Improving Boundary Lubrication of Phenolic-Based Coatings via Rare Earth Compound-Promoted Transfer Film Growth

Abstract

1. Introduction

2. Materials and Methods

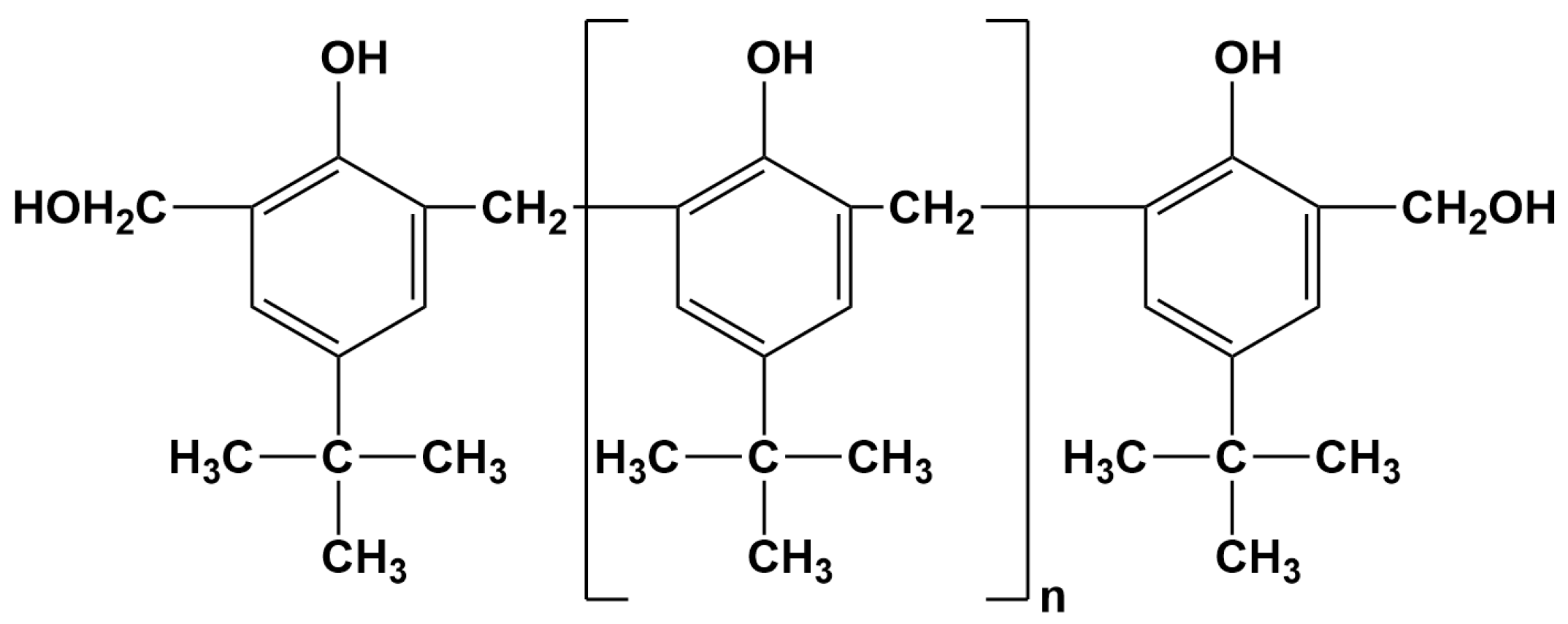

2.1. Materials and Specimens’ Preparation

