Effects of Coating Ageing on the Acoustic Properties of Norway Spruce (Picea abies)

Abstract

1. Introduction

2. Materials and Methods

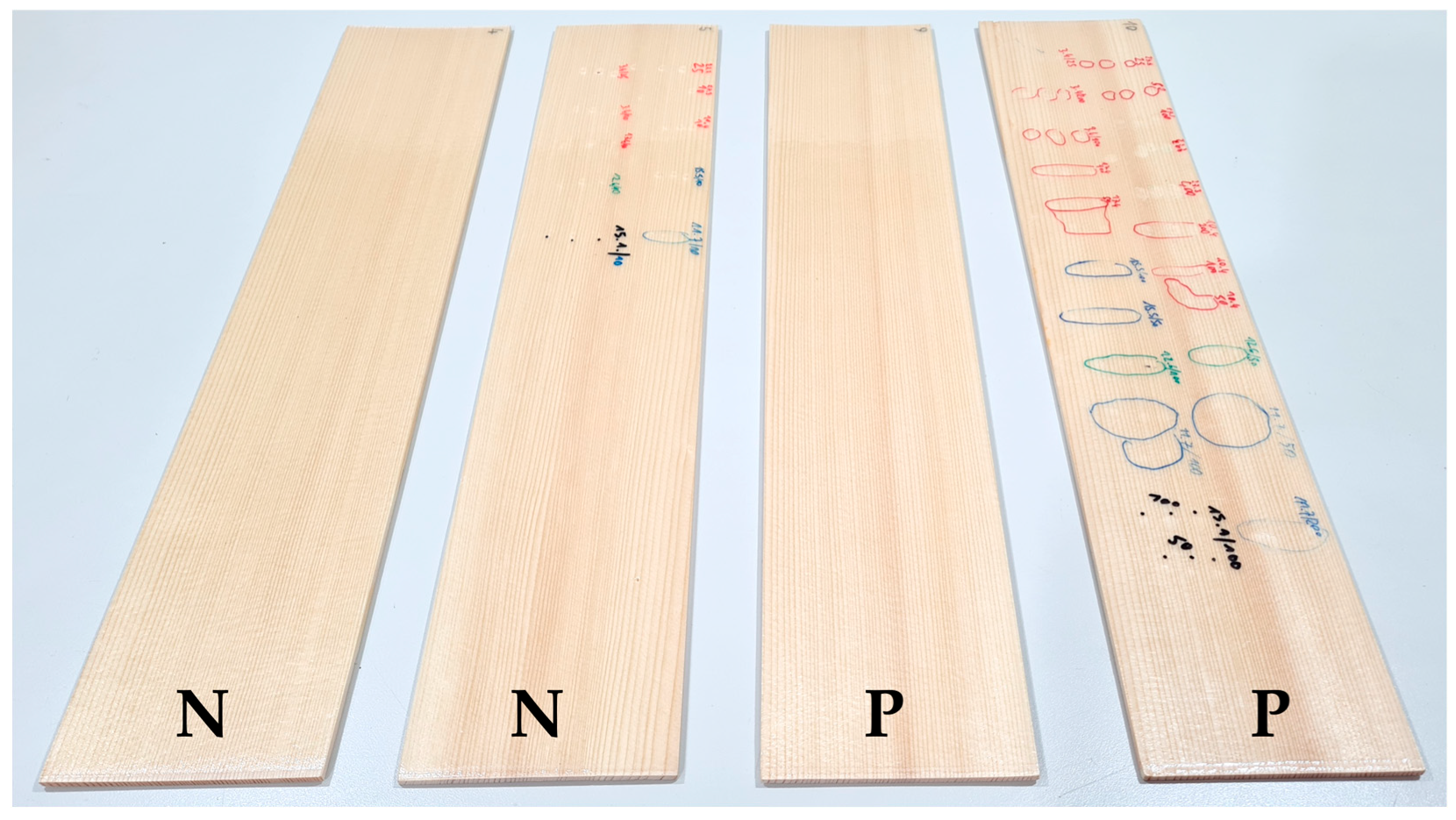

2.1. Wood Surface Treatment

