Influence of Surface Alignment Layers on Digital Memory PDLC Devices for Electrically Written Information Storage

Abstract

1. Introduction

2. Experimental Methods

2.1. Materials and Methods

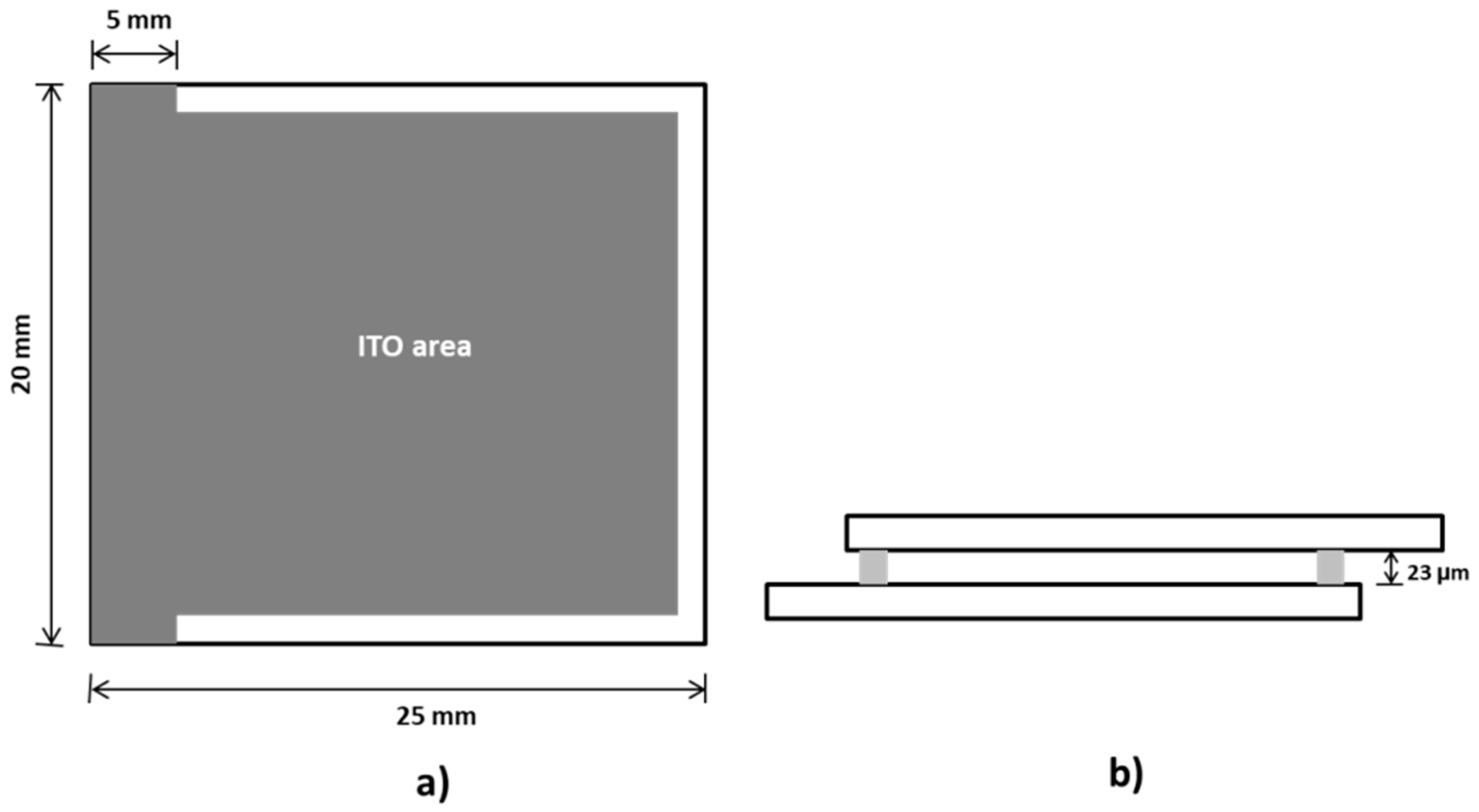

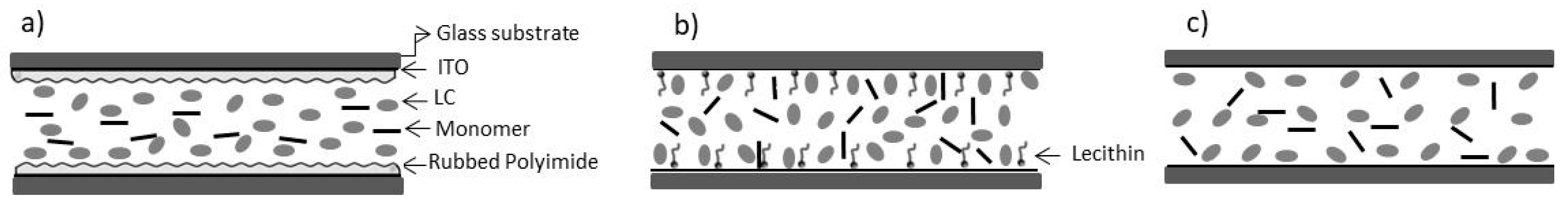

