Tribological Performance of TiN–WS2 Soft–Hard Multifunctional Composite Coatings Deposited by Magnetron Sputtering

Abstract

1. Introduction

2. Experiments

2.1. Equipment and Materials

2.2. Experimental Methods

2.3. Coating Characterisation

3. Results and Discussion

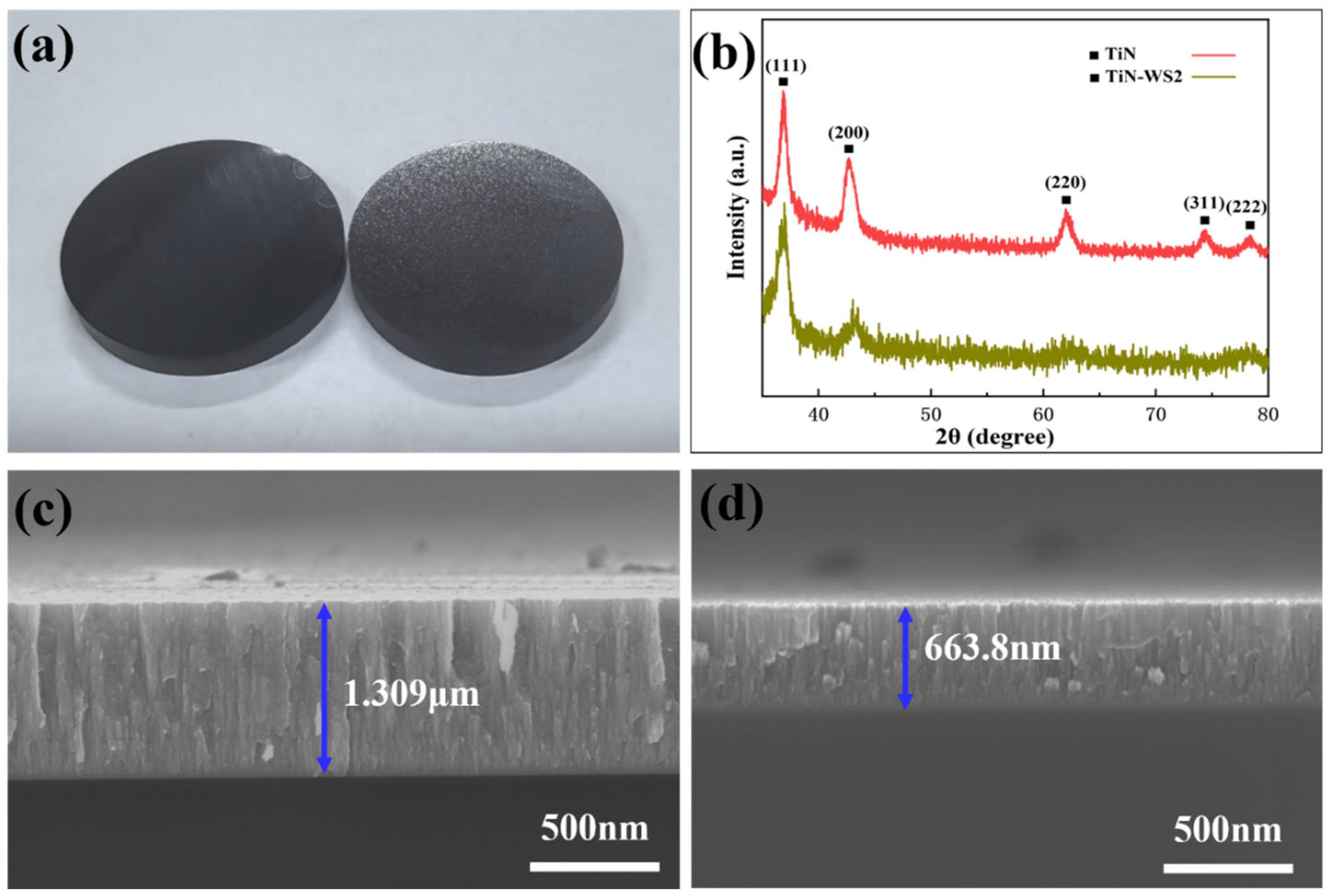

3.1. Thin Film Morphology and Structural Characterization

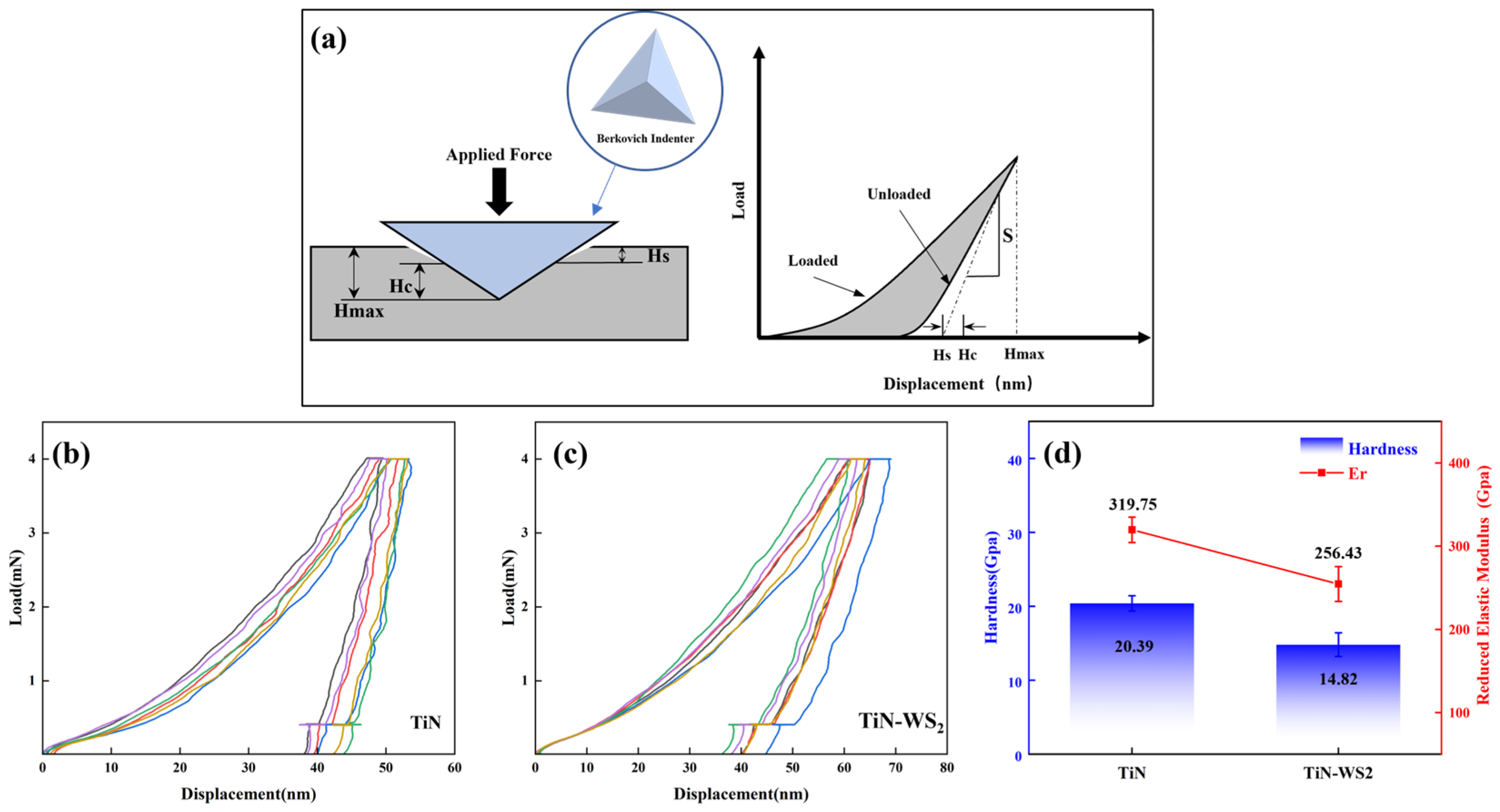

3.2. Hardness Analysis of the Coatings

3.3. Adhesion Strength Evaluation of the Coatings

