Abstract

Flattened bamboo (FB) exhibits pronounced structural and chemical heterogeneity between outer and inner layers and between nodes and internodes. These variations critically influence its interfacial performance with waterborne acrylic coatings. This study aimed to clarify how primer layer configuration and substrate heterogeneity jointly affect the coating adhesion, hardness, and abrasion resistance of FB. Three coating schemes—one primer and one topcoat (1P1T), two primers and one topcoat (2P1T), and three primers and one topcoat (3P1T)—were applied to four types of FB substrates defined by layer and structural position. Adhesion, pencil hardness, and abrasion resistance were measured according to GB/T standards, complemented by surface roughness, contact angle, XPS, and SEM analyses. Results showed that substrate heterogeneity dominated coating behavior. The parenchyma-rich inner-layer internodes, characterized by higher polarity (O/C = 0.296) and rougher texture, exhibited stronger adhesion and superior abrasion stability, whereas the fiber-dense outer layer nodes, with lower polarity (O/C = 0.262), showed weaker bonding. Increasing the number of primer layers improved film continuity only when the substrate microstructure allowed sufficient primer penetration. The combined findings indicate that coating adhesion and wear stability are primarily governed by substrate composition and surface polarity rather than by coating thickness. These results provide scientific and practical guidance for optimizing primer application and surface preparation in the industrial finishing of bamboo-based decorative panels, while also highlighting the environmental and economic advantages of waterborne coating optimization for sustainable bamboo manufacturing.

1. Introduction

Bamboo has long been recognized as a sustainable alternative to wood owing to its rapid growth, high strength-to-weight ratio, and renewability. With the increasing global demand for environmentally responsible materials, bamboo-based products have attracted significant attention in furniture manufacturing and interior decoration. However, the hollow and segmented structure of natural bamboo culms restricts utilization efficiency and complicates processing, thereby limiting the broader adoption of conventional laminated bamboo products. The raw material utilization of laminated bamboo panels is typically below 40%, leading to higher production costs and reduced market competitiveness [1]. Therefore, developing new processing approaches that enhance bamboo utilization efficiency is essential for advancing sustainable bamboo-based manufacturing.

Flattened bamboo (FB) has emerged as a promising solution to these limitations. Through thermal softening and flattening, cylindrical culms are reshaped into planar boards with improved dimensional stability and substantially higher yield [2]. Unlike laminated bamboo, FB retains the intrinsic anatomical heterogeneity of bamboo, comprising distinct outer and inner layers as well as node and internode regions, which enhances its decorative appeal but also introduces pronounced variations in surface chemistry and structure that critically influence coating performance [3]. Recent studies have demonstrated that optimizing waterborne coating formulations and interfacial regulation strategies can effectively improve the mechanical durability and environmental resistance of bamboo-based coatings [4]. With the continued industrial development of FB, a more specific understanding of its coating–substrate interactions is needed to enable consistent and high-quality finishing in furniture and decorative applications.

Surface finishing plays a vital role in determining the durability, functionality, and aesthetic quality of bamboo-based materials. However, coating procedures for FB are often directly adapted from conventional wood finishing systems and are therefore not optimized for its unique surface features. The outer epidermal layer of bamboo, composed of densely aligned fibers, waxy cuticles, and siliceous deposits such as phytoliths and residual inorganic minerals, exhibits low polarity and limited wettability, which hinder primer spreading and uniform film formation [5]. These siliceous deposits, mainly phytoliths and residual inorganic minerals naturally formed during bamboo growth, are partially retained after flattening, forming a thin mineralized layer that modifies surface energy and affects coating adhesion behavior [6]. In contrast, the inner layer, dominated by parenchyma cells, shows higher porosity and abundant hydrophilic groups, promoting coating absorption but often resulting in nonuniform film thickness and decreased mechanical integrity [7]. Structural heterogeneity is further accentuated at nodal regions, where irregular fiber orientation and compact vascular bundles disrupt coating continuity and reduce adhesion [8].

In recent years, research on waterborne coating systems has expanded considerably, focusing on formulation optimization and interfacial enhancement to improve adhesion and durability. Waterborne acrylic and polyurethane coatings with appropriate primer layers have been shown to yield superior surface hardness, adhesion, and moisture resistance [9]. In addition, plasma activation, chemical pretreatment, and nanoscale interfacial design have proven effective in enhancing adhesion by increasing surface polarity and minimizing interfacial voids in bamboo and wood composites [10]. Meanwhile, abrasion resistance has gained increasing attention as a key indicator of coating reliability, as mechanical durability is closely linked to adhesion stability and film continuity [11]. Collectively, these studies emphasize the growing importance of understanding interfacial compatibility between bamboo substrates and waterborne coatings to achieve both functional and aesthetic performance in industrial finishing.

Despite these advances, the coating behavior of flattened bamboo remains insufficiently understood. Most prior studies have focused on laminated or reconstituted bamboo [12], while the complex multi-layered structure of FB—with outer versus inner layers and node versus internode regions—has received limited attention [13]. Although surface modification techniques such as sanding, plasma treatment, and chemical activation have demonstrated moderate improvements in adhesion, they do not address how intrinsic substrate heterogeneity governs coating performance under practical finishing conditions [14]. Furthermore, the combined influence of primer configuration and substrate structure on adhesion and abrasion resistance has not been systematically investigated [15]. Existing research has largely emphasized surface wettability and chemical activation [12,16], yet few studies have elucidated the underlying mechanisms of interfacial bonding across structurally distinct regions of FB. As a result, it remains unclear whether primer layers function primarily as sealing agents or as true interfacial regulators when applied to substrates with variable polarity and porosity. These knowledge gaps constrain the optimization of coating processes and limit the stable application of FB in high-performance decorative materials.

Compared with the extensive research progress achieved in wood coating systems, systematic studies on bamboo finishing remain relatively limited and fragmented. For wood species such as poplar, birch, and oak, standardized waterborne acrylic and polyurethane coating processes have been established through optimization of sanding grit size, primer solid content, and coating thickness to achieve predictable adhesion and hardness levels [11,17]. These protocols enable consistent film formation in industrial furniture production. In contrast, bamboo-based substrates exhibit higher anisotropy and stronger surface energy gradients, leading to nonuniform wetting and stress accumulation during curing [10,18]. Consequently, bamboo finishing cannot simply replicate wood coating procedures; instead, process parameters—such as primer layer number, viscosity control, and spray deposition rate—must be specifically adjusted to accommodate bamboo’s unique surface morphology. From a practical perspective, establishing this substrate-specific finishing strategy is crucial for improving coating consistency and durability in bamboo furniture manufacturing.

To address these deficiencies, this study systematically investigates the interfacial adhesion and wear behavior of waterborne acrylic coatings on flattened bamboo. Both outer versus inner layers and node versus internode regions were examined to clarify how substrate heterogeneity and primer configuration jointly affect coating performance. Multi-scale characterization methods—including cross-cut adhesion tests, pencil hardness and abrasion resistance evaluations, X-ray photoelectron spectroscopy (XPS), and scanning electron microscopy (SEM)—were employed to correlate macroscopic coating properties with microstructural and chemical evidence. The overarching objective is to establish a substrate-dominant adhesion mechanism that elucidates how structural and chemical gradients dictate interfacial bonding, thereby providing a scientific basis for region-specific optimization of waterborne coating processes in bamboo-based decorative applications.

