Effect of Laser Cladding Technology on the Microstructure and Wear Properties of Gradient Coating on Crystallizer Copper Plate

Abstract

1. Introduction

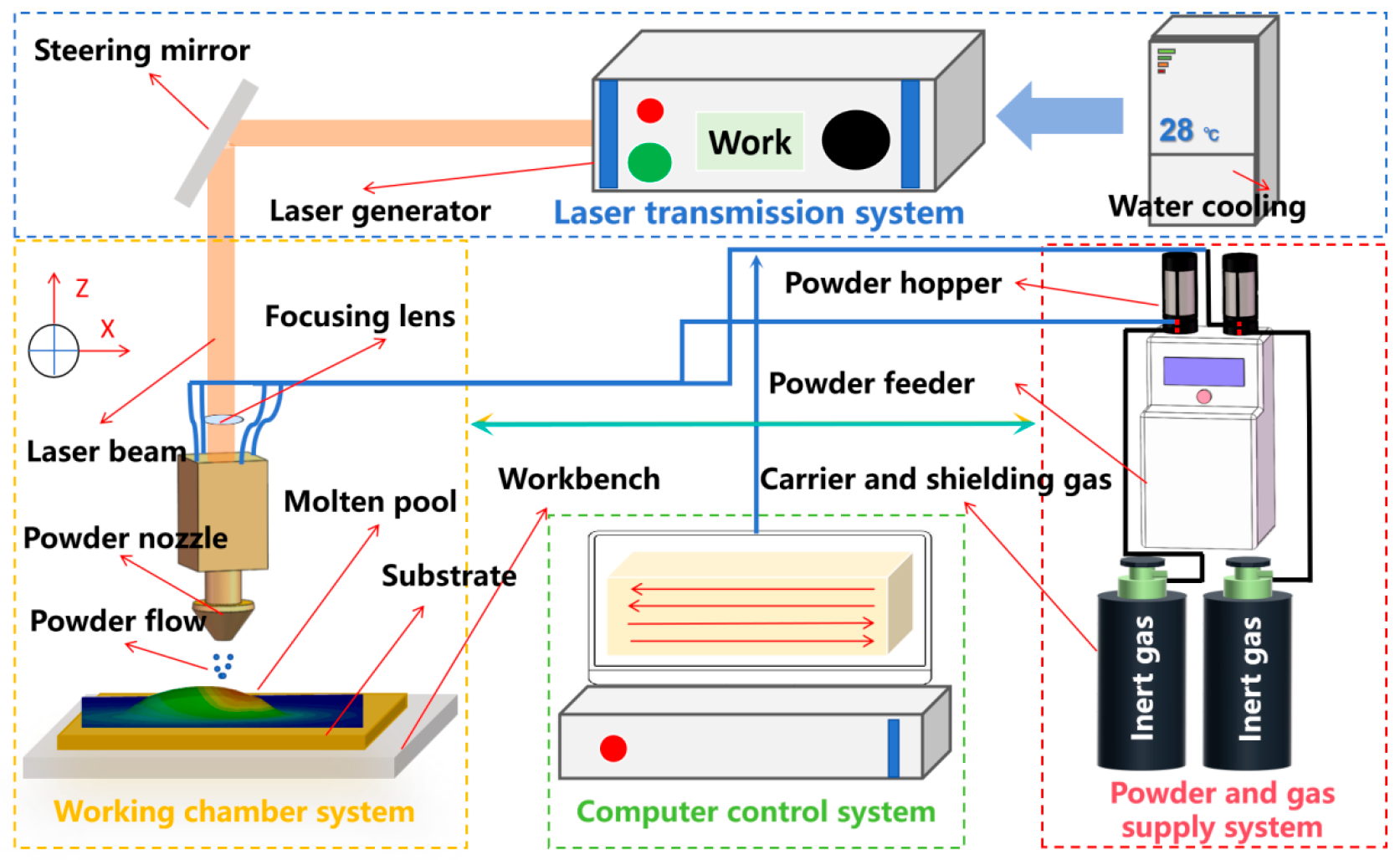

2. Experimental Equipment, Materials, and Characterization

