Research on the Influence of Surface Defects Under the Influence of Rail Corrosion on the Fatigue Damage of Wheel Rolling Contact

Abstract

1. Introduction

2. Experimental Methods and Details

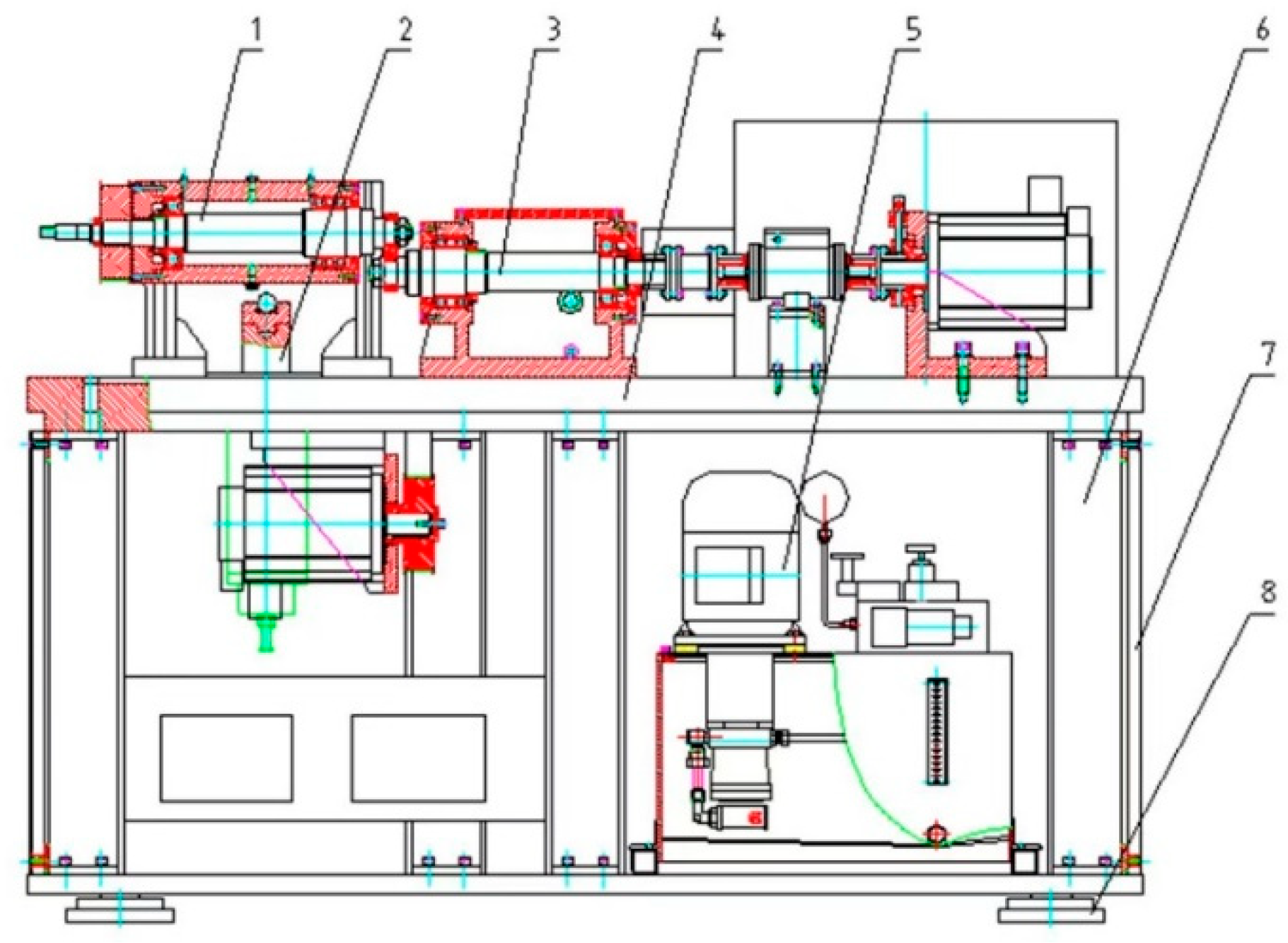

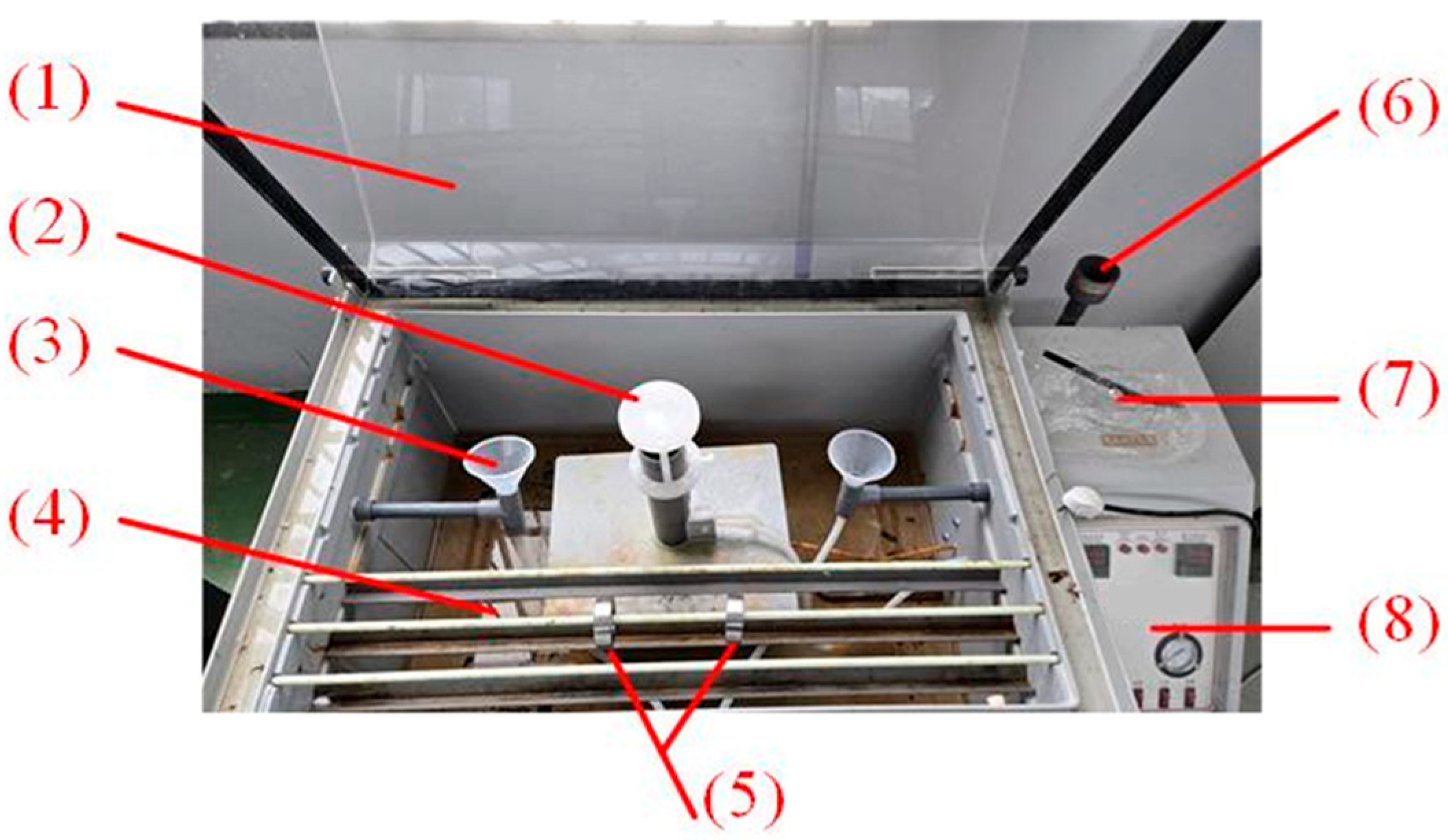

2.1. Experimental Machine

2.2. Experimental Parameters

3. Results

3.1. Changes in Wheel–Rail Contact Vibration Velocity

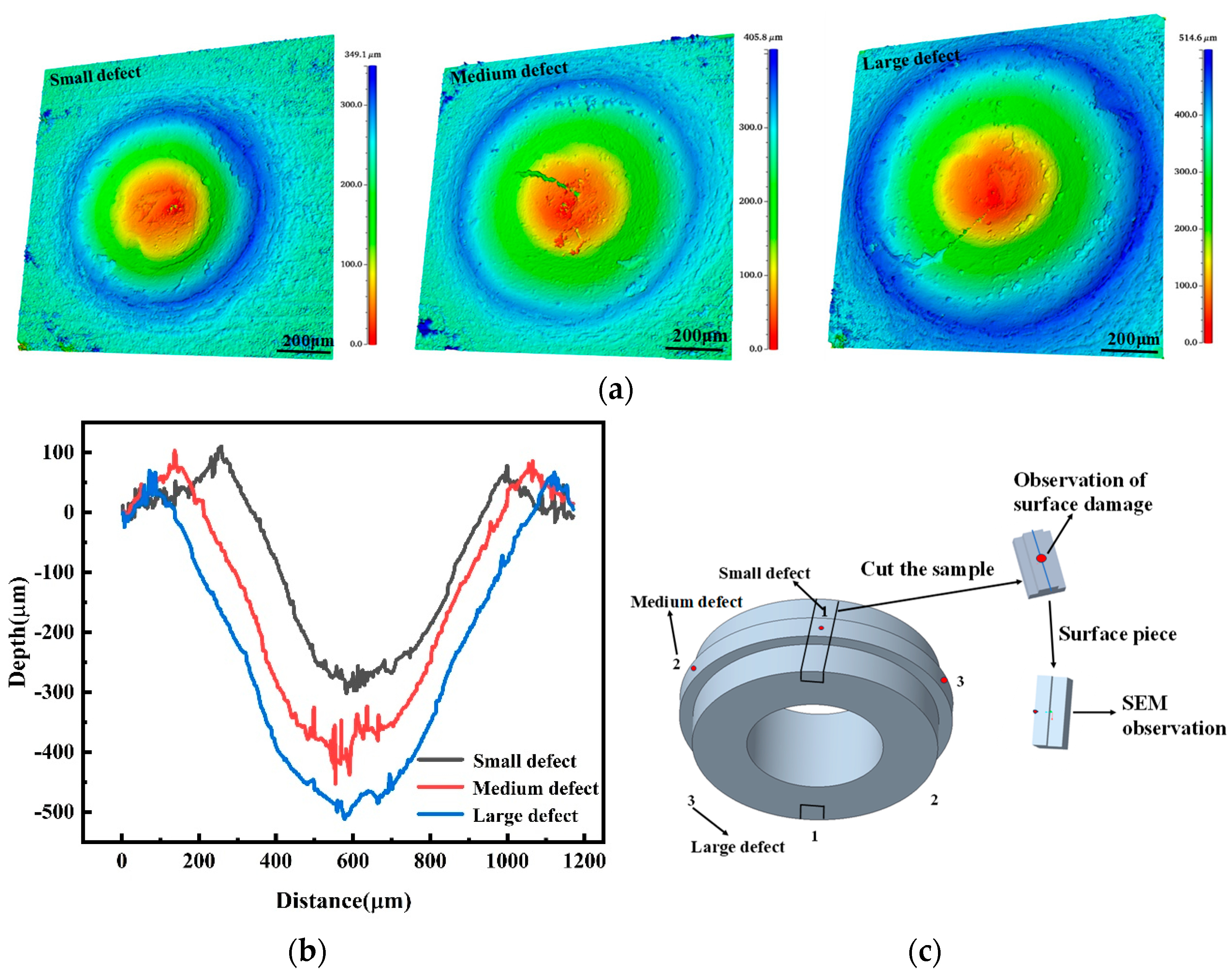

