Ultra-Long Carbon Nanotubes-Based Flexible Transparent Heaters

Abstract

1. Introduction

2. Materials and Methods

2.1. Film Deposition

2.2. Post-Treatments

2.3. Characterization

3. Results

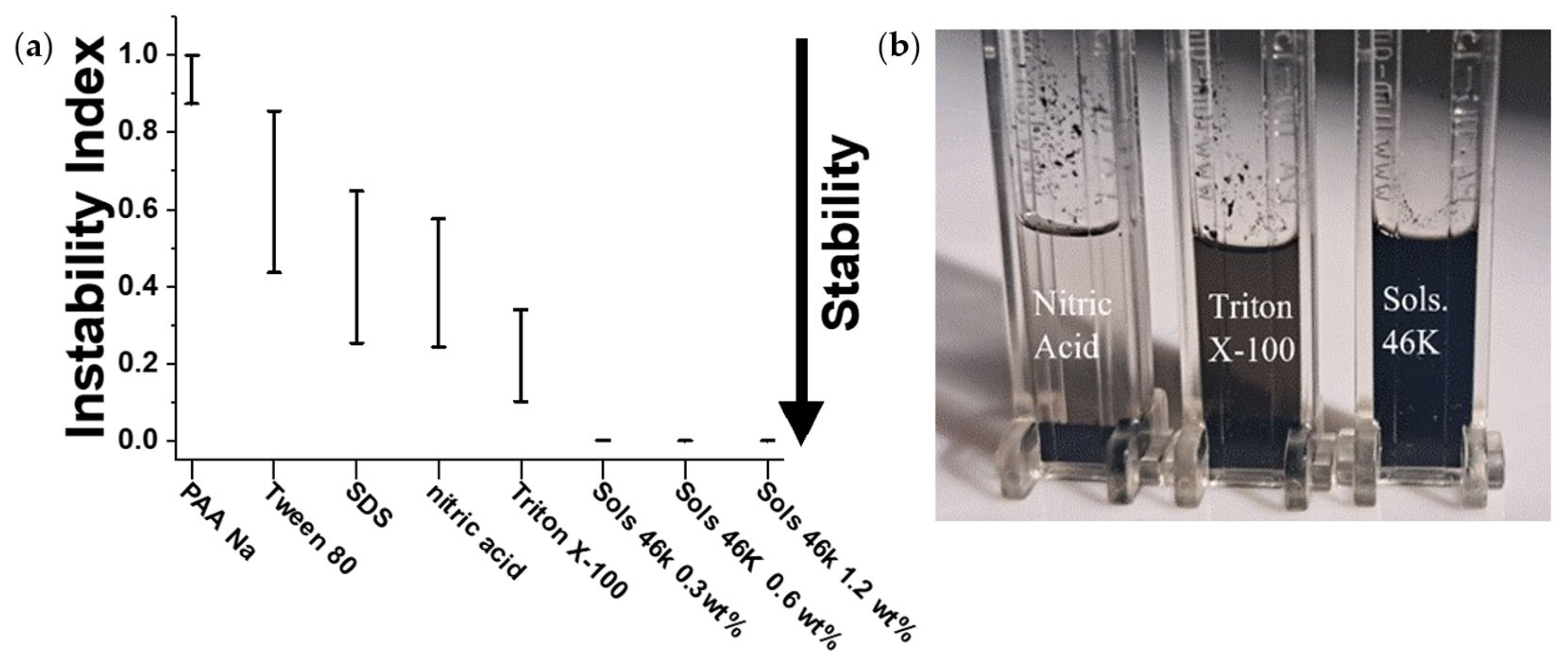

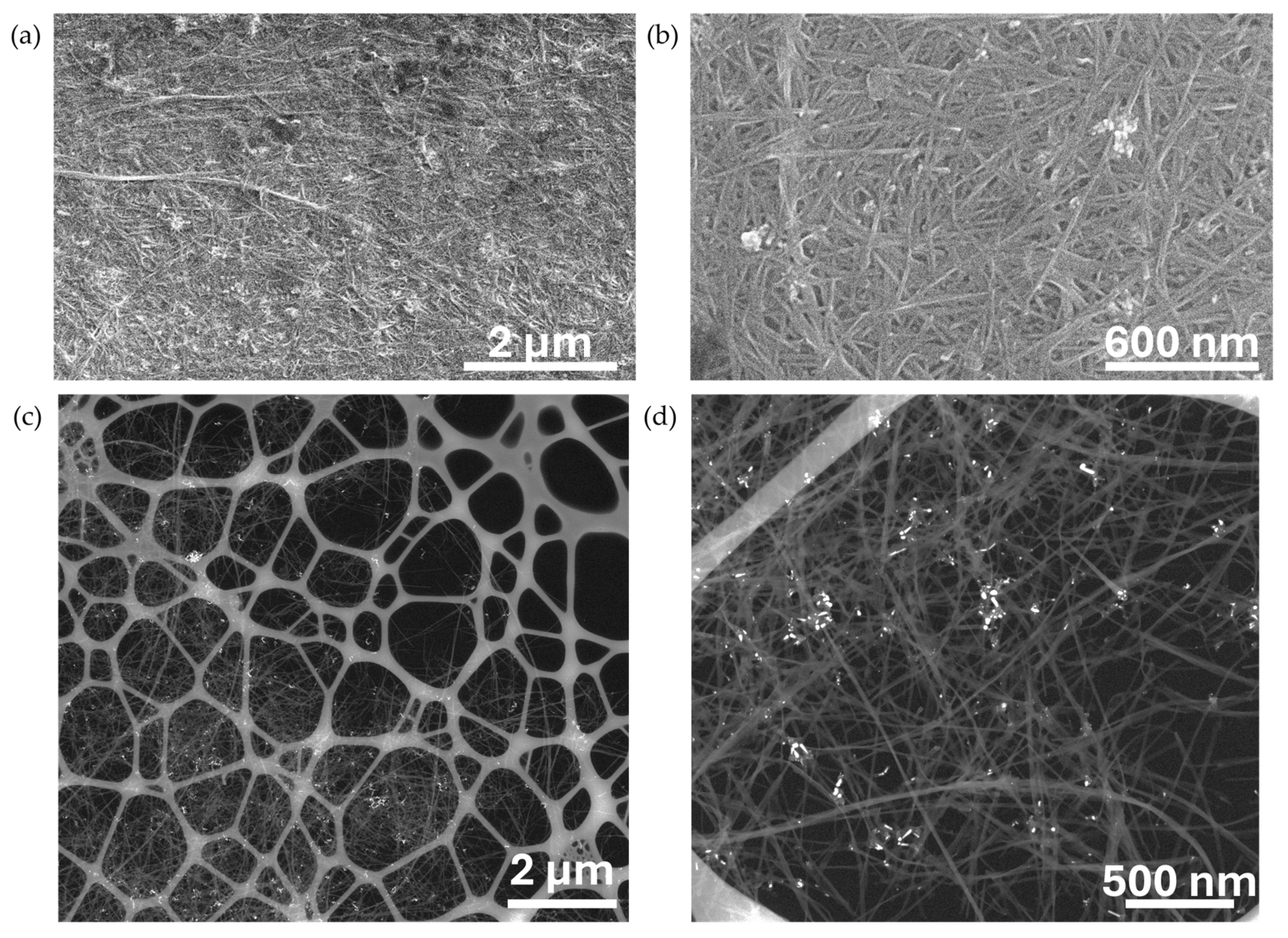

3.1. Ink Dispersion and Stability

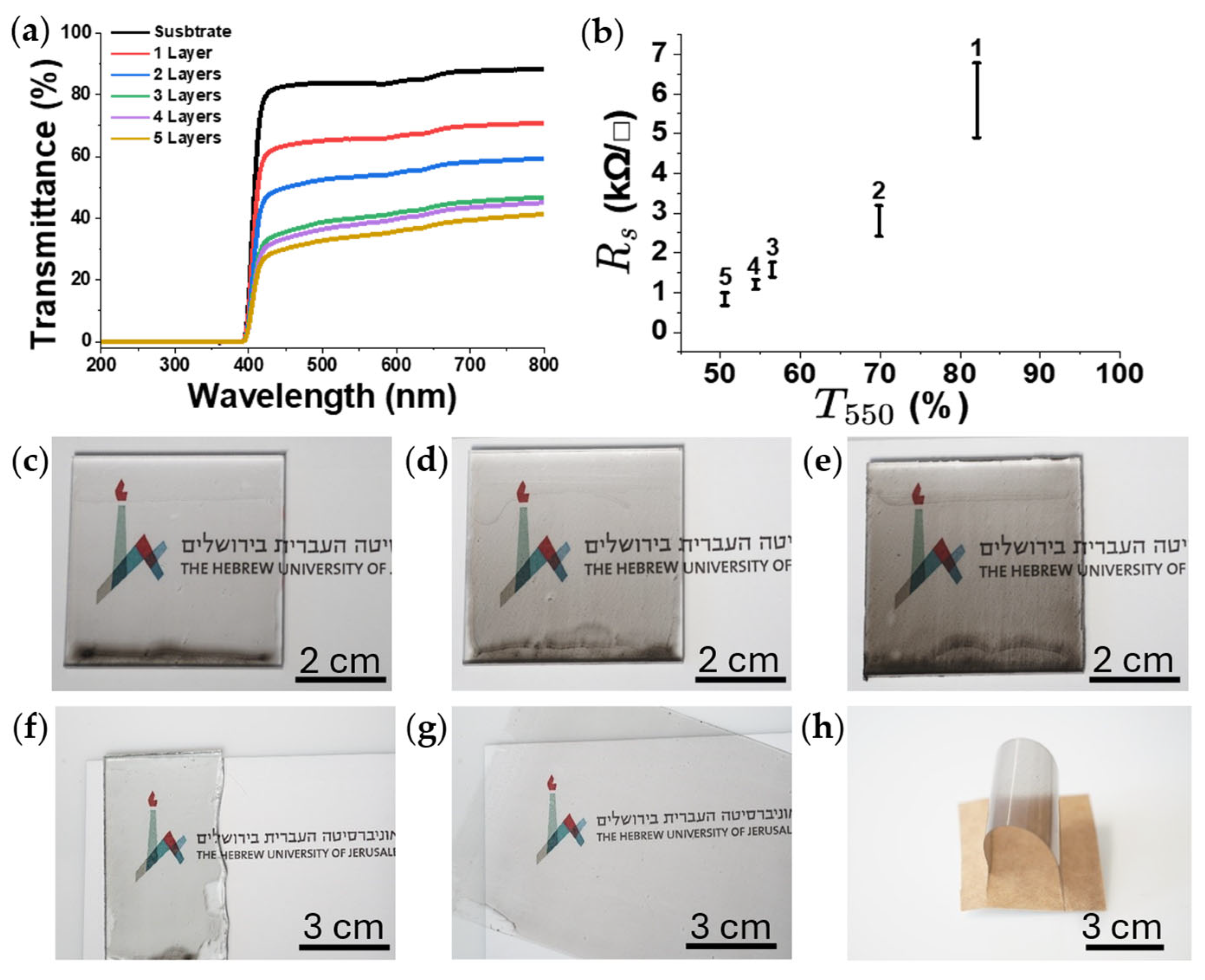

3.2. Optical and Electrical Properties of CNT Films

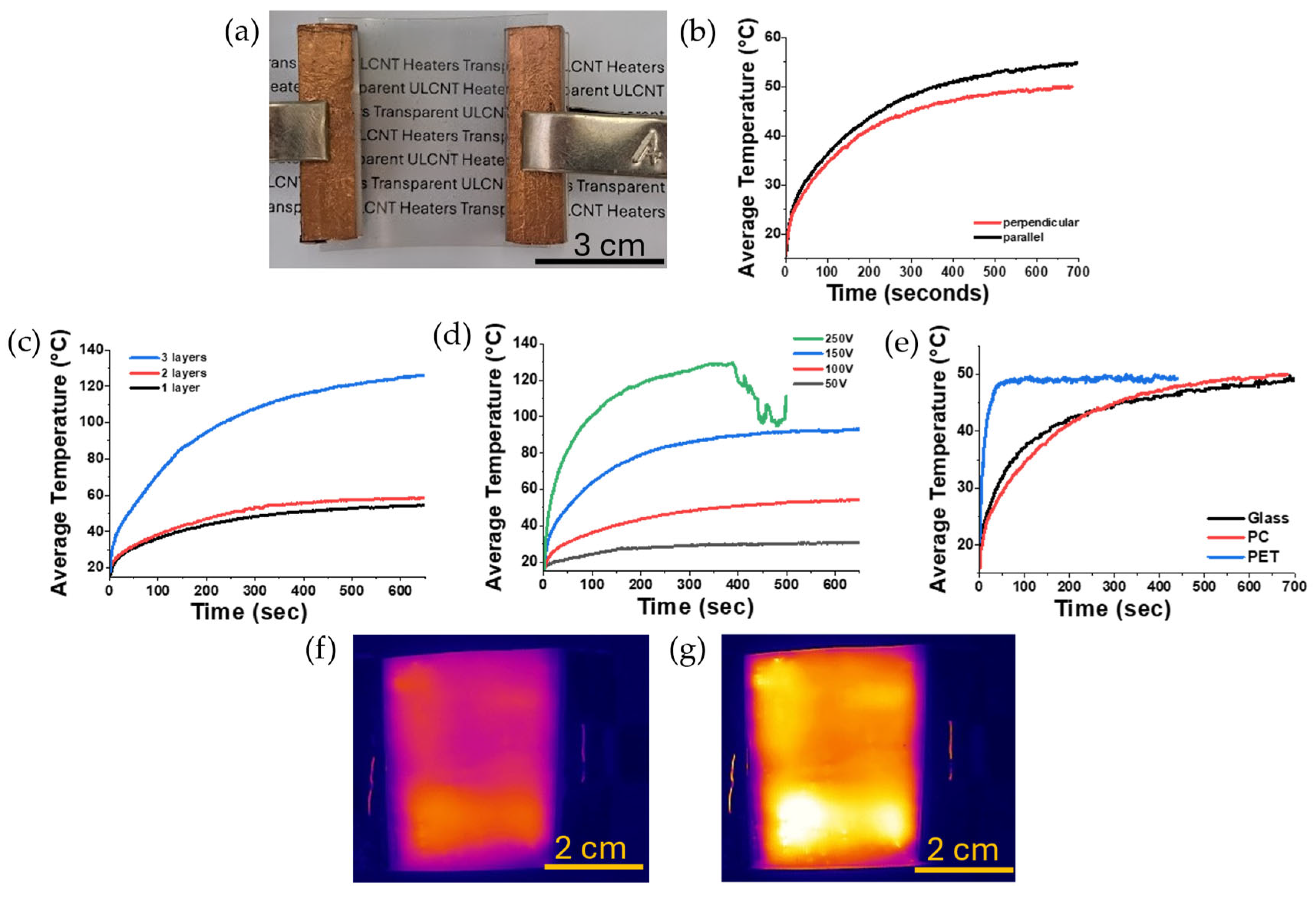

