Abstract

This study investigates the influence of multilayer architecture on the mechanical, corrosion, and tribological properties of Ti/TiN coatings deposited on biomedical Ti-6Al-4V alloy. Nine multilayer configurations were prepared by DC/RF magnetron sputtering using metallic Ti and ceramic TiN targets, with a fixed TiN/Ti ratio of 3:1 and varying total numbers of layers (3, 5, and 7) and deposition times (30, 60, and 120 min). A strict application of the 10% indentation depth rule was implemented to eliminate substrate effects, which revealed significantly higher intrinsic hardness values (540–740 HV) and indentation moduli (124–143 GPa) compared to the substrate (353 HV; 114 GPa). In contrast, conventional higher-load testing underestimated coating performance due to substrate dominance. Among the investigated architectures, the Ti/TiN-7 configuration exhibited the best balance of properties, combining high hardness (~690 HV), modulus (~137 GPa), improved corrosion resistance (Ecorr up to −0.13 V, Icorr reduced by an order of magnitude), and stable abrasive wear behavior. These findings demonstrate that both bilayer number and deposition time critically determine the mechanical and functional response of Ti/TiN multilayers. The results provide practical guidelines for the reliable characterization and design of multilayer coatings for biomedical and aerospace applications.

1. Introduction

The development of wear-resistant and durable coatings for titanium alloys remains one of the key challenges in modern surface engineering. Among these, the Ti-6Al-4V alloy is particularly prominent due to its high strength-to-weight ratio, corrosion resistance, and biocompatibility [1,2,3]. However, its limited hardness and low wear resistance under friction and impact loading conditions significantly reduce the service life of components, especially in medical implants and frictional parts [4,5].

One promising solution to this problem is the deposition of functional coatings by physical vapor deposition (PVD). Of particular interest are multilayer coatings of the Ti/TiN system, in which the alternation of metallic titanium and titanium nitride layers provides a comprehensive improvement of surface properties [6,7,8]. Such coatings provide high hardness, wear resistance, and thermal stability, while also maintaining ductility and redistributing internal stresses—critical under cyclic and impact loading [9].

Numerous studies have demonstrated that not only the chemical composition but also the architecture of multilayer coatings—including the thickness of individual layers, the bilayer period, and the total number of bilayers—plays a decisive role in determining their mechanical and tribological properties. For example, reducing the individual layer thickness enhances dislocation interactions at the interfaces (the Koehler effect), thereby increasing hardness [10,11,12]. Increasing the number of bilayers can improve crack resistance by introducing multiple barriers to crack propagation [13]. Recent investigations further confirmed this trend: Tu et al. (2023) showed that gradient multilayer designs significantly improve tribological stability [14], while Mathews et al. (2025) reported that elastic–plastic mismatch at interfaces controls fracture toughness in Ti/TiN thin films [13]. Similarly, Zhou et al. (2025) demonstrated that varying bilayer thickness strongly affects the corrosion–wear behavior and failure mechanisms of TiN/Ti multilayers [12].

At the same time, an excessive reduction in layer thickness may promote interdiffusion across interfaces and a loss of boundary definition, leading to deterioration in strength and adhesion [15]. This highlights the need to optimize the bilayer period and total number of layers to achieve a proper balance between hardness, crack resistance, wear resistance, and coating integrity.

However, few studies link the architecture of Ti/TiN multilayers directly to their performance on biomedical titanium alloys. Most previous studies have focused on coatings for cutting tools or single bilayer designs, while comprehensive investigations on Ti-6Al-4V substrates—widely used in aerospace and biomedical applications—are limited [9,16,17].

Previous studies have reported that the hardness of Ti/TiN coatings generally ranges from 18–30 GPa, depending on the bilayer period and deposition parameters, while the friction coefficient varies within 0.3–0.6 under dry sliding conditions [4,9,11,15]. Wear rates typically fall within the range of 10−6–10−5 mm3/N·m, depending on the applied load, counter body, and test environment. For instance, Vereschaka et al. [11] and Ali et al. [18] demonstrated that increasing the number of interfaces enhances wear resistance by promoting crack deflection, whereas excessive layer thickness or high residual stresses can deteriorate tribological stability. The tribological behavior of TiN-based coatings has also been shown to depend strongly on the applied load and testing configuration [9].

The novelty of the present work lies in providing the first systematic, architecture-resolved comparison of nine different Ti/TiN multilayer configurations deposited on biomedical Ti-6Al-4V alloy. Unlike previous studies that mainly addressed cutting tools, single bilayers, or gradient designs, our study uniquely combines controlled variation in bilayer number (3, 5, and 7) and deposition time per layer (30, 60, 120 min) at a fixed TiN/Ti ratio. This approach establishes direct correlations between multilayer architecture and hardness, elastic modulus, corrosion resistance, and tribological failure mechanisms. To the best of our knowledge, no prior work has reported such a comprehensive mapping of architecture–property relationships for Ti/TiN multilayers on Ti-6Al-4V. The results provide not only a scientific basis for understanding structure–property interactions but also practical design guidelines for optimizing protective coatings in biomedical and aerospace applications.

A large body of prior work clarifies how architectural parameters control properties in Ti/TiN multilayers. On the bilayer period (individual Ti and TiN layer thicknesses), Cheng et al. [4] showed that increasing Ti sublayer thickness decreases effective hardness and elastic modulus and increases wear rate, consistent with a weakening of interface-mediated (Koehler) strengthening; conversely, reducing the modulation thickness enhances barriers to dislocation and crack motion until interdiffusion and high residual stresses offset the benefit. Regarding the number of bilayers, both experiments and models report that adding interfaces improves hardness and adhesion by distributing stresses and deflecting cracks; for example, Ali et al. [18] found a ~22% adhesion increase for multilayers versus bilayers under reduced interfacial stress, and Santaella-González et al. [19] observed hardness and adhesion gains as bilayer count increased. Nonetheless, when the stack becomes overly thick or residual stresses accumulate, failure can transition to brittle delamination, aligning with our observations for specific architectures. In our study, optimized designs (e.g., Ti/TiN-1 and Ti/TiN-3) exhibited stable abrasive wear, whereas other configurations (e.g., Ti/TiN-6/-8/-9) failed by brittle delamination, underscoring that both bilayer period and bilayer number jointly tune the balance between strengthening and stress-driven failure.

In summary, the novelty of this work is twofold. First, it provides the first systematic, quantitative evaluation of nine Ti/TiN multilayer architectures on biomedical Ti-6Al-4V, which has not been reported previously. Second, it establishes clear correlations between layer number, deposition time, and performance indicators (hardness, stiffness, corrosion resistance, and wear mechanisms). The optimized configuration (Ti/TiN-7) demonstrates a unique combination of stable abrasive wear, improved corrosion resistance, and enhanced stiffness, offering practical guidance for designing multilayer coatings for biomedical implants and aerospace components. These findings significantly expand the current understanding of Ti/TiN multilayers and highlight architecture tailoring as an effective strategy to balance durability and failure resistance.

