1. Introduction

Electrical discharge machining (EDM) is a modern machining method that offers several notable advantages, such as the ability to machine extremely hard conductive materials, create complex geometries with high precision and surface finish, and perform without mechanical cutting forces, making it suitable for thin, delicate, or high-accuracy components. However, one of the most significant drawbacks of EDM is its slow machining speed, as material removal occurs through individual electrical discharges with limited energy input. This results in extended machining time, especially for large parts or when high productivity is required. To overcome this limitation, EDM combined with ultrasonic vibration (UV) has been studied and applied. The ultrasonic vibration of the electrode enhances debris removal and stabilizes the discharge process, thereby increasing the material removal rate and reducing machining time, while also improving surface quality and reducing tool wear. As a result, EDM with ultrasonic assistance is considered a promising advancement that enhances the efficiency of electrical discharge machining in modern manufacturing.

M. Goiogana et al. [

1] investigated the UVEDM process aimed at enhancing surface roughness during finishing operations. A copper rod tool electrode and a 1.2344 tempered alloy steel workpiece were utilized for this purpose. The findings indicated that the UVEDM process enhances the surface roughness and uniformity of machined surfaces during finishing EDM operations. Wang Y. et al. [

2] detailed the material removal mechanism of UVEDM by utilizing heat transfer theory. A model for the microscopic removal volume of a single pulse in UVEDM has been established, taking into account the characteristics of the EDM removal mechanism and the influence of ultrasonic vibration energy. The process of generating micro-surface topography has been detailed, and an analysis of the influence of ultrasonic vibration on the machined surface has been conducted. Simulation calculations and experimental validations are conducted to verify the accuracy of the theoretical derivation. Takashi Endo et al. [

3] provided the implementation of vibration-assisted machining in micro-EDM by utilizing PZT, which aimed to effectively remove debris from the gap between the tool electrode and the workpiece. The findings demonstrated that the implementation of vibration assistance enhances machining stability and leads to a significant decrease in machining time. A small square shaft was successfully fabricated using vibration-assisted micro-EDM to validate their experimental results. A. Schubert et al. [

4] presented the current status of investigation into the micro-EDM process with UV assistance—which was directly applied to the workpiece and which indirectly applied high-intensity ultrasonic to the dielectric—in metallic materials as well as in the machining of electrically nonconductive ceramic materials. Utilizing ultrasonically aided micro-EDM can increase process speed by as much as 40%, allowing for the creation of bores with diameters under 90 µm and aspect ratios exceeding 40 in metallic materials.

A. Abdullah and M. R. Shabgard [

5] investigated the influence of copper tool UV frequency on the EDM characteristics of cemented tungsten carbide (WC-Co). The effectiveness of the ultrasonic vibration of the tool in achieving a high MRR was observed to be greater when operating under conditions of low discharge currents and low pulse times, specifically in finishing regimes. The application of ultrasonic vibration increased both surface roughness and TWR. This study demonstrated that optimal conditions exist for the ultrasonic-assisted machining of cemented tungsten carbide. The study presented in [

6] details the implementation of an electrical discharge and ultrasonic-assisted mechanical combined machining process that utilized a bronze-bonded diamond grinding wheel. The correlation between the machining effects and the parameters of the combined machining process has been analyzed. The results of the experiment demonstrated that the parameters of pulse width, pulse interval, peak current, ultrasonic amplitude, and open-circuit voltage have a significant impact on the processing effects. M. Iwai et al. [

7] conducted an investigation into the EDM machinability of PCD utilizing a copper electrode that produces ultrasonic vibrations. This series of EDM experiments involved the selection of three types of ultrasonic vibration modes: axial vibration, flexural vibration, and complex vibration. The experimental results indicated that the efficiency of EDM increased to three times that of conventional EDM. Additionally, the results indicated that the effects were attributed to both the cavitation effect of the working fluid and the vibrational action of the electrode.

M. Goiogana et al. [

8] accomplished a study on the UVEDM process aimed at enhancing machining efficiency and workpiece precision. The case study under consideration involved a horizontal blind hole characterized by an external diameter of 1 mm and an aspect ratio of 14. This study utilized a copper rod tool electrode in conjunction with a 1.2379 tempered alloy steel workpiece. The results indicated that the EDM process utilized an ultrasonic-assisted cryogenically cooled copper electrode while machining M2 grade high-speed steel. The parameters observed were MRR and SR. The controllable process variables included discharge current, pulse on-time, duty cycle, and gap voltage. An analysis has been conducted on the effect of process variables on EWR, MRR, and SR [

9]. The MRR, EWR, and SR achieved in the EDM process using a normal electrode, a cryogenically cooled electrode, and an ultrasonic-assisted cryogenically cooled electrode have been analyzed and compared. The EWR and SR values were observed to be lower in the UVEDM process when compared to the conventional EDM, given the same set of process parameters. Meanwhile, the MRR was comparable to that of the conventional EDM process. P. Singh et al. [

10] developed a novel ultrasonic-assisted micro-EDM setup, which was integrated into the existing ZNC-EDM machine. This study aims to experimentally investigate the influence of gap current (Ig), pulse on-time (Ton), pulse off-time (T

off), and ultrasonic power on MRR, TWR, and hole taper (Ta) in the context of ultrasonic-assisted hole sinking micro-EDM applied to titanium alloy workpieces. Experimental results indicate that the incorporation of ultrasonic vibration in hole sinking micro-EDM significantly influences MRR, TWR, and tool life (Ta).

H. Tong et al. [

11] performed an investigation into the impact of utilizing gap servo control to assist workpiece vibration on the EDM performance of micro-structures. This study analyzes the process principle of the effects to elucidate our experimental results. It was noted that increased frequency vibration contributes to enhanced machining efficiency. Additionally, optimal machining results are achieved when the vibration amplitude is approximately equal to the discharge gap. J. Zhixin et al. [

12] employed the UVPEDM technique to create holes in engineering ceramics. This study outlines the principle of UVPEDM. The UVPEDM technique generates pulse discharge through the UV of the tool electrode, as opposed to utilizing a specialized pulse generator found in conventional EDM methods. The UV output of the tool electrode functions as a method for flushing the gap. The experimental results confirm that this new technique effectively achieves a high MRR. A. Hirao et al. [

13] conducted an investigation into the characteristics of EDM through the application of UV assistance to the tool electrode. The results indicated a significant increase in machining speed through the application of assisted UV on the tool electrode. The method demonstrated significant effectiveness in enhancing machining speed, even with a UV amplitude of 1 μm. The removal of machining wastes occurs effectively due to the tool electrode’s operation. Additionally, this method demonstrates high effectiveness in the machining of deeper holes. G. S. Prihandana et al. [

14] conducted a study on UVEDM utilizing micro-MoS2 powder in dielectric fluid. A notable aspect of this work is the application of UV to the dielectric fluid. It has been observed that the incorporation of MoS2 micro-powder into dielectric fluid during UVEDM can lead to a substantial enhancement in the material removal rate and an improvement in surface quality.

