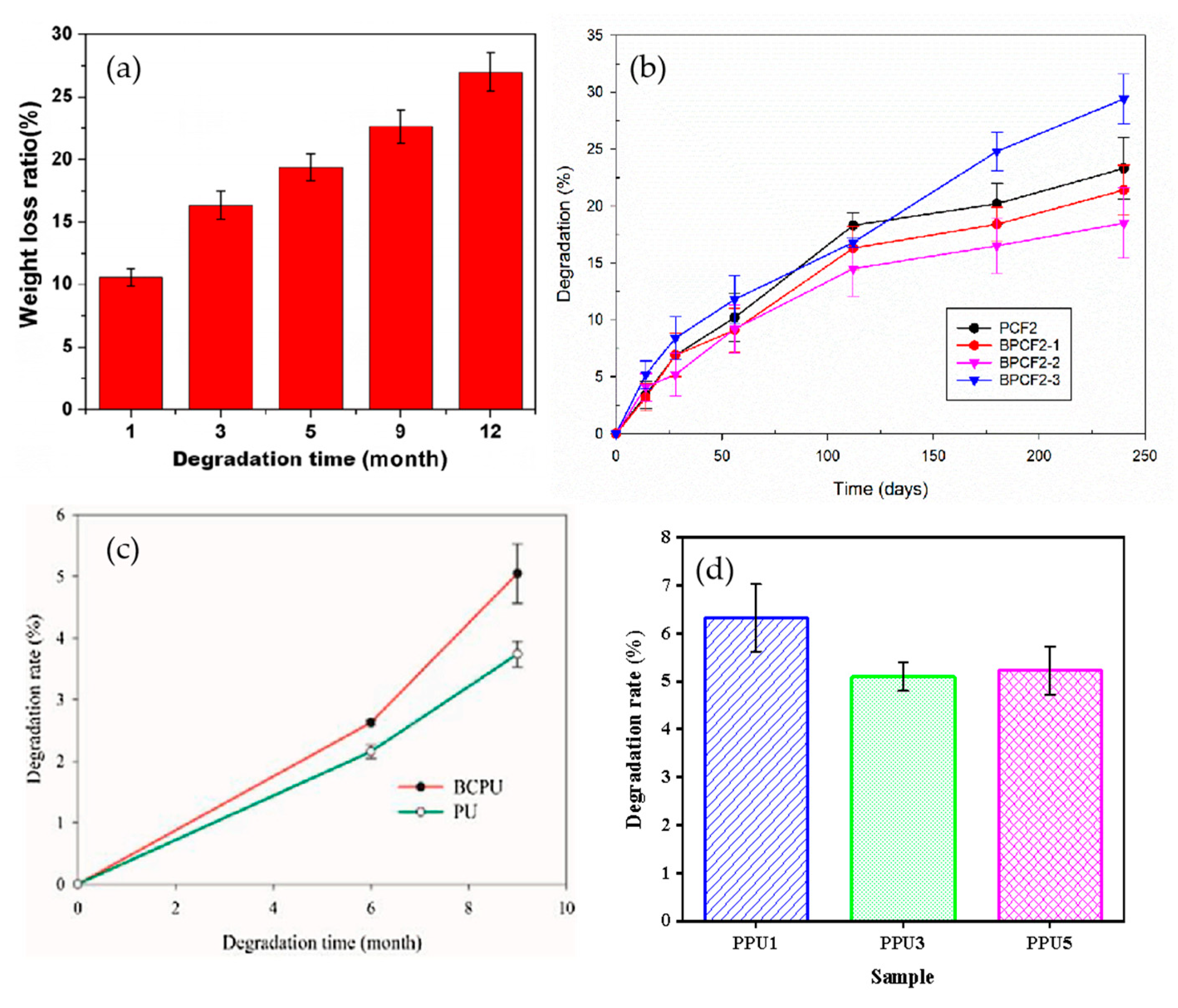

3. Controlled Release Properties of Vegetable-Oil-Based PU Coating for CRFs

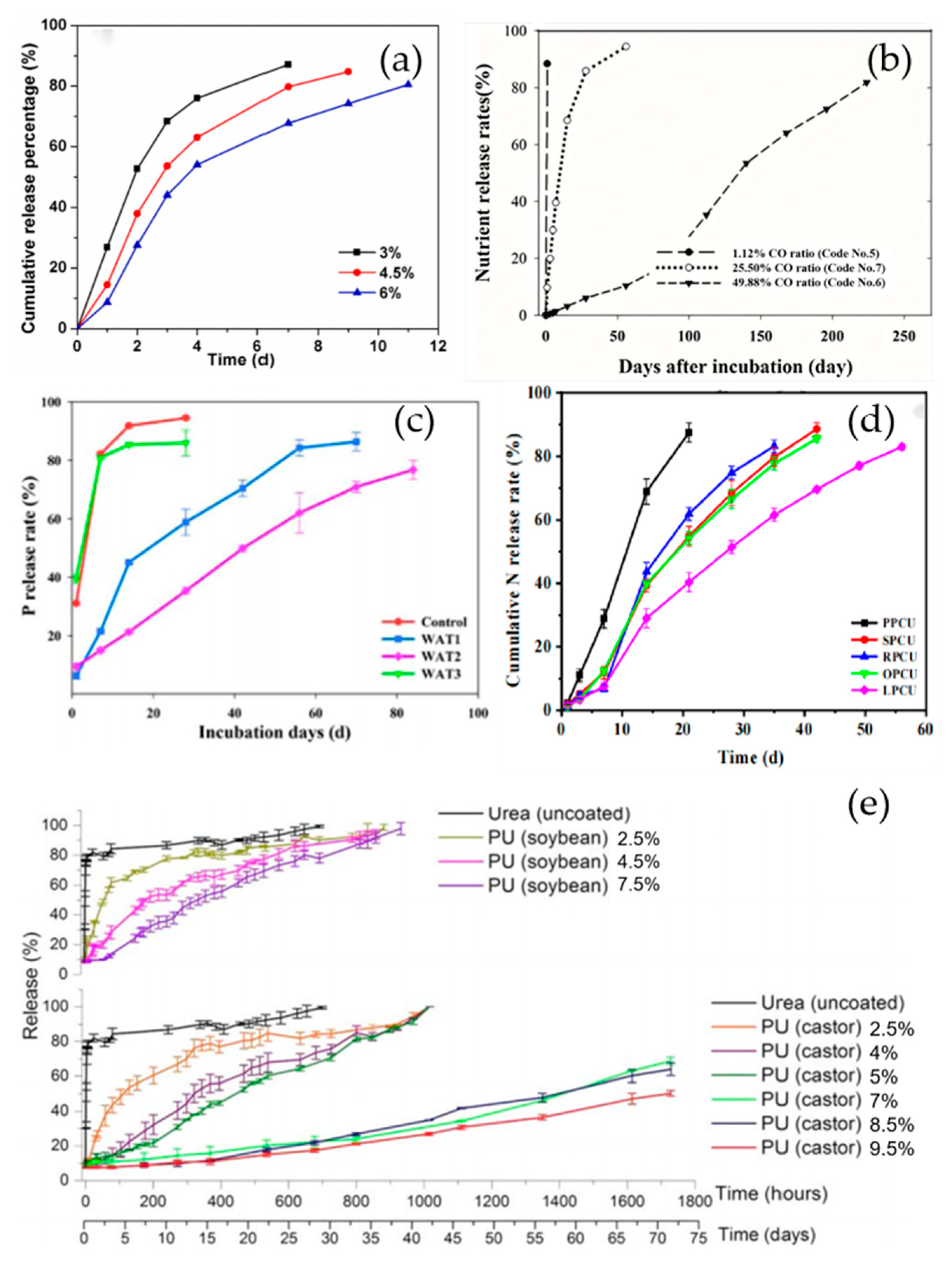

3.1. Nutrients Released in Water

3.2. Nutrients Released in Soil

3.3. Application in Planting Experiment

- 1.

- Design-Phase Cost Integration:

- 2.

- Retrospective Life-Cycle Assessment (LCA):

4. Environmental Impact of Vegetable-Oil-Based PU Coating for CRFs

4.1. Degradability of Vegetable-Oil-Based PU

4.2. Other Effects of Vegetable-Oil-Based PU-Coated CRFs on the Environment

5. Trends of Vegetable-Oil-Based PU-Coated Fertilizers

6. Conclusions and Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PU | Polyurethane |

| VPU | Vegetable-oil-based polyurethane |

| CRF | Controlled release fertilizer |

| MDI | Diphenylmethane diisocyanate |

| PAPI | Polyaryl polymethylene isocyanate |

| IPDI | Isophorone diisocyanate |

| WCO | Waste cooking oil |

| PHA | Polyhydroxyalkanoate |

References

- Sonnenschein, M.F. Polyurethanes: Science, Technology, Markets, and Trends; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Liu, Z.; Xu, H.; Fan, Z.; Zhang, X.; Cui, X.; Ji, J.; Li, H.; Guo, X. A polyurethane elastomer combining high strength and excellent self-healing properties for waterproofing coatings. J. Appl. Polym. Sci. 2024, 141, e55957. [Google Scholar] [CrossRef]