2. Materials and Methods

2.1. Materials

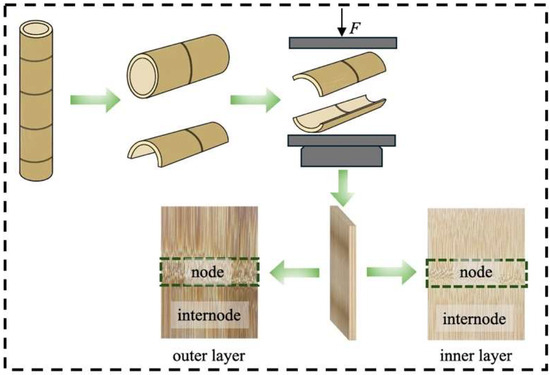

Flattened bamboo (FB) panels were supplied by Long Bamboo Technology Group Co., Ltd. (Nanping, China). The raw material was moso bamboo (Phyllostachys edulis), and the panels were manufactured using a high-temperature, notch-free flattening process. In this process, whole bamboo culms were first longitudinally split, then thermally softened at 175–180 °C, and finally hot-pressed into flat, dimensionally stable boards suitable for surface finishing. A schematic of the preparation and structural categorization of the FB panels is shown in Figure 1.

Figure 1.

Schematic diagram of the preparation of flattened bamboo (FB) panels and their structural categorization into outer layer–internode, outer layer–node, inner layer–internode, and inner layer–node regions.

The fabricated FB panels preserved the intrinsic anatomical heterogeneity of the bamboo culm, exhibiting two morphologically distinct surfaces. The outer layer originated from the original epidermal surface, while the inner layer was derived from the inner vascular tissue. To further reflect longitudinal variability, each layer was subdivided into node and internode regions. Accordingly, four types of FB substrates were defined for subsequent analyses: (1) outer layer–internode, (2) outer layer–node, (3) inner layer–internode, and (4) inner layer–node.

2.2. Coating Procedures

Four types of flattened bamboo (FB) specimens were prepared based on surface layer (outer and inner) and structural position (node and internode), resulting in outer layer–internode, outer layer–node, inner layer–internode, and inner layer–node. All specimens were cut to 400 mm × 80 mm × 2 mm, with five replicates per group, and conditioned at 20 ± 2 °C and 65 ± 5% relative humidity for 72 h prior to finishing. The outer layer was pre-sanded using 240# abrasive paper to remove surface wax residues, while the inner layer was left untreated to preserve its original surface condition. All samples were then uniformly sanded using 120# to 240# abrasive paper and cleaned with compressed air. A waterborne acrylic coating system was implemented via manual spray application. Three coating schemes were designed: one primer and one topcoat (1P1T), two primers and one topcoat (2P1T), and three primers and one topcoat (3P1T). An uncoated control group was included. Each layer was applied at 80 ± 5 g m−2 with a viscosity of 35 ± 2 s (DIN 4 cup), using a 1.3 mm nozzle at a travel speed of 30 ± 2 cm s−1 and a nozzle–surface distance of 25 ± 2 cm, perpendicular to the surface. These parameters were selected within the manufacturer’s recommended process window and verified through preliminary trials to ensure uniform film deposition and surface coverage.

In this study, both the primer and topcoat were commercial waterborne one-component acrylic coatings supplied by Chen Yang Water Paint (CYSQ, China). The primer (WB-FWZ4301) is a waterborne one-component styrene–acrylic clear primer formulated for wood and bamboo substrates, providing good wetting and adhesion to polar surfaces. The topcoat (WB-ZW51248) is a waterborne one-component acrylic copolymer clear coating with enhanced hardness and abrasion resistance, designed for furniture finishing applications. According to the manufacturer’s technical data sheets (TDS), the primer has a solids content of 30–32 wt % and a density of 1.01–1.05 g cm−3, whereas the topcoat has a solids content of 31–33 wt % and a density of 1.02–1.08 g cm−3 (Table 1). During the coating process, the wet film weight of each layer was controlled at approximately 80 ± 5 g m−2. Considering the applied wet mass and the manufacturer-provided solids and density data, the theoretical total dry-film thickness (DFT) of the three coating systems was estimated to be approximately 46–51 μm (1P1T), 69–77 μm (2P1T), and 92–102 μm (3P1T).

Table 1.

Technical specifications of the primer and topcoat coatings applied in this study.

Following each primer layer, specimens were dried at 30–50 °C (RH < 80%, airflow 0.5–1.0 m/s) and lightly sanded between coats. The final topcoat was cured under ambient conditions for at least 12 h. The coating process was identical for all groups except for the number of primer layers, ensuring consistent film formation and comparability.

2.3. Measurements and Characterization

2.3.1. Surface Roughness Analysis

Surface roughness was measured using a JB-4C contact profilometer (Shanghai, China) with a cutoff length of 0.8 mm and an evaluation length of 4.0 mm. Measurements were conducted on all four representative regions of the flattened bamboo, including outer–node, outer–internode, inner–node, and inner–internode surfaces, both parallel and perpendicular to the grain direction to account for anisotropic surface morphology. All roughness data refer to the uncoated (bare) bamboo surfaces prior to finishing. Four roughness parameters were recorded: Ra (arithmetic mean height), Rq (root mean square roughness), Rz (ten-point height), and Ry (maximum peak-to-valley height). At each location, three replicates were collected, and the mean was used for analysis. The instrument was calibrated prior to each testing session. The effects of coating process, surface type, and structural position on roughness were statistically analyzed using one-way analysis of variance (ANOVA).

2.3.2. Wettability and Contact Angle Measurement

Static contact angles were measured with a contact angle analyzer (Model: FCA2000A, Shanghai Aifeisi Precision Instrument Co., Ltd., Shanghai, China) using ultrapure water as the probe liquid. Prior to testing, sample surfaces were cleaned with lint-free cloths to remove any contaminants. Measurements were performed on all four representative regions of flattened bamboo, including outer–node, outer–internode, inner–node, and inner–internode surfaces, to ensure consistency with the surface roughness analysis. A 4 μL water droplet was dispensed onto the surface using a micro syringe, and the contact angle was recorded after 5 s using a high-speed camera. Since contact angle measurements are not direction-sensitive, only the longitudinal (grain-parallel) direction was tested for consistency. Time-dependent angles were also tracked up to 30 s to obtain stabilized values. Each group was measured at five random locations, and the results were reported as mean ± standard deviation. Notably, sanding of the outer layer led to a significant reduction in contact angle, indicating improved surface wettability.