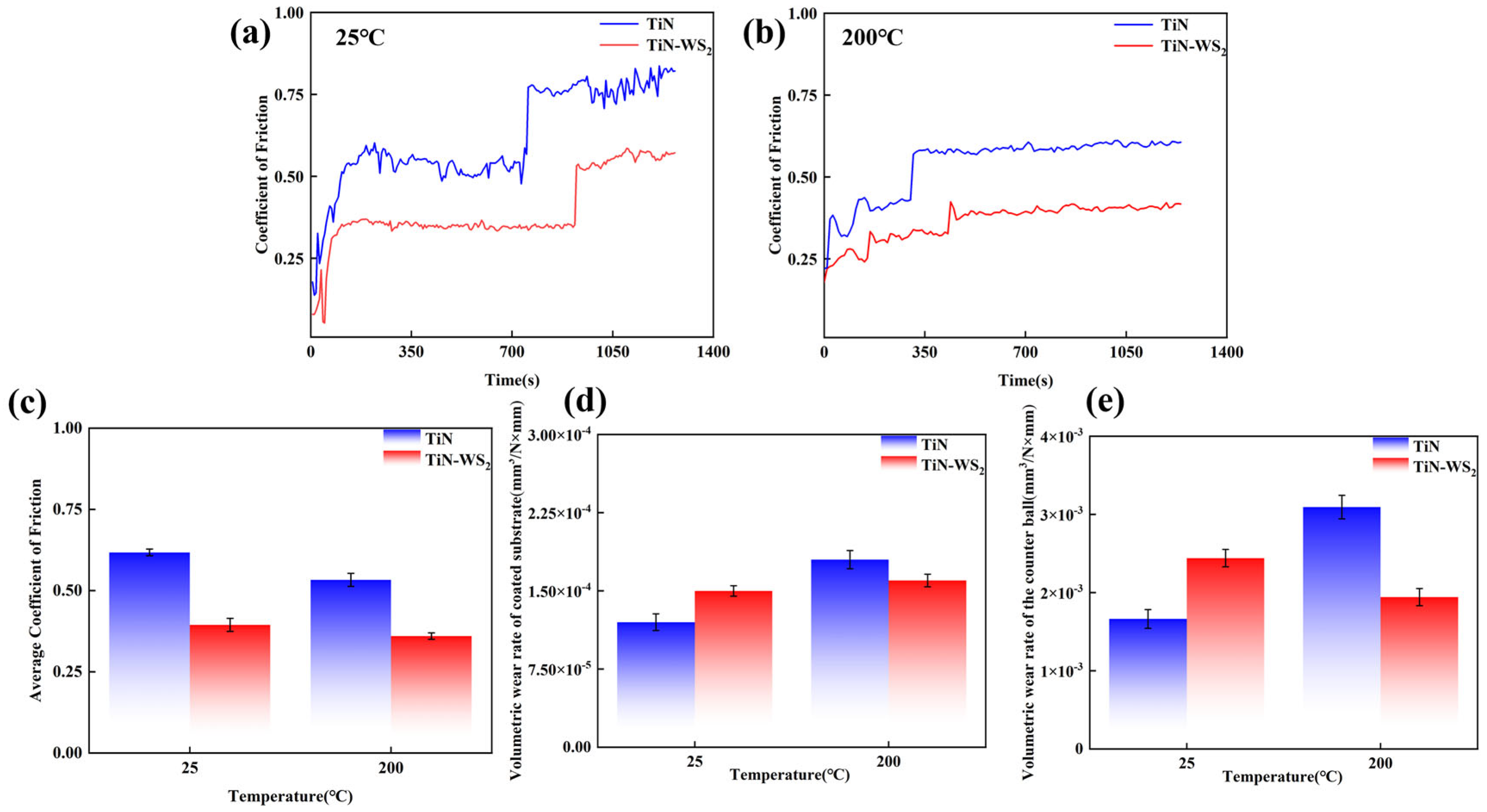

3.4. Tribological Performance and Analysis of the Coatings

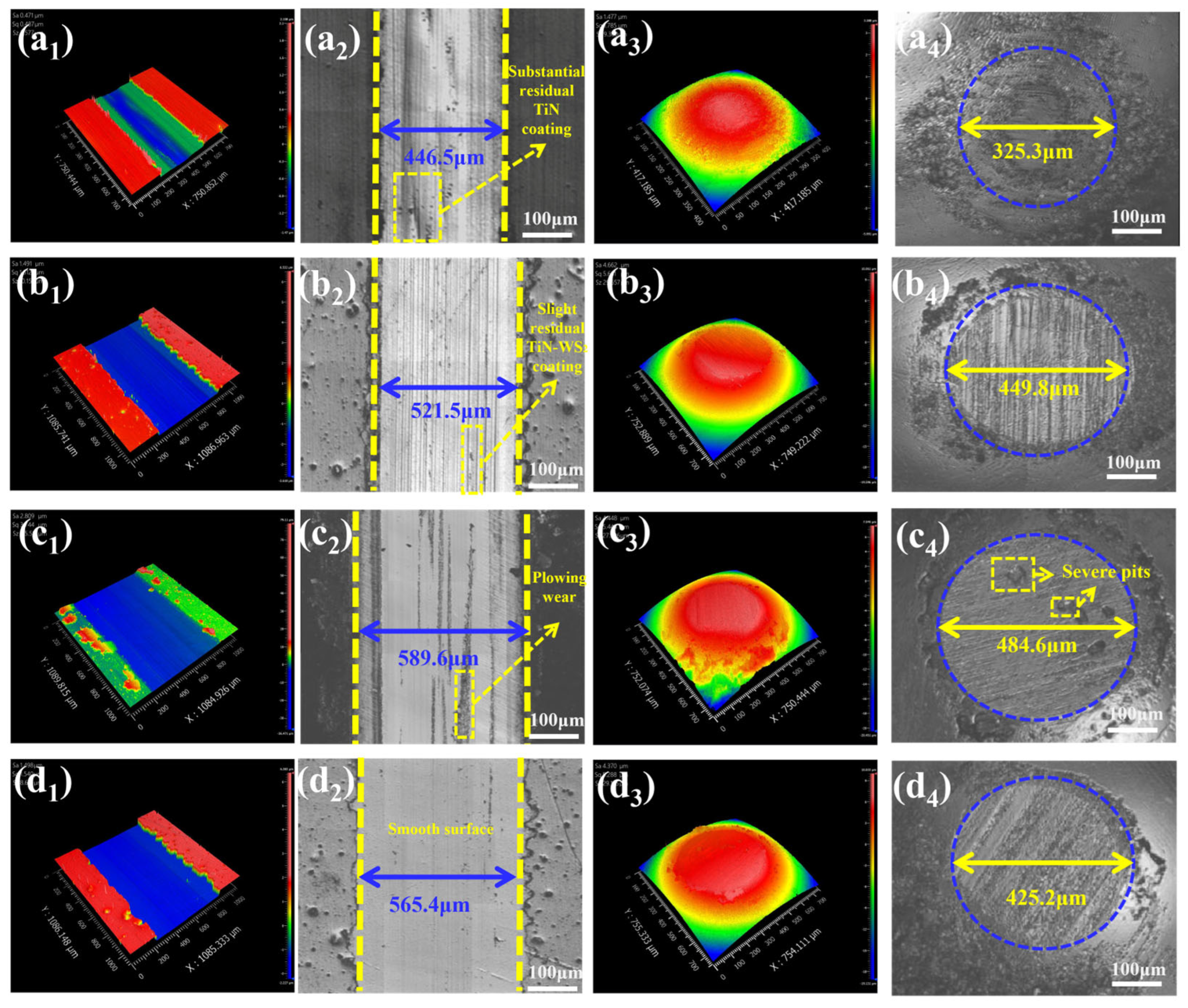

3.5. Post-Test Wear Track Analysis of Ball-on-Disk Tribological Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, J.J.; Zhang, G.Q.; Fan, G.H. Effects of tool coating materials and coating thickness on cutting temperature distribution with coated tools. Int. J. Appl. Ceram. Technol. 2022, 19, 2276–2284. [Google Scholar] [CrossRef]

