Abstract

Shape memory polymers (SMPs) are a class of smart materials that exhibit unique shape-fixing and recovery abilities, attracting wide attention for applications in electronics, aerospace, and biomedical engineering. Chitosan (CS) as a renewable biopolymer, possessing good biocompatibility, biodegradability, and antimicrobial properties; its use as a matrix enhances the environmental compatibility and bio-adaptability of SMPs. MXene, as a novel two-dimensional material, is characterized by high electrical conductivity, abundant surface functional groups and good hydrophilicity, showing potential in energy storage, electromagnetic shielding and sensing. In this work, CS and poly (vinyl alcohol) (PVA) were used as the polymer matrix, and carbon nanotubes (CNTs) together with MXene were introduced as co-fillers to construct multifunctional composites. The effect of the CNTs/MXene hybrid fillers on mechanical properties, electromagnetic shielding and multi-stimuli-responsive shape memory behavior was systematically investigated. After ratio optimization, the composites showed excellent comprehensive performance: tensile strength reached up to 20.0 MPa, Young’s modulus up to 292.2 MPa, and maximum elongation at break of 23.2%; electromagnetic interference shielding effectiveness (SET) in the X-band (8.2–12.4 GHz) reached a maximum of 10.6 dB; shape fixation rates exceeded 90%; under thermal stimulation, a shape recovery ratio of 98.3% was achieved within 41.7 s; light-driven recovery rate reached 86.5% with a minimal recovery time of 82.3 s; under electrical stimulation the highest recovery rate was 94.1% with a shortest recovery time of 30 s. This study successfully prepared functional multi-stimuli-responsive shape memory composite films and provided a new strategy for the design of green smart materials.

1. Introduction

In recent years, the rapid advancement of smart functional materials has significantly accelerated their integration into diverse daily and high-tech applications. Among these, shape memory polymers (SMPs) are a class of remarkable stimuli-responsive materials capable of achieving reversible changes in shape, transparency, or mechanical properties under external triggering conditions such as heat, light, electric fields, or magnetic fields [1,2,3,4,5,6]. This unique behavior stems from their ability to store a temporary shape and recover the original, permanent shape upon application of the appropriate stimuli, a phenomenon driven by the combination of a stable network and reversible switching segments. These exceptional shape-programming and recovery capabilities position SMPs as promising candidates for innovative applications across diverse fields, including aerospace (e.g., deployable structures [6,7]), biomedical engineering (e.g., self-tightening sutures, stents [8,9]), and soft robotics (e.g., actuators, grippers [10,11]).

As traditional SMPs are derived from petroleum-based resources, concerns have been raised regarding their environmental sustainability, biocompatibility, and end-of-life disposal. Consequently, the research community has increasingly focused on developing SMPs based on renewable and biodegradable raw materials to enhance their eco-friendliness and applicability in biomedical fields. Chitosan (CS), a linear polysaccharide obtained by the partial deacetylation of chitin, stands out as an excellent candidate for this purpose [12,13]. Chitin, the second most abundant natural polysaccharide after cellulose, is widely sourced from crustacean shells, insect exoskeletons, and fungal cell walls, ensuring a reliable and sustainable raw material base for large-scale CS production. Chemically, CS consists of β-(1→4)-linked D-glucosamine and N-acetyl-D-glucosamine units, which endow notable properties such as excellent biocompatibility, low toxicity, biodegradability and inherent antibacterial activity. These attributes have led to the extensive use of CS in wound dressings, drug delivery systems, and water purification. Utilizing CS as the matrix for SMPs can significantly improve their environmental compatibility and bio-adaptability, paving the way for “green” smart materials [14].

Meanwhile, the incorporation of functional nanofillers has been demonstrated to enhance the performance of SMPs, endowing the additional properties such as conductivity, thermal conductivity, or enhanced mechanical strength. In this context, two-dimensional (2D) materials have attracted considerable attention. MXene, a rapidly evolving family of two-dimensional transition metal carbides, nitrides, and carbonitrides, is typically fabricated by selectively etching the metal layer (A) from MAX phase precursors and has emerged as a highly promising filler. MXene materials (e.g., Ti3C2Tx, where Tx represents surface functional groups such as -OH, -O, -F) exhibit metallic electrical conductivity, outstanding mechanical properties, high specific surface area, rich surface chemistry, and good hydrophilicity [15,16,17]. These characteristics make them highly suitable for applications in energy storage (batteries, supercapacitors [18]), electromagnetic interference (EMI) shielding, sensors [19,20], and catalysis [21]. However, a common challenge with MXene nanosheets is their tendency to restack due to van der Waals forces and hydrogen bonding, which can limit the accessibility of their active surfaces and hinder performance in composite materials.

Complementing 2D MXenes, one-dimensional (1D) carbon nanotubes (CNTs) are another class of nanocarbon materials characterized by exceptional axial mechanical strength, high aspect ratio, and excellent electrical and thermal conductivity. CNTs have been extensively incorporated into polymer composites as reinforcing and conductive fillers in polymer composites. The combination of 1D CNTs and 2D MXenes as hybrid fillers within a polymer matrix has been demonstrated to yield synergistic effects. The CNTs can act as bridges between MXene sheets, mitigating restacking and facilitating the formation of an extensive, interconnected conductive network. This hybrid approach has been successfully exploited to develop composites with superior electrical conductivity, enhanced mechanical properties, and improved EMI shielding performance [22,23,24].