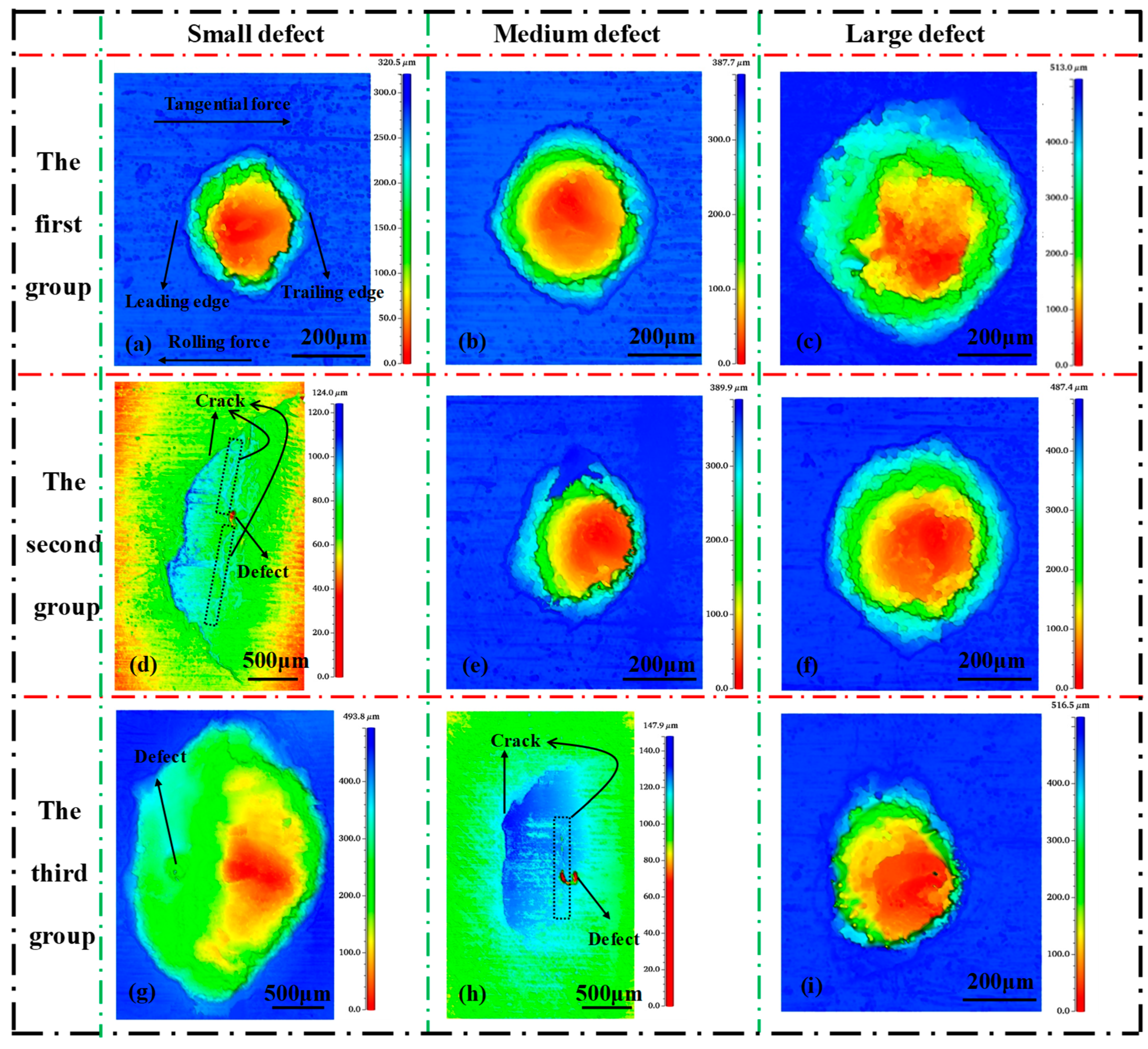

3.2. Surface Damage

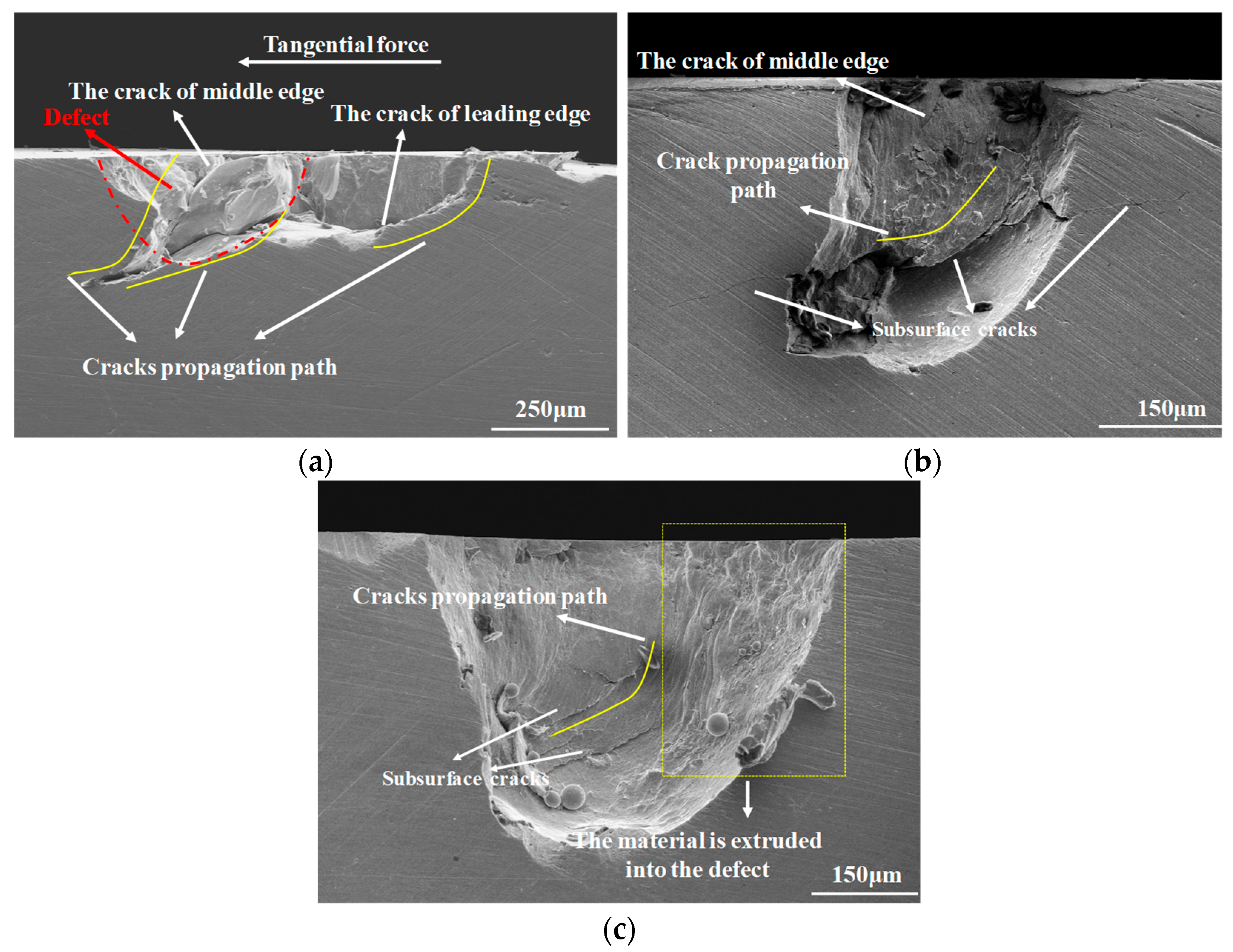

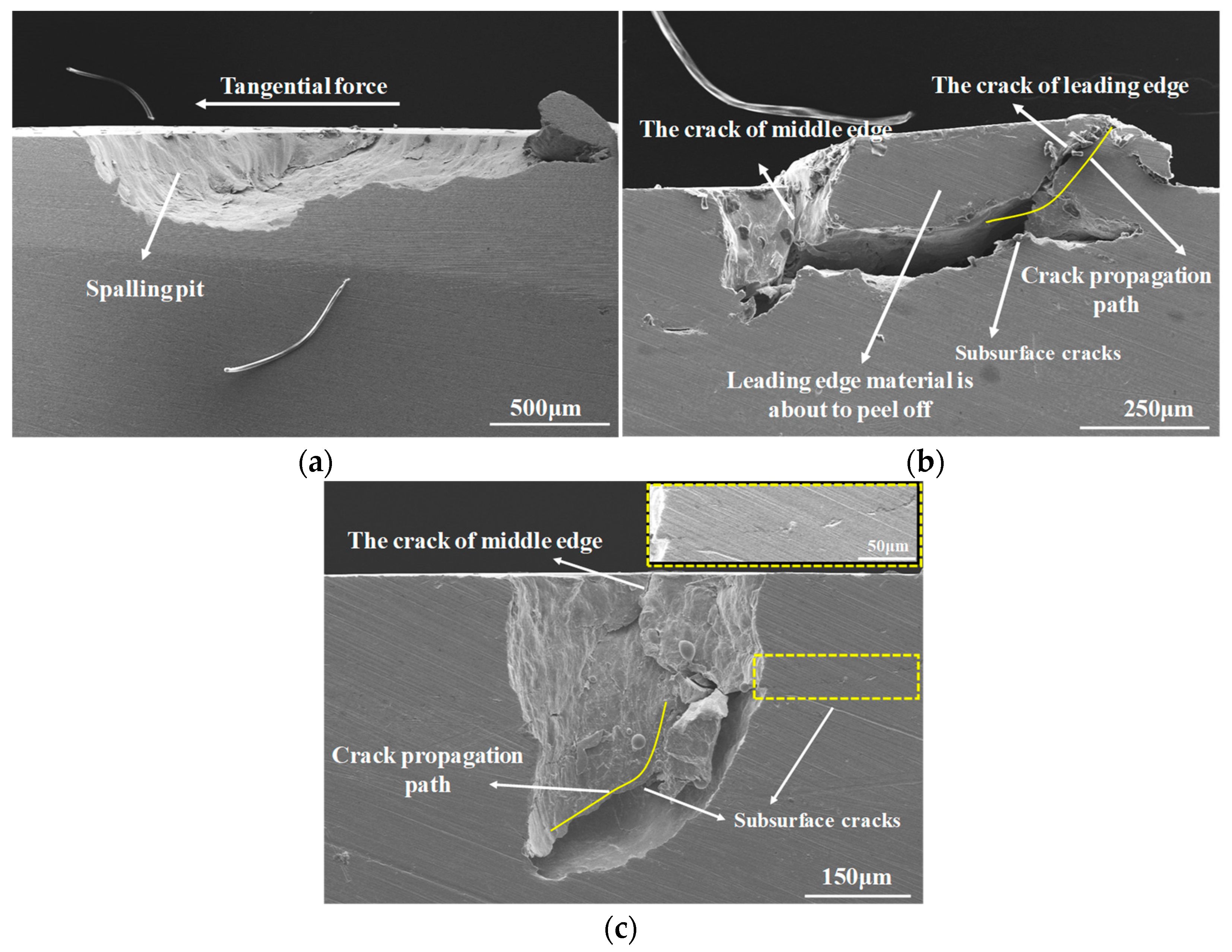

3.3. Subsurface Damage

4. Discussion

5. Conclusions

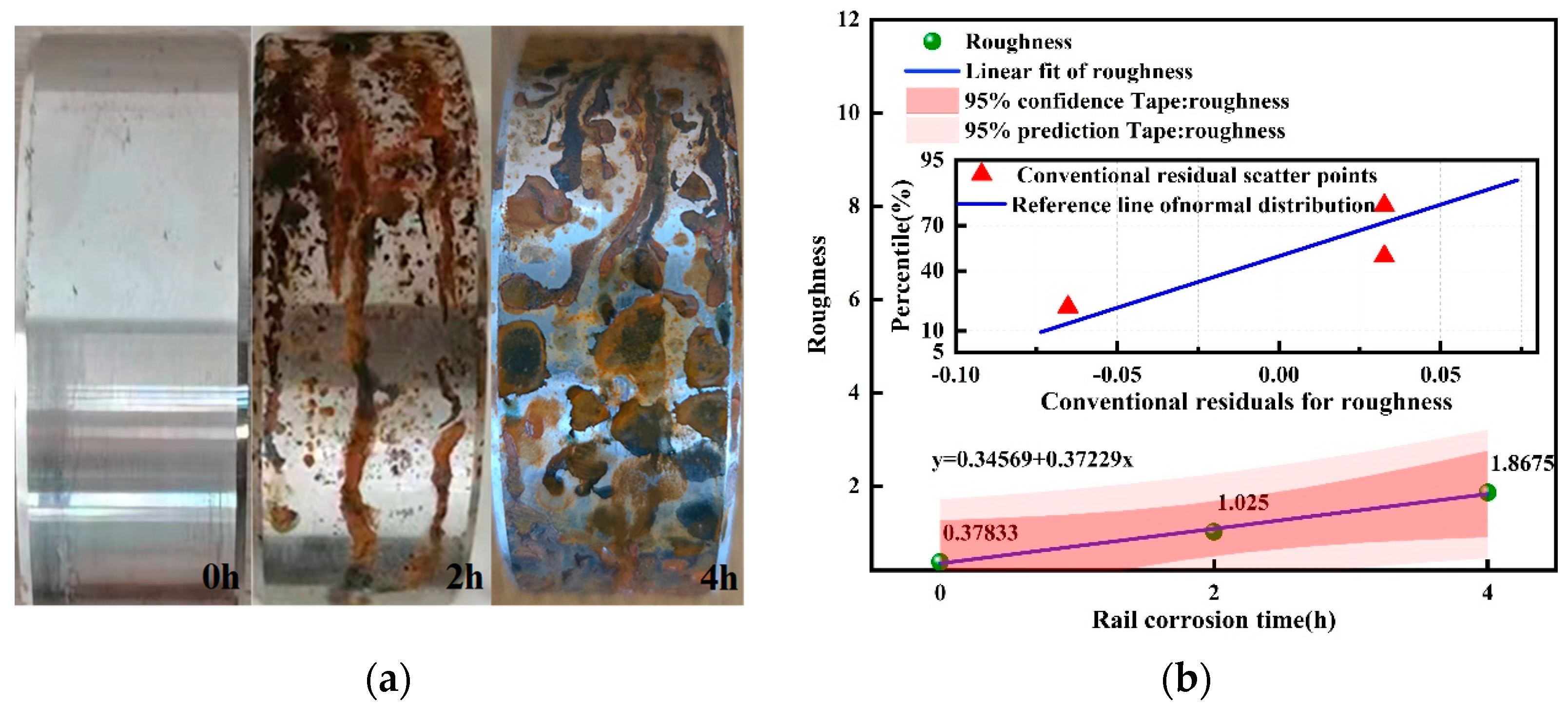

- The surface roughness of the rail after 0, 2, and 4 h of corrosion was measured at 0.37833, 1.025, and 1.8675 μm, respectively. Standard residual analysis confirmed an approximately linear increasing trend in roughness over time;