2.2. Tribology Tests

2.3. Characterization of Worn Surfaces and Tribofilms

3. Results and Discussion

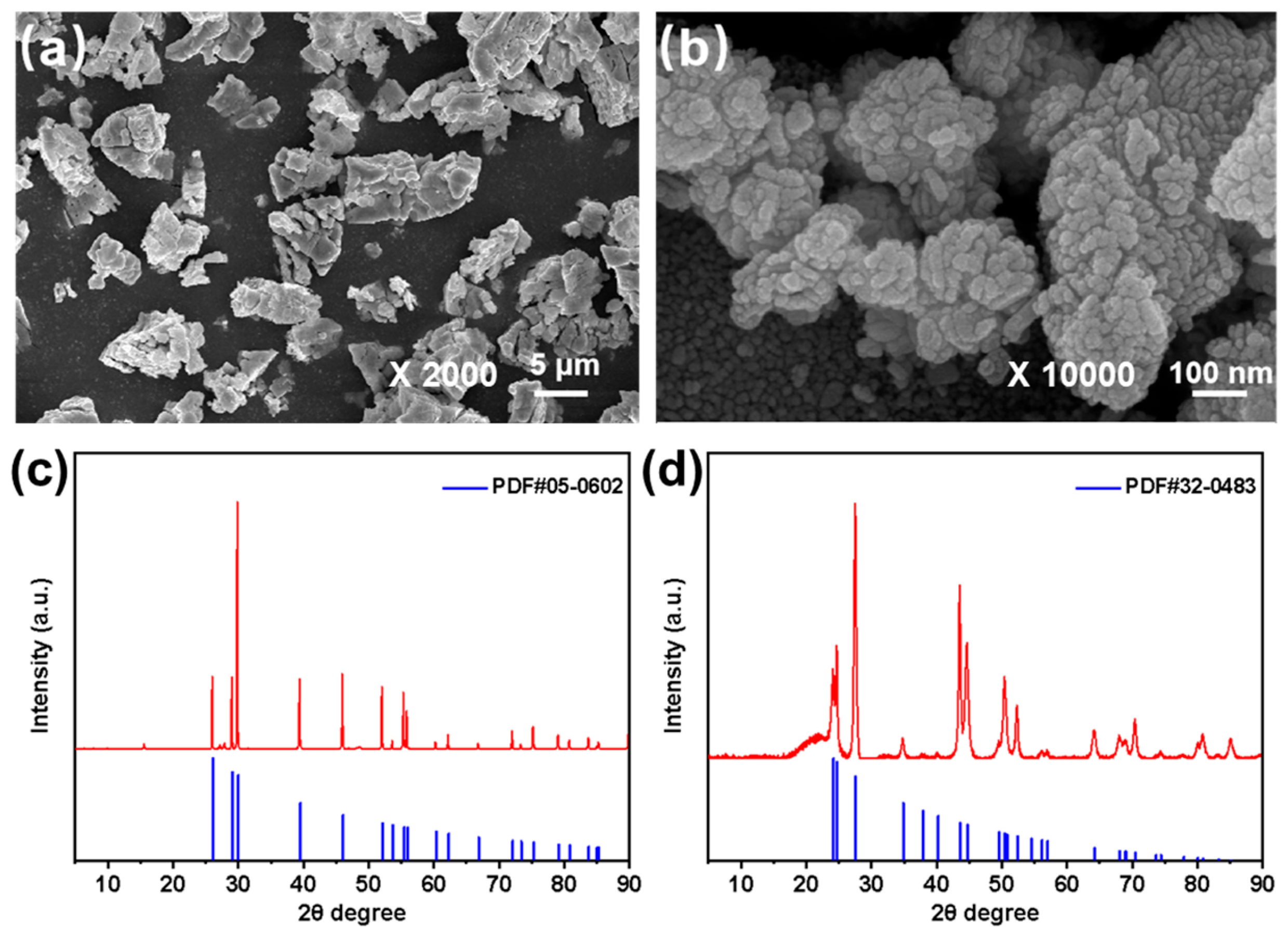

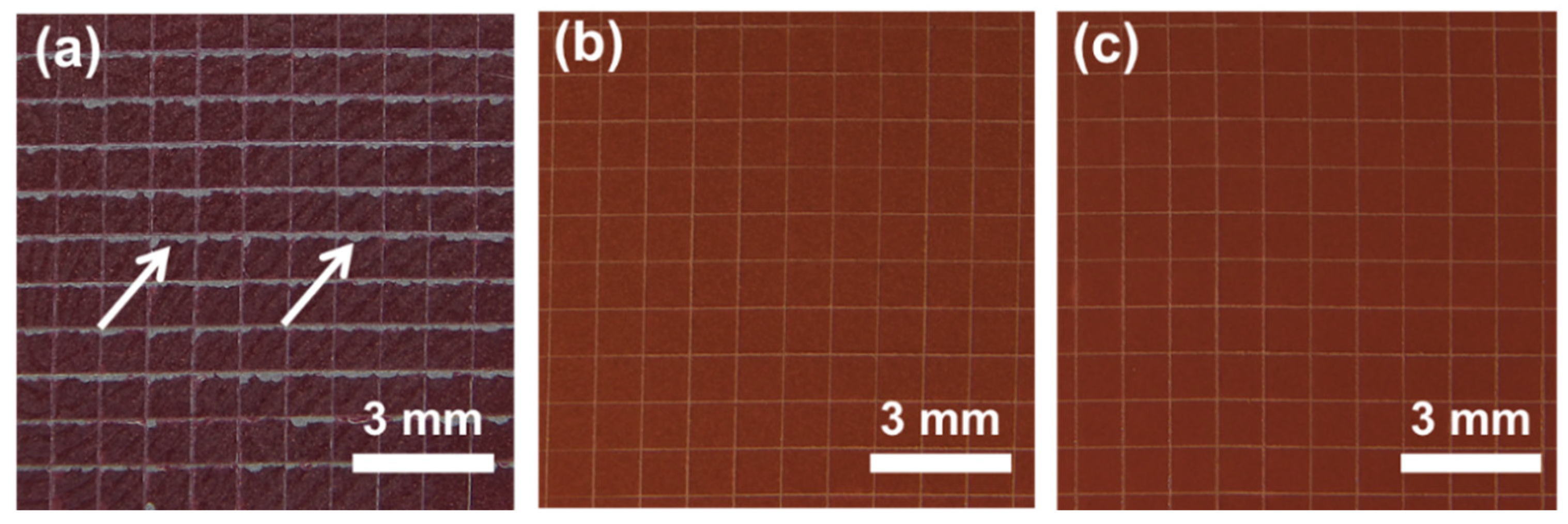

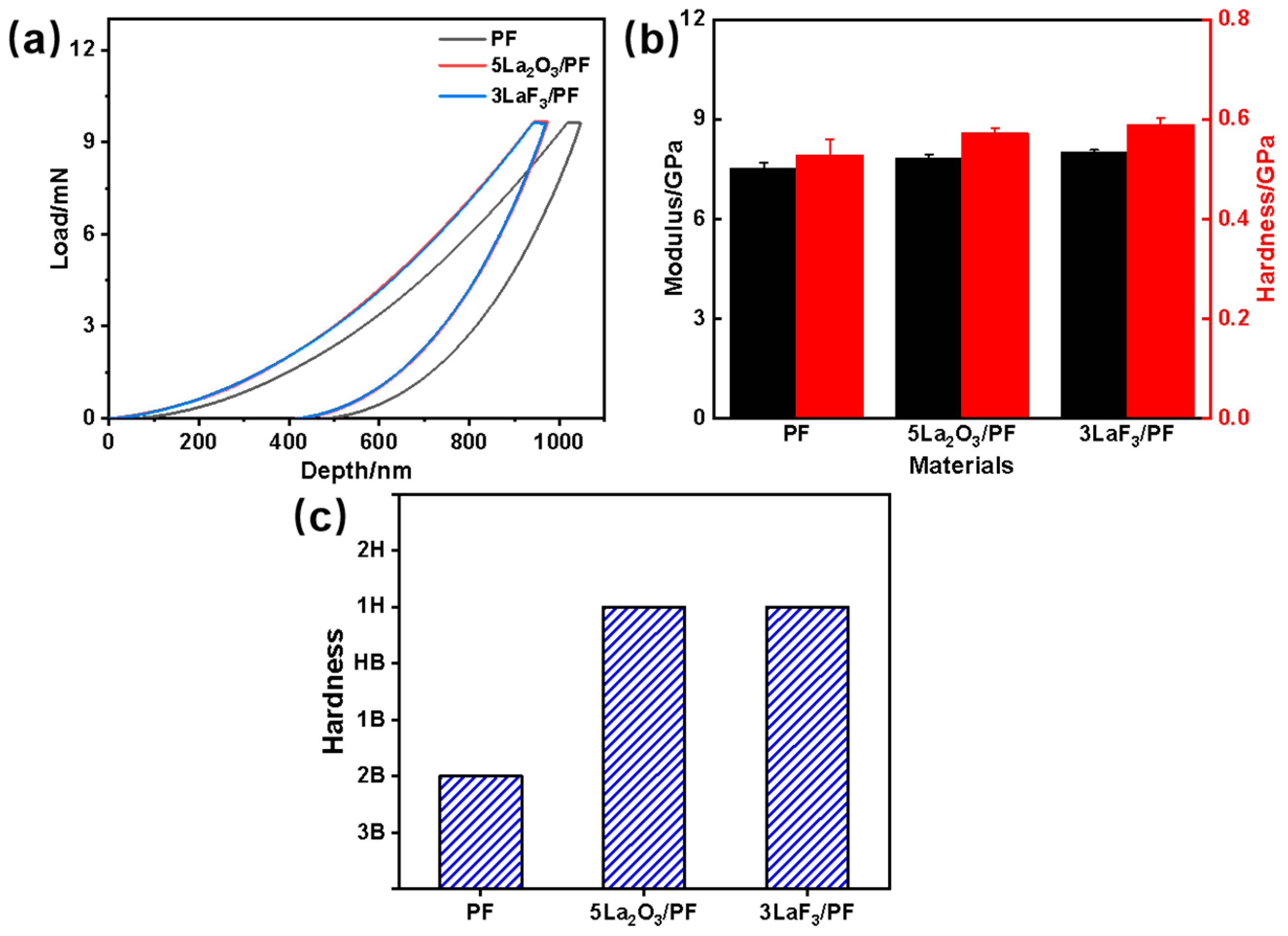