However, despite these advantages, MXene nanosheets are highly susceptible to oxidation and surface degradation, especially under humid or acidic conditions, leading to a rapid decline in electrical conductivity and EMI shielding performance. Moreover, the strong van der Waals interactions between adjacent layers promote restacking and poor colloidal stability, further restricting their utilization in polymer-based systems. To address these issues, surface stabilization and interfacial engineering strategies are often adopted. In this work, CS acts as a biopolymeric stabilizer, forming hydrogen bonds and electrostatic interactions with the terminal –OH and –F groups on MXene surfaces, which not only suppresses oxidation but also enhances dispersion in aqueous media. Meanwhile, CNTs serve as 1D spacers and conductive bridges, effectively preventing MXene sheet aggregation and constructing a continuous, interconnected 3D conductive network. This synergistic approach ensures both long-term electrical stability and high filler dispersion, laying the structural foundation for the subsequent improvements in mechanical reinforcement, multi-stimuli shape memory, and electromagnetic shielding performance. Such a stabilization–dispersion mechanism provides a promising route to overcome the intrinsic instability of MXene in bio-based polymer systems, which remains a critical yet underexplored challenge in current research.

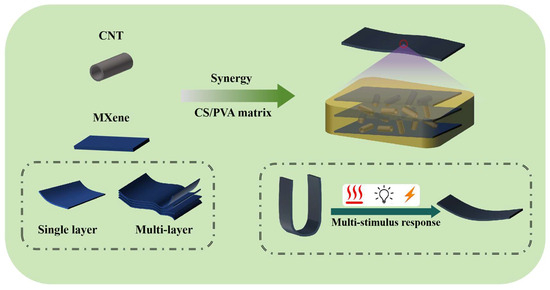

Despite the promising progress of MXene/CNT hybrid systems in conductive composites, current studies remain largely confined to synthetic polymer matrices, with limited exploration in biodegradable, bio-based materials [25,26,27,28,29,30,31]. Moreover, the integration of multi-stimuli responsiveness (thermal, light, and electrical) with electromagnetic shielding functionality in a single sustainable system has rarely been realized. To address these limitations, this work introduces a renewable chitosan matrix incorporated with dual-functional MXene and CNT hybrid fillers, aiming to construct a synergistic 1D/2D conductive network that enables tunable mechanical reinforcement, efficient electromagnetic attenuation, and multi-stimuli-responsive shape memory behaviors. As shown in Figure 1. A systematic investigation is carried out to correlate the hybrid filler ratio with the microstructure, mechanical performance, EMI shielding efficiency, and shape recovery characteristics, thereby identifying the optimal composition for balanced multifunctionality. This design concept not only extends the application of MXene/CNT hybrids to biodegradable systems but also provides a new paradigm for engineering sustainable smart materials with coupled mechanical–electrical–thermal responses. The findings offer fundamental insights into filler synergy in bio-based matrices, paving the way toward eco-friendly, multifunctional materials for flexible electronics, wearable sensors, and green intelligent devices.

Figure 1.

Preparation of multi-stimuli-responsive shape memory composite films.

2. Materials and Methods

2.1. Materials

Lithium fluoride, glacial acetic acid, hydrochloric acid and polyvinyl alcohol were purchased from Shanghai Aladdin Biochemical Technology Co., Ltd. (Shanghai, China); chitosan (≥90% deacetylation, Mw: 31,000–50,000) was obtained from Zhejiang Golden Shell Pharmaceutical Co., Ltd. (Yuhuan, China). Carbon nanotubes (MWCNT, OD: 10–20 nm, >98%)were supplied by Chengdu Institute of Organic Chemistry, Chinese Academy of Sciences.; Titanium aluminum carbide (Ti3AlC2) MAX phase ceramic material was obtained from Jiangsu Xianfeng Nanomaterials Co., Ltd. (Nanjing, China). It is imperative to note that all reagents utilized in this study are of chemical grade purity or higher, ensuring the highest standards of purity and quality. All reagents were used as received.

2.2. Preparation of MXene and Functional Composites

The synthesis of MXene (Ti3C2Tx) nanosheets was accomplished through a meticulous process of etching the Al layer from the Ti3AlC2 MAX phase. The etching was performed using a fluoride-assisted HCl/LiF system, in which hydrofluoric acid (HF) was generated in situ through the reaction of LiF with HCl to selectively remove the Al layer from the Ti3AlC2 MAX phase. In summary, 20 mL of 9 M HCl was added gradually to a solution comprising 2.0 g of LiF in a Teflon beaker under magnetic stirring. Once the etchant mixture became homogeneous, 2.0 g of Ti3AlC2 powder was gradually added over 5 min to avoid excessive effervescence. The mixture was then subjected to continuous stirring in a sealed oil bath at 35 °C for a period exceeding 24 h. Following the etching process, the resulting mixture was subjected to repeated washings with deionized water via centrifugation (3500 rpm, 2 min) until the pH of the upper layer approached neutrality. The collected precipitate was redispersed in deionized water and subjected to ultrasonic treatment in an ice-water bath for a period of 4 h with a view to exfoliating the multilayer MXene into few-layer flakes. The final dispersion was subjected to freeze-drying to obtain MXene powder for subsequent use.