The EDM process represents a highly accurate and efficient technique for the machining of hard, brittle materials and complex shapes. However, it exhibits notable limitations, especially regarding its low MRR, resulting in a time-consuming process. Furthermore, issues such as elevated tool wear, insufficient debris removal, and surface defects resulting from recast layers contribute to a decline in both efficiency and surface quality. UVEDM incorporates ultrasonic vibrations to effectively address these issues, facilitating debris removal, enhancing MRR, and stabilizing spark generation. UVEDM represents a significant advancement, addressing the limitations of traditional EDM and providing enhanced efficiency for high-demand applications.

In the EDM method, the machining tool functions as the negative electrode (cathode), whereas the workpiece acts as the positive electrode (anode). The electrodes or tools are engineered with a specific geometry intended to generate features that align with the inverse configuration of the electrode, including applications such as plastic mold cavities, forging, or pressing dies. In practical applications, many parts display a cylindrical configuration, such as shaped tablet punches (

Figure 1) and specialized punches intended for perforating steel plates, among others. To machine these components utilizing the EDM method, the electrode must feature a shaped cylindrical hole in its design. Recent studies have concentrated on EDM [

15,

16] and EDM that incorporates powder mixing [

17,

18], with a specific emphasis on outer cylindrical surfaces. No research has been conducted to date on the application of EDM machining for outer cylindrical surfaces using ultrasonic vibration.