- Mahesh, L.; Vinyas, M.; Reddy, J.S.; Muralidhara, B.K. Investigation of the microstructure and wear behaviour of titanium compounds reinforced aluminium metal matrix composites. Mater. Res. Express 2019, 6, 026516. [Google Scholar] [CrossRef]

- Ye, F.X.; Zhao, H.J.; Tian, X.B. The elevated-temperature wear properties of TiN and TiN/W2N coatings. Mater. Res. Express 2018, 5, 106404. [Google Scholar] [CrossRef]

- da Silva, F.C.; Macedo, M.D.; Miscione, J.M.C.; Fontana, L.C.; Sagás, J.C.; Cozza, R.C.; Schön, C.G. Use of ball-cratering wear test and nanoscratching test to compare the wear resistance of homogeneous and functionally graded titanium nitride thin films. J. Mater. Res. Technol. 2023, 22, 54–65. [Google Scholar] [CrossRef]

- Cheng, P.; DelaCruz, S.; Tsai, D.S.; Wang, Z.T.; Carraro, C.; Maboudian, R. Enhanced thermal stability by introducing TiN diffusion barrier layer between W and SiC. J. Am. Ceram. Soc. 2019, 102, 5613–5619. [Google Scholar] [CrossRef]

- Carabillò, A.; Sordetti, F.; Querini, M.; Magnan, M.; Azzolini, O.; Fedrizzi, L.; Lanzutti, A. Tribological optimization of titanium-based PVD multilayer hard coatings deposited on steels used for cold rolling applications. Mater. Today Commun. 2023, 34, 105043. [Google Scholar] [CrossRef]

- Lozovan, A.; Savushkina, S.; Lyakhovetsky, M.; Nikolaev, I.; Betsofen, S.; Kubatina, E. Investigation of Structural and Tribological Characteristics of TiN Composite Ceramic Coatings with Pb Additives. Coatings 2023, 13, 1463. [Google Scholar] [CrossRef]

- Intanon, N.; Wisitsoraat, A.; Saikaew, C. An application of statistical quality tools for process robustness and sustainability of titanium nitride coating on a machine component of a fishing net weaving machine. J. Clean. Prod. 2022, 363, 132603. [Google Scholar] [CrossRef]

- Liu, G.; Liao, T.C.; Wang, S.Z.; Li, Y.Q.; Guo, H.B.; Wu, H.H.; Huang, Y.H.; Yong, Q.L.; Mao, X.P. Revealing the precipitation kinetics of multi-stage and multi-scale Ti-bearing precipitation in a 460 MPa grade HSLA steel. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2024, 890, 145941. [Google Scholar] [CrossRef]

- Li, Z.H.; Liu, L.; You, X.; Yi, J.H.; Bao, R.; Zhu, M.Y.; Lu, S.; Pai, J.J. Cooperative enhancement of mechanical and tribological properties through tailoring TiN transition interface in boron nitride nanosheets reinforced copper composites. Rare Met. 2024, 43, 5202–5215. [Google Scholar] [CrossRef]

- Kupczyk, M.; Lelen, M.; Józwik, J.; Tomilo, P. Modeling Material Machining Conditions with Gear-Shaper Cutters with TiN0.85-Ti in Adhesive Wear Dominance Using Machine Learning Methods. Materials 2024, 17, 5567. [Google Scholar] [CrossRef]

- Zuo, B.; Yu, L.H.; Xu, J.H. Effect of Ag content on friction and wear properties of TiCN/Ag films in different service environments. Vacuum 2023, 212, 112029. [Google Scholar] [CrossRef]

- Ye, T.C.; Le, K.; Wang, G.G.; Ren, Z.H.; Liu, Y.Z.; Zheng, L.W.; Tian, H.; Xu, S.S. Structure Modulation and Self-Lubricating Properties of Porous TiN-MoS2 Composite Coating Under Humidity-Fluctuating Conditions. Lubricants 2025, 13, 61. [Google Scholar] [CrossRef]

- Ronadson, B.J.; Vijayan, K.; Sanmugam, S.; Badhirappan, G.P. Improving dry machining performance of surface modified cutting tools through combined effect of texture and TiN-WS2 coating. J. Manuf. Process. 2023, 85, 101–108. [Google Scholar] [CrossRef]

