Abstract

This study systematically explored the influence of Polycarboxylate Ether (PCE) content on the fluidity, setting time, and compressive and flexural strength of Ultra-fine Portland Cement (SPC) cement-based grout through the external admixture method. The microstructure and evolution of hydration products were analyzed using XRD and SEM to reveal the modification mechanism. The results showed that the optimal PCE content was 0.25% (calculated based on the mass of SPC), at which the fluidity of the grout reached 273 mm, and the initial and final setting times were extended from 130 min and 235 min to 268 min and 310 min, respectively, reflecting significant plasticizing and retarding effects. The mechanical properties were particularly improved, with the compressive strength of the hardened paste at 7 d and 28 d increasing by 28.78% and 37.09%, respectively, and the flexural strength increasing by 11.20% and 14.52%, respectively. Microscopic analysis indicated that PCE optimized particle packing through adsorption–dispersion effects and moderately delayed the early hydration process, promoting the more thorough and uniform growth of hydration products (such as C-S-H gel), thereby generating a denser microstructure. This is the fundamental reason for the improvement in macroscopic properties. This study provides important theoretical and experimental basis for the performance optimization and engineering application of SPC-based grouting materials under low water–cement ratios.

1. Introduction

With the gradual transition of coal mining towards deeper reserves, the deformation and failure extent of roadway surrounding rock intensifies, leading to increased challenges in ground control [1]. Grouting technology has been widely adopted due to its advantages such as low construction cost, simple process, rapid effectiveness, and minimal space requirements. In China, support systems for coal mine roadways have increasingly evolved into integrated technology packages centered on bolting and grouting reinforcement [2,3,4]. The core of grouting reinforcement lies in the selection of appropriate grouting materials, which mainly fall into two categories: organic and inorganic grouts. Organic grouts offer benefits such as high fluidity, ease of penetration into fine fractures, and adjustable setting time. However, they also present drawbacks including potential toxicity, high cost, and exothermic reactions that may lead to heat accumulation and trigger spontaneous combustion of coal—posing significant engineering safety concerns [5]. Cement-based materials, as representative inorganic grouting agents, have attracted considerable attention due to their high mechanical strength, low cost, and environmental friendliness. Nevertheless, ordinary cement exhibits relatively large particle size and poor fluidity. While increasing the water–cement ratio can improve fluidity, it significantly reduces the strength of the hardened grout [6,7]. Therefore, developing a simple and effective method to prepare high-performance cementitious grouts with excellent fluidity has become a key research focus in the field [8,9]. Although the performance of polycarboxylate superplasticizer (PCE) in ordinary Portland cement has been well documented, its behavior in high specific surface area (≥600 m2/kg) ultrafine Portland cement (SPC) systems is still poorly understood. The core question to be addressed in this study is: how does the extremely high specific surface area and unique mineralogical properties of SPC affect the effectiveness and mechanism of action of PCE high-efficiency water-reducing agents, and what impact does this have on the development of hydration kinetics and microstructure.

Reducing the particle size of cement-based materials is an effective approach to enhance fluidity and improve grouting performance. Compared with ordinary cement, SPC processed through advanced grinding techniques possesses smaller particle size and larger specific surface area, facilitating penetration into fine cracks or pores. Moreover, its high reactivity promotes the formation of more hydration products, thereby improving the strength of the hardened grout. For a given grouting material, appropriately reducing the water–cement ratio can increase the strength of the cement stone and reduce bleeding, though at the cost of reduced fluidity. Conversely, increasing the water–cement ratio improves both fluidity and bleeding capacity, but results in lower mechanical strength. Hence, to meet the requirements of grouting and bolt support applications in underground engineering, reducing the water–cement ratio is often adopted as a technical measure to enhance overall material performance.

According to the cement hydration theory established by powers and brownyard, the degree and quality of cement hydration can be modulated by chemical admixtures [10,11]. Indeed, admixtures play a “small but critical” role in modifying cement-based materials—their minor dosage can significantly enhance material properties [12,13]. PCE based superplasticizers are particularly notable for their low dosage and high water-reducing efficiency. They facilitate better dispersion of cement particles, improve grout fluidity, accelerate hydration, increase the density of the hardened paste, and enhance overall cement performance [14]. While existing studies have primarily focused on the influence of PCE on the rheology and strength of ordinary cement [15,16,17,18], research on the effectiveness and reinforcement mechanisms of PCE in SPC systems remains limited.

To establish a structure–property relationship between PCE and the performance of SPC-based grouts, this study designs a single-factor experimental scheme to quantitatively evaluate the effect of PCE dosage on the workability, setting and hardening process, and mechanical properties of the grouts. Furthermore, to uncover the underlying micro-mechanisms responsible for the observed macro-properties, scanning electron microscopy (SEM) and X-ray diffraction (XRD) were employed to characterize the morphology, distribution, and multi-scale structure of hydration products. This enables the establishment of a clear causal link between microstructural evolution and macroscopic mechanical behavior. The present work identifies the optimal PCE dosage for SPC grouts, successfully addressing the technical challenge of simultaneously enhancing fluidity and strength under low water–cement ratio conditions. The findings provide direct guidance for the design and optimization of high-performance SPC-based grouts, with significant practical implications for improving the construction quality, long-term durability, and safety of key engineering applications such as fractured rock mass reinforcement and foundation seepage prevention. Moreover, this study offers a reliable technical pathway for extending the application of ultra-fine cement under more demanding engineering conditions.