- Ashrafizadeh, H.; McDonald, A.; Mertiny, P. Erosive and Abrasive Wear Resistance of Polyurethane Liners; IntechOpen: London, UK, 2017. [Google Scholar]

- Ates, M.; Karadag, S.; Eker, A.A.; Eker, B. Polyurethane foam materials and their industrial applications. Polym. Int. 2022, 71, 1157–1163. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, C.; Gao, Y.; Li, Z.; Shang, Y.; Li, H. Porous thermal insulation polyurethane foam materials. Polymers 2023, 15, 3818. [Google Scholar] [CrossRef] [PubMed]

- Nogueira, P.; Costa, I.; Araújo, R.; Pasa, V. Bio-oil-based polyurethane coatings: A sustainable approach to corrosion protection. Prog. Org. Coat. 2024, 194, 108572. [Google Scholar] [CrossRef]

- Guo, Y.-H.; Guo, J.-J.; Miao, H.; Teng, L.-J.; Huang, Z. Properties and paper sizing application of waterborne polyurethane emulsions synthesized with isophorone diisocyanate. Prog. Org. Coat. 2014, 77, 988–996. [Google Scholar] [CrossRef]

- Chattopadhyay, D.K.; Raju, K. Structural engineering of polyurethane coatings for high performance applications. Prog. Polym. Sci. 2007, 32, 352–418. [Google Scholar] [CrossRef]

- Das, A.; Mahanwar, P. A brief discussion on advances in polyurethane applications. Adv. Ind. Eng. Polym. Res. 2020, 3, 93–101. [Google Scholar] [CrossRef]

- de Souza, F.M.; Kahol, P.K.; Gupta, R.K. Introduction to polyurethane chemistry. In Polyurethane Chemistry: Renewable Polyols and Isocyanates; ACS Publications: Washington, DC, USA, 2021; pp. 1–24. [Google Scholar]

- Kaur, R.; Singh, P.; Tanwar, S.; Varshney, G.; Yadav, S. Assessment of bio-based polyurethanes: Perspective on applications and bio-degradation. Macromol 2022, 2, 284–314. [Google Scholar] [CrossRef]

- Salzano de Luna, M. Recent trends in waterborne and bio-based polyurethane coatings for corrosion protection. Adv. Mater. Interfaces 2022, 9, 2101775. [Google Scholar] [CrossRef]

- Mo, Y.; Huang, X.; Hu, C. Recent Advances in the Preparation and Application of Bio-Based Polyurethanes. Polymers 2024, 16, 2155. [Google Scholar] [CrossRef]

- Silva, R.; Barros-Timmons, A.; Quinteiro, P. Life cycle assessment of fossil-and bio-based polyurethane foams: A review. J. Clean. Prod. 2023, 430, 139697. [Google Scholar] [CrossRef]

- Bhaskaran, S.K.; Boga, K.; Arukula, R.; Gaddam, S.K. Natural fibre reinforced vegetable-oil based polyurethane composites: A review. J. Polym. Res. 2023, 30, 325. [Google Scholar] [CrossRef]

- Ma, X.; Chen, J.; Zhu, J.; Yan, N. Lignin-based polyurethane: Recent advances and future perspectives. Macromol. Rapid Commun. 2021, 42, 2000492. [Google Scholar] [CrossRef] [PubMed]

- Tai, N.L.; Ghasemlou, M.; Adhikari, R.; Adhikari, B. Starch-based isocyanate-and non-isocyanate polyurethane hybrids: A review on synthesis, performance and biodegradation. Carbohydr. Polym. 2021, 265, 118029. [Google Scholar] [CrossRef]

- Tran, M.H.; Lee, E.Y. Production of polyols and polyurethane from biomass: A review. Environ. Chem. Lett. 2023, 21, 2199–2223. [Google Scholar] [CrossRef]

- vdMa, Y.; Xiao, Y.; Zhao, Y.; Bei, Y.; Hu, L.; Zhou, Y.; Jia, P.J.R.; Polymers, F. Biomass based polyols and biomass based polyurethane materials as a route towards sustainability. React. Funct. Polym. 2022, 175, 105285. [Google Scholar]

- Wienen, D.; Gries, T.; Cooper, S.L.; Heath, D.E. An overview of polyurethane biomaterials and their use in drug delivery. J. Control. Release 2023, 363, 376–388. [Google Scholar] [CrossRef]