2. Materials and Methods

The substrate material used in this study was Ti-6Al-4V (Grade 5) titanium alloy. Its chemical composition by weight percentage (wt.%) consists of 5.5%–6.75% aluminum (Al), 3.5%–4.5% vanadium (V), a maximum of 0.30% iron (Fe), a maximum of 0.20% oxygen (O), a maximum of 0.08% carbon (C), a maximum of 0.05% nitrogen (N), and a maximum of 0.015% hydrogen (H), with the balance being titanium (Ti).

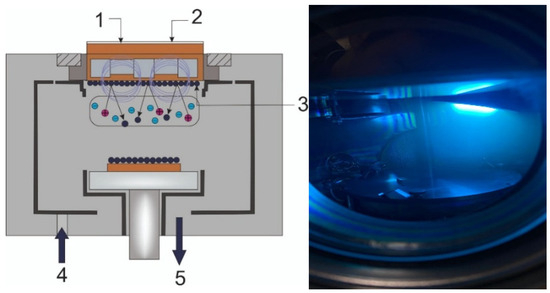

Multilayer Ti/TiN coatings were deposited onto Ti-6Al-4V substrates by magnetron sputtering in a high-vacuum chamber (3) in Figure 1. Two sputtering targets were used: a metallic Ti target and a ceramic TiN target. The Ti sublayers were deposited in DC mode, which provides stable discharge for conductive targets, whereas the TiN sublayers were deposited in RF mode to ensure stable plasma for the ceramic TiN target.

Figure 1.

Magnetron sputtering process. (1—vacuum chamber, 2—high-voltage power supply, 3—atoms of the material ejected from the target, 4—working gas, 5—vacuum pumping system).

Two sputtering targets were used: a metallic Ti target and a ceramic TiN target. The coatings were deposited in a Magnetron Plasma Sputtering System CY-MSC300M-DCRF (Shenyang Createy Vacuum Technology Co., Ltd., Shenyang, China). High-purity sputtering discs were employed: metallic titanium (Ti, 99.95%, Kurt J. Lesker Company, Jefferson Hills, PA, USA) and titanium nitride (TiN, 99.9%, Zhongnuo Advanced Material Technology, Beijing, China) with a diameter of 75 mm. The Ti target operated in DC mode at 200 W, while the TiN target was powered in RF mode (13.56 MHz) at 200 W. Deposition was carried out in pure argon at a pressure of 8 Pa and a gas flow rate of 80 sccm. The substrate was maintained at 300 °C with no applied bias, and the target-to-substrate distance was fixed at 15 cm.

The coating process involved the generation of plasma in an argon atmosphere, where accelerated Ar+ ions bombarded the target, sputtering atoms that then condensed on the substrate surface (1) in Figure 1. This approach enabled the formation of alternating Ti and TiN layers with sharp interfaces. A total of nine multilayer configurations were produced, varying in the total number of layers (3, 5, and 7) and deposition times (30, 60, and 120 min). An odd number of layers was selected so that each multilayer stack began and ended with a TiN layer, providing protective surface properties.

All coatings had a symmetrical architecture, beginning and ending with a TiN layer (e.g., TiN/Ti/TiN for a three-layer coating). It is important to note that, despite different absolute sputtering times in the regimes, the TiN/Ti deposition time ratio was kept constant at 3:1 for all nine configurations. The detailed parameters for each configuration are presented in Table 1. The selection of these architectures is justified by the works [4], which show that varying these parameters allows for the targeted manipulation of the coatings’ mechanical and tribological characteristics.

Table 1.

Parameters and structure of multilayer coatings.

For a comprehensive evaluation of the coatings, their mechanical, tribological, corrosion, and structural characteristics were studied. Mechanical properties, including microhardness (HV) and elastic modulus, were determined by instrumented indentation using a FISCHERSCOPE HM2000 system (Helmut Fischer GmbH, Sindelfingen, Germany) in accordance with DIN EN ISO 14577-1 (Metallic materials — Instrumented indentation test for hardness and materials parameters — Part 1: Test method, ISO, Geneva, 2015). A Vickers diamond indenter with an apex angle of 136° was used. The applied load was 5000 mN with a loading time of 10 s and a holding time of 5 s at maximum load, followed by unloading at the same rate. The indentation depth was controlled to remain below 10% of the coating thickness in order to minimize substrate influence. Each sample was measured at least five times, and average values were reported. The tribological behavior of the coatings was evaluated using a pin-on-disk configuration on a TRB3 tribometer (Anton Paar GmbH, Graz, Austria) in accordance with ASTM G99 (Standard Test Method for Pin-on-Disk Wear Testing, ASTM International, West Conshohocken, PA, USA).

A 6 mm diameter alumina (Al2O3) ball was used as the counter body. The tests were carried out under dry sliding conditions at a normal load of 5 N, a linear speed of 0.1 m/s, and a sliding distance of 300 m.

Each test was performed twice for the same coating series to ensure reproducibility. The wear track profiles were recorded after testing using a TalySurf contact profilometer (Taylor Hobson, Leicester, England) along the diameter of the wear scar, and the cross-sectional area was determined from the average of three measurements. The specific wear rate (W) was calculated according to the following equation:

where V is the wear volume (mm3), F is the applied normal load (N), and S is the sliding distance (m).

W = V/(F × S)

The phase composition of the coatings was analyzed using an X’Pert Pro X-ray diffractometer (Panalytical, Amsterdam, The Netherlands) with Cu-Kα radiation (40 kV, 30 mA). The scanning was performed in the 2θ range from 35° to 85° with a step size of 0.02°. The microstructure was investigated on the cross-sections of the samples using a TESCAN Vega scanning electron microscope (Tescan, Brno, Czech Republic). The electrochemical corrosion properties of the coated samples were studied by potentiodynamic polarization. All experiments were conducted in a corrosive medium consisting of an aqueous 0.5 M NaCl solution. A CS300M Potentiostat/Galvanostat (Wuhan Corrtest Instruments Corp., Ltd., Wuhan, China) was used with a three-electrode configuration: a working electrode, a counter electrode (graphite), and a reference electrode (Ag/AgCl). To achieve a stable and steady-state corrosion potential, the open-circuit potential was measured for 30 min before each test. This approach ensured the necessary conditions for an accurate and reproducible potentiodynamic analysis. All prepared configurations (Ti/TiN-1 to Ti/TiN-9) and the uncoated Ti-6Al-4V substrate were subjected to both tribological and electrochemical corrosion tests under identical conditions.

