Abstract

The objective of this study is to explore the high-temperature rheological properties and microscopic interaction mechanisms of styrene–butadiene–styrene (SBS) composite-modified asphalt with hydroxylated multi-walled carbon nanotubes (MWCNT-OH). SBS-modified asphalt, MWCNT-modified asphalt and MWCNT/SBS composite-modified asphalt were prepared with high-speed shearing apparatus and machine mixer. Physical property tests, dynamic shear rheological (DSR) tests, multiple stress creep recovery (MSCR) tests, X-ray diffraction (XRD) and Raman spectroscopy analyses were carried out to systematically compare the differences in macroscopic performance and changes in microscopic structure of different types of asphalts. According to the results of physical property tests, DSR tests and MSCR tests, the composite-modified asphalt was superior to the single-component-modified asphalt in terms of complex modulus (G*) and rutting factor (G*/sin δ). Its creep recovery rate (R) and unrecoverable compliance (Jnr) exhibited better anti-deformation ability under high temperatures, verifying the synergistic effect of SBS and MWCNTs-OH. XRD analysis showed that composite modification reduced the disorder degree of the crystalline phase of asphalt. Raman spectroscopy confirmed that there were changes in the vibration of chemical bonds between the modifier and asphalt, indicating that the modifier and asphalt acted on the asphalt system through physical dispersion and chemical cross-linking.

1. Introduction

In recent years, expressway construction in China has been developing rapidly. Continuously increasing traffic flow and harsh environmental conditions have led to serious rutting and cracking issues in asphalt pavement. So, to slow down the deterioration and improve the performance of asphalt pavement, modified asphalt is widely studied and used in the construction of asphalt pavement [1]. At present, the performance of asphalt has been significantly enhanced through the addition of modifiers such as polymers, rubbers, and resins into base asphalt [2,3,4,5,6]. However, with the continuous expansion of the scale of expressway construction, many traditional modifiers are unable to meet the high performance and standard requirements of asphalt pavement. With the continuous exploration and development of materials research, nanomaterials such as nanofibers, nanoparticles, nanoclays, and carbon nanotubes have opened up a new path for improving the asphalt performance [7,8,9]. Compared with other nanomaterials, carbon nanotubes have an extremely high aspect ratio and outstanding mechanical strength, which make them act as “reinforcing bars” during the modification process, effectively restricting the movement of asphalt molecules.

Mansourkhaki et al. [10] found that asphalt mixtures with carbon nanotubes exhibited higher abilities to resist the low-temperature cracking compared to unmodified asphalt mixtures. Xue et al. [11] discovered that carbon nanotubes could significantly improve the microwave thermal conductivity of asphalt, and the higher the dosage, the better the thermal conductivity. Santagata et al. [12] concluded that the addition of carbon nanotubes reduces the sensitivity of asphalt to oxidative aging, which is beneficial for extending its service life. Amin et al. [13] confirmed that both the fatigue cracking resistance and low-temperature cracking resistance of asphalt deteriorate as the content of carbon nanotubes increases. Gong et al. [14] reported that the addition of CNTs improved the high-temperature performance and aging resistance of asphalt while decreasing its low-temperature performance. Goli A et al. [15] pointed out that the addition of carbon nanotubes reduced the penetration index, and temperature sensitivity of asphalt, and effectively improved the physical properties, rheological properties, and stability of the asphalt binder. Shah et al. [16], based on basic physical tests and rheological tests, found that the addition of multi-walled carbon nanotubes improves the aging resistance of the asphalt binder, and the low-temperature performance of MWCNTs was not encouraging. Latifi et al. [17] evaluated the properties of carbon nanotube asphalt binders through microscopic and macroscopic tests. The results showed that modification with carbon nanotubes can enhance the stiffness of asphalt mixtures, and thus improve the rutting resistance. Modification with carbon nanotubes also improved the fatigue resistance of hot mix asphalt (HMA) specimens, especially under low-temperature conditions. After an in-depth analysis of the research status of carbon nanotube-modified asphalt, it was not difficult to find that, although carbon nanotubes show great potential in asphalt modification, the improvement of asphalt performance by a single nanomaterial has certain limitations. For example, carbon nanotubes are prone to agglomeration in asphalt, resulting in uneven dispersion and affecting the modification effect. Moreover, its improvement on asphalt performance is limited, and it is difficult to simultaneously optimize multiple performance aspects such as high-temperature stability, low-temperature crack resistance, and anti-aging properties. To further enhance the comprehensive performance of asphalt, researchers have carried out composite modification of asphalt using multiple materials to obtain modified asphalts with better performance.

Mamun et al. [18] demonstrated that, after adding carbon nanotubes, the moisture damage in a single-walled carbon nanotube/SBS composite-modified asphalt was reduced. In addition, Zhu et al. [19] revealed that carbon nanotubes could improve the high- and low-temperature performance of SBS-modified asphalt. Through microscopic tests, Fu et al. [20] found that carbon nanotubes restricted the movement between SBS particles and asphalt molecules, resulting in a more uniform dispersion of SBS in asphalt and improved its compatibility and storage stability. Sun et al. [21] confirmed that after adding CNTs, the temperature sensitivity of SBS-modified asphalt was improved, and its high-temperature performance and anti-aging properties were enhanced, while the low-temperature performance was less affected. Obukhova et al. [22] pointed out that single-walled carbon nanotubes increased the durability parameters of the binder by 150%, and improved the relaxation performance at low temperatures, and enhanced the resistance to fatigue damage. Tang et al. [23] studied the influence of carbon nanotubes on the high-temperature rheological properties and chemical properties of SBS-modified asphalt through molecular dynamics simulation, DSR, BBR, and FTIR tests. The addition of carbon nanotubes was able to improve the rheological properties, temperature sensitivity, and high-temperature rutting resistance of SBS-modified asphalt. Chen et al. [24] found that CNT/SBS composite-modified asphalt had an outstanding storage stability and workability, and the DSR results indicated that composite-modified asphalt exhibited excellent resistance to high temperatures, aging, and deformation. In general, the performance of carbon nanomaterial/SBS composite-modified asphalt is superior to that of individual polymer-modified asphalt and carbon nanomaterial-modified asphalt. In fact, the interfacial interactions, dispersion states, and molecular-level behaviors at the microscopic scale are the fundamental determinants of the macroscopic performance. Establishing a close connection between macroscopic performance and microscopic characteristics is not only essential for revealing the essence of asphalt modification, but also crucial for further enhancing the performance of composite modified asphalt and promoting its applications in engineering.

Nowadays, many studies are being carried out on the modification mechanisms of modified asphalt. Wang et al. [25] conducted Raman spectroscopy, XRD and Fourier transform infrared spectroscopy techniques, and concluded that the CNT/SBS modifier had high crystallinity, a high degree of graphitization and few defects, and chemical reactions did not occur between CNT and asphalt. Yu et al. [26] reported that carbon nanotubes made the distribution of aromatics and saturates more uniform, and alleviated the competition between SBS and asphaltenes. Zhang et al. [27] found that MWCNTs enhanced the cross-linking between the SBS modifier and the asphalt binder, and improved the distribution of the polar components in the asphalt binder by molecular dynamics and AFM testing methods. Wang et al. [28] pointed out that the C=C bonds of carbon nanotubes could interact with the alkanes and aromatic hydrocarbons in asphalt, and the synergistic effect between the carbon nanotubes and SBS due to the π-π conjugation of the benzene rings enabling SBS to adsorb and wind around the carbon nanotubes, thus improving the mechanical properties. Shu et al. [29] revealed that saturates and aromatics of asphalt penetrated into the network structure of SBS in the MWCNT/SBS-modified asphalt and formed a more stable network structure, and brought asphalt a significant improvement of high-temperature and low-temperature properties. Nie et al. [30] noticed that MWCNTs enhanced the intermolecular interactions by increasing the van der Waals energy of the MWCNT/SBS-modified asphalt, and resulted in increased stability in the system against external loads while improving the mechanical properties of the asphalt. Although plenty of studies have been conducted to characterize the morphology and dispersion of SBS and MWCNTs in asphalt binders, the reasons for the improvements gained by SBS and MWCNTs in the properties of base asphalt have not been explored thoroughly and comprehensively. Moreover, the use of X-ray diffraction and Raman spectroscopy methods to reveal the modification mechanisms of SBS/MWCNTs composite-modified asphalt is almost nonexistent in the literature.