- Lu, H.; Dun, C.; Jariwala, H.; Wang, R.; Cui, P.; Zhang, H.; Dai, Q.; Yang, S.; Zhang, H. Improvement of bio-based polyurethane and its optimal application in controlled release fertilizer. J. Control. Release 2022, 350, 748–760. [Google Scholar] [CrossRef]

- Rajan, M.; Shahena, S.; Chandran, V.; Mathew, L. Controlled release of fertilizers—Concept, reality, and mechanism. In Controlled Release Fertilizers for Sustainable Agriculture; Elsevier: Amsterdam, The Netherlands, 2021; pp. 41–56. [Google Scholar]

- Moradi, S.; Babapoor, A.; Ghanbarlou, S.; Kalashgarani, M.Y.; Salahshoori, I.; Seyfaee, A. Toward a new generation of fertilizers with the approach of controlled-release fertilizers: A review. J. Coat. Technol. Res. 2024, 21, 31–54. [Google Scholar] [CrossRef]

- Mendonca Cidreira, A.C.; Wei, L.; Aldekhail, A.; Islam Rubel, R. Controlled-release nitrogen fertilizers: A review on bio-based and smart coating materials. J. Appl. Polym. Sci. 2025, 142, e56390. [Google Scholar] [CrossRef]

- Laohhasurayotin, K.; Yiamsawas, D.; Kangwansupamonkon, W. Recent Developments in Bio-Based Materials for Controlled-Release Fertilizers. In High-Performance Materials from Bio-Based Feedstocks; Wiley: Hoboken, NJ, USA, 2022; pp. 361–397. [Google Scholar]

- Uyama, H. Polymers from Plant Oils. In Encyclopedia of Polymeric Nanomaterials; Kobayashi, S., Müllen, K., Eds.; Springer: Berlin/Heidelberg, Germany, 2015; pp. 2031–2035. [Google Scholar]

- Asare, M.A.; de Souza, F.M.; Gupta, R.K. Waste to resource: Synthesis of polyurethanes from waste cooking oil. Ind. Eng. Chem. Res. 2022, 61, 18400–18411. [Google Scholar] [CrossRef]

- Bo, G.; Xu, X.; Tian, X.; Wu, J.; He, X.; Xu, L.; Yan, Y. Synthesis and characterization of flame-retardant rigid polyurethane foams derived from gutter oil biodiesel. Eur. Polym. J. 2021, 147, 110329. [Google Scholar] [CrossRef]

- Patil, C.K.; Jung, D.W.; Jirimali, H.D.; Baik, J.H.; Gite, V.V.; Hong, S.C. Nonedible vegetable oil-based polyols in anticorrosive and antimicrobial polyurethane coatings. Polymers 2021, 13, 3149. [Google Scholar] [CrossRef]

- Ghasemlou, M.; Daver, F.; Ivanova, E.P.; Adhikari, B. Polyurethanes from seed oil-based polyols: A review of synthesis, mechanical and thermal properties. Ind. Crops Prod. 2019, 142, 111841. [Google Scholar] [CrossRef]

- Kaikade, D.S.; Sabnis, A.S. Polyurethane foams from vegetable oil-based polyols: A review. Polym. Bull. 2023, 80, 2239–2261. [Google Scholar] [CrossRef]

- Kaikade, D.S.; Sabnis, A.S. Recent advances in polyurethane coatings and adhesives derived from vegetable oil-based polyols. J. Polym. Environ. 2023, 31, 4583–4605. [Google Scholar] [CrossRef]

- Paraskar, P.M.; Prabhudesai, M.S.; Hatkar, V.M.; Kulkarni, R.D. Vegetable oil based polyurethane coatings–A sustainable approach: A review. Prog. Org. Coat. 2021, 156, 106267. [Google Scholar] [CrossRef]

- Singh, P.; Rana, A.; Karak, N.; Kumar, I.; Rana, S.; Kumar, P. Sustainable smart anti-corrosion coating materials derived from vegetable oil derivatives: A review. RSC Adv. 2023, 13, 3910–3941. [Google Scholar] [CrossRef]

- Khanderay, J.C.; Gite, V.V. Vegetable oil-based polyurethane coatings: Recent developments in India. Green Mater. 2017, 5, 109–122. [Google Scholar] [CrossRef]

- Yuan, S.; Cheng, L.; Tan, Z. Characteristics and preparation of oil-coated fertilizers: A review. J. Control. Release 2022, 345, 675–684. [Google Scholar] [CrossRef]