2. Test

2.1. Test Raw Materials

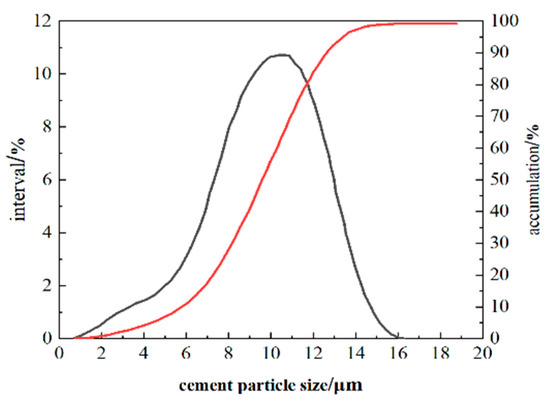

Ultra-fine Portland Cement (SPC): The SPC used in this study complies with the Chinese National Standard GB/T35161-2017 “Ultra-fine portland cement” for testing procedures [19]. The value of ≥600 m2/kg was calculated from the particle size distribution (assuming spherical particles) based on our initial size estimates. The chemical composition and respective mineral phase content of the SPC are detailed in Table 1. The properties of the Ultra-fine Portland cement are shown in Table 2. Particle size distribution, as shown in Figure 1, The measured value of D90 is 11.8 μm, and the D50 measured value is 5 μm, confirming its ultra-fine nature [20]. Polycarboxylate superplasticizer is shown in Figure 2.

Table 1.

Cement chemical composition of SPC.

Table 2.

Properties of the Ultra-fine Portland cement.

Figure 1.

SPC size distribution. (The black line represents differential distribution. The red color line is differential distribution).

Figure 2.

Polycarboxylate Superplasticizer.

2.2. Test Method

After thorough mixing of the SPC and the additive, the mixtures were prepared according to the designed proportions for testing. The PCE was incorporated at dosages of 0.20%, 0.25%, and 0.30% by mass of SPC, respectively. A constant water-to-cement ratio (W/C) of 0.35:1 was maintained for all mixtures. The mixing was conducted using a standard planetary mixer. The mixing procedure consisted of 1 min of slow mixing at 140 ± 5 rpm for homogenization, followed by 2 min of high-speed mixing at 285 ± 10 rpm to ensure a uniform paste/mortar. The specific mix proportions adopted in the experimental program are summarized in Table 3.

Table 3.

Cement-based grout ratio.

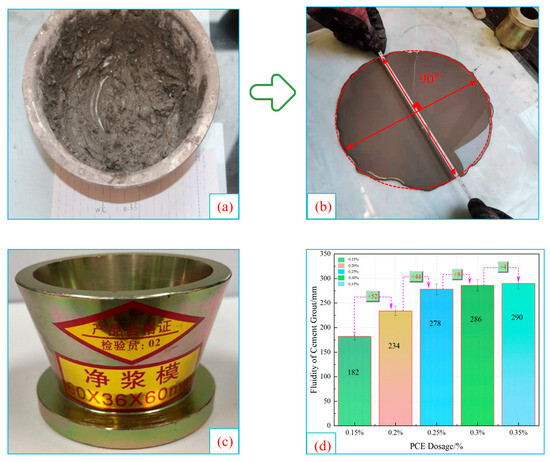

The fluidity of the cement paste was measured following the GB/T 2419-2005 test method. A standard truncated cone mold was used for testing, with an upper inner diameter of 36 mm, a lower inner diameter of 60 mm, and a height of 60 mm, placed on a flat glass plate. After filling the cone mold with fresh slurry, lift the mold vertically and allow the slurry to flow naturally under the action of gravity. Immediately (within approximately 10 s) measure the final expanded diameter of the slurry in two vertical directions, and take the average as the ‘flowability’ value of the sample, in millimeters (mm). All tests were conducted in a laboratory environment with a constant temperature of (23 ± 2) °C [21].

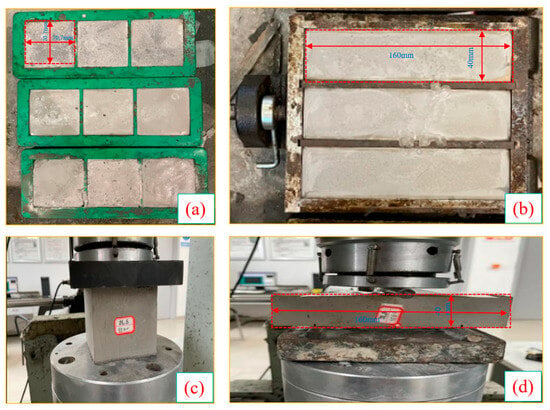

The specimens prepared for testing were cured in an environment with a controlled temperature of 20 ± 2 °C and in a standard curing room with relative humidity > 95%, until the specified testing age (3, 7, 28 d), the compressive strengths of the specimens were determined in accordance with the Chinese National Standard GB/T GB/T50080-2016 [22]. For each testing age and mix proportion, a minimum of three specimens were prepared and tested. The flexural strength (Rf) was tested on 40 mm × 40 mm × 160 mm prismatic specimens, as is standard for cement-based composites, using a three-point loading setup. For each testing age and mix proportion, a minimum of three specimens were prepared and tested.

In the experimental procedure, the SPC mass was used as the reference for all mix proportions. After dry-mixing the solid materials, water was added, and the mixture was homogenized using a high-speed mixer. The resulting fresh slurry was poured into standard cubic molds measuring 70.7 mm × 70.7 mm × 70.7 mm, as shown in Figure 3a. The standard flexural strength specimen is shown in Figure 3b. The compressive strength test is shown in Figure 3c. The flexural strength test is shown in Figure 3d. The molds were demolded after 24 h to obtain the test specimens.

Figure 3.

Strength test process: (a) Specimen preparation for compressive strength test, (b) Specimen preparation for flexural testing, (c) Compressive strength test, (d) Compressive strength evaluation.

For microstructural analysis, fragments obtained from the strength-tested specimens were dried in an oven at 50 °C for 2 h. These fragments were then sputter-coated with a thin layer of gold to enhance conductivity prior to observation under a scanning electron microscope (SEM).