2.1. Experimental Equipment and Materials

2.2. Experimental Methods and Characterization

3. Results and Discussion

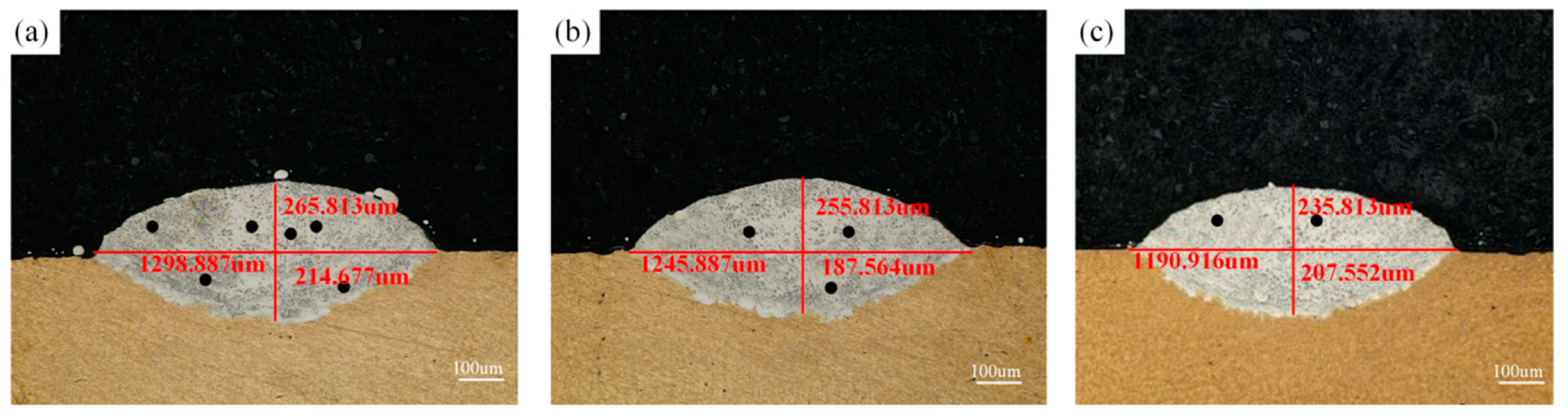

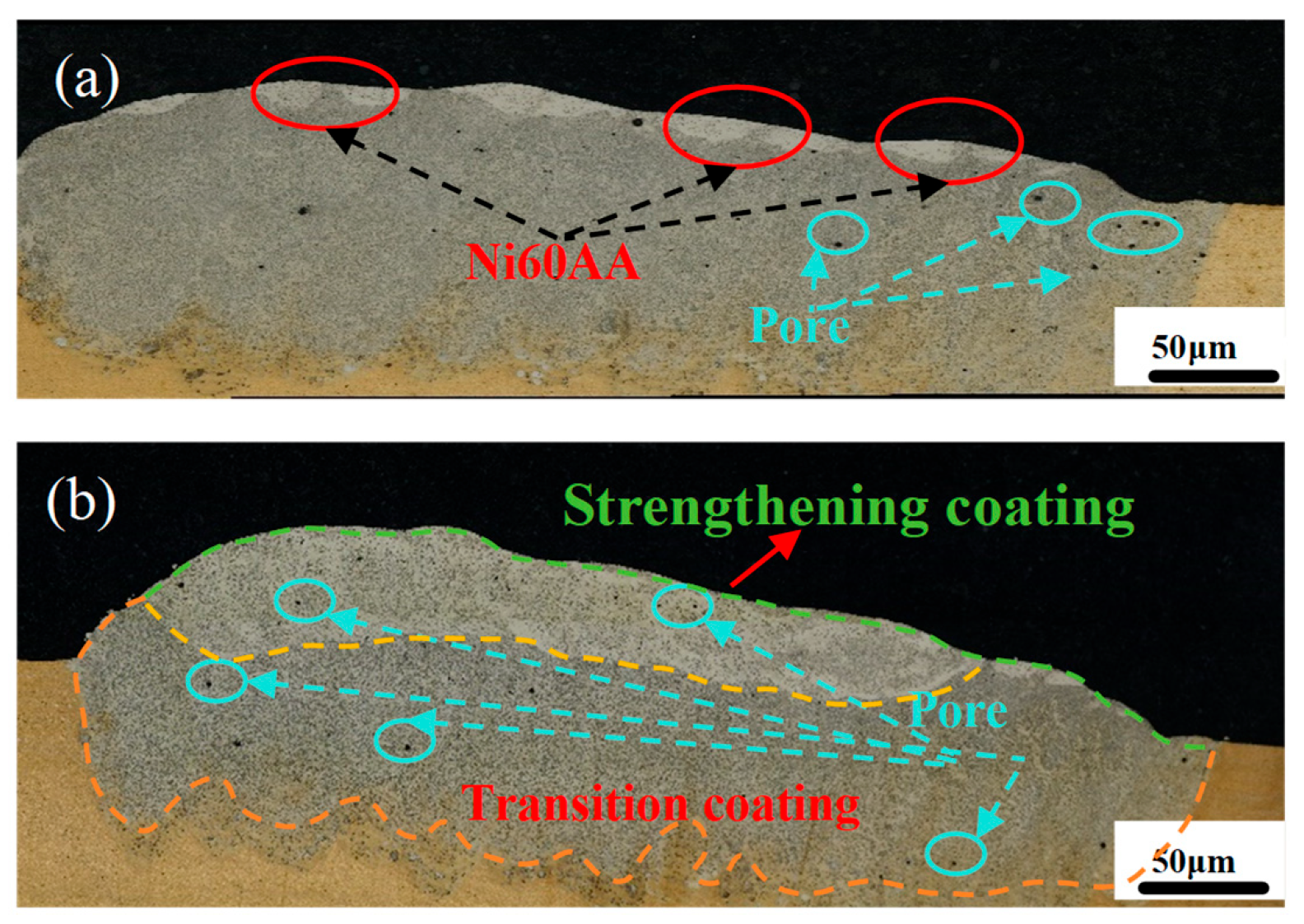

3.1. The Effect of Substrate Preheating on the Transition Coating