- The larger the surface defect size, the later the RCF crack in its neighborhood is initiated;

- The RCF crack growth trends of surface defects of different sizes are similar, and they all extend in a C–shape along the tangential force direction;

- The material near the leading edge is progressively compressed into the defect under the effect of the tangential force, forming a larger plastic deformation layer, which leads to more severe cracking of the RCF at the leading edge. In the meantime, under the combined effect of normal force and shear stress, the leading edge crack intersects with the middle edge crack, causing spalling to occur first at the defect’s leading edge;

- Among the three test groups, no spalling occurred in the first group, while the second and third groups exhibited spalling at 8278 and 7670 s, respectively. Taking large defects as an example, the wear volumes measured 0.068, 0.077, and 0.089 mm3 for the three groups. These results demonstrate that rail corrosion aggravates wheel wear and RCF damage. The longer the corrosion duration, the more severe the RCF damage and wear, leading to earlier material spalling and reduced fatigue life.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, Y.; Zhou, L.; Ding, H.H.; Lewis, R.; Liu, Q.Y.; Guo, J. Microstructure evolution of railway pearlitic wheel steels under rolling-sliding contact loading. Tribol. Int. 2021, 154, 106685. [Google Scholar] [CrossRef]

- Zhang, S.Y.; Zhao, X.J.; Ding, H.H.; Spiryagin, M.; Guo, J.; Liu, Q.Y.; Wang, W.J.; Zhou, Z.R. Effects of dent size on the evolution process of rolling contact fatigue damage on defective rail. Wear 2021, 477, 203894. [Google Scholar] [CrossRef]