3.1. Morphologies and Mechanical Performance

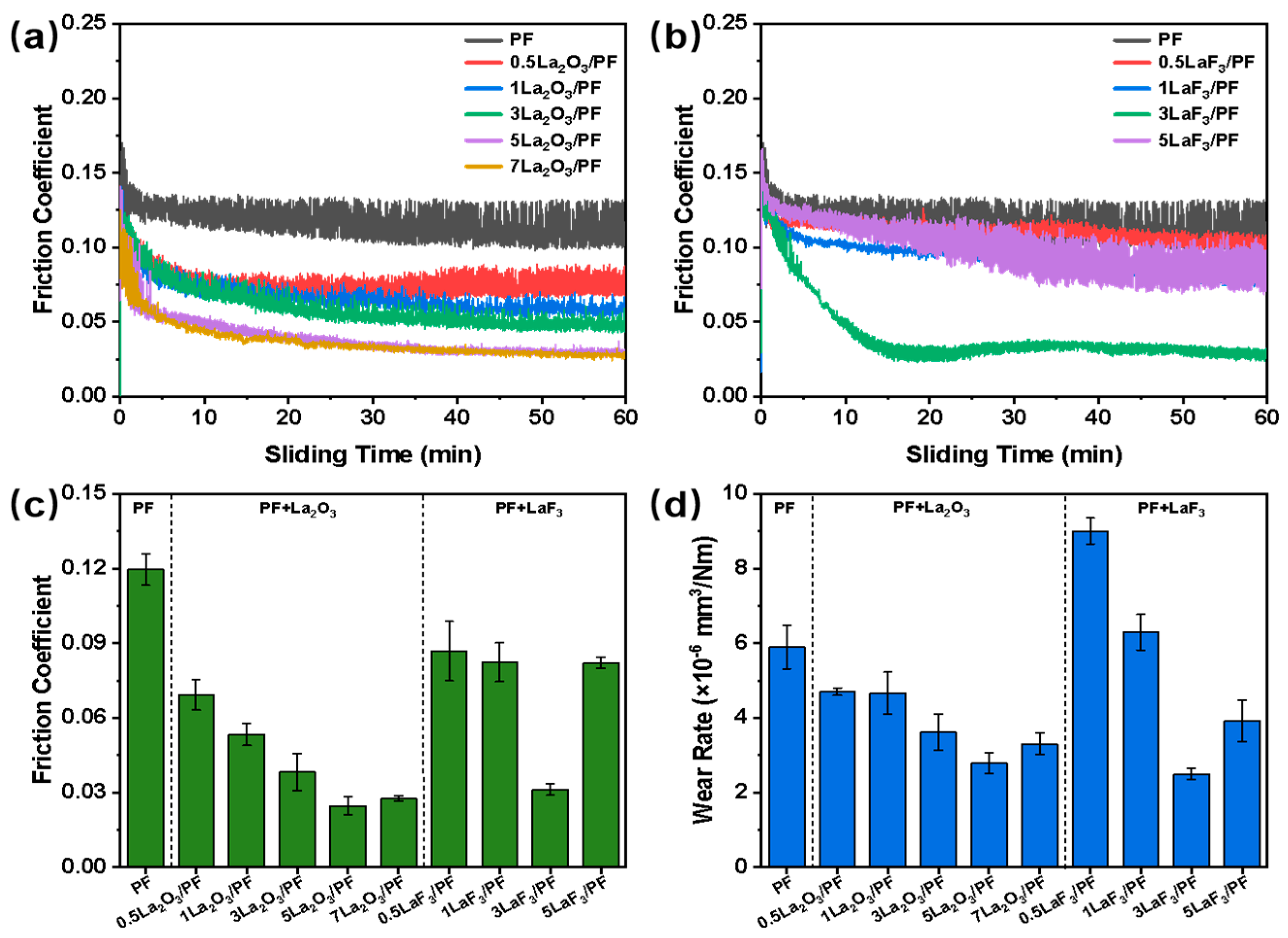

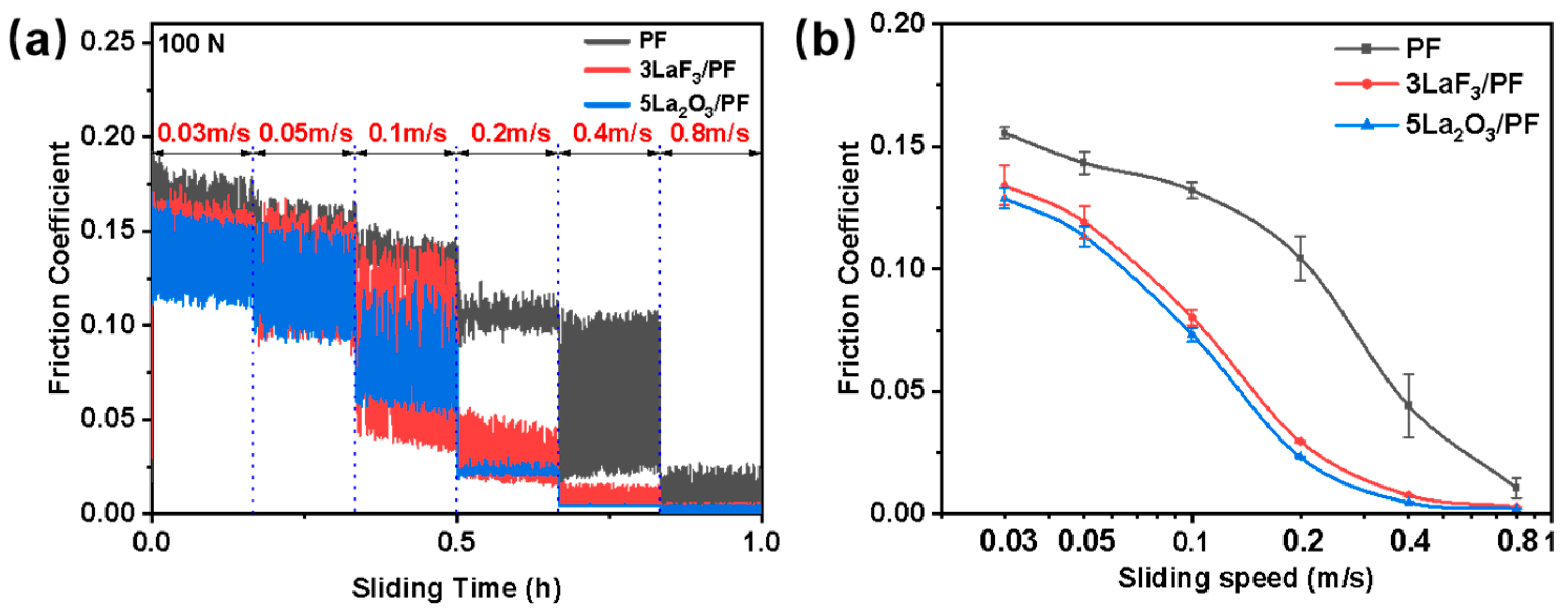

3.2. Tribological Behaviors

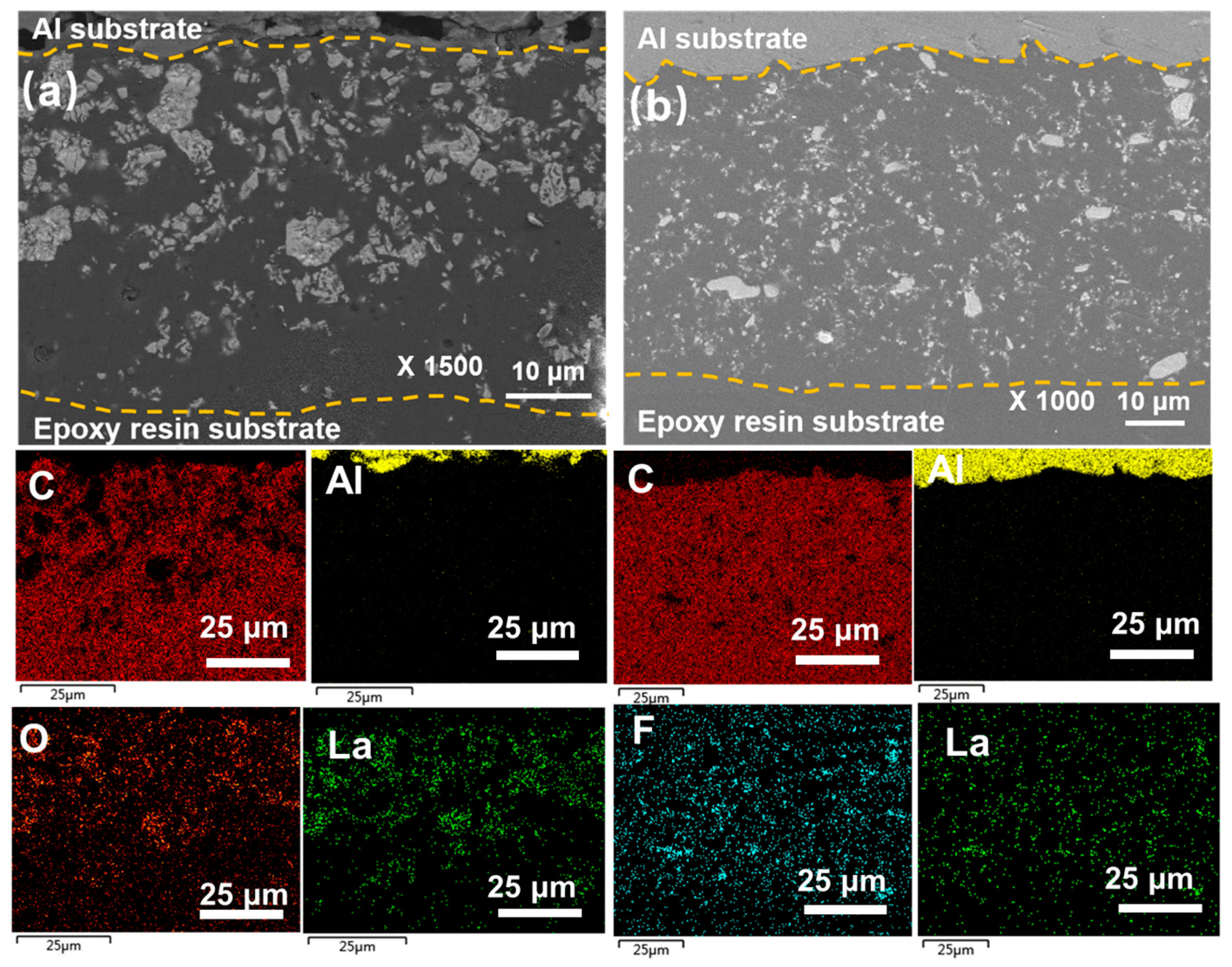

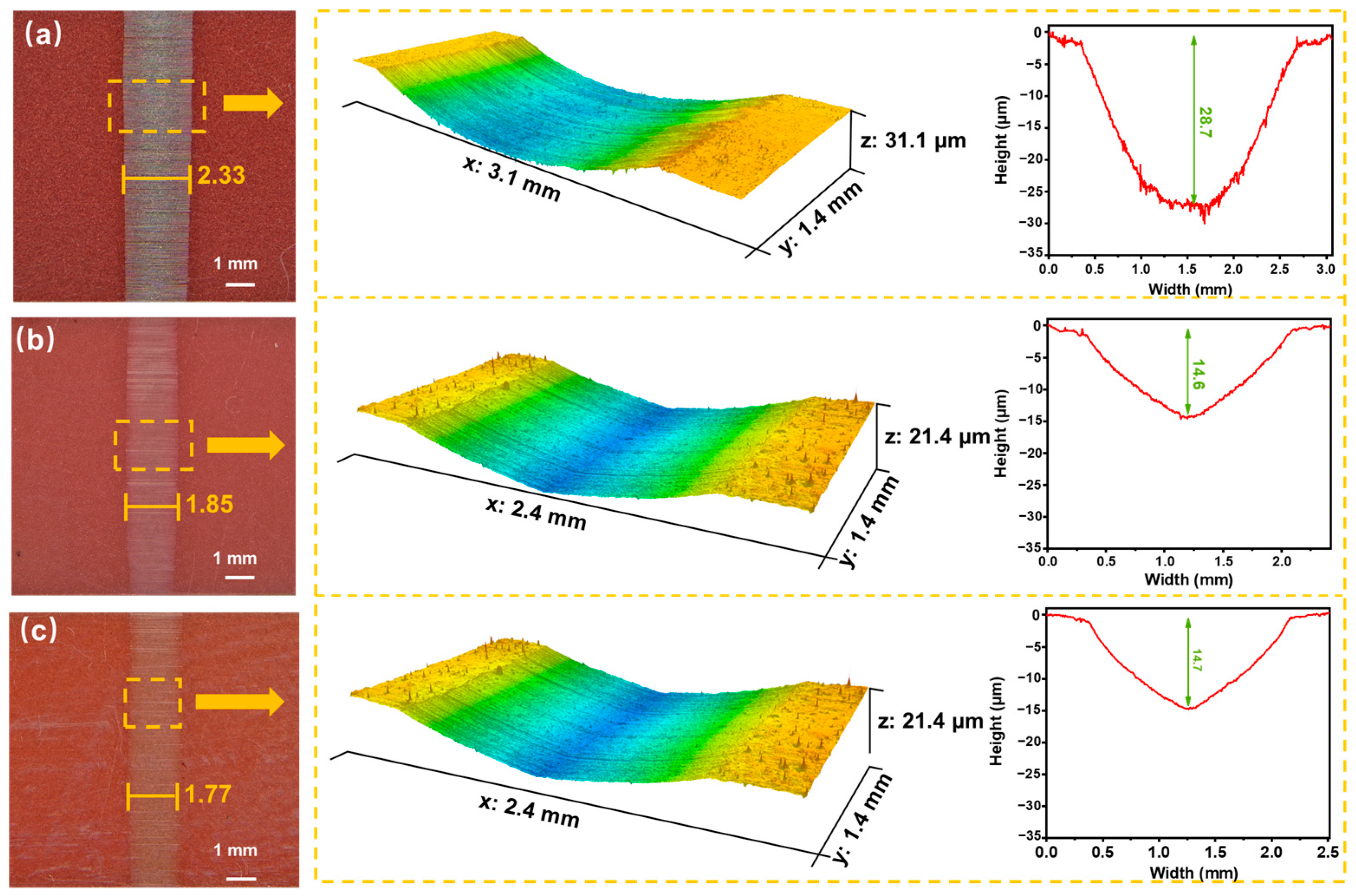

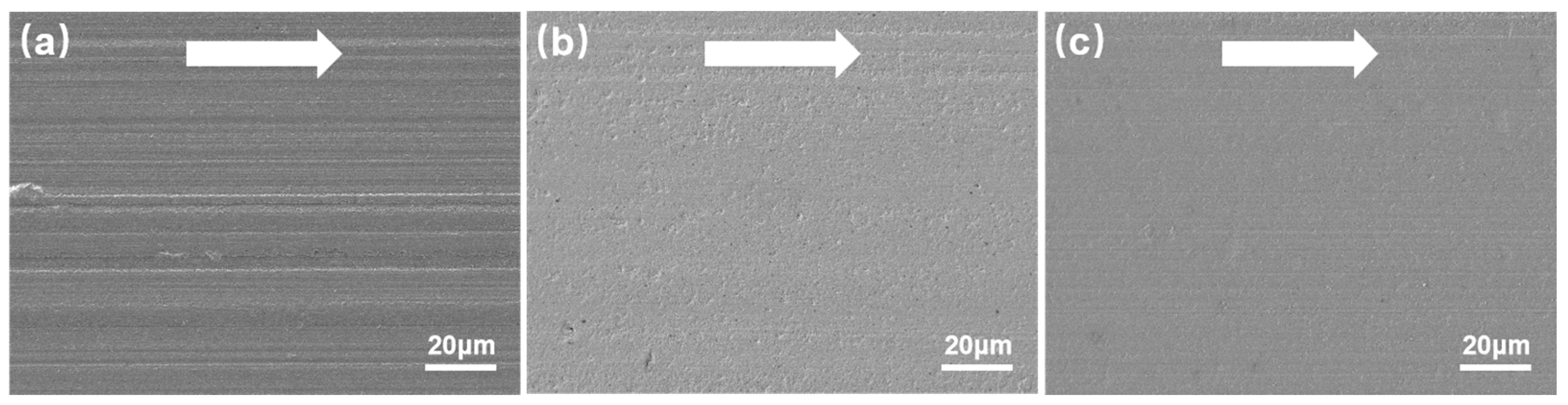

