Influence of the Surface Rolling Process on the Tribological and Electrical Behavior of T2 Copper Elastic Contact Pairs

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.3. Data Processing

2.3.1. Friction Coefficient

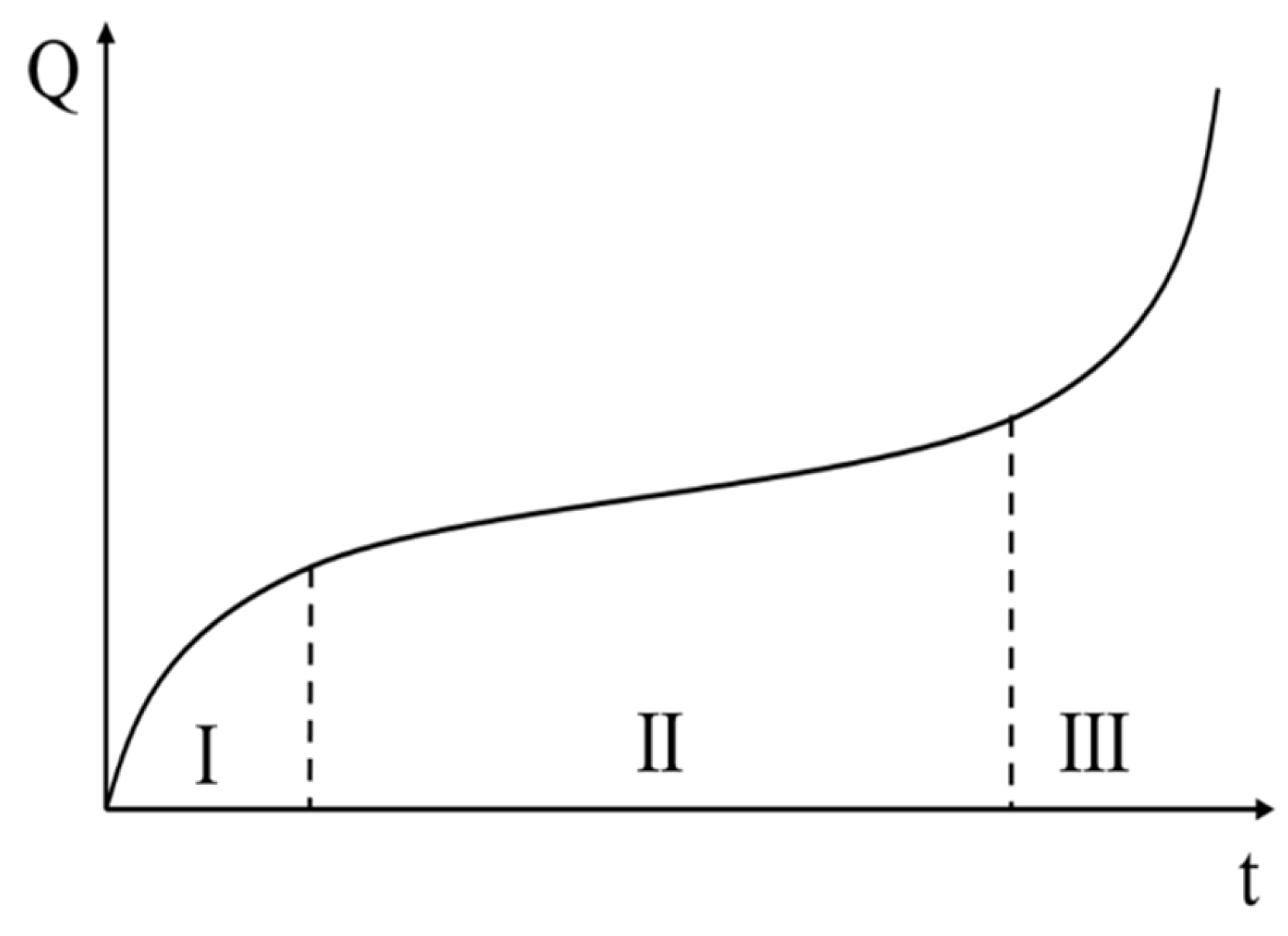

2.3.2. Wear Rate

3. Results

3.1. Effect of Surface Mechanical Rolling on the Hardness of T2 Copper Plate