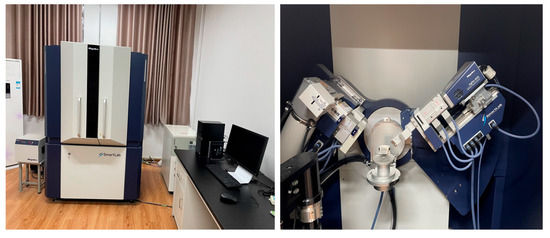

Similarly, for X-ray diffraction (XRD) analysis, small pieces from the broken specimens were dried at 50 °C for 2 h and subsequently ground in an agate mortar. The grinding process continued until a fine powder passing through a 320-mesh sieve was obtained. XRD testing utilizes a professional X-ray diffractometer (XRD, Rigaku Smartlab, Tokyo, Japan) produced by Smartlab SE for phase analysis. The instrument parameters are as follows: focal spot 1.0 mm × 10 mm, 2.0 mm × 1.2 mm; maximum power 2.7 kW; X-ray generator: maximum power 3 kW; output stability ±0.005% (power fluctuation 10%); maximum tube voltage 60 kV; maximum tube current 80 mA; voltage step width 1 kV; diffraction angle is continuously scanned within 2θ = 15°~80, with a scanning speed of 5°/min. The powdered samples were then subjected to XRD analysis. The X-ray diffractometer is shown in Figure 4.

Figure 4.

X-ray diffractometer.

3. Test Results and Analysis

3.1. The Influence of PCE Superplasticizer on the Fluidity of SPC Slurry

The water-to-cement (W/C) ratio is a critical parameter influencing the rheological behavior, coagulation structure, and compactness of the hardened cement matrix [23]. In this study, the W/C = 0.35 was selected for the preparation of the cement-based grouting material. Under this condition, however, the ultra-fine cement (SPC) particles exhibit a very low degree of hydration upon contact with water, resulting in a paste that is difficult to flow as shown in Figure 5a. Moreover, the hardened cement paste contains a certain amount of unhydrated cement due to insufficient water availability and poor initial workability.

Figure 5.

Test instrument and flow curve of cement grout: (a) Pristine Ultrafine Cement, (b) Modified Ultrafine Cement-Based Matrix, (c) Test mold for cement paste, (d) Flow curves of differently modified cement grouts.

To address this issue, a polycarboxylate ether (PCE)-based superplasticizer was introduced to improve the fluidity of the cementitious slurry and further promote the hydration reaction. The effect of PCE dosage on the fluidity of the SPC slurry is illustrated in Figure 5b. After adding PCE, the slurry immediately becomes shiny and smooth. After lifting the trial mold, the slurry will rapidly and uniformly spread out in all directions under the action of gravity, forming larger diffusion cakes and significantly increasing the flow diameter. Compared to Figure 5a, PCE significantly increases the flowability of cement slurry, transforming viscous slurry into easily flowable slurry, achieving good workability retention ability. As depicted in Figure 5d, when the PCE dosage was 0.20%, 0.25%, and 0.30%, the corresponding fluidity values of the SPC slurry reached 234 mm, 273 mm, and 286 mm, respectively. In contrast, the reference slurry without PCE failed to form a measurable fluid paste. The marked increase in fluidity with PCE addition indicates that PCE effectively disperses SPC particles and shows good compatibility with the ultra-fine cement, significantly enhancing the workability of the mixture.

This improvement in fluidity enables the grouting material to fully utilize the small particle size of SPC, facilitating its injection into fine fractures within weak coal mine surrounding rock. Thus, the use of PCE provides a viable solution to meet the injectability requirements for grouting materials used in roadway reinforcement under challenging ground conditions.

3.2. The Influence of PCE on the Setting Time of SPC Slurry

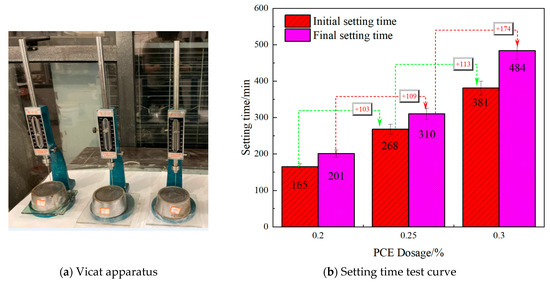

This test was conducted using a Vicat apparatus, as shown in Figure 6a. Load the prepared standard mortar into the test mold and cure it under the specified temperature and humidity environment. Start timing from adding water and mixing, by inserting the test needle into the mortar at a fixed weight and speed, and recording the penetration depth. When the test needle sinks into the mortar and is 4 mm ± 1 mm away from the bottom plate, the corresponding time is the initial setting time; when the penetration of the test needle into the surface of the mortar does not exceed 0.5 mm, the corresponding time is the final setting time. Figure 6 illustrates the influence of PCE superplasticizer on the setting time of the ultra-fine SPC slurry. As evidenced by the data, the initial setting times for SPC slurries incorporating PCE at dosages of 0.20%, 0.25%, and 0.30% were recorded as 165 min, 268 min, and 381 min, respectively. Correspondingly, the final setting times for these mixes were 201 min, 310 min, and 484 min.

Figure 6.

Effect of PCE on setting time.

Compared to the mixture with 0.20% PCE, the incorporation of 0.25% and 0.30% PCE resulted in a significant prolongation of the initial setting time by 62.42% and 130.91%, respectively. Similarly, the final setting time was extended by 54.23% and 140.79%, respectively. These test results clearly demonstrate that PCE exerts a substantial retarding effect on the setting behavior of the SPC slurry.

The observed retardation is attributed to the adsorption of PCE molecules onto the surface of cement particles, which hinders the contact between water and the cement phases and consequently slows down the early hydration kinetics. This leads to a delayed setting and hardening process with increasing PCE dosage. Therefore, while PCE effectively enhances fluidity, its dosage must be optimized within a suitable range. An appropriate PCE content not only provides the desired water-reducing effect but also serves as a set retarder, mitigating the rapid setting and hardening characteristics often associated with ultra-fine cement. This controlled retardation is crucial for improving the overall performance of the grout, ensuring adequate time for placement and injection in practical applications. The setting time measurement of the Vicat apparatus this time provides a key time parameter for the construction application of mortar.