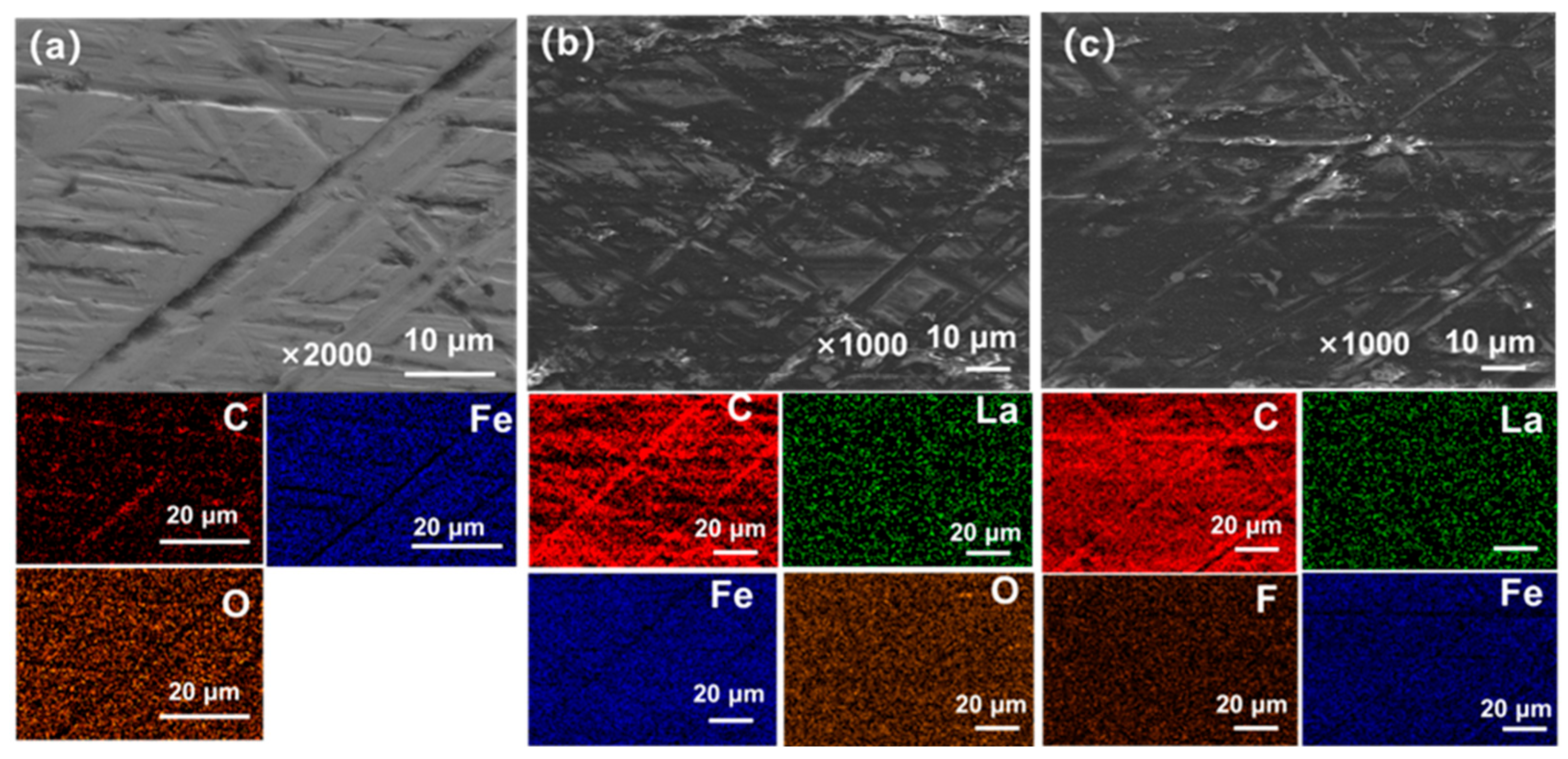

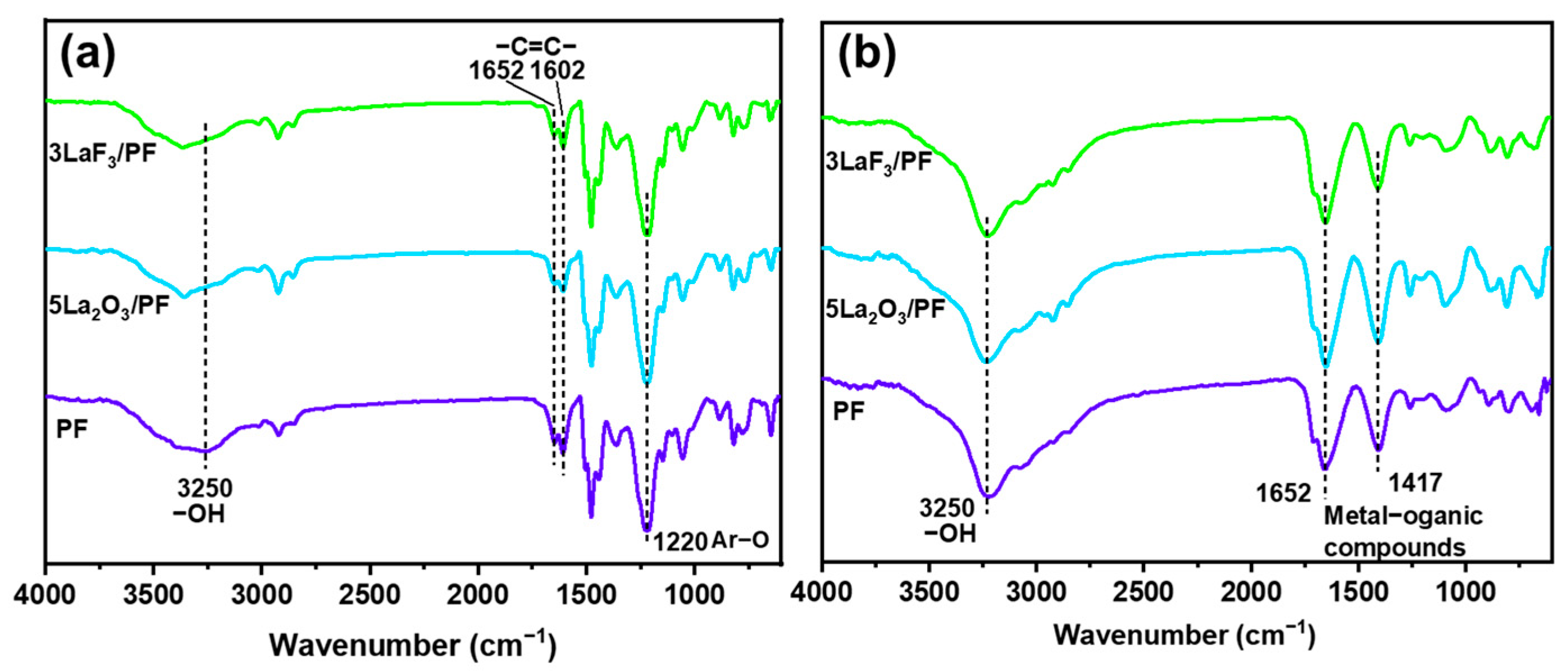

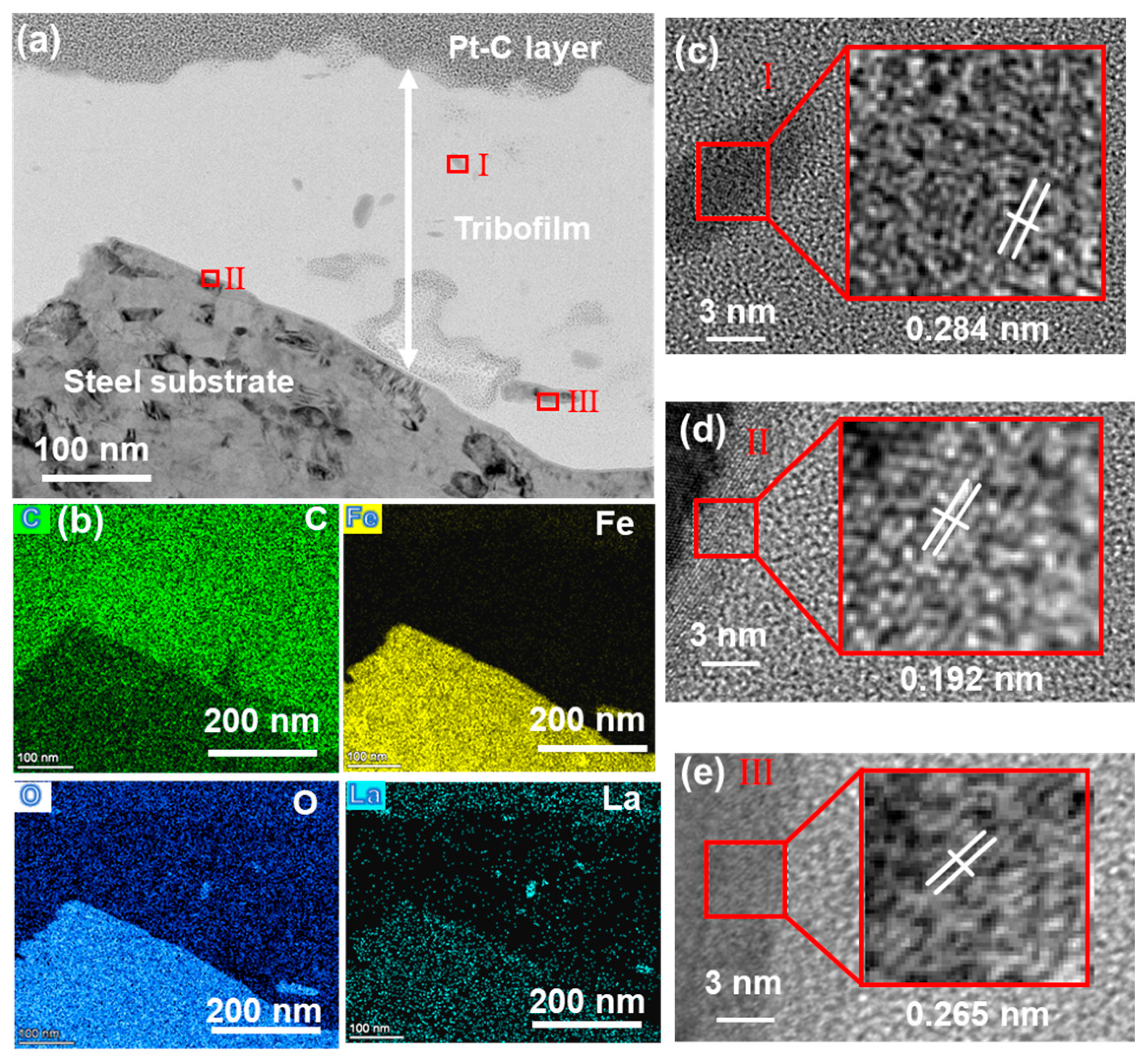

3.3. Worn Surfaces and Tribofilms

4. Conclusions

- (1)

- The incorporation of La2O3 and LaF3 significantly reduces the friction coefficient of the PF coating. Specifically, with the addition of 5 vol.% La2O3 and 3 vol.% LaF3, the friction coefficient of the PF coating is decreased by 80.0% and 73.95% compared to that of pure PF, respectively.

- (2)