The preparation of dual-filler composite materials is primarily achieved through the following methods. Initially, CS must be dissolved in a 1% (v/v) aqueous acetic acid solution. Polyvinyl alcohol (PVA) should be dissolved in deionized water via magnetic stirring at 90 °C for a period of two hours. The prepared MXene powder should then be dispersed in deionized water via ultrasonic treatment, forming a uniform suspension with a concentration of 5 mg/mL. Under mechanical stirring (300 rpm), sequentially add the MXene suspension, CNTs powder, and CS solution to the PVA solution. Continue stirring for 1 h, followed by ultrasonic treatment for 30 min. The total amount of dual fillers added was 12 wt.%, with the mass ratio of CNTs to MXene designed as (12-x): x. The corresponding samples were labeled as CNTs/MXene-x (C/M-x, where x = 1, 2, 3, 4). Under mechanical stirring (300 rpm), sequentially add the MXene suspension, carbon nanotube powder, and CS solution to the PVA solution. Continue stirring the mixture for 2 h, followed by ultrasonic treatment for 30 min to ensure uniform mixing. Finally, the homogeneous solution was cast onto a leveled polytetrafluoroethylene (PTFE) mold and dried at 40 °C in a vacuum oven for 24 h to obtain composites with a thickness of approximately 0.8 mm.

2.3. Characterization

X-ray diffraction (XRD) patterns were recorded on a Rigaku SmartLab SE diffractometer with continuous scanning over 2θ = 5–80° at 2°/min. Scanning electron microscopy (SEM) images were acquired on a ZEISS Sigma 360 after sputter coating the specimens with ~5 nm gold. Fourier transform infrared (FTIR) spectra were obtained with a Thermo Fisher Nicolet iS20 over 4000–400 cm−1 at 4 cm−1 resolution (32 scans).

Differential scanning calorimetry (DSC) was performed on a TA Q20 under high-purity nitrogen (50 mL·min−1) with a heating rate of 10 °C·min−1 from room temperature to 250 °C to determine glass transition temperatures (Tg). Thermogravimetric analysis (TGA) was carried out on a TA TGA550 in air atmosphere from ambient to 800 °C at 10 °C·min−1 to assess thermal stability.

Tensile tests were performed on specimens of dimensions 50 × 10 mm (gauge length as specified). The average thickness of the measured samples is as follows: C/M-1: 0.82 mm C/M-2: 0.67 mm C/M-3: 0.92 mm C/M-4: 0.94 mm. Tests were conducted at room temperature with a tensile speed of 5 mm·min−1. Five parallel specimens were tested for each condition and the average tensile strength and elongation at break were reported.

Shape memory tests were conducted using strips (30 × 10 × 0.5 mm). Samples were heated to 120 °C (above Tg) to soften the matrix, deformed into a U-shape under an external force, and then rapidly cooled while maintaining the force to fix a temporary shape. After fixation at room temperature for 5 min, the fixed angle θf was recorded. Each sample was repeated at least three times. Diverse shape recovery behaviors were induced by three stimuli: (1) direct heating on a hot plate, (2) exposure to a xenon lamp (light), and (3) electrical stimuli (applied voltage U = 20 V, current I = 0.05 A) to the two ends. The recovered angle θr and recovery time were recorded. Shape fixation rate Rf and shape recovery rate Rr were calculated as:

EMI shielding performance was measured using an Agilent E5071C vector network analyzer combined with an appropriate waveguide fixture. S-parameters (S11, S22, S21, S12) were measured in the X-band (8.2–12.4 GHz). Total shielding effectiveness (SET) and its components—reflection loss (SER), absorption loss (SEA) and multiple internal reflections (SEM)—were calculated from the measured S-parameters.