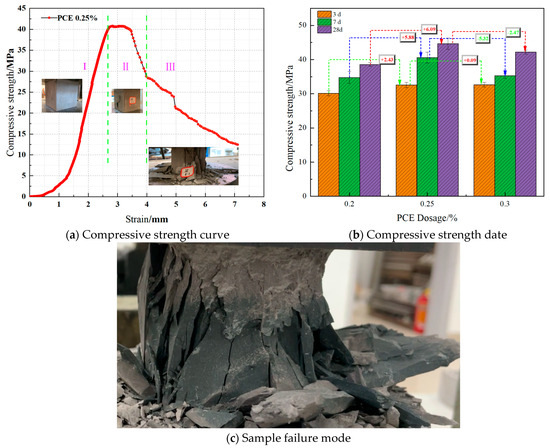

3.3. Effect of PCE on the Development of Compressive Strength in SPC Paste

In practical grouting reinforcement for weak surrounding rock roadways, cement-based grouting materials are required to possess not only satisfactory fluidity and appropriate setting time but also sufficient mechanical properties to ensure long-term stability. Figure 6 illustrates the influence of PCE dosage on the compressive strength development of the hardened ultra-fine cement (SPC) grout. Figure 7a shows a typical load displacement (PCE content 0.25%, 7 d) curve, which can reveal the complete mechanical behavior of the specimen during compression. In the initial stage of loading (Stage I), there is a good linear relationship between load and displacement, and the curve rises in a straight line. This stage indicates that the material is in a state of linear elastic deformation, and the internal microcracks are in a closed and stable stage. In the middle stage of loading (Stage II), the curve begins to deviate from the straight line and bends. This indicates that plastic deformation is beginning to occur inside the material, and microcracks are steadily expanding and converging. The material’s resistance to external loads is still increasing, but its stiffness is gradually decreasing. In the later stage of loading (Stage III), the curve decreases slowly or shows a longer ‘tail’, indicating that the material has a certain degree of toughness or residual strength, and can still maintain partial structural integrity after failure.

Figure 7.

Compressive strength.

The variation in PCE dosage resulted in a similar developmental trend of compressive strength across different curing ages. Notably, a PCE dosage of 0.25% led to a significant improvement in strength. Compared to the mixture with 0.20% PCE, the 3-day compressive strength increased from 30.14 MPa to 32.57 MPa, representing an enhancement of 8.06%. Similarly, the 7-day strength rose from 34.77 MPa to 40.58 MPa, an increase of 16.71%. However, when the PCE dosage was further increased to 0.30%, the 3-day strength showed no significant improvement compared to the 0.25% mixture, and the 7-day strength decreased from 40.58 MPa to 35.33 MPa, a reduction of 12.94%.

The specimen exhibits a typical failure mode. The failure surface clearly develops along the direction of the loading axis, indicating that the specimen fails mainly due to the combined action of transverse tensile strain and shear stress present inside under uniaxial pressure. This is an ideal and common failure mode in standardized testing. Multiple obvious inclined fracture surfaces appeared on the specimen. This indicates that shear stress dominates in the failure process. Possible reasons include strong frictional constraints between the two end faces of the specimen and the pressure plate (known as the ‘hoop effect’).

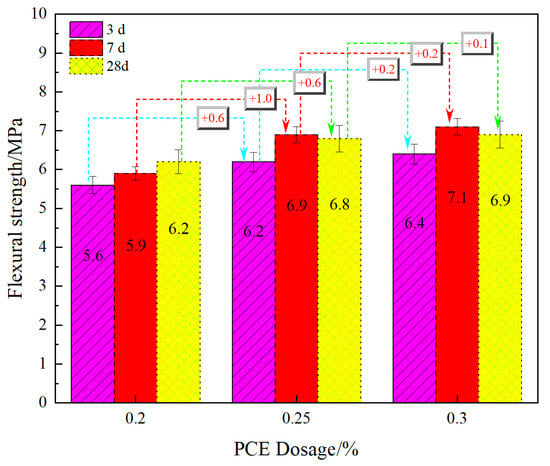

3.4. The Influence of PCE on the Mechanical Performance of SPC: A Focus on Flexural Strength

Figure 8 illustrates the influence of PCE dosage on the flexural strength of the hardened SPC grout. As observed from the results, the 3-day flexural strength generally exhibited an increasing trend with higher PCE dosages. Specifically, when the PCE dosage was raised from 0.20% to 0.25%, the flexural strength increased by 0.6 MPa, representing an enhancement of 10.71%. A further increase in dosage from 0.25% to 0.30%, however, resulted in a marginal gain of only 0.2 MPa, corresponding to an improvement of just 3.22%.

Figure 8.

Testing the flexural strength of PCE agent on slurry stone body.

A similar non-linear trend was observed at later ages. For the 7-day flexural strength, an increase in PCE dosage from 0.20% to 0.25% led to a significant improvement of 1.0 MPa (16.95%). In contrast, when the dosage was raised further to 0.30%, the flexural strength decreased by 0.1 MPa. At 28 days, the mix with 0.25% PCE continued to demonstrate the highest performance, with a strength increase of 0.9 MPa (14.51%) compared to the 0.20% dosage mixture. However, increasing the PCE content to 0.30% at this stage resulted in a reduction of 0.2 MPa in flexural strength.

The experimental data indicate that the development of flexural strength progresses gradually over time, a trend that aligns with the retarding effect of PCE on the hydration kinetics of the SPC paste. While a moderate dosage of PCE (0.25%) effectively enhances strength by improving particle dispersion and microstructure homogeneity, an excessive amount (0.30%) appears to adversely affect the long-term mechanical properties. This phenomenon can be primarily attributed to the over-dosage of the superplasticizer, which may lead to excessive air entrainment, hinder the formation of critical hydration products, and ultimately compromise the integrity of the cementitious matrix [24].