2.3.3. Coating Adhesion and Hardness Evaluation

Coating adhesion was evaluated according to GB/T 4893.4-2023 using a standard cross-cut tester [19]. A 6 × 6 grid with 2 mm spacing was cut over a 10 mm × 10 mm area, ensuring complete penetration through the coating layer to the bamboo substrate. The spacing selection followed the standard for soft substrates with coating thicknesses below 60 μm, as the final dry film thickness of the topcoat was approximately 40–50 μm, measured using a coating thickness gauge. After cutting, the grid area was gently brushed with a soft brush to remove loose coating fragments, and the adhesion performance was visually assessed in accordance with GB/T 4893.4-2023 [19]. Evaluation was performed based on the 0–5 rating scale defined in the standard, where 0 represents no peeling or detachment and 5 indicates complete flaking within the lattice area. Three regions were tested on each specimen, and the arithmetic mean (n = 3) was reported as the final adhesion grade.

The surface hardness of the coating films was evaluated in accordance with GB/T 6739-2022 [20]. Mitsubishi pencils ranging from 9B to 9H were used at an angle of 45° under a constant applied load of 7.5 N. Prior to each measurement, the pencil tip was freshly abraded, and the test surface was cleaned to remove debris. The hardness grade was defined as the hardest pencil that did not leave a permanent mark or scratch on the coating surface. Three measurements were performed for each specimen, and the mean value was reported as the representative hardness result.

2.3.4. Surface Chemistry and Microstructure Characterization

X-ray photoelectron spectroscopy (XPS) was employed to examine the surface elemental composition and chemical states. Specimens (5 mm × 5 mm × 2 mm) were analyzed under high vacuum using monochromatic Al Kα radiation. The C 1s peak at 284.8 eV served as the calibration reference, and peak fitting was performed using XPS Peak 4.1 software.

Scanning electron microscopy (SEM) was utilized to observe the interfacial morphology between the coating and bamboo substrate. Prior to imaging, samples were sputter-coated with a thin gold layer to enhance conductivity. Surface features including film uniformity, wetting behavior, and micro-defects were examined. Three representative regions were imaged for each sample to ensure result reliability.

2.3.5. Abrasion Resistance Test

Abrasion resistance was tested following GB/T 4893.8-2023 using a CS1-270 abrasion tester of Taber-type configuration (Chengsi Intelligent Technology Co., Ltd., Shanghai, China). Square specimens (100 mm × 100 mm) were conditioned at 20 ± 2 °C and 65 ± 5% RH for 72 h before testing [21]. A total load of 1000 g (500 g per wheel) was applied with CS-10 abrasive wheels rotating at 60 ± 2 rpm. Each coating condition was tested in triplicate, and the results are presented as mean ± standard deviation (n = 3) to ensure reproducibility. The wheels were resurfaced with standard S-11 paper prior to each run. Mass loss was recorded after N = 20 and N = 100 cycles, corresponding to the initial and stabilized wear stages defined by the standard. The use of these two predefined cycle numbers enabled consistent comparison and ensured reproducibility among different coating systems. The cumulative mass loss (), stage-specific wear rates (, ), and acceleration ratio (A) were calculated using Equation (1):

where ,

, and

denote the specimen masses before abrasion and after 20 and 100 cycles, respectively.

represents the total mass loss,

and

are the mean wear rates at the two stages, and A indicates wear stability, where values close to 1 reflect uniform wear. After testing, surface photographs were taken to document whitening and film damage, and abrasion grades were assigned according to the GB/T 4893.8-2023 rating system [21].

2.4. Statistical Analysis

All statistical analyses were performed using SPSS 26.0 (IBM, Corp., Armonk, NY, USA). Normality of residuals was tested with the Shapiro–Wilk test, and homogeneity of variance was examined using Levene’s test. A three-way ANOVA with number of primer layers, structural position, and material layer as factors was conducted to evaluate their effects on pencil hardness. Post hoc multiple comparisons were carried out using the LSD test when main effects were significant. Statistical significance was defined at p < 0.05. Adhesion grades, defined on an ordinal 0–5 scale according to GB/T 4893.4-2023, were summarized descriptively; no factorial ANOVA was performed for adhesion due to the categorical nature of the data [19]. The multi-scale experimental design—combining macroscopic adhesion and hardness tests with microstructural (SEM) and surface chemical (XPS) analyses—was developed to correlate physical properties with interfacial mechanisms rather than to perform isolated surface imaging.

3. Results and Discussion

3.1. Surface Morphology and Chemical Composition Characteristics

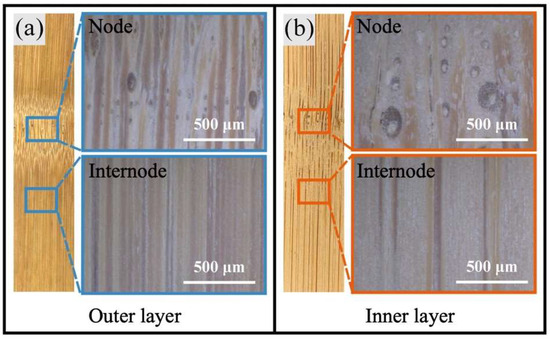

Optical microscopy (Figure 2) revealed clear anatomical contrasts between the outer and inner layers of flattened bamboo. The outer layer, particularly at nodes, is dominated by densely aligned fibers with thick cell walls, whereas the inner layer contains abundant parenchyma cells and vessels with larger lumina and looser distribution. Such structural heterogeneity implies intrinsic compositional divergence: fibers are rich in crystalline cellulose and lignin, while parenchyma cells contain higher levels of hemicellulose and starch [22,23]. This fiber–parenchyma differentiation underlies the observed surface chemical disparities [24].

Figure 2.

Optical microscopy images of flattened bamboo surfaces before coating: (a) Outer layer; (b) Inner layer.

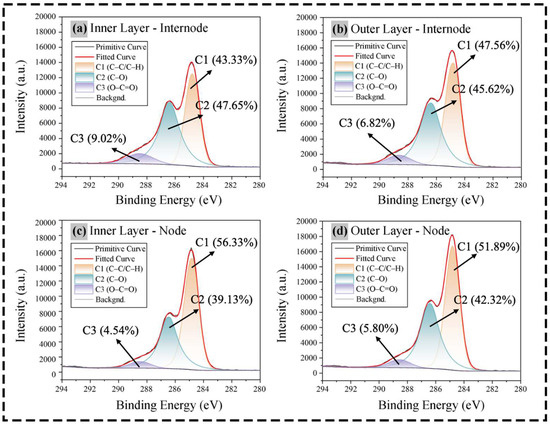

XPS analysis confirmed the correlation between cellular composition and surface chemistry. The C 1s spectra (Figure 3) were deconvoluted into three principal components. C1, centered at 284.8 eV, corresponds to C–C and C–H bonds derived from lignin aromatics and cellulose backbones. C2, located at 286.3 eV, represents C–O bonds primarily associated with hemicellulose and amorphous cellulose. C3, detected at 288.5 eV, is attributed to O–C=O species originating from acetyl groups in hemicellulose and carboxyl functionalities in lignin. These peak assignments are consistent with previous reports on lignocellulosic materials [25]. Among the four surface types, the inner layer–internode exhibited the highest O/C ratio (0.296), with C2 and C3 accounting for 47.65% and 9.02% of the C 1s spectrum, respectively, as summarized in Table 2. This is consistent with the hemicellulose-rich parenchyma cells, whose acetyl side chains are prone to deacetylation, producing additional hydroxyl and carboxyl groups. In contrast, the outer layer–node displayed the lowest O/C ratio (0.262) and the highest proportion of C1 (51.89%) (Table 1), reflecting its fiber-dominated composition with high cellulose crystallinity and lignin content, which favors hydrocarbon-rich and nonpolar domains.