2.2. Preparation of PDLC Test Cells

2.3. Electro-Optical Characterization of PDLC Test Cells

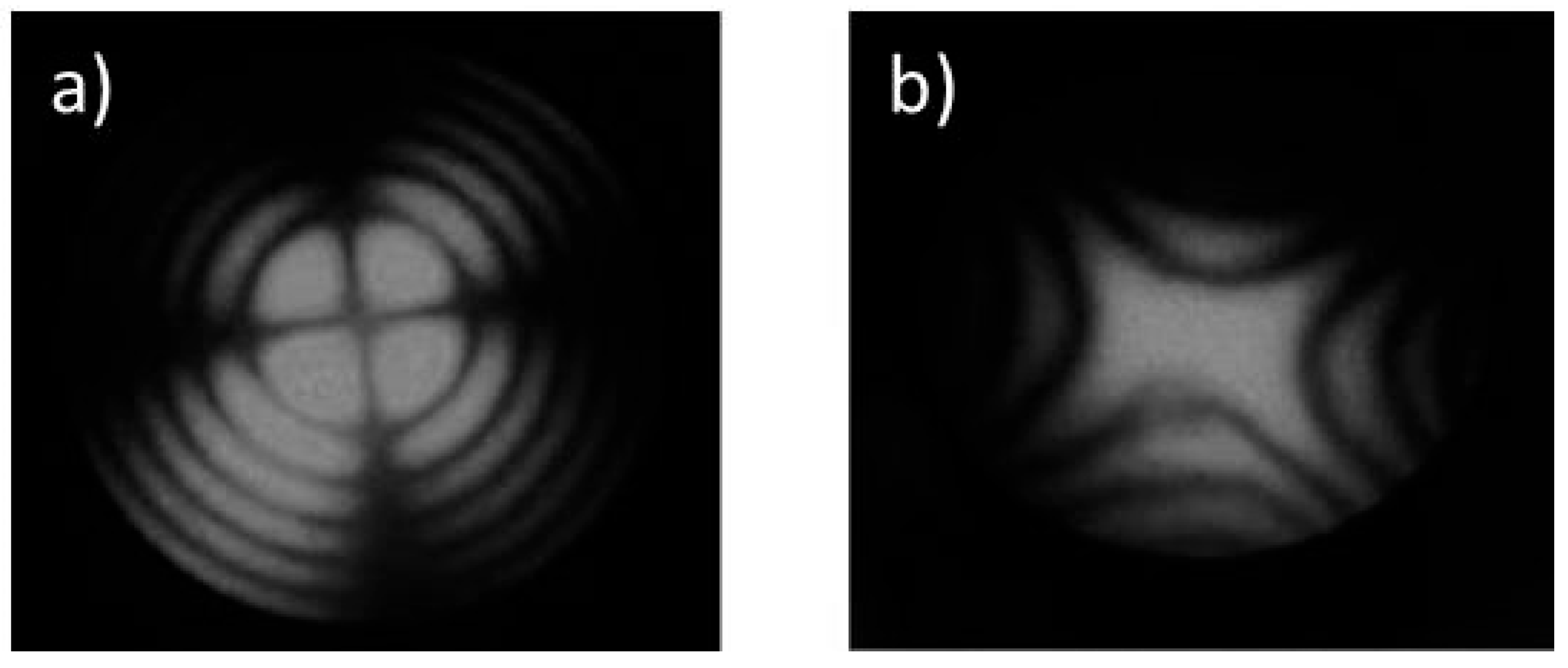

2.4. Conoscopic Observations of Liquid Crystal

3. Results and Discussion

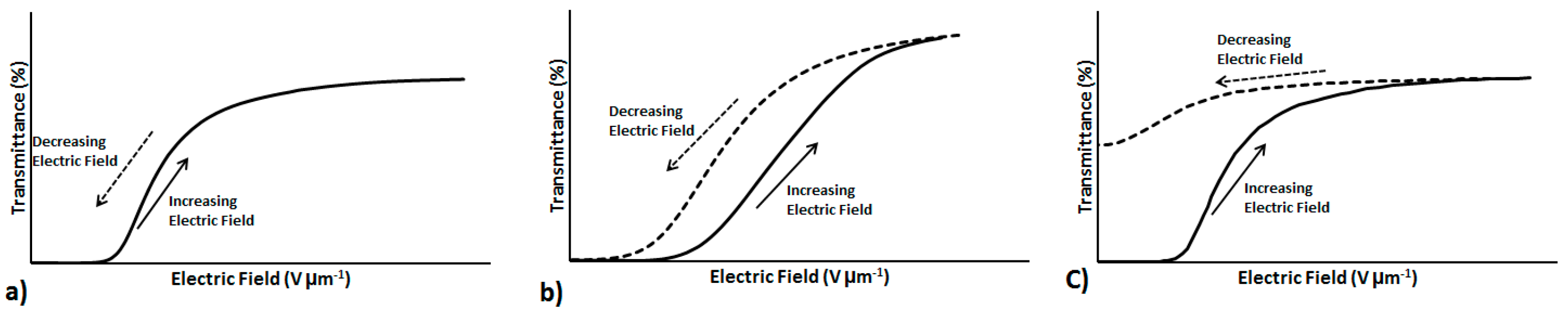

