The Evolution of Brake Disc Materials for Trains: A Review

Abstract

1. Introduction

2. Iron and Steel Brake Discs

2.1. Cast Iron Brake Discs

2.2. Steel Brake Discs

2.3. Surface Modification of Iron and Steel Brake Discs

3. Aluminum Matrix Composite Brake Discs

3.1. Manufacturing Process of AMC Brake Discs

3.2. Materials Design for AMC Brake Discs

4. Carbon Matrix Composite Brake Discs

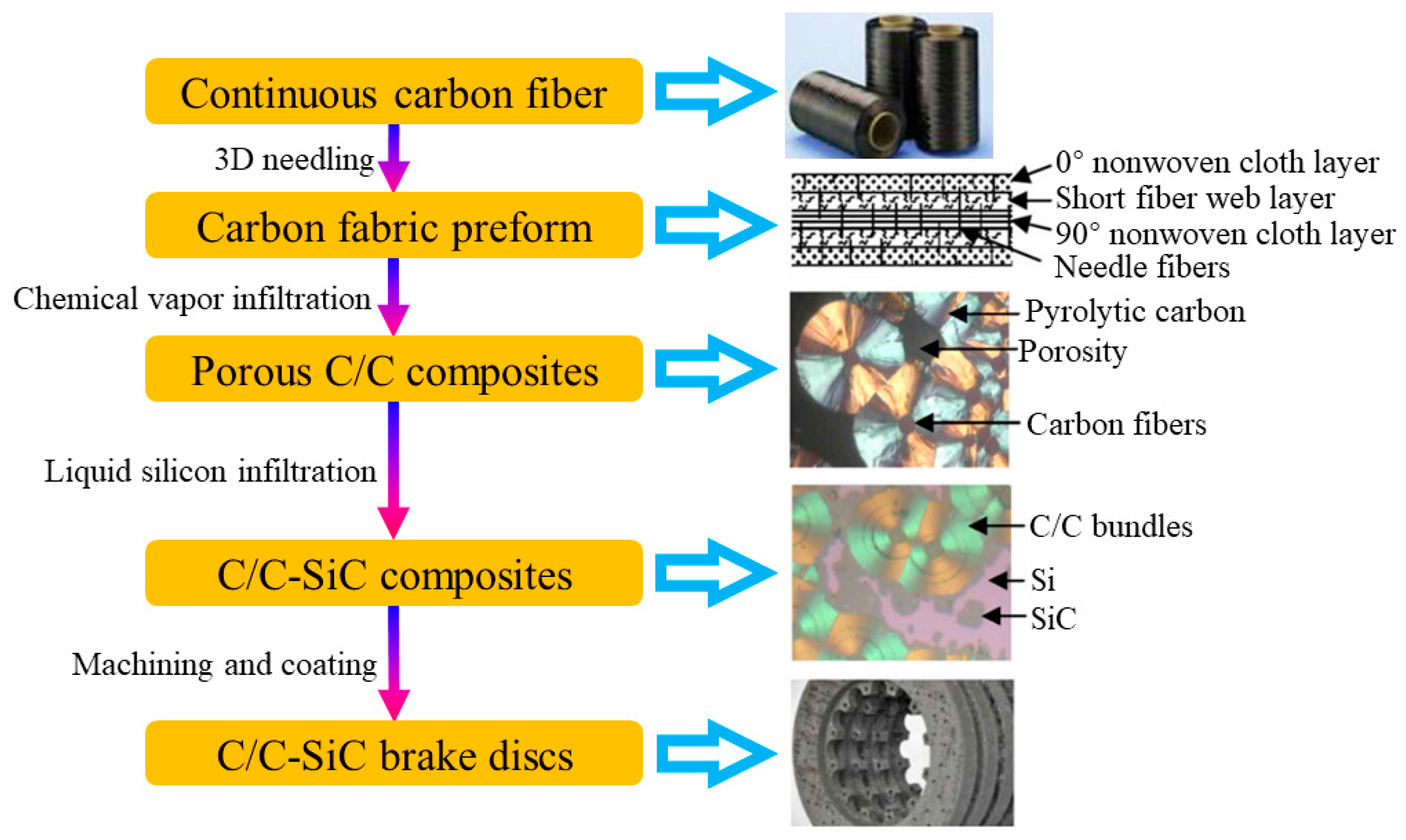

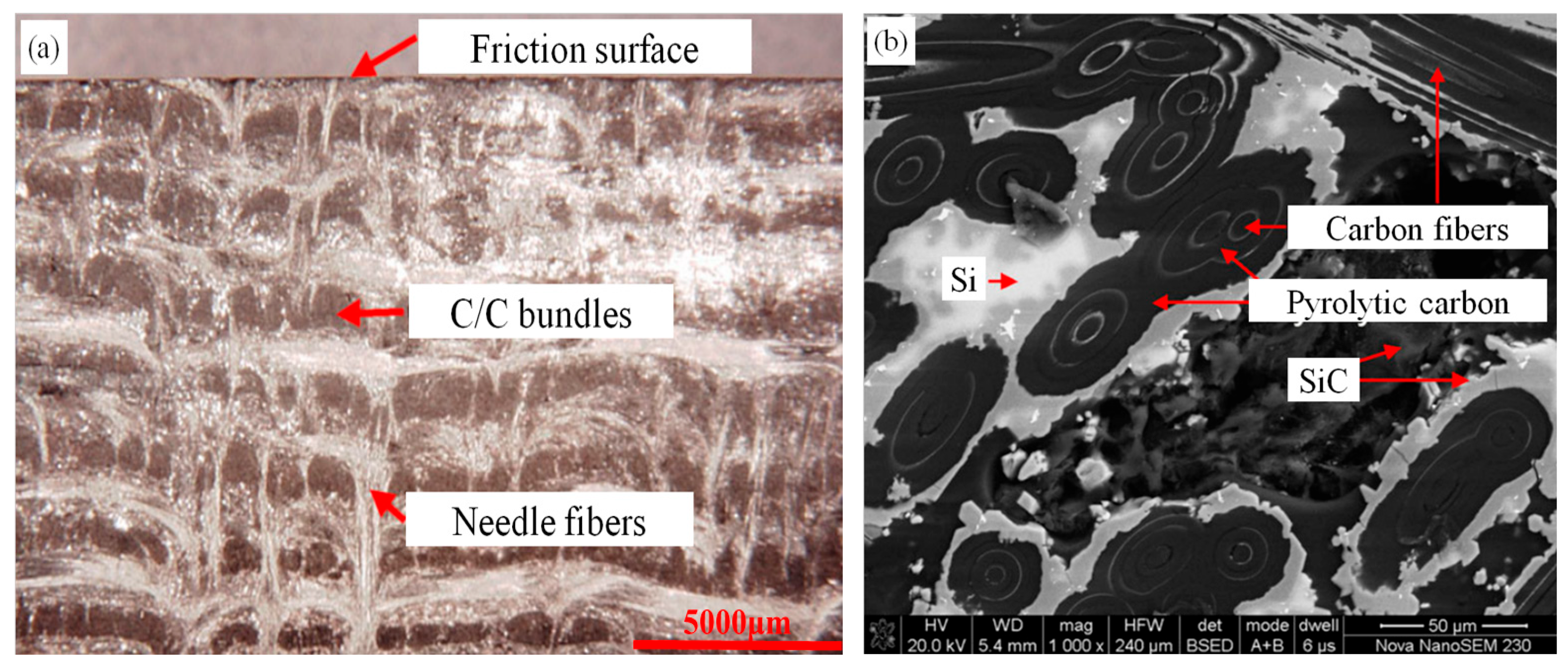

4.1. Manufacturing Process of C/C-SiC Brake Discs

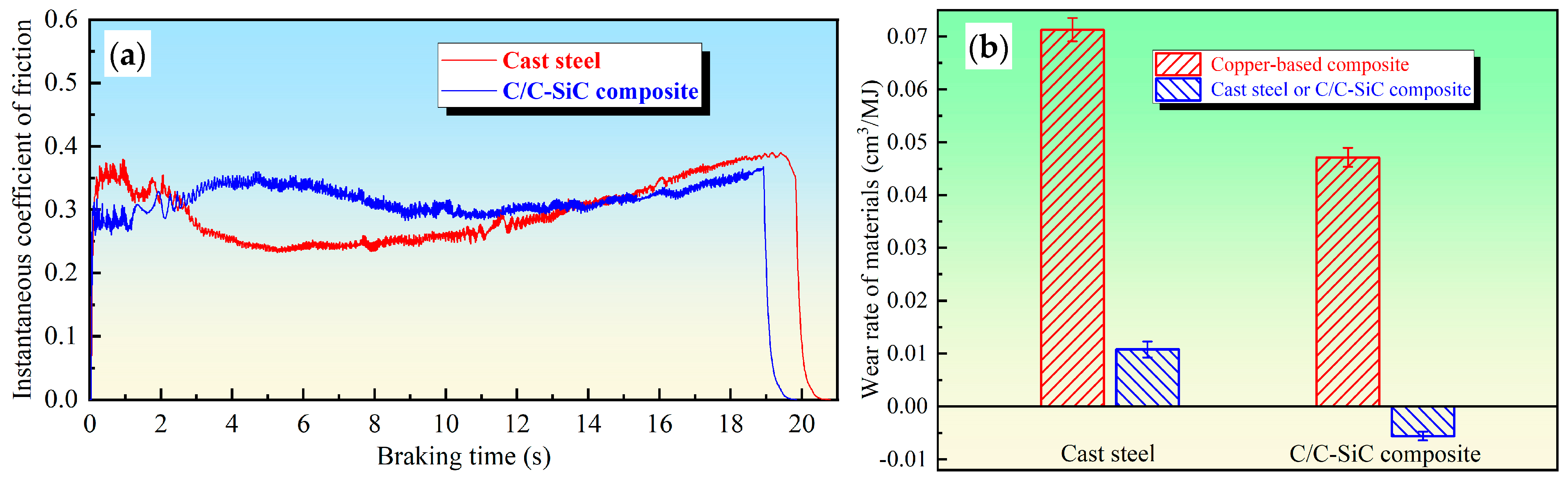

4.2. Materials Design for C/C-SiC Brake Discs

5. Conclusions and Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xiao, Y.; Zhang, Z.; Yao, P.; Fan, K.; Zhou, H.; Gong, T.; Zhao, L.; Deng, M. Mechanical and tribological behaviors of copper metal matrix composites for brake pads used in high-speed trains. Tribol. Int. 2018, 119, 585–592. [Google Scholar] [CrossRef]

- Xiao, Y.; Cheng, Y.; Shen, M.; Yao, P.; Du, J.; Ji, D.; Zhao, P.; Liu, S.; Hua, L. Friction and wear behavior of copper metal matrix composites at temperatures up to 800 °C. J. Mater. Res. Technol. 2022, 19, 2050–2062. [Google Scholar] [CrossRef]

- UIC CODE 541-3; Brakes-Disc Brakes and Their Application-General Conditions for the Certification of Brake Parts. International Union of Railways (UIC): Paris, France, 2017.

- Xiao, Y.; Cheng, Y.; Zhou, H.; Liang, W.; Shen, M.; Yao, P.; Zhao, H.; Xiong, G. Evolution of contact surface characteristics and tribological properties of a copper-based sintered material during high-energy braking. Wear 2022, 488–489, 204163. [Google Scholar] [CrossRef]

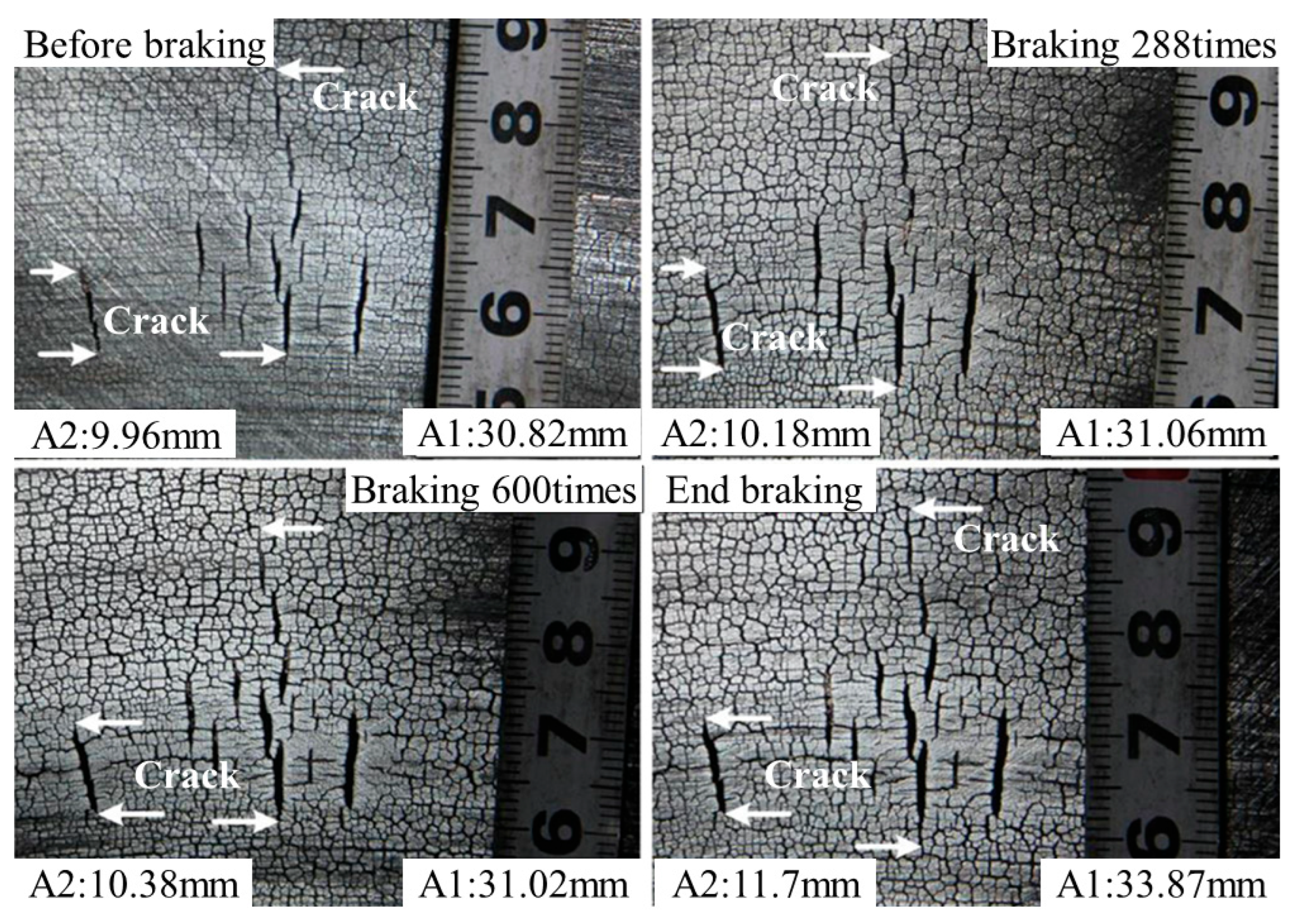

- Lu, C.; Shen, J.; Fu, Q.; Mo, J. Research on radial crack propagation of railway brake disc under emergency braking conditions. Eng. Fail. Anal. 2023, 143, 106877. [Google Scholar] [CrossRef]