Figure 3.

High-resolution C 1s XPS spectra of uncoated flattened bamboo surfaces: (a) Inner layer–internode; (b) Outer layer–internode; (c) Inner layer–node; (d) Outer layer–node.

Table 2.

Surface atomic composition and O/C ratio of different bamboo sites.

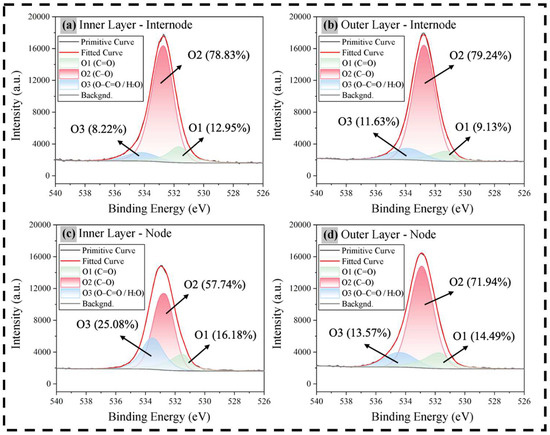

The O 1s spectra (Figure 4) corroborated these findings and were resolved into three components. O1 at 531.1 eV corresponds to carbonyl groups (C=O), O2 at 532.5 eV represents C–O bonds in cellulose and hemicellulose, and O3 at 533.8 eV is associated with carboxyl functionalities and adsorbed water molecules. The inner layer–node exhibited the highest O3 contribution (25.08%), indicating stronger hydration and higher chemical activity, whereas the outer layer–node contained only 13.57%. Collectively, the O/C ratios and the polarity index (PI = (C2 + C3)/C1) revealed a consistent polarity gradient: inner layer–internode > outer layer–internode ≈ inner layer–node > outer layer–node. The detection of Si 2p signals (Table 2) confirmed the presence of trace silica species naturally distributed on the bamboo surface. This element is most likely derived from epidermal silica deposition and minor inorganic residues introduced during the flattening process. In this study, the siliceous signal was more pronounced on the outer layer, consistent with its lower O/C ratio and reduced polarity. The occurrence of silica is considered to partially shield hydroxyl and carboxyl functionalities, thereby constraining hydrogen-bond formation and decreasing surface energy [26,27]. Such an effect provides a reasonable explanation for the reduced wettability and adhesion observed on the outer surface. Comparable phenomena have been documented for silica-modified lignocellulosic materials, in which SiO2-based layers generate amorphous, non-polar films that limit the availability of polar sites and suppress coating wetting [28].

Figure 4.

High-resolution O 1s XPS spectra of uncoated flattened bamboo surfaces: (a) Inner layer–internode; (b) Outer layer–internode; (c) Inner layer–node; (d) Outer layer–node.

Furthermore, correlations between diminished surface polarity and weakened coating adhesion have been consistently reported for both wood and bamboo substrates [29]. These collective findings substantiate the interpretation that even trace amounts of silica on the bamboo epidermis contribute to the outer layer’s hydrophobic and low-energy characteristics, thereby influencing coating adhesion behavior.

Overall, the combined microscopy and XPS results demonstrate that the chemical distinction between fibers and parenchyma cells governs the spatial distribution of surface polarity. Parenchyma-rich regions provide abundant polar oxygenated groups and hydration capacity, thereby offering a chemically favorable interface for coating adhesion, while fiber-dense regions remain dominated by nonpolar structures, constituting critical weak points in finishing performance. The consistent O/C and polarity index (PI) gradients across layers and structural positions, together with corresponding wettability trends, suggest spatially stable polarity distributions relevant to coating adhesion.

3.2. Surface Roughness and Wettability Analysis

Given the pronounced differences in fiber–parenchyma composition and surface polarity between the outer and inner bamboo layers, it is anticipated that such intrinsic heterogeneity is expected to manifest in surface roughness and wettability. These surface attributes serve as critical precursors to coating adhesion, as they directly influence both the mechanical interlocking of the substrate and the spreading behavior of waterborne coatings.

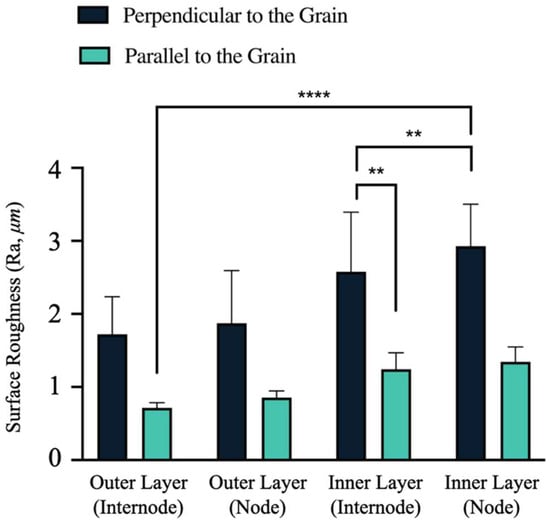

Surface roughness measurements (Figure 5) revealed significant differences between inner and outer bamboo layers across nodes and internodes. The inner layer–internode showed the highest Ra (3.0 μm in the perpendicular direction), while the outer layer–node was lowest (2.0 μm, p < 0.0001). The inner layer also displayed pronounced anisotropy, with perpendicular Ra consistently exceeding parallel values [30]. These contrasts persisted despite identical sanding, indicating that cellular composition, rather than surface treatment, governs roughness [31]. Parenchyma-rich inner regions are mechanically weaker, with middle lamella stronger than secondary walls, causing wall rupture and lumen exposure under abrasion, thus producing irregular textures. Fiber-dominated outer layers, with higher cellulose crystallinity and lignin, fail mainly at lamella interfaces, yielding smoother surfaces [32]. From a finishing perspective, rougher parenchyma-dominated internodes enlarge effective surface area and anchor primer infiltration, enhancing mechanical interlocking, whereas smoother fiber-rich nodes restrict penetration and weaken adhesion.

Figure 5.

Surface roughness (Ra) of uncoated flattened bamboo samples measured in parallel and perpendicular grain directions for the inner and outer layers at node and internode regions. Significance levels: ** p < 0.01, **** p < 0.0001.