- Rajakumar, N.; Subramanian, K.; Sozhan, G.; Ramasamy, K. Tribological studies of the sintered bronze-tungsten disulfide composites. Mater. Res. Express 2019, 6, 086568. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, R.Z.; Zhang, D.G.; Wang, Z.R.; Gu, X.L.; Wang, H. Enhancing tribological properties of carbon-based films through catalytic Ni3C. Diam. Relat. Mater. 2024, 144, 110957. [Google Scholar] [CrossRef]

- Vadivelmurugan, A.; Anbazhagan, R.; Lai, J.Y.; Tsai, H.C. Paramagnetic properties of manganese chelated on glutathione-exfoliated MoS2. Colloids Surf. A-Physicochem. Eng. Asp. 2021, 608, 125432. [Google Scholar] [CrossRef]

- Li, Q.; Zheng, S.X.; Pu, J.B.; Wang, W.Z.; Li, L.; Wang, L.P. Revealing the failure mechanism and designing protection approach for MoS2 in humid environment by first-principles investigation. Appl. Surf. Sci. 2019, 487, 1121–1130. [Google Scholar] [CrossRef]

- Dam, A.T.; Le, L.T.; Tran, P.D. Electrochemical unzipping of multiple-walled WS2 nanotubes for synthesis of WS2 nanoribbons being an attractive H2 evolution catalyst. Mater. Lett. 2024, 377, 137415. [Google Scholar] [CrossRef]

- Liu, J.; Yan, Z.; Hao, J.Y.; Liu, W.M. Two strategies to improve the lubricating performance of WS2 film for space application. Tribol. Int. 2022, 175, 107825. [Google Scholar] [CrossRef]

- Yan, Z.; Zhou, H.B.; Zhang, X.; Liu, J.; Wang, C.; Lu, X.L.; Hao, J.Y.; Sui, X.D. Interactive effect between WS2 films with different structures and space oils for improvement of tribological performance. Tribol. Int. 2022, 170, 107431. [Google Scholar] [CrossRef]

- Liang, D.W.; Zhang, C.; Shen, C.Y.; Cao, G.T.; Liao, N.B.; Zhang, M. First-Principles Study of Superlubricity of Two-Dimensional Graphene/ WS2 Heterostructures. Tribol. Lett. 2025, 73, 12. [Google Scholar] [CrossRef]

- Tian, J.Y.; Lu, K.; Liu, X.J. Hybrid heterostructure of transition metal dichalcogenides as potential photocatalyst for hydrogen evolution. Appl. Surf. Sci. 2022, 599, 154057. [Google Scholar] [CrossRef]

- Lu, Z.X.; Zhang, C.Z.; Zeng, C.; Ren, S.M.; Pu, J.B. A novel design by constructing MoS2/WS2 multilayer film doped with tantalum toward superior friction performance in multiple environment. J. Mater. Sci. 2021, 56, 17615–17631. [Google Scholar] [CrossRef]

- Asgary, S.; Ramezani, A.H.; Nejad, Z.E. Characterization of high quality, monolayer WS2 domains via chemical vapor deposition technique. Appl. Phys. A-Mater. Sci. Process. 2022, 128, 139. [Google Scholar] [CrossRef]

- Kim, S.J.; Luo, D.; Park, K.; Choe, M.; Kim, D.W.; Wang, M.; Jung, W.B.; Lee, Z.; Ruoff, R.S.; Jung, H.T. Mapping Graphene Grain Orientation by the Growth of WS2 Films with Oriented Cracks. Chem. Mater. 2020, 32, 7484–7491. [Google Scholar] [CrossRef]

- Bouska, M.; Nazabal, V.; Gutwirth, J.; Halenkovic, T.; Nemec, P. Radio-frequency magnetron co-sputtered Ge-Sb-Te phase change thin films. J. Non-Cryst. Solids 2021, 569, 121003. [Google Scholar] [CrossRef]

- Ren, Z.Y.; Chen, L.P.; Liu, X.M.; Li, G.J.; Wang, K.; Wang, Q. Preparation, characterization and simulation of Al@SiO2 nanoparticle composite films with infrared-visible stealth. Infrared Phys. Technol. 2020, 111, 103472. [Google Scholar] [CrossRef]