- Wang, Z.; Han, J.; Domblesky, J.P.; Li, Z.; Fan, X.; Liu, X. Crack propagation and microstructural transformation on the friction surface of a high-speed railway brake disc. Wear 2019, 428–429, 45–54. [Google Scholar] [CrossRef]

- Wu, S.C.; Zhang, S.Q.; Xu, Z.W. Thermal crack growth-based fatigue life prediction due to braking for a high-speed railway brake disc. Int. J. Fatigue 2016, 87, 359–369. [Google Scholar] [CrossRef]

- Serrano-Munoz, I.; Rapontchombo, J.; Magnier, V.; Brunel, F.; Kossman, S.; Dufr’enoy, P. Evolution in microstructure and compression behaviour of a metallic sintered friction material after braking. Wear 2019, 436–437, 202947. [Google Scholar] [CrossRef]

- Kasem, H.; Brunel, J.F.; Dufr’enoy, P.; Siroux, M.; Desmet, B. Thermal levels and subsurface damage induced by the occurrence of hot spots during high-energy braking. Wear 2011, 270, 355–364. [Google Scholar] [CrossRef]

- Kim, H.S.; Jo, M.; Park, J.Y.; Kim, B.J.; Kim, H.C.; Nam, D.; Kim, B.; Ahn, Y.S. Effects of Ti microalloying on the microstructure and mechanical properties of acicular ferrite casting steel for high-speed railway brake discs. Mater. Sci. Eng. A 2022, 857, 144125. [Google Scholar] [CrossRef]

- Xie, X.; Li, Z.; Domblesky, J.P.; Yang, Z.; Li, W.; Han, J. Study of material recrystallized regions on deformation and cracking behaviours in cast steel brake discs. Eng. Fail. Anal. 2022, 140, 106508. [Google Scholar] [CrossRef]

- Kasem, H.; Dufr’enoy, P.; Desplanques, Y. Relationships between surface thermal gradients and disc distortion during stop-braking with high energy dissipation. Tribol. Lett. 2012, 48, 169–181. [Google Scholar] [CrossRef]

- Yao, S.; Zhou, Y.; Xu, P.; Long, Y.; Yang, C. Progress of material−structure research on brake discs for lightweight high-speed trains. J. Cent. South. Univ. 2024, 55, 2414–2431. (In Chinese) [Google Scholar]