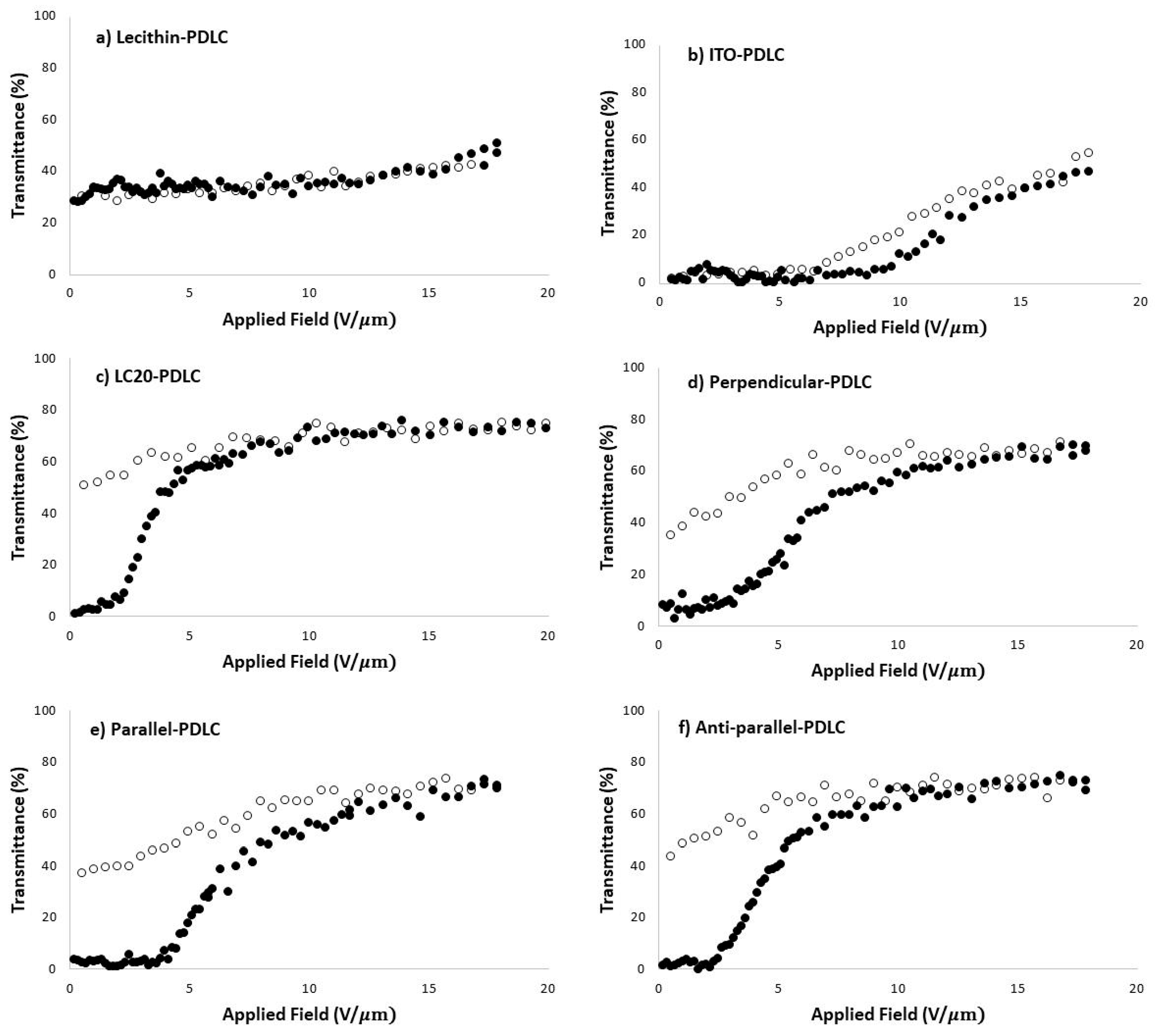

3.1. Electro-Optical Properties of PDLC Test Cells

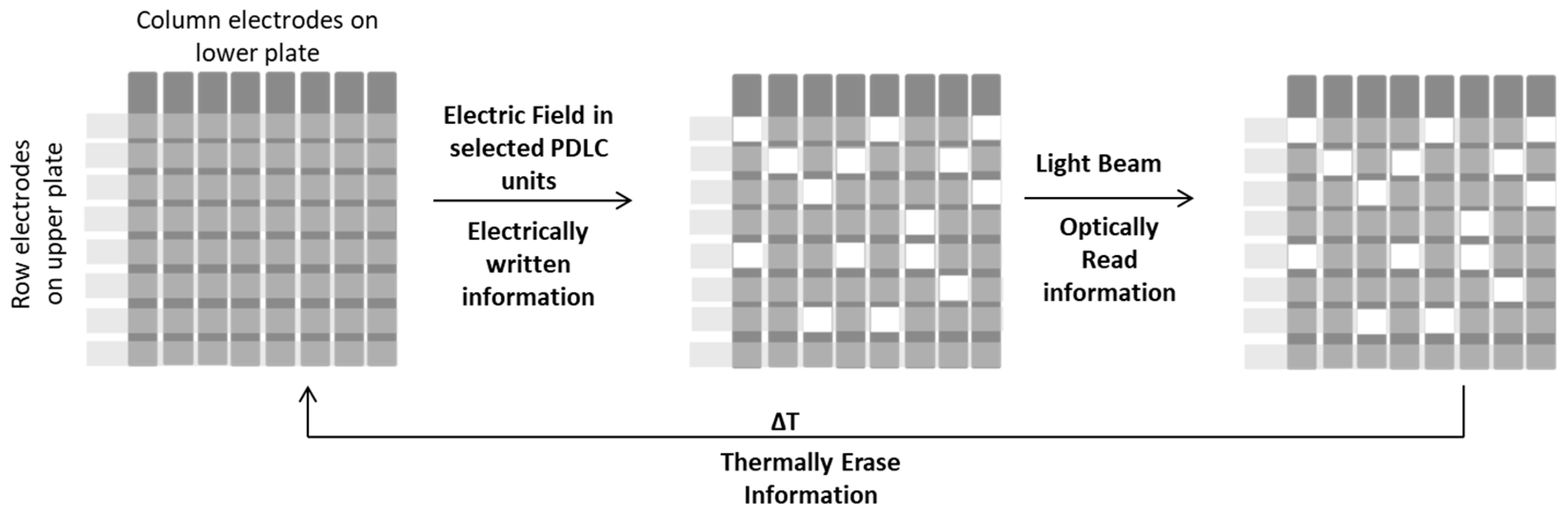

3.2. Manufacturing Passive PDLC Film Matrixes: Digital Memory PDLC Devices Based on Electrical Writing Digital Information

