Enhancing the Wear Resistance of CrAlN-Coated Tools in Milling and Turning Through Annealing with Optimized Duration

Abstract

1. Introduction

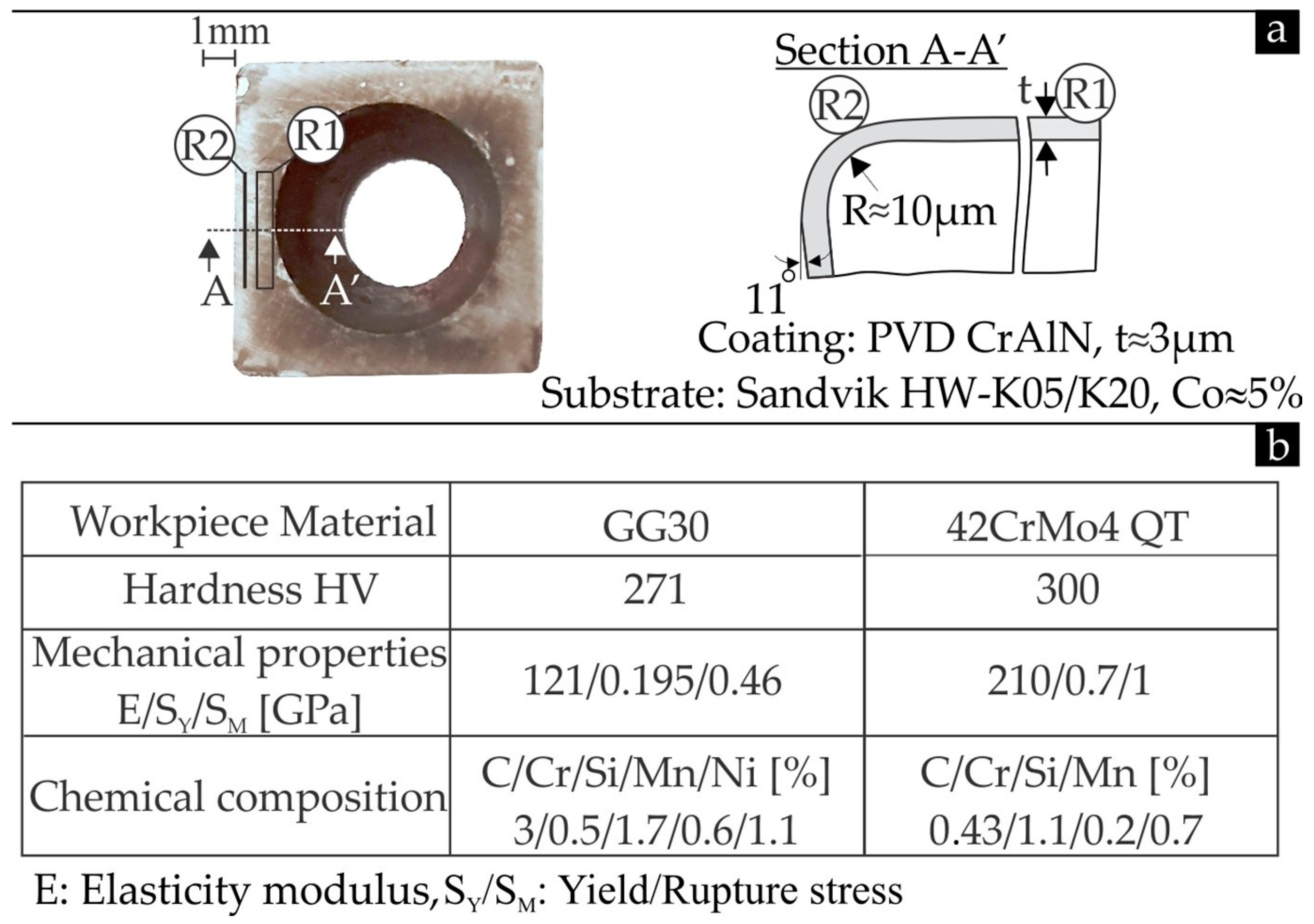

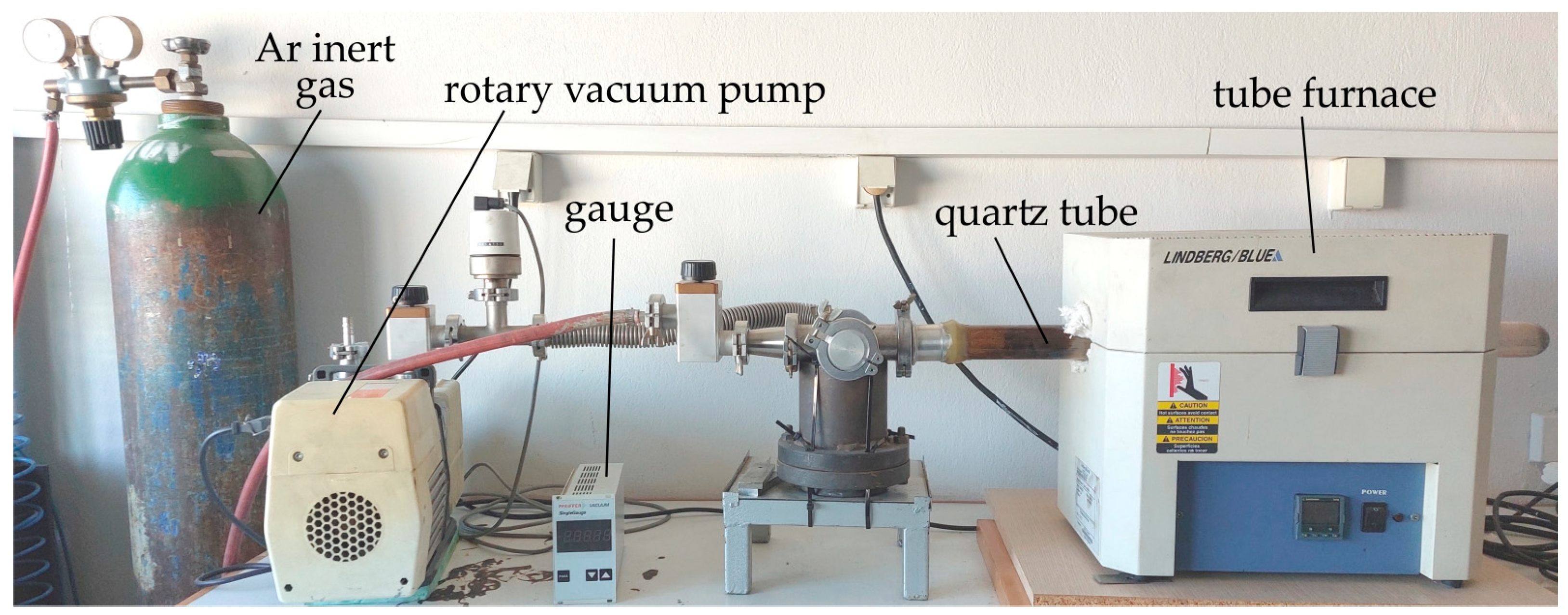

2. Materials and Methods