3.2. Effect of Surface Mechanical Rolling on the Carrier Friction and Wear Performance of T2 Copper Plates

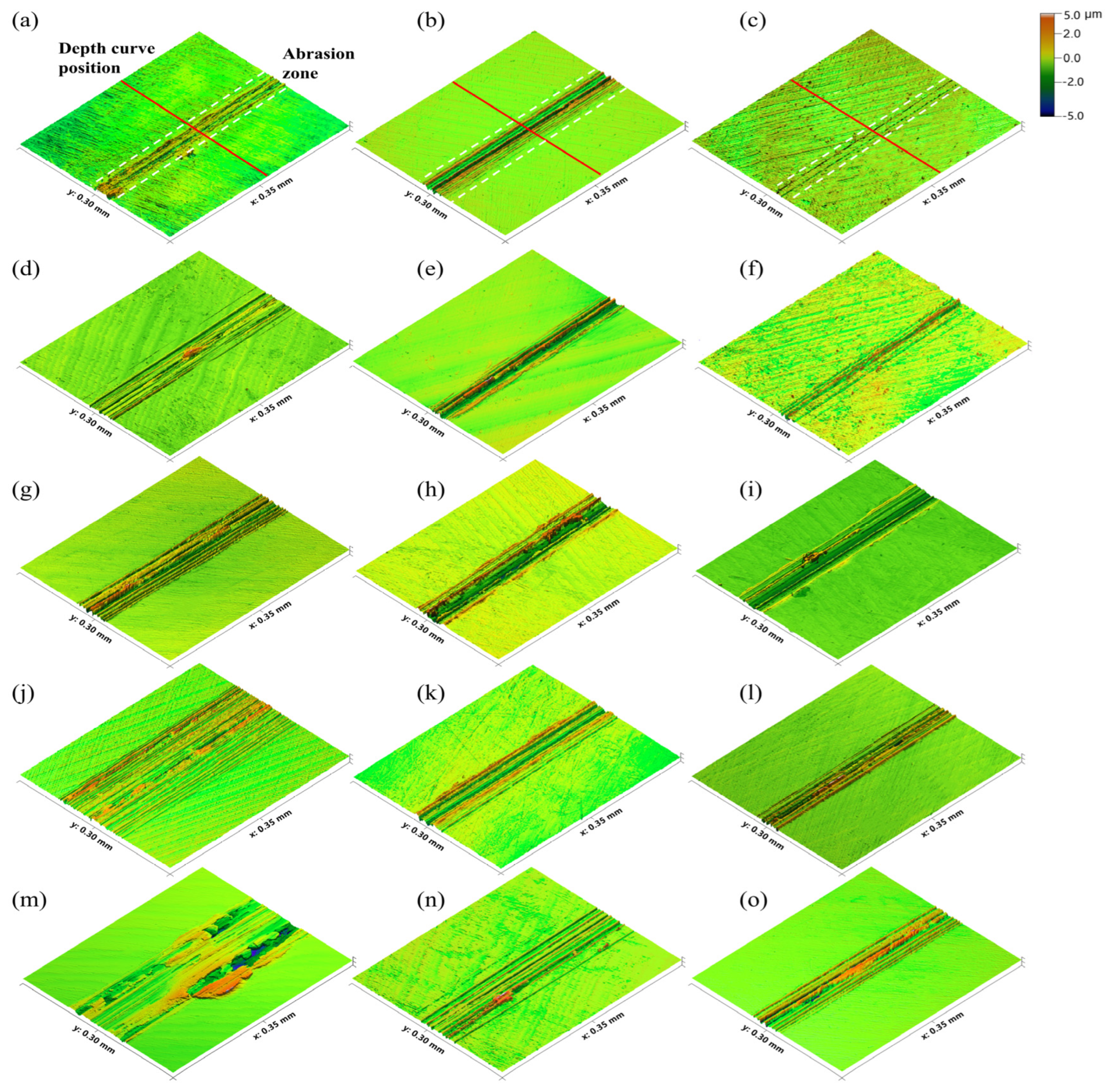

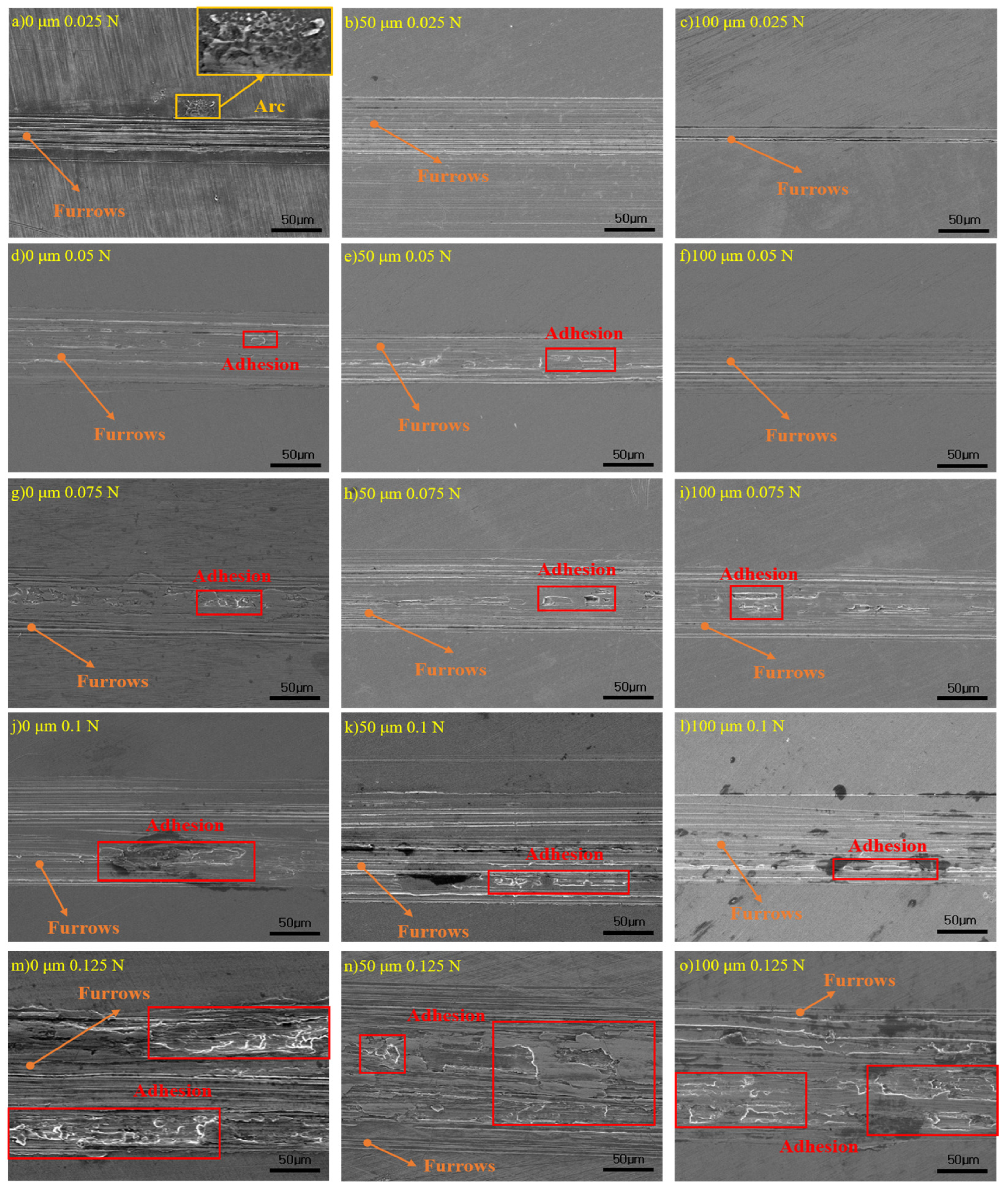

3.3. Effect of Surface Mechanical Rolling Feed Depth on the Current-Carrying Friction and Wear Behavior of T2 Copper Plates

4. Discussion

5. Conclusions

- (1)

- Under the experimental conditions, the contact resistance varied within the range of 0.0065 Ω to 0.0310 Ω with changes in surface rolling feed amount and applied load. The wear rate gradually decreased with increasing feed amount; at a feed of 100 μm and a load of 0.025 N, the material exhibited the lowest wear rate, which was reduced by 63.1% compared to the untreated specimen.