4. Microstructural Characterization

4.1. Analysis of XRD

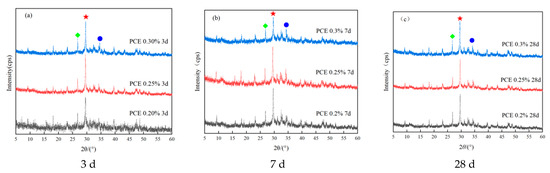

Figure 9 presents the X-ray diffraction (XRD) patterns of hydration products for pastes with varying PCE dosages at curing ages of 3, 7, and 28 days. In XRD analysis, the intensity of diffraction peaks is closely related to the content of crystalline phases; generally, a higher content of a specific phase results in greater diffraction peak intensity and area. The patterns indicate that the primary crystalline hydration products in SPC pastes, with or without PCE, are ettringite (AFt), calcium hydroxide (CH), and calcium monosulfoaluminate (AFm). These phases collectively contribute to the strength development of the hardened cement paste.

Figure 9.

XRD spectrum of different content of PCE in different hydration periods. (Red stars represent CH, green diamonds represent AFt, and blue circles represent AFm).

The microscopic phase composition of the cement mortar is normal, and the amorphous C-S-H gel ‘Mantou peak’ in the atlas constitutes the main part of the background, which is the main source of mortar strength. At the same time, the relative decrease in CH content and the increase in C-S-H gel package are microscopic manifestations of the continuous strength growth. The main strength contribution phases (C-S-H gel and CH) are rich, and their hydration degree is good, which is highly consistent with their excellent mechanical properties in the macro [25,26,27].

Analysis of the characteristic peaks for AFt (approximately 2θ = 27–32°) reveals that the peak intensity initially increases with PCE dosage up to 0.25% but then decreases at a dosage of 0.30%. This trend suggests that a moderate amount of PCE promotes the formation of ettringite, likely by improving the dispersion of cement particles and facilitating a more efficient hydration reaction. However, when the PCE dosage reaches 0.30%, the noticeable reduction in AFt peak intensity implies a lower content of this key strength-giving phase in the hardened paste. This can be attributed to an excessive dispersion of cement particles caused by the superplasticizer, which may reduce particle surface activity and ultimately slow down the overall hydration kinetics. The samples showing the most pronounced AFt peaks in XRD are the same ones that exhibit the highest mechanical strength at corresponding ages, reinforcing the correlation.

It is important to note that PCE does not directly contribute to the strength of cement. Instead, it acts by adsorbing onto the surface of SPC particles, effectively dispersing the flocculated structure in the cement paste and releasing trapped water. This mechanism allows for a reduction in water demand while simultaneously decreasing porosity and increasing the density of the hardened matrix, thereby significantly enhancing the overall mechanical performance.

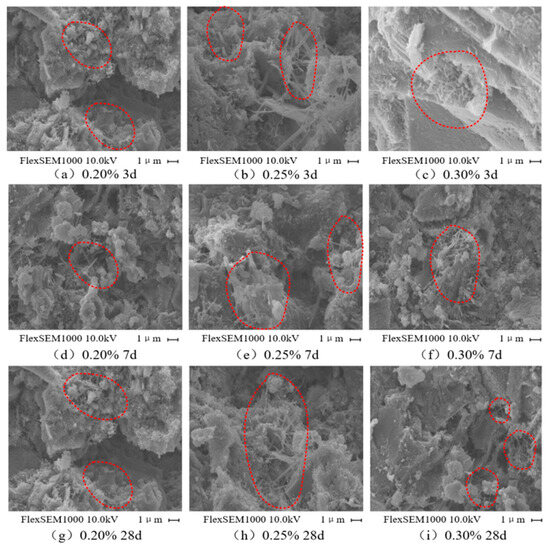

4.2. Analysis of SEM

Figure 10 presents SEM images of fracture surfaces of cement specimens with varying PCE dosages after 3 and 7 d of curing. The micrographs reveal the presence of acicular AFt crystals in all samples, regardless of age. Notably, at a PCE dosage of 0.25% Figure 10b, the 3-day sample exhibits a dense network of radiating needle-like and fibrous AFt crystals, which is markedly more abundant than that observed in samples with lower Figure 10a or higher Figure 10c PCE contents. According to established cement hydration theory, AFt contributes significantly to the early strength development of cement-based materials. This microstructural observation aligns well with the mechanical test results, where the 0.25% PCE dosage yielded the highest 3-day compressive strength.

Figure 10.

SEM microstructure of different ages. (The red dashed-line boxes represents AFt).

The enhanced performance can be attributed to the uniform dispersion of SPC particles by PCE, which provides sufficient space and time for the early-stage crystals to grow and fill pores effectively, resulting in a denser and more interconnected microstructure. When the curing age reaches 7 d, distinct microstructural differences remain evident. As shown in Figure 10d, the sample with lower PCE content shows relatively sparse AFt crystals with discrete distribution and higher porosity, corresponding to its lower mechanical strength. In contrast, the sample with 0.25% PCE Figure 10e displays robustly developed AFt crystals that effectively bridge adjacent phases and fill voids, contributing to a denser matrix and improved strength. However, when the PCE dosage increases to 0.30% Figure 10f, the formation of AFt crystals is visibly suppressed, leading to weakened interfacial bonding and reduced mechanical strength.