Therefore, to address the above-mentioned research gaps, this study innovatively conducts a systematic comparative analysis. In this study, the basic physical property experiments, including penetration, softening point, ductility and viscosity experiments, as well as rheological property tests, such as DSR and MSCR, were carried out on base asphalt, SBS-modified asphalt, MWCNTS-modified asphalt, and composite-modified asphalt. Unlike previous studies that mainly focused on single-component-modification, this comprehensive experimental design enables us to quantitatively analyze the individual and synergistic effects of SBS and MWCNTs on the viscoelastic behavior, rutting resistance, and stability of base asphalt. Moreover, in a pioneering approach, XRD and Raman spectroscopy are employed to unravel the molecular-level modification mechanism of the SBS/MWCNTs composite system, which has not been explored in the literature. By integrating structural and spectral analyses, this study not only provides a more in-depth understanding of the composite modification process but also offers new theoretical guidance for the development of high-performance asphalt binders.

2. Materials and Experimental Methods

2.1. Materials

2.1.1. Asphalt

In this study, the PG64-16 base asphalt produced by the China Petrochemical Corporation was used, and its basic property indices were tested in accordance with the Chinese specifications detailed in the ”Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering”, and the results are shown in Table 1.

Table 1.

Basic properties of base asphalt binder.

2.1.2. SBS Modifier

In this research, the linear SBS modifier produced by Dongguan Jinheng Company (Dongguan, China) was adopted. SBS particles (see Figure 1) with a diameter of 3 mm were used as modifiers in this study. The SBS had a linear structure, the ratio of styrene and butadiene was 31:69, and its basic properties are presented in Table 2.

Figure 1.

SBS modifier.

Table 2.

Properties of linear SBS modifier.

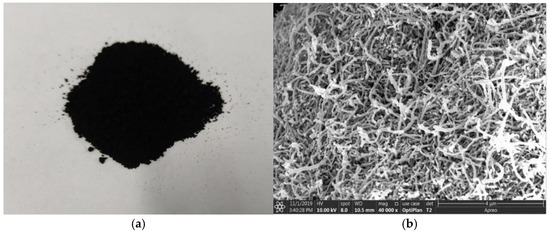

2.1.3. Multiwalled Carbon Nanotube

The hydroxylated multiwalled carbon nanotubes (MWCNTs-OH) produced by JiaCai Technology (Chengdu, China) were utilized. The MWCNTs were in a black powder state, and had lengths of less than 10 μm and diameters of 40–60 nm, as well as specific surface areas of 60–100 m2/g. The specific property indices of the MWCNTs are described in Table 3, and their macroscopic and microscopic morphologies are given in Figure 2.

Table 3.

Properties of MWCNTs.

Figure 2.

The morphology of multiwalled carbon nanotubes: (a) macroscopic and (b) microscopic (obtained by SEM, magnification: ×40,000).

2.2. Preparation of Modified Asphalt

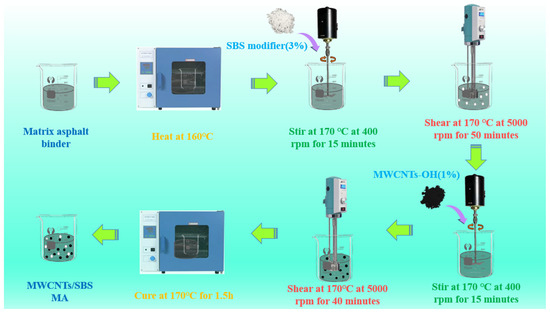

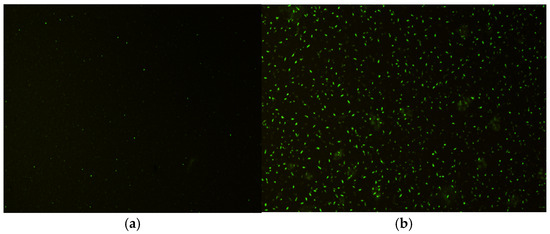

Due to the high surface energy and easy agglomeration of carbon nanotubes, it is difficult to disperse MWCNT modifier in the process of preparing MWCNT/SBS-modified asphalt. In this study, a high-speed shearing apparatus and machine mixer were used to prepare MWCNT/SBS composite-modified asphalt. The specific preparation steps are shown in Figure 3: Firstly, the base asphalt is heated to 160 °C to make it turn to the flow state, and then SBS modifier is added into the base asphalt, slowly. Then, to achieve a better dispersion of SBS in the base asphalt, the SBS and asphalt blends are stirred for 15 min at a rotation speed of 400 rpm using a machine mixer, and are then sheared for 50 min at a rotation speed of 5000 rpm by means of a high-speed shear apparatus. Then, the multiwalled carbon nanotubes are added slowly and stirred at a low speed of 400 rpm, and then the mixture is sheared at a speed of 5000 rpm for 40 min. The stirring and shearing process for the mixture was carried out at a temperature of 170 °C. Finally, curing in the oven at 170 °C for 1 h is carried out [32,33,34]. To verify the dispersion effect of MWCNTs, this study using a fluorescence microscope to conduct microscopic observations. As can be seen from Figure 4, MWCNTs exhibit a uniform dispersion state in the asphalt, and there is no obvious agglomeration.

Figure 3.

Preparation process for MWCNT/SBS composite-modified asphalt.

Figure 4.

The dispersion state of MWCNTs in asphalt is observed by fluorescence microscope: (a) base asphalt and (b) MWCNTs-modified asphalt.

2.3. Experimental Method

- (1)

- Basic physical property tests

The basic physical properties of base asphalt, SBS-modified asphalt (SBS MA), MWCNT-modified asphalt (MWCNTs MA) and MWCNT/SBS composite-modified asphalt (MWCNT/SBS MA) were evaluated through penetration, ductility, softening point tests, and Brookfield rotational viscosity tests. The penetration test reflects the ability of asphalt to resist shear deformation. The larger the penetration value, the softer the asphalt. The softening point is the temperature at which asphalt changes from a solid state to a visco-fluid state with a certain fluidity, which reflects the thermal stability of asphalt. The higher the softening point value, the better the high-temperature performance of the asphalt. The ductility represents the length of asphalt when it is stretched and broken under specified conditions, which measures the plasticity of the asphalt. The larger the ductility value, the stronger the plasticity of asphalt. The test temperatures for penetration, softening point, and ductility were set to 25 °C, 5 °C, and 5 °C, respectively. The viscosity test was carried out in a temperature range of 110–175 °C. All the above-mentioned tests were carried out in accordance with the specification of China’s “Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering”-(JTG E-20-2011).

- (2)

- Dynamic shear rheological test

The DSR (Dynamic Shear Rheometer) test evaluates the viscoelastic properties of asphalt under dynamic loading by applying sinusoidal shear strain or stress to an asphalt specimen and measuring the complex shear modulus and phase angle of the asphalt under different temperature and frequency conditions. In this research, DSR tests were conducted to base asphalt and modified asphalt by following AASHTO T315-19. In this test, a 25 mm parallel plate with a plate spacing of 1 mm was used. The frequency sweep range used was from 0.1 to 100 rad/s, at a constant sweep frequency of 10 rad/s. The temperature sweep test was carried out at a temperature of 50 °C, 58 °C, 66 °C, 74 °C, and 82 °C. The high-temperature rheological properties of the asphalt were analyzed through the complex modulus (G*), phase angle (δ), rutting factor (G*/sin δ), and fatigue factor (G*·sin δ).

- (3)

- Multiple stress creep test

The MSCR (multiple stress creep recovery) test is a method for evaluating the fatigue resistance and permanent deformation resistance of asphalt. It involves applying shear stresses of different magnitudes to an asphalt specimen and measuring its creep deformation and recovery ability to quantify the rheological properties of asphalt under repeated loading. The MSCR test was closely related to the high-temperature performance of asphalt. The creep recovery rate (R) and non-recoverable compliance (Jnr) of the asphalt binder were measured by MSCR according to ASTM D7405-15 [35]. The creep stress levels were set at 0.1 kPa and 3.2 kPa, which could simulate the deformation of asphalt under normal traffic loads and heavy traffic loads. Ten cycles were carried out at each stress level, with each cycle lasting 10 s (loading for 1 s and unloading for 9 s) [36].

