The Elemental Migration Characteristics and Structural Damage Process of a ZnO Arrester Unit Surface Under a High-Frequency Voltage and Impulse Current

Abstract

1. Introduction

2. A Lightning Arrester’s Temperature-Rise Analysis in a Mobile Train Situation

2.1. Frequent Overvoltages Occur When the Lightning Arrester of a Train in Motion Is in Operation

2.2. Analysis of the Thermal Process in Lightning Arresters

3. Experiment

3.1. Equipment for Testing the Aging of Resistors Used in Lightning Protection Systems

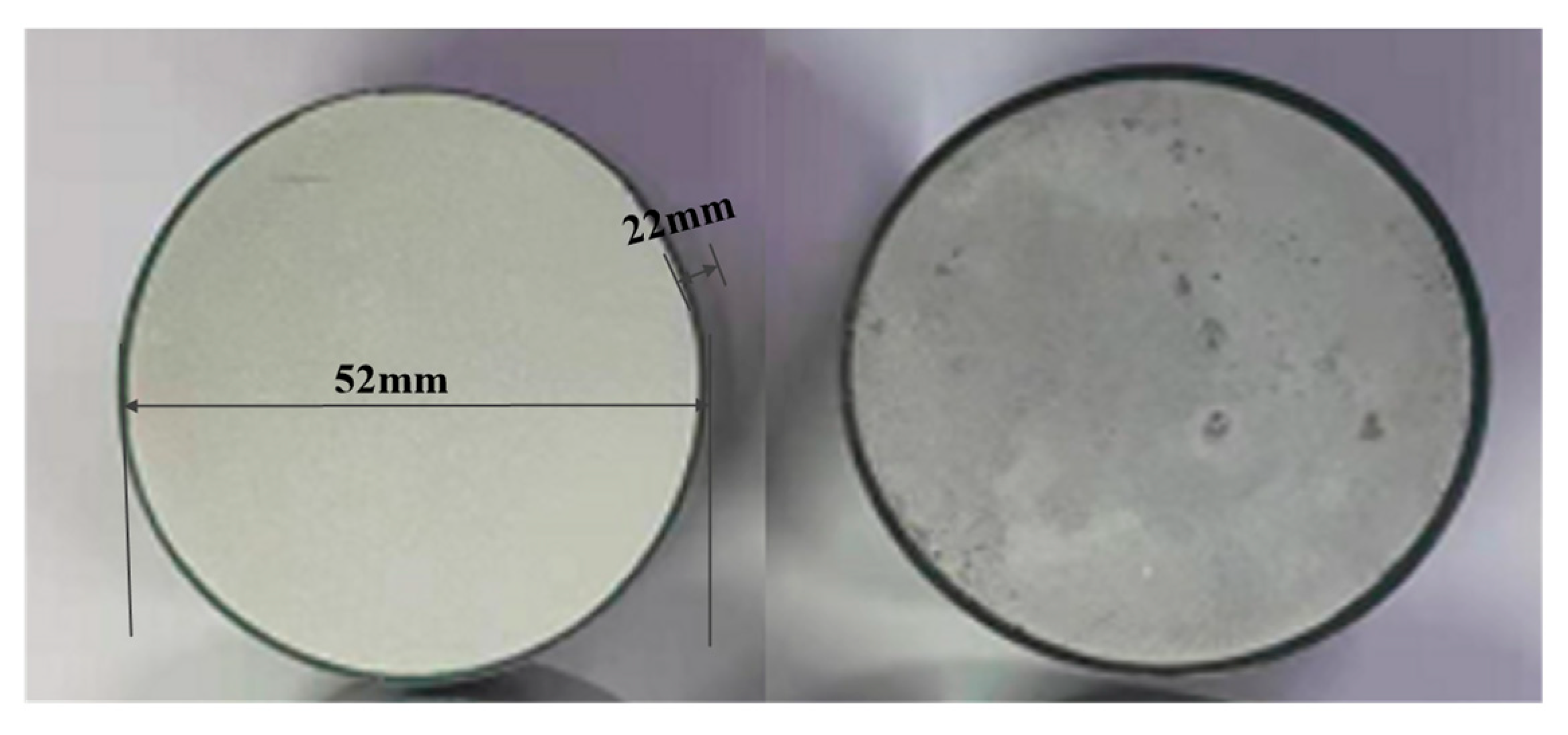

3.2. Arrester Resistor Test Product

3.3. Aging Test Program

4. Effects of High-Frequency Voltage on the Aging Characteristics of Surge Arresters

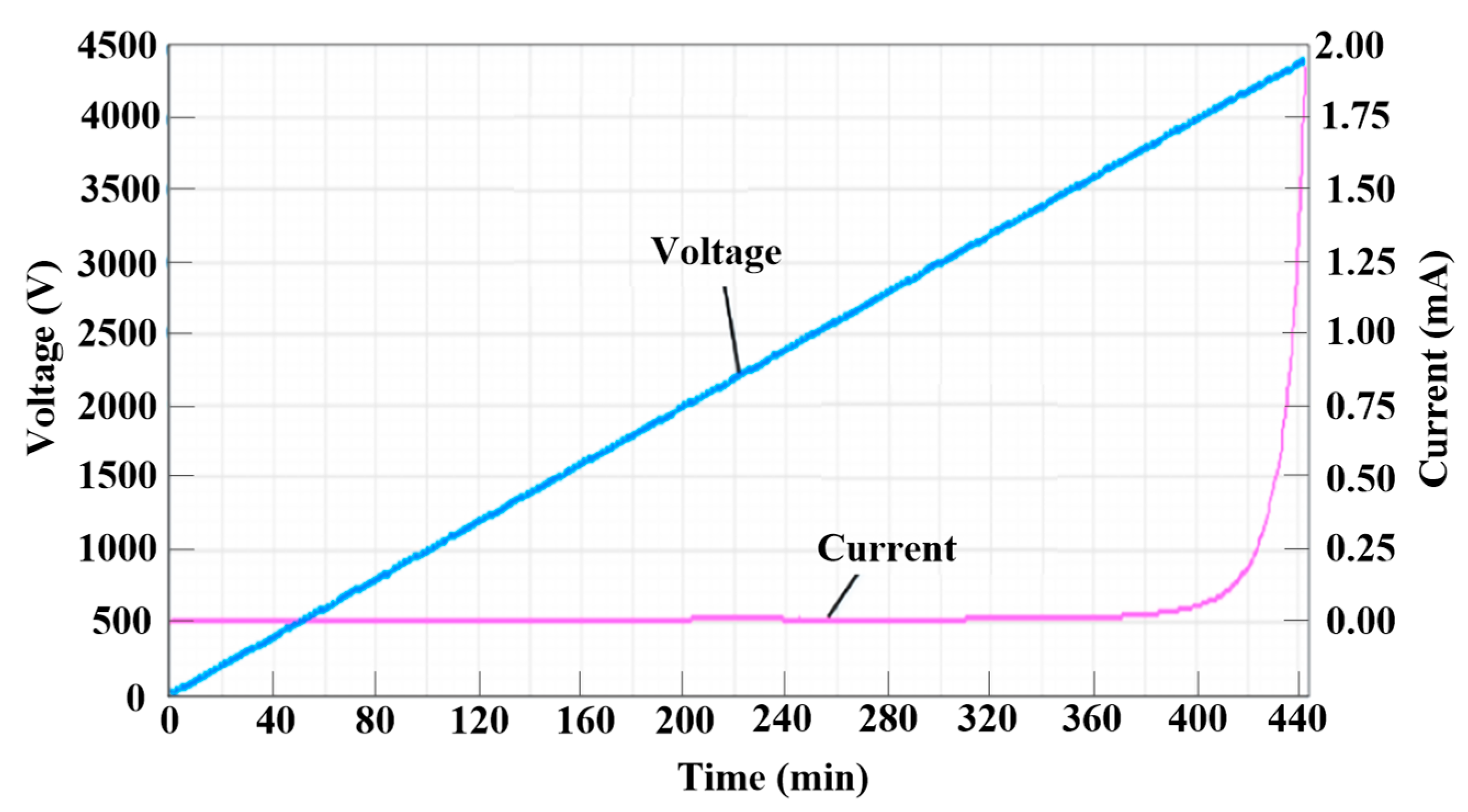

4.1. Effect of the Withstand Voltage Duration on the Resistor Plate