- Firmanda, A.; Fahma, F.; Syamsu, K.; Mahardika, M.; Suryanegara, L.; Munif, A.; Gozan, M.; Wood, K.; Hidayat, R.; Yulia, D. Biopolymer-based slow/controlled-release fertilizer (SRF/CRF): Nutrient release mechanism and agricultural sustainability. J. Environ. Chem. Eng. 2024, 12, 112177. [Google Scholar] [CrossRef]

- Niesiobędzka, J.; Datta, J. Challenges and recent advances in bio-based isocyanate production. Green Chem. 2023, 25, 2482–2504. [Google Scholar] [CrossRef]

- Kyriacos, D. Biobased Polyols for Industrial Polymers; John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

- Chen, C.; Lu, J.; Ma, T.; Zhang, Y.; Gu, L.; Chen, X. Applications of vegetable oils and their derivatives as Bio-Additives for use in asphalt binders: A review. Constr. Build. Mater. 2023, 383, 131312. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, R.; Li, Q.; Li, M.; Liu, C.; Jia, P. Castor oil as a platform for preparing bio-based chemicals and polymer materials. Green Mater. 2021, 10, 99–109. [Google Scholar] [CrossRef]

- Malani, R.S.; Malshe, V.C.; Thorat, B.N. Polyols and polyurethanes from renewable sources: Past, present and future—Part 1: Vegetable oils and lignocellulosic biomass. J. Coat. Technol. Res. 2022, 19, 201–222. [Google Scholar] [CrossRef]

- Wang, S.; Li, X.; Ren, K.; Huang, R.; Lei, G.; Shen, L.; Zhan, Y.; Jiang, L. Surface modification of pyrophyllite for optimizing properties of castor oil-based polyurethane composite and its application in controlled-release fertilizer. Arab. J. Chem. 2023, 16, 104400. [Google Scholar] [CrossRef]

- Su, B.; Yang, M.; Gao, B.; Li, Z.; Zhao, X.; Zhang, S.; Cheng, D.; Shen, T.; Yao, Y.; Yang, Y. Ceresin wax enhances hydrophobicity and density of bio-based polyurethane of controlled-release fertilizers: Streamlined production, improved nutrient release performance, and reduced cost. J. Clean. Prod. 2024, 452, 142145. [Google Scholar] [CrossRef]

- Majaron, V.F.; da Silva, M.G.; Bortoletto-Santos, R.; Klaic, R.; Giroto, A.; Guimaraes, G.G.; Polito, W.L.; Farinas, C.S.; Ribeiro, C. Synergy between castor oil polyurethane/starch polymer coating and local acidification by A. niger for increasing the efficiency of nitrogen fertilization using urea granules. Ind. Crops Prod. 2020, 154, 112717. [Google Scholar] [CrossRef]

- Bortoletto-Santos, R.; Ribeiro, C.; Polito, W.L. Controlled release of nitrogen-source fertilizers by natural-oil-based poly (urethane) coatings: The kinetic aspects of urea release. J. Appl. Polym. Sci. 2016, 133, 43790. [Google Scholar] [CrossRef]

- Lu, H.; Tian, H.; Zhang, M.; Liu, Z.; Chen, Q.; Guan, R.; Wang, H. Water Polishing improved controlled-release characteristics and fertilizer efficiency of castor oil-based polyurethane coated diammonium phosphate. Sci. Rep. 2020, 10, 5763. [Google Scholar] [CrossRef]

- Tian, H.; Li, Z.; Lu, P.; Wang, Y.; Jia, C.; Wang, H.; Liu, Z.; Zhang, M. Starch and castor oil mutually modified, cross-linked polyurethane for improving the controlled release of urea. Carbohydr. Polym. 2021, 251, 117060. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Yang, Y.; Wang, C.; Shi, G.; Xie, J.; Gao, B.; Li, Y.; Wan, Y.; Cheng, D.; Shen, T. Nano-soy-protein microcapsule-enabled self-healing biopolyurethane-coated controlled-release fertilizer: Preparation, performance, and mechanism. Mater. Today Chem. 2021, 20, 100413. [Google Scholar] [CrossRef]

- Liu, J.; Yang, Y.; Gao, B.; Wang, W.; Cheng, D.; Yao, Y.; Shen, T.; Yu, Z.; Zhang, T.; Wu, J. Hydrophobic-densified high-elastic waste-carton-derived biopolymer-coated fertilizers: Enhanced performance and controlled-release mechanism. J. Environ. Chem. Eng. 2023, 11, 110591. [Google Scholar] [CrossRef]