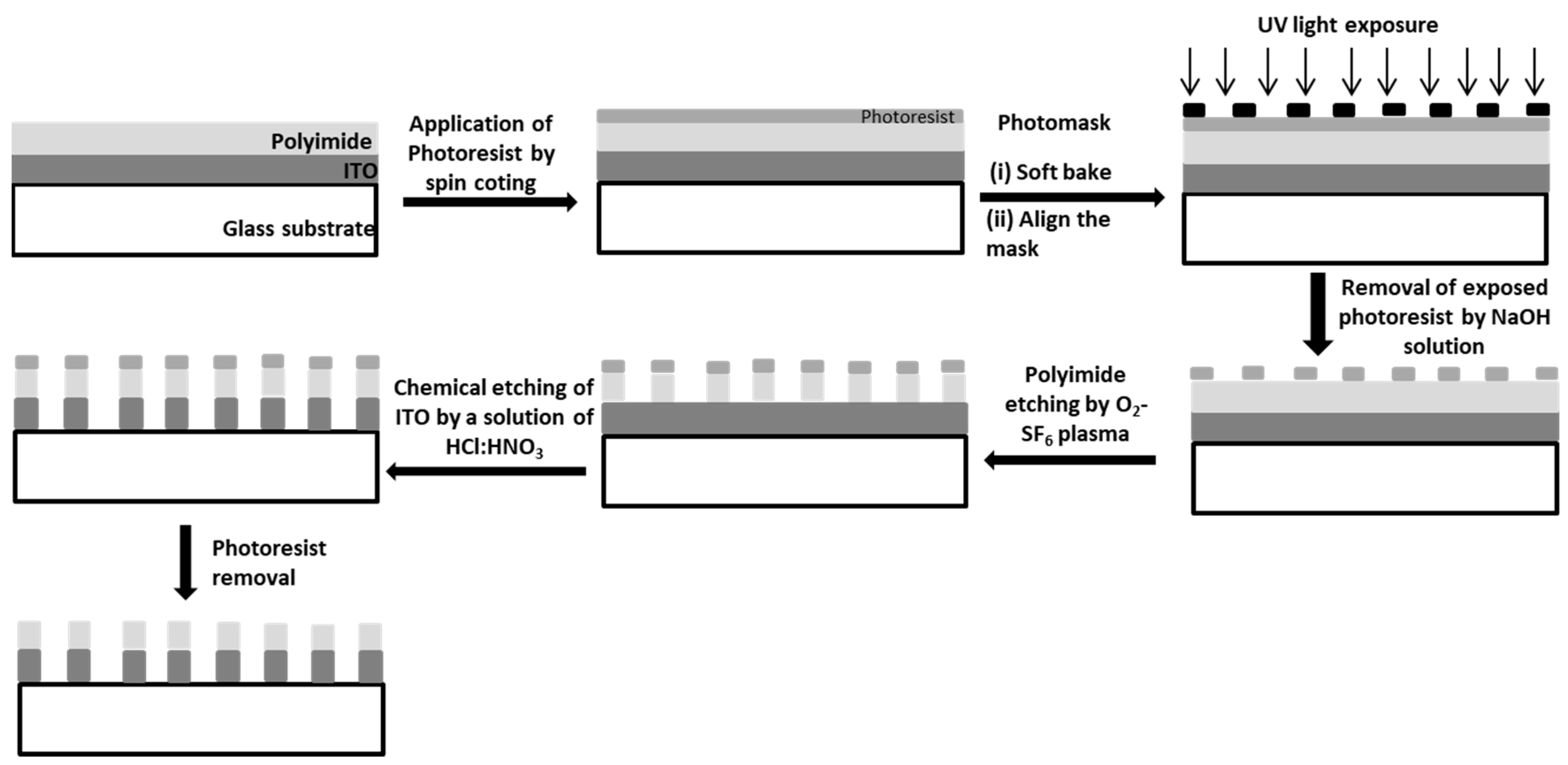

3.3. Pattern Fabrication on ITO Covered with an Alignment Layer

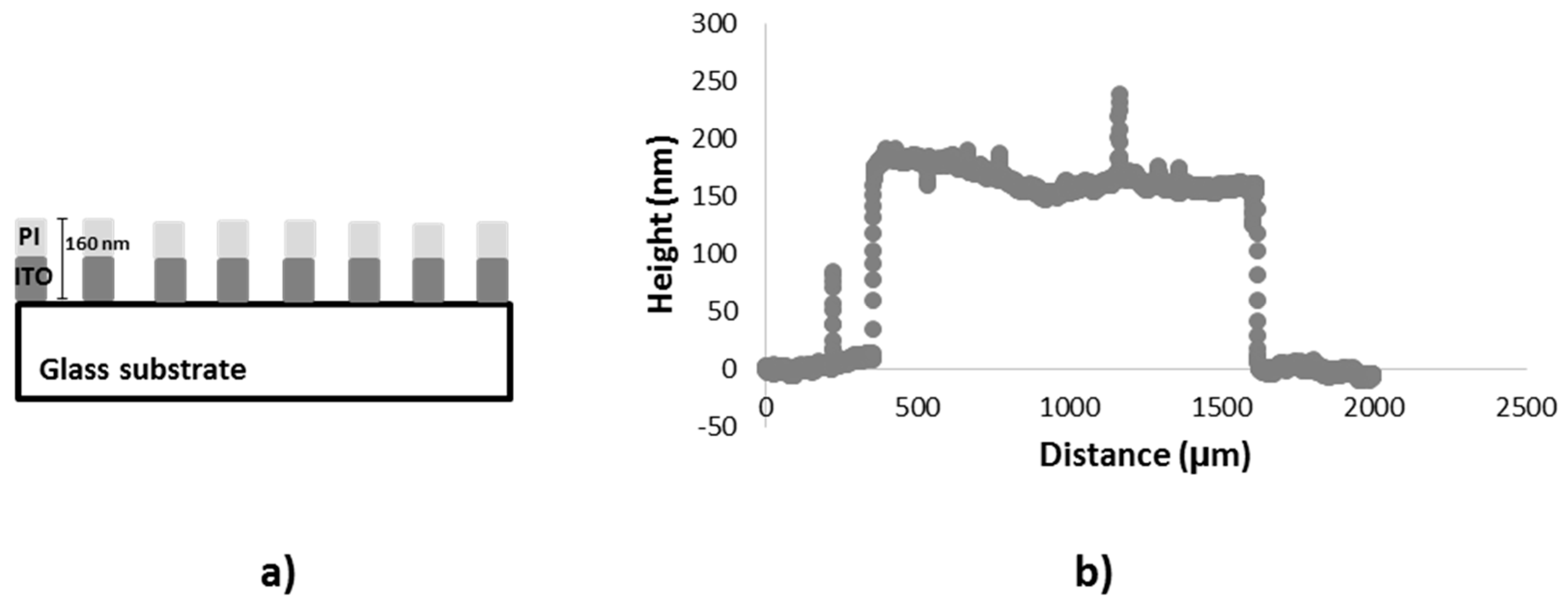

3.4. Line-Shaped ITO Electrodes Covered with Polyimide Thickness Measurement

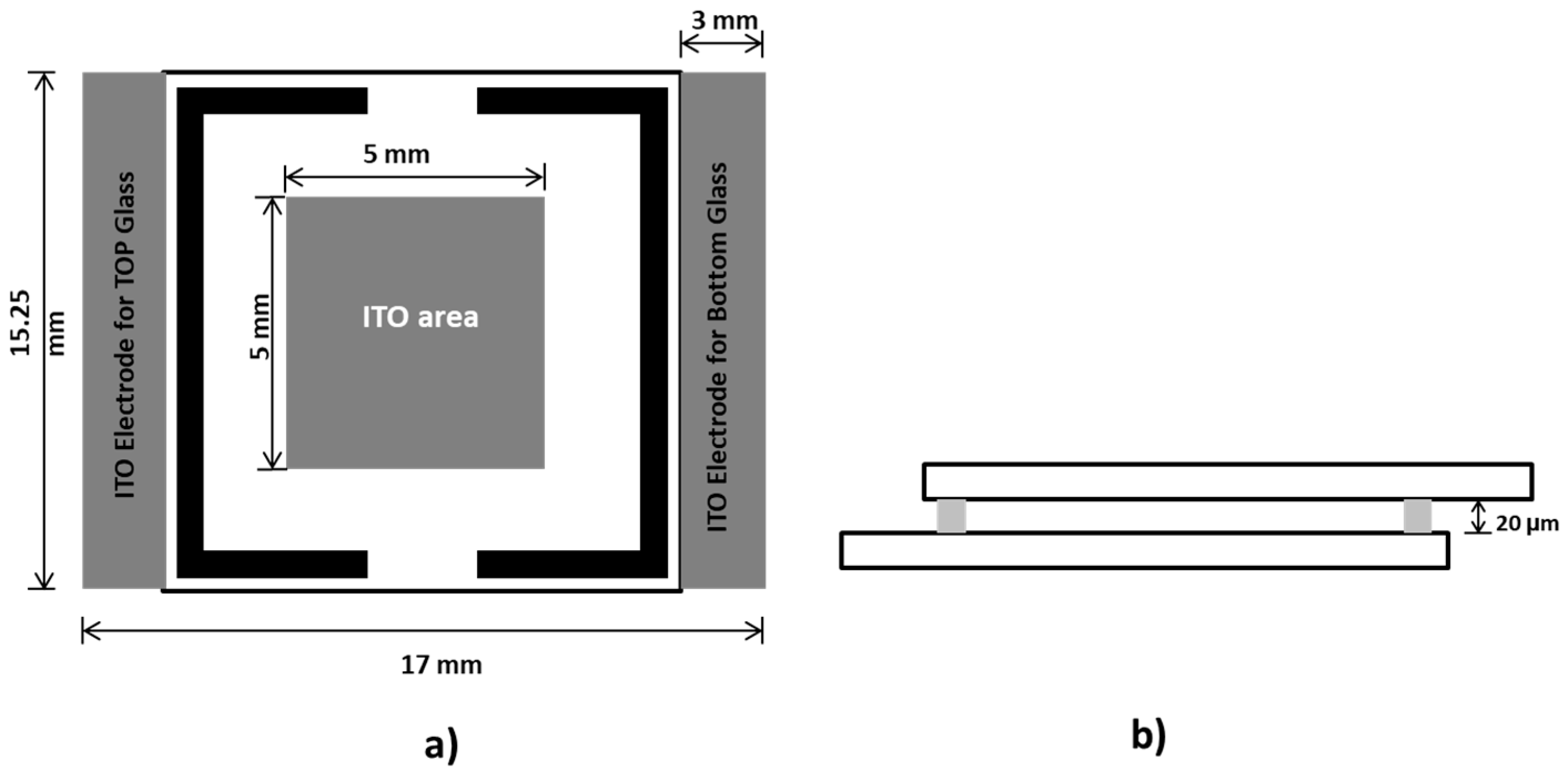

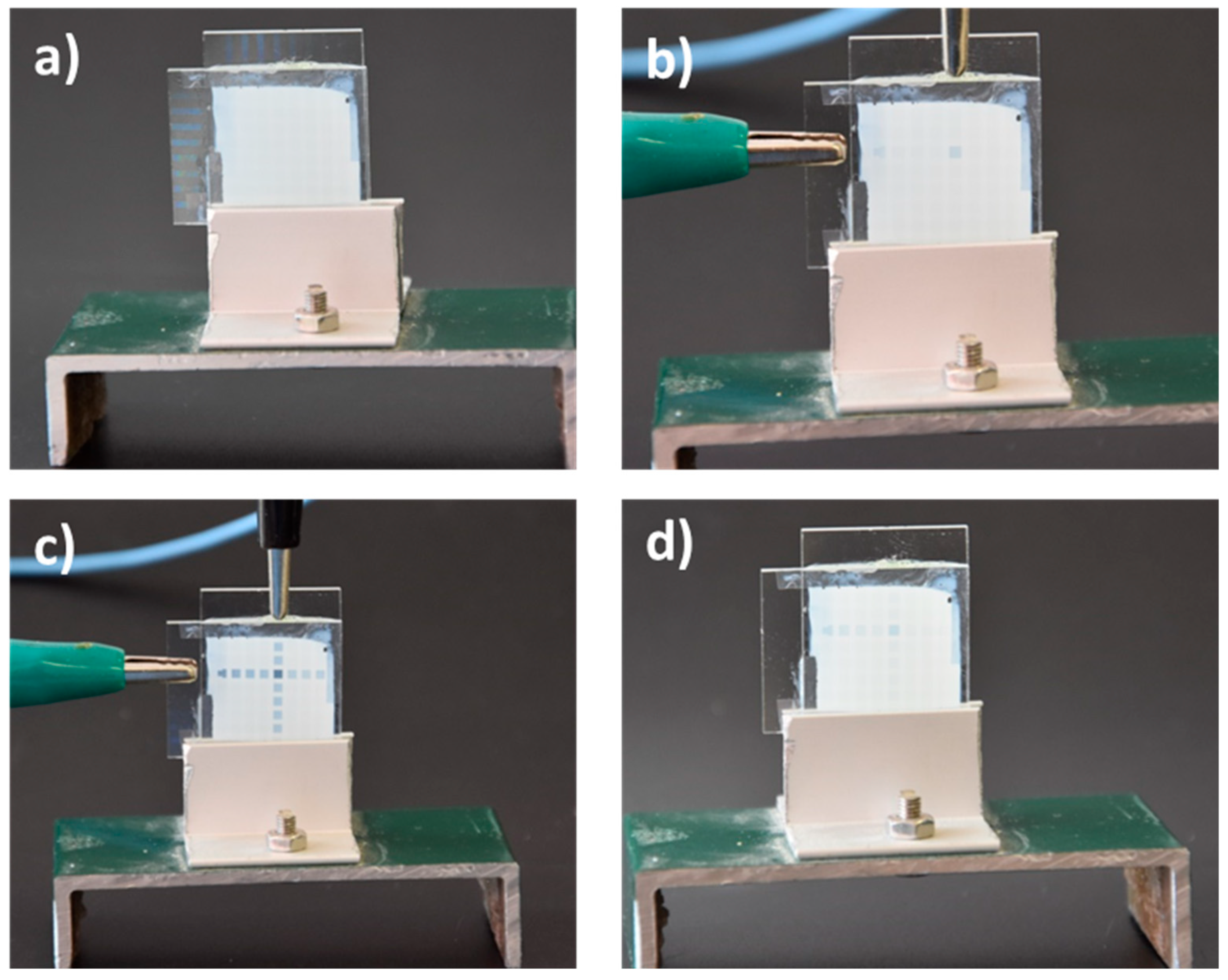

3.5. PDLC Passive Matrix Device Assembly

3.6. PDLC Passive Matrix Device Operation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Agarwal, S.; Srivastava, S.; Joshi, S.; Tripathi, S.; Singh, B.P.; Pandey, K.K.; Manohar, R. A Comprehensive Review on Polymer-Dispersed Liquid Crystals: Mechanisms, Materials, and Applications. ACS Mater. Au 2025, 5, 88–114. [Google Scholar] [CrossRef]