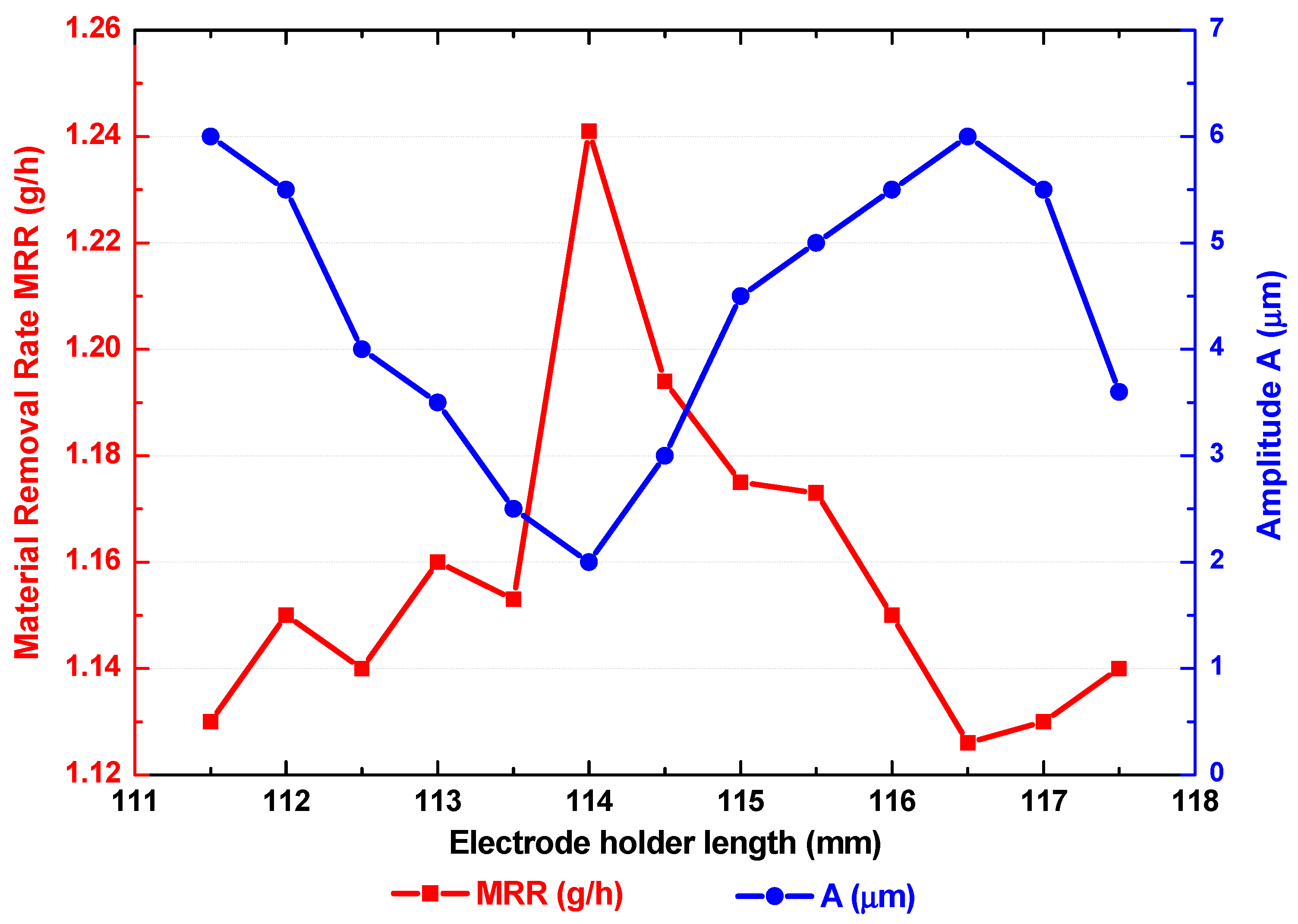

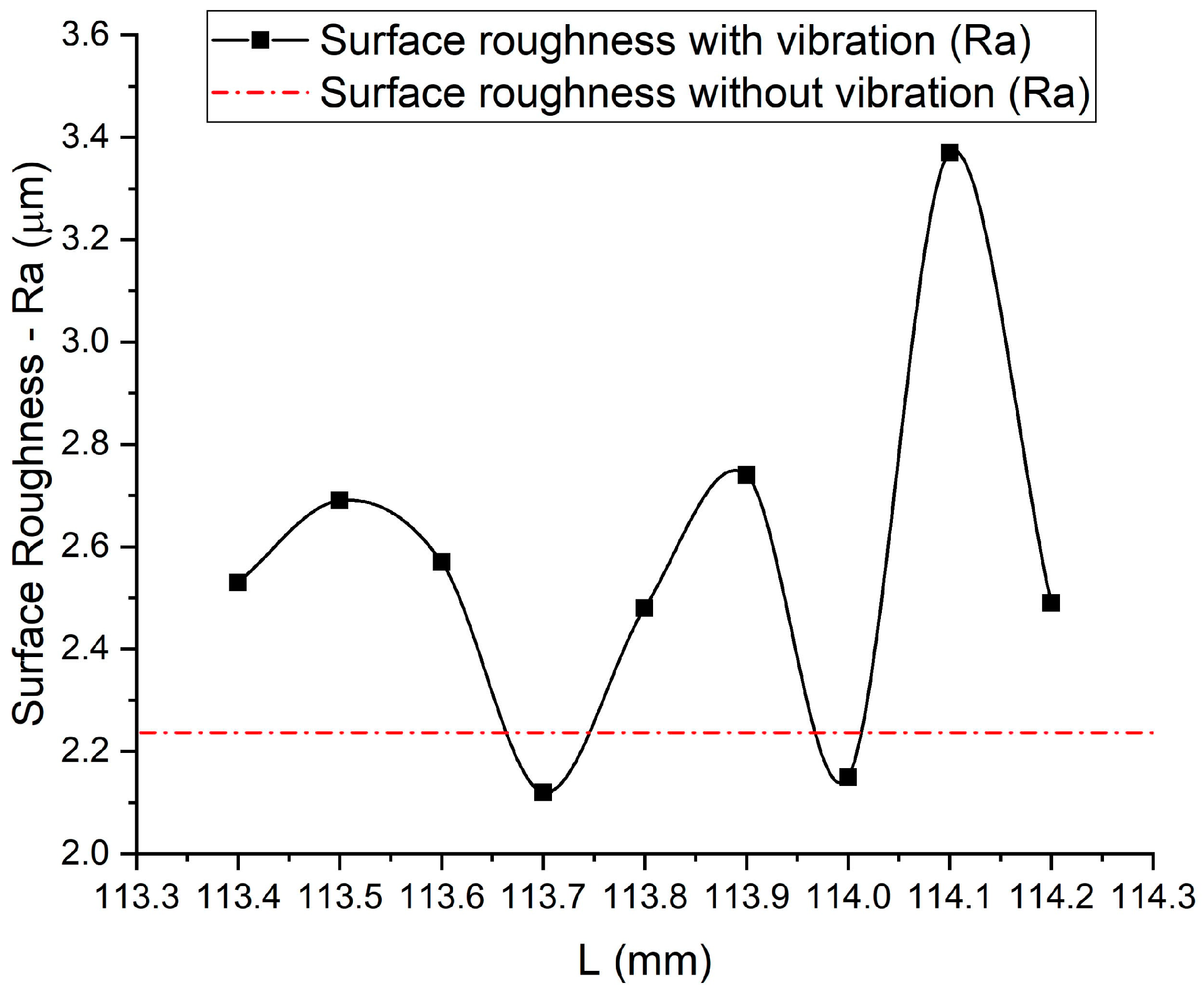

The present paper outlines an experimental study aimed at the development of a vibrating head for UVEDM, intended for the machining of cylindrical surfaces. The electrode holder designed in this study aims to ensure the safe keeping of the electrode while also providing a means for delivering a dielectric solution. The optimal length of the electrode holder was determined to enhance the MRR while maintaining the required surface roughness.

2. Methodology

UV-assisted machining (UVAM) is an advanced machining method that employs mechanical vibrations at ultrasonic frequencies (20 kHz or higher) applied to either the machining tool or the workpiece. High-frequency mechanical vibrations are generated by a system consisting of an ultrasonic generator, a transducer, and a tool. This approach enhances both the efficiency and quality of the machining process. In the UVEDM process, UV can be applied to the workpiece [

11], the electrode [

5,

12,

13], or the dielectric [

14]. In the usual EDM process, the tool, referred to as the electrode, maintains a stationary position while operating solely through translational movement. The implementation of ultrasonic vibration to the tool electrode is uncomplicated. Therefore, in this study, the electrodes, characterized by a hollow cylindrical shape, are subjected to UV application. In this case, the tool holder is suitable for machining components of different sizes, as long as they retain a consistent cylindrical geometry. Furthermore, as the tool remains stationary during EDM, the application of UV to the tool is straightforward.