3. Research Results

3.1. Results of SEM (Scanning Electron Microscopy)

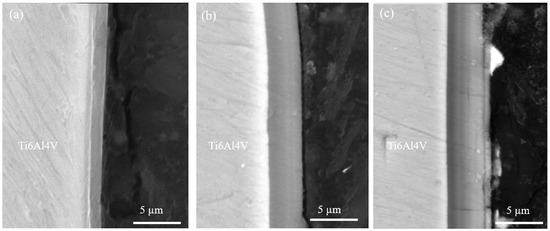

The analysis revealed (Figure 2) that all coatings are dense, free of visible pores or cracks, and exhibit strong adhesion to the Ti-6Al-4V substrate, as evidenced by a smooth and distinct interface. A primary feature of the structure is the presence of elongated columnar crystallites oriented perpendicular to the substrate surface. Although the columnar morphology is not distinctly visible at the current magnification, the contrast and elongated grain pattern in the cross-sectional view indicate a zone-T type columnar structure typical of Ti/TiN coatings deposited by magnetron sputtering [9,11,12]. Such a columnar morphology is characteristic of PVD coatings, which aligns with findings from other studies on similar systems [9,11,12]. Within these columns, a multilayered architecture comprising alternating Ti and TiN layers is clearly discernible. Consequently, the coatings possess a complex, hierarchical structure that is simultaneously columnar and multilayered. This combination is known to be crucial for enhancing mechanical properties, particularly hardness and fracture toughness [12]. The observed microstructure, consisting of columnar grains and internal nanolayers, directly accounts for the mechanical and tribological properties reported in this work. The integrity of the columns imparts overall strength to the coating, while the numerous internal nanolayer boundaries act as barriers, thereby increasing the resistance to cracking and wear. It should be noted that the total coating thickness does not increase linearly with deposition time or number of layers.

Figure 2.

Cross-sectional SEM of Ti/TiN multilayers on Ti-6Al-4V with different numbers of Ti/TiN bilayers (N): (a) N = 1, (b) N = 5, (c) N = 7.

This effect is attributed to the multilayer growth mechanism and stabilization processes occurring during target switching between Ti and TiN.

Each transition requires plasma re-ignition and target conditioning, which slightly reduces the effective deposition rate.

In addition, interface overlap, atomic intermixing, and partial re-sputtering at Ti/TiN boundaries lead to material densification and a decrease in the apparent total thickness.

As a result, the coatings formed at longer deposition times or with more bilayers are thinner than the ideal proportional values, yet they exhibit improved density and structural integrity.

3.2. X-Ray Diffraction (XRD)

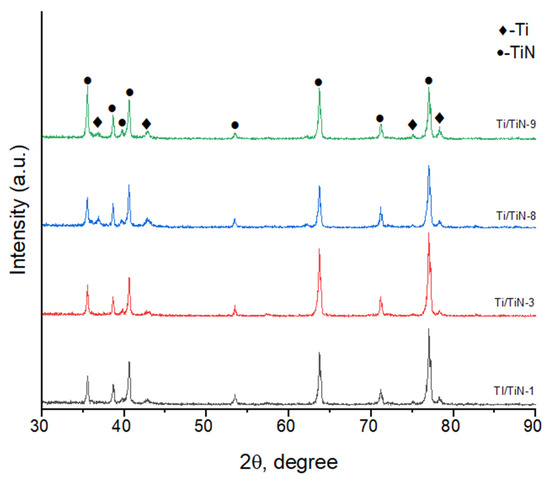

The phase composition and crystal structure of the multilayer coatings were analyzed using X-ray diffraction (XRD). The corresponding diffractograms are presented in Figure 3, which displays the characteristic peaks for titanium (Ti) and titanium nitride (TiN) phases. All coatings exhibit reflections from the face-centered cubic (FCC) TiN phase at approximately 2θ = 36.7° (111), 42.6° (200), 61.8° (220), and 74.0° (311), along with peaks from the hexagonal close-packed (HCP) Ti phase located at 2θ = 35.0° (100), 38.4° (002), 40.2° (101), 53.0° (102), and 63.0° (103). The presence of both metallic Ti and TiN peaks confirms the successful alternation of metallic and nitride sublayers within the multilayer architecture. It should be noted that the intensities of Ti peaks exceed those of TiN peaks, which is consistent with the higher X-ray scattering factor of metallic titanium and the presence of relatively thicker Ti sublayers within the multilayer stacks. A comparison between the coatings shows that as the total deposition time and number of layers increase (from Ti/TiN-1 to Ti/TiN-9), the relative intensity of the TiN peaks increases slightly, while the Ti peaks become narrower and better defined.

Figure 3.

X-ray diffraction (XRD).

This trend indicates improved crystallinity and a gradual enhancement of texture formation with increasing total film thickness.

The TiN (111) orientation remains predominant in all coatings, although its intensity relative to Ti peaks varies across the architectures. No additional impurity phases (such as oxides or sub-nitrides) were detected. These observations demonstrate that the multilayer structure effectively stabilizes both Ti and TiN crystalline phases, while the variation in deposition time and bilayer number affects the preferred orientation and relative volume fractions of the constituent layers. Similar textural behavior of TiN coatings has been reported in previous studies, where the (111) orientation was found to promote denser morphology and improved hardness and wear resistance [20,21,22].

3.3. Electrochemical Corrosion Performance

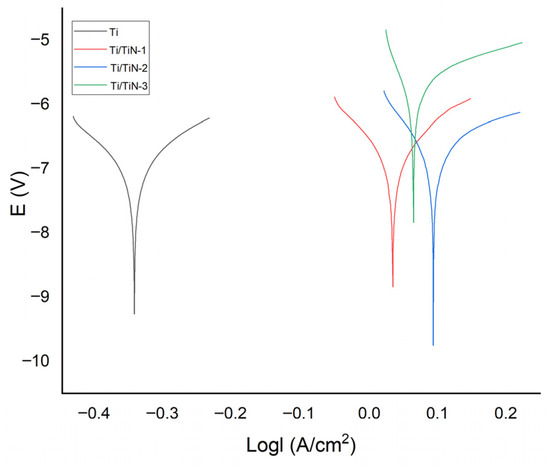

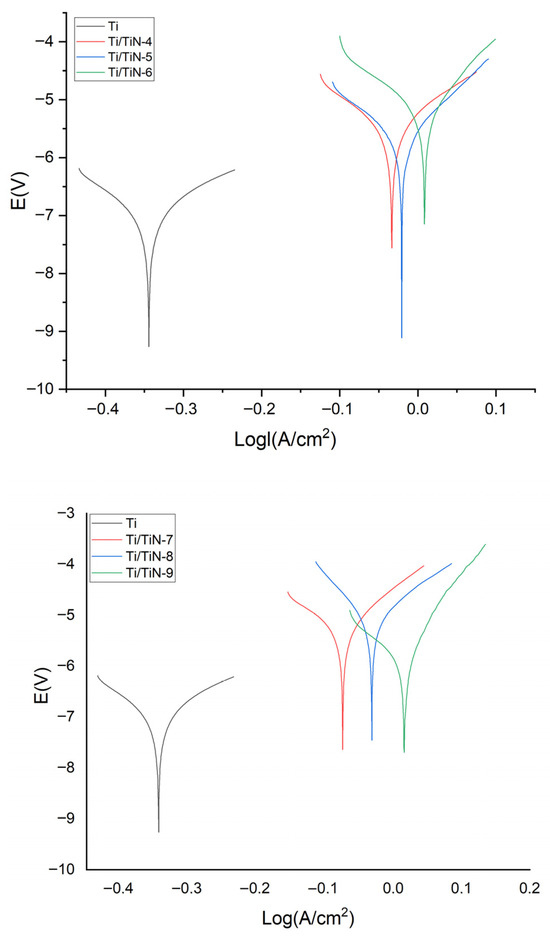

Analysis of the potentiodynamic polarization curves, presented in Figure 4, demonstrates a significant improvement in the corrosion resistance of the Ti-6Al-4V titanium alloy upon the application of multilayer Ti/TiN coatings.