- (2)

- Under all test conditions, plowing was consistently observed as the primary wear mechanism, with occasional occurrences of arc erosion. As the rolling feed amount increased, the wear scar width decreased, and both the onset and progression of adhesive wear were relatively delayed.

- (3)

- From an engineering application perspective, for connectors that are not highly sensitive to contact resistance, surface mechanical rolling can prolong service life without compromising electrical performance. These findings provide practical guidance for reducing wear under current-carrying friction conditions.

- (4)

- The current-carrying tribological performance of connectors is influenced not only by post-processing treatments but also by the initial forming methods (e.g., stamping), which affect the surface microstructure and properties. Future research could focus on the relationship between forming techniques and the resulting surface condition and wear behavior under current-carrying friction. This direction is expected to contribute positively to the optimization of connector performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ding, R.; Ni, J.; Huang, S. Multi-physical field coupling contact resistance study of electrical connectors. Electrotech. Electr. 2023, 7, 21–26. [Google Scholar]

- Zhao, L.; Deng, T.; Kong, Z.; Gong, D.; Yuan, Y. Failure Analysis and Targeted Quality Assurance Measures for Aerospace Electrical Connectors. Electromech. Compon. 2024, 44, 34–38. [Google Scholar]

- Song, J.; Hilmert, D.; Kiel, F. Mechanisms of failure and state analysis of electrical connectors in automobiles. Eng. Fail. Anal. 2025, 173, 109427. [Google Scholar] [CrossRef]

- Editorial Board of China Journal of Highway and Transport. Review of Chinese Automotive Engineering Research 2023. China J. Highw. Transp. 2023, 36, 1–192. [Google Scholar]

- Ren, W.; Jiao, Y.; Zhai, G. Review of Fretting Wear for Electrical Connector. Electromech. Compon. 2010, 30, 28–38. [Google Scholar]

- Wang, N. Reliability Analysis of Electrical Connector Contact Pieces; Xi’an Technological University: Xi’an, China, 2020. [Google Scholar]

- Yang, X.; Wu, C.; He, Y.; Zhang, C.; Ren, W. Research on Contact Resistance Degradation Mechanisms of Relay with Contact Bridge Structure Under Continuous Current Loading. Electr. Energy Manag. Technol. 2025, 1–5. [Google Scholar] [CrossRef]

- Yang, Z.; Li, W.; Zheng, X.; Zhao, M.; Zhang, Y. The Influence of Initial Surface Roughness on the Current-Carrying Friction Process of Elastic Pairs. Materials 2025, 18, 370. [Google Scholar] [CrossRef] [PubMed]

- Lu, J.; Zheng, B.; Guo, B.; Wang, Y.; Li, W.; Liu, Y. The current-carrying damage mechanism of gradient copper-based composite ceramics with different sliding speeds. Ceram. Int. 2025, 51, 3837–3845. [Google Scholar] [CrossRef]

- Lu, X.; Zhang, W.; Xiao, Q.; Zhong, Y.; Cao, Y.; Guan, X.; Zhang, S.; Zheng, Y.; Gao, M.; Yang, W.; et al. Study on the effect of different structural parameters on the wear mechanism in the anchor-segment joint of the rigid overhead catenary. Tribol. Int. 2024, 191, 109108. [Google Scholar] [CrossRef]

- Tyrer, N.; Yang, F.; Barber, G.; Pang, B.; Wang, B. Tribological Behavior of Electrical Connector Coatings Under Reciprocating Motion. J. Tribol. 2022, 144, 91401. [Google Scholar] [CrossRef]

- GB/T 41036-2021; General Specification for Super High-Low Temperature Circular Electrical Connector for Space Applications: GB/T 41036-2021. Standards Press of China: Beijing, China, 2021.