3.3. Electrical Heating Performance

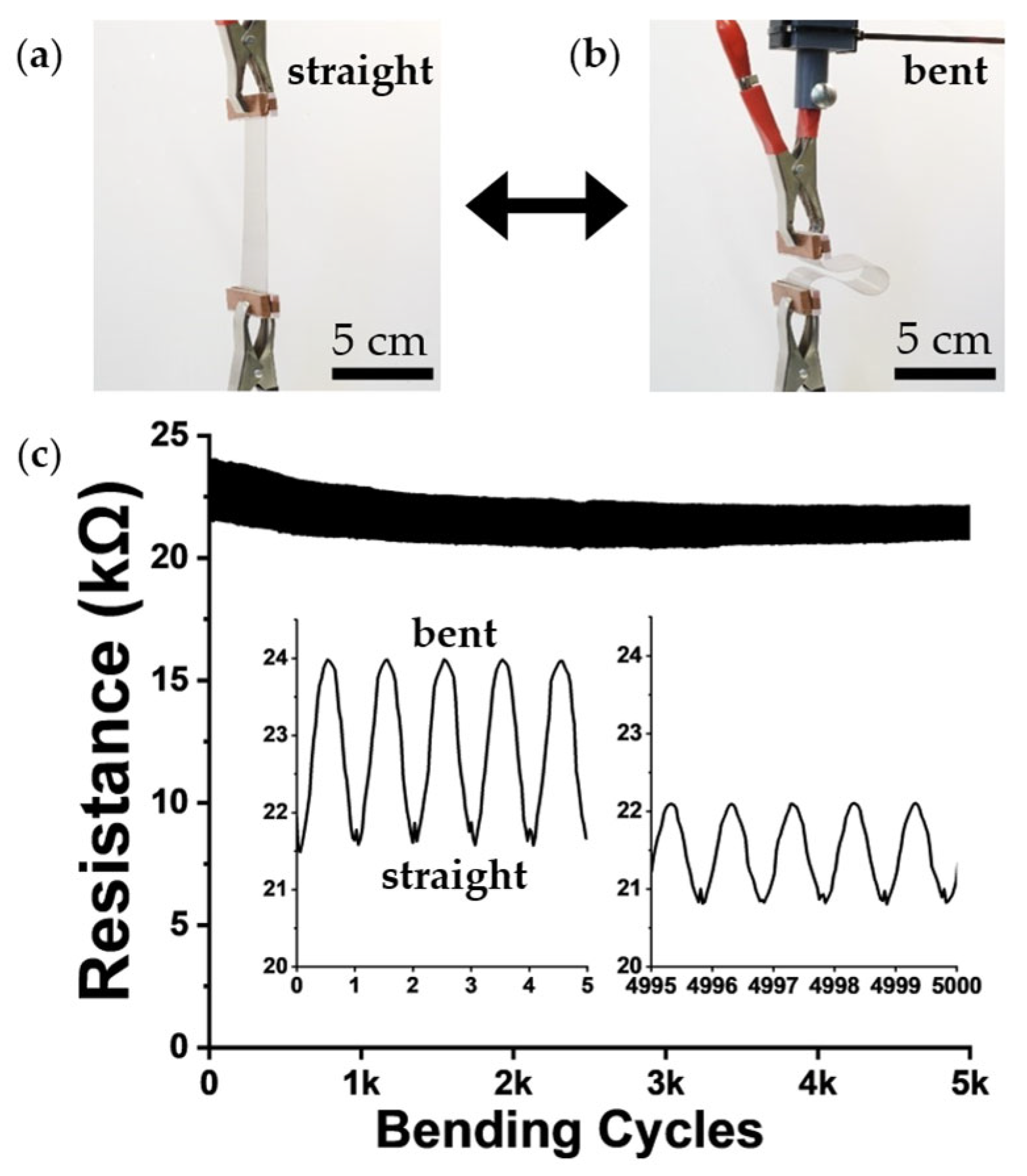

3.4. Flexibility and Durability

3.5. Post-Treatment Effects

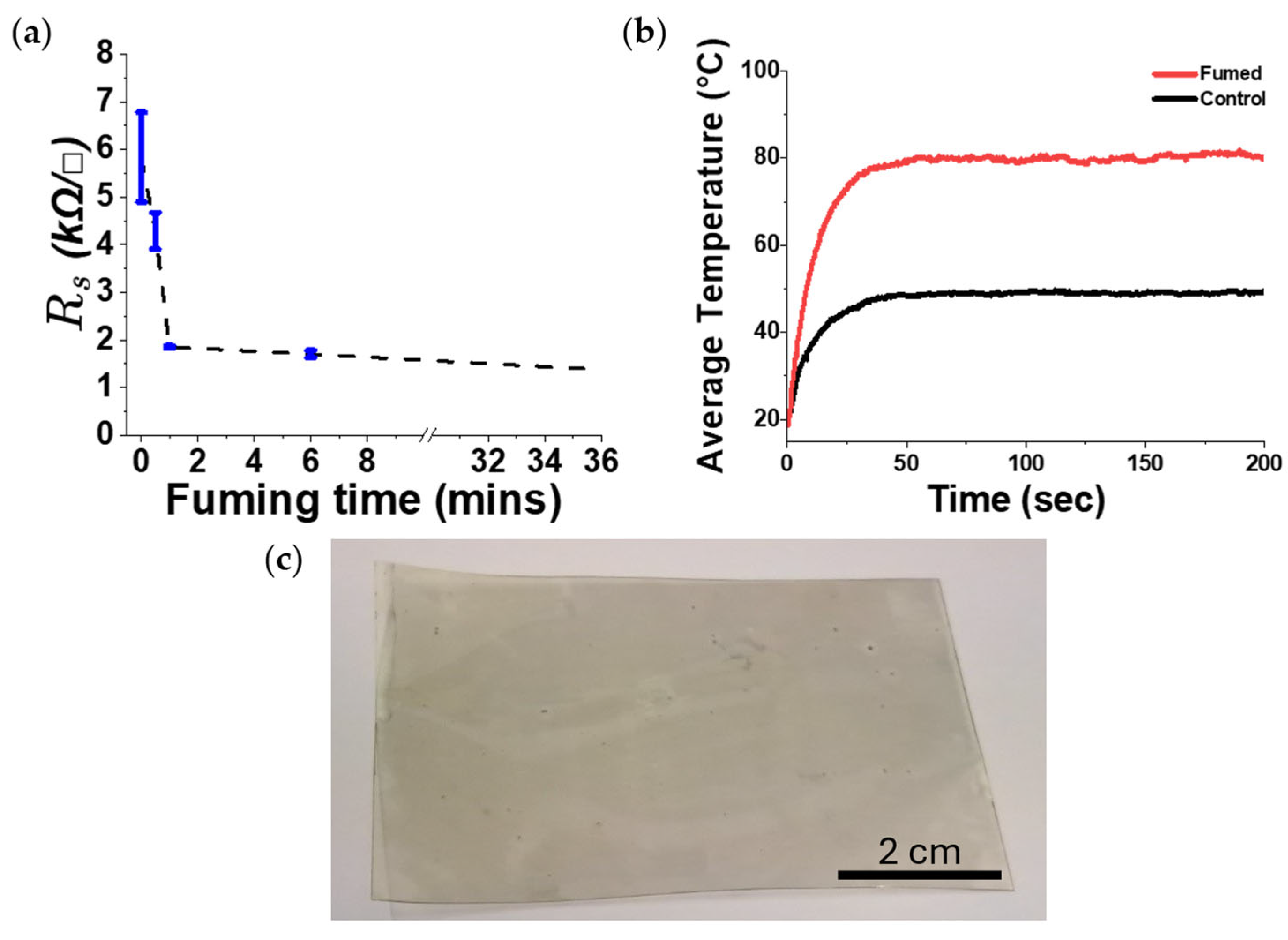

3.5.1. Nitric Acid Fuming

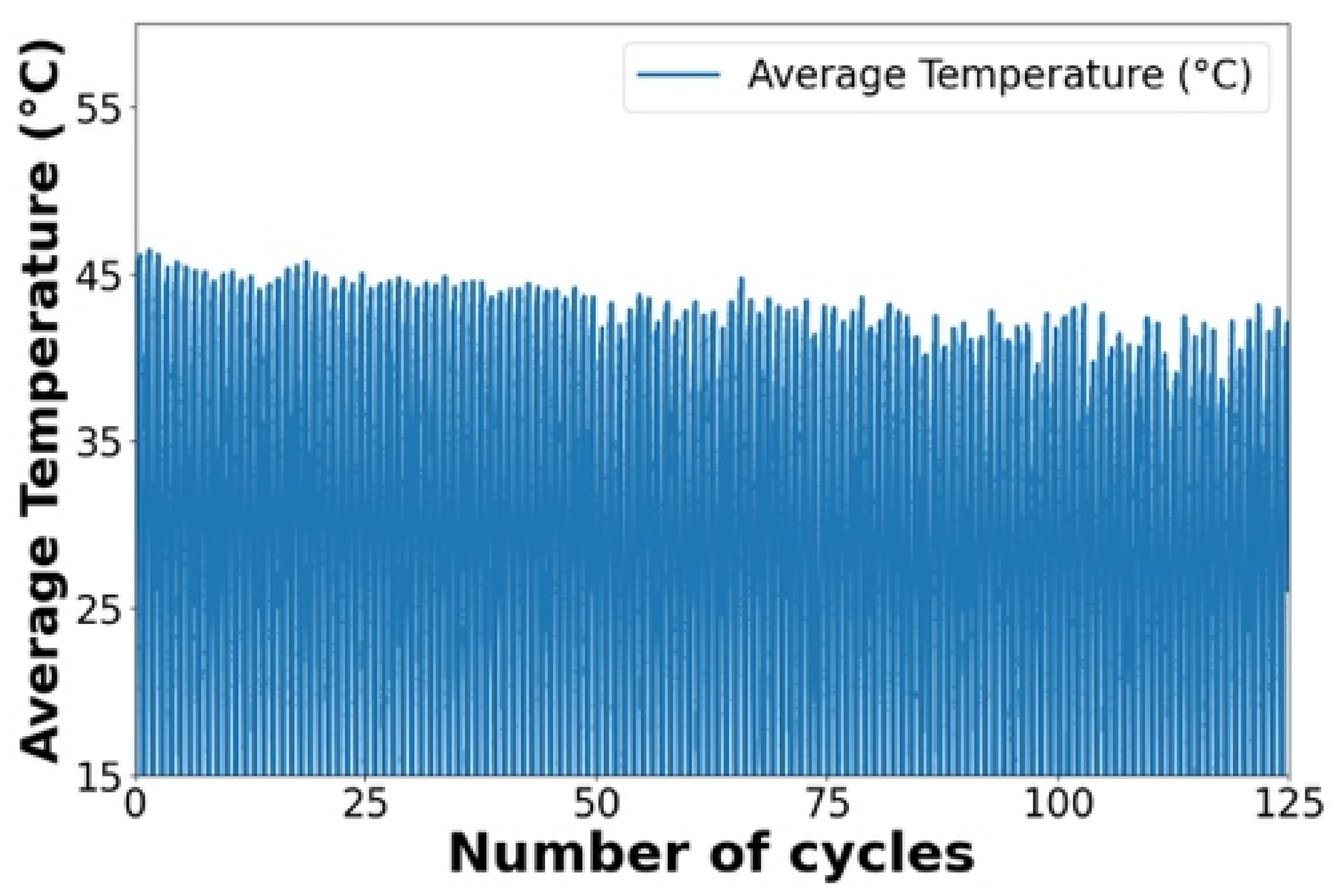

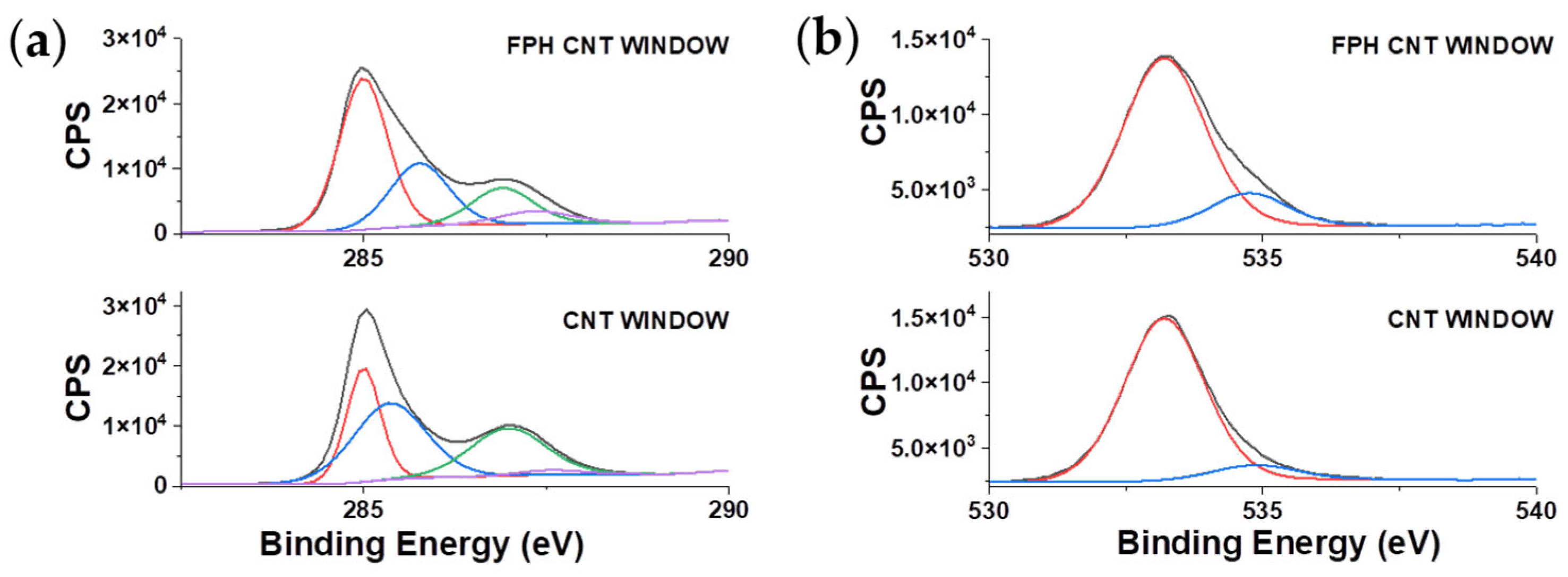

3.5.2. Flash Photonic Heating

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ellmer, K. Past Achievements and