- Polak, A.; Grzybek, J. The mechanism of changes in the surface layer of grey cast iron automotive brake disc. Mater. Res. 2005, 8, 475–479. [Google Scholar] [CrossRef]

- Kaleicheva, J.; Mishev, V.; Karaguiozova, Z.; Nikolcheva, G.; Miteva, A. Effect of nanoadditives on the wear behavior of spheroidal graphite cast irons. Tribol. Ind. 2017, 39, 294–301. [Google Scholar] [CrossRef][Green Version]

- Seo, H.; Lee, D.G.; Park, J.; Song, W.; Lee, J.J.; Sohn, S.S.; Jang, H. Quench hardening effect of gray iron brake discs on particulate matter emission. Wear 2023, 523, 204781. [Google Scholar] [CrossRef]

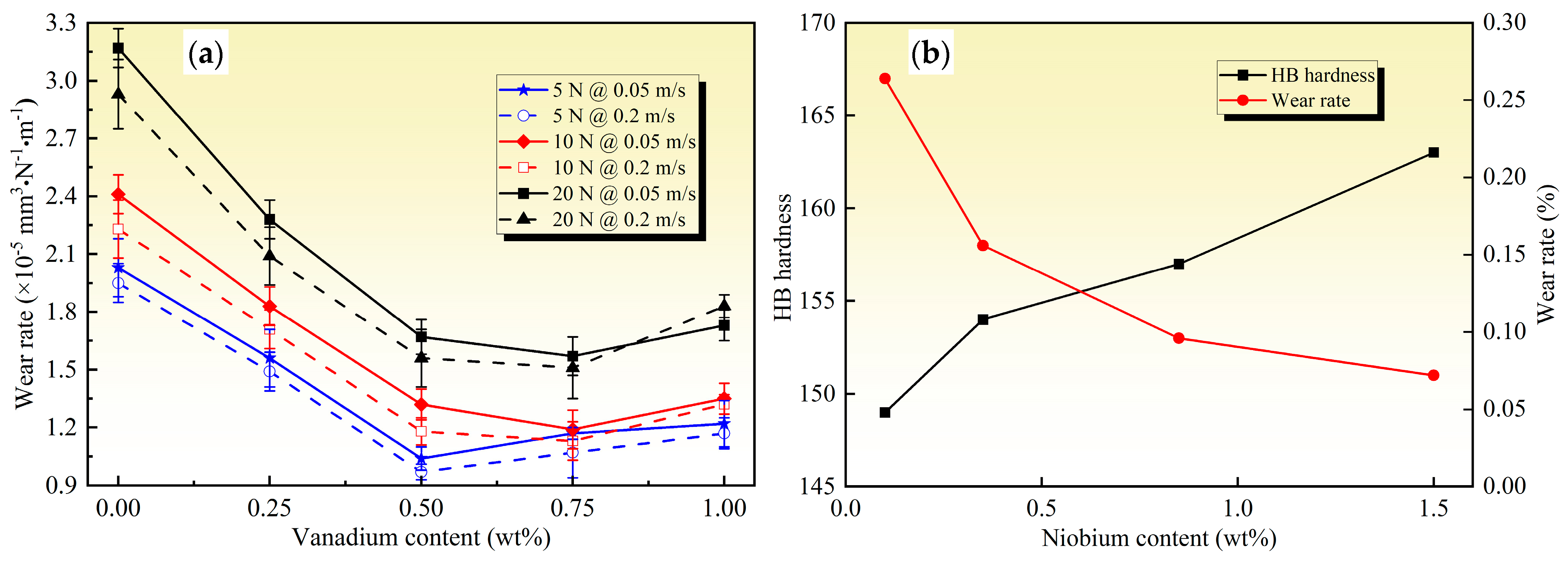

- Wu, L.L.; Xiao, F.R.; Wang, Y.C.; Liang, C.B.; Sun, G.P.; Liao, B. Effect of vanadium on microstructure and wear resistance of Ni-Cr alloyed cast iron. Int. J. Cast Met. Res. 2013, 26, 176–183. [Google Scholar] [CrossRef]

- Turu, I.C.; Gecu, R. Wear and corrosion behavior of vanadium-alloyed nodular cast irons fabricated by sand-casting. Wear 2023, 534–535, 205143. [Google Scholar] [CrossRef]

- Zhou, W.; Zhu, H.; Zheng, D.; Zheng, H.; Hua, Q.; Zhai, Q. Niobium alloying effect in high carbon equivalent grey cast iron. China Foundry 2011, 8, 36–40. [Google Scholar]

- Pimentel, A.S.O.; Guesser, W.L.; da Silva, W.J.R.C.; Portella, P.D.; Woydt, M.; Burbank, J. Abrasive wear behavior of austempered ductile iron with niobium additions. Wear 2019, 440–441, 203065. [Google Scholar] [CrossRef]

- Tonolini, P.; Montesano, L.; Pola, A.; Bontempi, G.; Gelfi, M. Wear behavior of Nb alloyed gray cast iron for automotive brake disc application. Metals 2023, 13, 365. [Google Scholar] [CrossRef]

- Alias, S.K.; Abdullah, B.; Jaffar, A.; Abdullah, A.H.; Jenal, N. Development of high strength ductile iron with niobium addition. Adv. Mater. Res. 2012, 576, 366–369. [Google Scholar] [CrossRef]

- Souza, T.N.F.; Nogueira, R.A.P.S.; Franco, F.J.S.; Aguilar, M.T.P.; Cetlin, P.R. Mechanical and microstructural characterization of nodular cast iron (NCI) with niobium additions. Mater. Res. 2014, 17, 1167–1172. [Google Scholar] [CrossRef]

- Sckudlarek, W.; Krmasha, M.N.; Al-Rubaie, K.S.; Preti, O.; Milan, J.C.G.; da Costa, C.E. Effect of austempering temperature on microstructure and mechanical properties of ductile cast iron modified by niobium. J. Mater. Res. Technol. 2021, 12, 2414–2425. [Google Scholar] [CrossRef]

- Ding, X.; Li, X.; Huang, H.; Matthias, W.; Huang, S.; Feng, Q. Effect of Mo addition on as-cast microstructures and properties of grey cast irons. Mat. Sci. Eng. A 2018, 718, 483–491. [Google Scholar] [CrossRef]

- Goo, B.; Lim, C. Thermal fatigue of cast iron brake disk materials. J. Mech. Sci. Technol. 2012, 26, 1719–1724. [Google Scholar] [CrossRef]

- Hamid, M.K.A.; Kaulan, A.M.; Syahrullail, S.; Bakar, A.R.A. Frictional characteristics under corroded brake discs. Procedia Eng. 2013, 68, 668–673. [Google Scholar] [CrossRef][Green Version]

- Gutiérrez Pérez, V.H.; Cruz Ramírez, A.; Olvera Vázquez, S.L.; Colin García, E.; Sánchez Alvarado, R.G.; Delgado Pamanes, M.F.; Rivera Salinas, J.E. Study of the effects of vanadium and molybdenum on the microstructure of ductile iron (DI) and austempered ductile iron (ADI) and their corrosion resistance. Acta Univ. 2022, 32, e3196. [Google Scholar] [CrossRef]

- Li, J.S.; Li, H.P.; Jiao, B.Q.; Lv, B.J.; Chen, D.F.; Gu, L.L. Development of cast steel for brake disc of high-speed train. Appl. Mech. Mater. 2013, 419, 370–375. [Google Scholar] [CrossRef]

- Ghadimi, B.; Sajedi, R.; Kowsary, F. 3D investigation of thermal stresses in a locomotive ventilated brake disc based on a conjugate thermo-fluid coupling boundary conditions. Int. Commun. Heat Mass. 2013, 49, 104–109. [Google Scholar] [CrossRef]

- Suo, R.; Shi, X. Temperature field and stress field distribution of forged steel brake disc for high speed train. Jordan J. Mech. Ind. En. 2022, 16, 113–121. [Google Scholar]

- He, Q.; Shi, X. Characteristics of microscopic crack and propagation life of forged steel brake disc for high-speed train. Mater. Express 2021, 11, 434–443. [Google Scholar]

- Liu, X.; Gao, P.; Cong, T.; Wng, S.; Wang, X.; Wang, W. Effects of thermal cracks on friction and wear properties of forged steel used in railway brake discs. Wear 2023, 520–521, 204650. [Google Scholar] [CrossRef]

- Harada, N.; Takuma, M.; Tsujikawa, M.; Higashi, K. Effects of V addition on improvement of heat shock resistance and wear resistance of Ni–Cr–Mo cast steel brake disc. Wear 2013, 302, 1444–1452. [Google Scholar] [CrossRef]