- Zhou, Q.; Ou, Y.X.; Li, F.Q.; Ou, C.Y.; Xue, W.B.; Liao, B.; Hua, Q.S.; Xu, Y.F.; Cao, J.D.; Qu, G.S. Friction and Wear of Hard Yet Tough TiN Coatings Deposited Using High-Power Impulse Magnetron Sputtering. Coatings 2024, 14, 598. [Google Scholar] [CrossRef]

- Cristea, D.; Velicu, I.L.; Cunha, L.; Barradas, N.; Alves, E.; Craciun, V. Tantalum-Titanium Oxynitride Thin Films Deposited by DC Reactive Magnetron Co-Sputtering: Mechanical, Optical, and Electrical Characterization. Coatings 2022, 12, 36. [Google Scholar] [CrossRef]

- Sun, Y.L.; Nabatame, T.; Chung, J.W.; Sawada, T.; Miura, H.; Miyamoto, M.; Tsukagoshi, K. Compositional changes between metastable SnO and stable SnO2 in a sputtered film for p-type thin-film transistors. Thin Solid Film. 2024, 807, 140548. [Google Scholar] [CrossRef]

- Gardella, M.; Zambito, G.; Ferrando, G.; Barusso, L.F.; Chennuboina, R.; Repetto, L.; Barelli, M.; Giordano, M.C.; de Mongeot, F.B. Maskless Synthesis of van der Waals Heterostructure Arrays Engineered for Light Harvesting on Large Area Templates. Small 2025, 21, e2400943. [Google Scholar] [CrossRef]

- Deng, W.H.; Wang, J.; Yang, M.; Li, G.; Xiong, Q.L.; Yin, Y.J. Effect of Brazing Temperature on Microstructure and Mechanical Properties of YG8/IN718 Joints. Trans. Indian Inst. Met. 2023, 76, 3253–3261. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Song, W.B.; Ji, H.Z. Study on Friction Reduction and Wear Resistance of Surface Micro-texture of YG8-Ti6Al4V Friction Pair. Integr. Ferroelectr. 2021, 218, 225–238. [Google Scholar] [CrossRef]

- Xiang, Y.T.; Xiong, J.; Xiang, Q.Z.; Guo, Z.X.; Li, L.S.; Chen, Y.F. Effect of Cr ion etching on the structure and properties of TiAlN-coated cemented carbide. Int. J. Refract. Met. Hard Mater. 2023, 116, 106357. [Google Scholar] [CrossRef]

- De Maio, D.; D’Alessandro, C.; Caldarelli, A.; De Luca, D.; Di Gennaro, E.; Casalino, M.; Iodice, M.; Gioffre, M.; Russo, R.; Musto, M. Multilayers for efficient thermal energy conversion in high vacuum flat solar thermal panels. Thin Solid Film. 2021, 735, 138869. [Google Scholar] [CrossRef]

- Changyom, P.; Leksakul, K.; Charoenchai, N.; Boonyawan, D. Designed and Produced the Rotary Substrate Holder and Its Optimized in Angular DC Magnetron Co- Sputtering System. Chiang Mai J. Sci. 2022, 49, 1633–1643. [Google Scholar] [CrossRef]

- Qiao, H.; Liu, M.H.; Xiang, Y.; Xu, X.L.; Wang, Z.; Wu, W.X.; Wang, Y.Q. Low-Friction Coatings Grown on Cemented Carbides by Modulating the Sputtering Process Parameters of TiN Targets. Coatings 2025, 15, 329. [Google Scholar] [CrossRef]

- Abd El-Fattah, H.A.; El-Mahallawi, I.S.; Shazly, M.H.; Khalifa, W.A. Optical Properties and Microstructure of TiNxOy and TiN Thin Films before and after Annealing at Different Conditions. Coatings 2019, 9, 22. [Google Scholar] [CrossRef]

- Ito, S.; Teraoka, K.; Imai, S.; Matsunaga, N.; Jang, J.; Muneta, I.; Kakushima, K.; Wakabayashi, H. Crystallinity improvement of physical-vapor-deposited WS2 films by controlling particle energy. Jpn. J. Appl. Phys. 2025, 64, 02sp08. [Google Scholar] [CrossRef]