Future Challenges in the Development of Optically Transparent Electrodes. Nat. Photonics 2012, 6, 809–817. [Google Scholar] [CrossRef]

- Granqvist, C.G. Transparent Conductors as Solar Energy Materials: A Panoramic Review. Sol. Energy Mater. Sol. Cells 2007, 91, 1529–1598. [Google Scholar] [CrossRef]

- Fortunato, E.; Ginley, D.; Hosono, H.; Paine, D.C. Transparent Conducting Oxides for Photovoltaics. MRS Bull. 2007, 32, 242–247. [Google Scholar] [CrossRef]

- Hecht, D.S.; Hu, L.; Irvin, G. Emerging Transparent Electrodes Based on Thin Films of Carbon Nanotubes, Graphene, and Metallic Nanostructures. Adv. Mater. 2011, 23, 1482–1513. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Cotterell, B.; Wang, W.; Guenther, E.; Chua, S.-J. A Mechanical Assessment of Flexible Optoelectronic Devices. Thin Solid Film. 2001, 394, 201–205. [Google Scholar] [CrossRef]

- Park, J.M.; Wang, Z.J.; Kwon, D.J.; Gu, G.Y.; Lawrence Devries, K. Electrical Properties of Transparent CNT and ITO Coatings on PET Substrate Including Nano-Structural Aspects. Solid State Electron. 2013, 79, 147–151. [Google Scholar] [CrossRef]

- Lee, J.Y.; Connor, S.T.; Cui, Y.; Peumans, P. Solution-Processed Metal Nanowire Mesh Transparent Electrodes. Nano Lett. 2008, 8, 689–692. [Google Scholar] [CrossRef] [PubMed]