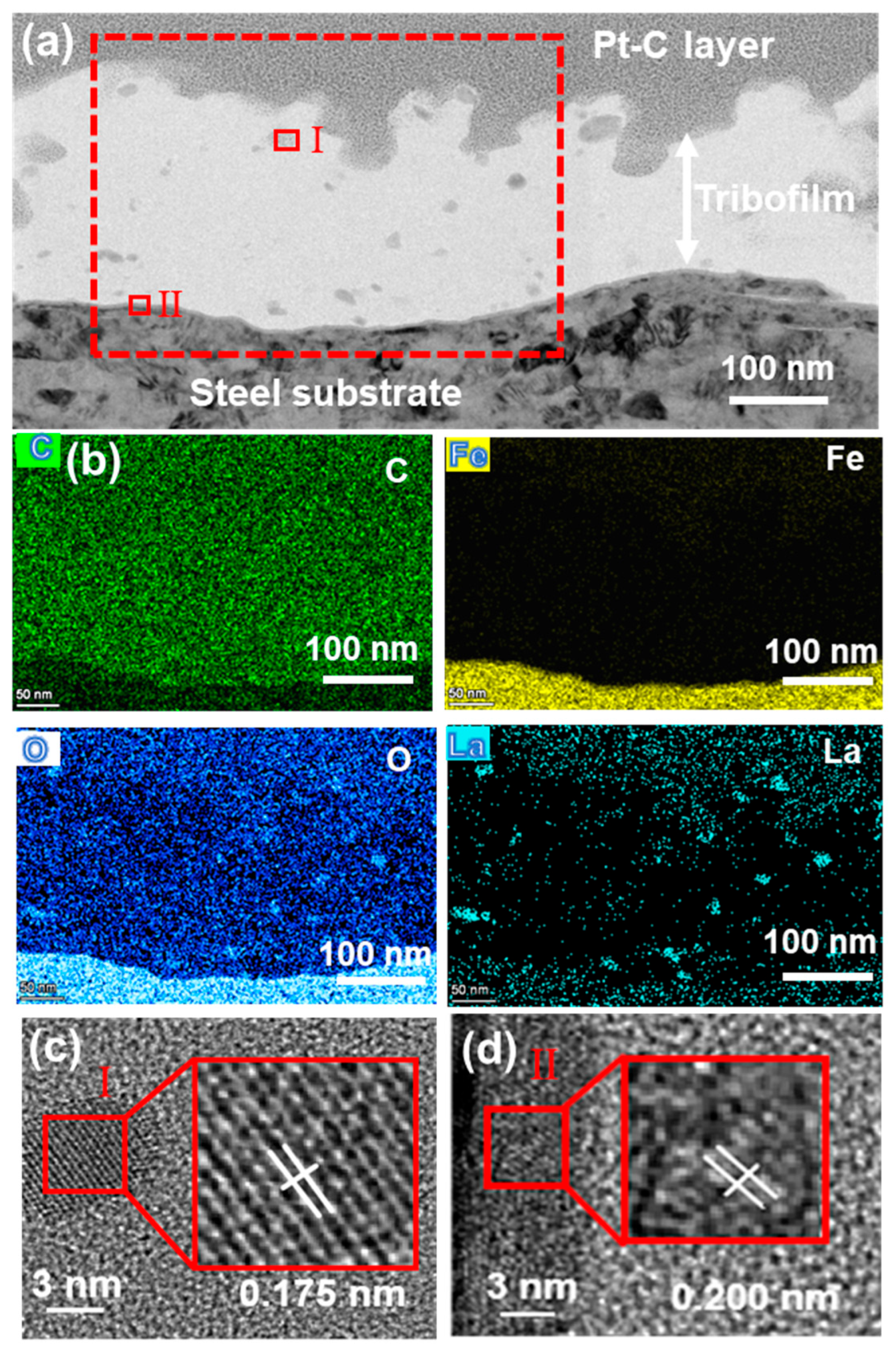

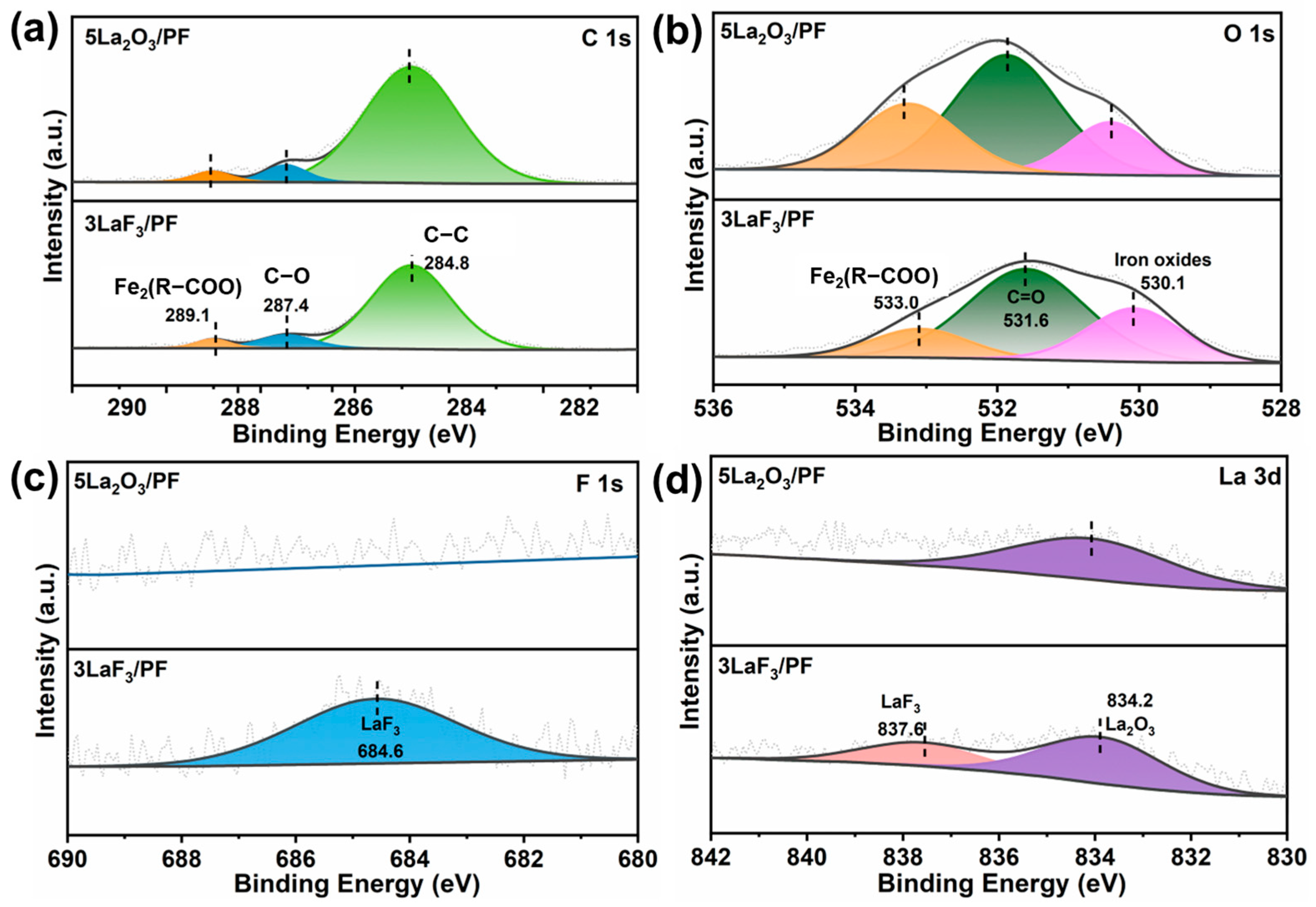

- Analysis of the EDS results reveals that uniform tribofilms form on the respective counterpart surfaces following sliding against the 5La2O3/PF and 3LaF3/PF coatings, indicating that the rare-earth compounds facilitate tribofilm growth.

- (3)

- Under the combined action of frictional heat and mechanical shear, LaF3 undergoes oxidation to form La2O3, which distributes uniformly within the tribofilms, thereby enhancing the load-bearing capacity and solid lubrication properties of the tribofilms.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Q.; Li, W. Recent development in surface/interface friction of two-dimensional black phosphorus: A review. Adv. Colloid Interface Sci. 2025, 340, 103464. [Google Scholar] [CrossRef]

- Chen, Z.; Shen, H.; Zhou, C.; Du, C.; Song, Y.; Yang, S.; Yin, X. Temperature-triggered self-lubricating behaviour via bioinspired multifunctional rigid polymer for adaptive friction control. Chem. Eng. J. 2025, 522, 167439. [Google Scholar] [CrossRef]

- de Souza Lamim, T.; Martinez, D.M.; Pigosso, T.; Klein, A.N.; Bendo, T.; Binder, C. Structural evolution of a carbon nanotube film under sliding wear: From a forest to a self-lubricating nanocomposite tribofilm. Carbon 2025, 238, 120224. [Google Scholar] [CrossRef]

- Dong, S.; Shi, J.; Li, H.; Zhang, R.; Ma, X.; Yang, Y.; Cui, C.; Wang, W.; Li, J. Phytic Acid-Modified Black Phosphorus Nanosheets Achieve Ultrahigh Load Bearing and Rapid Superlubrication on Engineered Steel Surfaces. Adv. Funct. Mater. 2025, 35, 2500057. [Google Scholar] [CrossRef]

- Li, S.; Gao, C.; Duan, C.; Zhang, S.; Zhang, P.; Zhang, Z. Achieving oil-based superlubricity with near-zero wear via synergistic effect between PEEK-PTFE and PAO40 containing DDP-Cu nanoparticles. Tribol. Int. 2025, 208, 110645. [Google Scholar] [CrossRef]

- He, L.; Zhang, J.; Zheng, Y.; Liu, S.; Liu, X.; Tong, L. Boosting thermal conductivity and tribological performance of polyarylene ether nitrile synergistically by fabricating SiCws-BNNS multidimensional networks. Compos. Part A Appl. Sci. Manuf. 2025, 194, 108888. [Google Scholar] [CrossRef]