- Yang, F. Electrical connector industry basic common technology outlook. Electromechanical Compon. 2023, 43, 53–60+63. [Google Scholar]

- Liang, X.M.; Xing, Y.Z.; Li, L.; Yuan, W.; Wang, G. An experimental study on the relation between friction force and real contact area. Sci. Rep. 2021, 11, 20366. [Google Scholar] [CrossRef] [PubMed]

- Greenwood, J.A.; Williamson, J.B.P. Contact of nominally flat surfaces. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1966, 295, 300–319. [Google Scholar]

- Kogut, L.; Etsion, I. Elastic-plastic contact analysis of a sphere and a rigid flat. J. Tribol. 2002, 124, 305–311. [Google Scholar] [CrossRef]

- Wen, S.; Huang, P.; Tian, Y. Principles of Tribology, 5th ed.; Tsinghua University Press: Beijing, China, 2018; pp. 297–298. [Google Scholar]

- Nie, J.P.; Jiang, Y.; Guan, Q. Effect of ultrasonic surface rolling treatment on the friction and wear performance of 7075 aluminum alloy. J. Cent. South Univ. Nat. Sci. Ed. 2025, 56, 443–457. [Google Scholar]

- Zheng, K.; Zhao, X.; Mou, G.; Ren, Z. Surface Quality, Friction and Wear Properties of TC11 Titanium Alloy Strengthened Using Ultrasonic Rolling. J. Mech. Eng. 2024, 60, 137–151. [Google Scholar]

- Zhuang, H.; Ji, D.; Shen, M.; Liu, S.; Xiao, Y.; Xiong, G. Tribological behavior of T2 copper induce by surface mechanical rolling treatment under current carrying condition. J. Chin. Nonferrous Met. 2023, 33, 521–530. [Google Scholar]

- Sun, J.; Zhang, Y.; Sun, Z.; Yu, T.; Wang, G. Microstructure and tribological property of laser cladding Stellite 6 alloy by laser remelting and ultrasonic surface rolling. Surf. Coat. Technol. 2025, 495, 131560. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, Y.; Chen, F.; ShangGuan, B.; Li, X.; Tian, L. Overview of Cu-C Sliding Contact Materials with Electrical Current Produced by Powder Metallurgy. Mater. Rev. 2012, 26, 106–110+125. [Google Scholar]

| Materials | Cu | Zn | Pb | Sb | S | Fe | Impurities |

|---|---|---|---|---|---|---|---|

| T2 | 99.95 | - | 0.005 | 0.002 | 0.005 | 0.005 | Bal. |

| H62 | 60.5–63.5 | Bal. | ≤0.08 | ≤0.005 | - | ≤0.15 | ≤0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Zhao, M.; Wang, X.; Tian, X.; Hu, K.; Li, W.; Zhang, Y. Influence of the Surface Rolling Process on the Tribological and Electrical Behavior of T2 Copper Elastic Contact Pairs. Coatings 2025, 15, 615. https://doi.org/10.3390/coatings15050615

Yang Z, Zhao M, Wang X, Tian X, Hu K, Li W, Zhang Y. Influence of the Surface Rolling Process on the Tribological and Electrical Behavior of T2 Copper Elastic Contact Pairs. Coatings. 2025; 15(5):615. https://doi.org/10.3390/coatings15050615

Chicago/Turabian StyleYang, Zhenghai, Mengfeng Zhao, Xiaowei Wang, Xiaojun Tian, Kaifeng Hu, Wenbo Li, and Yongzhen Zhang. 2025. "Influence of the Surface Rolling Process on the Tribological and Electrical Behavior of T2 Copper Elastic Contact Pairs" Coatings 15, no. 5: 615. https://doi.org/10.3390/coatings15050615

APA StyleYang, Z., Zhao, M., Wang, X., Tian, X., Hu, K., Li, W., & Zhang, Y. (2025). Influence of the Surface Rolling Process on the Tribological and Electrical Behavior of T2 Copper Elastic Contact Pairs. Coatings, 15(5), 615. https://doi.org/10.3390/coatings15050615