3. Results and Discussion

3.1. MXene Structure and Morphology

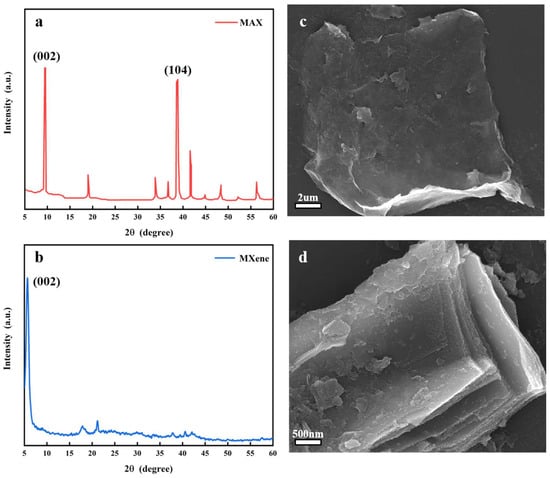

XRD patterns of the Ti3AlC2 MAX phase and the etched Ti3C2Tx MXene are presented in Figure 2a. The pristine MAX phase exhibits a sharp (104) diffraction peak near 38.8°, characteristic of the ordered Ti3AlC2 crystal structure, along with a (002) reflection at 9.4°, corresponding to an interlayer spacing (d) of 0.94 nm. After selective etching of Al in the fluoride-assisted HCl/LiF system, the (002) peak of the resulting Ti3C2Tx MXene shifted distinctly to 5.7°, indicating an expanded interlayer spacing of approximately 1.55 nm. This shift quantitatively demonstrates the removal of Al atomic layers and the introduction of surface termination groups (–OH, –O, –F), which enlarge the gallery distance between Ti3C2 layers. The observed peak broadening and intensity reduction further suggest partial delamination and decreased crystallinity—typical signatures of successful MXene formation. These results are consistent with previously reported Ti3C2Tx MXene synthesized via similar fluoride-assisted routes. In addition to the dominant MXene reflections, several weak peaks were observed. These minor signals were attributed to residual unreacted Ti3AlC2 and trace amounts of surface-oxidized TiO2, respectively. The latter likely formed during the etching or drying process due to partial oxidation of Ti atoms on exposed surfaces. Nevertheless, the low intensity of these peaks confirms that the product predominantly consists of few-layer Ti3C2Tx with high phase purity, suitable for subsequent composite fabrication.

Figure 2.

(a,b) XRD of MAX and MXene; (c,d) SEM of MXene at different magnifications.

SEM images (Figure 2c,d) clearly reveal the layered and accordion-like morphology characteristic of few-layer Ti3C2Tx MXene rather than completely delaminated nanosheets. The partial restacking can be attributed to van der Waals interactions between adjacent layers, as well as possible hydrogen bonding among surface-terminated groups (–O, –OH, and –F). This microstructure is consistent with previously reported Ti3C2Tx prepared via fluoride-assisted HCl/LiF etching routes. Although additional high-resolution analyses such as TEM or AFM were not performed in this study, the SEM observations correspond well with recent literature, showing the typical multilayered and expanded sheet structure with a loosely stacked configuration. These morphological characteristics confirm the successful selective removal of the Al atomic layers and partial delamination of the MXene sheets. Such a structure is widely recognized as evidence of effective MXene synthesis and provides a robust framework for ensuring uniform dispersion and strong interfacial compatibility when incorporated into the chitosan matrix for composite fabrication.

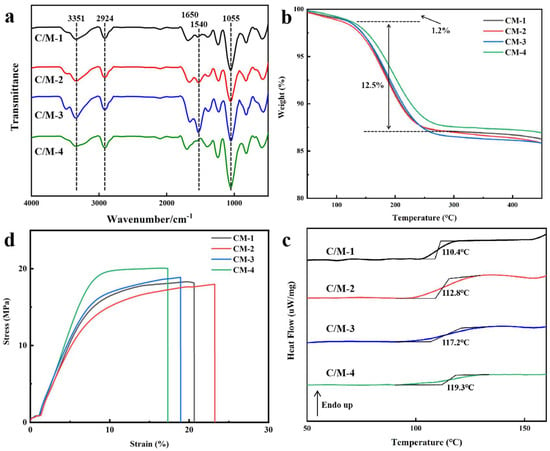

3.2. FTIR, TGA and DSC

FTIR spectra of the composites (Figure 3a) exhibited no dramatic macroscopic differences among the four samples; however, subtle spectral variations were observed with increasing MXene content, indicating interfacial interactions between the fillers and the polymeric matrix. The broad N–H/O–H stretching band in the 3500–3000 cm−1 region became slightly broadened and weakened, which can be ascribed to enhanced hydrogen bonding between the –OH/–F terminal groups of MXene and the hydroxyl and amino groups in the CS/PVA matrix. The characteristic C–H stretching vibrations at 3000–2800 cm−1 remained nearly unchanged, suggesting that the aliphatic backbone structure of the polymer matrix was retained after MXene incorporation. In contrast, the amide I (C=O stretching) and amide II (N–H bending) bands located in the 1650–1500 cm−1 range displayed minor redshifts accompanied by slight intensity decreases, confirming the formation of additional hydrogen-bonding interactions between MXene and CS molecular chains. Moreover, the absorption bands in the fingerprint region (1100–1020 cm−1), associated with C–O–C and C–O stretching of the polysaccharide framework, exhibited slight shifts and peak broadening, further supporting the presence of interfacial coupling.

Figure 3.

(a) FTIR spectra; (b) TGA curves, (c) DSC curves, (d) Stress–strain curves of composites.

TGA curves (Figure 3b) exemplified by C/M-1 showed an initial mass loss (~1.2%) near 140.0 °C due to removal of adsorbed and bound water. A further mass loss up to 240.0 °C (~12.5%) was assigned to the onset of polymer matrix decomposition, including partial glycosidic bond cleavage and dehydration reactions. At higher temperatures (above 450 °C), it is foreseeable that the polymer backbone will undergo significant decomposition and carbonization. The mass is expected to decrease sharply until only the weight of the fillers remains. Overall, the composites exhibited good thermal stability and the observed early-stage decomposition did not compromise shape memory or EMI properties in follow-up tests.