- (4)

- Microscopic tests

The X-ray diffraction (XRD) test involves the irradiation of asphalt samples with X-rays. Based on the diffraction effects of the crystal structure on X-rays, the crystal structure information of components such as minerals and asphaltenes in the samples and the characteristic peak data are obtained. These are used to analyze the micro-crystal composition and crystallization behaviors of the asphalt, and to reveal the influence mechanisms of its chemical structure on its macroscopic properties. In this study, a German Bruker-D8Advance model X-ray diffractometer was used to conduct XRD tests on the four types of asphalt. The asphalt samples were in the form of 2 × 2 cm thin films. The test required the film thickness to be about 1 mm. A co-target was used for testing, and the asphalt was scanned at a rate of 8°/min in the conventional mode, with a test angle range of 10–90°. The Raman spectroscopy test excites the vibration of asphalt molecules with a laser, detects the Raman shift in elastic scattered light, and obtains the vibration characteristic spectra of functional groups such as carbon—carbon bonds and aromatic rings in the asphalt molecular structure. Thus, it conducts qualitative and quantitative analyses of the chemical composition and molecular structure of the asphalt, providing a microscopic basis for studying the aging and modification mechanisms of the asphalt. In the Raman test, a 633 nm excitation light source was selected, the scanning range was 50–4000, and the sample size was 2 × 2 cm. By analyzing the characteristic peaks of the crystal structure in the XRD spectrum and the changes in the peak position and intensity of the Raman spectrum, the differences in the microscopic structure of different types of asphalt were deeply explored.

3. Results and Analysis

Previous research has determined that when the dosage of SBS-modified asphalt is 3% and that of carbon nanotube-modified asphalt is 1%, the high-temperature rutting resistance and deformation resistance of asphalt can be effectively enhanced. In this study, an SBS modifier (3%) and MWCNT modifier (1%) were applied to explore the effect on the mechanical properties of composite-modified asphalt.

3.1. Basic Physical Properties

3.1.1. Penetration, Softening Point and Ductility

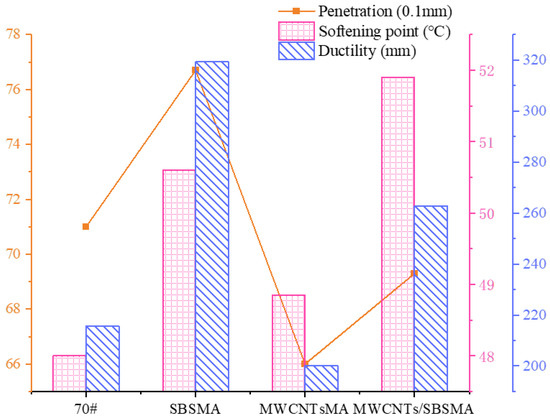

The results for the penetration, softening point, and ductility of base asphalt and modified asphalts were described in Figure 5. As can be witnessed, the penetration of base asphalt, SBS-modified asphalt, carbon nanotube-modified asphalt and composite-modified asphalt was 7.1 mm, 7.67 mm, 6.6 mm, and 6.93 mm, respectively. Compared to other asphalts, SBS increased the penetration value greatly with its thermoplastic rubber characteristic, which indicated that SBS improved the toughness of the asphalt. While, when the MWCNTs-OH was added to base asphalt, the surface active groups of MWCNTs-OH adsorbed onto the asphalt and restricted the molecular movement of the asphalt, which resulted in a decrease in penetration.

Figure 5.

Results for penetration, softening point, and ductility.

The results showed that, compared with base asphalt, the softening points of SBS-modified asphalt, MWCNT-modified asphalt, and composite-modified asphalt increased by 2.6 °C, 0.9 °C, and 3.9 °C, respectively. This implied that the MWCNTs and SBS modifiers could significantly improve the high-temperature properties of asphalt, and the MWCNTs had a positive effect on the stability of SBS-modified asphalt and brought MWCNT/SBS composite-modified asphalt better anti-deformation ability. The changes can be explained that the outstanding surface area of multiwalled carbon nanotubes led to a strong interface with asphalt and SBS, and resulted in a favorable network structure for asphalt.

It also can be seen that among the four types of asphalts, the improvement effect of SBS in terms of ductility was the most obvious, while the MWCNTs exhibited a negative effect on the ductility of the asphalt. That is because the aggregation of MWCNTs affected the uniformity of the modified asphalt, which caused stress concentration in local areas. Compared with the base asphalt, the ductility of the MWCNT/SBS composite-modified asphalt increased from 215.6 mm to 262.8 mm, which indicated that the MWCNT/SBS modifier improved the anti-cracking performance at low temperatures. The reason may be that the adding of SBS alleviated the aggregation of MWCNTs in matrix asphalt and enhanced the flexibility of asphalt.

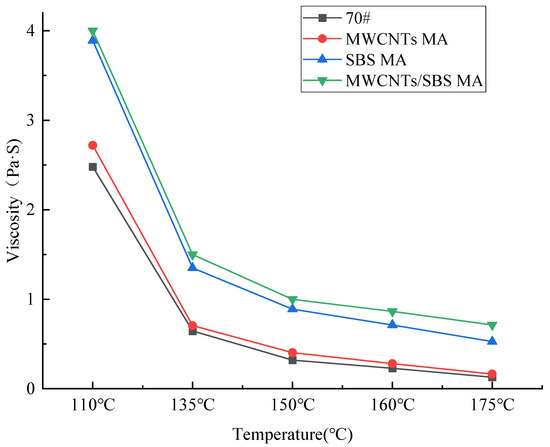

3.1.2. Viscosity–Temperature Relationship

The Brookfield viscosity reflects the frictional resistance generated by the relative motion between two fluid layers in asphalt. The higher the viscosity, the better the high-temperature rutting performance of the asphalt. Figure 6 showed the viscosity–temperature relationship of asphalt. From 110 °C to 175 °C, the viscosity of different types of asphalt decreased with increases in temperature. The addition of MWCNTs or SBS led to an increase in viscosity. With the same SBS content (3%), the viscosity of MWCNT/SBS composite-modified asphalt exceeded that of SBS-modified asphalt. This is attributed to the strengthening effect of carbon nanotubes. Carbon nanotubes were uniformly dispersed in the asphalt to form a reinforcing skeleton, which increased the internal friction force, and hindered the flow of asphalt molecules. Compared with the SBS-modified asphalt, the viscosity values of the composite-modified asphalt at each temperature increased by 0.11 Pa·s, 0.15 Pa·s, 0.111 Pa·s, 0.153 Pa·s, and 0.186 Pa·s, respectively. The results of the viscosity experiment indicated that adding carbon nanotubes to SBS-modified asphalt can further reduce its fluidity, increase its viscosity, and enhance its high-temperature rutting resistance.

Figure 6.

Viscosity–temperature curves.

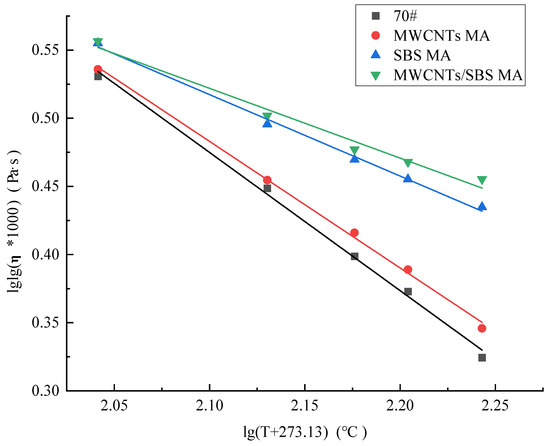

In addition, the optimal fitting equation was determined by comparing three common fitting equations for the viscosity–temperature relationship [37,38,39]. The comparison of fitting equations is as follows:

where η is the viscosity (Pa·s); T is the temperature in Celsius (°C); n and m are fitting parameters; and A and b are both regression constants.

lgη = n − m × T

lglg(η × 103) = n − mlg (T + 273.13)

η = ATb

The fitting information for the three fitting equations is displayed in Table 4, Table 5 and Table 6. The smaller the Reduced Chi-Sqr value, the higher the fitting accuracy. The Reduced Chi-Sqr values of the three fitting equations are sorted as follows: Equation (1) > Equation (3) > Equation (2). Therefore, the Saal equation was chosen to fit the viscosity–temperature curve. The fitting information is shown in Figure 7. The slope of the linear equation represents the temperature sensitivity. It can be seen that the slopes of the three modified asphalts were lower than that of the base asphalt, and the slope of MWCNT/SBS composite-modified asphalt was the lowest, indicating that adding SBS or MWCNTs to the asphalt binder can improve the temperature sensitivity, and adding carbon nanotubes to SBS-modified asphalt can effectively improve the workability of the asphalt pavement.