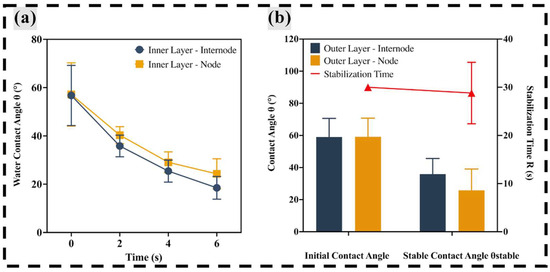

Dynamic contact angle tests (Figure 6) further demonstrated substrate-dependent wettability. The inner layer–internode showed rapid droplet absorption, with the initial angle (56.75° ± 12.46°) declining to 18.50° ± 4.72° within 6 s, while the outer layer–internode stabilized at a higher value (35.87° ± 9.73°) after 30 s, indicating a lower degree of wetting compared with the inner surface. These behaviors stem from both structure and chemistry: parenchyma cells are rich in hemicellulose and acetylated side chains, which undergo deacetylation to generate hydroxyl and carboxyl groups, enhancing polarity and capillary action. In contrast, fiber-rich regions contain abundant lignin and crystalline cellulose, dominated by nonpolar C–C/C–H bonds, resisting wetting. Higher roughness in parenchyma internodes further amplifies liquid spreading, while dense fiber bundles at nodes limit diffusion. From a coating standpoint, strong wettability in inner internodes promotes uniform spreading and reduces voids, whereas the comparatively weaker wetting of outer surfaces may hinder primer infiltration and increases interfacial defects [33].

Figure 6.

Contact angle measurements of uncoated flattened bamboo surfaces. (a) Inner layer–internode and inner layer–node regions, showing time-dependent decline within the initial 6 s; (b) Outer layer–internode and outer layer–node regions, showing initial and stabilized values.

In summary, roughness and wettability follow a consistent gradient: inner > outer; internode > node. Such gradients in surface structure and polarity provide the foundation for the coating performance differences discussed in the following section.

3.3. Coating Performance and Influencing Factors

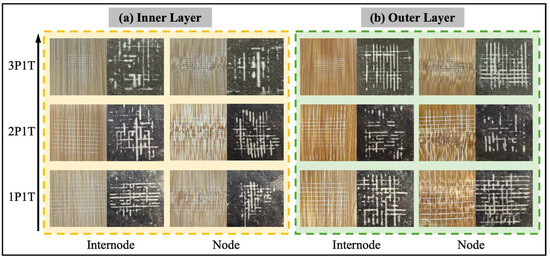

The performance of waterborne acrylic coatings on flattened bamboo exhibited pronounced structural variation in both adhesion and hardness (Table 3, Figure 7). Internode regions consistently outperformed nodes owing to their abundance of parenchyma cells and vessels. These features increase surface polarity and roughness, facilitating primer penetration and interfacial anchoring [17]. In contrast, nodal regions, characterized by compact vascular bundles, closed lumina, and lower polarity, restricted wetting and resin diffusion [17,34]. Adhesion was evaluated according to the cross-cut test specified in GB/T 4893.4-2023, and the corresponding surface photographs shown in Figure 7 represent macroscopic regions (approximately 20 × 20 mm) captured after testing [19]. For example, the inner layer–internode maintained adhesion grade 1 under the 1P1T process and improved to grade 0 under 3P1T, whereas the inner layer–node improved only marginally from grade 2 to grade 1. Outer layer–internodes remained stable at grade 1 across all primer schemes, indicating that the dense fiber-dominated, low-porosity structure limited further improvement by additional primers. Quantitatively, the adhesion grades ranged between 0 and 2 across all specimens, reflecting moderate variations among different structural regions. The inner–internode region showed a noticeable improvement from grade 1 under 1P1T to grade 0 under 3P1T, indicating enhanced coating–substrate bonding with additional primer application. By contrast, the outer–node region remained consistently at grade 1 regardless of primer configuration, suggesting limited responsiveness to further priming. Overall, these results confirm that primer efficiency is governed by substrate receptivity and microstructural openness rather than by the mere increase in coating thickness.

Table 3.

Adhesion grade and pencil hardness of waterborne acrylic coatings on flattened bamboo under different layer types, structural positions, and primer configurations.

Figure 7.

Macroscopic surface appearance and cross-cut adhesion results of waterborne acrylic coatings on flattened bamboo under different coating schemes: (a) Inner layer samples; (b) Outer layer samples. A grid spacing of 2 mm serves as the scale reference for the cross-cut area.

Hardness showed an opposite trend. Outer layer specimens consistently achieved higher values (HB) compared to inner layer specimens (B or 2B), attributed to their greater fiber density and higher silica content [35]. In certain cases, multilayer priming improved film continuity and density, thereby enhancing hardness—for instance, inner layer–nodes increased from 2B under 1P1T to B under 3P1T. Three-way ANOVA confirmed this trend: hardness differed significantly between outer and inner layers (p_layer = 0.011), whereas the number of primer layers (p_primer = 1.000) and structural position (p_position = 0.272) showed no significant main effects, and all interaction terms were non-significant (p > 0.5). This indicates that hardness is predominantly controlled by material composition—particularly fiber content and inorganic constituents—rather than by primer configuration or nodal location.

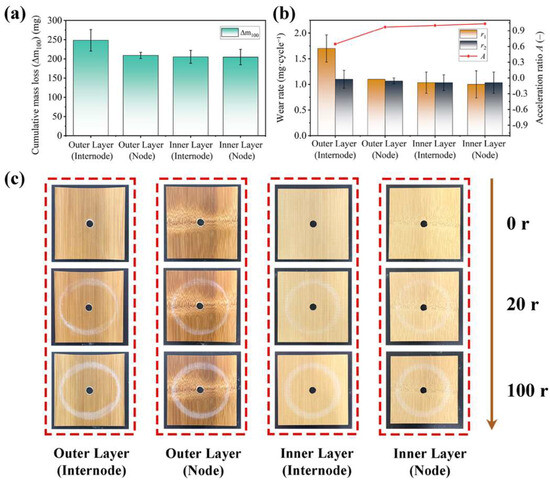

To further evaluate the surface durability of the coatings, abrasion resistance tests were conducted under a total load of 1000 g for up to N = 100 abrasion cycles (Figure 8). The abrasion resistance was evaluated at N = 20 and N = 100, corresponding to the early and stabilized wear stages, respectively, as preliminary observations revealed the onset of visible film whitening at around N = 20 under this load. The cumulative mass loss () and stage-specific wear rates (, corresponding to 0–20 and 20–100 cycles, respectively) were calculated to describe both overall and progressive wear behavior. As shown in Figure 8a, the outer layer–internode samples exhibited the highest cumulative mass loss (248.33 ± 28.02 mg), indicating relatively poor abrasion resistance. For comparison, the inner–internode surface recorded a of 204.67 ± 17.35 mg, which was approximately 18% lower than that of the outer–internode region, demonstrating that stronger interfacial adhesion reduced progressive material loss. In contrast, both inner layer regions showed lower

values (205.33 ± 18.12 mg and 204.67 ± 17.35 mg), suggesting more stable coating–substrate interfaces due to enhanced adhesion and film flexibility. The wear-rate analysis (Figure 8b) revealed a distinct two-stage trend:

was highest for the outer layer–internode (1.70 ± 0.26 mg·cycle−1), while the inner layer–node exhibited the lowest

(1.00 ± 0.26 mg·cycle−1). In the subsequent stage,

decreased and stabilized (1.03–1.10 mg·cycle−1), reflecting the formation of a compact residual film. The calculated acceleration ratio (A =

/) further supported this finding—A < 1 for the outer layer–internode (0.65) indicated a decelerating wear process, while A ≈ 1 for the inner layer regions denoted steady, uniform wear. Combined with adhesion results (Table 3), these findings confirmed that stronger coating–substrate bonding promoted gradual and uniform material removal, whereas weaker adhesion resulted in localized peeling and rapid delamination.