Figure 4.

Results of corrosion tests.

The uncoated Ti-6Al-4V substrate exhibits a relatively low corrosion potential (Ecorr). In contrast, all nine investigated Ti/TiN coating configurations show a shift in the corrosion potential to a more noble (positive) region compared to the substrate. This clearly indicates that the coatings act as an effective barrier, retarding electrochemical reactions and protecting the base material from corrosion. A more positive Ecorr value corresponds to a lower thermodynamic propensity for corrosion to occur [23,24].

Alongside the corrosion potential, a key parameter characterizing the rate of the corrosion process is the corrosion current density (icorr). A decrease in this value directly indicates a reduction in the material’s degradation rate [25]. The polarization curves for the coated samples suggest a significant decrease in icorr, indicating the kinetic inhibition of both anodic and cathodic processes.

The degree of protection is directly dependent on the coating’s architecture. A comparative analysis of the curves shows that certain configurations provide better protection than others. For instance, the Ti/TiN-7 and Ti/TiN-9 samples demonstrate some of the highest Ecorr values, which suggests the formation of a denser, more inert, and integral protective layer. This confirms that optimizing the number and thickness of the bilayers plays a crucial role in minimizing defects, such as pores and through-cracks, and enhancing the overall corrosion resistance of the system. The alternation of Ti and TiN layers interrupts the columnar structure characteristic of nitride coatings, thereby blocking direct pathways for the corrosive medium to penetrate to the substrate [26].

Thus, the results of the electrochemical tests convincingly prove that the deposition of multilayer Ti/TiN coatings is an effective method for increasing the corrosion resistance of the Ti-6Al-4V alloy. The best protective performance is achieved with a specific, optimized coating architecture that ensures minimal defects and provides a maximum barrier function [27].

3.4. Tribology Evaluation Results

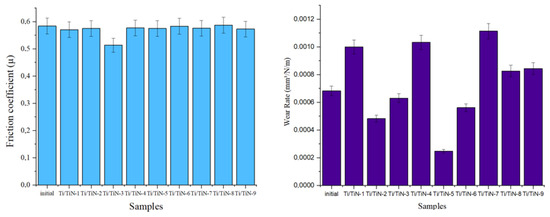

An analysis of the graph showing the coefficient of friction (µ) as a function of sliding distance (Figure 5) allows for the evaluation of the tribological behavior of the multilayer Ti/TiN coatings in comparison to the Ti-6Al-4V alloy substrate.

Figure 5.

Results of tribological tests of multilayer Ti/TiN coatings.

Two characteristic stages are clearly discernible on all curves. The first is the initial running-in period, observed over a distance of approximately 0 to 50 m, where the coefficient of friction increases. This phenomenon is typical for tribological tests and is associated with the intensive interaction of the initial surfaces, the smoothing of micro-asperities, and the removal of any adsorbed layers or oxide films [28]. The second stage is the steady-state friction regime, which is reached after 50 m. In this phase, the coefficient of friction (µ) for all samples stabilizes and fluctuates within a narrow range of approximately 0.55 to 0.65.

In addition to the friction coefficient, the average wear volume was also evaluated for all samples, as shown in Figure 6. The results demonstrate that, although the frictional response of the multilayer Ti/TiN coatings remained comparable to the Ti-6Al-4V substrate, the coatings provided a significant reduction in material loss. The combined presentation of the friction coefficient and wear volume enables a more comprehensive assessment of the tribological performance of the investigated systems.

Figure 6.

Evolution of the friction coefficient (µ), average wear volume, and representative wear track profiles of Ti/TiN multilayer coatings obtained after tribological tests.

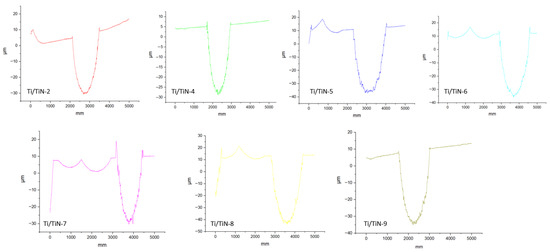

To further illustrate the wear behavior of the multilayer coatings, the cross-sectional wear track profiles for representative Ti/TiN architectures are presented in Figure 6. The profiles were recorded using a TalySurf contact profilometer (Taylor Hobson Ltd., Leicester, UK) after tribological testing under dry sliding conditions. The profiles clearly demonstrate differences in wear depth and morphology depending on the multilayer architecture. The Ti/TiN-5 and Ti/TiN-7 coatings exhibit shallow and smooth wear scars (~25–30 µm depth), indicating stable abrasive wear and high coating integrity. In contrast, coatings with longer deposition times and higher total thickness (e.g., Ti/TiN-8 and Ti/TiN-9) show deeper and more irregular grooves (up to 45–50 µm), suggesting localized delamination and brittle failure.

The quantitative wear-rate analysis (Table 2 and Figure 6) confirms that Ti/TiN-3 exhibited the lowest wear rate among all tested coatings.

Table 2.

Summary of mechanical, corrosion and tribological properties of multilayer Ti/TiN coatings.

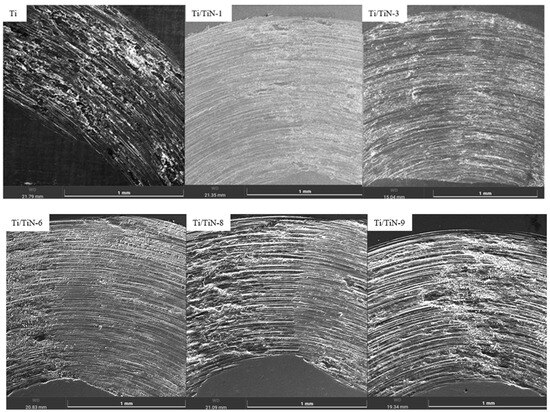

These observations correlate well with the SEM results (Figure 7) and with the calculated specific wear rates, confirming that optimized multilayer configurations (particularly Ti/TiN-5 and Ti/TiN-7) provide the best balance between hardness, adhesion, and wear stability.

Figure 7.

SEM images of the worn surfaces of the samples.