These results demonstrate that PCE significantly influences the morphology and growth dynamics of ettringite. The retarding effect of PCE, which stems from its adsorption on cement particle surfaces, slows down the dissolution of silicate and aluminate phases as well as the subsequent hydration reactions. This delayed reaction kinetics initially promotes the development of well-crystallized AFt at optimal dosage. However, excessive PCE overdose further prolongs the induction period, ultimately reducing the overall volume of hydration products. In the early hydration stage, the continuously growing microcrystalline aggregates form fibrous crystals that radiate outward, creating pores of varying sizes around cement particles [28]. The number of hydration products formed in these finer pores can serve as a critical microstructural indicator for evaluating the strength of the hardened cement paste. The observed strength behavior can be attributed to the synergistic effect of hydration products and the retarding action of PCE. The primary hydration products of SPC, including ettringite (AFt), calcium hydroxide (CH), and calcium sulfoaluminate (AFm), collectively contribute to the early-age strength of the hardened grout. However, PCE retards the hardening process of the SPC paste by delaying the transformation of gels during hydration, which influences the early-age mechanical properties. At the optimal dosage of 0.25%, PCE effectively improves particle dispersion and promotes a more compact microstructure, thereby enhancing strength development. In contrast, at an excessive dosage of 0.30%, the saturation of PCE molecules on cement particles may hinder interparticle hydration reactions, reducing cohesion and resulting in slower strength gain and lower later-age strength.

The sample with 0.25% PCE, which exhibited a moderate setting delay, achieved the highest 3-day strength. This suggests that an optimal retardation allows for a more organized and complete precipitation of early hydration products (such as AFt), leading to a denser initial microstructure than in the faster-setting 0.20% PCE sample, This optimized early-age microstructure appears to create a favorable foundation for later-age strength development. By 28 days, the sample with 0.25% PCE continued to demonstrate superior performance. The optimal 28-day compressive and flexural strength was consistently achieved with 0.25% PCE. The inferior strength at 0.30% PCE is likely due to excessive retardation and potential air entrainment, which disrupts the microstructural continuity. In summary, the mechanical strength is not merely a function of PCE dosage, but a reflection of the dosage-dependent microstructural evolution. An optimal dosage (0.25%) promotes a balanced hydration kinetics and the formation of a dense, interlocked matrix of AFt and C-S-H, whereas deviations from this optimum lead to microstructural deficiencies that compromise strength.

4.3. Analysis of the Modification Mechanism

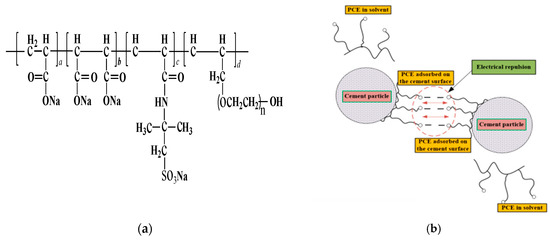

Polycarboxylate ether (PCE) is recognized as a new-generation high-performance water-reducing agent, distinguished by its unique molecular architecture. The polymer backbone contains multiple functional groups, including carboxyl (-COOH), hydroxyl (-OH), amino (-NH2), and polyoxyalkyl (-O-R)n chains. These groups exhibit strong affinity for water molecules and play a critical role in the dispersion of cement particles through mechanisms such as adsorption, lubrication, and steric hindrance. By adsorbing onto cement surfaces, PCE reduces interparticle friction, lowers the interfacial free energy between cement and water, and significantly enhances the workability of cement-based materials. A schematic representation of the adsorption of PCE molecules onto cement particles is provided in Figure 11. For our SPC system, we propose that at 0.30%, excess unadsorbed PCE in the pore solution leads to excessive retardation, potentially disrupting the synergistic crystallization of hydration products. the slower strength development and lower final strength at 0.30%, which is consistent with both a disrupted matrix (SEM) and the presence of additional porosity. The optimal dosage (0.25%) leads to a “synergistic microstructure” where well-dispersed particles allow for the simultaneous, dense growth of AFt and C-S-H, as qualitatively observed in our SEM/XRD.

Figure 11.

Schematic diagram of molecular structure of PCE and adsorption of cement particles. (a) Schematic Diagram of the PCE Molecular Structure. (b) Proposed Interaction Mechanism Between PCE Molecules and Cement Particles.

When introduced into an SPC slurry, PCE molecules dissociate, releasing numerous anionic groups. During the early stages of hydration, the surfaces of cement particles are predominantly positively charged due to the presence of Ca2+ ions. Anionic functional groups from PCE, such as -SO3− and -COO−, adsorb onto these positively charged surfaces, forming an electrical double layer. This adsorption alters the zeta potential of the cement particles, rendering them negatively charged and leading to interparticle electrostatic repulsion, which contributes to particle dispersion.

We no longer merely state that “PCE has a retarding effect”, but have added a discussion on its specific mechanism. The observed retarding effect in this study can mainly be attributed to the adsorption of PCE molecules on the surface of cement particles and their influence on the nucleation and growth of hydration products. In particular, XRD results show that in the early hydration stage, the characteristic diffraction peak intensity of ettringite in the sample with 0.30% PCE added is lower than that in the control group. This quantitatively indicates that PCE delays the reaction kinetics between aluminate phase and sulfate ions, possibly by adsorbing on C3A particles or their initial hydration products, forming a diffusion barrier layer.

We propose that this peak in performance is a direct consequence of a refined microstructure. As qualitatively observed in the SEM images (Figure 10) and XRD patterns (Figure 11) for this sample, there is an apparent abundance of well-developed AFt crystals and a denser C-S-H matrix compared to other dosages. This aligns with the well-established role of AFt in contributing to early strength and the C-S-H phase as the primary strength-giving component.

Considering the significant delay in setting, slow strength development, and underdeveloped microstructure, we infer that the strong adsorption of excessive PCE (0.30%) on the surface of cement particles may form a layer of steric hindrance, significantly hindering the contact of water molecules and the dissolution/migration of ions, thereby inhibiting early hydration kinetics.

It is worth noting that there is an optimal dosage for this ‘optimized retarding’ effect. In this study, a 0.25% PCE dosage achieved the best balance between microstructure improvement and strength gain. However, excessive dosage (0.30%) may lead to excessive retarding, causing the early microstructure formation to be too slow, thus failing to exhibit optimal strength within 28 days.