3.2. Macroscopic and Microscopic Morphology

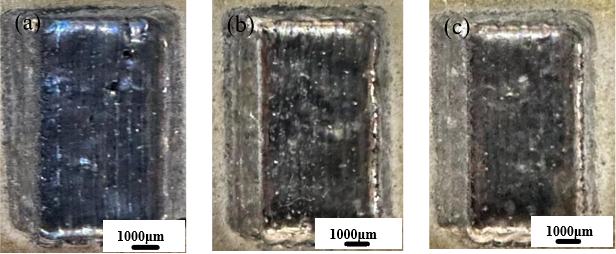

3.2.1. Macroscopic Morphology

3.2.2. Microscopic Morphology

3.3. Microstructure of TiB2 Reinforced Coating

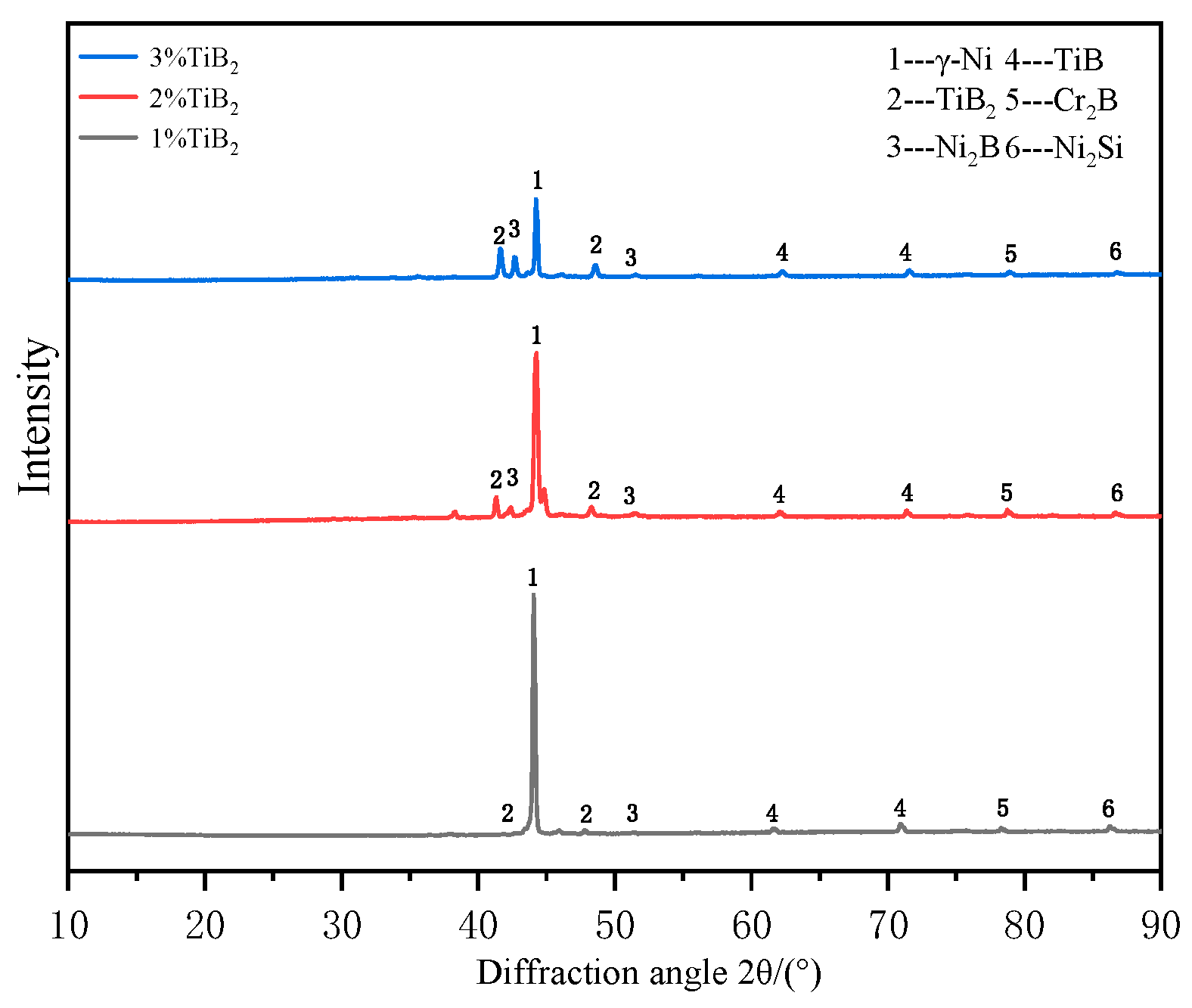

3.3.1. Phase Composition

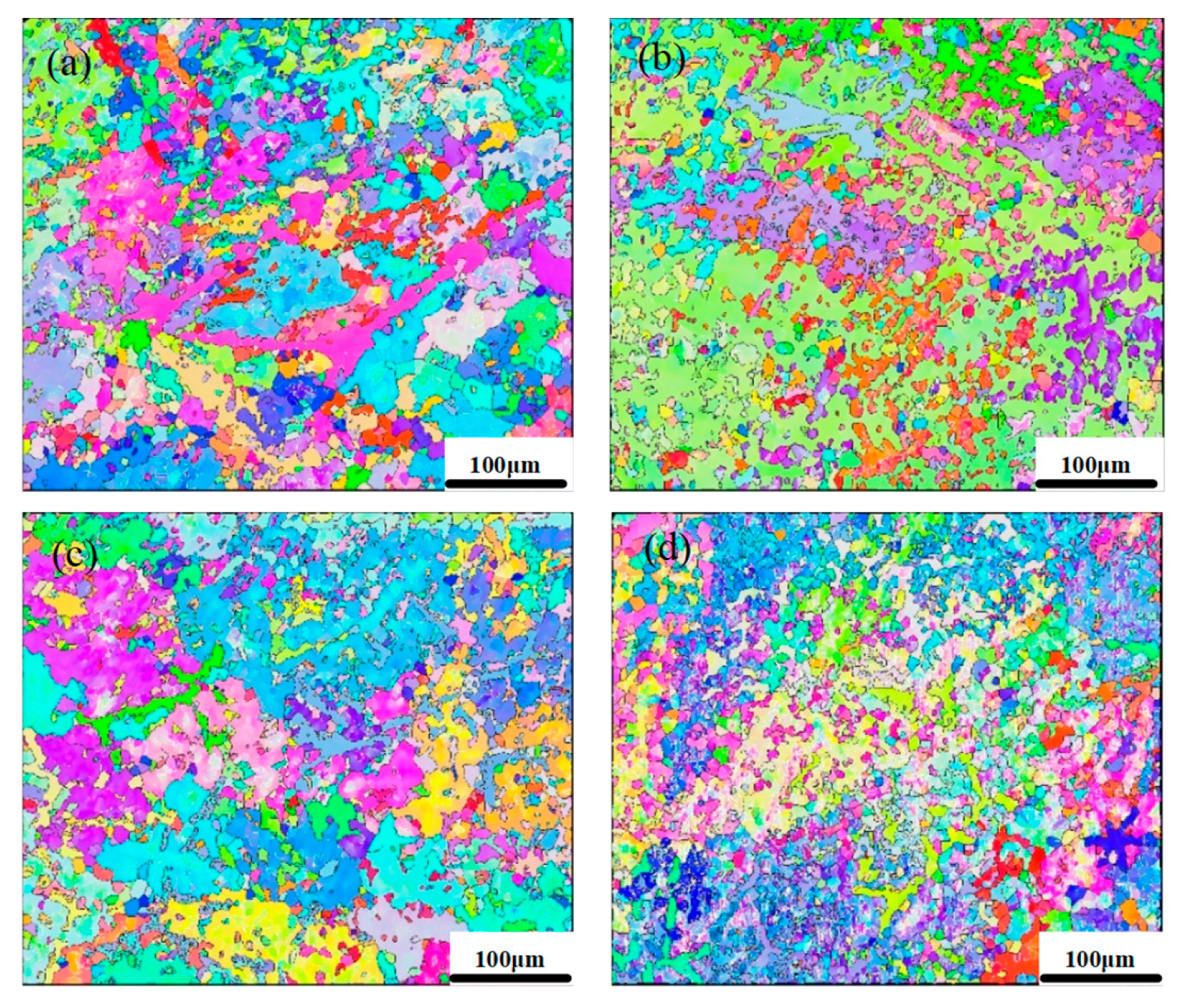