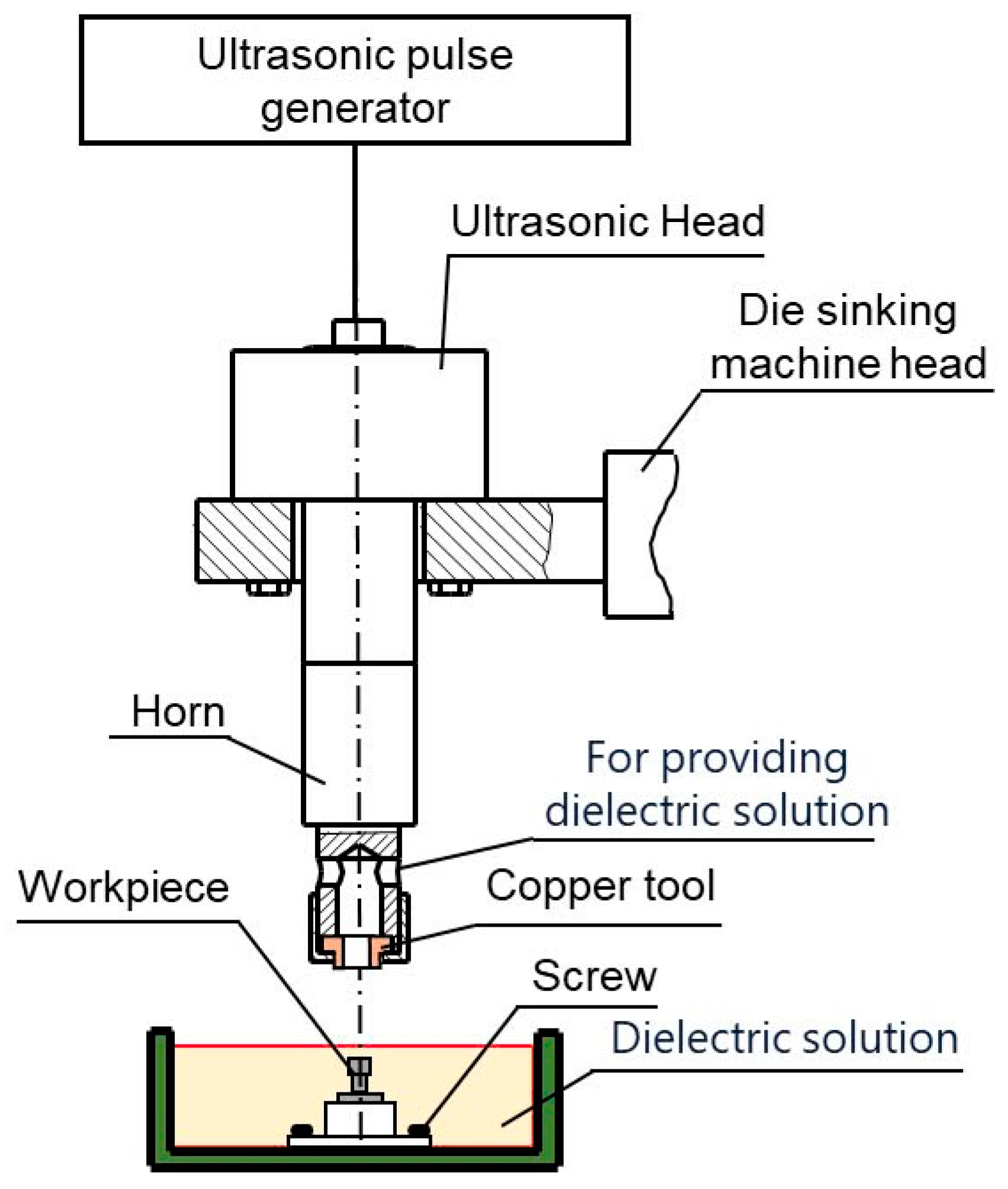

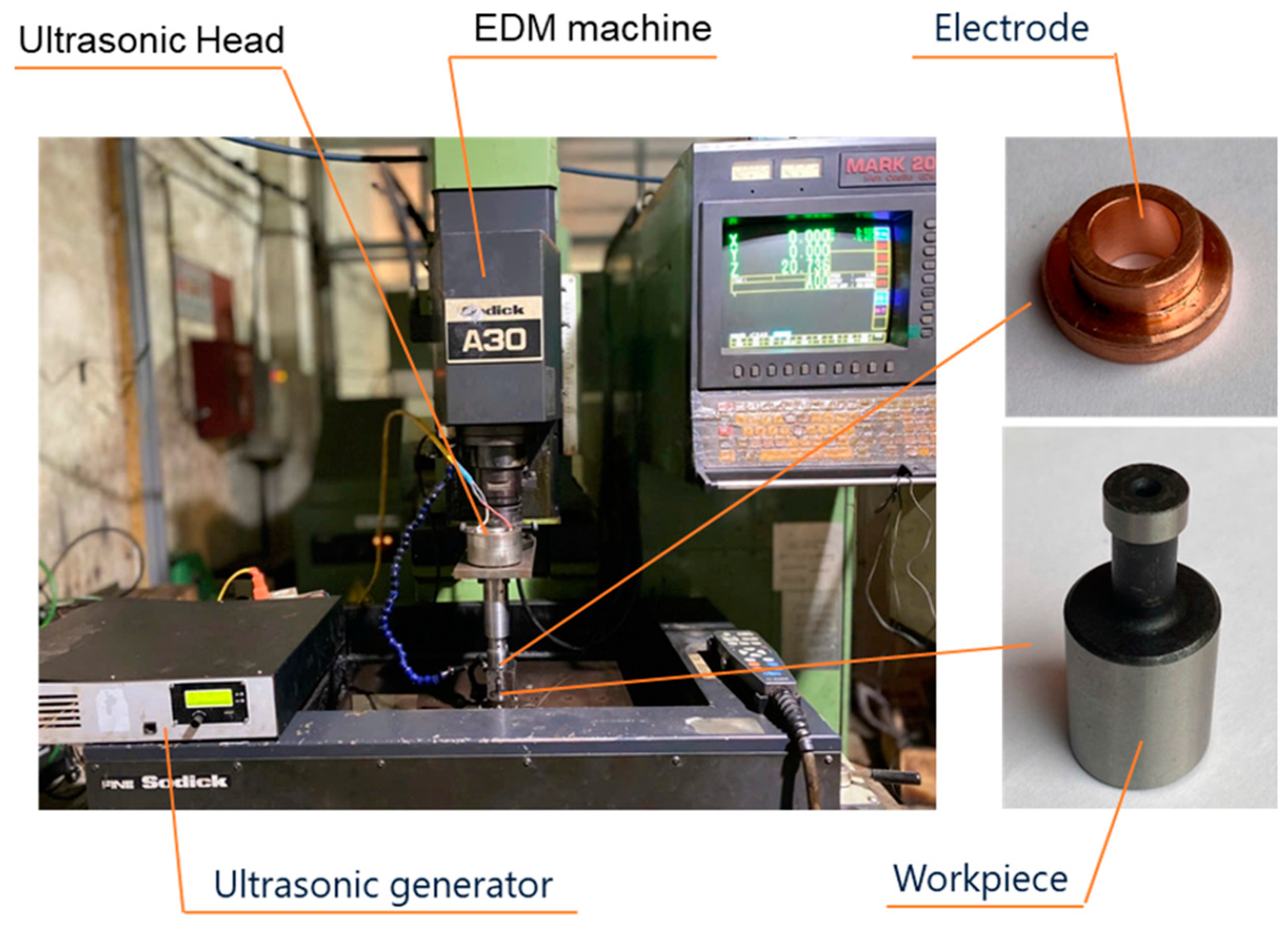

The vibration head was designed as illustrated in the schematic presented in

Figure 2.