In addition to electrostatic interactions, the long polyoxyethylene side chains of PCE extend into the aqueous phase, creating a steric hindrance effect that further prevents particle flocculation. Thus, the combined action of electrostatic repulsion and steric hindrance disrupts the flocculated structure of cement particles, resulting in a more homogeneous slurry with improved fluidity and stability.

5. Conclusions

Based on the test results, the following conclusions can be drawn:

- (1)

- The optimal PCE dosage was determined to be 0.25%, at which the SPC slurry exhibited a fluidity of 273 mm. The initial and final setting times were recorded at 268 min and 310 min, respectively, confirming that PCE serves as an effective plasticizer and set retarder.

- (2)

- The PCE content of 0.25% significantly improved the long-term mechanical properties, resulting in 28-day compressive and flexural strengths of 44.65 ± 0.5 MPa and 7.1 ± 0.2 MPa. This represents a 15.79% increase in compressive strength and a 14.52% increase in flexural strength compared to the mixture with 0.20% PCE.

- (3)

- SEM and XRD analyses elucidated the underlying mechanism, revealing that PCE influences the crystallization kinetics of ettringite (AFt). The optimal dosage promoted the formation of needle-like and rod-shaped AFt crystals, which contributed to a denser microstructure. A strong correlation was observed between the rate of crystal growth, the abundance of hydration products, and the resultant macroscopic mechanical strength.

6. Outlook and Future Work

- (1)

- Quantifying Hydration Kinetics and Adsorption Behavior

Future work will employ direct quantitative techniques to elucidate the retardation mechanism and hydration kinetics. Isothermal calorimetry (e.g., per ASTM C1702) will be used to precisely monitor heat flow and directly link PCE dosage to the rate of hydration reactions. Furthermore, the adsorption dynamics of PCE will be quantified directly via Total Organic Carbon (TOC) analysis, complemented by zeta potential measurements to deconvolute the respective contributions of electrostatic and steric hindrance to dispersion and retardation.

- (2)

- Correlating Macroscopic Properties with Quantitative Microstructure

To move beyond qualitative microstructural observation, future studies will focus on establishing robust quantitative structure–property relationships. Mercury Intrusion Porosimetry (MIP) will be utilized to its full potential in quantifying the evolution of pore size distribution, which directly influences permeability and strength. This will be coupled with Quantitative X-ray Diffraction (QXRD) and Thermogravimetric Analysis (TGA) to precisely determine the phase assemblage (e.g., AFt, CH, C-S-H content), allowing for a direct correlation between the abundance of hydration products and the resulting macroscopic properties.

- (3)

- From Observation to Active Microstructural Design

The temporal variation in fluidity serves as an excellent indirect indicator of slurry structure reconstruction, providing a practical reference for estimating the operational pumpability window. Building on the observation that PCE guides the nucleation and growth of crystalline phases, our ultimate goal is to transition from describing microstructure to actively designing it. We posit that in PC-PCE systems, the admixture essentially regulates the dissolution, migration, and precipitation of ionic species, thereby directing the spatial distribution of AFt and AFm. This cross-disciplinary perspective elevates the concept of “microstructure optimization” to the theoretical level of active microstructural reconstruction, framing the admixture not merely as a modifier but as a molecular-scale architect for designing denser and more uniform cementitious matrices.

Author Contributions

S.H.: Methodology, Data curation, Writing—original draft preparation. Z.Z.: Supervision, Resources. X.M.: Supervision, Funding acquisition. G.Z.: Supervision, Funding acquisition. X.P.: Data curation, Software. Q.Y.: Data curation, Software. F.L.: Writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (52404068, 52374074), the Excellent scientific research and innovation team of universities in Anhui Province (2022AH010053), and School Research Start up Fund Project (24KQ114).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be made available on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kang, H.; Zheng, Y.; Jiang, P.; Huang, B.; Guan, X.; Wang, Z.; Wu, Y. Roadway soft coal control technology by means of grouting bolts with high pressure-shotcreting in synergy in more than 1000 m deep coal mines. J. China Coal Soc. 2020, 45, 845–864. [Google Scholar]

- Wang, Y.; Fu, C.; Kuang, H.; Qin, H.; Xu, T.; Meng, W. Experimental study on the mechanical properties of cement-based grouting materials after exposed to high temperatures. Case Stud. Constr. Mater. 2024, 20, e03068. [Google Scholar] [CrossRef]

- Yao, J.; Feng, D.; Wang, Z.; Peng, C.; Zhang, Y.; Han, L. Experimental Study on Performance of Modified Cement-Based Building Materials under High-Water-Pressure Surrounding Rock Environment. Coatings 2023, 13, 501. [Google Scholar] [CrossRef]

- Wang, Q.; Li, W.Z. Physical and mechanical performance test and application of modified cement base grouting material. Coal Sci. Technol. 2016, 44, 57–63. [Google Scholar]

- Zhang, J.; Guan, X.; Li, H.; Liu, X. Performance and hydration study of ultra-fine sulfoaluminate cement-based double liquid grouting material. Constr. Build. Mater. 2017, 132, 262–270. [Google Scholar] [CrossRef]

- Ai, J.; Wang, Y.; Cheng, X.; Zhao, G.; Meng, X.; Huang, S. Influence of calcination temperature of industrial by-product gypsum on sulphoaluminate cement-based grouting material. Constr. Build. Mater. 2025, 478, 141455. [Google Scholar] [CrossRef]

- Wei, M.; Chen, L.; Lei, N.; Li, H.; Huang, L. Mechanical properties and microstructures of thermally activated ultrafine recycled fine powder cementitious materials. Constr. Build. Mater. 2025, 475, 141195. [Google Scholar] [CrossRef]

- Ren, J.; Guo, J.; Jin, Y.; Liu, F.; Liu, B.; Yan, S.; Shi, S. Enhancing workability of high-volume calcined clay blend cement pastes through optimized addition sequences of PCE superplasticizer. Case Stud. Constr. Mater. 2024, 21, e03541. [Google Scholar] [CrossRef]