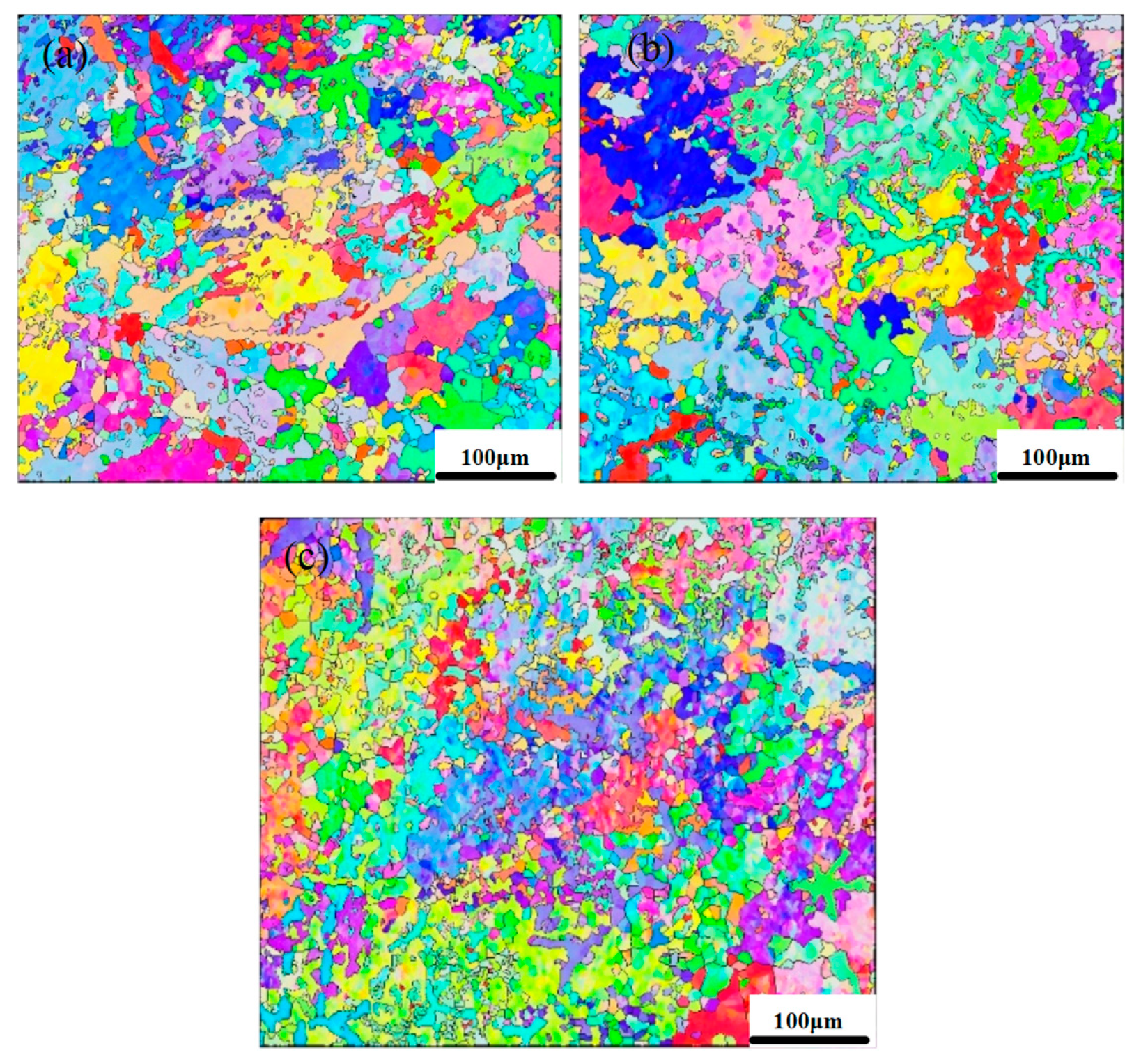

3.3.2. Strengthening Coating Grain Size

3.4. Mechanical Properties

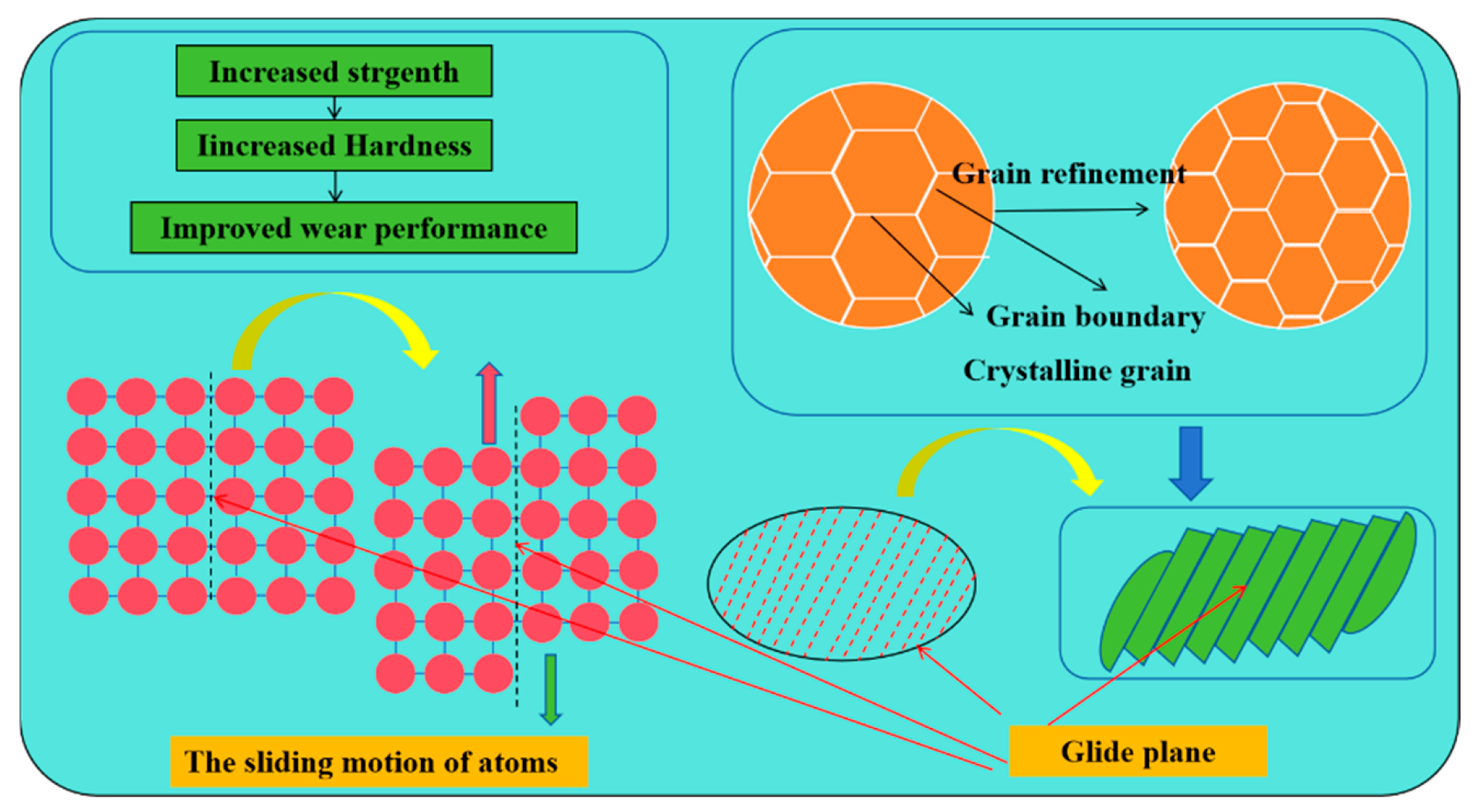

3.4.1. Mechanism of Hardness and Wear Improvement

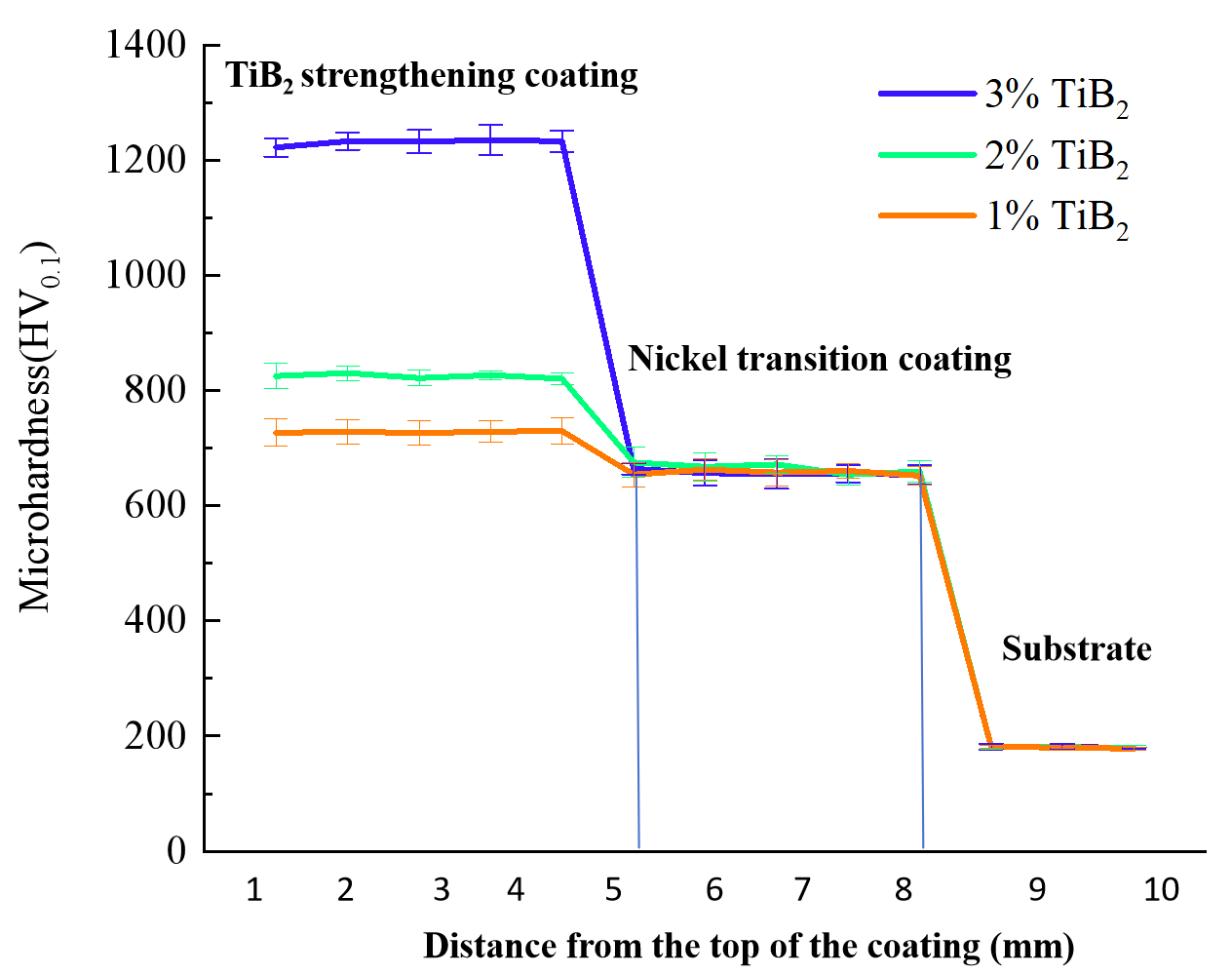