DSC analysis (Figure 3c) indicated glass transition temperatures (Tg) in the range of ~110–120 °C. As shown in Table 1. As the MXene content increases, the Tg of the composite material increased slightly. The following synergistic factors have been identified as the primary contributors to this phenomenon: As a two-dimensional layered filler, functional groups (–OH, –F) on the surface of MXene form strong hydrogen bonds with polymer chains, significantly restricting segment motion. Concurrently, MXene layers function as physical crosslinking points within the matrix, thereby further augmenting this restrictive effect. In contrast, while one-dimensional CNTs also restrict segment motion, their smaller specific surface area and morphological characteristics result in weaker spatial confinement compared to MXene layers. Consequently, as the proportion of MXene—which exhibits stronger confinement effects—increases and the proportion of CNTs—which exhibit weaker effects—decreases, the overall mobility of polymer segments becomes further restricted, collectively leading to an elevated Tg. However, because MXene tended to agglomerate at higher loadings, the Tg increase was modest.

Table 1.

Tg of the sample.

3.3. Mechanical Properties

Engineering stress–strain curves (Figure 3d) showed that the mechanical response varied non-monotonically with filler ratio but followed a clear trend: tensile strength increased from 18.3 MPa for C/M-1 to 20.0 MPa for C/M-4, and Young’s modulus rose to a maximum of 292.2 MPa (C/M-4), indicating enhanced stiffness with higher MXene content. Conversely, elongation at break decreased from a maximum of 23.2% (C/M-2) to 17.3% (C/M-4). For more detailed data, please refer to Table 2. The enhancement in strength and stiffness was credited to the augmented stress-transfer capability of the three-dimensional structure formed by MXene and CNTs, in addition to stronger interfacial interactions between the hybrid filler and polymer chains. The reduction in extensibility was attributed to restricted chain motion and potential filler agglomeration at high MXene loading levels. C/M-2 appeared to represent an optimal balance between strength and toughness, while C/M-4 achieved the highest stiffness and strength but at the expense of ductility. This outcome is attributable to the combined effects of two filler morphologies and their synergistic interactions. As a two-dimensional layered filler, MXene possesses a larger specific surface area and stronger interfacial interactions, enabling more efficient stress transfer and restriction of polymer chain motion, thereby significantly enhancing strength and stiffness. However, this rigid layered structure also becomes more prone to acting as stress concentration points under loading, promoting crack propagation. Concurrently, the reduced content of one-dimensional CNTs diminishes their characteristic fiber crosslinking and pull-out effects—mechanisms crucial for achieving high toughness and ductility. Consequently, the compromise in filler proportions gives rise to a performance “trade-off”: the toughness contributed by CNTs is sacrificed to achieve the stiffness enhancement dominated by MXene.

Table 2.

Tensile properties of the sample.

It is worth noting that, although the increase in Young’s modulus with increasing MXene fraction suggests more efficient stress transfer from the matrix to the 2D component of the hybrid network, a rigorous quantification of the stress-transfer efficiency is not straightforward in the present system. This is because the total filler loading was kept constant (12 wt.%), while the MXene content (1–4 wt.%) increased at the expense of CNTs. Consequently, the measured modulus reflects a combined effect of the higher stiffness of MXene, the gradual loss of CNT bridging, and variations in filler dispersion. When the experimental data are simply normalized to the MXene content, the modulus shows an effective increment of ~15–16 MPa per additional 1 wt.% MXene, which is consistent with a MXene-dominated stiffening mechanism. However, this value should be interpreted as an effective parameter for this hybrid system rather than an intrinsic modulus-per-wt.% of MXene.