- Jaiswal, S.; Vishwakarma, J.; Nema, S.; Ohlan, A.; Ashiq, M.; Dhand, C.; Dwivedi, N. Slippery and wear-resistant shape memory polymers enabled by the reinforcement of double transition metal-based MAX phase (Mo2TiAlC2). Carbon 2025, 244, 120635. [Google Scholar] [CrossRef]

- Peng, S.; Zhang, L.; Xie, G.; Guo, Y.; Si, L.; Luo, J. Friction and wear behavior of PTFE coatings modified with poly (methyl methacrylate). Compos. Part B Eng. 2019, 172, 316–322. [Google Scholar] [CrossRef]

- Zhang, L.; Song, W. Friction Behavior of Molybdenum Disulfide/Polytetrafluoroethylene-Coated Cemented Carbide Fabricated with a Spray Technique in Dry Friction Conditions. Coatings 2025, 15, 324. [Google Scholar] [CrossRef]

- Ma, J.; Qi, X.; Dong, Y.; Zhao, Y.; Zhang, Q.; Fan, B.; Yang, Y. Transfer film formation mechanism and tribochemistry evolution of a low-wear polyimide/mesoporous silica nanocomposite in dry sliding against bearing steel. Tribol. Int. 2018, 120, 233–242. [Google Scholar] [CrossRef]

- Ye, J.; Burris, D.; Xie, T. A Review of Transfer Films and Their Role in Ultra-Low-Wear Sliding of Polymers. Lubricants 2016, 4, 4. [Google Scholar] [CrossRef]

- Campbell, K.L.; Sidebottom, M.A.; Atkinson, C.C.; Babuska, T.F.; Kolanovic, C.A.; Boulden, B.J.; Junk, C.P.; Krick, B.A. Ultralow Wear PTFE-Based Polymer Composites—The Role of Water and Tribochemistry. Macromolecules 2019, 52, 5268–5277. [Google Scholar] [CrossRef]

- Jia, Y.; Wan, H.; Chen, L.; Zhou, H.; Chen, J. Effects of nano-LaF3 on the friction and wear behaviors of PTFE-based bonded solid lubricating coatings under different lubrication conditions. Appl. Surf. Sci. 2016, 382, 73–79. [Google Scholar] [CrossRef]

- Zheng, K.; Gao, C.; He, F.; Lin, Y. The Role of Rare Earth Lanthanum Oxide in Polymeric Matrix Brake Composites to Replace Copper. Polymers 2018, 10, 1027. [Google Scholar] [CrossRef]

- Xiong, D.; Chen, L.; Zhang, D. Tribological Properties of PA1010 Composites Filled with Rare Earth Compounds. J. China Univ. Min. Technol. 2001, 30, 5. [Google Scholar]

- GB/T 3880-2012; Wrought Aluminium and Aluminium Alloy Plates, Sheets and Strips for General Engineering. Standardization Administration of the People’s Republic of China: Beijing, China, 2012.