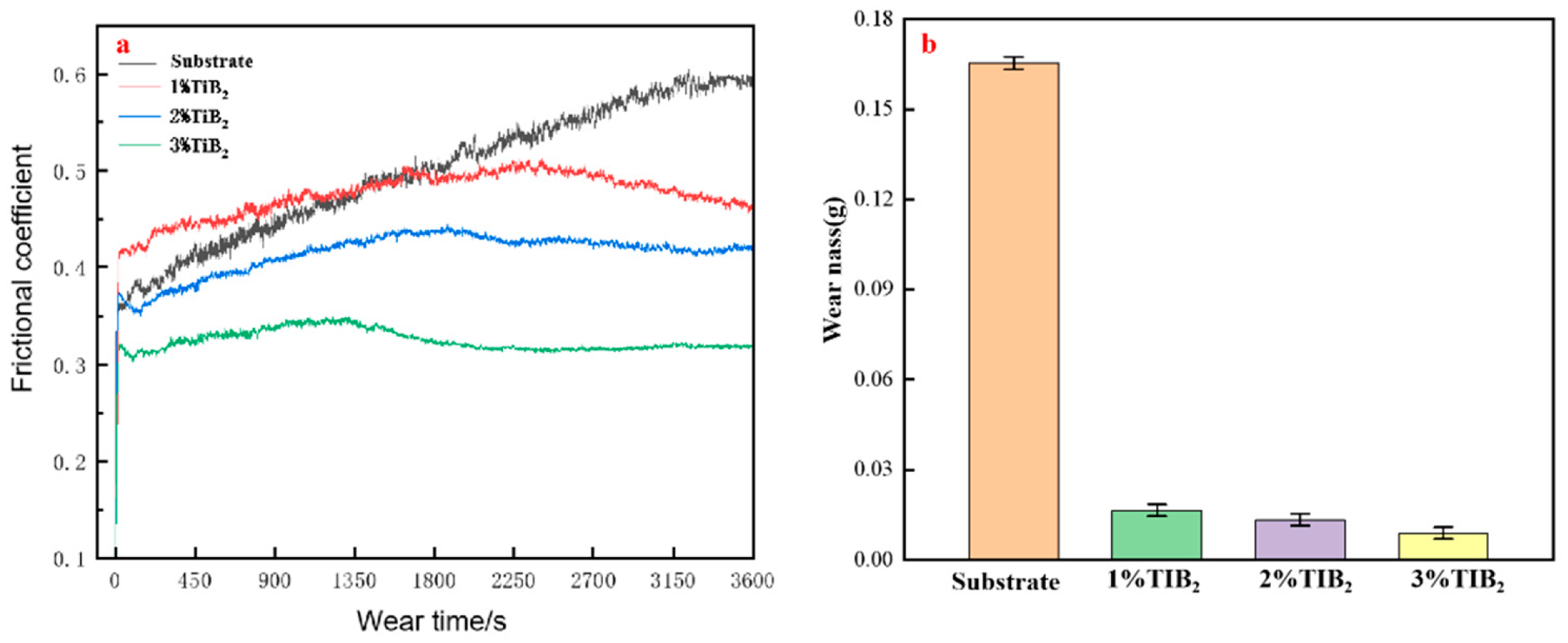

3.4.2. Hardness and Wear

4. Conclusions

- (1)

- Through microstructural analysis of the coating, the optimal preheating temperature was determined to be 400 °C, revealing the mechanism by which preheating suppresses porosity and cracking.

- (2)

- Laser cladding technology process experiments were conducted with different Ni60AA-TiB2 powder ratios, and a comparative analysis was performed to evaluate the effects of varying TiB2 content on the morphology and microstructure of the functionally graded coating.