Table 4.

Fitting information for Equation (1).

Table 5.

Fitting information for Equation (2).

Table 6.

Fitting information for Equation (3).

Figure 7.

Asphalt viscosity–temperature curve.

3.2. Dynamic Shear Rheological Test

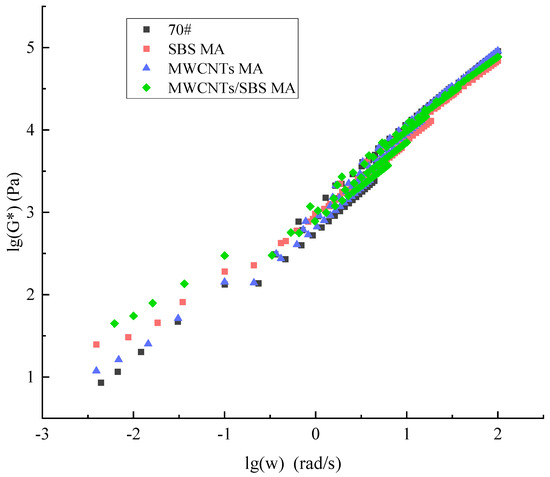

3.2.1. Frequency Sweeping

Frequency sweeping is a method for studying the rheological properties of asphalt. In order to evaluate the influence of additives on the viscoelastic properties of asphalt and understand the mechanical responses of asphalt under different loading frequencies, we can take the MWCNT/SBS composite-modified asphalt as an example, with the master curves being generated at a reference temperature of 50 °C, and considering the time–temperature equivalence principle [40]. The Williams–Landel–Ferry (WLF) non-linear equation was applied as the fitting equation for the shifting factor [41]. The equation was given in Equation (4). The shifting factor at each temperature is shown in Table 7.

where ϕT is the shifting factor; T is the actual loading temperature; T0 is the reference temperature; and C1 and C2 are the fitting parameters of the WLF non-linear equation.

Table 7.

Information for shifting factors of different asphalts.

Figure 8 displays the master curve of the complex modulus frequencies at temperatures of 50 °C, 58 °C, 64 °C, 74 °C, and 82 °C. As shown in Figure 8, the addition of 3% SBS or 1% MWCNT modifiers increased the complex modulus in the overall loading frequency range and at different temperatures. The higher the complex modulus, the greater the rutting resistance. Attributed to the complex interactions between carbon nanotubes and SBS, the MWCNT/SBS composite-modified asphalt demonstrated superior complex moduli compared with the SBS-modified asphalt and the carbon nanotube-modified asphalt, indicating that the addition of carbon nanotubes to SBS-modified asphalt endows SBS-modified asphalt with strong rutting resistance. With the increase in frequency, the complex modulus of asphalt showed an upward trend. It can be observed that the slope of the MWCNT/SBS composite-modified asphalt is smaller than that of SBS-modified asphalt, which exhibits a better temperature-sensitive performance.

Figure 8.

Master curve of complex modulus frequency.

3.2.2. Temperature Sweeping

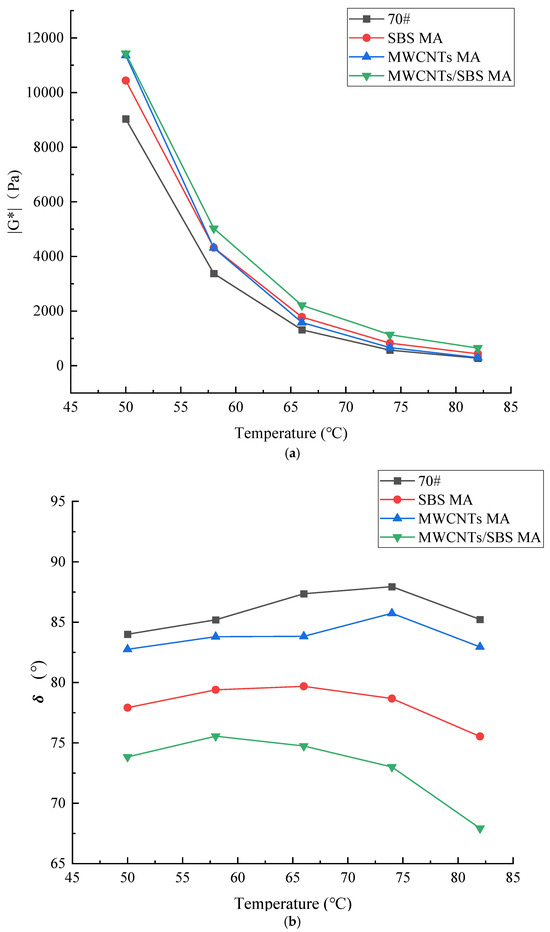

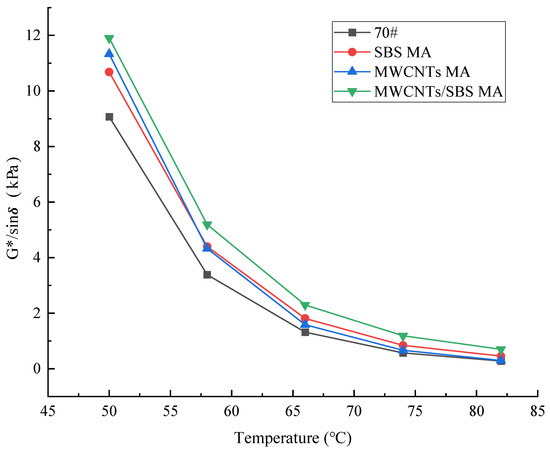

As a typical viscoelastic material, asphalt displayed remarkable temperature dependence. The temperature sweeping test can systematically explore the viscoelastic response of asphalt within various temperature ranges. Figure 9 illustrated the results of the temperature sweeping tests for base asphalt, SBS-modified asphalt, carbon nanotube-modified asphalt and MWCNT/SBS composite-modified asphalt at temperatures of 50, 58, 66, 74, and 82 °C, and at a sweeping frequency of 10 rad/s. The outcomes demonstrated that both the complex modulus and the phase angle of different types of asphalts displayed the same trend. With an increase in temperature, the complex shear modulus decreased, and the phase angle increased and then decreased. A possible reason is that the asphalt closes to a Newtonian fluid state at high temperatures, and the phase difference between stress and strain are determined by its viscous characteristics. The phase angle values are sorted as follows: base asphalt > carbon nanotube-modified asphalt > SBS-modified asphalt > MWCNT/SBS composite-modified asphalt. In comparison with the base asphalt, the separate incorporation of MWCNTs and SBS significantly improved the complex shear modulus and phase angle of the asphalt. Compared with the SBS-modified asphalt, the co-incorporation of MWCNTs and SBS into the asphalt contributed to a higher complex modulus and a lower phase angle. This is due to the fact that carbon nanotubes possess large specific surface areas and high aspect ratios. After adding carbon nanotubes to the SBS-modified asphalt, the structure of the SBS-modified asphalt became more compact, and, thus, the MWCNTs substantially enhanced the deformation recovery ability of the SBS-modified asphalt. The SHRP specification defined the rutting factor to signify the resistance of asphalt materials to permanent deformation, which can characterize the high-temperature properties of the asphalt. The greater the rutting factor, the more superior the rutting resistance of the asphalt is at high temperatures [42]. Figure 10 presents the rutting factors of different types of asphalt at different temperatures. As the temperature increased, the rutting factor of the asphalts diminished. After adding carbon nanotubes or SBS-modifiers into an asphalt binder, the rutting factors were improved to different extents. As a filler for the SBS-modified asphalt, carbon nanotubes had high rigidity, such that they could provide support for the structure of the asphalt, thereby increasing the rutting factor of the asphalt, and effectively enhancing its high-temperature rutting resistance. The results of the temperature sweeping tests suggest that carbon nanotubes improve the high-temperature performance of SBS-modified asphalt and enhance the ability of asphalt binders to resist permanent deformation.