3. Results and Discussion

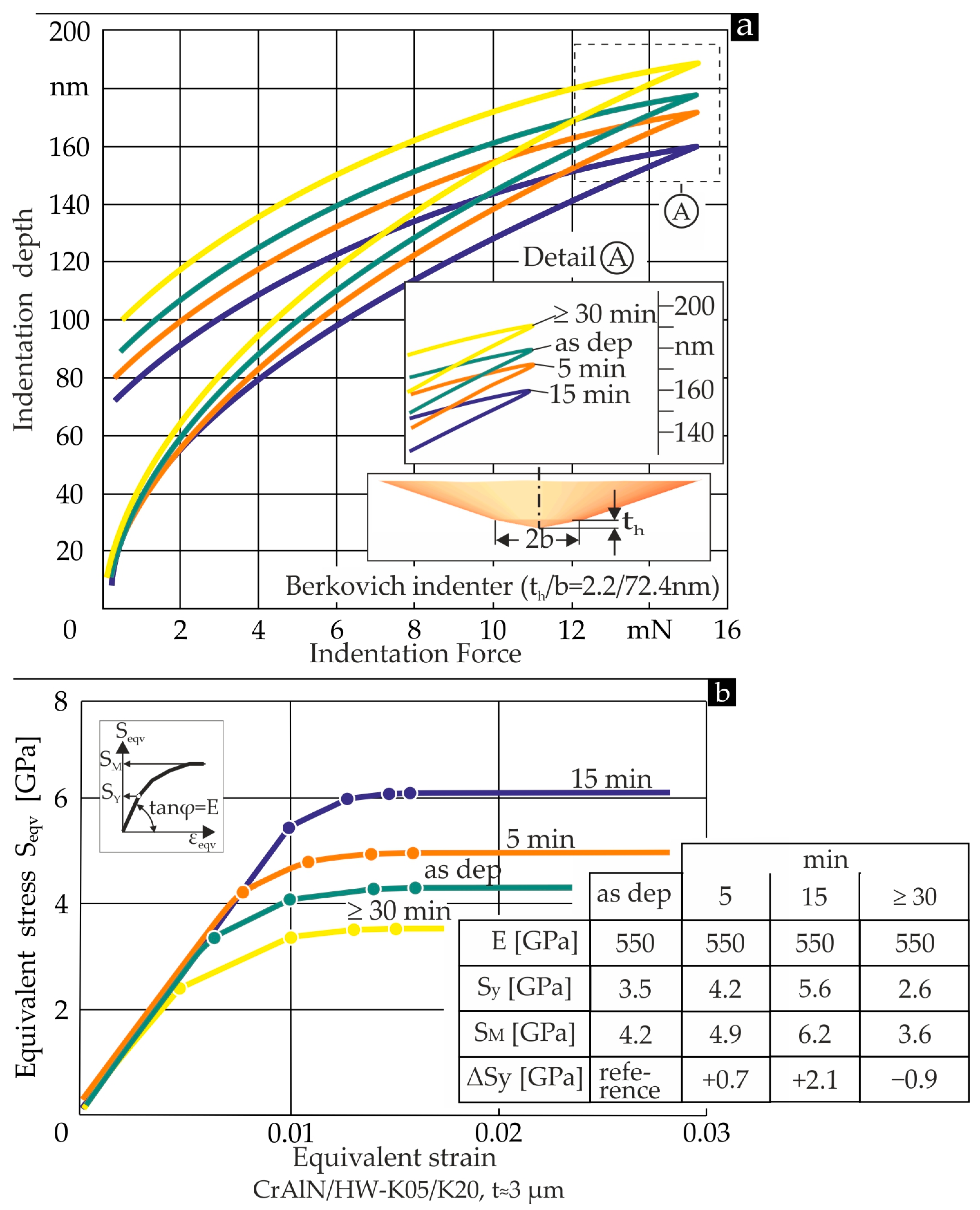

3.1. Determination of Coating’s Mechanical Properties Before and After Annealing