- (3)

- When the TiB2 content was 3 wt.%, significant grain refinement was observed, with coarse columnar grains transforming into fine equiaxed grains. The wear depth was measured at 97.09 µm, the hardness reached 1225.3 HV0.1, the wear mass loss was only 0.0089 g, and the friction coefficient remained stable at 0.32.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Srnec, N.J.; Lanzutti, A.; Benasciutti, D.; De Bona, F.; Moro, L.; De Luca, A. On the damage mechanisms in a continuous casting mold: After-service material characterization and finite element simulation. Eng. Fail. Anal. 2018, 94, 480–492. [Google Scholar] [CrossRef]

- Gaiser, P.; Klingler, M.; Wilde, J. The influence of strain hardening of copper on the crack path in Cu/Al2O3/Cu direct bonded copper substrates. Int. J. Fatigue 2020, 140, 105821. [Google Scholar] [CrossRef]

- Pingale, A.D.; Owhal, A.; Katarkar, A.S.; Belgamwar, S.U.; Rathore, J.S. Recent researches on Cu-Ni alloy matrix composites through electrodeposition and powder metallurgy methods: A review. Mater. Today Proc. 2021, 47, 3301–3308. [Google Scholar] [CrossRef]

- Liu, A.; Jiang, X.; Song, B.; Chen, K.; Xu, X.; Yang, G.; Liu, W. A multi-objective optimization method of directed energy deposition manufacturing process considering carbon emission. J. Clean. Prod. 2024, 452, 142144. [Google Scholar] [CrossRef]

- Oliveira, J.; Correia, V.; Castro, H.; Martins, P.; Lanceros-Mendez, S. Polymer-based smart materials by printing technologies: Improving application and integration. Addit. Manuf. 2018, 21, 269–283. [Google Scholar] [CrossRef]

- Han, Y.J.; Zhou, C.Y.; Li, H.; Zhang, J.J. Green precision manufacturing of ultrathin copper foil leadframes by ultraviolet nanosecond pulsed laser microdrilling. Sustain. Mater. Technol. 2025, 45, e01553. [Google Scholar] [CrossRef]

- Mao, Z.; Zhang, D.Z.; Jiang, J.; Fu, G.; Zhang, P. Processing optimisation, mechanical properties and microstructural evolution during selective laser melting of Cu-15Sn high-tin bronze. Mater. Sci. Eng. A 2018, 721, 125–134. [Google Scholar] [CrossRef]

- Bateni, M.R.; Ashrafizadeh, F.; Szpunar, J.A.; Drew, R.A.L. Improving the tribological behavior of copper through novel Ti-Cu intermetallic coatings. Wear 2002, 253, 626–639. [Google Scholar] [CrossRef]

- Qu, L.K.; Wang, H.X.; Wang, K.Z. Characterization of VC-VB particles reinforced Fe-based composite coatings produced by laser cladding. Surf. Rev. Lett. 2016, 23, 1650019. [Google Scholar] [CrossRef]

- Liu, F.; Liu, C.S.; Tao, X.Q.; Chen, S. Laser cladding of Ni-based alloy on copper substrate. J. Univ. Sci. Technol. Beijing 2006, 13, 329–332. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, J.; Zhang, P.L.; Yu, Z.; Li, C.; Xu, P.; Lu, Y. Laser cladding of Co-based alloy/TiC/CaF2 self-lubricatingcomposite coatings on copper for continuous casting mold. Surf. Coat. Technol. 2013, 232, 362–369. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, T.H.; Liu, Y.; Gao, Y.L.; Di, C. Wear and heat shock resistance of Ni-WC coating on mould copper plate fabricated by laser. J. Mater. Res. Technol. 2020, 9, 8283–8288. [Google Scholar] [CrossRef]

- Wang, K.; Wang, H.L.; Zhu, G.Z.; Zhu, X. Cr13Ni5Si2-Based Composite Coating on Copper Deposited Using Pulse Laser Induction Cladding. Materials 2017, 10, 160. [Google Scholar] [CrossRef] [PubMed]

- Günther, I.; Zillmann, B.; Niendorf, T. Metal powder bed fusion of pure and coated copper for power electronics applications using a green laser. J. Mater. Res. Technol. 2025, 38, 5250–5262. [Google Scholar] [CrossRef]

- Jin, L.; Jiang, K.Y.; Kang, L.; Yan, B.G. Laser Cladding on Copper with Composite Powder C-Al2O3-Cu. J. Mater. Eng. Perform. 2022, 31, 1317–1324. [Google Scholar] [CrossRef]

- Lemya, L.; Hachemi, B.; Elhachmi, G.T. Microstructural, surface and electrochemical properties of electrodeposited Ni-WC nanocomposites coatings. Main Group Chem. 2022, 21, 763–772. [Google Scholar] [CrossRef]

- Ng, K.W.; Man, H.C.; Cheng, F.T.; Yue, T.M. Laser cladding of copper with molybdenum for wear resistance enhancement in electrical contacts. Appl. Surf. Sci. 2007, 253, 6236–6241. [Google Scholar] [CrossRef]

- Liu, F.; Liu, C.S.; Chen, S.Y.; Tao, X.Q.; Zhang, Y. Laser cladding Ni-Co duplex coating on copper substrate. Opt. Lasers Eng. 2010, 48, 792–799. [Google Scholar] [CrossRef]

- Zang, J.J.; Li, H.; Sun, J.; Shen, Y.F.; Su, N.N.; Feng, X.M. Microstructure and thermal conductivity of Cu-Cu2AlNiZnAg/diamond coatings on pure copper substrate via high-energy mechanical alloying method. Surf. Interfaces 2020, 21, 100742. [Google Scholar] [CrossRef]

- Zhang, D.Y.; Peng, Z.J.; Liu, Z.L.; Yu, J.K.; Yuan, L. Study on wear properties of high hardness and high thermal conductivity copper alloy for crystallization roller. J. Mater. Res. Technol. 2024, 28, 3225–3231. [Google Scholar] [CrossRef]