Figure 9.

The results of the temperature sweeping tests: (a) complex modulus; (b) phase angle.

Figure 10.

Rutting factors of different asphalts at different temperatures.

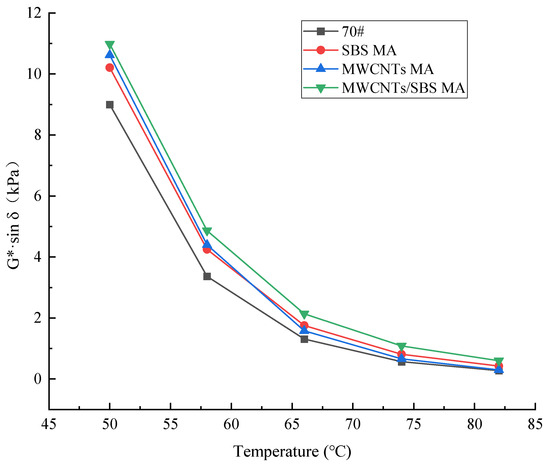

The fatigue factor (G*·sin δ) can be used to evaluate the fatigue performance of asphalt under repeated loading. The larger the fatigue factor, the worse the fatigue resistance performance. Figure 11 showed the fatigue factors of different types of asphalt at different temperatures. It can be seen that the fatigue factor of the asphalts decreased with increases in temperature. This is because when the temperature rises, the viscosity of asphalt decreases, making it softer and increasing its fluidity. When asphalt was subjected to external forces, it was more likely to be deformed, and its ability to resist deformation weakened. The fatigue factor value of the base asphalt is the lowest compared with the other modified asphalts. The addition of SBS/MWCNT modifiers can significantly increase its fatigue factor, which is attributed to the network structure of SBS and the strengthening and toughening effects of carbon nanotubes. Compared with SBS-modified asphalt, the addition of MWCNTs further increased its fatigue factor. The results indicate that the addition of carbon nanotubes and SBS modifiers has an adverse effect on the fatigue resistance performance of asphalt.

Figure 11.

Fatigue factors of different asphalts at different temperatures.

3.3. Multiple Stress Creep Recovery Test (MSCR)

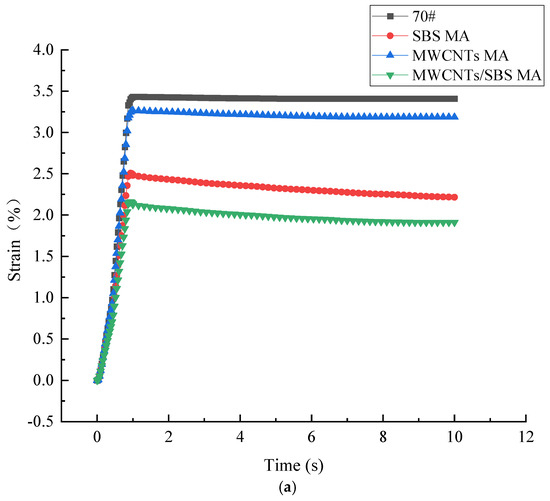

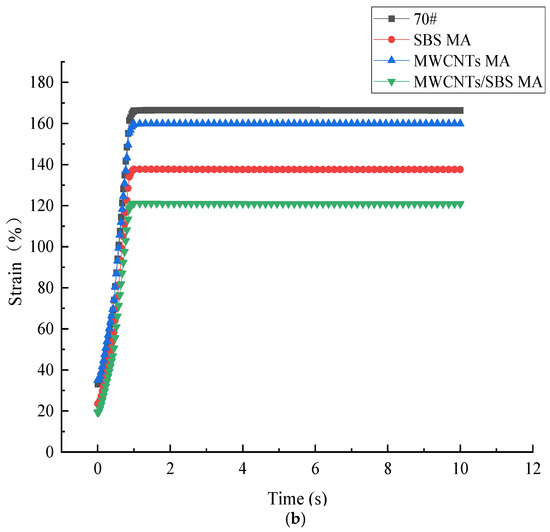

3.3.1. Stress–Strain Characteristic Analysis

Figure 12 describes the time–strain response in the first cycle at a temperature of 50 °C. With an increase in stress from 0.1 kPa to 3.2 kPa, the strain increased significantly, strain recovery became weaker, and the residual strain became larger, which means that the shear stress has a great impact on the recovery ability of asphalt. The strain of the base asphalt, SBS-modified asphalt, carbon nanotube-modified asphalt and MWCNT/SBS composite-modified asphalt at both stress levels of 0.1 kPa and 3.2 kPa were ranked as base asphalt > carbon nanotube-modified asphalt > SBS-modified asphalt > MWCNT/SBS composite-modified asphalt. In addition, the shear strain recovery rate of the MWCNT/SBS composite-modified asphalt was higher in comparison with the other three asphalts after the stress was unloaded, indicating that the addition of carbon nanotubes can effectively enhance the high-temperature deformation resistance of SBS-modified asphalt.

Figure 12.

Time–strain response curve in the first cycle. (a) Shear strain under 0.1 kPa. (b) Shear strain under 3.2 kPa.