- Ma, B.; Yuan, H.; He, Z.; Shang, H.; Hou, Y.; Ju, H.; Fernandes, F. Microstructure and Mechanical Properties of Magnetron Sputtering TiN-Ni Nanocrystalline Composite Films. Coatings 2023, 13, 1902. [Google Scholar] [CrossRef]

- Liu, K.; Yan, H.; Zhang, P.; Zhao, J.; Yu, Z.; Lu, Q. Wear Behaviors of TiN/WS2 + hBN/NiCrBSi Self-Lubricating Composite Coatings on TC4 Alloy by Laser Cladding. Coatings 2020, 10, 747. [Google Scholar] [CrossRef]

- Zhang, Z.; Qin, X.; Ma, S.; Liu, Y.; Wang, L.; Zhao, X. Synergistic Effect of WS2 and Micro-Textures to Inhibit Graphitization and Delamination of Micro-Nano Diamond-Coated Tools. Crystals 2023, 13, 1034. [Google Scholar] [CrossRef]

- Jakab, M.; Ali, O.I.; Gyurika, I.G.; Korim, T.; Telegdi, J. The Tribological Behavior of TiN/TiC CVD Coatings under Dry Sliding Conditions against Zirconia and Steel Counterparts. Coatings 2023, 13, 832. [Google Scholar] [CrossRef]

- Zhao, Z.L.; Li, Y.F.; Li, Y.L.; Zheng, Q.L. Effect of Ti and TiN inter-layers on the composite interfacial wettability and composite abrasive wear resistance. Tribol. Int. 2025, 207, 110615. [Google Scholar] [CrossRef]

| Substrate | Amount | Dimensions (mm) | Serve as |

|---|---|---|---|

| YG8 | 2 | Φ 20 × 2.5 | Mechanical performance test (Ra ≈ 0.025 μm). |

| Si (111) | 2 | 10 × 10 × 0.5 | Microscopic morphology, physical phase testing, etc. |

| No. | 1 | 2 | |

|---|---|---|---|

| Coating Material | TiN | TiN-WS2 | |

| Target Material | TiN | TiN | WS2 |

| Power Supply Type | RF | DC | RF |

| Sputtering Power (W) | 150 | 150 | 120 |

| Working Pressure (Pa) | 0.5 | 0.5 | |

| Deposition Time (min) | 180 | 180 | |

| Deposition Temperature (°C) | 100 | 100 | |

| Substrate Rotation Speed (rpm) | 0 | 10 | |

| Working Gas | Ar | Ar | |

| Gas Flow Rate (sccm) | 20 | 20 | |

| Substrate Bias Voltage (V) | −50 | −50 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiao, H.; Zhu, S.; Fan, S.; Kang, J.; Tian, P.; Yang, J.; Wang, Y. Tribological Performance of TiN–WS2 Soft–Hard Multifunctional Composite Coatings Deposited by Magnetron Sputtering. Coatings 2025, 15, 596. https://doi.org/10.3390/coatings15050596

Qiao H, Zhu S, Fan S, Kang J, Tian P, Yang J, Wang Y. Tribological Performance of TiN–WS2 Soft–Hard Multifunctional Composite Coatings Deposited by Magnetron Sputtering. Coatings. 2025; 15(5):596. https://doi.org/10.3390/coatings15050596

Chicago/Turabian StyleQiao, Hu, Shengchao Zhu, Suixin Fan, Jiawei Kang, Peichao Tian, Jianxin Yang, and Youqing Wang. 2025. "Tribological Performance of TiN–WS2 Soft–Hard Multifunctional Composite Coatings Deposited by Magnetron Sputtering" Coatings 15, no. 5: 596. https://doi.org/10.3390/coatings15050596

APA StyleQiao, H., Zhu, S., Fan, S., Kang, J., Tian, P., Yang, J., & Wang, Y. (2025). Tribological Performance of TiN–WS2 Soft–Hard Multifunctional Composite Coatings Deposited by Magnetron Sputtering. Coatings, 15(5), 596. https://doi.org/10.3390/coatings15050596