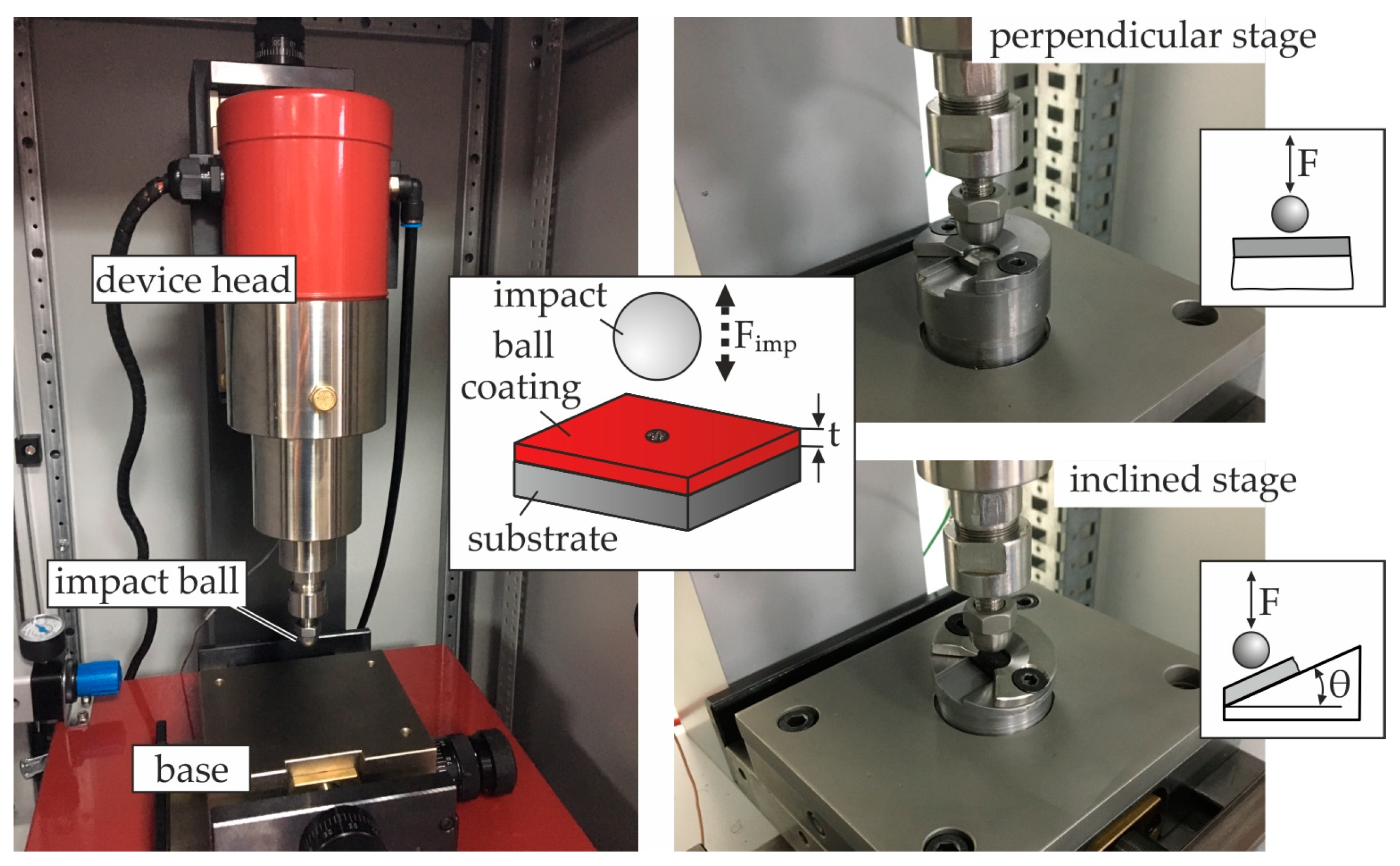

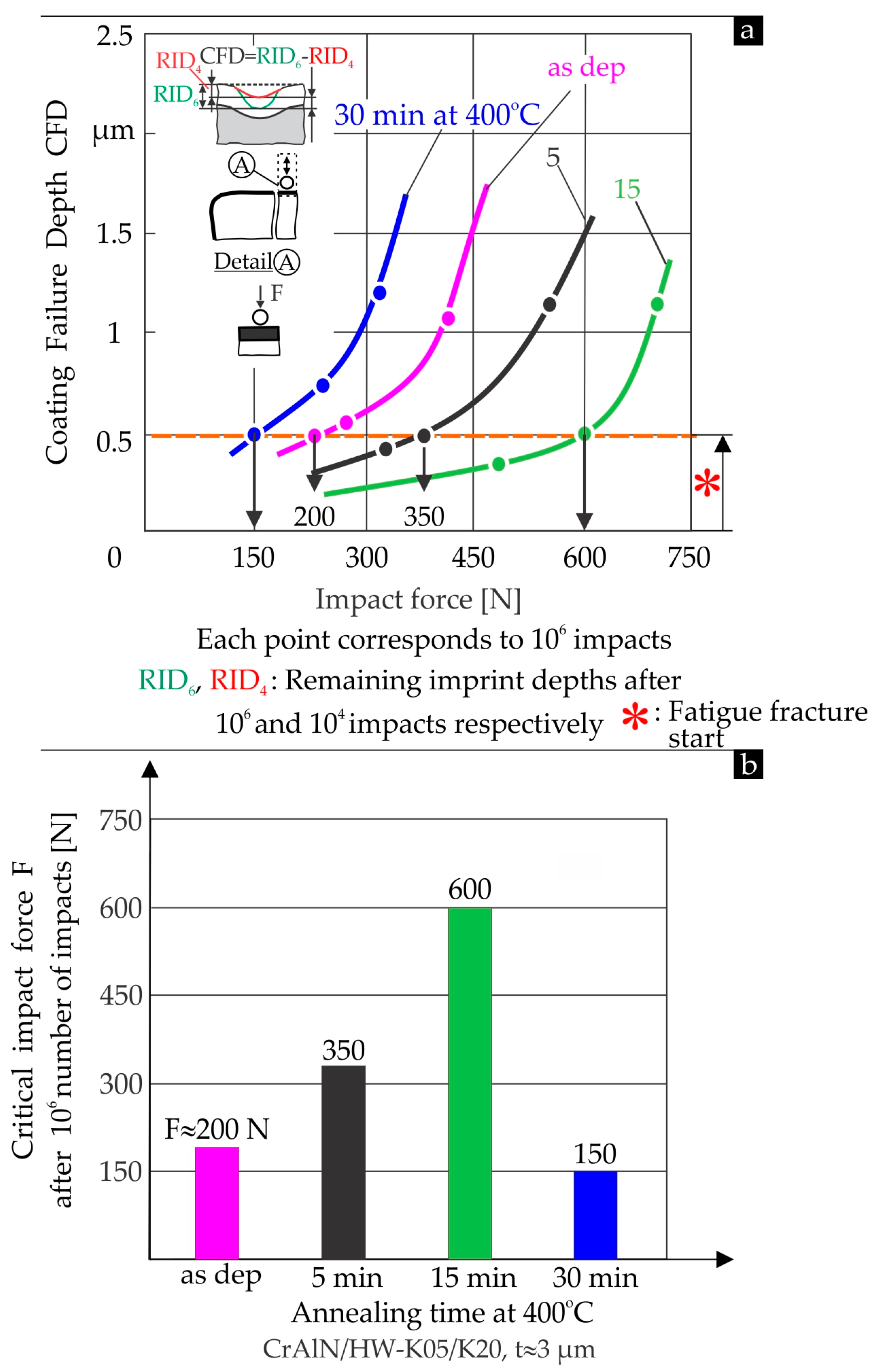

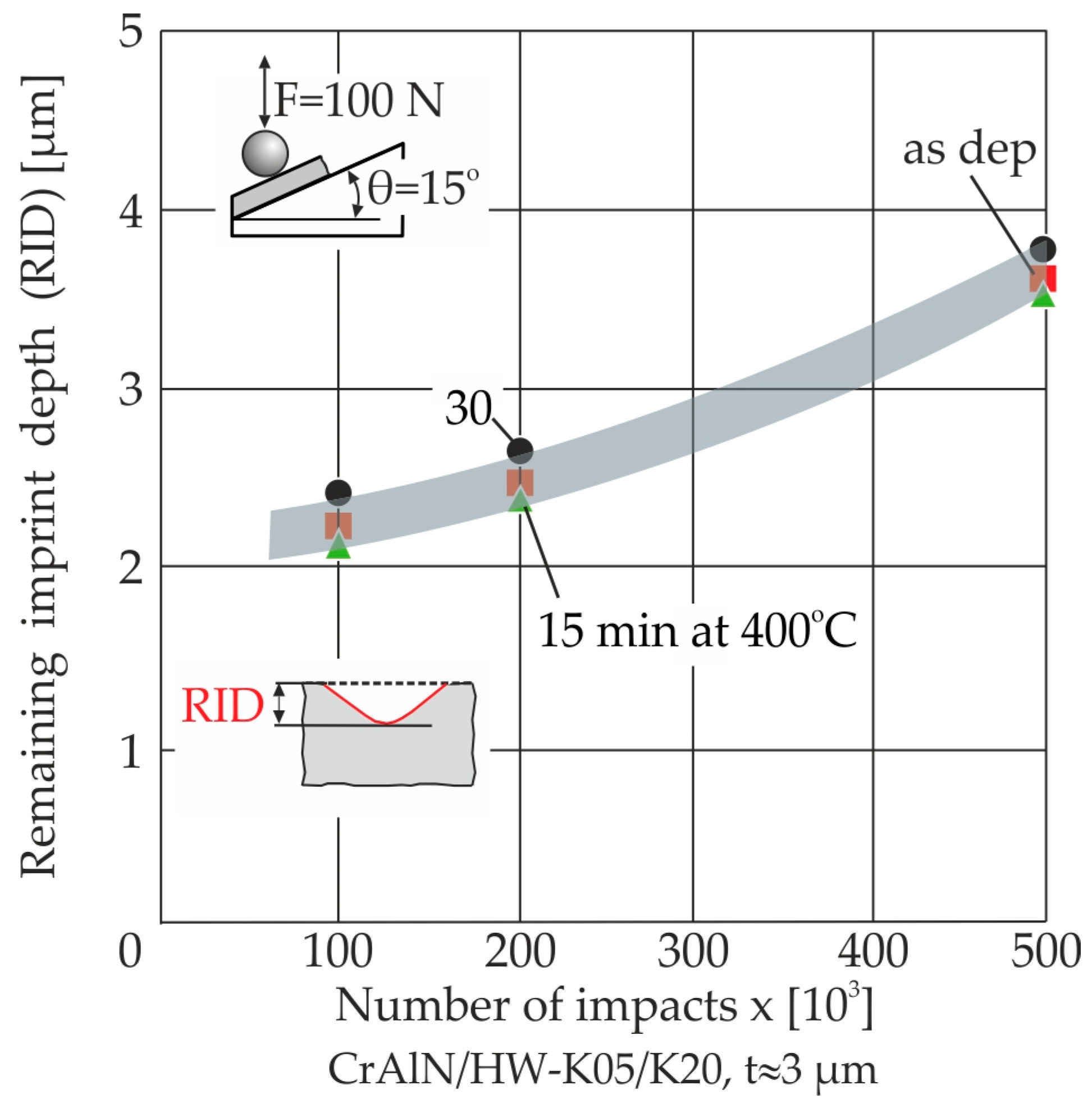

3.2. Characterization of the Fatigue Strength and Adhesion of Coatings After PVD Deposition and Annealing at Different Time Periods