A key result is that all investigated Ti/TiN coating configurations demonstrate nearly identical frictional behavior, both among themselves and in comparison to the substrate. No significant or systematic differences in the coefficient of friction are observed between the samples.

This behavior is not unexpected, as titanium alloys themselves are known for their relatively high coefficient of friction, and the primary function of hard PVD coatings like TiN is to drastically improve wear resistance, rather than to reduce friction [29,30]. The stability of the friction coefficient at a level comparable to the substrate, coupled with the expected increase in wear resistance, is itself a positive outcome, indicating that the coating does not degrade the frictional characteristics of the system [31].

The tribological tests revealed the critical influence of the coating’s architecture on its wear resistance and failure mechanism. Figure 7 presents a comparative analysis of the samples that exhibited the most contrasting results.

The Ti/TiN-1 and Ti/TiN-3 coatings demonstrated significantly enhanced wear resistance. The wear track is narrow and uniform. The dominant mechanism was identified as abrasive wear, characterized by fine, parallel grooves. This indicates that the coating maintained its integrity and wore in a stable manner. This result is consistent with the findings of other authors who describe a similar mechanism for dense Ti/TiN coatings with high adhesion [32,33].

Among the tested samples, the Ti/TiN-5 coating exhibited the lowest wear rate. This can be attributed to its optimized multilayer architecture, which provides a balanced combination of hardness and adhesion strength. The intermediate number of bilayers (five) ensured effective redistribution of contact stresses and delayed crack propagation during sliding, leading to enhanced wear resistance.

In contrast, the Ti/TiN-6, Ti/TiN-8, and Ti/TiN-9 coatings exhibited poor tribological performance. The primary mode of failure was brittle delamination, where large sections of the coating detached from the substrate. This failure mechanism, indicative of poor adhesion, is often associated with high levels of residual stress in multilayer systems, as shown in studies [34,35]. These results clearly illustrate that the coating’s architecture is a key factor determining its failure mechanism and overall wear resistance. Thus, the tribological test results prove that the coating’s architecture directly governs its wear mechanism. The optimized structure of Ti/TiN-1 and Ti/TiN-3 provides high adhesion and mechanical stability, leading to predictable abrasive wear. The inferior tribological performance observed in certain multilayer coatings (e.g., Ti/TiN-8 and Ti/TiN-9) can be attributed to the accumulation of residual stresses and interfacial defects caused by excessive total thickness and a large number of bilayers. These factors lead to partial delamination and accelerated wear under sliding conditions. Moreover, an imbalance between hardness and toughness in these architectures results in brittle failure of the outer TiN layers once the underlying Ti sublayers lose support. Thus, optimizing the bilayer period and total thickness is crucial to maintaining stable wear behavior and minimizing friction [9,11,35].

3.5. Hardness and Elastic Modulus

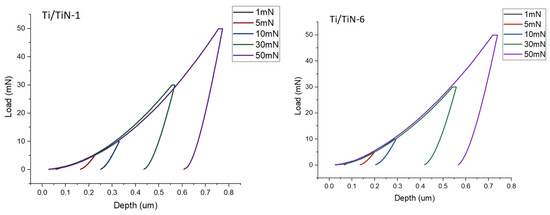

Accurate determination of hardness and elastic modulus in thin films requires strict application of the 10% rule, which states that the indentation depth should not exceed 10% of the coating thickness to avoid substrate effects. To validate this criterion, three representative multilayer samples (Ti/TiN-1, Ti/TiN-7, and Ti/TiN-8) were tested at indentation loads of 5, 10, and 50 mN (Figure 8). The analysis showed that at 50 mN, the penetration depth exceeded 700 nm (>15% of the ~4.5 µm coating thickness), leading to substrate-dominated values. At 10 mN, the depth was close to the threshold (≈340–450 nm), whereas at 5 mN it remained within 200–250 nm, well below the 10% limit.

Figure 8.

Instrumented indentation results for Ti/TiN multilayer coatings: Ti/TiN-1, Ti/TiN-6, Ti/TiN-8 load–displacement curves at different maximum loads and hardness versus load.

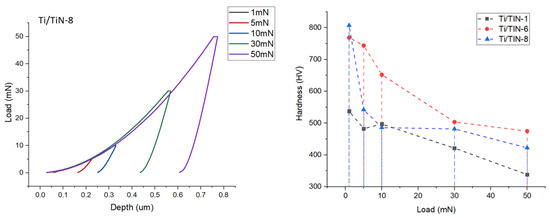

Figure 9 presents the load–displacement curves obtained at 5 mN for all Ti/TiN multilayer configurations. The penetration depths for all samples remained within the 10% rule (~180–230 nm), confirming that this load is suitable for reliable evaluation of intrinsic coating properties. The curves also reveal differences in slope and maximum penetration depth among the multilayers, reflecting architecture-dependent variations in mechanical response. Notably, the Ti/TiN-7 sample exhibited the lowest penetration depth at the same load, consistent with its superior hardness and stiffness obtained in the quantitative analysis.

Figure 9.

Load–displacement curves at 5 mN for all Ti/TiN multilayer coatings.

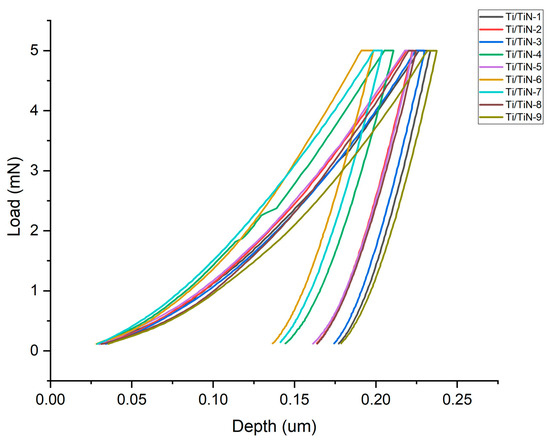

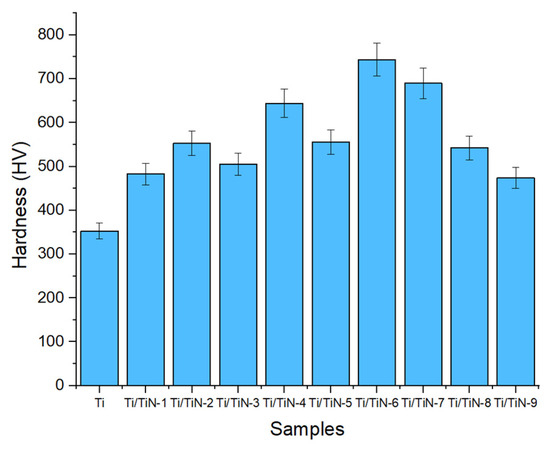

On this basis, the 5 mN load was selected for recalculating hardness and elastic modulus across all multilayer architectures. The corrected hardness results (Figure 10) ranged between 620 and 710 HV (≈6.1–7.0 GPa), significantly higher than the Ti-6Al-4V substrate (353 HV). The Ti/TiN-6 coating exhibited the highest hardness (~740 HV), while the Ti/TiN-7 coating also demonstrated a comparably high value (~690 HV) and superior adhesion stability. This indicates that the multilayer design significantly strengthens the coating and that the optimal performance results from the balance between hardness and interfacial integrity. Previously reported lower values (~430–490 HV) were artifacts of excessive penetration at 50 mN, where the substrate contribution masked the coating response.