- Wu, D.; Wang, F.; Cheng, J.; Li, C. Effect of Nb and V on the continuous cooling transformation of undercooled austenite in Cr–Mo–V steel for brake discs. Int. J. Min. Met. Mater. 2018, 25, 892–901. [Google Scholar] [CrossRef]

- Wang, J.; Chen, Y.; Zuo, L.; Zhao, H.; Ma, N. Evaluation of thermal fatigue life and crack morphology in brake discs of low-alloy steel for high-speed trains. Materials 2022, 15, 6837. [Google Scholar] [CrossRef]

- Podgornik, B.; Vizintin, J.; Thorbjornsson, I.; Johannesson, B.; Thorgrimsson, J.T.; Martinez Celis, M.; Valle, N. Improvement of ductile iron wear resistance through local surface reinforcement. Wear 2012, 274–275, 267–273. [Google Scholar] [CrossRef]

- Quazi, M.M.; Fazal, M.A.; Haseeb, A.S.M.A.; Yusof, F.; Masjuki, H.H.; Arslan, A. A review to the laser cladding of self-lubricating composite coatings. Lasers Manuf. Mater. Process. 2016, 3, 67–99. [Google Scholar] [CrossRef]

- Qunshuang, M.; Yajiang, L.; Juan, W. Surface modification of Q550 HSLA steel with Co–Fe–Cr composite coatings manufactured by fibre laser cladding. Surf. Eng. 2016, 32, 934–942. [Google Scholar] [CrossRef]

- Xu, J.; Zhou, J.; Tan, W.; Huang, S.; Wang, S.; He, W. Ultrasonic vibration on wear property of laser cladding Fe-based coating. Surf. Eng. 2018, 36, 1261–1269. [Google Scholar] [CrossRef]

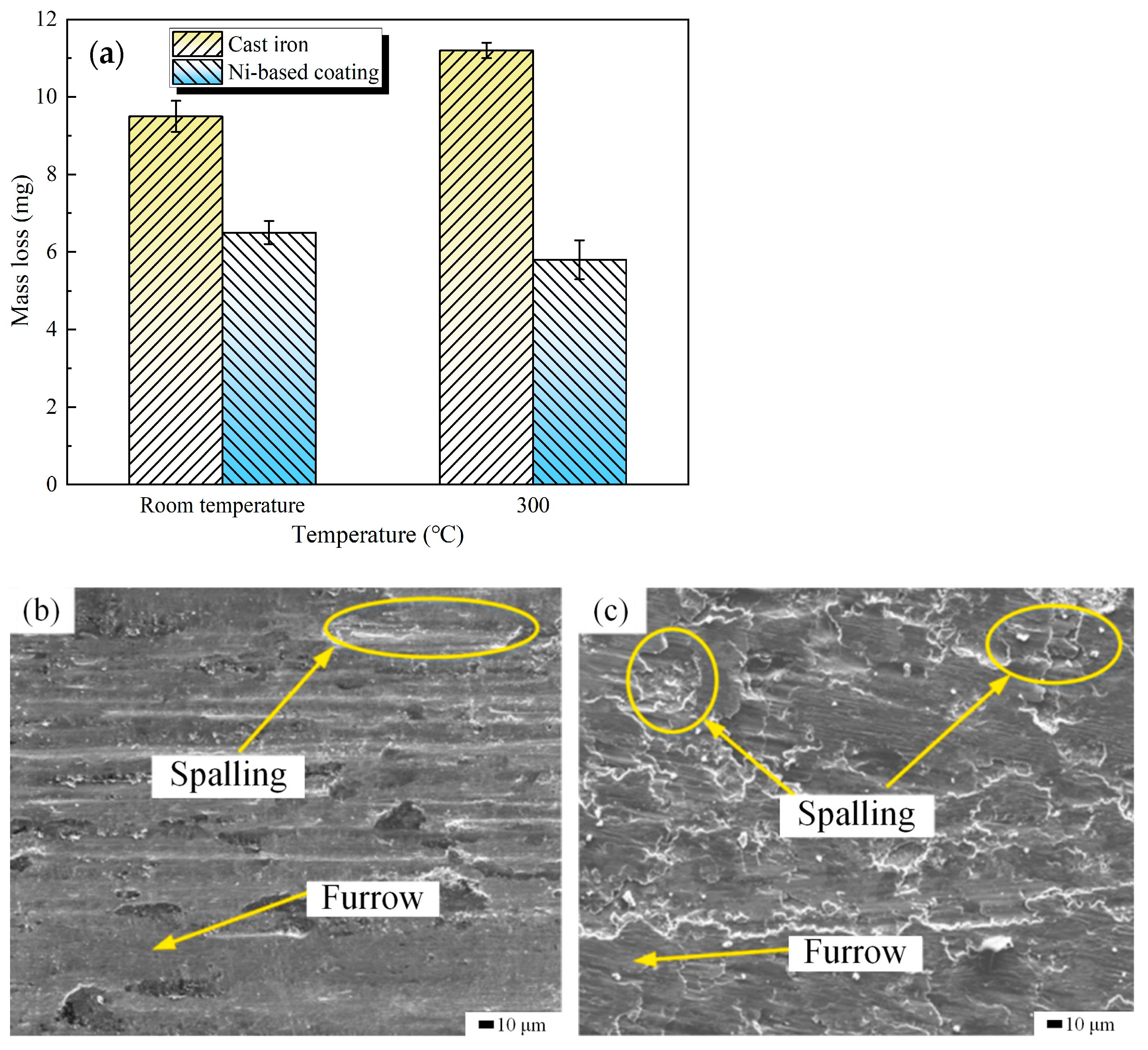

- Manoj, A.; Saurabh, A.; Narala, S.K.R.; Saravanan, P.; Natu, H.P.; Verma, P.C. Surface modification of grey cast iron by laser cladding for automotive brake disc application. Wear 2023, 532–533, 205009. [Google Scholar] [CrossRef]

- Pant, P.; Chatterjee, D.; Nandi, T.; Samanta, S.K.; Lohar, A.K.; Changdar, A. Statistical modelling and optimization of clad characteristics in laser metal deposition of austenitic stainless steel. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 283. [Google Scholar] [CrossRef]

- Devojno, O.G.; Feldshtein, E.; Kardapolava, M.A.; Lutsko, N.I. On the formation features, structure, microhardness and tribological behavior of single tracks and coating layers formed by laser cladding of Al-Fe powder bronze. Surf. Coat. Technol. 2019, 358, 195–206. [Google Scholar] [CrossRef]

- Moeinfar, K.; Khodabakhshi, F.; Kashani-Bozorg, S.; Mohammadi, M.; Gerlich, A. A review on metallurgical aspects of laser additive manufacturing (LAM): Stainless steels, nickel superalloys, and titanium alloys. J. Mater. Res. Technol. 2022, 16, 1029–1068. [Google Scholar] [CrossRef]

- Janicki, D. Laser cladding of Inconel 625-based composite coatings reinforced by porous chromium carbide particles. Opt. Laser Technol. 2017, 94, 6–14. [Google Scholar] [CrossRef]

- Fu, F.; Zhang, Y.; Chang, G.; Dai, J. Analysis on the physical mechanism of laser cladding crack and its influence factors. Optik 2016, 127, 200–202. [Google Scholar] [CrossRef]

- Balu, P.; Leggett, P.; Hamid, S.; Kovacevic, R. Multi-response optimization of laser-based powder deposition of multi-track single layer hastelloy C-276. Mater. Manuf. Process. 2013, 28, 173–182. [Google Scholar] [CrossRef]

- Muvvala, G.; Karmakar, D.P.; Nath, A.K. Online monitoring of thermo-cycles and its correlation with microstructure in laser cladding of nickel based super alloy. Opt. Lasers Eng. 2017, 88, 139–152. [Google Scholar] [CrossRef]

- Urbanic, R.J.; Saqib, S.M.; Aggarwal, K. Using predictive modeling and classification methods for single and overlapping bead laser cladding to understand bead geometry to process parameter relationships. J. Manuf. Sci. Eng. 2016, 138, 051012. [Google Scholar] [CrossRef]