- Tokuno, T.; Nogi, M.; Karakawa, M.; Jiu, J.; Nge, T.T.; Aso, Y.; Suganuma, K. Fabrication of Silver Nanowire Transparent Electrodes at Room Temperature. Nano Res. 2011, 4, 1215–1222. [Google Scholar] [CrossRef]

- Khaligh, H.H.; Xu, L.; Khosropour, A.; Madeira, A.; Romano, M.; Pradére, C.; Tréguer-Delapierre, M.; Servant, L.; Pope, M.A.; Goldthorpe, I.A. The Joule Heating Problem in Silver Nanowire Transparent Electrodes. Nanotechnology 2017, 28, 425703. [Google Scholar] [CrossRef]

- Choo, D.C.; Kim, T.W. Degradation Mechanisms of Silver Nanowire Electrodes under Ultraviolet Irradiation and Heat Treatment. Sci. Rep. 2017, 7, 1696. [Google Scholar] [CrossRef] [PubMed]

- Jeong, Y.C.; Nam, J.; Kim, J.; Kim, C.S.; Jo, S. Enhancing Thermal Oxidation Stability of Silver Nanowire Transparent Electrodes by Using a Cesium Carbonate-Incorporated Overcoating Layer. Materials 2019, 12, 1140. [Google Scholar] [CrossRef] [PubMed]

- Park, S.; Vosguerichian, M.; Bao, Z. A Review of Fabrication and Applications of Carbon Nanotube Film-Based Flexible Electronics. Nanoscale 2013, 5, 1727–1752. [Google Scholar] [CrossRef]

- Zhou, Y.; Azumi, R. Carbon Nanotube Based Transparent Conductive Films: Progress, Challenges, and Perspectives. Sci. Technol. Adv. Mater. 2016, 17, 493–516. [Google Scholar] [CrossRef]

- Carbon Nanotube Price: A Comparison Between Asia and Europe. Available online: https://graphenerich.com/carbon-nanotube-price-a-comparison-between-asia-and-europe/ (accessed on 28 October 2025).

- Jung, D.; Kim, D.; Lee, K.H.; Overzet, L.J.; Lee, G.S. Transparent Film Heaters Using Multi-Walled Carbon Nanotube Sheets. Sens. Actuators A Phys. 2013, 199, 176–180. [Google Scholar] [CrossRef]

- Jia, S.L.; Geng, H.Z.; Wang, L.; Tian, Y.; Xu, C.X.; Shi, P.P.; Gu, Z.Z.; Yuan, X.S.; Jing, L.C.; Guo, Z.Y.; et al. Carbon Nanotube-Based Flexible Electrothermal Film Heaters with a High Heating Rate. R. Soc. Open Sci. 2018, 5, 172072. [Google Scholar] [CrossRef]

- Kang, J.; Kim, H.; Kim, K.S.; Lee, S.K.; Bae, S.; Ahn, J.H.; Kim, Y.J.; Choi, J.B.; Hong, B.H. High-Performance Graphene-Based Transparent Flexible Heaters. Nano Lett. 2011, 11, 5154–5158. [Google Scholar] [CrossRef]

- Hu, L.; Hecht, D.S.; Gruner, G. Percolation in Transparent and Conducting Carbon Nanotube Networks. Nano Lett. 2004, 4, 2513–2517. [Google Scholar] [CrossRef]

- Ilatovskii, D.A.; Gilshtein, E.P.; Glukhova, O.E.; Nasibulin, A.G. Transparent Conducting Films Based on Carbon Nanotubes: Rational Design toward the Theoretical Limit. Adv. Sci. 2022, 9, 2201673. [Google Scholar] [CrossRef]

- Hecht, D.S.; Heintz, A.M.; Lee, R.; Hu, L.; Moore, B.; Cucksey, C.; Risser, S. High Conductivity Transparent Carbon Nanotube Films Deposited from Superacid. Nanotechnology 2011, 22, 075201. [Google Scholar] [CrossRef]

- Challenges in Industrial-Scale Production of Single-Walled Carbon Nanotubes (SWCNTs) and Strategies for Breakthroughs. Available online: https://graphenerich.com/challenges-in-industrial-scale-production-of-single-walled-carbon-nanotubes-swcnts-and-strategies-for-breakthroughs/ (accessed on 28 October 2025).

- Carbon Nanotubes Price: Best Deals in 2025. Available online: https://www.accio.com/plp/carbon-nanotubes-price (accessed on 28 October 2025).

- Nie, B.; Wang, J.; Cui, T.; Zhu, Y.; Peng, W.; Zhu, M.; Xi, R.; Fan, S.; Wei, R. High-Aspect-Ratio Multiwalled Carbon Nanotube Structures for Flexible Transparent Electrothermal Films. Langmuir 2025, 41, 11454–11462. [Google Scholar] [CrossRef] [PubMed]

- Hecht, D.S.; Hu, L.; Grüner, G. Conductivity Scaling with Bundle Length and Diameter in Single-Walled Carbon Nanotube Networks. Appl. Phys. Lett. 2006, 89, 133112. [Google Scholar] [CrossRef]

- Kim, Y.J.; Yu, S.J.; Jeong, Y.G. Carbon Nanotube/Polyimide Bilayer Thin Films with High Structural Stability, Optical Transparency, and Electric Heating Performance. RSC Adv. 2016, 6, 30106–30114. [Google Scholar] [CrossRef]

- Kang, P.S.; Kim, G.T. Effects of Junctions on Carbon Nanotube Network-Based Devices. Phys. Status Solidi (B) 2011, 248, 2644–2648. [Google Scholar] [CrossRef]

- Kyrylyuk, A.V.; Van Der Schoot, P. Continuum Percolation of Carbon Nanotubes in Polymeric and Colloidal Media. Proc. Natl. Acad. Sci. USA 2008, 105, 8221–8226. [Google Scholar] [CrossRef]

- Bae, S.; Kim, H.; Lee, Y.; Xu, X.; Park, J.S.; Zheng, Y.; Balakrishnan, J.; Lei, T.; Ri Kim, H.; Song, Y.I.; et al. Roll-to-Roll Production of 30-Inch Graphene Films for Transparent Electrodes. Nat. Nanotechnol. 2010, 5, 574–578. [Google Scholar] [CrossRef] [PubMed]