- ISO 2409:2020; Paints and Varnishes-Cross-Cut Test. International Organization for Standardization: Geneva, Switzerland, 2020.

- Guo, L.; Zhang, G.; Wang, D.; Zhao, F.; Wang, T.; Wang, Q. Significance of combined functional nanoparticles for enhancing tribological performance of PEEK reinforced with carbon fibers. Compos. Part A Appl. Sci. Manuf. 2017, 102, 400–413. [Google Scholar] [CrossRef]

- Hasan, M.; Björling, M.; Matta, C.; Meeuwenoord, R.; Jantel, U.; Larsson, R. An investigation of film formation and pressure-viscosity relationship of water-based lubricants in elastohydrodynamic contacts. Tribol. Int. 2025, 208, 110654. [Google Scholar] [CrossRef]

- Qi, H.; Zhang, G.; Zheng, Z.; Yu, J.; Hu, C. Tribological properties of polyimide composites reinforced with fibers rubbing against Al2O3. Friction 2020, 9, 2. [Google Scholar] [CrossRef]

- Baş, H.; Özen, O.; Beşirbeyoğlu, M.A. Tribological properties of MoS2 and CaF2 particles as grease additives on the performance of block-on-ring surface contact. Tribol. Int. 2022, 168, 107433. [Google Scholar] [CrossRef]

- Li, W.; Kumara, C.; Luo, H.; Meyer, H.M.; He, X.; Ngo, D.; Kim, S.H.; Qu, J. Ultralow Boundary Lubrication Friction by Three-Way Synergistic Interactions among Ionic Liquid, Friction Modifier, and Dispersant. ACS Appl. Mater. Interfaces 2020, 12, 17077–17090. [Google Scholar] [CrossRef]

- Duan, C.; Xie, S.; Ye, W.; Zhang, S.; Zhang, P. Sandwich-like tribofilm induced highly effective lubrication for MoDTP coupled with hydroxy-magnesium silicate (MSH). Tribol. Int. 2024, 198, 109902. [Google Scholar] [CrossRef]

- Wang, C.; Yu, H.; Yin, Y.; Zhang, Z.; Zhou, X.; Wang, H.; Song, Z.; Zhao, Z.; Guo, Z.; Algadi, H. Dual-phase enhanced polytetrafluoroethylene composites with friction-trigged self-healing interfaces: Role of antigorite and graphene in tribofilm evolution. Colloids Surf. A Physicochem. Eng. Asp. 2025, 725, 137733. [Google Scholar] [CrossRef]

- Duan, C.; Li, D.; Gu, J.; Gao, C.; Zhang, S.; Zhang, P.; Xu, J.; Wang, C.; Wang, T.; Wang, Q. Smart polymer self-lubricating material: Optimal structure of porous polyimide with base oils for super-low friction and wear. Friction 2025, 13, 9441007. [Google Scholar] [CrossRef]

- Han, Y.; He, R.; Li, H.; Pei, X.; Zhang, G. Ultra-low Friction and Wear of Phenolic Composites Reinforced with Halloysite Nanotubes. Tribol. Int. 2025, 204, 110419. [Google Scholar] [CrossRef]

- Han, Y.; Cheng, Q.; Li, G.; Qi, H.; Zhang, G. Extraordinary solid lubrication performance achieved via the growth of multi-layered tribofilms facilitated by halloysite nanotubes. Wear 2025, 582–583, 206332. [Google Scholar] [CrossRef]

- Villa, N.; Bonoldi, L.; Assanelli, G.; Notari, M.; Lucotti, A.; Tommasini, M.; Cuppen, H.M.; Galimberti, D.R. Digging into the friction reduction mechanism of organic friction modifiers on steel surfaces: Chains packing vs. molecule–metal interactions. Tribol. Int. 2024, 195, 109649. [Google Scholar] [CrossRef]

- Chhowalla, M.; Amaratunga, G.A. Thin films of fullerene-like MoS2 nanoparticles with ultra-low friction and wear. Nature 2000, 407, 164–167. [Google Scholar] [CrossRef]

- Wang, K.; Chang, Q.; Gao, K.; Wang, B.; Gao, R.; Yan, Q. Octadecyltrimethoxysilane modified freeze-drying magnesium silicate hydroxide towards high-performance wear-resistance: Synthesis, characterization, and tribological evaluation. Wear 2023, 523, 204768. [Google Scholar] [CrossRef]

- Sanes, J.; Avil´es, M.-D.; Saurín, N.; Espinosa, T.; Carrion´, F.-J.; Bermúdez, M.-D. Synergy between graphene and ionic liquid lubricant additives. Tribol. Int. 2017, 116, 371–382. [Google Scholar] [CrossRef]

- Romeu, J.G.F.; Dixon, D.A. Energetic and Electronic Properties of AcX and LaX (X = O and F). J. Phys. Chem. A 2025, 129, 1396–1410. [Google Scholar] [CrossRef]

| Abbreviation Form | PF | La2O3 | LaF3 |

|---|---|---|---|

| Pure PF | 100 | 0 | 0 |

| 0.5La2O3/PF | 99.5 | 0.5 | 0 |

| 1La2O3/PF | 99 | 1 | 0 |

| 3La2O3/PF | 97 | 3 | 0 |

| 5La2O3/PF | 95 | 5 | 0 |

| 7La2O3/PF | 93 | 7 | 0 |

| 0.5LaF3/PF | 99.5 | 0 | 0.5 |

| 1LaF3/PF | 99 | 0 | 1 |

| 3LaF3/PF | 97 | 0 | 3 |

| 5LaF3/PF | 95 | 0 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Wang, D.; Qi, H.; Zhang, G. Improving Boundary Lubrication of Phenolic-Based Coatings via Rare Earth Compound-Promoted Transfer Film Growth. Coatings 2025, 15, 1417. https://doi.org/10.3390/coatings15121417

Li G, Wang D, Qi H, Zhang G. Improving Boundary Lubrication of Phenolic-Based Coatings via Rare Earth Compound-Promoted Transfer Film Growth. Coatings. 2025; 15(12):1417. https://doi.org/10.3390/coatings15121417

Chicago/Turabian StyleLi, Guitao, Delong Wang, Huimin Qi, and Ga Zhang. 2025. "Improving Boundary Lubrication of Phenolic-Based Coatings via Rare Earth Compound-Promoted Transfer Film Growth" Coatings 15, no. 12: 1417. https://doi.org/10.3390/coatings15121417

APA StyleLi, G., Wang, D., Qi, H., & Zhang, G. (2025). Improving Boundary Lubrication of Phenolic-Based Coatings via Rare Earth Compound-Promoted Transfer Film Growth. Coatings, 15(12), 1417. https://doi.org/10.3390/coatings15121417