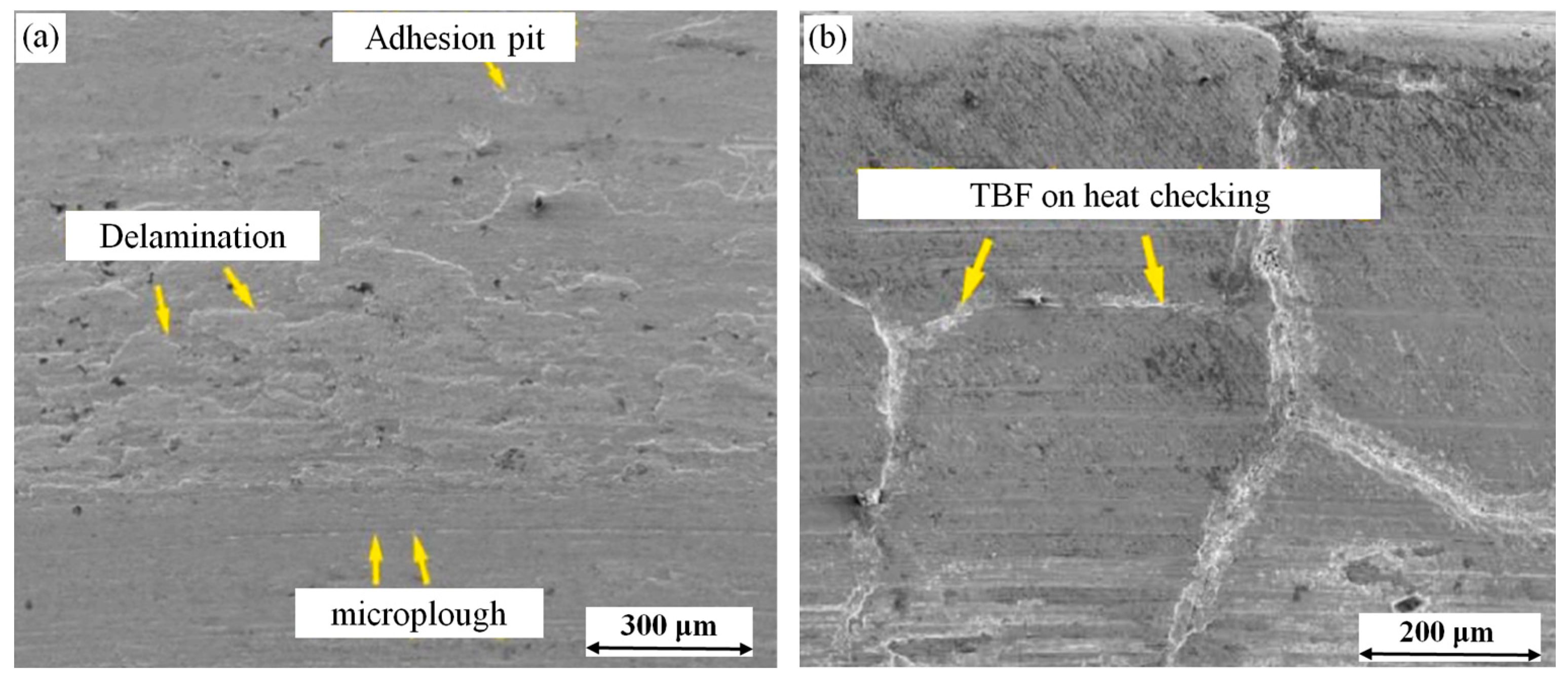

- Shi, X.; Wen, D.; Wang, S.; Wang, G.; Zhang, M.; Li, J.; Xue, C. Investigation on friction and wear performance of laser cladding Ni-based alloy coating on brake disc. Optik 2021, 242, 167227. [Google Scholar] [CrossRef]

- Tonolini, P.; Montesano, L.; Pola, A.; Landriani, E.; Gelfi, M. The effect of laser-cladding on the wear behavior of gray cast iron brake disc. Procedia Struct. Integr. 2021, 33, 1152–1161. [Google Scholar] [CrossRef]

- Lin, P.; Zhang, Z.; Kong, S.; Zhou, H.; Tong, X.; Ren, L. Mechanical properties of composite coating on cast iron by laser. Surf. Eng. 2018, 34, 289–295. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, Y.; Wu, Y.; Zhang, Z.; Liu, J.; Xie, S.; Deng, L.; Ge, C.; Chen, C.; Chen, H. Steel-based brake disc laser cladding coating preparation method and brake performance study. Eng. Fail. Anal. 2025, 167, 108962. [Google Scholar] [CrossRef]