- Zheng, B.; Wang, H.; Wu, X.; Yang, K.; Yu, Y.; Cui, H.; Gao, F.; Qian, K.; Yao, H.; Li, J.; et al. Flexible Nanocomposite Electrothermal Films Based on Carbon Nanotubes and Waterborne Polyurethane with High Reliability, Stretchability and Low-Temperature Performance for Wind Turbine Blade Deicing. Compos. Part A Appl. Sci. Manuf. 2022, 158, 106979. [Google Scholar] [CrossRef]

- Choi, Y.J.; Nacpil, E.J.C.; Han, J.; Zhu, C.; Kim, I.S.; Jeon, I. Recent Advances in Dispersant Technology for Carbon Nanotubes toward Energy Device Applications. Adv. Energy Sustain. Res. 2024, 5, 2300219. [Google Scholar] [CrossRef]

- Rastogi, R.; Kaushal, R.; Tripathi, S.K.; Sharma, A.L.; Kaur, I.; Bharadwaj, L.M. Comparative Study of Carbon Nanotube Dispersion Using Surfactants. J. Colloid. Interface Sci. 2008, 328, 421–428. [Google Scholar] [CrossRef] [PubMed]

- Siljander, S.; Keinänen, P.; Räty, A.; Ramakrishnan, K.R.; Tuukkanen, S.; Kunnari, V.; Harlin, A.; Vuorinen, J.; Kanerva, M. Effect of Surfactant Type and Sonication Energy on the Electrical Conductivity Properties of Nanocellulose-CNT Nanocomposite Films. Int. J. Mol. Sci. 2018, 19, 1819. [Google Scholar] [CrossRef]

- Wang, J.; Sun, J.; Gao, L.; Wang, Y.; Zhang, J.; Kajiura, H.; Li, Y.; Noda, K. Removal of the Residual Surfactants in Transparent and Conductive Single-Walled Carbon Nanotube Films. J. Phys. Chem. C 2009, 113, 17685–17690. [Google Scholar] [CrossRef]

- Abdulhameed, A.; Halin, I.A.; Mohtar, M.N.; Hamidon, M.N. Optimization of Surfactant Concentration in Carbon Nanotube Solutions for Dielectrophoretic Ceiling Assembly and Alignment: Implications for Transparent Electronics. ACS Omega 2022, 7, 3680–3688. [Google Scholar] [CrossRef]

- Di Crescenzo, A.; Aschi, M.; Fontana, A. Toward a Better Understanding of Steric Stabilization When Using Block Copolymers as Stabilizers of Single-Walled Carbon Nanotubes (SWCNTs) Aqueous Dispersions. Macromolecules 2012, 45, 8043–8050. [Google Scholar] [CrossRef]

- Coleman, J.N. Liquid-Phase Exfoliation of Nanotubes and Graphene. Adv. Funct. Mater. 2009, 19, 3680–3695. [Google Scholar] [CrossRef]

- Jo, J.W.; Jung, J.W.; Lee, J.U.; Jo, W.H. Fabrication of Highly Conductive and Transparent Thin Films from Single-Walled Carbon Nanotubes Using a New Non-Ionic Surfactant via Spin Coating. ACS Nano 2010, 4, 5382–5388. [Google Scholar] [CrossRef] [PubMed]

- Fanchini, G.; Unalan, H.E.; Chhowalla, M. Optoelectronic Properties of Transparent and Conducting Single-Wall Carbon Nanotube Thin Films. Appl. Phys. Lett. 2006, 88, 191919. [Google Scholar] [CrossRef]

- Goh, P.S.; Ismail, A.F.; Ng, B.C. Directional Alignment of Carbon Nanotubes in Polymer Matrices: Contemporary Approaches and Future Advances. Compos. Part A Appl. Sci. Manuf. 2014, 56, 103–126. [Google Scholar] [CrossRef]

- Kim, I.T.; Tannenbaum, A.; Tannenbaum, R. Anisotropic Conductivity of Magnetic Carbon Nanotubes Embedded in Epoxy Matrices. Carbon 2011, 49, 54–61. [Google Scholar] [CrossRef]

- Gupta, P.; Rajput, M.; Singla, N.; Kumar, V.; Lahiri, D. Electric Field and Current Assisted Alignment of CNT inside Polymer Matrix and Its Effects on Electrical and Mechanical Properties. Polymer 2016, 89, 119–127. [Google Scholar] [CrossRef]

- Sharp, D.E.; Ginther, L.B. Effect of Composition and Temperature on the Specific Heat of Glass. J. Am. Ceram. Soc. 1951, 34, 260–271. [Google Scholar] [CrossRef]

- Kim, D.-S.; Matyáš, J. Batch Reactions of a Soda-Lime Silicate Glass (Report for G Plus Project for Libbey Inc.); Pacific Northwest National Lab: Richland, WA, USA, 2002. [Google Scholar]

- Jo, W.H.; Yim, H.; Kwon, I.H.; Son, T.W. Thermal Properties of Thermotropic Liquid Crystalline Polymer/Polycarbonate Blends. Polym. J. 1992, 24, 519–526. [Google Scholar] [CrossRef]

- Gaur, U.; Lau, S.F.; Wunderlich, B.B.; Wunderlich, B. Heat Capacity and Other Thermodynamic Properties of Linear Macromolecules. VIII. Polyesters and Polyamides. J. Phys. Chem. Ref. Data 1983, 12, 65–89. [Google Scholar] [CrossRef]

- Haly, A.R.; Snaith, J.W. The Specific Heat of Polyethyleneterephthalate (PET) and the Fusion of Its Absorbed Water. Text. Res. J. 1969, 39, 906–911. [Google Scholar] [CrossRef]

- Assfalg, A. Study of Thermal Conductivity and Specific Heat of Amorphous and Partially Crystalline Poly(Ethylene Terephthalate) in Relation to Its Structure. J. Phys. Chem. Solids 1975, 36, 1389–1396. [Google Scholar] [CrossRef]

- Wu, Z.; Yang, F.; Yang, J.; Yang, P.; Zhang, X.; Zhang, T.; Lu, M.; Wu, Z.; Yang, F.; Yang, J.; et al. Durable and Flexible PET-Based Bending Sensor Obtained by Immobilizing Carbon Nanotubes via Surface Micro-Dissolution for Body Motion Monitoring. Macromol. Mater. Eng. 2022, 307, 2100502. [Google Scholar] [CrossRef]

- Cho, D.Y.; Eun, K.; Choa, S.H.; Kim, H.K. Highly Flexible and Stretchable Carbon Nanotube Network Electrodes Prepared by Simple Brush Painting for Cost-Effective Flexible Organic Solar Cells. Carbon 2014, 66, 530–538. [Google Scholar] [CrossRef]