- Ding, H.; Mu, X.; Zhu, Y.; Yang, W.; Xiao, Q.; Wang, W.; Liu, Q.; Guo, J.; Zhou, Z. Effect of laser claddings of Fe-based alloy powder with different concentrations of WS2 on the mechanical and tribological properties of railway wheel. Wear 2022, 488–489, 204174. [Google Scholar] [CrossRef]

- Donzella, G.; Faccoli, M.; Mazzù, A.; Petrogalli, C.; Roberti, R. Progressive damage assessment in the near-surface layer of railway wheel–rail couple under cyclic contact. Wear 2011, 271, 408–416. [Google Scholar] [CrossRef]

- Zhang, S.Y.; Liu, Q.Y.; Wang, W.J.; Spiryagin, M.; Lin, Q.; Ding, H.H.; Wu, Q.; Zhou, Z.R. Implications of water medium for the evolution of rolling contact fatigue under rail surface defect conditions. Tribol. Int. 2022, 175, 107870. [Google Scholar] [CrossRef]

- Gao, N.; Dwyer-Joyce, R.S.; Beynon, J.H. Effects of surface defects on rolling contact fatigue of 60/40 brass. Wear 1999, 225–229, 983–994. [Google Scholar] [CrossRef]

- Zhao, X.J.; Guo, J.; Liu, Q.Y.; Butini, E.; Marini, L.; Meli, E.; Rindi, A.; Wang, W.J. Effect of spherical dents on microstructure evolution and rolling contact fatigue of wheel/rail materials. Tribol. Int. 2018, 127, 520–532. [Google Scholar] [CrossRef]

- Zhang, S.-Y.; Spiryagin, M.; Lin, Q.; Ding, H.-H.; Wu, Q.; Guo, J.; Liu, Q.-Y.; Wang, W.-J. Study on wear and rolling contact fatigue behaviours of defective rail under different slip ratio and contact stress conditions. Tribol. Int. 2022, 169, 107491. [Google Scholar] [CrossRef]

- Gao, N.; Dwyer-Joyce, R.S. The effects of surface defects on the fatigue of water-and oil-lubricated contacts. Proc. Inst. Mech. Eng. Part J. 2000, 214, 611–626. [Google Scholar] [CrossRef]

- Gao, N.; Dwyer-Joyce, R.S.; Grieve, D.G. Disc machine testing to assess the life of surface-damaged railway track. Proc. Inst. Mech. Eng.-Part F J. Rail Rapid Transit. 2001, 215, 261–275. [Google Scholar] [CrossRef]

- Seo, J.; Kwon, S.; Lee, D. Effects of surface defects on rolling contact fatigue of rail. Proc. Eng. 2011, 10, 1274–1278. [Google Scholar] [CrossRef]

- Zhao, X.J.; Guo, L.C.; Guo, J.; Liu, Q.Y.; Butini, E.; Marini, L.; Meli, E.; Rindi, A.; Wang, W.J. Effect of spherical and ballast dents on rolling contact fatigue of rail materials. Wear 2020, 450–451, 203254. [Google Scholar] [CrossRef]

- Zeng, D.; Xu, T.; Liu, W.; Lu, L.; Zhang, J.; Gong, Y. Investigation on rolling contact fatigue of railway wheel steel with surface defect. Wear 2020, 446–447, 203207. [Google Scholar] [CrossRef]

- Kráčalík, M.; Trummer, G.; Daves, W. Application of 2D finite element analysis to compare cracking behaviour in twin-disc tests and full scale wheel/rail experiments. Wear 2016, 346–347, 140–147. [Google Scholar] [CrossRef]

- Carroll, R.I.; Beynon, J.H. Rolling contact fatigue of white etching layer: Part 1: Crack morphology. Wear 2007, 262, 1253–1266. [Google Scholar] [CrossRef]

- Zhao, X.; An, B.; Zhao, X.; Wen, Z.; Jin, X. Local rolling contact fatigue and indentations on high-speed railway wheels: Observations and numerical simulations. Int. J. Fatigue 2017, 103, 5–16. [Google Scholar] [CrossRef]

- Innocenti, A.; Marini, L.; Meli, E.; Pallini, G.; Rindi, A. Development of a wear model for the analysis of complex railway networks. Wear 2014, 309, 174–191. [Google Scholar] [CrossRef]

- Daves, W.; Kubin, W.; Scheriau, S.; Pletz, M. A finite element model to simulate the physical mechanisms of wear and crack initiation in wheel/rail contact. Wear 2016, 366–367, 78–83. [Google Scholar] [CrossRef]