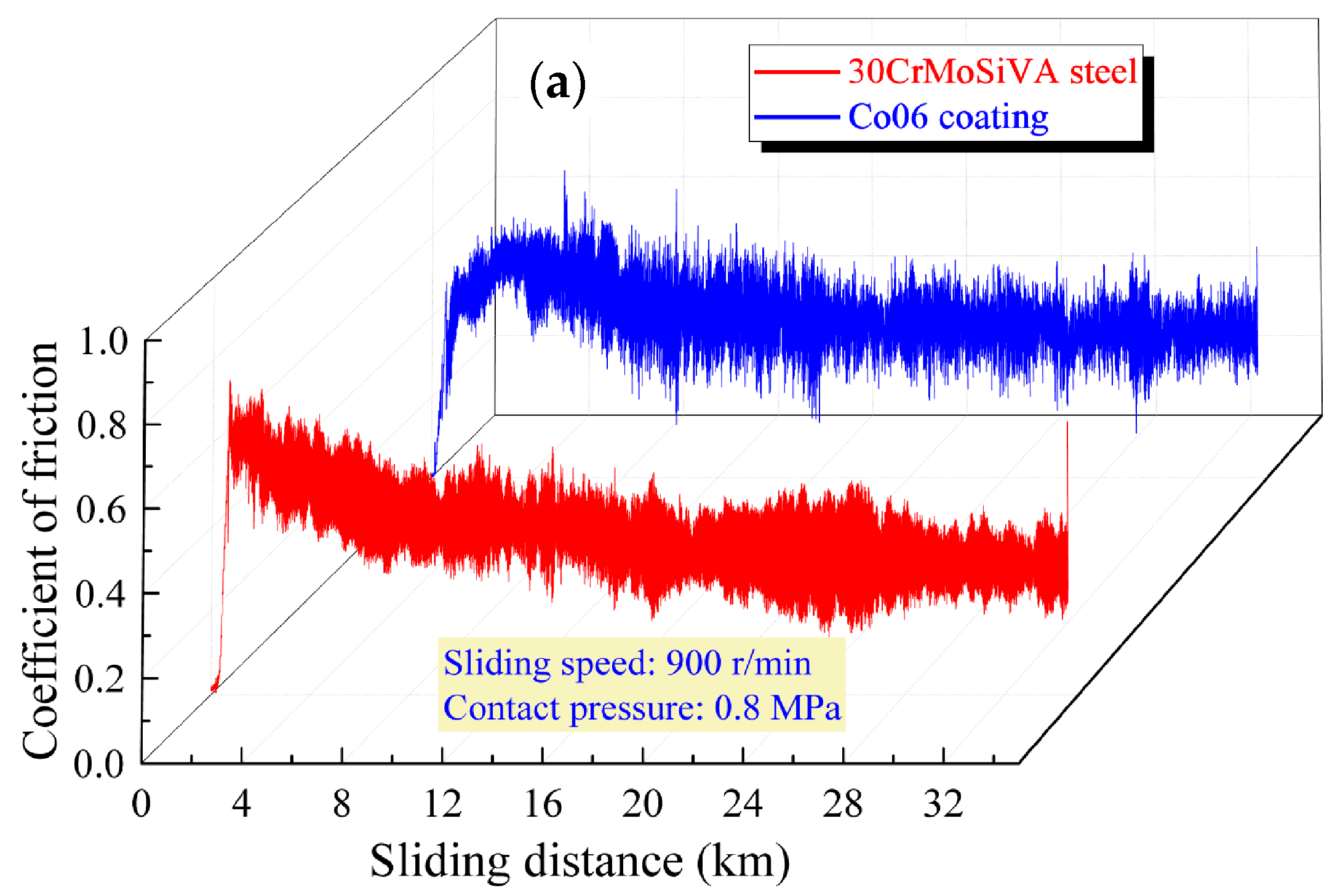

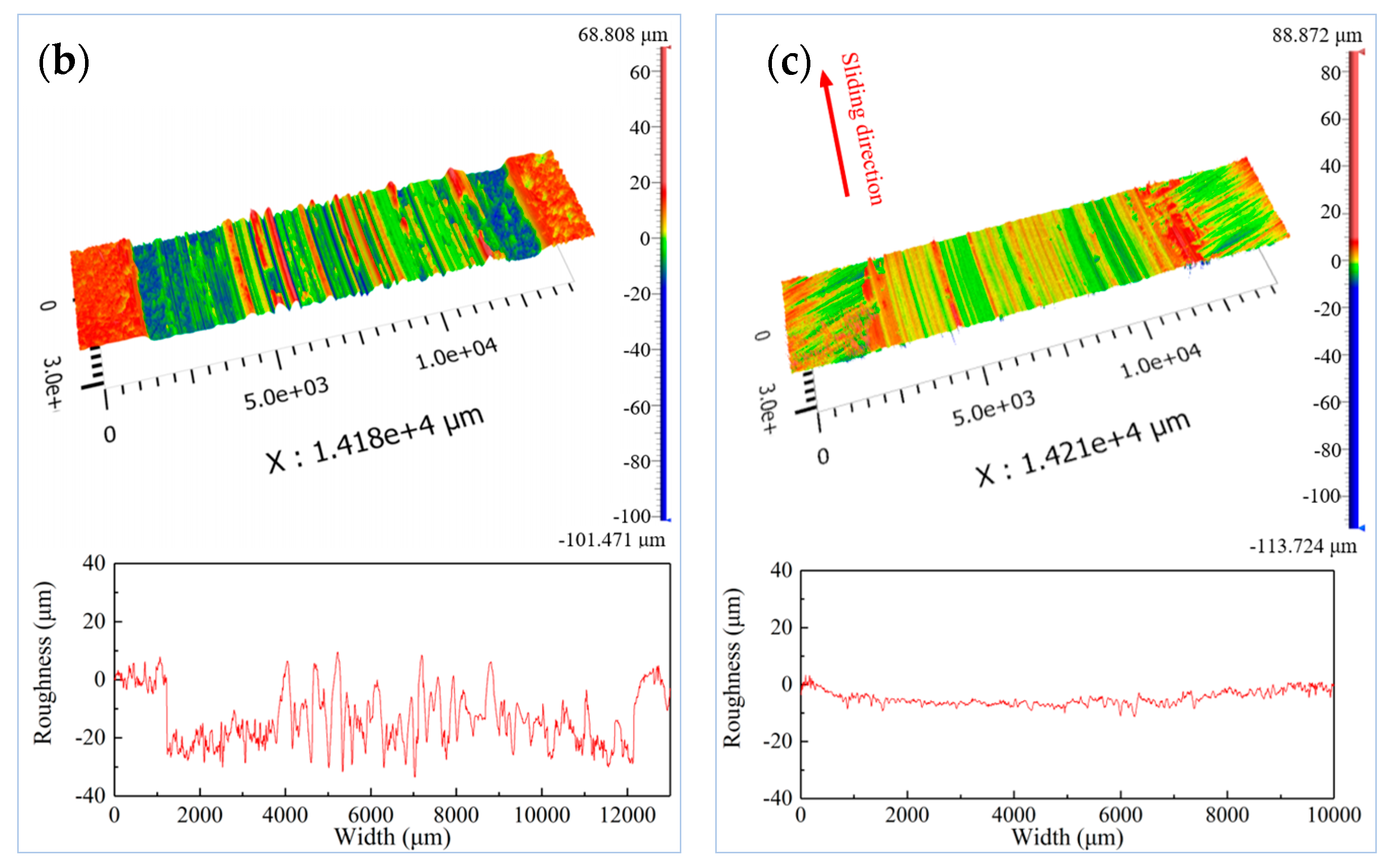

- Liu, Y.; Wu, Y.; Ma, Y.; Gao, W.; Yang, G.; Fu, H.; Xi, N.; Chen, H. High temperature wear performance of laser cladding Co06 coating on high-speed train brake disc. Appl. Surf. Sci. 2019, 481, 761–766. [Google Scholar] [CrossRef]

- Xiao, Y.; Shen, L.; Zhao, H.; Cheng, Y.; Du, J.; Shen, M. Tribological properties of copper-matrix composites against laser-cladded Co06 coating on 30CrMoSiVA steel at elevated temperatures. Tribol. Int. 2024, 192, 109333. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, D.; He, L.; Ye, X.; Ouyang, W.; Xu, Z.; Zhang, W.; Zhou, X. Microstructure and elevated temperature wear behavior of laser-cladded AlCrFeMnNi high-entropy alloy coating. Opt. Laser Technol. 2022, 149, 107845. [Google Scholar] [CrossRef]

- Rajaei, H.; Menapace, C.; Straffelini, G.; Gialanella, S. Characterization, wear and emission properties of MnS containing laser cladded brake disc. Wear 2022, 504–505, 204405. [Google Scholar] [CrossRef]

- Vasiljević, S.; Glišović, J.; Stojanović, B.; Vencl, A. Review of the coatings used for brake discs regarding their wear resistance and environmental effect. Proc. Inst. Mech. Eng. J-J. Eng. 2022, 236, 1932–1949. [Google Scholar] [CrossRef]

- Shi, C.; Chen, S.; Xia, Q.; Li, Z. Preparation and printability of 24CrNiMo alloy steel powder for selective laser melting fabricating brake disc. Powder Metall. 2018, 61, 73–80. [Google Scholar] [CrossRef]

- Kumar, P.K.D.; Gnanaraj, S.D. Aluminium-silicon based metal matrix composites for brake rotor applications: A review. Eng. Res. Express 2023, 5, 022002. [Google Scholar] [CrossRef]

- Christy, J.V.; Mourad, A.H.I.; Sherif, M.M.; Shivamurthy, B. Review of recent trends in friction stir welding process of aluminum alloys and aluminum metal matrix composites. Trans. Nonferrous Met. Soc. China 2021, 31, 3281–3309. [Google Scholar] [CrossRef]

- Devaganesh, S.; Kumar, P.K.D.; Venkatesh, N.; Balaji, R. Study on the mechanical and tribological performances of hybrid SiC-Al7075 metal matrix composites. J. Mater. Res. Technol. 2020, 9, 3759–3766. [Google Scholar] [CrossRef]

- Shabani, M.O.; Tofigh, A.A.; Heydari, F.; Mazahery, A. Superior tribological properties of particulate aluminum matrix nano composites. Prot. Met. Phys. Chem. Sur. 2016, 52, 244–248. [Google Scholar] [CrossRef]

- Soltani, S.; Azari Khosroshahi, R.; Taherzadeh Mousavian, R.; Jiang, Z.Y.; Fadavi Boostani, A.; Brabazon, D. Stir casting process for manufacture of Al–SiC composites. Rare Met. 2017, 36, 581–590. [Google Scholar] [CrossRef]

- Laden, K.; Guérin, J.D.; Watremez, M.; Bricout, J.P. Frictional characteristics of Al-SiC composite brake discs. Tribolo. Lett. 2000, 8, 237–247. [Google Scholar] [CrossRef]

- Adebisi, A.A.; Maleque, M.A.; Rahman, M.M. Metal matrix composite brake rotor: Historical development and product life cycle analysis. Int. J. Automot. Mech. Eng. 2011, 4, 471–480. [Google Scholar] [CrossRef]

- Madhukar, P.; Selvaraj, N.; Rao, C.S.P.; Kumar, G.B.V. Tribological behavior of ultrasonic assisted double stir casted novel nano-composite material (AA7150-hBN) using Taguchi technique. Compos. Part B-Eng. 2019, 175, 107136. [Google Scholar] [CrossRef]

- Chebolu, R.; Nallu, R.; Chanamala, R. Experimental investigation on mechanical behavior of as cast Zn-Al-Cu/SiC/TiB2 hybrid metal matrix composite by ultrasonic assisted stir casting technique. Eng. Res. Express 2022, 4, 025040. [Google Scholar] [CrossRef]

- Harichandran, R.; Selvakumar, N. Effect of nano/micro B4C particles on the mechanical properties of aluminium metal matrix composites fabricated by ultrasonic cavitation-assisted solidification process. Archiv. Civ. Mech. Eng. 2016, 16, 147–158. [Google Scholar] [CrossRef]

- Rao, T.B. Microstructural, mechanical, and wear properties characterization and strengthening mechanisms of Al7075/SiCnp composites processed through ultrasonic cavitation assisted stir-casting. Mat. Sci. Eng. A 2021, 805, 140553. [Google Scholar] [CrossRef]

- Mahanta, S.; Chandrasekaran, M.; Samanta, S.; Sasikumar, C. Fabrication of Al7075-B4C-fly ash hybrid nanocomposites by ultrasonic assisted stir casting and tensile analysis. AIP Conf. Proc. 2019, 2128, 020026. [Google Scholar]

- Singh, J.; Chauhan, A. Overview of wear performance of aluminium matrix composites reinforced with ceramic materials under the influence of controllable variables. Ceram. Int. 2016, 42, 56–81. [Google Scholar] [CrossRef]

- Muratoğlu, M.; Aksoy, M. Abrasive wear of 2124Al–SiC composites in the temperature range 20–200 °C. J. Mater. Process. Technol. 2006, 174, 272–276. [Google Scholar] [CrossRef]

- Ahamad, N.; Mohammad, A.; Sadasivuni, K.K.; Gupta, P. Structural and mechanical characterization of stir cast Al–Al2O3–TiO2 hybrid metal matrix composites. J. Compos. Mater. 2020, 54, 2985–2997. [Google Scholar] [CrossRef]

- Ahamad, N.; Mohammad, A.; Sadasivuni, K.K.; Gupta, P. Phase, microstructure and tensile strength of Al–Al2O3–C hybrid metal matrix composites. Proc. Inst. Mech. Eng. C-J. Mec. 2020, 234, 2681–2693. [Google Scholar] [CrossRef]