- Yang, D.-K.; Wu, S.-T. Fundamentals of Liquid Crystal Devices; Anthony, C.L., Sage, I., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2006. [Google Scholar]

- Loiko, V.; Zyryanov, V.Y.; Konkolovich, A.V.; Miskevich, A.A. Light transmission of polymer-dispersed liquid crystal layer composed of droplets with inhomogeneous surface anchoring. Opt. Spectrosc. 2016, 120, 143–152. [Google Scholar] [CrossRef]

- Jain, S.C.; Rout, D.K. Electro-optic response of polymer dispersed liquid-crystal films. J. Appl. Phys. 1991, 70, 6988–6992. [Google Scholar] [CrossRef]

- Vicari, L. Optical Applications of Liquid Crystals, 1st ed.; Institute of Physics Publishing: Philadelphia, PA, USA, 2003. [Google Scholar] [CrossRef]

- Drzaic, P.S. Liquid Crystal Dispersions; Ong, H.L., Ed.; World Scientific Publishing: London, UK, 1995. [Google Scholar] [CrossRef]

- Roussel, F.; Buisine, J.-M.; Maschke, U.; Coqueret, X. Photopolymerization kinetics and phase behavior of acrylate based polymer dispersed liquid crystals. Liq. Cryst. 1998, 24, 555–561. [Google Scholar] [CrossRef]

- Deshmukh, R.R.; Malik, M.K. Effect of temperature on the optical and electro-optical properties of poly(methyl methacrylate)/E7 polymer-dispersed liquid crystal composites. J. Appl. Polym. Sci. 2008, 109, 627–637. [Google Scholar] [CrossRef]