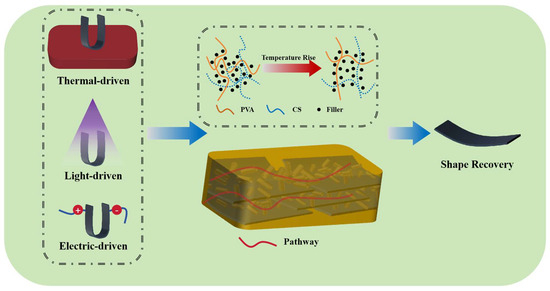

3.4. Multi-Stimuli-Responsive Shape Memory Behaviors

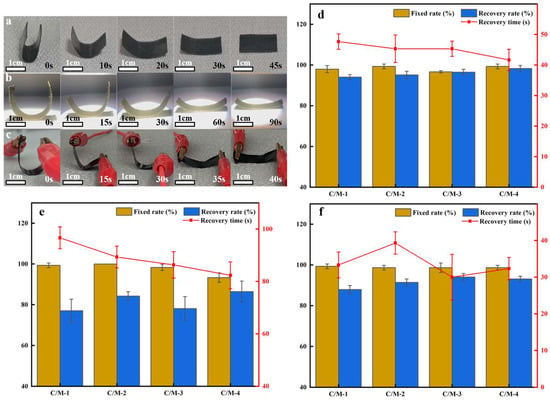

We evaluated shape memory performance under thermal, light and electrical stimuli, respectively. In all three modes the composites exhibited significant shape memory capabilities. As shown in Figure 4 and Figure 5. Under thermal stimulation (direct heating above Tg), recovery rates (Rr) were generally the highest of 98.3% for C/M-4 and the shortest recovery time of 41.7 s, indicating that higher MXene content improved thermal response—likely due to enhanced thermal conductivity and optimized internal network structure that facilitated faster stress release. Under light stimulation (xenon lamp), Rr decreased with a larger standard deviation compared to thermal activation. However, the recovery time shortened as the MXene content increased, a trend accounted for by its inherent superior photothermal conversion capability. C/M-4 exhibited the fastest light response (82.3 s) and a recovery rate of 86.5%, whereas some intermediate compositions (e.g., C/M-2, C/M-3) showed comparably high recoveries; the variability was attributed to non-uniform light-induced heating and local temperature gradients. Electrical stimulation produced rapid recovery behaviors across all samples (30–40 s) due to the efficient Joule heating within the conductive filler network. Rr ranged from 88.0% to 94.1%, with C/M-3 showing the highest electrical recovery of 94.1% (recovery time ~30 s). The increasing MXene content improved the conductivity and uniformity of the conductive network, enhancing electro-thermal conversion efficiency; however, excessive filler loading (C/M-4) slightly reduced electrical recovery, likely due to filler aggregation compromising network homogeneity. Representative summary data were given in Table 3, Table 4 and Table 5. Key observations included Rf >90% across all modes, thermal driving with the highest Rr (up to 98.3%), electrical driving with the fastest response time (as low as 30 s), and light driving showing fast response for high MXene content but with a significant standard deviation in recovery completeness.

Figure 4.

Multi-stimuli-responsive shape memory behaviors of composites.

Figure 5.

The shape memory performance of composites. (a–c) Shape memory behaviors and (d–f) Shape memory performances, including fixed rate, recovery rate and recovery time under various stimuli (thermal, light, electrical).

Table 3.

Thermal driven shape memory performance.

Table 4.

Light driven shape memory performance.

Table 5.

Electric driven shape memory performance.

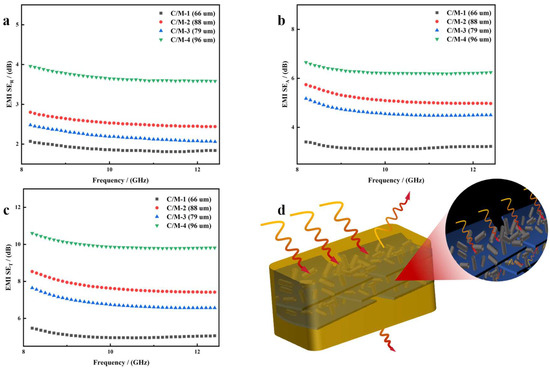

3.5. EMI Shielding Performance

The EMI shielding results (Figure 6) show a significant improvement in the total shielding effectiveness (SET, Figure 6c) as the MXene content increased, rising from 5.5 dB in C/M-1 to 10.6 dB in C/M-4 in the X-band. This increase is attributed to the metallic conductivity of MXene, combined with the synergistic effect with CNTs that forms a more efficient conductive network. The MXene sheets, interspersed with 1D CNTs, help create continuous, robust three-dimensional (3D) pathways, which enhance both charge transport and interfacial polarization. With higher MXene content, this hybrid network also boosts the number of internal reflections and further strengthens the absorption of electromagnetic waves, ensuring that the absorption mechanism dominates. For example, in C/M-4, the absorption (SEA) reached 6.7 dB, about 1.7 times higher than the reflection (SER) at 4.0 dB (Figure 6a,b), indicating that absorption plays a major role in shielding. This mechanism effectively reduces secondary reflections and improves the material’s real-world EMI shielding efficiency. The overall shielding mechanism is depicted in Figure 6d.

Figure 6.

EMI shielding performance of composites. (a–c) SER, SEA, SET of composites and (d) EMI shielding mechanism.

In conclusion, the EMI shielding in these composites involves a combination of reflection, absorption, and multiple internal reflections, with absorption being the dominant factor. The interconnected conductive network of MXene and CNTs facilitates both ohmic losses and eddy currents, while the interfaces between MXene, CNTs, and the polymer matrix promote interfacial polarization and dipole relaxation, which converts electromagnetic energy into heat. Additionally, the layered MXene structure enhances attenuation by scattering the waves and extending their paths. The moderate conductivity of the hybrid network ensures impedance matching, allowing waves to penetrate rather than reflecting off the surface entirely. Thus, the superior shielding performance of these composites is driven primarily by conductive losses, polarization effects, and internal scattering, confirming that the shielding mechanism is absorption-dominated.

4. Conclusions

In summary, the present study successfully prepared and systematically characterized CS/PVA composite films doped with CNTs/MXene hybrid fillers. Structural and morphological analysis confirmed the successful preparation of MXene and its layered characteristics; FTIR results supported the formation of additional hydrogen bonds, leading to a slight increase in the glass transition temperature. Increasing MXene content, the material demonstrated enhanced mechanical strength and stiffness (tensile strength reaching 20.0 MPa, Young’s modulus reaching 292.2 MPa), though the elongation at break correspondingly decreased, indicating a trade-off between the reinforcing effect of the filler and the material’s embrittlement. Thermal analysis revealed initial mass loss between 140 and 240 °C, with significant thermal loss anticipated above 450 °C. This finding suggests that the material exhibits adequate thermal stability and is suitable for the intended shape memory requirements.