- Zhao, X.; Ma, F.; Yan, L.; Liu, J.; Zhang, T.; Su, X.; Wang, W.; Yang, Y.; Xu, J.; Xie, J. Double-modified biopolymer-coatings based on recyclable poplar-catkin: Efficient performance, controlled-release mechanism and rice application. Prog. Org. Coat. 2024, 186, 107980. [Google Scholar] [CrossRef]

- Wang, C.; Song, S.; Yang, Z.; Liu, Y.; He, Z.; Zhou, C.; Du, L.; Sun, D.; Li, P. Hydrophobic modification of castor oil-based polyurethane coated fertilizer to improve the controlled release of nutrient with polysiloxane and halloysite. Prog. Org. Coat. 2022, 165, 106756. [Google Scholar] [CrossRef]

- Tang, J.; Zhang, Z.; Ge, T.; Huang, J.; Wang, Y.; Shi, M.; Liu, Y.; Wang, B.; Liu, P. Development and application of vegetable oil-based polyurethane coated fertilizers. Chem. Eng. Sci. 2025, 301, 120705. [Google Scholar] [CrossRef]

- Bortoletto-Santos, R.; Cavigelli, M.A.; Montes, S.E.; Schomberg, H.H.; Le, A.; Thompson, A.I.; Kramer, M.; Polito, W.L.; Ribeiro, C. Oil-based polyurethane-coated urea reduces nitrous oxide emissions in a corn field in a Maryland loamy sand soil. J. Clean. Prod. 2020, 249, 119329. [Google Scholar] [CrossRef]

- Zhao, X.; Qi, X.; Chen, Q.; Ao, X.; Guo, Y. Sulfur-modified coated slow-release fertilizer based on castor oil: Synthesis and a controlled-release model. ACS Sustain. Chem. Eng. 2020, 8, 18044–18053. [Google Scholar] [CrossRef]

- Feng, G.-D.; Ma, Y.; Liu, H.-H.; Zhang, M.; Jia, P.-Y.; Hu, L.-H.; Liu, C.-G.; Hu, Y.; Zhou, Y.-H. Developing polysulfide castor oil–based polymer coating for controlled-release urea fertilizers. Prog. Org. Coat. 2024, 190, 108312. [Google Scholar] [CrossRef]

- Dong, S.; Cao, B.; Wang, X.; Liang, L.; Zou, G.; Yuan, L.; Chen, Y. Fully bio-based polyurethane coating for environmentally friendly controlled release fertilizer: Construction, degradation mechanism and effect on plant growth. Ind. Crops Prod. 2025, 225, 120437. [Google Scholar] [CrossRef]

- Pang, M.; Liu, Z.; Li, H.; Liang, L.; Li, L. Effect of fatty acids on vegetable-oil-derived sustainable polyurethane coatings for controlled-release fertilizer. Coatings 2024, 14, 1183. [Google Scholar] [CrossRef]

- Liu, X.; Yang, Y.; Gao, B.; Li, Y. Organic silicone-modified transgenic soybean oil as bio-based coating material for controlled-release urea fertilizers. J. Appl. Polym. Sci. 2016, 133, 44097. [Google Scholar] [CrossRef]

- Sun, S.; Wang, W.; Liu, F.; Zhang, L.; Fan, X. Coating layer preparation with mixed vegetable oil and nutrient release regulation of fertilizer. Eur. Polym. J. 2019, 120, 109194. [Google Scholar] [CrossRef]

- El Gharrak, A.; Essamlali, Y.; Amadine, O.; Aboulhrouz, S.; Hafnaoui, A.; Ghalfi, H.; Zahouily, M. Tunable physicochemical properties of lignin and rapeseed oil-based polyurethane coatings with tailored release property of coated NPK fertilizer. Prog. Org. Coat. 2022, 170, 106982. [Google Scholar] [CrossRef]

- Sair, S.; Aboulhrouz, S.; Amadine, O.; Ayouch, I.; Jioui, I.; Essamlali, Y.; Danoun, K.; Ouadil, B.; Zahouily, M. Bio-based alkyd urethane formulations: Advancing sustainable agriculture and environmental protection through slow-controlled release of NPK fertilizers. Eur. Polym. J. 2023, 199, 112477. [Google Scholar] [CrossRef]

- Jiazhuo, X.; Yuechao, Y.; Bin, G.; Yongshan, W.; Jing, X.; Qinghua, Z. Biomimetic Superhydrophobic Biobased Polyurethane-Coated Fertilizer with Atmosphere “Outerwear”. ACS Appl. Mater. Interfaces 2017, 9, 15868–15879. [Google Scholar]