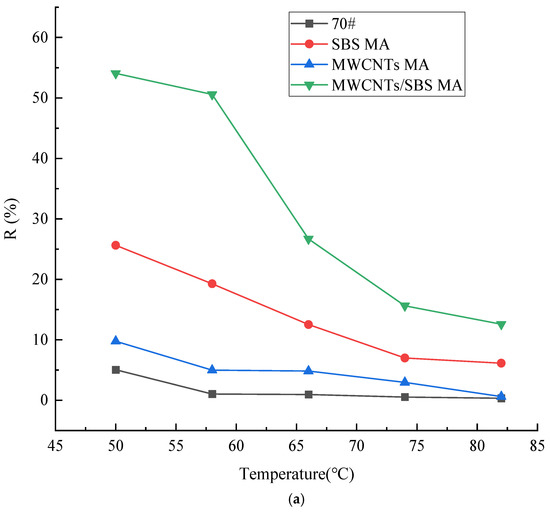

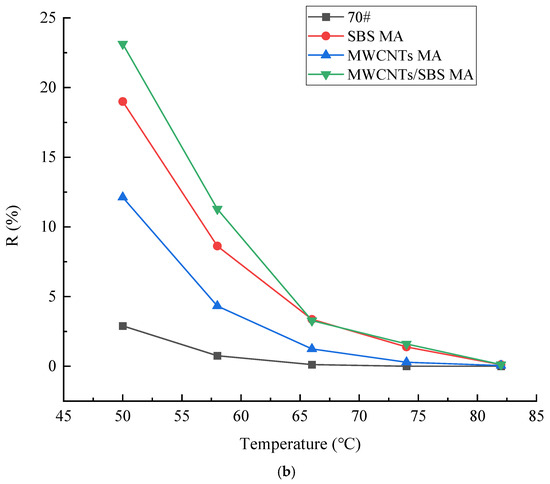

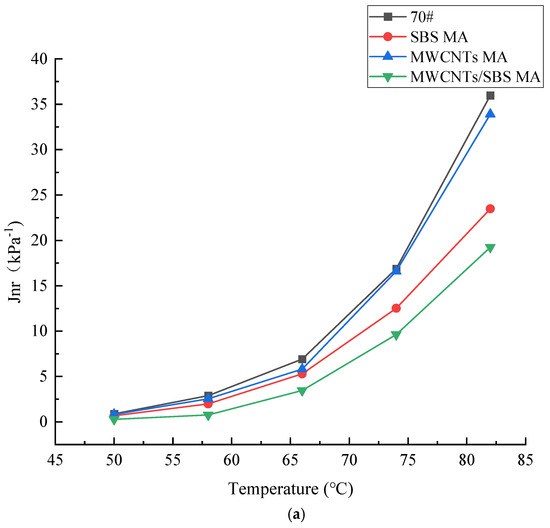

3.3.2. Creep Characteristic Analysis

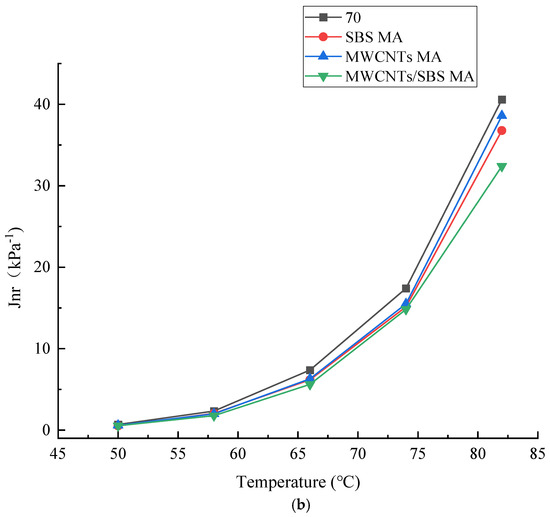

The present study has shown that the MSCR test can more effectively characterize the high-temperature performance of asphalt than rutting factor. In this study, the unrecoverable creep compliance Jnr and creep recovery rate R of the base asphalt, SBS-modified asphalt, carbon nanotube-modified asphalt, and MWCNT/SBS composite-modified asphalt under different stress levels were measured through the multiple stress creep recovery test. The creep recovery rate R reflects the asphalt’s ability to return to its initial deformed state during the unloading stage. The non-recoverable compliance directly reflects the permanent deformation resistance of asphalt. The test results were shown in Figure 13 and Figure 14. It should be known that, compared at a stress level of 0.1 kPa, Jnr3.2 is significantly higher than Jnr0.1, and R3.2 is significantly lower than R0.1. This verifies that the higher the stress level, the more significant the influence will be on the deformation recovery of asphalt. The main reason is that the network-restraining effect of carbon nanotubes and SBS is weakened along with increases in stress. As the temperature rises, the creep recovery rate decreases and the non-recoverable creep compliance shows an increasing trend, with change trends being consistent for all samples. This can be explained with the understanding that the elastic component endows asphalt with an excellent capacity for deformation recovery. As the temperature rises, the fluidity of asphalt increases at high temperatures, and the enhancement of the viscous component increases the accumulation of unrecoverable deformation during processes of repeated loading and unloading. When evaluating the rutting resistance of asphalt binders under high-temperature conditions, the lower the Jnr value, the less the unrecoverable deformation, and the higher the R value, the more the recoverable elastic deformation. In this study, the three modified asphalts exhibited smaller Jnr values and larger R values compared with unmodified asphalt. This implies that adding the MWCNT/SBS modifier to the asphalt binder can effectively improve its rutting resistance at high temperatures. The asphalt binder, modified by the MWCNT+SBS modifier, has the highest R value and the lowest Jnr value. This results from the fact that the carbon nanotubes were adsorbed on the surface of the SBS copolymer, which promoted the cross-linking between the SBS phase and the asphalt phase. The MSCR test showed that adding carbon nanotubes to the SBS-modified asphalt can increase the elastic components of the asphalt binder so that the MWCNT/SBS composite-modified asphalt will have excellent resistance to permanent deformation under high-temperature conditions.

Figure 13.

Creep recovery rate under different stress levels: (a) 0.1 kPa; (b) 3.2 kPa.

Figure 14.

Jnr of different modified asphalts under different stress levels: (a) 0.1 kPa; (b) 3.2 kPa.

3.4. Micro-Properties

3.4.1. XRD Characterization

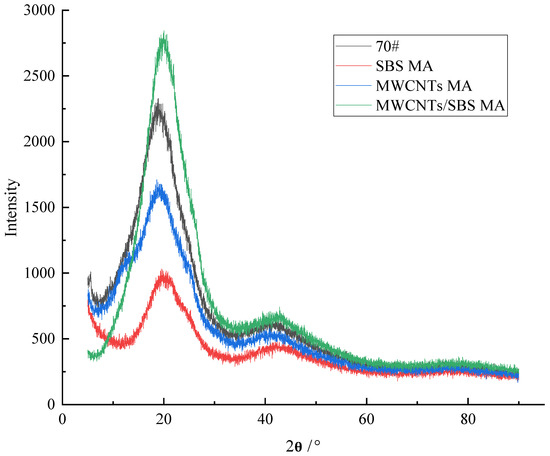

Figure 15 and Table 8 described the XRD peak data and diffraction patterns of base asphalt, SBS-modified asphalt, carbon nanotube-modified asphalt and MWCNT/SBS composite-modified asphalt, respectively. As can be seen from Figure 15, base asphalt, SBS-modified asphalt, carbon nanotube-modified asphalt, and MWCNT/SBS composite-modified asphalt all exhibited obvious characteristic peaks at around 25° and 44°, corresponding to the (002) and (100) crystal planes, respectively. The intensity of the γ peak is too weak to be shown in the XRD spectrum. Hence, the γ peak was manually added through Gaussian peak fitting. This study focused on the γ peak and the (002) graphite peak to evaluate the crystal structure and crystallinity of asphalt. The (002) peak in the XRD patterns of asphalt originated from the diffraction phenomenon of polycyclic aromatic hydrocarbons, and the γ peak originated from the diffraction phenomenon of saturated hydrocarbons in the asphalt components. As seen in Figure 15, four types of asphalt exhibited similar peak patterns, revealing that they may contain the same crystalline phase components. A higher intensity value means better crystallinity. The XRD intensities of different asphalts were in the order of MWCNT/SBS composite-modified asphalt > base asphalt > carbon nanotube-modified asphalt > SBS-modified asphalt. It is obvious that the addition of MWCNTs/SBS decreased the intensity of asphalt binder. Asphalt with MWCNT+SBS modifiers showed exceeding intensity in comparison with SBS-modified asphalt, contributing to better crystallinity. From the “Area” data in Table 8, the peak area of the γ and (002) peaks of the base asphalt are 1571.23573 and 36.17641, respectively. Compared with SBS/MWCNT-modified asphalt, the peak area of the base asphalt is larger, which indicates that the addition of SBS/MWCNTs reduced the crystallinity of the crystalline phase components in the asphalt mixture. The peak areas of the γ and (002) peaks of MWCNT+SBS composite-modified asphalt were 2089.34551 and 270.0296, respectively, which were higher than those of SBS-modified asphalt. This suggested that carbon nanotubes endowed SBS-modified asphalt with better crystallinity and a higher content in the crystalline phase, which is consistent with the results of the intensity analysis. In addition, the XRD patterns showed that the interlayer distance of the MWCNT/SBS composite-modified asphalt is smaller in comparison with SBS-modified asphalt, indicating that the addition of carbon nanotubes made the crystal structure of the SBS-modified asphalt more compact and ordered, and enhanced the intermolecular force; thus, the deformation resistance of SBS-modified asphalt was improved.

Figure 15.

XRD patterns.

Table 8.

Details of each diffraction peak.