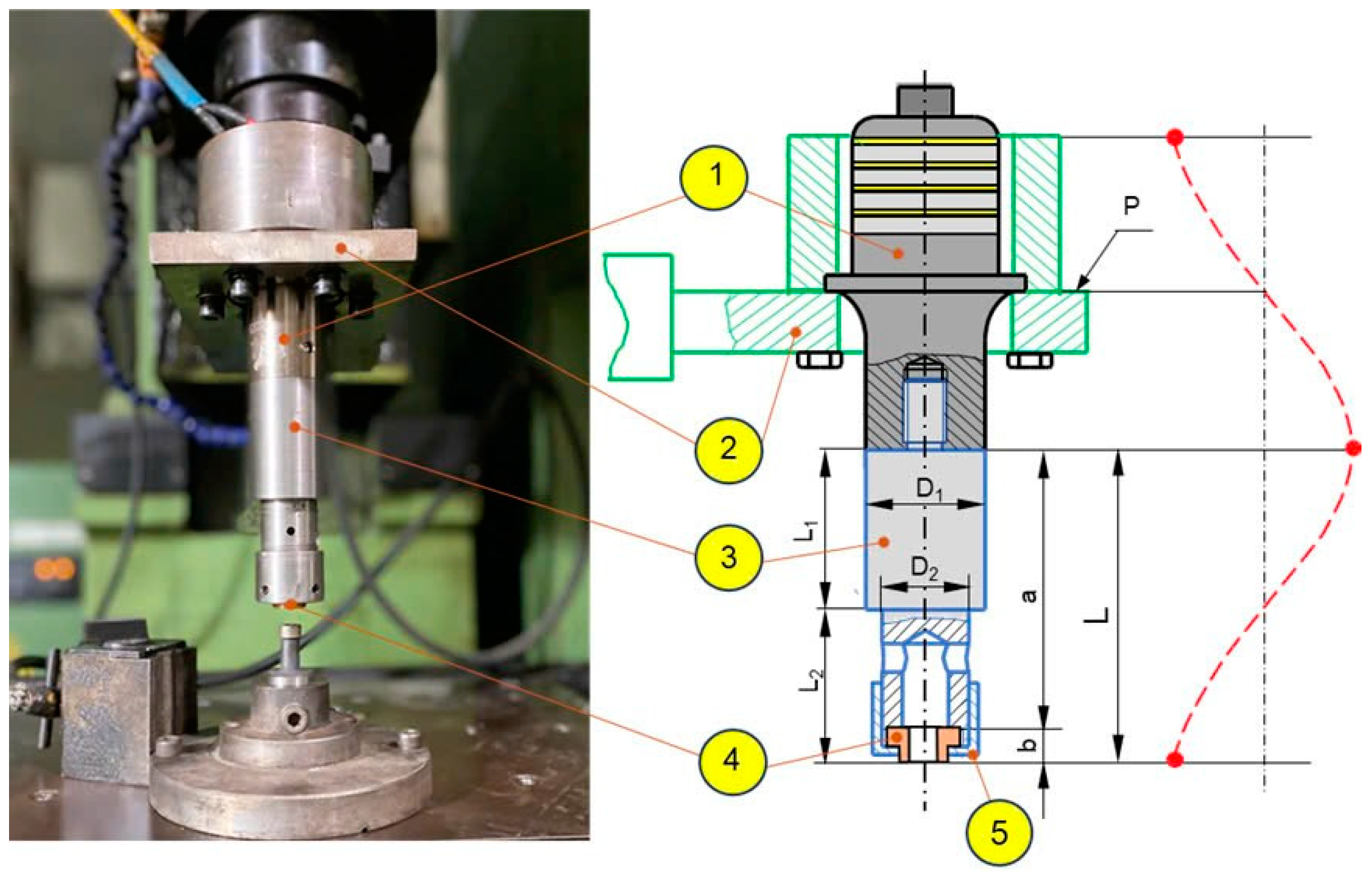

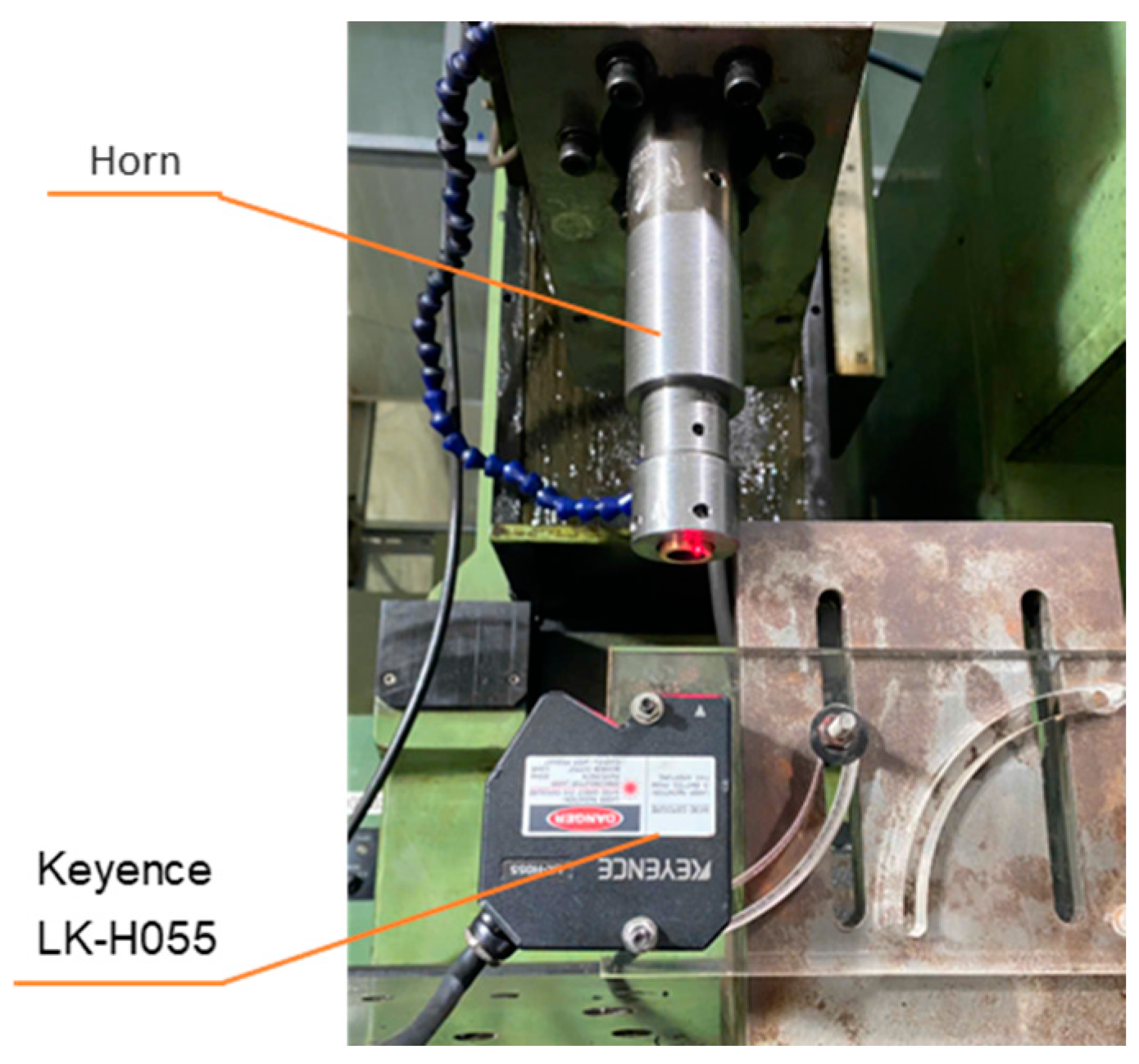

Figure 3 presents the arrangement of the vibrating head along with the schematic representation of the ultrasonic vibration path. As illustrated in