- Pang, M.; Dong, S.; Zou, G.; Zhao, J.; Li, H.; Li, L. Study on reduction potential of curing agent in sustainable bio-based controlled release coatings. Polym. Test. 2023, 127, 108193. [Google Scholar] [CrossRef]

- Onn, M.; Jalil, M.J.; Yusoff, N.I.S.M.; Edward, E.B.; Wahit, M.U. A comprehensive review on chemical route to convert waste cooking oils to renewable polymeric materials. Ind. Crops Prod. 2024, 211, 118194. [Google Scholar] [CrossRef]

- Liu, J.; Yang, Y.; Gao, B.; Li, Y.C.; Xie, J. Bio-based elastic polyurethane for controlled-release urea fertilizer: Fabrication, properties, swelling and nitrogen release characteristics. J. Clean. Prod. 2019, 209, 528–537. [Google Scholar] [CrossRef]

- Wang, Q.; Dong, F.; Dai, J.; Zhang, Q.; Jiang, M.; Xiong, Y. Recycled-oil-based polyurethane modified with organic silicone for controllable release of coated fertilizer. Polymers 2019, 11, 454. [Google Scholar] [CrossRef]

- Liu, X.; Wu, L.; Zhou, W.; Hu, L.; Lv, J.; Du, W. Environment-friendly bio-based controlled-release phosphate fertilizer with waste kitchen oil as coating material: Preparation, characterization, and mechanisms. J. Environ. Manag. 2022, 324, 116409. [Google Scholar] [CrossRef]

- Mansouri, H.; Ait Said, H.; Noukrati, H.; Oukarroum, A.; Ben youcef, H.; Perreault, F. Advances in Controlled Release Fertilizers: Cost-Effective Coating Techniques and Smart Stimuli-Responsive Hydrogels. Adv. Sustain. Syst. 2023, 7, 2300149. [Google Scholar] [CrossRef]

- Wang, X.; Yang, Y.; Zhong, S.; Meng, Q.; Li, Y.; Wang, J.; Gao, Y.; Cui, X. Advances in controlled-release fertilizer encapsulated by organic-inorganic composite membranes. Particuology 2024, 84, 236–248. [Google Scholar] [CrossRef]

- Kassem, I.; Ablouh, E.-H.; El Bouchtaoui, F.-Z.; Jaouahar, M.; El Achaby, M. Polymer coated slow/controlled release granular fertilizers: Fundamentals and research trends. Prog. Mater. Sci. 2024, 144, 101269. [Google Scholar] [CrossRef]

- Chen, S.; Chen, Y.; Mu, X.; Wang, P.; Miao, L.; Tanemura, S.; Cai, H. Strategies for enhancing ionic conductivity and energy density of gel polymer electrolytes for next-generation flexible energy storage devices. Sustain. Mater. Technol. 2023, 36, e00635. [Google Scholar] [CrossRef]

- Morales-Cerrada, R.; Tavernier, R.; Caillol, S. Fully bio-based thermosetting polyurethanes from bio-based polyols and isocyanates. Polymers 2021, 13, 1255. [Google Scholar] [CrossRef]

- Cross, L.; Gruère, A. Public Summary Medium-Term Fertilizer Outlook 2023–2027; International Fertilizer Association: Prague, Czech Republic, 2023. [Google Scholar]

- Dong, J.; Zhang, Z.; Tian, H.; Chen, S.; Hu, X.; Li, M.; Wang, T.; Wan, J.; Yu, C.; Zhu, X. Soybean-Oil-Modified Petrochemical-Source Polyester Polyurethane Improves the Nutrient Release Performance of Coated Urea. Agronomy 2023, 13, 3008. [Google Scholar] [CrossRef]

- Wei, B.; Jiang, J.; Gao, C.; Zhang, L.; Zhan, Y.; Jiang, S.; Li, Y.; Sun, S.; Xie, J.; Fan, X. Revealing channel controlled nutrient release mechanism of bio-oil polymer coated controlled-release fertilizer. Ind. Crops Prod. 2021, 173, 114096. [Google Scholar] [CrossRef]

- Gungula, D.T.; Andrew, F.P.; Joseph, J.; Kareem, S.A.; Barminas, J.T.; Adebayo, E.F.; Saddiq, A.M.; Tame, V.T.; Dere, I.; Ahinda, W.J. Formulation and characterization of water retention and slow-release urea fertilizer based on Borassus aethiopum starch and Maesopsis eminii hydrogels. Results Mater. 2021, 12, 100223. [Google Scholar] [CrossRef]