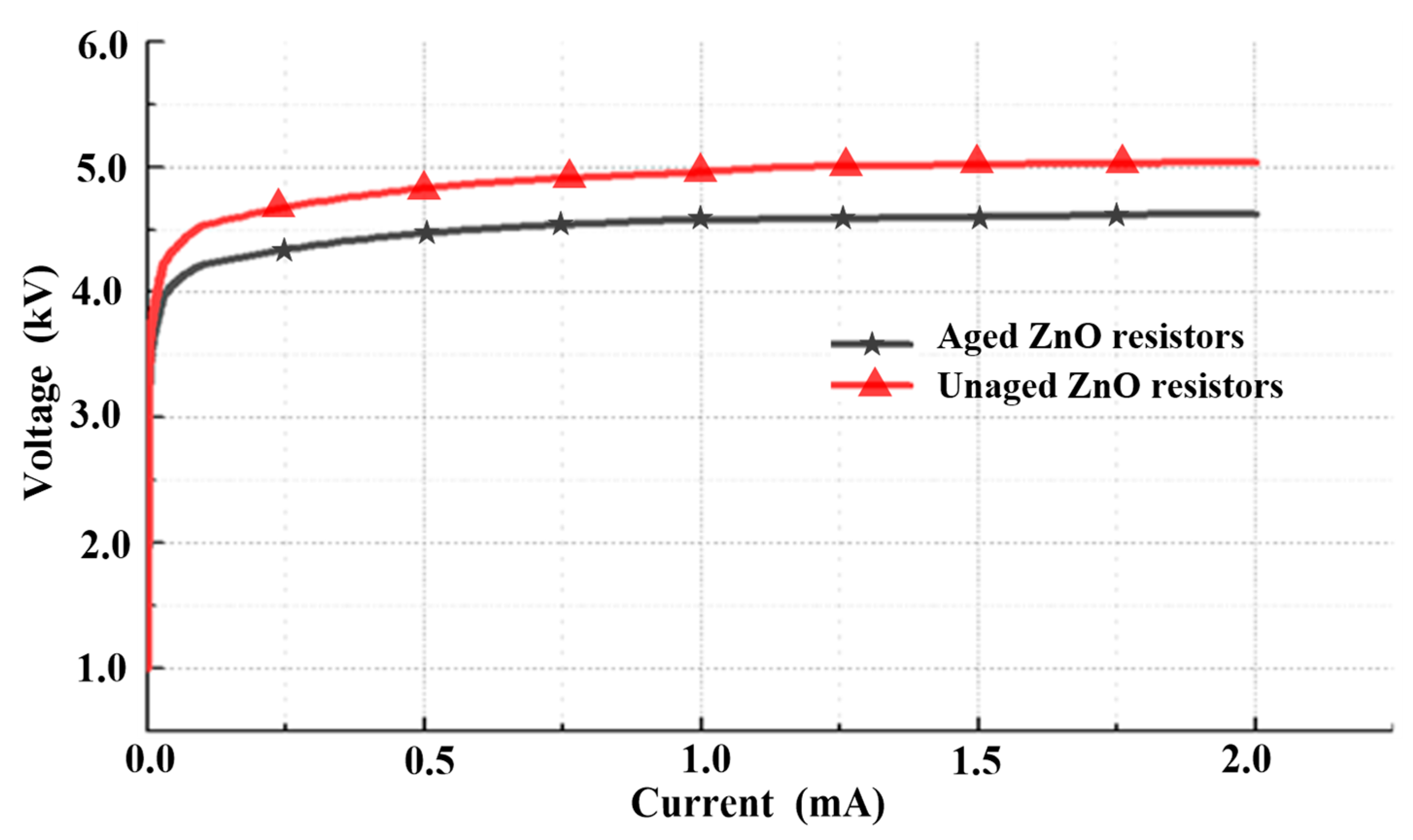

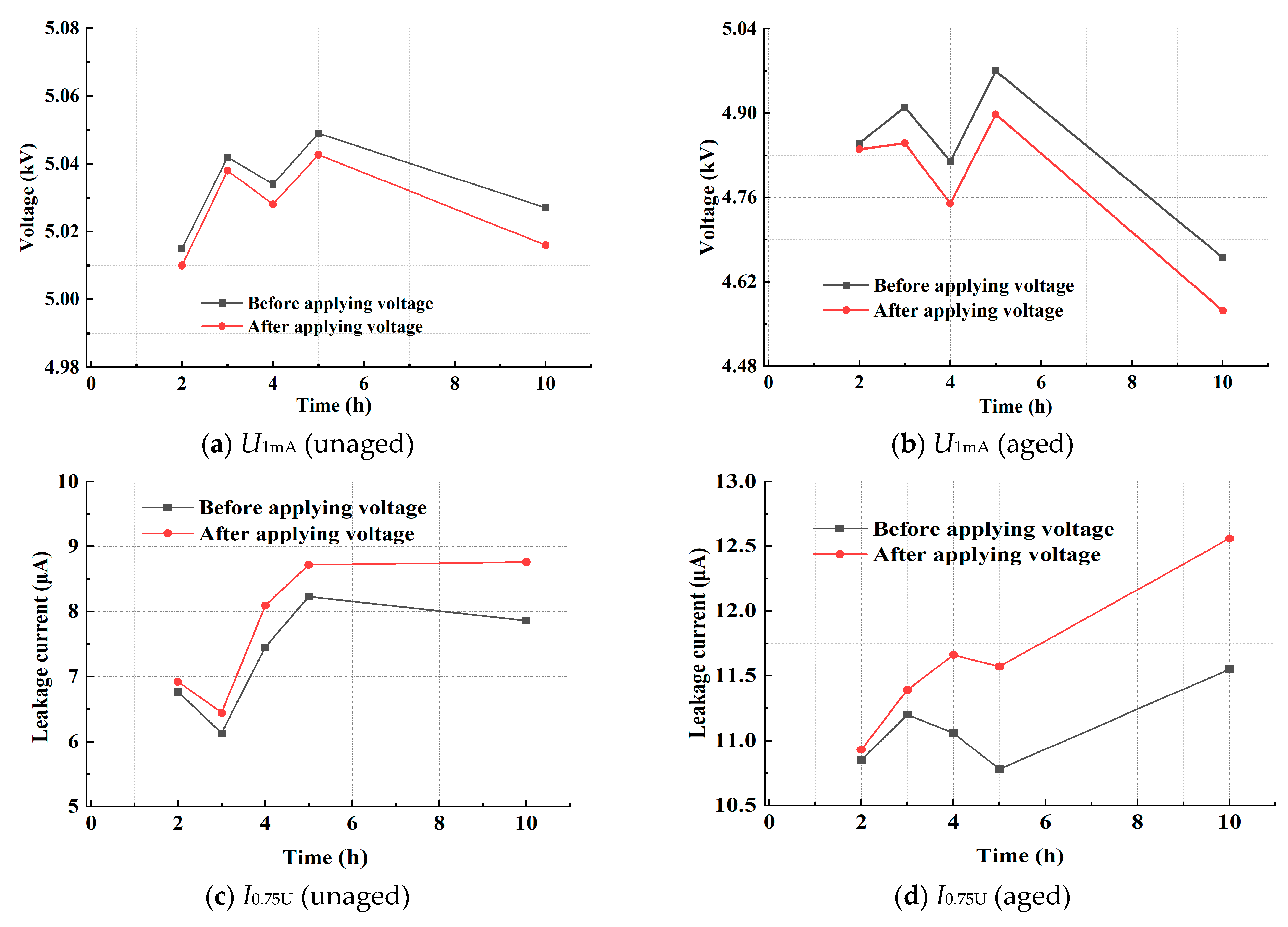

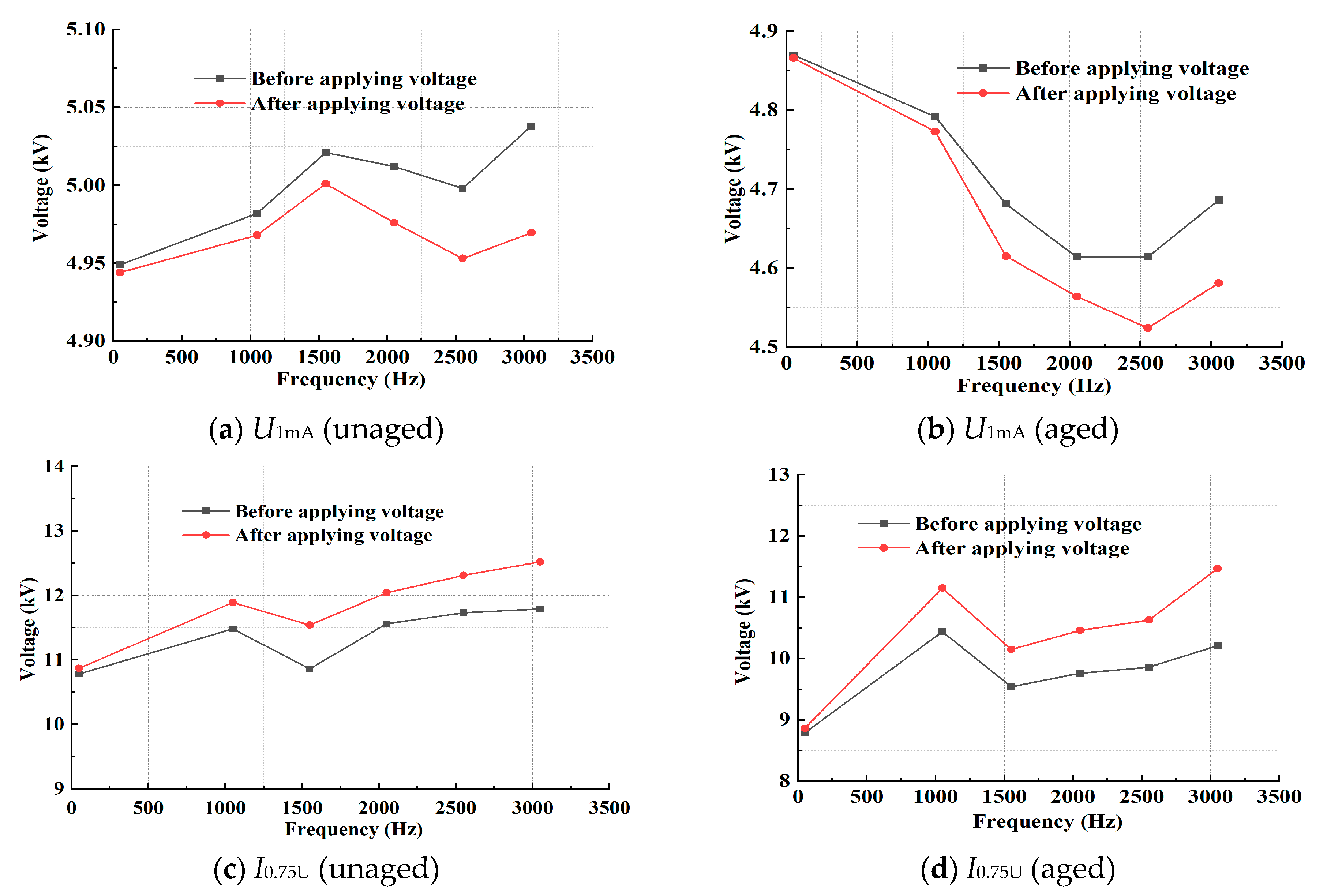

4.2. Impact of Varying the Withstand Voltage Frequencies on Resistor Aging

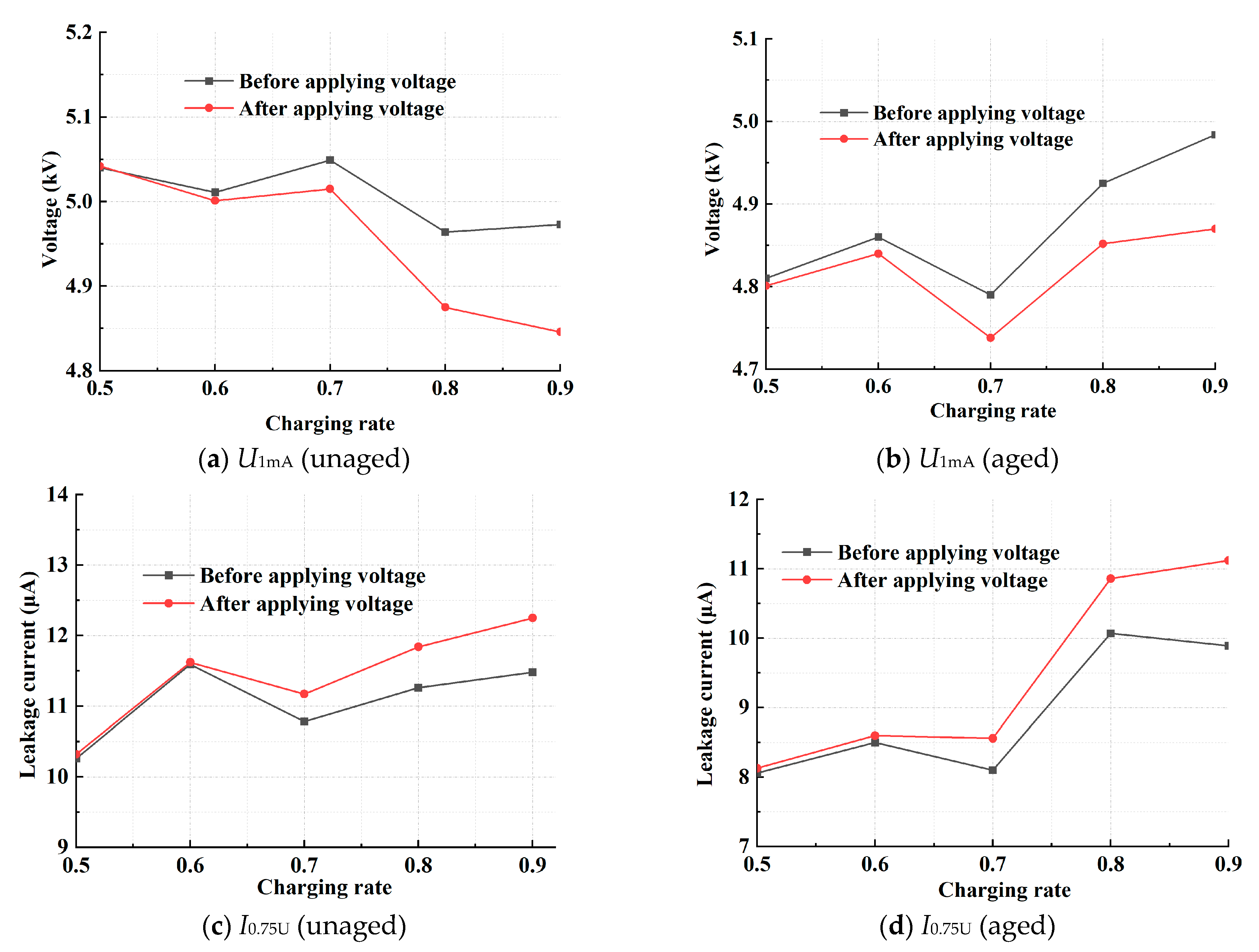

4.3. The Impact of the Charging Speed on the Deterioration of Resistors

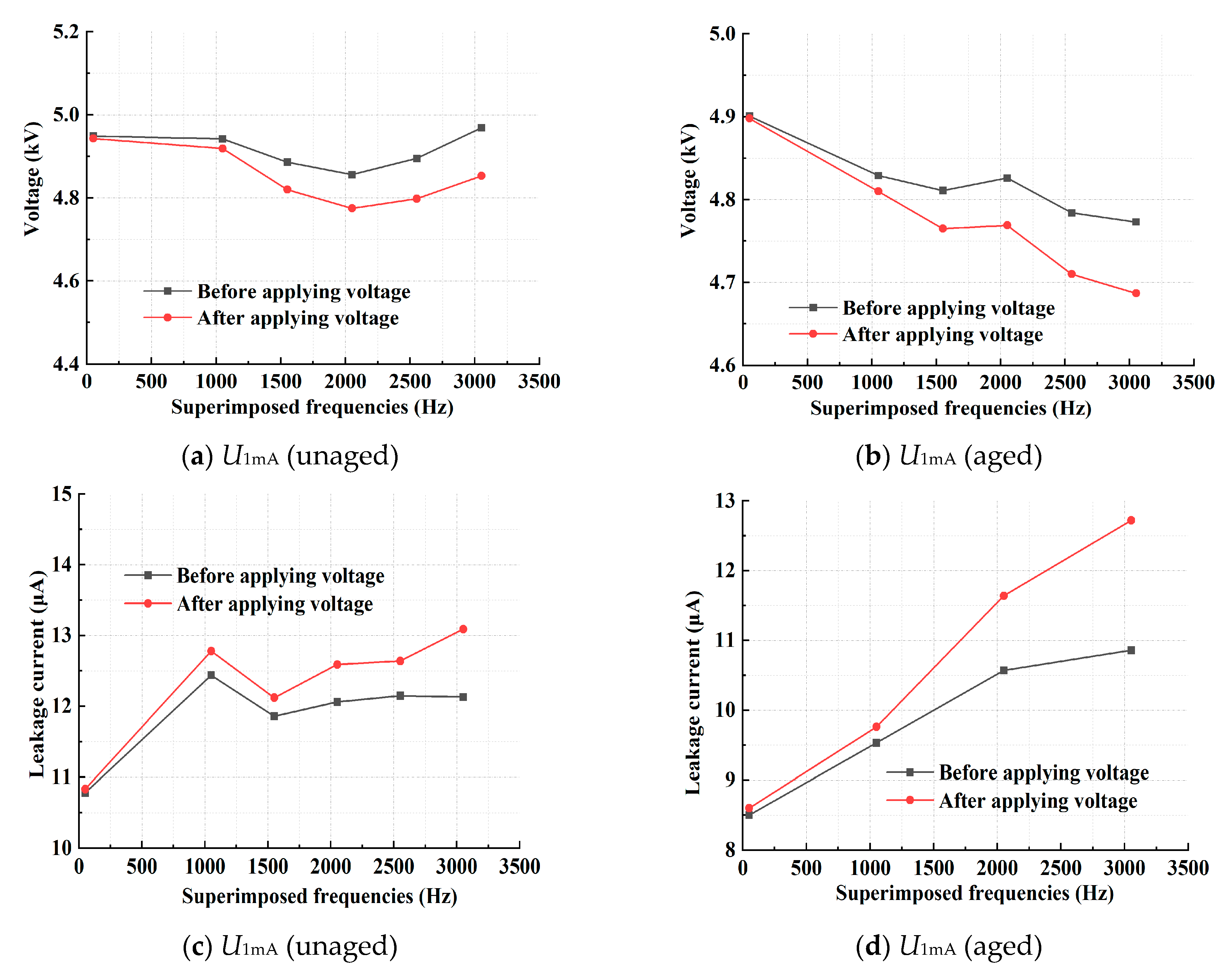

4.4. Effect of the Withstand Voltage Frequency on the Aging of the Resistor