Figure 8.

Abrasion performance of waterborne acrylic coatings on flattened bamboo under the one primer and one topcoat (1P1T) process and a total load of 1000 g. (a) Cumulative mass loss after 100 abrasion cycles; (b) Stage-specific wear rates and acceleration ratio (A); (c) Representative photographs of worn surfaces at 0, 20, and 100 cycles.

Surface photographs after 0, 20, and 100 N (Figure 8c) visually corroborated these results. All specimens exhibited ring-like whitening, but the extent varied with substrate structure. The outer layer–internode region showed early whitening and partial fiber exposure by 20 N, which intensified after 100 N, while inner layer coatings displayed only mild whitening and film thinning without extensive peeling, consistent with their lower

values and stable A ≈ 1. According to GB/T 4893.8-2023, these corresponded to level 2–3 surface damage [21]. Overall, the results demonstrate that the improved interfacial adhesion characteristic of inner layer surfaces effectively enhances coating durability and abrasion stability.

Collectively, the coating performance of flattened bamboo was governed by the interplay between substrate structure and coating configuration, where inner–outer and node–internode heterogeneity produced distinct responses in adhesion, hardness, and abrasion resistance. Outer layer regions, dominated by densely aligned fibers and lower surface polarity, exhibited higher hardness yet weaker interfacial bonding and earlier film whitening during abrasion. In contrast, inner layer regions with parenchyma-rich surfaces promoted primer penetration and adhesion strength, resulting in more stable wear behavior and reduced mass loss. These findings indicate that the macroscopic coating performance reflects the underlying structural and chemical heterogeneity of flattened bamboo—where fiber-rich, nonpolar zones restrict resin diffusion, while parenchyma-rich areas provide favorable sites for interfacial anchoring. At the panel level, these trends suggest that process windows can be set by layer/position grading to accommodate culm-to-culm variability in industrial production. These results suggest that primer optimization should be substrate-specific, with additional primers applied selectively to low-energy, fiber-dense regions rather than uniformly across all surfaces to improve coating efficiency and performance consistency. Therefore, the following section focuses on the microstructural and chemical evidence that elucidates the interfacial bonding mechanisms underlying these observed behaviors.

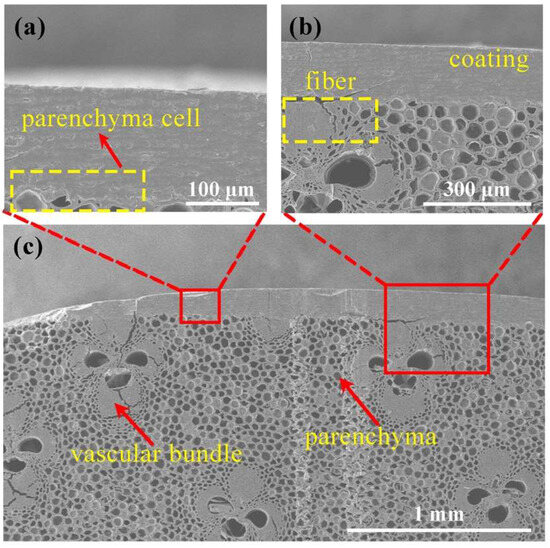

3.4. Coating Adhesion Characteristics Revealed by SEM

Cross-sectional SEM observations (Figure 9) reveal how the heterogeneous cellular architecture of flattened bamboo strongly influences coating–substrate interfacial behavior. In the inner layer–internode treated with the 3P1T process, primer infiltration into parenchyma lumina and vessel pits was clearly visible (Figure 9a), producing close interfacial contact and effective anchoring with adjacent fibers. The continuous film across both parenchyma-rich and fiber-dense domains (Figure 9b) indicates that the porous microstructure and open lumina provided sufficient pathways for primer penetration, reducing voids and interfacial discontinuities. In contrast, outer layer–node regions (Figure 9c) exhibited incomplete coverage and localized separation between film and substrate, attributable to compact vascular bundles and the dominance of thick-walled fibers that restrict primer entry [36].These morphological distinctions are consistent with the chemical and surface property analyses. Inner layer–internodes, enriched in thin-walled parenchyma cells with higher O/C ratios and abundant polar groups, combine chemical receptivity with structural openness, which jointly favor wetting and interfacial continuity. Conversely, fiber-dominated outer nodes, characterized by lower polarity and reduced porosity, restrict liquid spreading and mechanical interlocking. The SEM evidence thus reinforces that adhesion enhancement from multilayer priming is effective only when substrate microstructure permits sufficient primer accommodation [37].

Figure 9.

SEM cross-sections of the inner layer–internode coated with the 3P1T process: (a) primer penetration into parenchyma lumina; (b) coating–fiber interface; (c) overall morphology showing vascular bundles and parenchyma distribution.

Collectively, the SEM findings demonstrate that coating adhesion on flattened bamboo is not universally enhanced by increasing primer layers, but rather depends on the substrate’s receptivity and structural openness [38,39]. In fiber-dense outer layers, additional primers offer limited benefit, whereas in parenchyma-rich regions they effectively reinforce interfacial bonding through improved wetting and anchoring. Regions where parenchyma cells predominate offer porous, chemically active interfaces conducive to robust bonding, whereas fiber-dense domains with compact bundles remain intrinsic weak points that limit adhesion stability. These observations align with the macroscopic adhesion trends, confirming that primer configuration alone cannot compensate for inherent substrate heterogeneity. This mechanism highlights the synergistic effects of chemical polarity and microstructural porosity in defining interfacial bonding stability, representing a conceptual advance over empirical coating optimization approaches.

Despite these advances, this study was limited to a single coating system (waterborne acrylic), one bamboo species (Phyllostachys edulis), and a brushing-based application method, which may not fully represent other coating–substrate interactions. Future research should extend to alternative waterborne systems such as polyurethane or hybrid coatings, and investigate interfacial enhancement strategies including coupling agents, plasma activation, or nano-scale surface modification. Such work would provide a more comprehensive understanding of coating–substrate compatibility and facilitate the establishment of adaptive finishing protocols for diverse bamboo-based materials.

From an environmental and economic perspective, the optimized primer layer configuration proposed in this study contributes to both sustainability and cost efficiency in industrial finishing. Reducing unnecessary primer layers lowers material consumption and energy demand during coating and drying, while maintaining adequate adhesion and abrasion resistance. Moreover, the exclusive use of waterborne acrylic coatings minimizes volatile organic compound (VOC) emissions and aligns with the global trend toward low-carbon and eco-friendly manufacturing in the furniture industry. These advantages highlight the dual technical and environmental benefits of process optimization for flattened bamboo panels.