- Maschke, U.; Coqueret, X.; Benmouna, M. Electro-Optical Properties of Polymer-Dispersed Liquid Crystals. Macromol. Rapid Commun. 2002, 23, 159–170. [Google Scholar] [CrossRef]

- Han, J. Memory and Depolarization Effects of Polymer-Dispersed Liquid Crystal Films Based on E7/NOA61. J. Korean Phys. Soc. 2003, 43, 45–50. [Google Scholar]

- Jeong, E.H.; Sun, K.R.; Kang, M.C.; Jeong, H.M.; Kim, B.K. Memory effect of polymer dispersed liquid crystal by hybridization with nanoclay. Express Polym. Lett. 2010, 4, 39–46. [Google Scholar] [CrossRef]

- Rumiko, Y.; Susumu, S. Memory Effects of Light Transmission Properties in Polymer-Dispersed-Liquid-Crystal (PDLC) Films. Jpn. J. Appl. Phys. 1991, 30, L616–L618. [Google Scholar] [CrossRef]

- Fuh, A.Y.-G.; Li, T.C.K. Polymer Dispersed Liquid Crystal Films with Memory Characteristics. Jpn. J. Appl. Phys. 1992, 31, 3366–3369. [Google Scholar] [CrossRef]

- Mouquinho, A.I.; Petrova, K.; Barros, M.T.; Sotomayor, J. New Polymers Networks for PDLC Films Application; Souza Gomes, A., Ed.; InTech: Houston, TX, USA, 2012. [Google Scholar] [CrossRef][Green Version]

- Yamaguchi, R.; Sato, S. Highly transparent memory states in polymer dispersed liquid crystal films. Liq. Cryst. 1993, 14, 929–935. [Google Scholar] [CrossRef]

- Buscaglia, M.; Bellini, T.; Chiccoli, C.; Mantegazza, F.; Pasini, P.; Rotunno, M.; Zannoni, C. Memory effects in nematics with quenched disorder. Phys. Rev. E 2006, 74, 011706. [Google Scholar] [CrossRef][Green Version]

- Yamaguchi, R.; Sato, S. Highly transparent memory states by phase transition with a field in polymer dispersed liquid crystal films. Jpn. J. Appl. Phys. 1992, 31, L254–L256. [Google Scholar] [CrossRef]

- Jákli, A. Structure and Optical Properties of Liquid Crystal Dispersed Polymers. Mol. Cryst. Liq. Cryst. 1994, 251, 289–301. [Google Scholar] [CrossRef]

- Bulgakova, S.A.; Mashin, A.I.; Kazantseva, I.A.; Kashtanov, D.E.; Jones, M.M.; Tsepkov, G.S.; Korobkov, A.V.; Nezhdanov, A.V. Influence of the composition of the polymer matrix on the electrooptical properties of films with a dispersed liquid crystal. Russ. J. Appl. Chem. 2008, 81, 1446–1451. [Google Scholar] [CrossRef]

- He, J.; Yan, B.; Yu, B.; Wang, S.; Zeng, Y.; Wang, Y. The effect of molecular weight of polymer matrix on properties of polymer-dispersed liquid crystals. Eur. Polym. J. 2007, 43, 2745–2749. [Google Scholar] [CrossRef]

- Li, W.; Cao, H.; Kashima, M.; Liu, F.; Cheng, Z.; Yang, Z.; Zhu, S.; Yang, H. Control of the microstructure of polymer network and effects of the microstructures on light scattering properties of UV-cured polymer-dispersed liquid crystal films. J. Polym. Sci. Part B Polym. Phys. 2008, 46, 2090–2099. [Google Scholar] [CrossRef]

- Amundson, K.; van Blaaderen, A.; Wiltzius, P. Morphology and electro-optic properties of polymer-dispersed liquid-crystal films. Am. Phys. Soc. 1997, 55, 1646–1654. [Google Scholar] [CrossRef]

- Du, X.; Yan, B.; Wang, Y.J. Influence of matrix glass transition temperature on the memory effect of polymer-dispersed liquid crystals. Polym. Sci. Part B Polym. Phys. 2010, 48, 729–732. [Google Scholar] [CrossRef]

- Ahmad, F.; Jamil, M.; Jeon, Y.J.; Woo, L.J.; Jung, J.E.; Jang, J.E.; Lee, G.H.; Park, J.J. Comparative study on the electroopticalproperties of polymer-dispersed liquid crystal films with different mixtures of monomers and liquid crystals. Appl. Polym. Sci. 2011, 121, 1424–1430. [Google Scholar] [CrossRef]

- Han, J. Study of Memory Effects in Polymer Dispersed Liquid Crystal Films. J. Korean Phys. Soc. 2006, 49, 1482–1487. [Google Scholar]

- Brás, A.R.E.; García, O.; Viciosa, M.T.; Martins, S.; Sastre, R.; Dias, C.J.; Figueirinhas, J.L.; Dionísio, M. Dielectric relaxation studies and electro-optical measurements in poly(triethylene glycol dimethacrylate)/nematic E7 composites exhibiting an anchoring breaking transition. Liq. Cryst. 2008, 35, 429–441. [Google Scholar] [CrossRef]

- Kato, K.; Tanaka, K.; Tsuru, S.; Sakai, S. Reflective Color Display Using Polymer-Dispersed Cholesteric Liquid Crystal. Jpn. J. Appl. Phys. 1994, 33, 2635–2640. [Google Scholar] [CrossRef]

- Lucchetti, L.; Bella, S.D.; Simoni, F. Optical storage of hidden images in ultraviolet-cured polymer dispersed liquid crystals. Liq. Cryst. 2002, 29, 515–519. [Google Scholar] [CrossRef]