Figure 10.

Hardness dependence in multilayer Ti/TiN coatings.

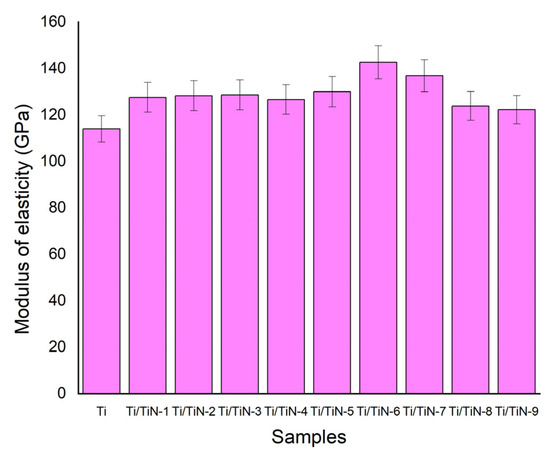

The indentation modulus (EIT), recalculated under the same conditions, also increased markedly compared to the substrate (114 GPa). Coatings exhibited modulus values of ~124–143 GPa, with the maximum observed for Ti/TiN-6 (~143 GPa), while Ti/TiN-7 showed a comparably high modulus (~137 GPa) combined with improved adhesion stability. Figure 11 presents the mean indentation modulus values (EIT) for each Ti/TiN coating, measured at a fixed load of 5 mN corresponding to indentation depths below 10% of the coating thickness. These results characterize the averaged elastic response of the multilayer coatings rather than depth-dependent behavior.

Figure 11.

Elastic modulus of Ti/TiN-coated.

For comparison with the literature, the approximation 1 GPa ≈ 100 HV was applied. Cheng et al. [4] reported hardness values of 15–35 GPa and indentation modulus of 200–450 GPa for TiN/Ti multilayers, corresponding to ≈1500–3500 HV for hardness. Jiang et al. [12] reported hardness values of 14–20 GPa (≈1400–2000 HV). Our corrected hardness values (620–710 HV, ≈6.1–7.0 GPa) are lower than those ranges, while our indentation modulus (185–230 GPa) lies within the lower end of published data (200–450 GPa [4]; 220–280 GPa [12]). The lower hardness in this study can be explained by the use of a softer biomedical substrate (Ti-6Al-4V) compared with tool steels or Si, by the smaller total coating thickness (~4–5 µm), and by the fixed TiN/Ti ratio (3:1) that was selected to provide balanced properties rather than extreme superhardness.

Despite these differences, the trends are consistent with the literature: multilayer design enhances stiffness relative to the substrate, and optimized architectures improve hardness when measured under valid depth conditions. Within the investigated design space, the Ti/TiN-7 coating demonstrated the most favorable balance of hardness (~700 HV ≈ 7 GPa) and indentation modulus (~230 GPa), supporting its potential for biomedical applications where reliable mechanical performance is required.

3.6. Summary Table and Quantitative Analysis

To provide a comprehensive overview of the results obtained, all measured mechanical, corrosion, and tribological parameters are summarized in Table 2.

The summarized data reveal a strong dependence of coating performance on multilayer architecture. With respect to hardness, all Ti/TiN coatings demonstrated significantly higher values compared to the Ti-6Al-4V substrate (353 HV). The hardness of the multilayers ranged from ~540 HV (Ti/TiN-8) to ~740 HV (Ti/TiN-6), while the optimized Ti/TiN-7 configuration exhibited a consistently high value (~690 HV). This confirms that multilayering provides effective strengthening relative to the substrate, with architecture-dependent variations in performance.

The indentation modulus of the substrate (114 GPa) also increased for all multilayer designs, reaching values in the range of ~124–143 GPa. The highest modulus was measured for Ti/TiN-6 (~143 GPa), whereas other coatings, including Ti/TiN-7 (~137 GPa), also showed a significant stiffening effect compared to the uncoated alloy. Electrochemical testing demonstrated a shift in Ecorr from −0.45 V (substrate) to more noble values up to −0.12 V (Ti/TiN-9), while Icorr decreased nearly by an order of magnitude (from 1.2 × 10−5 to 1.0 × 10−6 A/cm2). This indicates that the multilayer architecture effectively blocks diffusion paths for aggressive ions and improves corrosion protection. The beneficial effect of multilayer design in blocking ion diffusion paths is in line with earlier reports on plasma-modified steels, where enhanced phase stability and hardness were achieved through surface quenching and nitriding treatments [33,36].

The friction coefficient remained relatively stable (0.51–0.59), comparable to the substrate, yet the wear mechanisms differed markedly. Optimized coatings (Ti/TiN-1, Ti/TiN-3, Ti/TiN-7) exhibited stable abrasive wear with narrow grooves, while non-optimized configurations (Ti/TiN-6, Ti/TiN-8, Ti/TiN-9) failed by brittle delamination.

These results confirm that the number and thickness of layers govern the overall performance of Ti/TiN coatings. Optimized multilayer structures ensure a balanced enhancement of hardness, stiffness, and corrosion resistance, while minimizing the risk of brittle failure under tribological loading.

4. Discussion

The obtained tribological and mechanical results are in good agreement with previously reported data for Ti/TiN multilayer coatings produced by magnetron sputtering. The average friction coefficient (0.45–0.55) observed in this study corresponds well to the values of 0.4–0.6 typically reported for Ti/TiN multilayers under dry sliding conditions [4,11,18].

Similarly, the measured specific wear rate (~10−6 mm3/N·m) is consistent with literature data, confirming that the multilayer design effectively reduces wear by distributing the applied stress across multiple Ti/TiN interfaces [4,12].

The microhardness values (11–14 GPa) obtained in this work are also comparable to those reported for Ti/TiN multilayers (10–15 GPa) in other studies [9,18], where the increase in hardness is attributed to interface strengthening and dislocation blocking at Ti/TiN boundaries.

The results demonstrate that an optimal balance between TiN sublayer thickness and total number of bilayers is critical for achieving enhanced performance. Thinner TiN sublayers and a higher number of interfaces contribute to better load distribution and improved corrosion resistance by minimizing pore connectivity and acting as an efficient diffusion barrier [4,19].

It is also known that the surface roughness increases slightly with total film thickness due to the accumulation of columnar growth features, which can influence the friction coefficient by increasing real contact area during sliding [19]. Although detailed roughness values were not measured in this work, this tendency is consistent with previously reported results for TiN-based coatings.