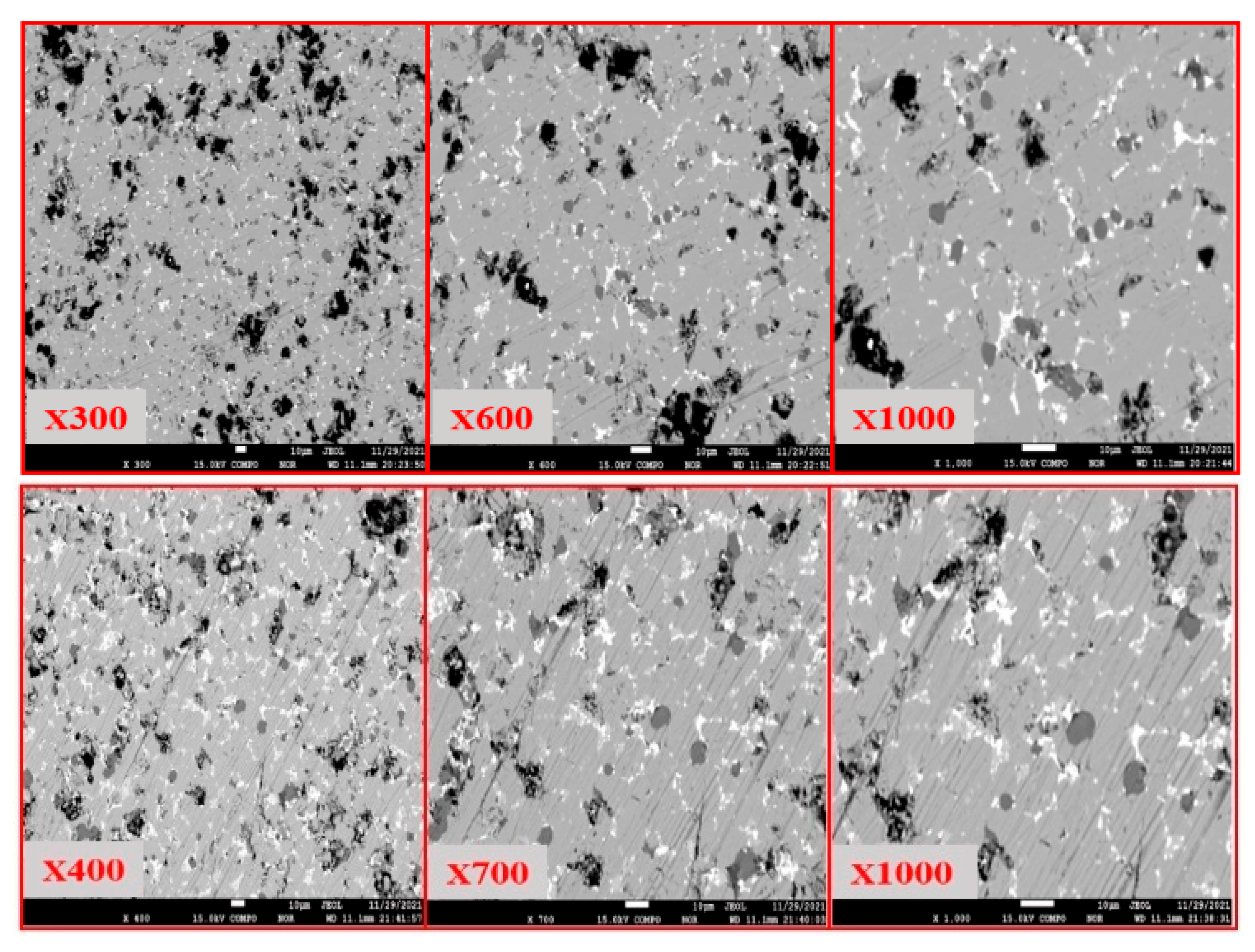

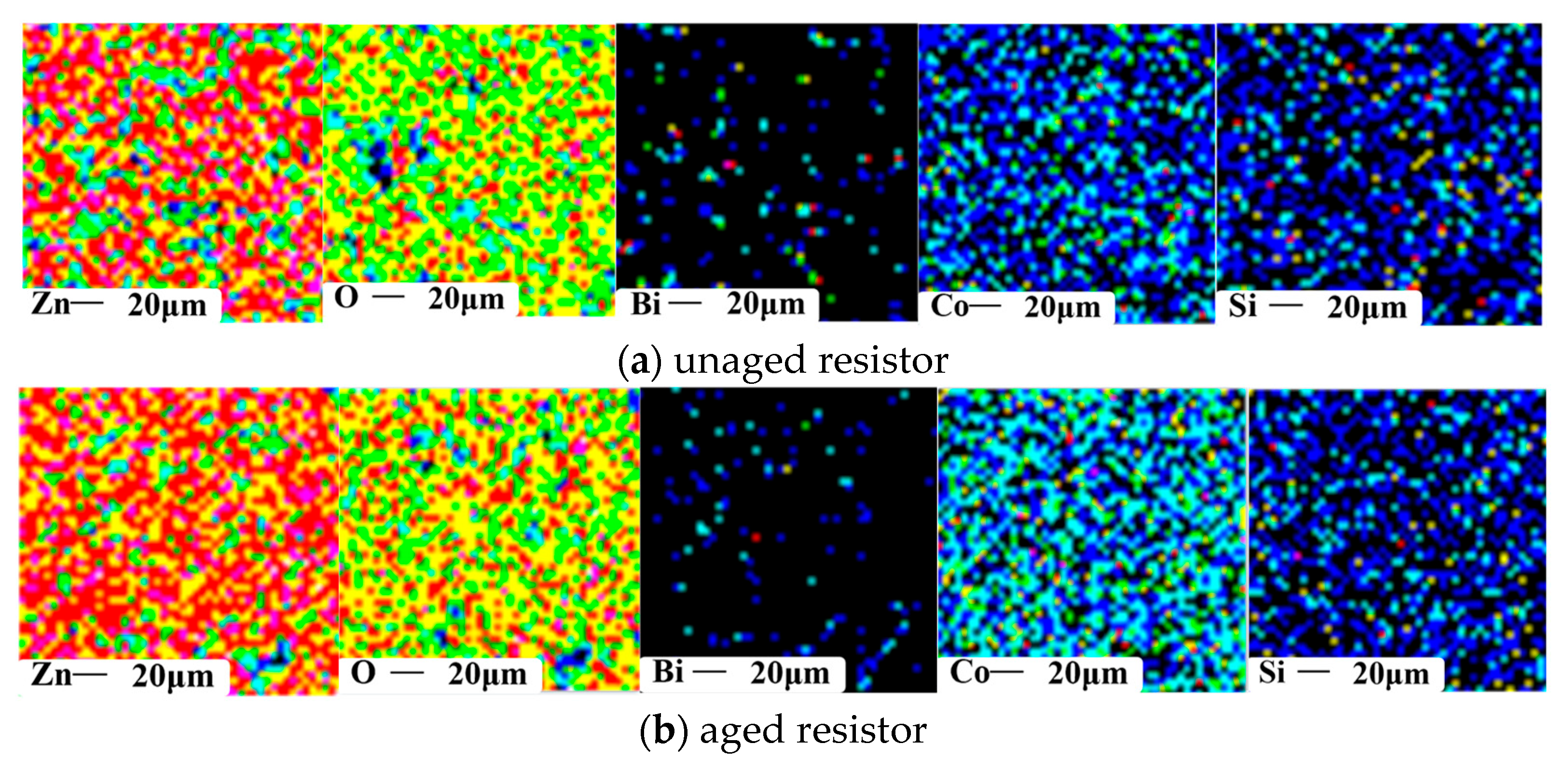

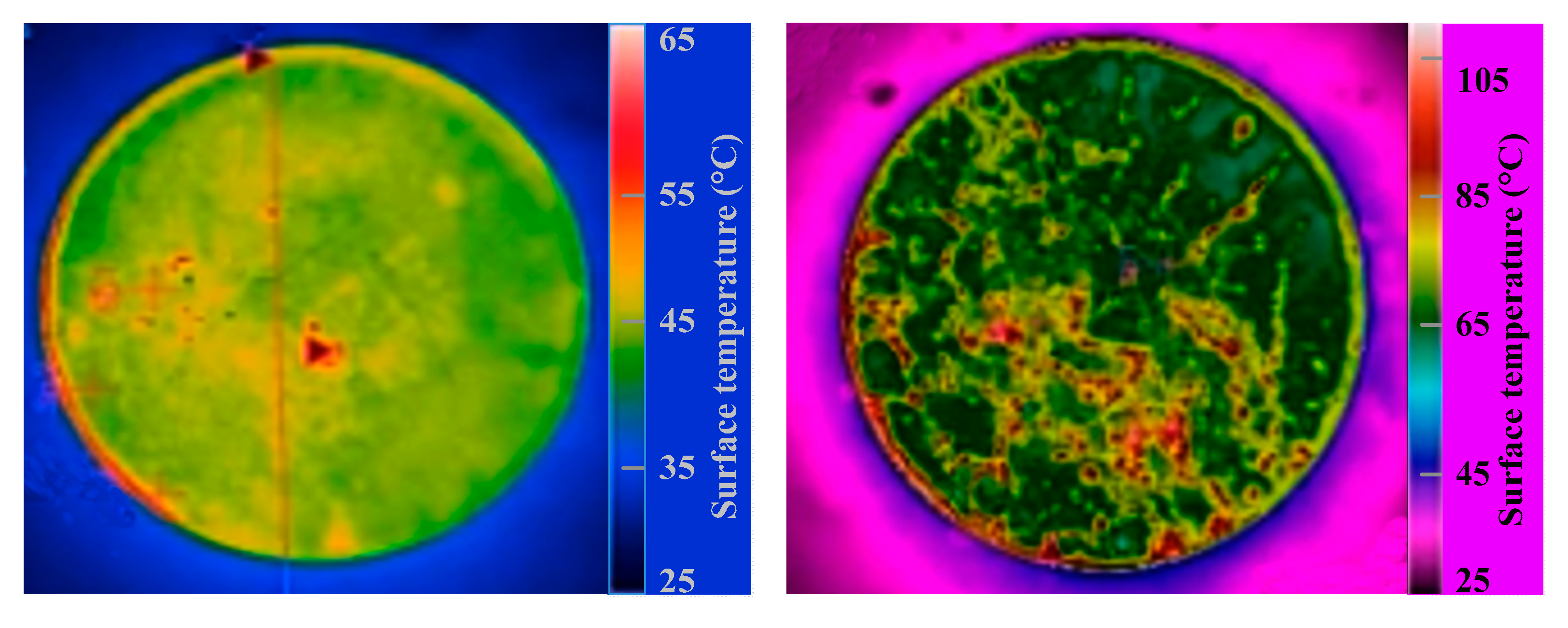

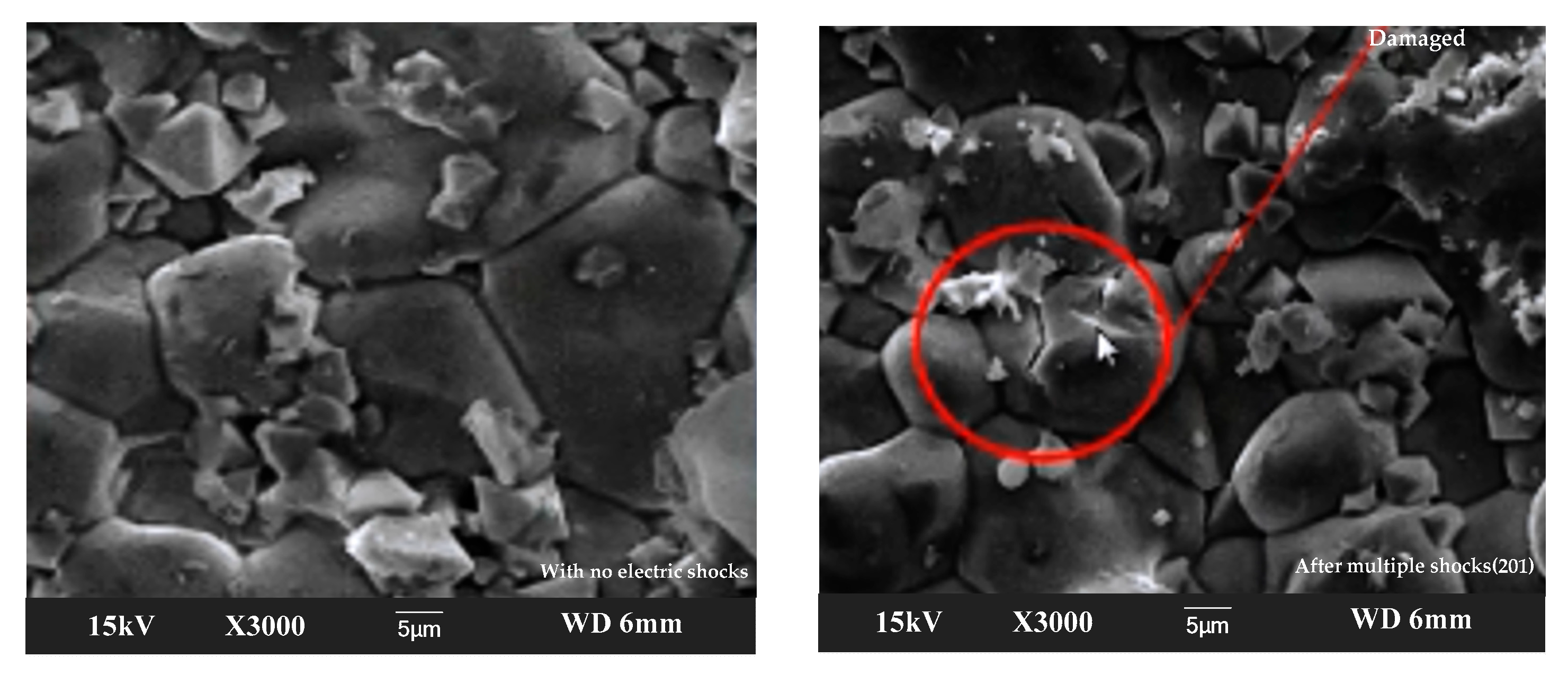

5. Apparent Morphology and Element Migration Characteristics of the Surge Arrester

6. Discussion on the Aging Characteristics of the Arrester

7. Conclusions

- (1)

- The aging duration with the ZnO resistor’s charge rate increases with increased applied voltage frequencies. After the process of aging, there is a noticeable decline in the 1 mA DC reference voltage, accompanied by an upward trend in the leakage current under this voltage. Nevertheless, the rise observed in this regard is significantly less compared to that in the frequency of the applied voltage.

- (2)

- When subjected to high-frequency voltage conditions, the resistor element migrates. During the aging process, the resistors absorb energy and heat up. The internal heat activation can push the Bi, Co, and other cations to the depletion layer and cause the Bi and Co elements to appear on the aluminum electrode’s outermost layer. Meanwhile, water vapor is more likely to invade, resulting in a significant increase in oxygen elements in the resistors.