- Gao, J.; Wang, W.Y.; Cui, L.J.; Chen, L.T.; Hu, X.Y.; Li, H.; Geng, H.Z. Effect of Different Concentrations of Nitric Acid on the Conductivity of Single-Walled Carbon Nanotube Transparent Films. Adv. Mat. Res. 2013, 658, 3–7. [Google Scholar] [CrossRef]

- Jang, W.S.; Chae, S.S.; Lee, S.J.; Song, K.M.; Baik, H.K. Improved Electrical Conductivity of a Non-Covalently Dispersed Graphene–Carbon Nanotube Film by Chemical p-Type Doping. Carbon 2012, 50, 943–951. [Google Scholar] [CrossRef]

- Gottesman, R. Physical Vapor Deposition with Rapid Photonic Annealing: Enhanced Stability in Metal Oxide Photoelectrodes. J. Phys. Chem. C 2025, 129, 17363–17379. [Google Scholar] [CrossRef]

- Hwang, H.J.; Oh, K.H.; Kim, H.S. All-Photonic Drying and Sintering Process via Flash White Light Combined with Deep-UV and near-Infrared Irradiation for Highly Conductive Copper Nano-Ink. Sci. Rep. 2016, 6, 19696. [Google Scholar] [CrossRef]

- Potts, S.J.; Lau, Y.C.; Dunlop, T.; Claypole, T.; Phillips, C. Effect of Photonic Flash Annealing with Subsequent Compression Rolling on the Topography, Microstructure and Electrical Performance of Carbon-Based Inks. J. Mater. Sci. 2019, 54, 8163–8176. [Google Scholar] [CrossRef]

- Hwang, H.J.; Joo, S.J.; Kim, H.S. Copper Nanoparticle/Multiwalled Carbon Nanotube Composite Films with High Electrical Conductivity and Fatigue Resistance Fabricated via Flash Light Sintering. ACS Appl. Mater. Interfaces 2015, 7, 25413–25423. [Google Scholar] [CrossRef] [PubMed]

- Alemán, B.; Vila, M.; Vilatela, J.J. Surface Chemistry Analysis of Carbon Nanotube Fibers by X-Ray Photoelectron Spectroscopy. Phys. Status Solidi (A) 2018, 215, 1800187. [Google Scholar] [CrossRef]

- Acosta, S.; Sierra-Castillo, A.; Colomer, J.F.; Snyders, R.; Quintana, M.; Ewels, C.; Bittencourt, C. Thermal Stability of Oxygen Functionalization in V-CNTs by Low Kinetic Energy Ion Irradiation. Vacuum 2021, 192, 110423. [Google Scholar] [CrossRef]

- Ogrin, D.; Chattopadhyay, J.; Sadana, A.K.; Billups, W.E.; Barron, A.R. Epoxidation and Deoxygenation of Single-Walled Carbon Nanotubes: Quantification of Epoxide Defects. J. Am. Chem. Soc. 2006, 128, 11322–11323. [Google Scholar] [CrossRef]

- Acosta, S.; Casanova-Chafer, J.; Sierra-Castillo, A.; Llobet, E.; Snyders, R.; Colomer, J.F.; Quintana, M.; Ewels, C.; Bittencourt, C. Low Kinetic Energy Oxygen Ion Irradiation of Vertically Aligned Carbon Nanotubes. Appl. Sci. 2019, 9, 5342. [Google Scholar] [CrossRef]

- Bao, L.; Martin, O.; Wei, T.; Pérez-Ojeda, M.E.; Hauke, F.; Hirsch, A. A Straightforward Reductive Approach for the Deoxygenation, Activation and Functionalization of Ultrashort Single-Walled Carbon Nanotubes. Carbon 2021, 171, 768–776. [Google Scholar] [CrossRef]

- King Lai, W.C.; Xi, N.; Carmen Fung, K.M.; Chen, H.; Zhang, J.; Luo, Y. Photonic Effect on Oxygen-Doped and de-Doped Carbon Nanotubes. In Proceedings of the 2008 8th IEEE Conference on Nanotechnology, Arlington, TX, USA, 8–21 August 2008; IEEE-NANO: Washington, DC, USA, 2008; pp. 251–254. [Google Scholar] [CrossRef]

- Jung, S.; Han, J.T.; Woo, J.S.; Kim, J.H.; Jeong, H.J.; Lee, G.W. Microwave Flash Annealing for Stability of Chemically Doped Single-Walled Carbon Nanotube Films on Plastic Substrates. Nanoscale 2014, 6, 2971–2977. [Google Scholar] [CrossRef]

| Bond Type (C 1s) | CNT Window (Area) | CNT Window (%Area) | FPH-Treated (Area) | FPH-Treated (%Area) |

|---|---|---|---|---|

| CH | 11,224.8 | 29.25 | 19,500.5 | 51.90 |

| C-O | 16,090.1 | 41.91 | 9873.2 | 26.26 |

| C=O | 10,342.6 | 26.90 | 5894.1 | 15.66 |

| COOH | 747.9 | 1.94 | 2330.0 | 6.19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dubnov, N.; Artzi, S.; Farraj, Y.; Gottesman, R.; Yeshurun, S.; Magdassi, S. Ultra-Long Carbon Nanotubes-Based Flexible Transparent Heaters. Coatings 2025, 15, 1487. https://doi.org/10.3390/coatings15121487

Dubnov N, Artzi S, Farraj Y, Gottesman R, Yeshurun S, Magdassi S. Ultra-Long Carbon Nanotubes-Based Flexible Transparent Heaters. Coatings. 2025; 15(12):1487. https://doi.org/10.3390/coatings15121487

Chicago/Turabian StyleDubnov, Nov, Shahar Artzi, Yousef Farraj, Ronen Gottesman, Shuki Yeshurun, and Shlomo Magdassi. 2025. "Ultra-Long Carbon Nanotubes-Based Flexible Transparent Heaters" Coatings 15, no. 12: 1487. https://doi.org/10.3390/coatings15121487

APA StyleDubnov, N., Artzi, S., Farraj, Y., Gottesman, R., Yeshurun, S., & Magdassi, S. (2025). Ultra-Long Carbon Nanotubes-Based Flexible Transparent Heaters. Coatings, 15(12), 1487. https://doi.org/10.3390/coatings15121487