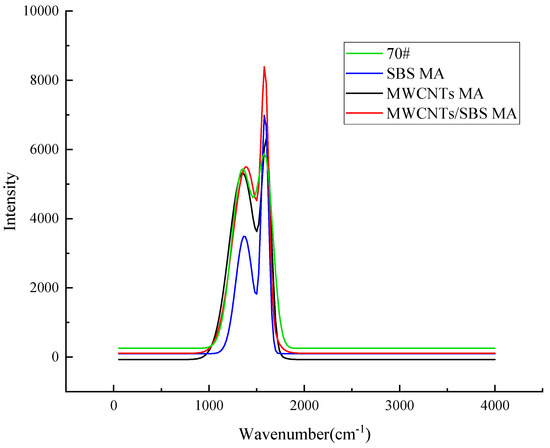

3.4.2. Raman Characterization

This study mainly analyzed the characteristic peaks of the two modes (D peak and G peak) in the Raman spectrum to obtain their microscopic information. The D peak reflected the structural defects of MWCNTs. Such defects can promote the mutual fusion and interaction between MWCNTs and the components of the asphalt binder. The Raman shift range was 1250–1450 cm−1. The G peak reflected the tangential stretching vibration of the C=C bond in MWCNTs, and its Raman shift range was between 1500 cm−1 and 1605 cm−1. The ratio of the intensity of the D peak to the G peak (ID/IG) characterized the degree of order of the system and the degree of interaction of each of the components, and its reciprocal (IG/ID) served as the graphitization index of the MWCNTs [43]. The fitted Raman spectrum is shown in Figure 16. The detailed information for the Raman spectrum peak is shown in Table 9. As can be seen from Figure 16, the D peak and G peak can be observed both in the Raman spectra of the base asphalt, SBS-modified asphalt, carbon nanotube-modified asphalt, and MWCNT/SBS composite-modified asphalt. There is no obvious shift in the Raman spectra of the D and G peaks. With the addition of MWCNTs, the intensity of the D peak of the SBS-modified asphalt increased, and its structural defects increased. Adding MWCNT/SBS into asphalt binders significantly increased the intensity of the G peak of in comparison with unmodified asphalt. Also, the intensity increased from 6982.6528 for SBS-modified asphalt to 8954.3102 when the SBS-modified asphalt was modified by MWCNTs. The reason for this may be that the molecules of the asphalt’s components adhered to the MWCNTs, or that the MWCNTs molecules penetrated into the SBS molecules, and the C=C bonds of different molecules interfered with each other. The ID/IG values of the base asphalt, SBS-modified asphalt, carbon nanotube-modified asphalt, and MWCNT/SBS composite-modified asphalt were 0.9237, 0.4992, 0.8416, and 0.6137, respectively. After adding the MWCNT/SBS modifier, the ID/IG values of the asphalt binder decreased to different extents. After adding MWCNTs to the SBS-modified asphalt, the ID/IG value decreased. The reason could be that during the composite modification process, SBS and carbon nanotubes interacted with each other. SBS mainly reduced the relative intensity of the disordered carbon structure, and carbon nanotubes also had a certain effect. SBS and carbon nanotubes jointly optimized the order of the internal carbon structure of the asphalt. This demonstrates that SBS with MWCNTs could reduce the defects of the SBS-modified asphalt and improve its crystal quality.

Figure 16.

The fitting results of the D peak and G peak.

Table 9.

The Raman peak data of the D peak and G peak.

4. Conclusions

In this study, the high-temperature performances of base asphalt, SBS-modified asphalt, carbon nanotube-modified asphalt, and MWCNT/SBS composite-modified asphalt were comprehensively investigated. In summary, the MWCNT/SBS composite-modified asphalt shows marked superiority in improving the high-temperature performance of asphalt, providing an effective material option for enhancing the service performance of asphalt pavements. The following main conclusions were obtained:

- (1)

- Enhanced resistance to high-temperature deformation: In asphalt pavement engineering, increasing the softening point and viscosity of asphalt directly mitigates rutting issues, while improved ductility helps to prevent cracking under stress. When compared with the base asphalt, the softening points of the SBS-modified asphalt, MWCNT-modified asphalt, and MWCNT/SBS composite-modified asphalt increased by 2.6 °C, 0.9 °C, and 3.9 °C, respectively, and the ductility of the composite-modified asphalt improved from 215.6 mm to 262.8 mm. Moreover, the composite-modified asphalt showed a viscosity increase of 0.11–0.186 Pa·s at different temperatures compared to SBS-modified asphalt. These results indicate that the composite modification effectively enhances the resistance to high-temperature deformation, providing a more durable material for hot-weather road construction.

- (2)

- Superior dynamic load-bearing capacity: Asphalt pavements endure continuous dynamic vehicle loads, and materials with high complex moduli and low temperature sensitivity can better withstand fatigue and deformation. The composite-modified asphalt exhibited the highest complex modulus in the low-frequency region, and a smaller slope in the high-frequency region, indicating excellent resistance to permanent deformation and rapid load changes. In the temperature sweep test, it showed the largest complex shear modulus and smallest phase angle. These findings suggest that the composite-modified asphalt can significantly improve the durability of pavements under heavy traffic conditions.

- (3)

- Exceptional self-recovery ability: Under repeated traffic loads in hot climates, asphalt materials with high creep recovery rates can minimize permanent deformation. The composite-modified asphalt demonstrated a smaller peak strain, higher creep recovery rate, and the lowest non-recoverable creep compliance in the MSCR test. This indicates its superior ability to recover from deformation, reducing rutting, and extend the service life of asphalt pavements.

- (4)

- Revealing the modification mechanism: Microscopic analysis provides insights into the molecular-level changes that drive macroscopic performance improvements. XRD results showed that modifiers altered the crystalline structure of asphalt, while Raman tests revealed that carbon nanotubes enhanced the order of the internal carbon structures (as indicated by the ID/IG ratio). These findings explain the synergistic effects of SBS and carbon nanotubes, which can provide a reference for the development of high-performance asphalt materials in the future.

Overall, the MWCNT/SBS composite-modified asphalt offers significant advantages in enhancing asphalt’s high-temperature performance, providing a cost-effective and reliable material option for modern pavement engineering. In the future, microstructural characterization will be supplemented; the dimensions of performance research will be expanded; low-temperature performance, aging performance test, storage stability test and field experiments will be carried out; and the prediction of life fatigue will be explored to improve the state of research in modified asphalt.

Author Contributions

Methodology, M.S. and E.Z.; Software, Q.D.; Validation, Z.H. and L.H.; Formal analysis, X.H.; Data curation, L.H.; Writing—original draft, Z.H.; Writing—review & editing, Q.D.; Visualization, M.S.; Supervision, M.S. and E.Z.; Project administration, X.H. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Natural Science Foundation of Shandong Province of China (No. ZR2022QE216).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

Author Zuohong He was employed by the company China Railway 23rd Bureau Group Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Zhang, Z.; Liu, H.; Ban, X.; Liu, X.; Guo, Y.; Sun, J.; Liu, Y.; Zhang, S.; Lei, J. Thermosetting resin modified asphalt: A comprehensive review. J. Traffic Transp. Eng. 2023, 10, 1001–1036. [Google Scholar] [CrossRef]

- Jin, D.; Xin, K.; Yin, L.; Mohammadi, S.; Cetin, B.; You, Z. Performance of rubber modified asphalt mixture with tire-derived aggregate subgrade. Constr. Build. Mater. 2024, 449, 138261. [Google Scholar] [CrossRef]

- Yao, H.; Cao, Y.; Zhou, X.; Wang, J.A.; Wang, Q. Improvement on the high-temperature performance and fuel resistance of SBS modified asphalt by hybridizing with polyamide resin. Constr. Build. Mater. 2021, 309, 124987. [Google Scholar] [CrossRef]

- Kakar, M.R.; Mikhailenko, P.; Piao, Z.; Bueno, M.; Poulikakos, L. Analysis of waste polyethylene (PE) and its by-products in asphalt binder. Constr. Build. Mater. 2021, 280, 122492. [Google Scholar] [CrossRef]

- Mojabi, S.A.; Kordani, A.A.; Hajikarimi, P.; Nazari, M. Evaluating fracture performance of stone mastic asphalt with SBS and SEBS modifications. Theor. Appl. Fract. Mech. 2024, 134, 104703. [Google Scholar] [CrossRef]

- Ren, S.; Liang, M.; Fan, W.; Zhang, Y.; Qian, C.; He, Y.; Shi, J. Investigating the effects of SBR on the properties of gilsonite modified asphalt. Constr. Build. Mater. 2018, 190, 1103–1116. [Google Scholar] [CrossRef]

- Loise, V.; Vuono, D.; Policicchio, A.; Teltayev, B.; Gnisci, A.; Messina, G.; Rossi, C.O. The effect of multiwalled carbon nanotubes on the rheological behaviour of bitumen. Colloids Surf. A: Physicochem. Eng. Asp. 2019, 566, 113–119. [Google Scholar] [CrossRef]

- Monteiro, L.; Moghaddam, T.B.; Freed, K.; Shafiee, M.; Maadani, O.; Hashemian, L. Investigation of self-healing properties of nanoclay-modified asphalt binder using two-piece healing test. Can. J. Civ. Eng. 2022, 50, 126–136. [Google Scholar] [CrossRef]

- Ghabchi, R.; Castro, M.P.P. Effect of laboratory-produced cellulose nanofiber as an additive on performance of asphalt binders and mixes. Constr. Build. Mater. 2021, 286, 122922. [Google Scholar] [CrossRef]

- Mansourkhaki, A.; Aghasi, A. Low-temperature fracture resistance of asphalt mixtures modified with carbon nanotubes. In Proceedings of the Institution of Civil Engineers-Transport; Thomas Telford Ltd.: London, UK, 2021; Volume 174, pp. 78–86. [Google Scholar]