- Ahamad, N.; Mohammad, A.; Rinawa, M.L.; Sadasivuni, K.K.; Gupta, P. Correlation of structural and mechanical properties for Al-Al2O3-SiC hybrid metal matrix composites. J. Compos. Mater. 2021, 55, 3267–3280. [Google Scholar] [CrossRef]

- Ahamad, N.; Mohammad, A.; Sadasivuni, K.K.; Gupta, P. Wear, optimization and surface analysis of Al-Al2O3-TiO2 hybrid metal matrix composites. Proc. Inst. Mech. Eng. J-J. Eng. 2021, 235, 93–102. [Google Scholar] [CrossRef]

- Mann, V.S.; Pandey, O.P. Effect of dual particle size corundum particles on the tribological properties of LM30 aluminium alloy composites for brake rotor applications. Arab. J. Sci. Eng. 2021, 46, 12445–12463. [Google Scholar] [CrossRef]

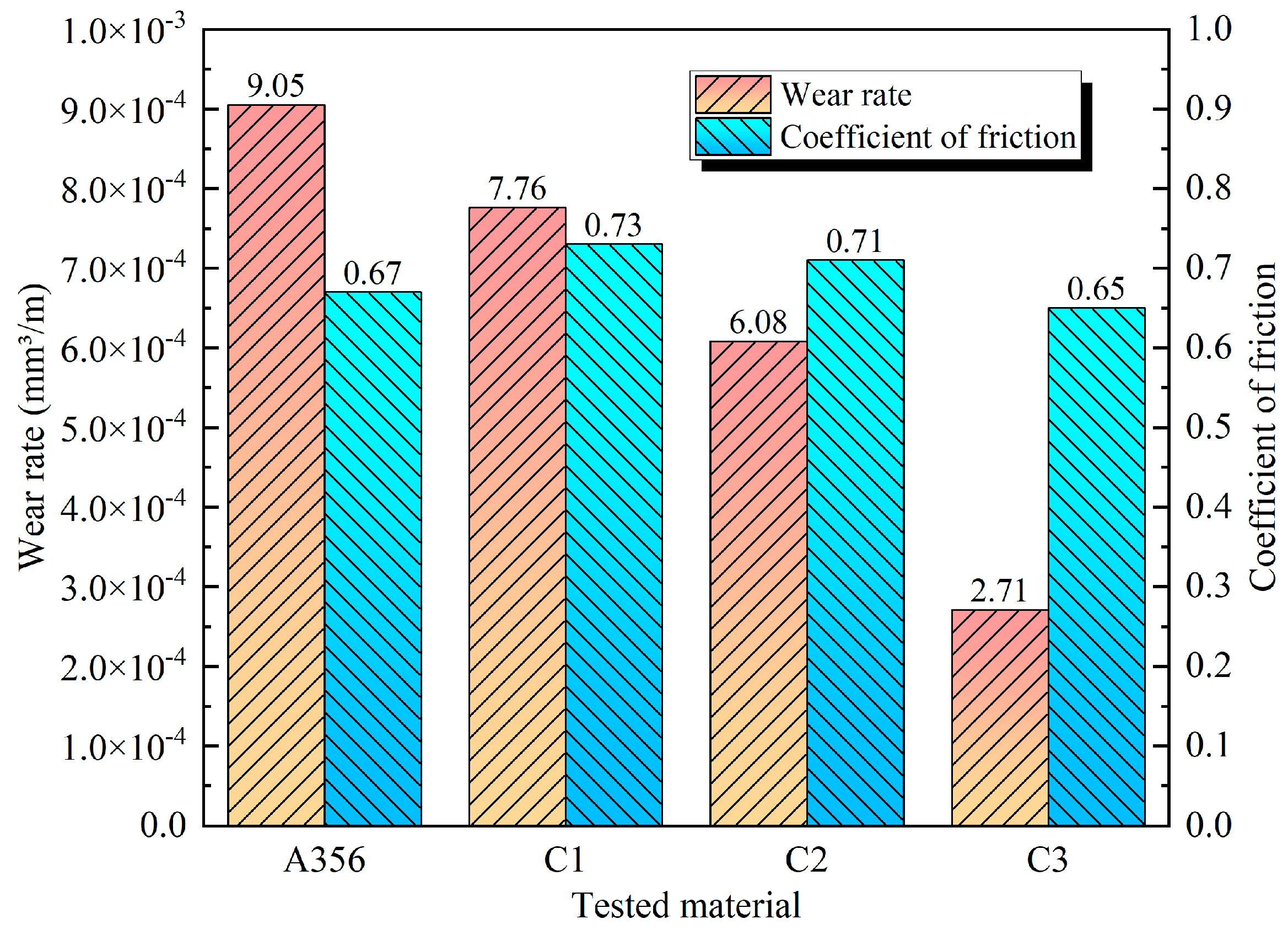

- Vencl, A.; Bobic, I.; Arostegui, S.; Bobic, B.; Marinković, A.; Babić, M. Structural, mechanical and tribological properties of A356 aluminium alloy reinforced with Al2O3, SiC and SiC+graphite particles. J. Alloy. Compd. 2010, 506, 631–639. [Google Scholar] [CrossRef]

- Tan, D.; Xia, S.; Yob, A.; Yang, K.; Yan, S.; Givord, M.; Liang, D. Evaluation of the wear resistance of aluminium-based hybrid composite brake discs under relevant city rail environments. Mater. Des. 2022, 215, 110504. [Google Scholar] [CrossRef]

- Ferraris, M.; Gili, F.; Lizarralde, X.; Igartua, A.; Mendoza, G.; Blugan, G.; Gorjan, L.; Casalegno, V. SiC particle reinforced Al matrix composites brazed on aluminum body for lightweight wear resistant brakes. Ceram. Int. 2022, 48, 10941–10951. [Google Scholar] [CrossRef]

- Ahmad, F.; Lo, S.H.J.; Aslam, M.; Haziq, A. Tribology behaviour of alumina particles reinforced aluminium matrix composites and brake disc materials. Procedia. Eng. 2013, 68, 674–680. [Google Scholar] [CrossRef]

- Lattanzi, L.; Awe, S.A. Thermophysical properties of Al-based metal matrix composites suitable for automotive brake discs. JALMES 2024, 5, 100059. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, F.; Qiu, X.; An, D.; He, Z.; Zhang, Q.; Xie, Z. Effects of La and Ce on microstructure and properties of SiC/Al composites. Ceram. Int. 2020, 46, 1232–1235. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Y.; Wang, J.; Hu, D.; Li, J. Microstructure and wear resistance of direct laser-deposited TiC-enhanced aluminum-based composite coating for brake discs. Surf. Coat. Technol. 2023, 455, 129193. [Google Scholar] [CrossRef]

- Shrestha, S.; Francis, R.; Smith, A. Alloy selection for wear-resistant lightweight aluminium brake disc. Surf. Eng. 2024, 40, 142–156. [Google Scholar] [CrossRef]

- Jiang, L.; Jiang, Y.; Yu, L.; Yang, H.; Li, Z.; Ding, Y. Thermo-mechanical coupling analyses for Al alloy brake discs with Al2O3-SiC(3D)/Al alloy composite wear-resisting surface layer for high-speed trains. Materials 2019, 12, 3155. [Google Scholar] [CrossRef]

- Li, S.; Xiong, D.; Liu, M.; Bai, S.; Zhao, X. Thermophysical properties of SiC/Al composites with three dimensional interpenetrating network structure. Ceram. Int. 2014, 40, 7539–7544. [Google Scholar] [CrossRef]

- Shinde, D.; Öktem, H.; Uygur, I. A nature-inspired optimal design for a ventilated brake disc. Proc. Inst. Mech. Eng. E-J. Pro. 2024, 238, 2587–2598. [Google Scholar] [CrossRef]

- Chen, G.; Li, Z.; Xiao, P.; OuYang, X.; Ma, W.; Li, P.; Li, J.; Li, Y. Tribological properties and thermal-stress analysis of C/C-SiC composites during braking. Trans. Nonferrous Met. Soc. China 2019, 29, 123–131. [Google Scholar] [CrossRef]

- Diao, Q.; Zou, H.; Ren, X.; Wang, C.; Wang, Y.; Li, H.; Sui, T.; Lin, B.; Yan, S. A focused review on the tribological behavior of C/SiC composites: Present status and future prospects. J. Eur. Ceram. Soc. 2023, 43, 3875–3904. [Google Scholar] [CrossRef]

- Li, Z.; Xiao, P.; Zhang, B.; Li, Y.; Lu, Y.; Zhu, S. Preparation and dynamometer tests of 3D needle-punched C/C-SiC composites for high-speed and heavy-duty brake systems. Int. J. Appl. Ceram. Tec. 2016, 13, 423–433. [Google Scholar] [CrossRef]