- Taraf, M.; Zahaf, E.H.; Oussouaddi, O.; Zeghloul, A. Numerical analysis for predicting the rolling contact fatigue crack initiation in a railway wheel steel. Tribol. Int. 2010, 43, 585–593. [Google Scholar] [CrossRef]

- Kaneta, M.; Murakami, Y. Effects of oil hydraulic pressure on surface crack growth in rolling/sliding contact. Tribol. Int. 1987, 20, 210–217. [Google Scholar] [CrossRef]

- Diab, Y.; Coulon, S.; Ville, F.; Flamand, L. Experimental investigations on rolling contact fatigue of dented surface using artificial defects: Subsurface analyses. In Proceedings of the 29th Leeds-Lyon Symposium on Tribology, Leeds, UK, 3–6 September 2002. [Google Scholar]

- Hertz, H. The contact of elastic solids. J. Reine. Angew. Math. 1881, 92, 156–171. [Google Scholar]

- Lewis, R.; Magel, E.; Wang, W.-J.; Olofsson, U.; Lewis, S.; Slatter, T.; Beagles, A. Towards a standard approach for the wear testing of wheel and rail materials. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit. 2017, 231, 760–774. [Google Scholar] [CrossRef]

- Manson, S.S. Behavior of Materials Under Conditions of Thermal Stress; Manson BehaviorOM: Ann Arbor City, MI, USA, 1953. [Google Scholar]

- Ekberg, A.; Kabo, E.; Andersson, H. An engineering model for prediction of rolling contact fatigue of railway wheels. Fatig. Fract. Eng. Mater. Struct. 2002, 25, 899–909. [Google Scholar] [CrossRef]

- Su, X.; Xu, G.; Zhu, M.; Zhang, Q.; Cai, F.; Liu, M. Investigation on the interaction between corrosion and wear of U68CuCr rail steel with different corrosion periods. Wear 2023, 516–517, 204598. [Google Scholar] [CrossRef]

- Ekberg, A.; Kabo, E. Fatigue of railway wheels and rails under rolling contact and thermal loading—An overview. Wear 2005, 258, 1288–1300. [Google Scholar] [CrossRef]

- Chen, D.; Zhong, M.; Mou, M.; Xiao, Q.; Liu, X.; Yang, W.; Zhu, S.; Liu, B.; Lin, F.; Shi, X. Research on the damage mechanism of the rolling contact fatigue of a wheel–rail contact system under the influences of surface defects. Eng. Fail. Anal. 2024, 164, 108631. [Google Scholar] [CrossRef]

- Xu, K.W.; He, J.W.; Zhou, H.J. Effect of residual stress on fatigue behaviour of notches. Int. J. Fatig. 1994, 16, 337–343. [Google Scholar] [CrossRef]

| C | P | Mn S | Si | Mn | V | |

|---|---|---|---|---|---|---|

| ER8 | 0.52 | 0.016 | 0.002 | 0.26 | 0.73 | ≤0.06 |

| U75V | 0.71–0.80 | ≤0.03 | ≤0.03 | 0.50–0.80 | 0.70–1.05 | 0.12 |

| No. of Groups | Rail Disc | Wheel Disc | Rotating Speed | Loading Force | Maximum Contact Stress |

|---|---|---|---|---|---|

| 1 | Corrosion time 0 h | There are 2 small defects, 2 medium defects, and 2 large defects | 1000 r/min | 2945 N | 1200 MPa |

| 2 | Corrosion time 2 h | ||||

| 3 | Corrosion time 4 h |

| Defect | Description |

|---|---|

| When the contact zone contains small defects, the contact area has the most rust spots. |

| When the contact zone contains medium defects, the rust spots in the contact area are moderate |

| When the contact zone contains large defects, the rust spots in the contact area are minimal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, L.; Mou, M.; Chen, D.; Zhong, M. Research on the Influence of Surface Defects Under the Influence of Rail Corrosion on the Fatigue Damage of Wheel Rolling Contact. Coatings 2025, 15, 589. https://doi.org/10.3390/coatings15050589

Zhao L, Mou M, Chen D, Zhong M. Research on the Influence of Surface Defects Under the Influence of Rail Corrosion on the Fatigue Damage of Wheel Rolling Contact. Coatings. 2025; 15(5):589. https://doi.org/10.3390/coatings15050589

Chicago/Turabian StyleZhao, Longzhi, Minghui Mou, Daoyun Chen, and Minshi Zhong. 2025. "Research on the Influence of Surface Defects Under the Influence of Rail Corrosion on the Fatigue Damage of Wheel Rolling Contact" Coatings 15, no. 5: 589. https://doi.org/10.3390/coatings15050589

APA StyleZhao, L., Mou, M., Chen, D., & Zhong, M. (2025). Research on the Influence of Surface Defects Under the Influence of Rail Corrosion on the Fatigue Damage of Wheel Rolling Contact. Coatings, 15(5), 589. https://doi.org/10.3390/coatings15050589