- Torgova, S.; Dorozhkina, G.; Novoseletskii, N.; Umanskii, B. Investigation Of Memory Effect In Dichroic Dyes Based PDLC Films. Mol. Cryst. Liq. Cryst. 2004, 412, 513–517. [Google Scholar] [CrossRef]

- Simoni, F.; Bella, S.D.I.; Lucchetti, L.; Cipparrone, G.; Mazzulla, A. Polymer Dispersed Liquid Crystals As Optical Storage Materials. Mater. Res. Soc. Symp. Proc. 1999, 559, 65–74. [Google Scholar] [CrossRef]

- Cipparrone, G.; Mazzulla, A.; Nicoletta, F.P.; Lucchetti, L.; Simoni, F. Optical Storage Effect in Dye Doped Polymer Dispersed Liquid Crystals. Mol. Cryst. Liq. Cryst. 1998, 320, 249–263. [Google Scholar] [CrossRef]

- Mouquinho, A.; Barros, M.T.; Sotomayor, J. Pre-Polymer Chain Length: Influence on Permanent Memory Effect of PDLC Devices. Crystals 2024, 14, 249. [Google Scholar] [CrossRef]

- Mouquinho, A.; Figueirinhas, J.L.; Sotomayor, J. Digital Optical Memory Devices based on Polymer Dispersed Liquid Crystals Films: Appropriate polymer matrix morphology. Liq. Cryst. 2020, 47, 636–649. [Google Scholar] [CrossRef]

- Mouquinho, A.; Corvo, M.C.; Almeida, P.L.; Feio, G.M.; Sotomayor, J. Influence of Chain Length of pre-Polymers in Permanent Memory Effect of PDLC assessed by solid-state NMR. Liq. Cryst. 2020, 47, 522–530. [Google Scholar] [CrossRef]

- Silva, M.C.; Figueirinhas, J.L.; Sotomayor, J. Effect of an additive on the Permanent Memory Effect of Polymer Dispersed Liquid Crystal Films. J. Chem. Technol. Biotechnol. 2015, 90, 1565–1569. [Google Scholar] [CrossRef]

- Mouquinho, A.; Sotomayor, J. The Impact of Curing Temperature and UV Light Intensity on the Performance of PDLC Devices Exhibiting Permanent Memory Effect. Crystals 2024, 14, 571. [Google Scholar] [CrossRef]

- No, Y.; Jeon, C. Effect of Alignment Layer on Electro-Optic Properties of Polymer-Dispersed Liquid Crystal Displays. Mol. Cryst. Liq. Cryst. 2009, 513, 98–105. [Google Scholar] [CrossRef]

- Marinov, Y.G.; Hadjichristov, G.B.; Petrov, A.G.; Marino, S.; Versace, C.; Scaramuzza, N. Electro-optical response of polymer-dispersed liquid crystal single layers of large nematic droplets oriented by rubbed teflon nanolayers. J. Appl. Phys. 2013, 113, 064301. [Google Scholar] [CrossRef]

- Rajaram, C.; Hudson, S.D. Morphology of Polymer-Stabilized Liquid Crystals. Chem. Mater. 1995, 7, 2300–2308. [Google Scholar] [CrossRef]

- Instec_LC_Cells_in_Stock. Available online: https://instec.com/portal/article/index/id/93/cid/66.html (accessed on 2 November 2025).

- Parshin, A.M.; Zyryanov, V.Y.; Shabanov, V.F. Alignment of liquid crystals by polymers with residual amounts of solvents. Sci. Rep. 2017, 7, 3042. [Google Scholar] [CrossRef] [PubMed]

- Mendes, L.A.; Pinho, R.; Ácila, L.; Lima, C.R.A.; Rocco, M.L.M. AZ-1518 Photoresist analysis with synchrotron radiation using high-resolution time-of-flight mass spectrometry. Polym. Degrad. Stab. 2007, 92, 933–938. [Google Scholar] [CrossRef]

- Turban, G.; Rapeaux, M. Dry Etching of Polyimide in O2-CF4, and O2-SF6 Plasmas. J. Electrochem. Soc. 1983, 130, 2231–2236. [Google Scholar] [CrossRef]

- Koretsky, M.D.; Reimer, J.A. A simple model for the etching of photoresist with plasma-generated reactants. J. Appl. Phys. 1992, 72, 5081–5088. [Google Scholar] [CrossRef]

| Substrate Type | Patterned ITO Covered with Polyimide-Coated Glass |

|---|---|

| Glass type | soda lime |

| Substrate size (mm2) | 25 × 25 |

| Active area (mm2) | 21 × 20 |

| Number of pixels | 8 × 8 |

| Pixel size (mm2) | 1 × 1 |

| Gap between pixels (mm) | 0.023 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mouquinho, A.; Pereira, L.; Sotomayor, J. Influence of Surface Alignment Layers on Digital Memory PDLC Devices for Electrically Written Information Storage. Coatings 2025, 15, 1308. https://doi.org/10.3390/coatings15111308

Mouquinho A, Pereira L, Sotomayor J. Influence of Surface Alignment Layers on Digital Memory PDLC Devices for Electrically Written Information Storage. Coatings. 2025; 15(11):1308. https://doi.org/10.3390/coatings15111308

Chicago/Turabian StyleMouquinho, Ana, Luís Pereira, and João Sotomayor. 2025. "Influence of Surface Alignment Layers on Digital Memory PDLC Devices for Electrically Written Information Storage" Coatings 15, no. 11: 1308. https://doi.org/10.3390/coatings15111308

APA StyleMouquinho, A., Pereira, L., & Sotomayor, J. (2025). Influence of Surface Alignment Layers on Digital Memory PDLC Devices for Electrically Written Information Storage. Coatings, 15(11), 1308. https://doi.org/10.3390/coatings15111308