- Wang, H.; Sun, Y.; Qiao, Y.; Du, X. Effect of Ni-coated WC reinforced particles on microstructure and mechanical properties of laser cladding Fe-Co duplex coating. Opt. Laser Technol. 2021, 142, 107209. [Google Scholar] [CrossRef]

- Chen, S.; Liang, J.; Sun, K.; Mazumder, J. Preparation of a novel Ni/Co-based alloy gradient coating on surface of the crystallizer copper alloy by laser. Appl. Surf. Sci. 2011, 258, 1443–1450. [Google Scholar]

- Pogrebnyak, A.D.; Il’yashenko, M.V.; Kshnyakin, V.S.; Tyurin, Y.N.; Ivanov, Y.F. The structure and properties of a hard alloy coating deposited by high-velocity pulsed plasma jet onto a copper substrate. Tech. Phys. Lett. 2001, 27, 749–751. [Google Scholar] [CrossRef]

- Bysakh, S.; Chattopadhyay, K.; Maiwald, T.; Galun, R.; Mordike, B.L. Microstructure evolution in laser alloyed layer of Cu-Fe-Al-Si on Cu substrate. Mater. Sci. Eng. A 2004, 375–377, 661–665. [Google Scholar] [CrossRef]

- Hara, T.; Sato, Y.; Higashino, R.; Funada, Y.; Ohkubo, T.; Morimoto, K.; Abe, N.; Tsukamoto, M. Pure copper layer formation on pure copper substrate using multi-beam laser cladding system with blue diode lasers. Appl. Phys. A 2020, 126, 418. [Google Scholar] [CrossRef]

- Takenaka, K.; Tokumoto, J.; Kobayashi, K.; Osanai, H.; Toji, K.; Sato, Y.; Tsukamoto, M. Direct formation of pure copper layer on aluminum nitride by multibeam laser deposition with blue diode lasers. J. Laser Appl. 2024, 36, 042043. [Google Scholar] [CrossRef]

- Yoshida, T.; Sato, Y.; Takenaka, K.; Chen, P.; Kanetaka, H.; Mokudai, T.; Tsukamoto, M. Pure copper coating by multibeam directed energy deposition with blue lasers for antimicrobial effect. J. Laser Appl. 2024, 36, 042035. [Google Scholar] [CrossRef]

- Bauch, A.; Herzog, D. Influence of temperature and beam size on weld track shape in laser powder bed fusion of pure copper using near-infrared laser system. J. Laser Appl. 2024, 36, 012007. [Google Scholar] [CrossRef]

- Maly, M.; Koutny, D.; Pantelejev, L.; Pambaguian, L.; Palousek, D. Effect of high-temperature preheating on pure copper thick-walled samples processed by laser powder bed fusion. J. Manuf. Process. 2022, 73, 924–938. [Google Scholar] [CrossRef]

- Sciacca, G.; Sinico, M.; Cogo, G.; Bigolaro, D.; Pepato, A.; Esposito, J. Experimental and numerical characterization of pure copper heat sinks produced by laser powder bed fusion. Mater. Des. 2022, 214, 110415. [Google Scholar] [CrossRef]

- Khamei, A.A.; Dehghani, K. A study on the mechanical behavior and microstructural evolution of Ni60wt%–Ti40wt% (60Nitinol) intermetallic compound during hot deformation. Mater. Chem. Phys. 2010, 123, 269–277. [Google Scholar] [CrossRef]

| Elemental (wt.%) | C | Cr | Si | Fe | B | Ni |

|---|---|---|---|---|---|---|

| content | 0.7 | 17 | 4 | ≤2.4 | 3.2 | Bal |

| Density (g/cm3) | Hardness GPa | Melting Point °C | Thermal Expansion Coefficient °C−1 | Thermal Conductivity W/(m*k) | Electrical Resistivity (Ω*m) |

|---|---|---|---|---|---|

| 4.50 | 34 | 2900 | 6~8 × 10−6 | 20~30 | 1.0–3.0 × 10−7 |

| Level | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 | |

|---|---|---|---|---|---|---|

| Laser Power (W) | 760 | 790 | 820 | 850 | 880 | 910 |

| Scanning Speed (mm/min) | 320 | 360 | 400 | 440 | 480 | 520 |

| Powder Feed Rate (r/min) | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 |

| No. | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| TiB2 Mass Fraction (wt.%) | Ni60AA + 1 wt.% TiB2 + 0.5%Y2O3 | Ni60AA + 2 wt.% TiB2 + 0.5%Y2O3 | Ni60AA + 3 wt.% TiB2 + 0.5%Y2O3 | Ni60AA + 1 wt.% TiB2 + 0.5%Y2O3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, D.; Liu, W.; Jiang, X.; Liu, A. Effect of Laser Cladding Technology on the Microstructure and Wear Properties of Gradient Coating on Crystallizer Copper Plate. Coatings 2025, 15, 1300. https://doi.org/10.3390/coatings15111300

Liu D, Liu W, Jiang X, Liu A. Effect of Laser Cladding Technology on the Microstructure and Wear Properties of Gradient Coating on Crystallizer Copper Plate. Coatings. 2025; 15(11):1300. https://doi.org/10.3390/coatings15111300

Chicago/Turabian StyleLiu, Dan, Weijun Liu, Xingyu Jiang, and Ao Liu. 2025. "Effect of Laser Cladding Technology on the Microstructure and Wear Properties of Gradient Coating on Crystallizer Copper Plate" Coatings 15, no. 11: 1300. https://doi.org/10.3390/coatings15111300

APA StyleLiu, D., Liu, W., Jiang, X., & Liu, A. (2025). Effect of Laser Cladding Technology on the Microstructure and Wear Properties of Gradient Coating on Crystallizer Copper Plate. Coatings, 15(11), 1300. https://doi.org/10.3390/coatings15111300