2.2. Characterisation of the Coated Surfaces

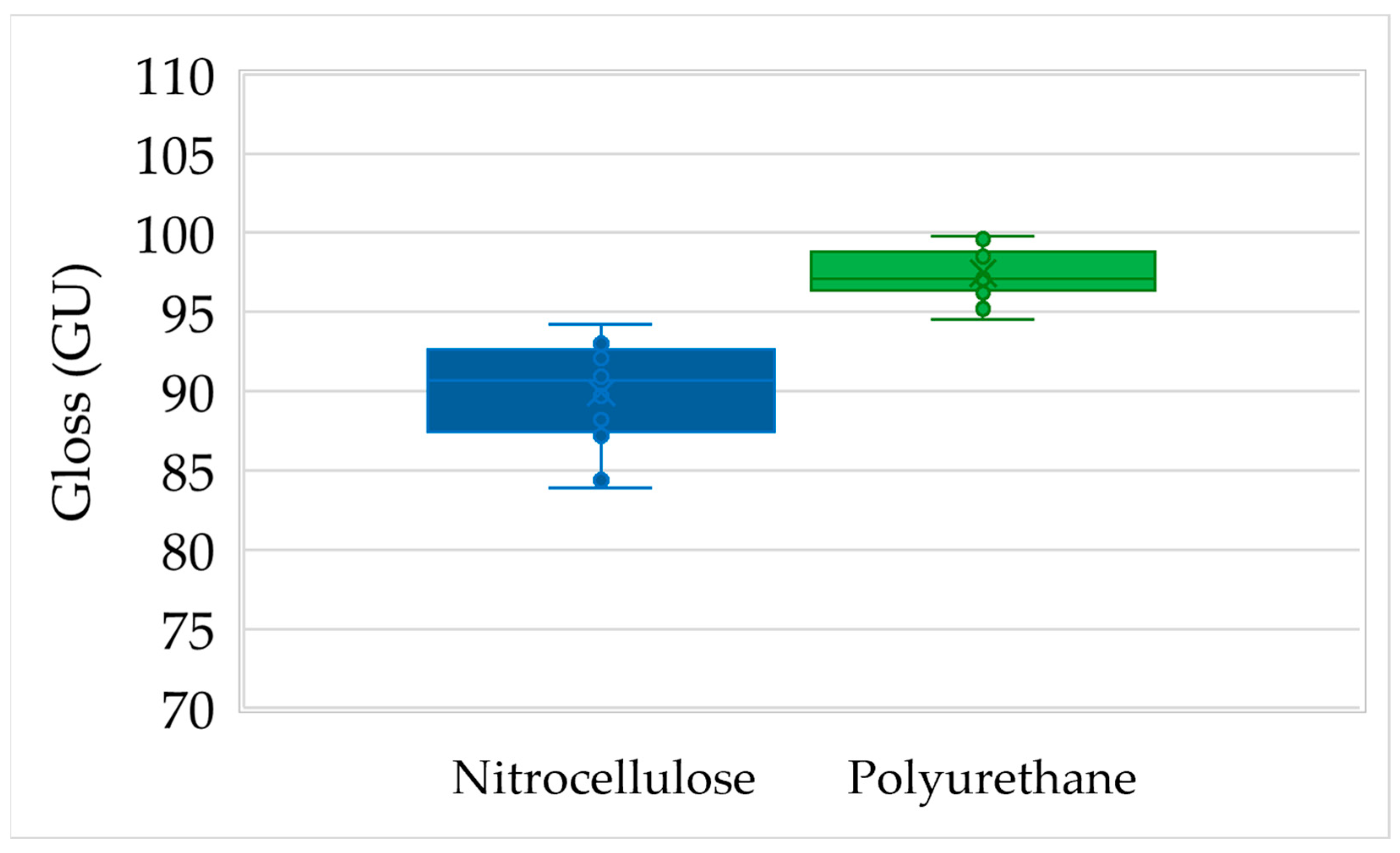

2.2.1. Gloss Measurements

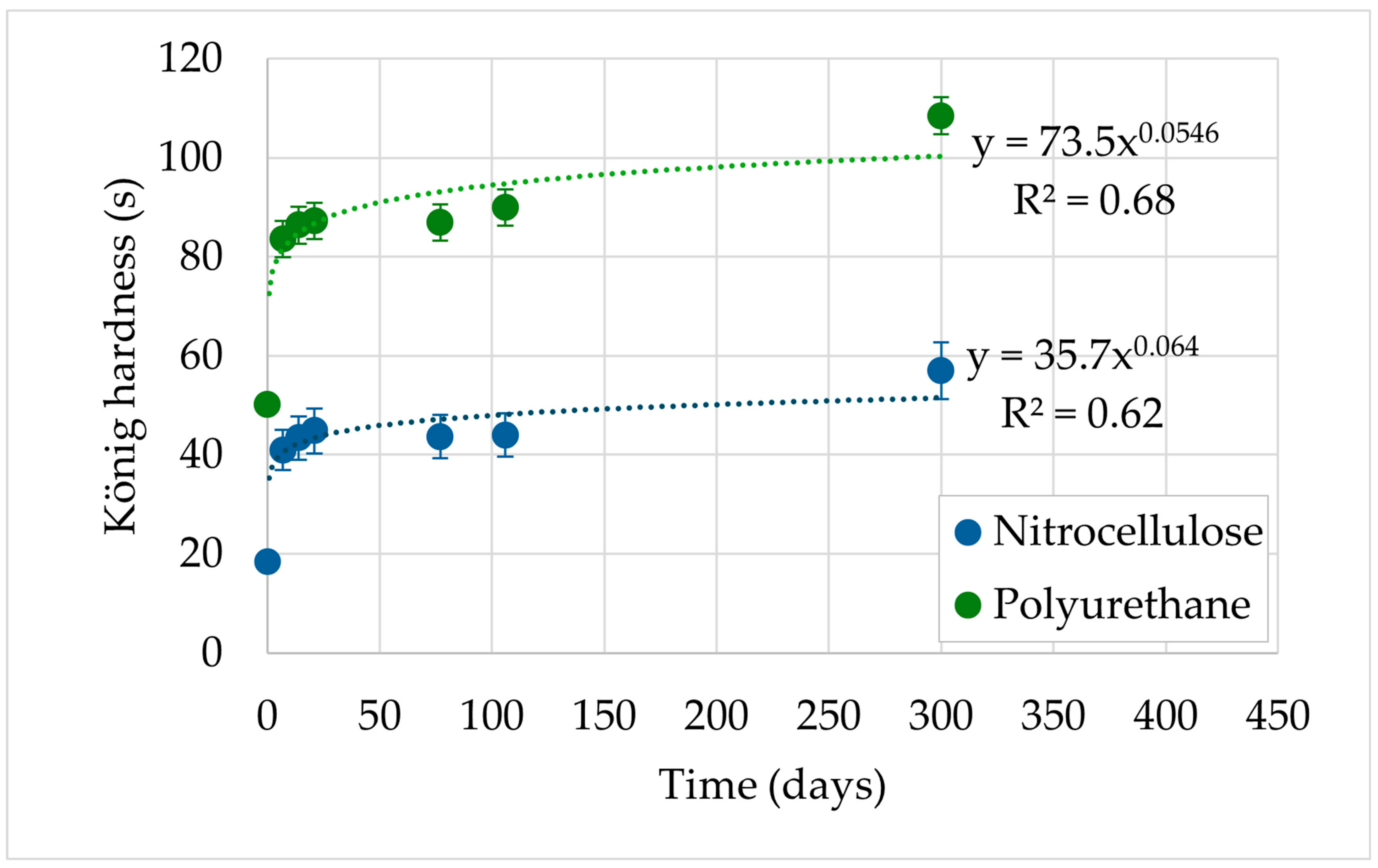

2.2.2. Determination of Surface Hardness

2.2.3. Assessment of Surface Resistance to Impact