3.3. Evaluation of the Cutting Performance of Coated Tools Before and After Various Long Annealing

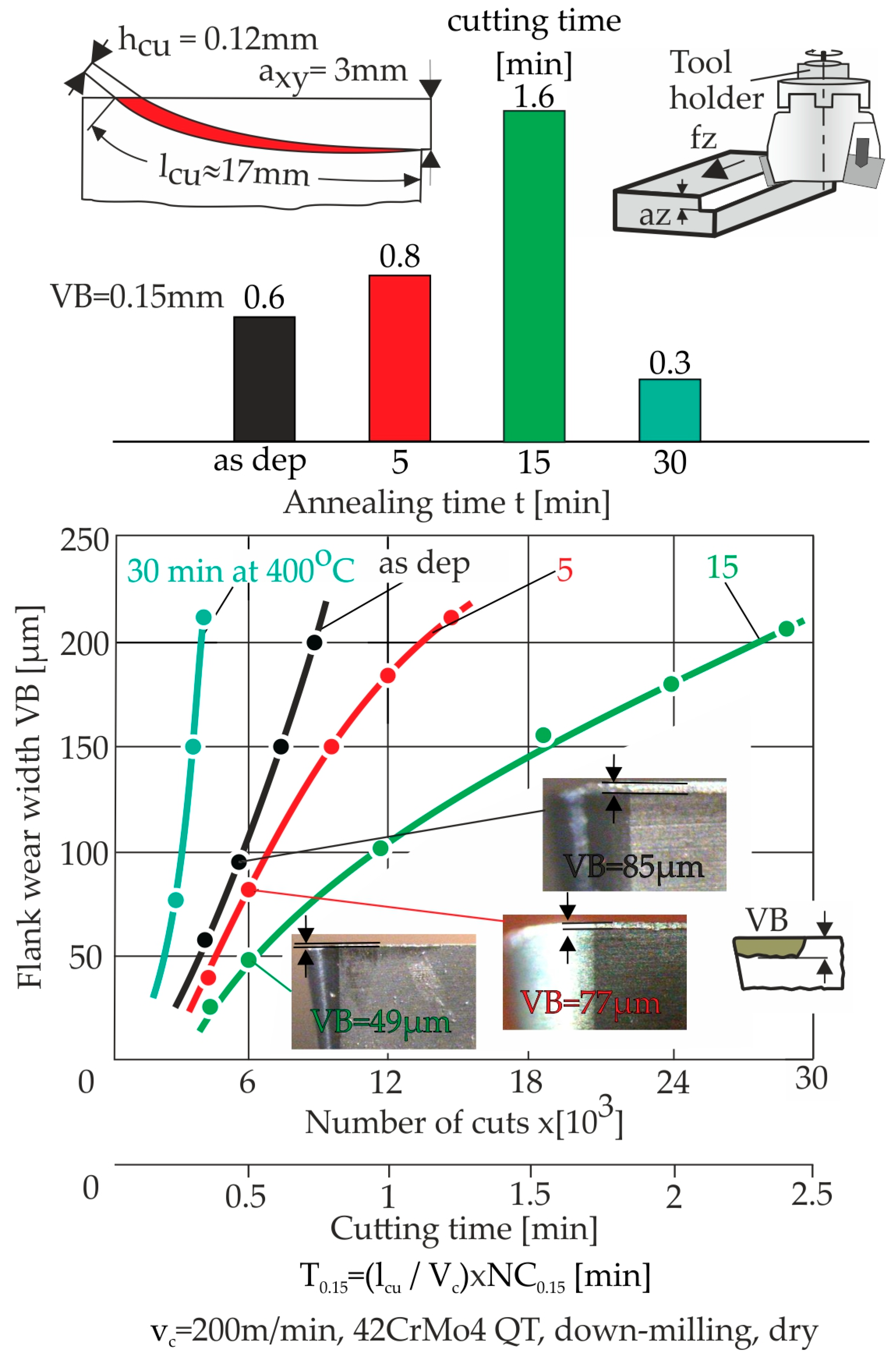

3.3.1. Cutting Investigations in Milling Hardened 42CrMo4 QT Steel

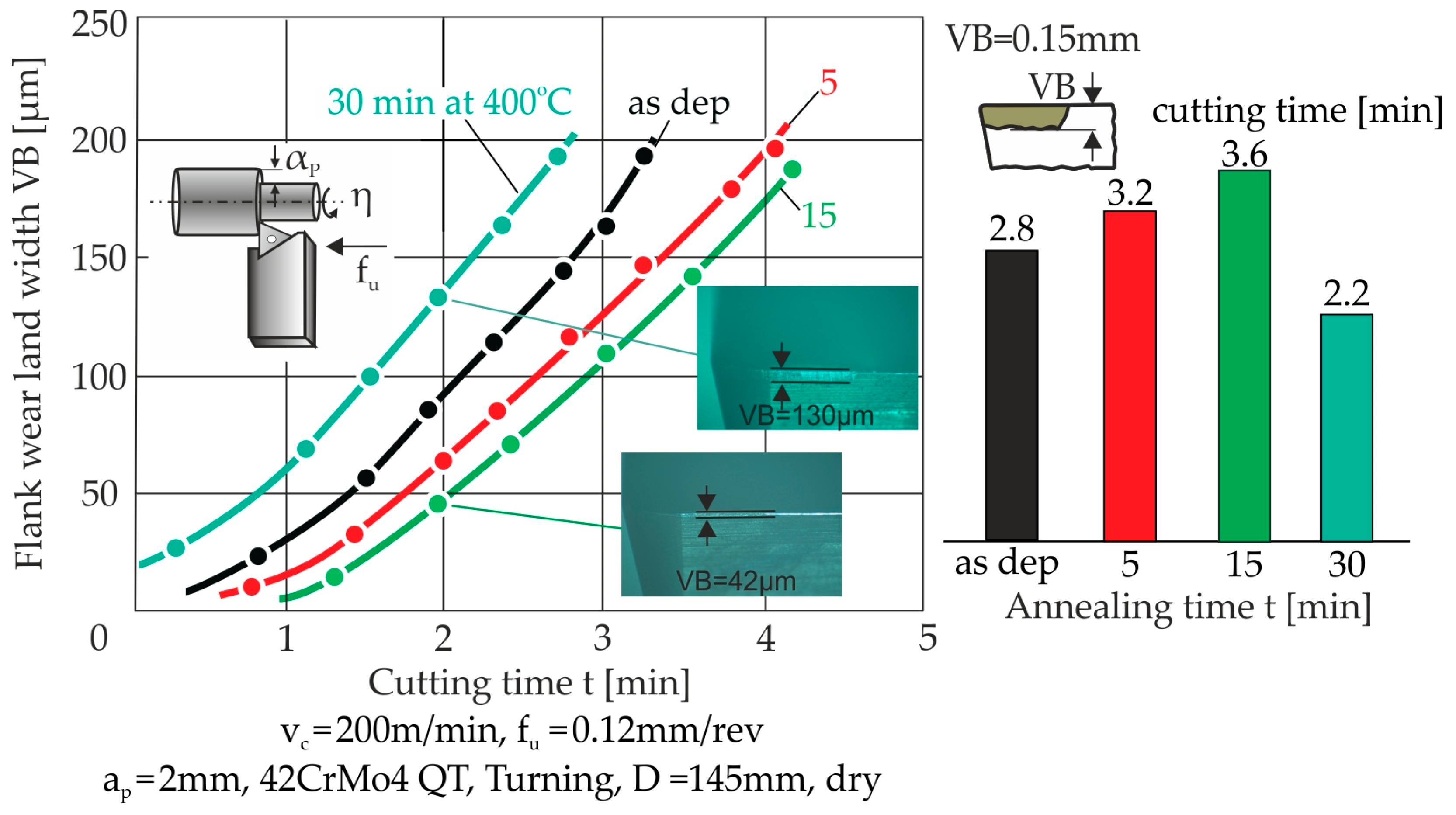

3.3.2. Cutting Investigations in Turning Hardened Steel 42CrMo4 QT and Cast Iron GG30

3.3.3. Theoretical Explanation of the Results Obtained Based on FEM Calculations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Deng, Y.; Chen, W.; Li, B.; Wang, C.; Kuang, T.; Li, Y. Physical vapor deposition technology for coated cutting tools: A review. Ceram. Int. 2020, 46, 18373–18390. [Google Scholar] [CrossRef]

- Al-Zubaidi, S.; Ghani, J.A.; Che Haron, C.H.; Mohammed, M.N.; Jameel Al-Tamimi, A.N.; M.Sarhan, S.; Salleh, M.S.; Abdulrazaq, M.; Abdullah, O.I. Development of Hybrid Intelligent Models for Prediction Machining Performance Measure in End Milling of Ti6Al4V Alloy with PVD Coated Tool under Dry Cutting Conditions. Lubricants 2022, 10, 236. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Michailidis, N.; Skordaris, G.; Bouzakis, E.; Biermann, D.; M’Saoubi, R. Cutting with coated tools: Coating technologies, characterization methods and performance optimization. CIRP Ann. Manuf. Technol. 2012, 61, 703–723. [Google Scholar] [CrossRef]