The composites exhibited excellent multi-stimuli-responsive shape memory behaviors. Shape fixation rates were consistently >90%; thermal driving produced the highest recovery (up to 98.3%), electrical driving delivered the fastest response (down to 30 s), and light driving achieved rapid responses at high MXene loadings but with a significant standard deviation in recovery completeness. EMI shielding effectiveness increased with MXene loading (from 5.5 to 10.6 dB), with absorption being the major shielding mechanism. Among the formulations, C/M-3 and C/M-4 delivered the best overall performance under different stimuli, whereas C/M-2 provided a favorable balance between mechanical toughness and extensibility. This work demonstrated that tuning MXene content effectively optimized mechanical, electromagnetic and multi-stimuli-responsive shape memory properties, suggesting potential applications in flexible electronics, wearable devices, electromagnetic shielding and biodegradable smart devices. The study provided experimental guidance for the design of green intelligent materials.

Author Contributions

Conceptualization, S.Y.; methodology, Z.L.; validation, S.W. and J.L.; formal analysis, Z.S., Z.H. and N.G.; investigation, S.W. and J.L.; writing—original draft preparation, Z.L.; writing—review and editing, S.Y.; visualization, Z.S.; supervision, S.Y.; project administration, Y.L.; All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by China Postdoctoral Science Foundation (Grant No. 2024M752991), Fundamental Research Program of Shanxi Province (Grant No. 202303021212177, 202303021212174 and 202303021222103) and Research Project Supported by Shanxi Scholarship Council of China (2023-137).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be made available on request.

Conflicts of Interest

Author Ning Guo was employed by the company Shanxi Rail Transit Company. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Yang, S.; Song, Z.; He, Z.; Ye, X.; Li, J.; Wang, W.; Zhang, D.; Li, Y. A review of chitosan-based shape memory materials: Stimuli-responsiveness, multifunctionalities and applications. Carbohydr. Polym. 2024, 323, 121411. [Google Scholar] [CrossRef]

- Dayyoub, T.; Maksimkin, A.V.; Filippova, O.V.; Tcherdyntsev, V.V.; Telyshev, D.V. Shape Memory Polymers as Smart Materials: A Review. Polymers 2022, 26, 3511. [Google Scholar] [CrossRef]

- Delaey, J.; Dubruel, P.; Van Vlierberghe, S. Shape Memory Polymers for Biomedical Applications. Adv. Funct. Mater. 2020, 30, 1909047. [Google Scholar] [CrossRef]

- Xia, Y.; He, Y.; Zhang, F.; Liu, Y.; Leng, J. A Review of Shape Memory Polymers and Composites: Mechanisms, Materials, and Applications. Adv. Mater. 2021, 33, 2000713. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Lou, J.; Yuan, J.; Deng, J. A review of shape memory polymers based on the intrinsic structures of their responsive switches. RSC Adv. 2021, 11, 28838–28850. [Google Scholar] [CrossRef]

- Zhao, W.; Li, N.; Liu, L.; Leng, J.; Liu, Y. Mechanical behaviors and applications of shape memory polymer and its composites. Appl. Phys. Rev. 2023, 10, 011306. [Google Scholar] [CrossRef]

- Liu, W.; Kong, D.; Zhao, W.; Leng, J. Multi-stimulus responsive shape memory polyurea incorporating stress-mismatching structure for soft actuators and reversible deployable structures. Compos. Struct. 2024, 334, 117966. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhao, Z.; Wu, D.; Chen, K.; Weng, S. Mechanics-guided design of inflatable heterogeneous shape memory polymer vascular stents. Int. J. Mech. Sci. 2023, 254, 108405. [Google Scholar] [CrossRef]

- Hicks, A.J.; Roberts, C.; Robinson, A.; Wilson, K.; Kotamreddy, V.; LaRue, T.; Veyssi, A.; Beltran, F.; Hakim, J.; Rausch, M.K.; et al. Polycaprolactone-based shape memory foams as self-fitting vaginal stents. Acta Biomater. 2024, 187, 172–182. [Google Scholar] [CrossRef]

- Linghu, C.; Zhang, S.; Wang, C.; Yu, K.; Li, C.; Zeng, Y.; Zhu, H.; Jin, X.; You, Z.; Song, J. Universal SMP gripper with massive and selective capabilities for multiscaled, arbitrarily shaped objects. Sci. Adv. 2020, 6, eaay5120. [Google Scholar] [CrossRef]

- Wu, S.; Liu, Y.; Zhang, Y.; Zeng, L.; Fang, J.; Chen, C.; Zhang, C.; Wu, D.; Lao, Z.; Xia, H. High-Load Shape Memory Microgripper with Embedded Resistive Heating and Magnetic Actuation. Adv. Funct. Mater. 2025, 35, 2421798. [Google Scholar] [CrossRef]

- Iqbal, Y.; Ahmed, I.; Irfan, M.F.; Chatha, S.A.S.; Zubair, M.; Ullah, A. Recent advances in chitosan-based materials; The synthesis, modifications and biomedical applications. Carbohydr. Polym. 2023, 321, 121318. [Google Scholar] [CrossRef]

- Negm, N.A.; Hefni, H.H.; Abd-Elaal, A.A.; Badr, E.A.; Kana, M.T.A. Advancement on modification of chitosan biopolymer and its potential applications. Int. J. Biol. Macromol. 2020, 152, 681–702. [Google Scholar] [CrossRef]