- Xue, Z.H.; Fan, X.H. Study on the Performance and Modification Mechanism of Carbon Nanotube—Modified Asphalt. New Build. Mater. 2021, 48, 5. [Google Scholar] [CrossRef]

- Santagata, E.; Baglieri, O.; Tsantilis, L.; Dalmazzo, D. Rheological characterization of bituminous binders modified with carbon nanotubes. Procedia-Soc. Behav. Sci. 2012, 53, 546–555. [Google Scholar] [CrossRef]

- Amin, I.; El-Badawy, S.M.; Breakah, T.; Ibrahim, M.H. Laboratory evaluation of asphalt binder modified with carbon nanotubes for Egyptian climate. Constr. Build. Mater. 2016, 121, 361–372. [Google Scholar] [CrossRef]

- Gong, M.; Yang, J.; Yao, H.; Wang, M.; Niu, X.; Haddock, J.E. Investigating the performance, chemical, and microstructure properties of carbon nanotube-modified asphalt binder. Road Mater. Pavement Des. 2018, 19, 1499–1522. [Google Scholar] [CrossRef]

- Goli, A.; Ziari, H.; Amini, A. Influence of carbon nanotubes on performance properties and storage stability of SBS modified asphalt binders. J. Mater. Civ. Eng. 2017, 29, 04017070. [Google Scholar] [CrossRef]

- Shah, P.M.; Mir, M.S. Investigating the influence of carbon nanotube on the performance of asphalt binder. Prog. Rubber Plast. Recycl. Technol. 2021, 37, 422–440. [Google Scholar] [CrossRef]

- Latifi, H.; Hayati, P. Evaluating the effects of the wet and simple processes for including carbon Nanotube modifier in hot mix asphalt. Constr. Build. Mater. 2018, 164, 326–336. [Google Scholar] [CrossRef]

- Mamun, A.A.; Arifuzzaman, M. Nano-scale moisture damage evaluation of carbon nanotube-modified asphalt. Constr. Build. Mater. 2018, 193, 268–275. [Google Scholar] [CrossRef]

- Zhu, Y.Q.; Shu, B.A. Influence of Carbon Nanotubes on the High and Low Temperature Performance of SBS—Modified Asphalt. J. Wuhan Univ. Technol. 2018, 42, 103–107. [Google Scholar]

- Fu, Z.; Tang, Y.J.; Sun, Q.Y.; Wang, Y.J.; Liu, S.R. Study on the Pavement Performance and Compatibility of Carbon Nanotube/SBS Composite—Modified Asphalt. Appl. Chem. Ind. 2021, 50, 2031–2036. [Google Scholar]

- Sun, Q.Y. Study on the Rheological Properties of Carbon Nanotube/SBS Composite—Modified Asphalt. Master’s Thesis, Chang’an University, Xi’an, China, 2020. [Google Scholar]

- Obukhova, S.; Korolev, E.; Gladkikh, V. The Influence of Single-Walled Carbon Nanotubes on the Aging Performance of Polymer-Modified Binders. Materials 2023, 16, 7534. [Google Scholar] [CrossRef]

- Tang, Y.; Fu, Z.; Ma, F.; Liu, J.; Sun, Q.; Li, C. Carbon nanotubes for improving rheological and chemical properties of styrene–butadiene–styrene modified asphalt binder. Int. J. Pavement Eng. 2023, 24, 2211212. [Google Scholar] [CrossRef]

- Chen, J.; Huang, Z.; Wang, H.; Yang, Z.; Zhang, T. Investigating the rheological properties of styrene-butadiene-styrene-based high-viscosity modified asphalt using carbon nanotubes. Sustainability 2022, 15, 71. [Google Scholar] [CrossRef]

- Wang, R.; Yue, M.; Xiong, Y.; Yue, J. Experimental study on mechanism, aging, rheology and fatigue performance of carbon nanomaterial/SBS-modified asphalt binders. Constr. Build. Mater. 2020, 268, 121189. [Google Scholar] [CrossRef]

- Yu, C.H.; Hu, K.; Chen, G.X.; Chang, R.; Wang, Y. Molecular dynamics simulation and microscopic observation of compatibility and interphase of composited polymer modified asphalt with carbon nanotubes. J. Zhejiang Univ.-Sci. A 2021, 22, 528–546. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, X.; Ji, W.; Zhang, F.; Otto, F. Characterizing the mechanical properties of Multi-Layered CNTs reinforced SBS modified Asphalt-Binder. Constr. Build. Mater. 2021, 296, 123658. [Google Scholar] [CrossRef]

- Wang, P.; Zhai, F.; Dong, Z.J.; Wang, L.Z.; Liao, J.P.; Li, G.R. Micromorphology of asphalt modified by polymer and carbon nanotubes through molecular dynamics simulation and experiments: Role of strengthened interfacial interactions. Energy Fuels 2018, 32, 1179–1187. [Google Scholar] [CrossRef]

- Shu, B.; Wu, S.; Pang, L.; Javilla, B. The utilization of multiple-walled carbon nanotubes in polymer modified bitumen. Materials 2017, 10, 416. [Google Scholar] [CrossRef] [PubMed]

- Nie, G.; Huang, W.; Wu, K.; Cai, X.; Huang, J.; Xie, J.; Zheng, Y. Modification Mechanism of MWCNTs and SBS Composite modified Asphalt Binder: Laboratory Investigation and Molecular Dynamic Simulation. J. Mater. Civ. Eng. 2024, 36, 04024279. [Google Scholar] [CrossRef]

- JTG E20-2017; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. People’s Transportation Press: Beijing, China, 2017.

- Xie, S.R. Experimental Study on the Influence of Carbon Nanotubes on the Performance of SBS Modified Asphalt and Mixtures. Master’s Thesis, Northeast Forestry University, Harbin, China, 2020. [Google Scholar]

- Yang, Z.H. Research on Rheological Properties and Modifier Dosage of SBS Modified Asphalt. Master’s Thesis, Chang’an University, Xi’an, China, 2011. [Google Scholar] [CrossRef]

- Zhu, H.; Wei, J.; Gong, M.; Yao, H.; Yang, J. Research Progress of Carbon Nanotube Modified Asphalt. Acta Pet. Sin. 2017, 33, 386–394. [Google Scholar]

- ASTM D7405; Standard Test Method for Multiple Stress Creep and Recovery(MSCR) of Asphalt Binder Using a Dynamic Shear Rheometer. ASTM: Washington, DC, USA, 2010.

- Ministry of Transport of the People’s Republic of China. Test Specifications for Asphalt and Asphalt Mixtures in Highway Engineering (JTG E20-2011); China Communications Press: Beijing, China, 2011.

- Li, F.J.; Shen, J.A. Implementation Manual of Technical Specifications for Construction of Highway Asphalt Pavement; China Communications Press: Beijing, China, 2005. [Google Scholar]

- ASTM D2493/2493M; ASTM Standard Viscosity-Temperature Chart for Asphalt. ASTM: West Conshohocken, PA, USA, 2009.

- Shen, J.A. Road Performance of Asphalt and Asphalt Mixtures; China Communications Press: Beijing, China, 2001. [Google Scholar]

- Huang, W.; Guo, R.X.; Zhou, B.; Yan, F.; Li, N. Research on Viscoelastic Behavior of SBS/PPA Modified Asphalt Based on Frequency Sweep. J. Highw. Transp. Res. Dev. 2016, 12, 134–136. [Google Scholar]

- Williams, M.L.; Landel, R.F.; Ferry, J.D. The Temperature Dependence of Relaxation Mechanisms in Amorphous Polymers and Other Glass-Forming Liquid. J. Am. Chem. Soc. 1955, 77, 3701–3707. [Google Scholar] [CrossRef]

- Rusbintardjo, G.; Hainin, M.R.; Yusoff, N.I.M. Fundamental and rheological properties of oil palm fruit ash modified bitumen. Constr. Build. Mater. 2013, 49, 702–711. [Google Scholar] [CrossRef]

- Bounos, G.; Andrikopoulos, K.S.; Karachalios, T.K.; Voyiatzis, G.A. Evaluation of multi-walled carbon nanotube concentrations in polymer nanocomposites by Raman spectroscopy. Carbon Int. J. Spons. By Am. Carbon Soc. 2014, 76, 301–309. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).