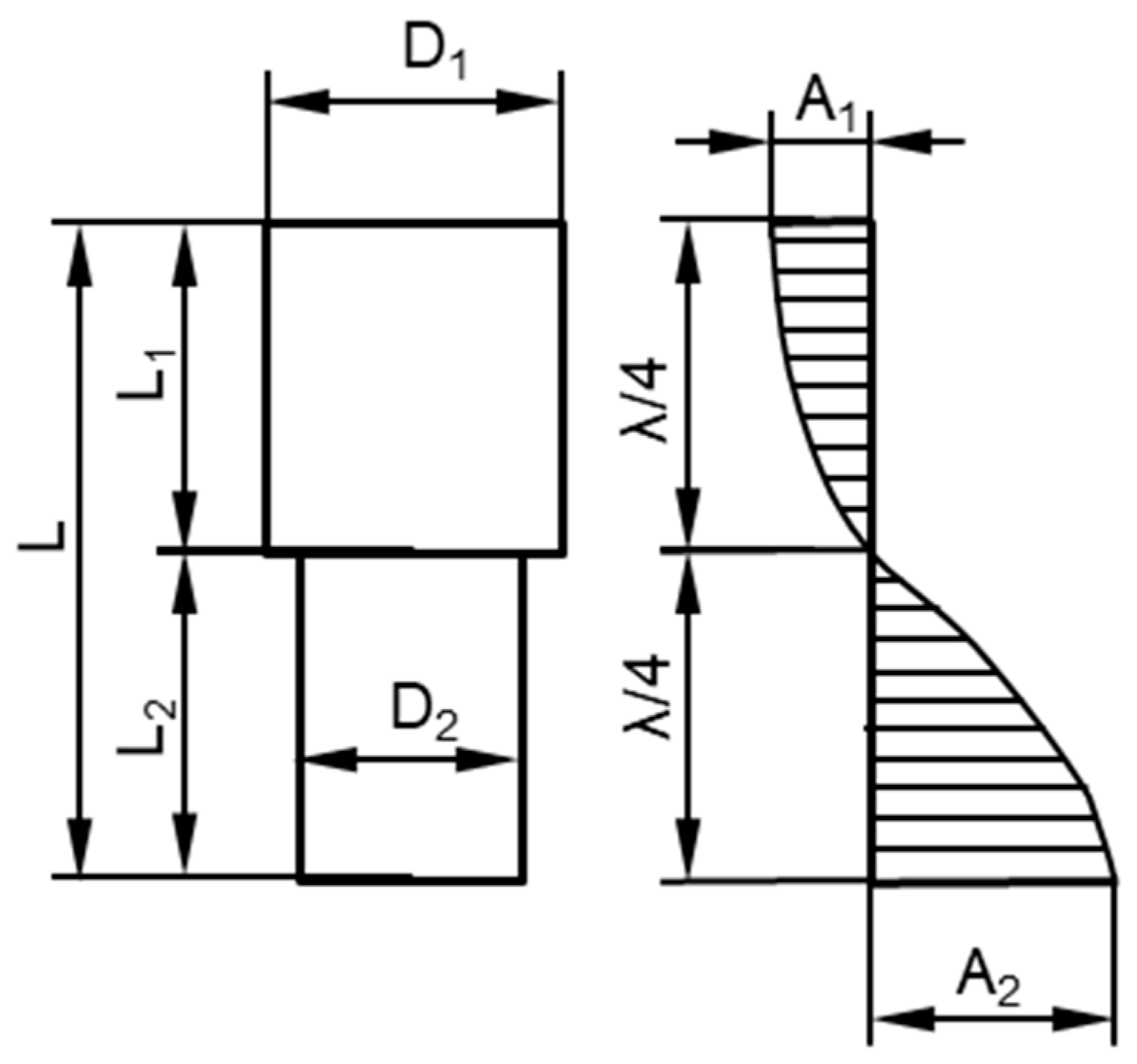

Figure 3, the transducer (1) is securely mounted on the head (2) of the die-sinking EDM machine at surface P, which corresponds to the zero vibration amplitude node. The horn (3) is directly connected to the transducer (1) via an internal thread in its upper section (diameter D1), ensuring a stable mechanical and vibrational connection. The lower section of the horn (diameter D2) features a central bore to accommodate the electrode (4) and an external thread for fastening the electrode using a nut (5).

The end face of the electrode (4), determined by the total length L = a + b, is the critical location that must coincide with the position of maximum vibration amplitude. Properly adjusting this length ensures that the ultrasonic energy is efficiently transmitted to the electrode face, enhancing material removal efficiency during the UVEDM process. To further facilitate the machining operation, the electrode holder (horn) is also equipped with lateral holes, allowing for the effective delivery of dielectric fluid into the discharge gap.

The ultrasonic vibration system used in this study consists of a transducer and a generator. Specifically, the ultrasonic transducer is model RPS-5020-4Z, manufactured in China, and the ultrasonic generator is model MPI WG-3000, produced in Switzerland. These components provide a stable vibration source at a nominal frequency of 20 ± 0.5 kHz with a maximum power of 2000 W from the transducer and 3000 W from the generator, supporting a wide operating frequency range between 15 and 100 kHz. These components were procured from manufacturers specializing in ultrasonic machining equipment, and their technical specifications are consistent with commercial standards for high-precision EDM applications.

Table 1 presents the technical specifications of the ultrasonic transducer and generator.