Overall, the presented findings confirm that the mechanical and tribological properties of Ti/TiN multilayer coatings obtained in this study are fully consistent with established literature trends and demonstrate the effectiveness of multilayer architectures in improving surface performance. These results clearly demonstrate the interrelation between the architecture and properties of Ti/TiN multilayer coatings. The increase in the number of Ti/TiN interfaces enhances dislocation blocking and stress redistribution, resulting in improved hardness and wear resistance. The Ti interlayers act as ductile barriers that accommodate plastic deformation, thereby improving adhesion and delaying crack propagation. Conversely, excessive total thickness or prolonged deposition leads to residual stress accumulation and interface defects, which reduce adhesion and promote delamination. The observed corrosion behavior also correlates with coating density and defect content: coatings with optimized bilayer periods exhibit fewer open pathways for ion penetration, resulting in lower corrosion current densities. Hence, the combined effect of crystallographic texture, interface density, and residual stress determines the overall mechanical, tribological, and corrosion performance of the multilayers.

5. Conclusions

In this study, nine Ti/TiN multilayer coatings with different numbers of layers (3, 5, and 7) and deposition times (30, 60, and 120 min) were successfully deposited on Ti-6Al-4V alloy substrates. The obtained experimental results and analysis lead to the following conclusions:

All coatings exhibited dense and well-defined multilayer structures composed of alternating Ti (HCP) and TiN (FCC) phases. Increasing the number of layers and deposition time improved the crystallinity of the TiN (111) phase and the overall structural integrity of the coatings.

Mechanical characterization revealed a significant increase in hardness (540–740 HV) and indentation modulus (124–143 GPa) compared to the Ti-6Al-4V substrate (353 HV and 114 GPa). These enhancements are attributed to interface strengthening and stress redistribution between Ti and TiN sublayers.

Electrochemical measurements demonstrated a positive shift in the corrosion potential (Ecorr ≈ −0.13 V) and a reduction in corrosion current density (Icorr ≈ 1 × 10−6 A cm−2), confirming the effective barrier function of the multilayer architecture in preventing ion diffusion.

Tribological tests showed that coatings with optimized bilayer configurations, particularly Ti/TiN-7, exhibited stable friction behavior and the lowest wear rate (~10−6 mm3 N−1 m−1). Coatings with excessive total thickness displayed brittle delamination due to residual stress accumulation.

Overall, the Ti/TiN-7 multilayer architecture provided the most balanced combination of high hardness, wear resistance, and corrosion stability. The results confirm that the structural design—specifically the Ti/TiN layer thickness ratio and the total number of bilayers—plays a decisive role in determining the mechanical, tribological, and electrochemical performance of Ti/TiN coatings.

Author Contributions

Conceptualization, B.R.; methodology, N.M.; software, A.S.; validation, A.S.; formal analysis, N.M.; investigation, A.K.; resources, Y.B.; data curation, Y.B.; writing—original draft preparation, Z.A. and N.M.; writing—review and editing, B.R. and N.M.; visualization, A.K.; supervision, B.R.; project administration, Z.A.; funding acquisition, Z.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Committee of Science of the Ministry of Science and Higher Education of the Republic of Kazakhstan (Grant No. AP19680457).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in this study.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

Author Bauyrzhan Rakhadilov and Yelaman Batanov were employed by the company PlasmaScience LLP. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Bocchetta, P.; Chen, L.-Y.; Tardelli, J.D.C.; Reis, A.C.D.; Almeraya-Calderón, F.; Leo, P. Passive Layers and Corrosion Resistance of Biomedical Ti-6Al-4V and β-Ti Alloys. Coatings 2021, 11, 487. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Baizhan, D. Creation of Bioceramic Coatings on the Surface of Ti–6Al–4V Alloy by Plasma Electrolytic Oxidation Followed by Gas Detonation Spraying. Coatings 2021, 11, 1433. [Google Scholar] [CrossRef]

- Marin, E.; Lanzutti, A. Biomedical Applications of Titanium Alloys: A Comprehensive Review. Materials 2023, 17, 114. [Google Scholar] [CrossRef]

- Cheng, Y.H.; Browne, T.; Heckerman, B.; Bowman, C.; Gorokhovsky, V.; Meletis, E.I. Mechanical and Tribological Properties of TiN/Ti Multilayer Coating. Surf. Coat. Technol. 2010, 205, 146–151. [Google Scholar] [CrossRef]

- Aringozhina, Z.; Magazov, N.; Rakhadilov, B.; Uazyrkhanova, G.; Amanov, A. Effect of Ultrasonic Nanocrystalline Surface Modification on Hardness and Elastic Modulus of Ti-6Al-4V Alloy. AIMS Mater. Sci. 2025, 12, 101–117. [Google Scholar] [CrossRef]

- Chen, X.; Mi, W.; Wu, J.; Yang, Z.; Zhang, K.; Zhao, J.; Luan, C.; Wei, Y. A Solar-Blind Photodetector Based on β-Ga2O3 Film Deposited on MgO (100) Substrates by RF Magnetron Sputtering. Vacuum 2020, 180, 109632. [Google Scholar] [CrossRef]

- Musil, J. Hard and Superhard Nanocomposite Coatings. Surf. Coat. Technol. 2000, 125, 322–330. [Google Scholar] [CrossRef]

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti Based Biomaterials, the Ultimate Choice for Orthopaedic Implants–A Review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Bemporad, E.; Sebastiani, M.; Pecchio, C.; De Rossi, S. High Thickness Ti/TiN Multilayer Thin Coatings for Wear Resistant Applications. Surf. Coat. Technol. 2006, 201, 2155–2165. [Google Scholar] [CrossRef]

- Keles, O.; Taptik, Y.; Eryilmaz, O.L.; Urgen, M.; Çakir, A.F. Optimization of arc-PVD TiN coating process parameters by Taguchi technique. Qual. Eng. 1999, 12, 29–36. [Google Scholar] [CrossRef]

- Vereschaka, A.; Grigoriev, S.; Tabakov, V.; Migranov, M.; Sitnikov, N.; Milovich, F.; Andreev, N. Influence of the Nanostructure of Ti-TiN-(Ti,Al,Cr)N Multilayer Composite Coating on Tribological Properties and Cutting Tool Life. Tribol. Int. 2020, 150, 106388. [Google Scholar] [CrossRef]

- Zhou, K.; Liu, D.; Li, M.; Zhang, X.; Gao, F.; Liu, Y.; Gao, Y.; Li, X. Investigation of the corrosion and wear failure behavior and mechanism of TiN/Ti multilayer with varying thickness. Eng. Fail. Anal. 2025, 176, 109648. [Google Scholar] [CrossRef]

- Mathews, N.G.; Lambai, A.; Hans, M.; Schneider, J.M.; Mohanty, G.; Jaya, B.N. The Effect of Elastic-Plastic Mismatch and Interface Proximity on the Fracture Toughness of Ti-TiN Thin Films. Adv. Eng. Mater. 2025, 27, 2500285. [Google Scholar] [CrossRef]