- Li, Z.; Xiao, P.; Xiong, X.; Huang, B. Preparation and tribological properties of C fibre reinforced C/SiC dual matrix composites fabrication by liquid silicon infiltration. Solid. State. Sci. 2013, 16, 6–12. [Google Scholar] [CrossRef]

- Li, Z.; Xiao, P.; Xiong, X.; Zhu, S.H. Tribological characteristics of C/C-SiC braking composites under dry and wet conditions. Trans. Nonferrous Met. Soc. China 2008, 18, 1071–1075. [Google Scholar] [CrossRef]

- Xiao, P.; Li, Z.; Zhu, Z.; Xiong, X. Preparation, properties and application of C/C-SiC composites fabricated by warm compacted-in situ reaction. J. Mater. Sci. Technol. 2010, 26, 283–288. [Google Scholar] [CrossRef]

- Mor, M.; Meiser, M.; Langhof, N.; Vinci, A.; Failla, S.; Alber-Laukant, B.; Tremmel, S.; Schafföner, S.; Sciti, D. Tribological behavior of carbon fiber reinforced ZrB2 based ultra high temperature ceramics. J. Eur. Ceram. Soc. 2023, 43, 5413–5424. [Google Scholar] [CrossRef]

- Goo, B.C. Development and characterization of C/C-SiC brake disc. Mater. Manuf. Process. 2016, 31, 979–988. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, J.; Liu, J.; Fan, S.; Cheng, L. Fabrication of oxidation protective coatings on C/C–SiC brake materials at room temperature. Surf. Coat. Technol. 2012, 207, 467–471. [Google Scholar] [CrossRef]

- Arai, Y.; Inoue, R.; Goto, K.; Kogo, Y. Carbon fiber reinforced ultra-high temperature ceramic matrix composites: A review. Ceram. Int. 2019, 45, 14481–14489. [Google Scholar] [CrossRef]

- Li, W.; Yang, X.; Wang, S.; Xiao, J.; Hou, Q. Research and prospect of ceramics for automotive disc-brakes. Ceram. Int. 2020, 47, 10442–10463. [Google Scholar] [CrossRef]

- Langhof, N.; Rabenstein, M.; Rosenlöcher, J.; Hackenschmidt, R.; Krenkel, W.; Rieg, F. Full-ceramic brake systems for high performance friction applications. J. Eur. Ceram. Soc. 2016, 36, 3823–3832. [Google Scholar] [CrossRef]

- Ma, X.; Fan, S.; Sun, H.; Luan, C.; Deng, J.; Zhang, L.; Cheng, L. Investigation on braking performance and wear mechanism of full-carbon/ceramic braking pairs. Tribol. Int. 2020, 142, 105981. [Google Scholar] [CrossRef]

- Ma, X.; Sun, H.; Kou, S.; Fan, S.; Deng, J.; Zhang, L.; Cheng, L. Flexural strength and wear resistance of C/C–SiC brake materials improved by introducing SiC ceramics into carbon fiber bundles. Ceram. Int. 2021, 47, 24130–24138. [Google Scholar] [CrossRef]

- Ma, X.; Fan, S.; Luan, C.; Li, W.; Deng, J.; Cheng, L.; Zhang, L. Effect of Cu addition on the braking performance of Fe–Si alloy-modified C/C–SiC brake materials. Wear 2021, 477, 203851. [Google Scholar] [CrossRef]

- Flauder, S.; Langhof, N.; Krenkel, W.; Schafföner, S. Frictional performance of C/C–SiC materials at high loads: The role of composition and third-body. Open Ceram. 2023, 14, 100364. [Google Scholar] [CrossRef]

- Bian, G.; Wu, H. Friction surface structure of a Cf/C–SiC composite brake disc after bedding testing on a full-scale dynamometer. Tribol. Int. 2016, 99, 85–95. [Google Scholar] [CrossRef][Green Version]

- Li, Z.; Xiao, P.; Xiong, X. Tribological characteristics of different components on C/C-SiC composites fabricated by warm compacted in situ reaction. Appl. Mech. Mater. 2012, 268–270, 59–62. [Google Scholar] [CrossRef]

- Qu, J.; Wang, W.; Shangguan, Y.; Wang, X.; Jiao, B. Thermomechanical modelling and strength assessment of C/C-SiC composite brake disc. Appl. Compos. Mater. 2023, 30, 1547–1568. [Google Scholar] [CrossRef]

- Zhao, S.; Yan, Q.; Peng, T.; Zhang, X.; Wen, Y. The braking behaviors of Cu-based powder metallurgy brake pads mated with C/C–SiC disk for high-speed train. Wear 2020, 448–449, 203237. [Google Scholar] [CrossRef]

- Hui, Y.; Liu, G.; Zhang, Q.; Zhang, Y.; Zang, Y.; Wang, S.; Shi, R. Fading behavior and wear mechanisms of C/C–SiC brake disc during cyclic braking. Wear 2023, 526–527, 204930. [Google Scholar] [CrossRef]

- Chen, F.; Li, Z.; Luo, Y.; Li, D.; Ma, W.; Zhang, C.; Tang, H.; Li, F.; Xiao, P. Braking behaviors of Cu-based PM brake pads mating with C/C–SiC and 30CrMnSi steel discs under high-energy braking. Wear 2021, 486–487, 204019. [Google Scholar] [CrossRef]

- Xiao, Y.; Xu, Y.; Shen, M.; Zhou, H.; Yao, P. Comparison of the braking behavior among cast steel, carbon/carbon (C/C) and carbon/carbon-silicon carbide (C/C-SiC) materials mated with copper-based composites. Tribol. Trans. 2024, 67, 1042–1056. [Google Scholar] [CrossRef]

- Fan, S.; Yang, C.; He, L.; Deng, J.; Zhang, L.; Cheng, L. The effects of phosphate coating on friction performance of C/C and C/SiC brake materials. Tribol. Int. 2017, 114, 337–348. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, X.; Zhong, W.; Wen, Y.; Yan, Q. The wet braking and recovery behaviors of the P/M pad mated with C/C–SiC disc for high-speed trains. Wear 2021, 468–469, 203609. [Google Scholar] [CrossRef]

- Tang, H.; Li, P.; Li, Z.; Li, J.; Zhao, J.; Xu, Y.; Li, Y.; Xiao, P. Braking behaviours of C/C–SiC mated with iron/copper-based PM in dry, wet and salt fog conditions. Ceram. Int. 2022, 48, 3261–3273. [Google Scholar] [CrossRef]

- Deng, P.; Li, P.; Xiao, P.; Li, Z.; Li, J.; Chen, P.; Liu, P.; Li, F. Oxidation behaviour of C/C–SiC brake discs tested on full-scale bench rig. Ceram. Int. 2021, 47, 34783–34793. [Google Scholar] [CrossRef]

- Fan, S.; Zhang, L.; Cheng, L.; Zhang, J.; Yang, S.; Liu, H. Wear mechanisms of the C/SiC brake materials. Tribol. Int. 2010, 44, 25–28. [Google Scholar] [CrossRef]

| Material Class | Advantages | Limitations |

|---|---|---|

| Iron and steel brake discs [7,14,26,29] | High mechanical strength (>600 MPa); Stable braking performance; Mature manufacturing. | Excessive density (about 7.8 g/cm3); Poor thermal fatigue resistance (<106 cycles); Poor high-temperature stability (degradation > 800 °C). |

| Aluminum matrix composite brake discs [60,72,73,90] | Lightweight (2.7–3.0 g/cm3); High thermal conductivity (>50 mm2/s); Good wear resistance. | Moderate high-temperature capability (degradation >600 °C); Complex fabrication processes increase cost. |

| Carbon matrix composite brake discs [90,101,108,109,110] | Lightweight (1.6–2.2 g/cm3); Exceptional thermal stability (>1000 °C); Superior thermal fatigue life (>107 cycles). | High brittleness (fracture risk under impact); High production costs; Moderate tensile strength (400–550 MPa). |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Y.; Zhou, L.; Zhao, H.; Wang, T.; Du, J.; Shen, M. The Evolution of Brake Disc Materials for Trains: A Review. Coatings 2025, 15, 628. https://doi.org/10.3390/coatings15060628

Xiao Y, Zhou L, Zhao H, Wang T, Du J, Shen M. The Evolution of Brake Disc Materials for Trains: A Review. Coatings. 2025; 15(6):628. https://doi.org/10.3390/coatings15060628

Chicago/Turabian StyleXiao, Yelong, Leliang Zhou, Huoping Zhao, Tianyong Wang, Junhua Du, and Mingxue Shen. 2025. "The Evolution of Brake Disc Materials for Trains: A Review" Coatings 15, no. 6: 628. https://doi.org/10.3390/coatings15060628

APA StyleXiao, Y., Zhou, L., Zhao, H., Wang, T., Du, J., & Shen, M. (2025). The Evolution of Brake Disc Materials for Trains: A Review. Coatings, 15(6), 628. https://doi.org/10.3390/coatings15060628