4. Multi-Objective Optimization of Experimental Data Using Box–Behnken Design (BBD)

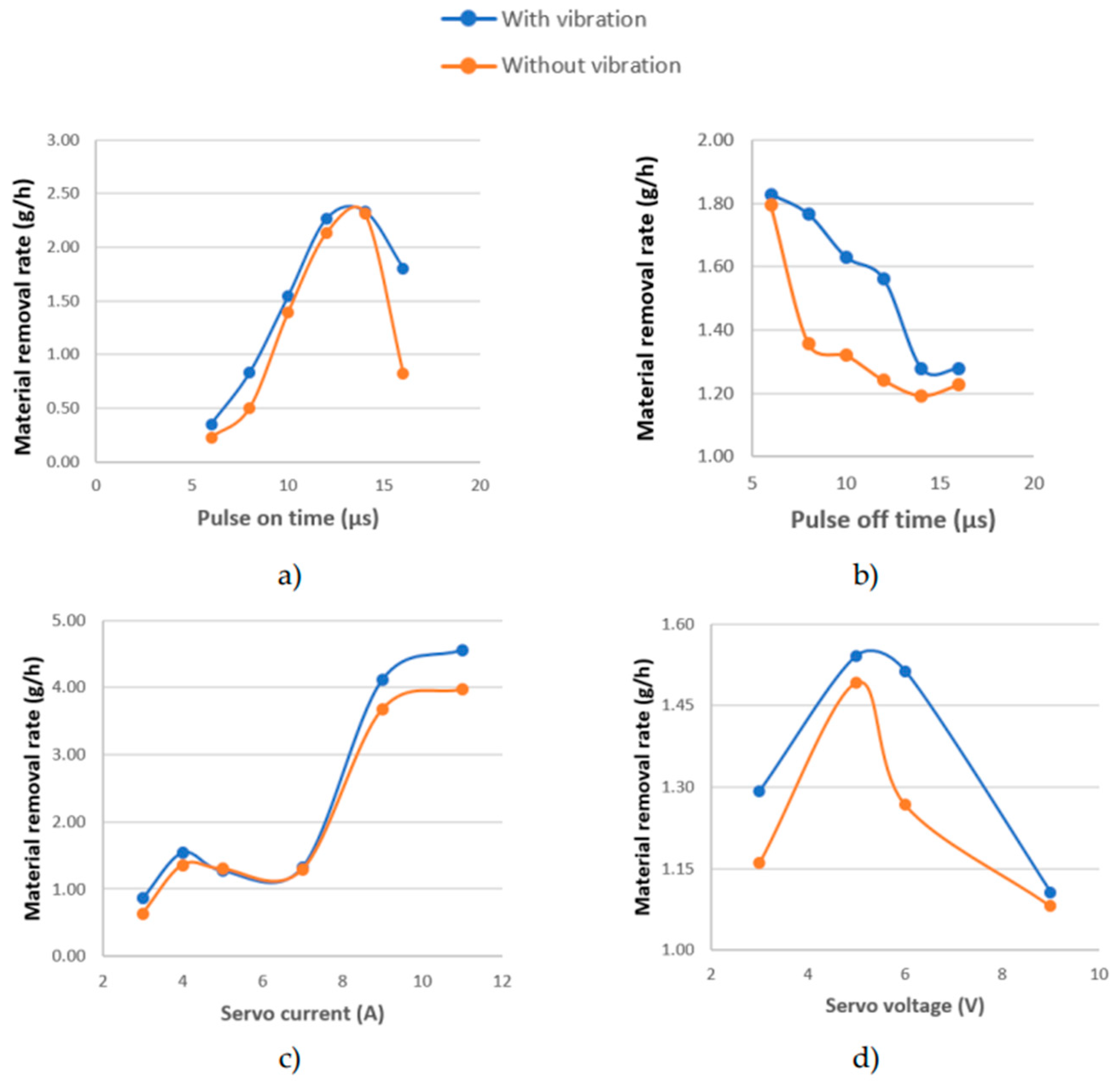

To further enhance the academic quality of this study, we conducted a multi-objective optimization using the Box–Behnken Design (BBD) method. This approach allows for the selection of the most optimal machining parameters by simultaneously considering two conflicting objectives, maximizing material removal rate (MRR) and minimizing surface roughness (SR), while also investigating the interaction effects between machining parameters.

4.1. Optimization Problem Definition

Ultrasonic vibration-assisted electrical discharge machining (UVEDM) is an advanced machining process that combines ultrasonic vibration with traditional EDM to enhance material removal rate (MRR) and improve surface quality. The machining process is influenced by several key input parameters, including ultrasonic vibration amplitude (A), pulse on-time (Ton), pulse off-time (Toff), peak current (IP), and supply voltage (SV).

The optimization challenge lies in balancing the trade-off between maximizing MRR and minimizing surface roughness (Ra).

This study aims to determine the optimal machining conditions that achieve a high MRR while maintaining a low Ra using the Box–Behnken Design (BBD) for experimental planning and employing both nonlinear regression and multi-objective decision-making techniques, specifically TOPSIS.

4.2. Experimental Planning with BBD

The Box–Behnken Design (BBD), a type of response surface methodology (RSM), is utilized to design the experiments systematically. The BBD approach provides an efficient way to explore the effects of multiple machining parameters without requiring a full factorial design, thus reducing the number of experimental trials while maintaining statistical validity.

The five machining parameters (A, Ton, Toff, IP, and SV) were considered as independent variables, each set at three levels (low, medium, and high). Details of the machine, electrode, and workpiece are consistent with the experimental setup described in

Section 3.3. The response variables, MRR (g/h) and Ra (µm), were measured as output performance indicators. The total number of experimental runs was determined based on the BBD matrix.

Table 7 describes the experimental plan).

4.3. Experimental Implementation and Data Collection

The experiments were conducted on a UVEDM setup with a tool electrode vibrating at an ultrasonic frequency. Workpiece material, dielectric medium, and machining conditions were kept consistent to minimize variability. After each machining trial, MRR was computed by measuring weight loss, while Ra was evaluated using a surface profilometer. These output results are presented in

Table 7.

The collected data were analyzed to observe parameter interactions and identify significant factors influencing MRR and Ra. The results served as input for regression modeling and optimization.

4.4. Nonlinear Regression Model Construction and Data Analysis

To establish mathematical relationships between input parameters and response variables, a nonlinear regression model was developed using the following quadratic polynomial equation:

where

Y represents MRR or Ra,

Xi represents the input parameters,

βi represents regression coefficients, and

ϵ is the error term.

The regression model was trained using the least squares estimation approach, and model adequacy was verified using ANOVA. Results indicated that IP and A significantly influenced MRR, while Ra was more sensitive to variations in A and Toff. The model demonstrated high predictive accuracy (R

2 > 90%), confirming its suitability for optimization. The regression coefficients for MRS (g/h) and Ra (µm) are described in

Table 8 and

Table 9, respectively.