- Tu, R.; Jiao, J.; Jiang, M.; Yang, M.; Ji, B.; Gao, T.; Li, Q.; Zhang, S.; Zhang, L. Effect of gradient multilayer design on tribological performance of TiN/TiSiN coatings prepared by cathodic arc ion plating. Coatings 2023, 13, 836. [Google Scholar] [CrossRef]

- Bonu, V.; Jeevitha, M.; Kumar, V.P.; Srinivas, G.; Barshilia, H.C. Solid particle erosion and corrosion resistance performance of nanolayered multilayered Ti/TiN and TiAl/TiAlN coatings deposited on Ti6Al4V substrates. Surf. Coat. Technol. 2020, 387, 125531. [Google Scholar] [CrossRef]

- Yurddaskal, M.; Durmuş, H. Tribological properties and studies in SBF of Ta2O5/TiN/TiO2 monolayer and bilayer coatings on biomedical Ti6Al4V alloy. J. Mech. Sci. Technol. 2022, 36, 2631–2641. [Google Scholar] [CrossRef]

- Bhaskar, S.V.; Kudal, H.N. Tribology of nitrided-coated steel-a review. Arch. Mech. Technol. Mater. 2017, 37, 50–57. [Google Scholar] [CrossRef]

- Ali, R.; Sebastiani, M.; Bemporad, E. Influence of Ti–TiN multilayer PVD-coatings design on residual stresses and adhesion. Mater. Des. 2015, 75, 47–56. [Google Scholar] [CrossRef]

- Santaella-González, J.B.; Hernández-Torres, J.; Morales-Hernández, J.; Flores-Ramírez, N.; Ferreira-Palma, C.; Rodríguez-Jiménez, R.C.; García-González, L. Effect of the number of bilayers in Ti/TiN coatings on AISI D2. Mater. Lett. 2022, 320, 132394. [Google Scholar] [CrossRef]

- Kolaklieva, L.; Kakanakov, R.; Chaliampalias, D.; Vourlias, G.; Cholakova, T.; Pashinski, C.; Chitanov, V.; Bahchedjiev, C.; Petkov, N.; Polychroniadis, E.K. Mechanical, structural and thermal properties of multilayered gradient nanocomposite coatings. J. Nano Res. 2012, 17, 193–202. [Google Scholar] [CrossRef]

- Li, Y.; Gu, D.; Zhang, H.; Xi, L. Effect of trace addition of ceramic on microstructure development and mechanical properties of selective laser melted AlSi10Mg alloy. Chin. J. Mech. Eng. 2020, 33, 33. [Google Scholar] [CrossRef]

- Almeraya-Calderón, F.; Jáquez-Muñoz, J.M.; Maldonado-Bandala, E.; Cabral-Miramontes, J.; Nieves-Mendoza, D.; Olgui-Coca, J.; Lopez-Leon, L.D.; Estupiñán-López, F.; Lira-Martínez, A.; Gaona Tiburcio, C. Corrosion Resistance of Titanium Alloys Anodized in Alkaline Solutions. Metals 2023, 13, 1510. [Google Scholar] [CrossRef]

- Jiang, C.L.; Zhu, H.L.; Shin, K.S.; Tang, Y.B. Influence of titanium interlayer thickness distribution on mechanical properties of Ti/TiN multilayer coatings. Thin Solid Films 2017, 632, 97–105. [Google Scholar] [CrossRef]

- McCafferty, E. Introduction to Corrosion Science; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2010; ISBN 978-1-4419-0454-6. [Google Scholar]

- Aliofkhazraei, M. (Ed.) Characterization of Nanostructured Coatings. In Nanocoatings: Size Effect in Nanostructured Films; Springer: Berlin/Heidelberg, Germany, 2011; pp. 77–110. ISBN 978-3-642-17966-2. [Google Scholar]

- Wood, R.J.K.; Lu, P. Coatings and surface modification of alloys for tribo-corrosion applications. Coatings 2024, 14, 99. [Google Scholar] [CrossRef]

- Stachowiak, G.; Batchelor, A.W. Engineering Tribology; Butterworth-Heinemann: Oxford, England, 2013; ISBN 978-0-12-397776-2. [Google Scholar]

- Donnet, C.; Erdemir, A. Tribology of Diamond-Like Carbon Films: Fundamentals and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2007; ISBN 978-0-387-49891-1. [Google Scholar]

- Vancoille, E.; Celis, J.P.; Roos, J.R. Dry sliding wear of TiN based ternary PVD coatings. Wear 1993, 165, 41–49. [Google Scholar] [CrossRef]

- Larsson, M.; Bromark, M.; Hedenqvist, P.; Hogmark, S. Mechanical and tribological properties of multilayered PVD TiN/NbN coatings. Surf. Coat. Technol. 1997, 91, 43–49. [Google Scholar] [CrossRef]

- Yang, Z.; Gao, J.; Song, J.; Wang, Y. Effects of layer thickness ratio on residual stress, microstructure and mechanical properties of TiB2-TiC/TiB2-TiN laminated ceramics. J. Mater. Sci. 2024, 59, 21251–21264. [Google Scholar] [CrossRef]

- Samanta, A.; Bhattacharya, M.; Ratha, I.; Chakraborty, H.; Datta, S.; Ghosh, J.; Bysakh, S.; Sreemany, M.; Rane, R.; Joseph, A.; et al. Nano-and micro-tribological behaviours of plasma nitrided Ti6Al4V alloys. J. Mech. Behav. Biomed. Mater. 2018, 77, 267–294. [Google Scholar] [CrossRef]

- Klimenko, I.; Belous, V.; Ovcharenko, V.; Tolmachova, H.; Kuprin, O. Tribological Properties of Tin and Crn Cathodic Arc Coatings on Ti-6al-4v Alloy. In Proceedings of the Materials Science and Surface Engineering; Karpenko Physico-Mechanical Institute of the NAS of Ukraine: Lviv, Ukraine, 2023; pp. 118–121. [Google Scholar]

- Yin, B.; Liu, J.; Peng, B.; Zhou, M.; Liu, B.; Ma, X.; Wang, C.; Wen, P.; Tian, Y.; Zheng, Y. Influence of layer thickness on formation quality, microstructure, mechanical properties, and corrosion resistance of WE43 magnesium alloy fabricated by laser powder bed fusion. J. Magnes. Alloys 2024, 12, 1367–1385. [Google Scholar] [CrossRef]

- Popova, N.A.; Nikonenko, E.L.; Tabieva, E.E.; Uazyrkhanova, G.K. Structure and phase composition of ferritic–perlitic steel surface after electrolytic plasma quenching. Russ. Phys. J. 2020, 63, 791–796. [Google Scholar] [CrossRef]

- Chang, Y.Y.; Amrutwar, S. Effect of Plasma Nitriding Pretreatment on the Mechanical Properties of Steel. Materials 2019, 12, 795. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).