- (3)

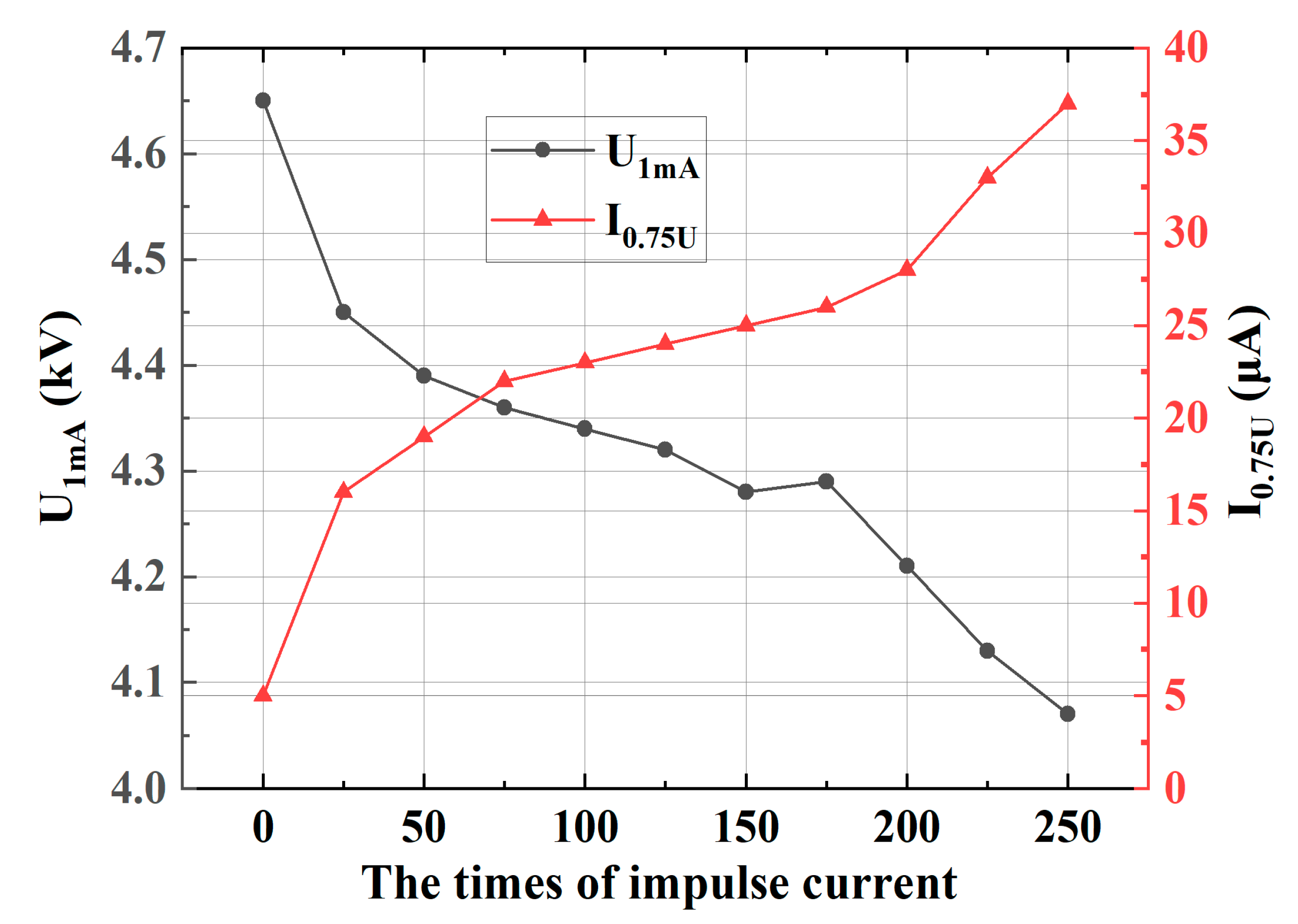

- When subjected to various impacts, the arrester resistor experiences a decrease in its 1 mA DC reference voltage, which is approximately 0.75 times the leakage current under the same reference voltage. This leads to an increase in the valve temperature and uneven heat distribution, which ultimately causes grain rupture and compromises the functionality of the resistor.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tian, F.; Li, X.; Chen, J.; Cao, J.; Zhang, S. Research on the Structural Optimization and Electrical Characteristics of the Ar-rester in Electric Multiple Units. IEEE Trans. Instrum. Meas. 2025, 74, 3514411. [Google Scholar] [CrossRef]

- Ambrósio, J.; Pombo, J.; Pereira, M. Optimization of high-speed railway pantographs for improving pantograph-catenary contact. Theor. Appl. Mech. Lett. 2013, 3, 013006. [Google Scholar] [CrossRef]

- Yang, S.; Gao, B.J.; Gao, G.Q.; Chen, P.; Huang, X.; Wang, Y.T. Analysis of surge overvoltage of dropping pantograph for high-speed EMUs. J. China Railw. Soc. 2015, 37, 46–50. [Google Scholar]

- Pan, C.; Tong, X.; Qin, P.; Yang, Z.G.; Zhou, Z.B. Condition Maintenance Techniques for Screening Tank Metal Oxide Arrester Insulation Aging. Power Energy 2015, 36, 516–520. [Google Scholar]

- Eda, K.; Iga, A.; Matsuoka, M. Degradation mechanism of non-Ohmic zinc oxide ceramics. J. Appl. Phys. 1980, 51, 2678–2684. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, J.; Qiu, R.; Liu, Z. VCT-AOC Comprehensive Method to Suppress High-Frequency Resonance and Low-Frequency Oscillation in Railway Traction Power Supply System. IEEE Access 2019, 7, 152202–152213. [Google Scholar] [CrossRef]

- Thipprasert, W.; Sritakaew, P. Electrical Performance of Porcelain Surge Arrester in 22 kV Distribution System under Contaminated Conditions. J. Power Energy Eng. 2015, 3, 75–81. [Google Scholar] [CrossRef]

- Gupta, T.K.; Carlson, W.G. A grain-oundary defect model for instability or stability of a ZnO resistor. J. Mater. Sci. 1985, 20, 3487–3500. [Google Scholar] [CrossRef]

- Imai, T.; Udagawa, T.; Ando, H.; Tanno, Y.; Kayano, Y.; Kan, M. Development of high gradient zinc oxide nonlinear resistors and their application to surge arresters. IEEE Trans. Power Deliv. 1998, 13, 1182–1187. [Google Scholar] [CrossRef]

- Sonder, E.; Levinson, L.M.; Katz, W. Role of short-circui-ting pathways in reduced ZnO Varitors. J. Appl. Phys. 1985, 58, 4420–4425. [Google Scholar] [CrossRef]

- Liu, J.; Yang, Q.; Zheng, T.Q. Harmonic analysis of traction networks based on the CRH380 series EMUs accident. In Proceedings of the 2012 IEEE Transportation Electrification Conference and Expo (ITEC), Dearborn, MI, USA, 18–20 June 2012; pp. 1–6. [Google Scholar]

- Bui, A.; Loubiere, A.; Hassanzadeh, M. Electrical characteristic degradation of ZnO resistors subjected topartial discharges. J. Appl. Phys. 1989, 65, 4048–4050. [Google Scholar]

- Mizukoshi, A.; Ozawa, J.; Shirakawa, S.; Nakano, K. Influence of Uniformity on Energy Absorption Capabilities of Zinc Oxide Elements as Applied in Arresters. IEEE Power Eng. Rev. 1983, PAS-102, 1384–1390. [Google Scholar]

- Takahashi, K.; Miyoshi, T.; Keada, K. Degradation of zinc oxide resistors. In Proceedings of the Materials Research Society Annual Meeting, Boston, MA, USA, 16 November 1981; Volume 33, pp. 16–19. [Google Scholar]

- Vanadamme, L.K.J.; Brugman, J.C. Conduction mechanisms in ZnO resistors. J. Appl. Phys. 1980, 51, 4240–4244. [Google Scholar]

- Coffeen, L.; McBride, J. High voltage AC resistive current measurements using a computer based digital watts technique. IEEE Trans. Power Deliv. 1991, 6, 550–556. [Google Scholar] [CrossRef]