- Bobzin, K. High-performance coatings for cutting tools. CIRP J. Manuf. Sci. Technol. 2017, 18, 1–9. [Google Scholar] [CrossRef]

- Yaqoob, S.; Ghani, J.A.; Jouini, N.; Juri, A.Z. Performance Evaluation of PVD and CVD Multilayer-Coated Tools in Machining High-Strength Steel. Coatings 2024, 14, 865. [Google Scholar] [CrossRef]

- Liu, W.; Chu, Q.; Zeng, J.; He, R.; Wu, H.; Wu, Z.; Wu, S. PVD-CrAlN and TiAlN coated Si3N4 ceramic cutting inserts-2. High speed face milling performance and wear mechanism study. Ceram. Int. 2017, 43, 9488–9492. [Google Scholar] [CrossRef]

- Paiva, J.M.; Fox-Rabinovich, G.; Junior, E.L.; Stolf, P.; Ahmed, Y.S.; Martins, M.M.; Bork, C.; Veldhuis, S. Tribological and Wear Performance of Nanocomposite PVD Hard Coatings Deposited on Aluminum Die Casting Tool. Materials 2018, 11, 358. [Google Scholar] [CrossRef] [PubMed]

- Zimmer, O.; Krülle, T.; Litterst, T. The Influence of Bias Voltage and Gas Pressure on Edge Covering during the Arc-PVD Deposition of Hard Coatings. Coatings 2024, 14, 732. [Google Scholar] [CrossRef]

- Mativenga, P.; Schoop, J.; Jawahir, I.S.; Biermann, D.; Kipp, M.; Murat Kilic, Z.; Ozel, T.; Wertheim, R.; Arrazola, P.; Boing, D. Engineered design of cutting tool material, geometry, and coating for optimal performance and customized applications: A review. CIRP-J. Manuf. Sci. Technol. 2024, 52, 212–228. [Google Scholar] [CrossRef]