- Hu, Q.; Zhang, L.; Luo, Q.; Yu, K.; Connolly, D.P.; Qin, L.; Wang, T. Impact of polycarboxylate superplasticizer dosage on controlled low strength material flowability and bleeding: Insights from water film thickness. Constr. Build. Mater. 2024, 447, 138145. [Google Scholar] [CrossRef]

- Taylor, H.F.W. Chemistry for Engineers. In Cement Chemistry; Thomas Telford Publishing: London, UK, 1997; p. 134. [Google Scholar] [CrossRef]

- Cao, M.; Zhang, C.; Wei, J. Microscopic reinforcement for cement based composite materials. Constr. Build. Mater. 2013, 40, 14–25. [Google Scholar] [CrossRef]

- Liu, D.; Jing, H.; Meng, Y. Experimental study of the direct shear characteristics of cement grout under constant normal loading and stiffness boundary conditions. Eur. J. Environ. Civ. Eng. 2024, 28, 718–735. [Google Scholar] [CrossRef]

- Ji, X.; Liu, C.B.; Liu, Q.; Hong, F.; Hou, D.; Wang, M. Molecular scale study on polyphosphate superplasticizers for cement fluidity improvement: Impact of phosphorus-containing functional groups. Mater. Struct. 2025, 58, 199. [Google Scholar] [CrossRef]

- Wei, X.; Li, X.; Di, J.; Qin, F.; Zhang, Z.; Liang, F. Flexural performance of U-shaped high-strength ECC permanent formwork-concrete composite beams. Structures 2025, 74, 108641. [Google Scholar] [CrossRef]

- Mirghaderi, S.R.; Taheri, G.; Ebrahimi, S. Improving a Conventional Connection of Beam-to-Weak Axis of H-shaped Column to Modify Load Path in Panel Zone. J. Earthq. Tsunami 2024, 18, 2450001. [Google Scholar] [CrossRef]

- Men, P.F.; Chen, F.M.; Qin, F.J.; Peng, X.; Di, J.; Jiao, H.R. Behavior of composite beams with UHPC-concrete composite slabs under negative bending moment. J. Constr. Steel Res. 2025, 227, 109415. [Google Scholar] [CrossRef]

- Shu, B.; Zhou, M.; Yang, T.; Li, Y.; Song, P.; Chen, A.; Barbieri, D.M. Performance study and engineering application of grouting materials with a large content of solid waste. Constr. Build. Mater. 2021, 312, 125464. [Google Scholar] [CrossRef]

- Yin, X.; Wu, Z.; Weng, L.; Xu, X.; Zhou, Y.; Liu, Q. A microstructure-based model for quantifying irreversible yield stress evolution in cement-based pastes during hydration. Cem. Concr. Res. 2024, 180, 107503. [Google Scholar] [CrossRef]

- Wang, X.; Yang, Q.; Peng, X.; Qin, F. A Review of Concrete Carbonation Depth Evaluation Models. Coatings 2024, 14, 386. [Google Scholar] [CrossRef]

- Li, K.; Wei, Z.Q.; Qiao, H.X.; Lu, C.G.; Guo, J.; Qiao, G.B. Research Progress of the Influence of Four Kinds of Admixtures on the Properties of Polymer Cement-based Materials. Mater. Rep. 2021, 35, 654–661. [Google Scholar]

- Huang, X.W.; Wang, Z.X.; Chen, Y.; Song, B.L.; Guan, K.X. Assessment of thermal conductivity of unsaturated frozen soils based on three-dimensional numerical models. Phys. Fluids 2025, 37. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, Z.; Wang, W.; Li, G.; Guo, H.; Zhang, H. Property enhancement and mechanism of cement-based composites from the perspective of nano-silica dispersion improvement. Case Stud. Constr. Mater. 2025, 22, e04125. [Google Scholar] [CrossRef]

- Yang, K.; Liu, S.; Liu, Y.; Wu, K.; Duan, Z.; Xiao, J.; Xu, L. Unravelling determining role of recycled powder adsorbing polycarboxylate ethers in recycled cement paste dispersion. Constr. Build. Mater. 2025, 485, 141535. [Google Scholar] [CrossRef]

- Yang, Y.Z.; Tan, Y.; Li, Z.J.; Zhou, G.L.; Yu, X.M.; Xu, D.; Yong, Q.W.; Zhao, H.W.; Xie, Z.H. Interaction mechanisms between polycarboxylate superplasticizers and cement, and the influence of functional groups on superplasticizer performance: A review. Polym. Bull. 2024, 81, 10415–10438. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Yao, F.; Lin, C.; Xu, S.; Li, Y.; Pan, L. What are the mechanisms of functional monomers’ effect on air entrainment of polycarboxylate superplasticizers in cement paste and mortar? Constr. Build. Mater. 2024, 442, 137038. [Google Scholar] [CrossRef]

- Ma, B.G.; Peng, Y.; Cao, X.R.; Tan, H.B.; Guo, Y.L.; Gu, B.Q.; Deng, X.F. Influence of Small Molecular Carboxylic Acid Polymer on Adsorption Mechanism of Polycarboxylate Superplasticizer. Bull. Chin. Ceram. Soc. 2018, 37, 2130–2135. [Google Scholar]

- Anwar, A.; Liu, X.; Zhang, L. To what extent can polycarboxylate superplasticizers enhance the dispersion characteristics of modified graphene oxide in cement? Insights from ultrasonication and high-shear mixing methods. Cem. Concr. Res. 2025, 195, 107881. [Google Scholar] [CrossRef]

- Pustovgar, A.P.; Krivoborodov, Y.R.; Adamtsevich, A.O.; Elenova, A.A.; Butenko, K.A.; Kramerov, D.V.; Bugaev, A.M. The Impact of Plasticizers on the Nature of the Alkali-Silicate Corrosion in Cement Composites. Buildings 2024, 14, 172. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).