4. Conclusions

The interfacial performance of waterborne acrylic coatings on flattened bamboo is primarily governed by the substrate’s structural and chemical heterogeneity, while the number of primer layers serves as a secondary modifying factor. The principal conclusions are as follows:

- (1)

- Parenchyma-rich regions (high O/C ratio, rough) promote strong adhesion and superior abrasion resistance, whereas fiber-dominated regions (low O/C ratio, smooth) constitute inherent weak points for interfacial failure.

- (2)

- Multilayer priming enhances film integrity and wear stability in the porous, high-polarity inner layer but has limited efficacy on the dense, low-polarity outer layer. The higher pencil hardness observed on outer-layer surfaces is mainly attributed to their underlying fiber-dense composition.

- (3)

- SEM analysis confirms that robust adhesion relies on primer infiltration and mechanical interlocking within parenchyma lumina, a mechanism impeded by compact fiber bundles.

Overall, coating adhesion performance was governed by the combined effects of cellular architecture, surface polarity, and primer–substrate interaction, highlighting a substrate-dominant adhesion mechanism that provides a practical basis for region-specific finishing optimization in bamboo-based decorative applications. This study was limited to a single waterborne acrylic system, one bamboo species (Phyllostachys edulis), and a brushing-based method. Future research should focus on interfacial enhancement through coupling agents or plasma treatment to improve coating–substrate compatibility.

Author Contributions

Conceptualization, Y.Y. and W.X.; methodology, Y.Y.; investigation, Y.Y.; data curation, Y.Y.; formal analysis, H.C.; validation, H.C. and W.X.; writing—original draft preparation, Y.Y.; writing—review and editing, H.C., S.W. and W.X.; supervision, W.X.; project administration, W.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Qing Lan Project of Jiangsu Province, China; the International Cooperation Joint Laboratory for Production, Education, Research and Application of Ecological Health Care on Home Furnishing; and the Ministry of Education Industry–University Cooperation Collaborative Education Project, grant number 202101148004.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to institutional restrictions.

Acknowledgments

We thank the staff of the Advanced Analysis and Testing Center of Nanjing Forestry University for their assistance with instrument testing. We are also grateful to the editors and anonymous reviewers for their valuable time and constructive comments, which have significantly improved the quality of this manuscript.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Yuan, T.; Wang, X.; Liu, X.; Lou, Z.; Mao, S.; Li, Y. Bamboo Flattening Technology Ebables Efficient and Value-Added Utilization of Bamboo in the Manufacture of Furniture and Engineered Composites. Compos. Part B Eng. 2022, 242, 110097. [Google Scholar] [CrossRef]

- Ma, L.; Zhao, Y.; Zhang, T.; Yuan, T.; Wang, X.; Li, Y. Functionalized Flattened Bamboo Board: In-Situ Immersion Assembly of Flame-Retardant, Waterproof and Anti-Mold Composite Coatings. Int. J. Biol. Macromol. 2024, 278, 134881. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Xie, X.; Wang, X.; Mao, S.; Li, Y. In Situ Retention of Lignin-Rich Bamboo Green Effectively Improves the Surface Properties of Flattened Bamboo. Int. J. Biol. Macromol. 2024, 264, 130411. [Google Scholar] [CrossRef] [PubMed]

- Mucci, V.L.; Hormaiztegui, M.E.V.; Amalvy, J.I.; Aranguren, M.I. Formulation, Structure and Properties of Waterborne Polyurethane Coatings: A Brief Review. J. Adhes. Sci. Technol. 2024, 38, 489–516. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, Y.; Li, J.; Feng, Y.; Zhang, J.; Yu, H.; Zhuang, X. Improved Wettability and Dimensional Stability of Bamboo Timber by Coating Graphene/Silica Composites. Int. J. Polym. Sci. 2021, 2021, 1–10. [Google Scholar] [CrossRef]

- Duan, S.; Li, M.; Xie, D.; Xu, R.; Wang, S.; Wang, C.; Zhan, H. Silicon Deposition and Phytolith Morphological Variation in Culm Sheaths of Dendrocalamus brandisii at Different Growth Stages. Plants 2025, 14, 841. [Google Scholar] [CrossRef]

- Choi, Y.-H.; Kim, B.; Sim, J.-Y.; Kim, K.-J.; Park, S.-Y. Coating Performance Enhancement of Moso Bamboo (Phyllostachys edulis) via Hand Sanding: Effects of Surface Dewaxing and Fibrillation. BioRes 2025, 20, 9625–9640. [Google Scholar] [CrossRef]

- Zhao, Y.; Ma, L.; Xie, X.; Yuan, T.; Yu, X.; Chen, L.; Li, Y. Mechanisms of Two Types of Flattening Treatments on the Bonding Characteristics of Bamboo and the Effect of Laminate Design on Flexural Properties. Constr. Build. Mater. 2023, 408, 133673. [Google Scholar] [CrossRef]

- Rajan, R.; Zulkifli, R.; Mat Tahir, M.F.; Ude, A.U. Surface Wettability of Gigantochloa scortechinii Bamboo Fibers: Effects of Heat Treatment and Epoxy Coating in Seawater. J. Nat. Fibers 2024, 21, 2400532. [Google Scholar] [CrossRef]

- Alcantara, B.J.; Ilasin, M.D.; Gilos, M.N.R.; Wada, M.; Vasquez, M.R. Enhancing Polyvinyl Acetate Adhesion via Atmospheric Pressure Plasma Treatment of Bamboo (Bambusa spinosa Roxb.). Adv. Bamboo Sci. 2025, 13, 100200. [Google Scholar] [CrossRef]

- Liu, C.; Xu, W. Effect of Coating Process on Properties of Two-Component Waterborne Polyurethane Coatings for Wood. Coatings 2022, 12, 1857. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, Y.; Lu, Y.; Yu, W.; Wang, S. Effects of Heat Treatment on Surface Physicochemical Properties and Sorption Behavior of Bamboo (Phyllostachys edulis). Constr. Build. Mater. 2021, 282, 122683. [Google Scholar] [CrossRef]

- Wang, Q.; Han, H.; Lou, Z.; Han, X.; Wang, X.; Li, Y. Surface Property Enhancement of Bamboo by Inorganic Materials Coating with Extended Functional Applications. Compos. Part A Appl. Sci. Manuf. 2022, 155, 106848. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, Y.; Yang, X.; Ji, H.; Zhong, T.; Wang, G. A Comparative Study of the Microstructure and Water Permeability between Flattened Bamboo and Bamboo Culm. J. Wood Sci. 2019, 65, 64. [Google Scholar] [CrossRef]

- Zheng, Z.; Yan, N.; Lou, Z.; Jiang, X.; Zhang, X.; Chen, S.; Xu, R.; Liu, C.; Xu, L. Modification and Application of Bamboo-Based Materials: A Review—Part I: Modification Methods and Mechanisms. Forests 2023, 14, 2219. [Google Scholar] [CrossRef]