- -

For MRR: Higher IP and SV increase material removal, while Toff negatively impacts MRR, suggesting that longer pulse off-times reduce efficiency.

- -

For Ra: Higher IP and SV lead to rougher surfaces, while increasing A and Toff improves surface quality.

- -

Quadratic terms suggest that extreme values of A, IP, and SV may have diminishing returns or negative effects.

Using the nonlinear regression model, the optimal parameters were determined to achieve the best trade-off between maximizing MRR and minimizing Ra, and these are shown as follows:

A = 1.1836 (μm); Ton = 12.8914 (µs); Toff = 11.2518 (µs); IP = 5.7919 (A); SV = 5.4418 (V).

- -

The low amplitude of ultrasonic vibration (A) ensures improved surface quality without significantly reducing MRR.

- -

The moderate pulse on-time (Ton) and pulse off-time (Toff) maintain a balanced energy input, preventing excessive tool wear while ensuring stable machining.

- -

The moderate peak current (IP) allows efficient material removal without excessive discharge energy that could increase surface roughness.

- -

The moderate supply voltage (SV) helps stabilize the discharge process, ensuring a uniform surface finish.

- -

These optimal conditions effectively maximize productivity while maintaining acceptable surface integrity, demonstrating the effectiveness of nonlinear regression in UVEDM process optimization.

4.5. Multi-Objective Optimization

To optimize both MRR and Ra simultaneously, in this work, a multi-objective optimization approach using nonlinear regression was implemented. The approach involved the following:

4.5.1. Defining the Objective Functions

Maximizing the MRR function obtained from regression:

Minimizing the Ra function:

4.5.2. Applying Constraints

Constraints were set based on practical machining limits and experimental data.

The search for optimal parameters was constrained within the tested parameter range to ensure realistic and feasible results.

4.5.3. Solving the Optimization Problem

A Pareto-based trade-off analysis was conducted to identify solutions that provide a balance between MRR and Ra.

The weighted sum method was applied to convert the multi-objective problem into a single objective function as follows:

where

w1 and

w2 are weight factors representing the relative importance of each objective.

4.5.4. Optimization Results

The following parameters were found to provide the best trade-off: A = 1.22 (μm), Ton = 12.5 (µs), Toff = 11.5 (µs), IP = 6.2 (A), and SV = 5.6 (V).

These values provide an improved MRR = 3.85 (g/h) while maintaining Ra = 3.76 (μm) within an acceptable range.

- -

The optimization results align with practical requirements in UVEDM machining by offering a compromise between high material removal efficiency and good surface finish.

- -

Using nonlinear regression for optimization allows for a more accurate prediction of machining performance compared to heuristic methods.

- -

The obtained results serve as a guideline for selecting machining parameters to achieve the desired balance between productivity and quality.

- -

The combination of regression modeling with multi-objective optimization offers a systematic approach that can be extended to other advanced machining processes.

4.5.5. Evaluation of Multi-Objective Optimization Results Using Nonlinear Regression

While an experimental validation with a newly designed horn for UVEDM would provide the highest level of accuracy, it requires significant resources and setup modifications, making it a future research goal. In the meantime, applying an MCDM method allows for an objective comparison, validating the efficiency of the nonlinear regression results before committing to physical trials.

Multi-criteria decision-making (MCDM) techniques are widely used in engineering optimization where multiple conflicting objectives must be balanced. In the context of UVEDM, MRR and Ra present opposing goals—higher MRR is desirable for productivity, while lower Ra ensures better surface quality. While nonlinear regression provides an optimized parameter set, its evaluation requires an additional validation method to assess trade-offs objectively.

In this work, TOPSIS was chosen among MCDM methods for the evaluation of multi-objective optimization results using nonlinear regression. The TOPSIS method (Technique for Order of Preference by Similarity to Ideal Solution) was proposed by C.L. Hwang and K. Yoon in 1981 [

21]. This is one of the influential multi-criteria decision-making (MCDM) methods and is widely used in many fields, such as engineering, management, finance, and logistics. It was selected for this evaluation due to the following advantages:

- -

Closeness to the Ideal Solution: TOPSIS ranks alternatives based on their Euclidean distance to an ideal best and worst solution, ensuring that the selected parameters align well with practical machining goals.

- -

Straightforward Computation: Unlike genetic algorithms or fuzzy logic approaches, TOPSIS is computationally efficient and can be directly applied to experimental data.

- -

Quantitative Ranking: It provides a clear ranking of parameter sets, helping to compare regression-based optimization with experimental outcomes.

The fundamentals of TOPSIS were presented in detail in [

21] as well as many other scientific documents. TOPSIS ranks solutions by the following:

- -

Normalizing the decision matrix to ensure comparability across different scales;

Weighting the criteria to reflect their importance;

- -

Determining the ideal best and worst solutions based on the most and least desirable values for each parameter;

- -

Calculating the Euclidean distance of each alternative from the ideal best and worst solutions;

- -

Computing a TOPSIS score where the best solution is the one closest to the ideal best and farthest from the ideal worst.

Using the experimental dataset and applying the TOPSIS method,

Table 10 presents several calculated results by the TOPSIS technique, and from these, it was found that option 12 is the best. In addition, using

Table 10 and

Table 11, the following machining parameters were found to be optimal: A = 1.15 (μm), Ton = 12 (µs), Toff = 8 (µs), IP = 5 (A), and SV = 3 (V).

Table 11 clearly shows the following predicted values of MRR and Ra for both methods:

- -

Nonlinear regression yields the highest predicted MRR (3.85 g/h) while maintaining a relatively low Ra (3.76 µm).

- -

TOPSIS, though simpler to apply based on experimental data, results in a slightly lower MRR (3.546 g/h) and a similar Ra (3.770 µm).

- -

These differences demonstrate that the nonlinear regression method provides a more favorable balance between the two objectives. The results validate the use of nonlinear modeling combined with multi-objective optimization strategies to derive practical and effective UVEDM parameter settings.

- -

TOPSIS favors a lower peak current (IP = 5 A) and supply voltage (SV = 3 V), which contribute to a reduced energy input during machining.

- -

Nonlinear regression finds a more balanced setting (IP = 6.2 A, SV = 5.6 V), ensuring a high MRR while keeping Ra within acceptable limits.

- -

TOPSIS and nonlinear regression produce similar recommendations for Ton, but differ significantly in Toff, suggesting that pulse off-time is a key trade-off factor in UVEDM optimization.