- Gadge, M.; Lohar, G.; Chinchanikar, S. A review on micro-blasting as surface treatment technique for improved cutting tool performance. Mater. Today Proc. 2022, 64, 725–730. [Google Scholar] [CrossRef]

- Faksa, L.; Daves, W.; Ecker, W.; Klünsner, T.; Tkadletz, M.; Czett, C. Effect of shot peening on residual stresses and crack closure in CVD coated hard metal cutting inserts. Int. J. Refract. Met. Hard Mater. 2019, 82, 174–182. [Google Scholar] [CrossRef]

- Bagherifard, S.; Parienete, I.F.; Ghelichi, R.; Guagliano, M.; Vezzù, S. Effect of Shot Peening on Residual Stresses and Surface Work-Hardening in Cold Sprayed Coatings. Key Eng. Mater. 2009, 417–418, 397–400. [Google Scholar] [CrossRef]

- Liu, G.; Shen, Z.; Huang, G.; He, L.; Mu, R.; Zhao, W. Effects of shot peening on microstructure, thermal performance, and failure mechanism of thermal barrier coatings. J. Am. Ceram. Soc. 2022, 105, 4521–4531. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.S.; Endrino, J.L.; Beake, B.D.; Aguirre, M.H.; Veldhuis, S.C.; Quinto, D.T.; Bauer, C.E.; Kovalev, A.I.; Gray, A. Effect of temperature of annealing below 900 °C on structure, properties and tool life of an AlTiN coating under various cutting conditions. Surf. Coat. Technol. 2008, 202, 2985–2992. [Google Scholar] [CrossRef]

- Priyadarshini, B.; Anwar, S.; Choudhary, B.; Anwar, S. Influence of annealing temperature on microstructural, mechanical and chemical properties of CrAlN coatings. Phys. B Condens. Matter 2023, 669, 415304. [Google Scholar] [CrossRef]

- Wang, L.; Nie, X. Effect of Annealing Temperature on Tribological Properties and Material Transfer Phenomena of CrN and CrAlN Coatings. J. Mater. Eng. Perform. 2014, 23, 560–571. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Skordaris, G.; Hadjiyiannis, S.; Mirisidis, I.; Michailidis, N.; Erkens, G.; Wirth, I. The effect of annealing duration at deposition temperature on the strength properties gradation of PVD films and on the wear behaviour of coated cemented carbide inserts. Surf. Coat. Technol. 2006, 200, 500–4510. [Google Scholar] [CrossRef]

- Cremer, R.; Witthaut, M.; Neuschuetz, D. Experimental determination of the metastable (Ti,Al)N phase diagram up to 700 °C. In Proceedings of the TMS Annual Meeting, San Antonio, TX, USA, 15–19 February 1998; pp. 249–258. [Google Scholar]

- Chou, W.-J.; Yu, G.-P.; Huang, J.-H. Effect of heat treatment on the structure and properties of ion-plated TiN films. Surf. Coat. Technol. 2003, 168, 43–50. [Google Scholar] [CrossRef]

- Bunshah, R.F. Handbook of Hard Coatings, Noyes Publications; William Andrew Publishing, LLC: Norwich, NY, USA, 2001. [Google Scholar]

- Bouzakis, A.; Skordaris, G.; Bouzakis, E.; Bouzakis, K.-D.; Tsakalidis, D. Wear evolution on PVD coated cutting tool flank and rake explained considering stress, strain and strain-rate dependent material properties. Coatings 2023, 13, 1082. [Google Scholar] [CrossRef]

- Impact-BZ Ltd. Available online: www.impact-bz.com (accessed on 28 February 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skordaris, G.; Tsakalidis, D.; Bouzakis, K.-D.; Stergioudi, F.; Bouzakis, A. Enhancing the Wear Resistance of CrAlN-Coated Tools in Milling and Turning Through Annealing with Optimized Duration. Coatings 2025, 15, 311. https://doi.org/10.3390/coatings15030311

Skordaris G, Tsakalidis D, Bouzakis K-D, Stergioudi F, Bouzakis A. Enhancing the Wear Resistance of CrAlN-Coated Tools in Milling and Turning Through Annealing with Optimized Duration. Coatings. 2025; 15(3):311. https://doi.org/10.3390/coatings15030311

Chicago/Turabian StyleSkordaris, Georgios, Dimitrios Tsakalidis, Konstantinos-Dionysios Bouzakis, Fani Stergioudi, and Antonios Bouzakis. 2025. "Enhancing the Wear Resistance of CrAlN-Coated Tools in Milling and Turning Through Annealing with Optimized Duration" Coatings 15, no. 3: 311. https://doi.org/10.3390/coatings15030311

APA StyleSkordaris, G., Tsakalidis, D., Bouzakis, K.-D., Stergioudi, F., & Bouzakis, A. (2025). Enhancing the Wear Resistance of CrAlN-Coated Tools in Milling and Turning Through Annealing with Optimized Duration. Coatings, 15(3), 311. https://doi.org/10.3390/coatings15030311