- Sofyane, A.; Lahcini, M.; El Meziane, A.; Khouloud, M.; Dahchour, A.; Caillol, S.; Raihane, M. Properties of coated controlled release diammonium phosphate fertilizers prepared with the use of bio-based amino oil. J. Am. Oil Chem. Soc. 2020, 97, 751–763. [Google Scholar] [CrossRef]

- Tian, H.; Wang, L.; Zhu, X.; Zhang, M.; Li, L.; Liu, Z.; Abolfathi, S. Biodegradation of microplastics derived from controlled release fertilizer coating: Selective microbial colonization and metabolism in plastisphere. Sci. Total Environ. 2024, 920, 170978. [Google Scholar] [CrossRef] [PubMed]

- Panda, P.K.; Sadeghi, K.; Seo, J. Recent advances in poly (vinyl alcohol)/natural polymer based films for food packaging applications: A review. Food Packag Shelf Life 2022, 33, 100904. [Google Scholar] [CrossRef]

- Eddarai, E.M.; El Mouzahim, M.; Ragaoui, B.; Eladaoui, S.; Bourd, Y.; Bellaouchou, A.; Boussen, R. Review of current trends in chitosan based controlled and slow-release fertilizer: From green chemistry to circular economy. Int. J. Biol. Macromol. 2024, 278, 134982. [Google Scholar] [CrossRef] [PubMed]

| Vegetable Oil | Fertilizer Core | Coating Technique | Modification | Reference |

|---|---|---|---|---|

| Castor oil | Urea | Drum Coating machine | Sulfur modification | [56] |

| Castor oil | Urea | Sulfur modification | [55] | |

| Castor oil | Urea | Water-repellent and compact double-modification | [51] | |

| Castor oil | Urea | Hydrophobic modification | [52] | |

| Castor oil | Urea | Hydrophobic modification and co-polymerization | [50] | |

| Castor oil | Urea | Self-healing | [49] | |

| Castor oil | DAP | Surface modification | [47] | |

| Castor oil | Urea | Sulfur modification | [54] | |

| Castor oil | Urea | Add bio-composite layer | [45] | |

| Castor oil | Urea | Surface modification and co-polymerization with starch-based polyol | [48] | |

| Castor oil | Urea | Composite modification | [43] | |

| Castor oil | Urea | None | [53] | |

| Castor oil | Urea | Co-polymerization and surface modification | [44] | |

| Castor oil | Urea | Composite modification | [57] | |

| Soybean oil | Urea | Co-polymerization | [75] | |

| Soybean oil | Urea | Silicone modification | [59] | |

| Soybean oil/castor oil | Urea | None | [46] | |

| 80% castor oil and 20% epoxidized soybean oil | NPK (15-15-15) | Co-polymerization | [76] | |

| 80% castor oil and 20% hydroxylated soybean oil | NPK (15-15-15) | Stannous chloride | [60] | |

| Palm oil/olive oil/linseed oil/rapeseed oil/soybean oil | Urea | 1,4-butanediol | [58] | |

| Rapeseed oil | NPK (15-15-15) | Co-polymerization | [61] | |

| Rapeseed oil | NPK (15-15-15) | Composite modification | [62] | |

| Palm oil | Urea | Stannous octoate | [64] | |

| Cottonseed oil | Urea | Surface hydrophobic modification | [63] | |

| Recycled Oil | Urea | Silicone modification | [67] | |

| Recycled Oil | DAP | Surface modifcaiton and composite modification | [68] | |

| Recycled palm Oil | Urea | Composite modification | [66] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, L.; Baharum, A.; Yu, L.J.; Yan, Z.; Badri, K.H. A Vegetable-Oil-Based Polyurethane Coating for Controlled Nutrient Release: A Review. Coatings 2025, 15, 665. https://doi.org/10.3390/coatings15060665

Yao L, Baharum A, Yu LJ, Yan Z, Badri KH. A Vegetable-Oil-Based Polyurethane Coating for Controlled Nutrient Release: A Review. Coatings. 2025; 15(6):665. https://doi.org/10.3390/coatings15060665

Chicago/Turabian StyleYao, Lyu, Azizah Baharum, Lih Jiun Yu, Zibo Yan, and Khairiah Haji Badri. 2025. "A Vegetable-Oil-Based Polyurethane Coating for Controlled Nutrient Release: A Review" Coatings 15, no. 6: 665. https://doi.org/10.3390/coatings15060665

APA StyleYao, L., Baharum, A., Yu, L. J., Yan, Z., & Badri, K. H. (2025). A Vegetable-Oil-Based Polyurethane Coating for Controlled Nutrient Release: A Review. Coatings, 15(6), 665. https://doi.org/10.3390/coatings15060665