- Xie, X.; Yuan, T.; Yao, Y.; Li, G.; Li, Y.; Wang, X. Phytic Acid-Based Hybrid Complexes for Improving the Interfacial Property and Mildew-Resistance of Heat-Treated Bamboo. Colloids Surf. A Physicochem. Eng. Asp. 2023, 659, 130749. [Google Scholar] [CrossRef]

- Zhou, X.; Guo, H.; Wang, S.; Yu, L.; Li, H.; Yang, Z. Performance Testing of Modified Waterborne Polyurethane Coating Applied on Laminated Bamboo. Bioresources 2022, 17, 6191–6202. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, Y.; Yuan, S.; Zhang, J.; Li, Q.; Wang, H. Drying Process of Waterborne Paint Film on Bamboo Laminated Lumber for Furniture. Polymers 2023, 15, 1288. [Google Scholar] [CrossRef]

- GB/T 4893.4-2023; Physical and Chemical Property Test of Furniture Surface Paint Film Part 4: Adhesion Cross-Cutting Method. Standardization Administration of the People’s Republic of China: Beijing, China, 2023.

- GB/T 6739-2022; Determination of Paint Film Hardness by the Pencil Method for Color Paints and Varnishes. Standardization Administration of the People’s Republic of China: Beijing, China, 2022.

- GB/T 4893.8-2023; Physical and Chemical Property Test of Furniture Surface Paint Film Part 8: Determination of Resistance to Abrasion. Standardization Administration of the People’s Republic of China: Beijing, China, 2023.

- Chen, H.; Wu, J.; Shi, J.; Zhang, W.; Wang, H. Effect of Alkali Treatment on Microstructure and Thermal Stability of Parenchyma Cell Compared with Bamboo Fiber. Ind. Crops Prod. 2021, 164, 113380. [Google Scholar] [CrossRef]

- Zhang, W.; Tian, G.; Polle, A.; Janz, D.; Euring, D.; Yue, X.; Zhao, H.; Fei, B.; Jiang, Z. Comparative Characterization of Ethanol Organosolv Lignin Polymer from Bamboo Green, Timber and Yellow. Wood Sci. Technol. 2018, 52, 1331–1341. [Google Scholar] [CrossRef]

- Rocky, B.P.; Thompson, A.J. Analyses of the Chemical Compositions and Structures of Four Bamboo Species and Their Natural Fibers by Infrared, Laser, and X-Ray Spectroscopies. Fibers Polym. 2021, 22, 916–927. [Google Scholar] [CrossRef]

- Li, J.; Lian, C.; Wu, J.; Zhong, T.; Zou, Y.; Chen, H. Morphology, Chemical Composition and Thermal Stability of Bamboo Parenchyma Cells and Fibers Isolated by Different Methods. Cellulose 2023, 30, 2007–2021. [Google Scholar] [CrossRef]

- Mitani, A.; Kamperidou, V.; Terzopoulou, P. Surface Treatment of Oak Wood with Silica Dioxide Nanoparticles and Paraloid B72. Forests 2024, 15, 1842. [Google Scholar] [CrossRef]

- Jian, Y.; Xu, T.; Hess, D.W.; Tang, W.; Chai, X.; Zhang, L.; Xu, K.; Guo, Z.; Wan, H.; Xie, L. Efficient Synthesis of Durable Superhydrophobic SiO2@PFDMS Coatings on Bamboo by Liquid Deposition. Ind. Crops Prod. 2024, 219, 119078. [Google Scholar] [CrossRef]

- Chang, H.; Tu, K.; Wang, X.; Liu, J. Facile Preparation of Stable Superhydrophobic Coatings on Wood Surfaces Using Silica-Polymer Nanocomposites. Bioresources 2015, 10, 2585–2596. [Google Scholar] [CrossRef]

- Yu, Q.; Pan, X.; Yang, Z.; Zhang, L.; Cao, J. Effects of the Surface Roughness of Six Wood Species for Furniture Production on the Wettability and Bonding Quality of Coating. Forests 2023, 14, 996. [Google Scholar] [CrossRef]

- Du, J.; Yang, K.-L.; Yuan, Z.-Q.; Li, X.-Y.; Liu, S.-J.; Li, C.-C.; Meng, S. Preparation of a Robust and Stable Superhydrophobic Coating with Self-Cleaning and Mold Resistance Properties on Natural Bamboo Substrate. Constr. Build. Mater. 2024, 411, 134454. [Google Scholar] [CrossRef]

- He, L.; Chen, L.; Shao, H.; Qi, J.; Jiang, Y.; Xiao, H.; Chen, Y.; Huang, X.; Xie, J. Microstructure and Physicochemical Properties of the Anisotropic Moso Bamboo (Phyllostachys pubescens) Surface. Eur. J. Wood Prod. 2022, 80, 277–288. [Google Scholar] [CrossRef]

- Wu, J.; Zhong, T.; Zou, Y.; Li, J.; Zhao, W.; Chen, H. Microstructure, Chemical Composition and Thermal Stability of Alkali-Treated Bamboo Fibers and Parenchyma Cells: Effects of Treatment Time and Temperature. Cellulose 2023, 30, 1911–1925. [Google Scholar] [CrossRef]

- Lu, K.-T. Effects of Hydrogen Peroxide Treatment on the Surface Properties and Adhesion of Ma Bamboo (Dendrocalamus latiflorus). J. Wood Sci. 2006, 52, 173–178. [Google Scholar] [CrossRef]

- Xu, J.; Liu, R.; Wu, H.; Qiu, H.; Yu, Y.; Long, L. Coating Performance of Water-Based Polyurethane-Acrylate Coating on Bamboo/Bamboo Scrimber Substrates. Adv. Polym. Technol. 2019, 2019, 1–8. [Google Scholar] [CrossRef]

- Mariappan, T.; Kamble, A.; Naik, S.M. An Investigation of Primer Adhesion and Topcoat Compatibility on the Waterborne Intumescent Coating to Structural Steel. Prog. Org. Coat. 2019, 131, 371–377. [Google Scholar] [CrossRef]

- Cicek, H.; Akar, O.C.; Efeoglu, I. Structure and Adhesion Properties of TiNi/MoS2 Coatings. Ceram. Int. 2021, 47, 14033–14040. [Google Scholar] [CrossRef]

- Chen, L.; Lian, C.; Chen, M.; Wu, Z. Effects of Microstructure and Chemical Composition on the Visual Characteristics of Flattened Bamboo Board. Forests 2023, 14, 2220. [Google Scholar] [CrossRef]

- Xu, J.; Liu, R.; Wu, H.; Qiu, H.; Yu, Y.; Long, L.; Ni, Y. A Comparison of the Performance of Two Kinds of Waterborne Coatings on Bamboo and Bamboo Scrimber. Coatings 2019, 9, 161. [Google Scholar] [CrossRef]

- Hora, G. Improving Wet Adhesion of Water-Borne Acrylic Dispersion on Wood by Bond Activation. Surf. Coat. Int. Part B 2004, 87, 175–179. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).