- Peterson, G.I.; Dobrynin, A.V.; Becker, M.L. Biodegradable shape memory polymers in medicine. Adv. Healthc. Mater. 2017, 6, 1700694. [Google Scholar] [CrossRef]

- Jin, S.; Guo, Y.; Wang, F.; Zhou, A. The synthesis of MXenes. MRS Bull. 2023, 48, 245–252. [Google Scholar] [CrossRef]

- Gao, S.; Ding, J.; Wang, W.; Lu, J. MXene based flexible composite phase change material with shape memory, self-healing and flame retardant for thermal management. Compos. Sci. Technol. 2023, 234, 109945. [Google Scholar] [CrossRef]

- Zhou, C.; Zhao, X.; Xiong, Y.; Tang, Y.; Ma, X.; Tao, Q.; Sun, C.; Xu, W. A review of etching methods of MXene and applications of MXene conductive hydrogels. Eur. Polym. J. 2022, 167, 111063. [Google Scholar] [CrossRef]

- Iqbal, M.Z.; Khan, M.W.; Siddique, S.; Aftab, S. MXenes: An exotic material for hybrid supercapacitors and rechargeable batteries. J. Energy Storage 2022, 56, 105914. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Y.; Zhao, X. MXene Composite Electromagnetic Shielding Materials: The Latest Research Status. ACS Appl. Mater. Interfaces 2024, 16, 41596–41615. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Z.; Li, J.; Fang, L.; Zheng, C.; Chen, H.; Huang, J.; Qian, K.; Li, H.; Li, W. Flexible and durable shape memory EVA/MXene/EVA fiber membrane for programmable EMI shielding. Chem. Eng. J. 2024, 501, 157599. [Google Scholar] [CrossRef]

- Li, Z.; Wu, Y. 2D Early Transition Metal Carbides (MXenes) for Catalysis. Small 2019, 15, e1804736. [Google Scholar] [CrossRef]

- Xu, T.; Wang, Y.; Liu, K.; Zhao, Q.; Liang, Q.; Zhang, M.; Si, C. Ultralight MXene/carbon nanotube composite aerogel for high-performance flexible supercapacitor. Adv. Compos. Hybrid Mater. 2023, 6, 108. [Google Scholar] [CrossRef]

- Cui, Y.; Yang, K.; Zhang, F.; Lyu, Y.; Zhang, Q.; Zhang, B. Ultra-light MXene/CNTs/PI aerogel with neat arrangement for electromagnetic wave absorption and photothermal conversion. Compos. Part A Appl. Sci. Manuf. 2022, 158, 106986. [Google Scholar] [CrossRef]

- Xu, W.; Xu, Z.; Liang, Y.; Liu, L.; Weng, W. Enhanced tensile and electrochemical performance of MXene/CNT hierarchical film. Nanotechnology 2021, 32, 355706. [Google Scholar] [CrossRef] [PubMed]

- Sanaka, R.; Sahu, S.K.; Sreekanth, P.S.R.; Giri, J.; Mohammad, F.; Al-Lohedan, H.A.; Saharudin, M.S.; Ma, Q. Heat-responsive PLA/PU/MXene shape memory polymer blend nanocomposite: Mechanical, thermal, and shape memory properties. Polymers 2025, 17, 338. [Google Scholar] [CrossRef]

- Yang, W.; Zhou, W.; Ding, N.; Shen, S.; Gao, D.; Puglia, D.; Duan, Y.; Xu, P.; Liu, T.; Wang, Z.; et al. Biobased photothermal responsive shape memory polythioether/MXene nanocomposites with self-extinguishing performance. Chem. Eng. J. 2024, 497, 154591. [Google Scholar] [CrossRef]

- Zhu, M.; Yan, X.; Xu, H.; Xu, Y.; Kong, L. Highly conductive and flexible bilayered MXene/cellulose paper sheet for efficient electromagnetic interference shielding applications. Ceram. Int. 2021, 47, 17234–17244. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, Y.; Dong, H.; Xu, R.; Jiang, S. Flame-retardant shape memory polyurethane/MXene paper and the application for early fire alarm sensor. Compos. Part B Eng. 2021, 223, 109149. [Google Scholar] [CrossRef]

- Guo, X.-R.; Sheng, P.-H.; Hu, J.-W.; Liu, J.; Wang, S.-L.; Ma, Q.; Yu, Z.-Z.; Ding, Y. Multistimuli-Responsive Shape-Memory Composites with a Water-Assisted Self-Healing Function Based on Sodium Carboxymethyl Cellulose/Poly(vinyl alcohol)/MXene. ACS Appl. Mater. Interfaces 2024, 16, 17981–17991. [Google Scholar] [CrossRef]

- Mohajer, F.; Ziarani, G.M.; Badiei, A.; Iravani, S.; Varma, R.S. MXene-Carbon Nanotube Composites: Properties and Applications. Nanomaterials 2023, 13, 345. [Google Scholar] [CrossRef]

- Thalji, M.R.; Mahmoudi, F.; Bachas, L.G.; Park, C. MXene-Based Electrocatalysts for Water Splitting: Material Design, Surface Modulation, and Catalytic Performance. Int. J. Mol. Sci. 2025, 26, 8019. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).