- Eda, K. Destruction mechanism of ZnO varistors due to high currents. J. Appl. Phys. 1984, 56, 2948–2955. [Google Scholar] [CrossRef]

- Heinrich, C.; Hinrichsen, V. Diagnostics and monitoring of metal-oxide surge arresters in high-voltage networks-comparison of existing and newly developed procedures. IEEE Trans. Power Deliv. 2001, 16, 138–143. [Google Scholar] [CrossRef]

- Almeida, C.A.L.; Braga, A.P.; Nascimento, S.; Paiva, V.; Martins, H.J.A.; Torres, R.; Caminhas, W.M. Intelligent Thermographic Diagnostic Applied to Surge Arresters: A New Approach. IEEE Trans. Power Deliv. 2009, 24, 751–757. [Google Scholar] [CrossRef]

- Wong, K.L. Electromagnetic emission based monitoring technique for polymer ZnO surge arresters. IEEE Trans. Dielectr. Electr. Insul. 2006, 13, 181–190. [Google Scholar]

- Khodsuz, M.; Mirzaie, M. Monitoring and identification of metal–oxide surge arrester conditions using multi-layer support vector machine. IET Gener. Transm. Distrib. 2015, 9, 2501–2508. [Google Scholar] [CrossRef]

- Khodsuz, M.; Mirzaie, M. Harmonics ratios of resistive leakage current as metal oxide surge arresters diagnostic tools. Measurement 2015, 70, 148–155. [Google Scholar] [CrossRef]

- Carminati, M.; Gervasoni, G.; Sampietro, M.; Ferrari, G. Note: Differential configurations for the mitigation of slow fluctuations limiting the resolution of digital lockin amplifier. Rev. Sci. Instrum. 2016, 87, 13–16. [Google Scholar]

- Maya-Hernandez, P.M.; Sanz-Pascual, M.T.; Calvo, B. CMOS Low-Power Lock-In Amplifiers with Signal Rectification in Current Domain. IEEE Trans. Instrum. Meas. 2014, 64, 1858–1867. [Google Scholar] [CrossRef]

- Tominaga, S.; Azumi, K.; Shibuya, Y.; Imataki, M.; Fujiwara, Y.; Nishida, S. Protective Performance of Metal Oxide Surge Arrester Based on the Dynamic V-I Characteristics. IEEE Trans. Power Appar. Syst. 1979, PAS-98, 1860–1871. [Google Scholar] [CrossRef]

- Pinceti, P.; Giannettoni, M. A simplified model for zinc oxide surge arresters. IEEE Trans. Power Deliv. 1999, 14, 393–398. [Google Scholar] [CrossRef]

- Lira, G.R.S.; Barbosa, V.R.N.; Brito, V.S.; Costa, E.G.; Filho, C.R.A.; Maia, M.J.A. Methodology to evaluate the performance of metal-oxide surge arresters monitoring techniques based on the resistive leakage current. In Proceedings of the 2018 Simposio Brasileiro de Sistemas Eletricos (SBSE), Niteroi, Brazil, 12–16 May 2018; pp. 1–6. [Google Scholar]

- Levinson, L.M.; Philipp, H.R. ac properties of metal-oxide varistors. J. Appl. Phys. 1976, 47, 1117–1122. [Google Scholar] [CrossRef]

- Bhattacharyya, S.; Ahmed, R.N.; Purkayastha, B.B.; Bhattacharyya, K. Implementation of Digital Lock-in Amplifier. J. Phys. Conf. Ser. 2016, 29, 42–44. [Google Scholar]

- Liu, W.; Xiao, J.; Jin, S.; Yang, S.; Gao, M.; Zhang, Y. Analysison Damp Defect of 500 kV Zinc Oxide Arrester Based on Field CircuitCoupling. Insul. Surge Arresters 2022, 1, 118–125. [Google Scholar]

- Fang, Z.; Wu, X.; Guo, J.; Xie, P.; Hu, J.; Li, C. Heat Dissipation Model of Arrester Under Transient Time-varying Load. High Volt. Eng. 2020, 46, 34–41. [Google Scholar]

- Zheng, Z.; Boggs, S.A.; Imai, T.; Nishiwaki, S. Computation of Arrester Thermal Stability. IEEE Trans. Power Deliv. 2010, 25, 1526–1529. [Google Scholar] [CrossRef]

- Huang, L.; Zhou, L.; Yang, J.; Liu, C.; Wang, D.; Yuan, S.; Ma, Y.; Zhao, H. An Impulse Aging Assessment Method for Arrester Under Multiple Strokes Based on Frequency Domain Dielectric Spectroscopy. IEEE Trans. Power Deliv. 2023, 38, 2933–2943. [Google Scholar] [CrossRef]

- Wu, Y.Y.; Xie, Y.Z.; Ge, Y.P.; Wang, Y.B.; Li, Z.T.; Cao, H. Experimental Study on Response of Non- and Externally-Gapped Metal-Oxide Arresters Excited by Nanosecond-Level Transient Electromagnetic Disturbances. IEEE Trans. Power Deliv. 2023, 38, 1239–1247. [Google Scholar]

- Teymourian, M.H.; Seyyedbarzegar, S.; Khodsuz, M. Harmonic Analysis of Metal Oxide Surge Arrester Leakage Current Considering Fan-Shaped Type Pollution Effect. IEEE Trans. Dielectr. Electr. Insul. 2024, 31, 1547–1556. [Google Scholar]

| Parameter | Numerical Value |

|---|---|

| Diameter (mm) | 52 |

| Thickness (mm) | 22 |

| Weight (g) | 264 |

| U1mA (kV) | 5.0 |

| I0.75U (μA) | 10.0 |

| Electrical Parameters | Numerical Values |

|---|---|

| Rated voltage (V) | 220 |

| Output voltage (kV) | 0~20 |

| Range (A) | 0–10 |

| Power (W) | 1000 |

| Accuracy (μA) | 0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Sun, J.; Kun, Z.; Liu, Y.; Tian, F.; Liu, B.; Chen, W. The Elemental Migration Characteristics and Structural Damage Process of a ZnO Arrester Unit Surface Under a High-Frequency Voltage and Impulse Current. Coatings 2025, 15, 417. https://doi.org/10.3390/coatings15040417

Liu J, Sun J, Kun Z, Liu Y, Tian F, Liu B, Chen W. The Elemental Migration Characteristics and Structural Damage Process of a ZnO Arrester Unit Surface Under a High-Frequency Voltage and Impulse Current. Coatings. 2025; 15(4):417. https://doi.org/10.3390/coatings15040417

Chicago/Turabian StyleLiu, Jiyong, Jixing Sun, Zhang Kun, Yide Liu, Fusheng Tian, Baipeng Liu, and Wang Chen. 2025. "The Elemental Migration Characteristics and Structural Damage Process of a ZnO Arrester Unit Surface Under a High-Frequency Voltage and Impulse Current" Coatings 15, no. 4: 417. https://doi.org/10.3390/coatings15040417

APA StyleLiu, J., Sun, J., Kun, Z., Liu, Y., Tian, F., Liu, B., & Chen, W. (2025). The Elemental Migration Characteristics and Structural Damage Process of a ZnO Arrester Unit Surface Under a High-Frequency Voltage and Impulse Current. Coatings, 15(4), 417. https://doi.org/10.3390/coatings15040417