2.3. Determination of the Acoustic Properties

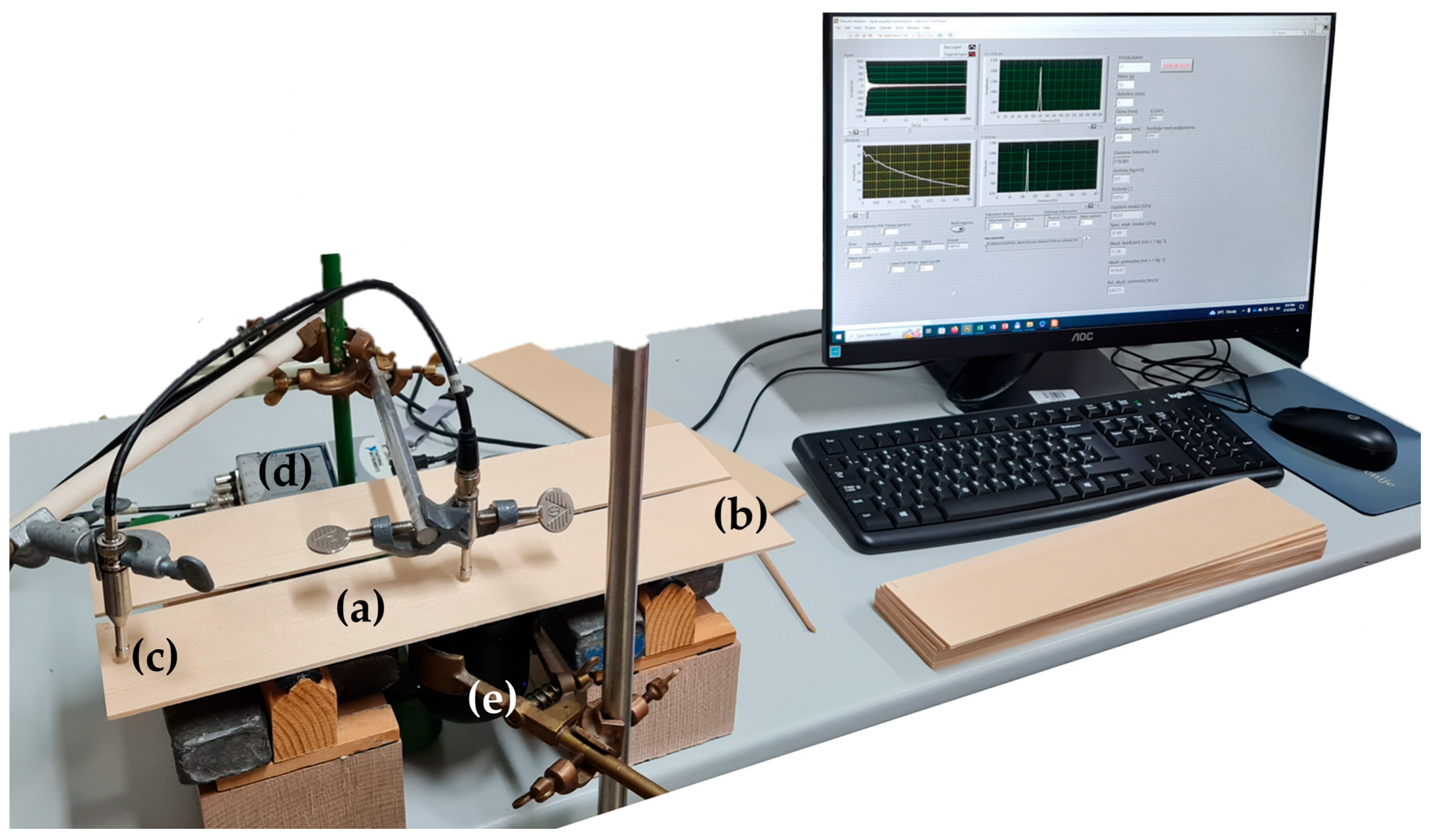

2.3.1. Determination of the Fundamental Resonance Frequency

2.3.2. Analysis of the Free-Free Vibration Resonance

2.4. Observation of the Surface and Acoustic Properties of the Coated Lamellae over Time

2.5. Data Processing and Statistical Analysis

3. Results

3.1. Properties of Coatings Applied to Spruce Lamellas

3.1.1. Gloss of Finished Surfaces

3.1.2. Surface Hardness

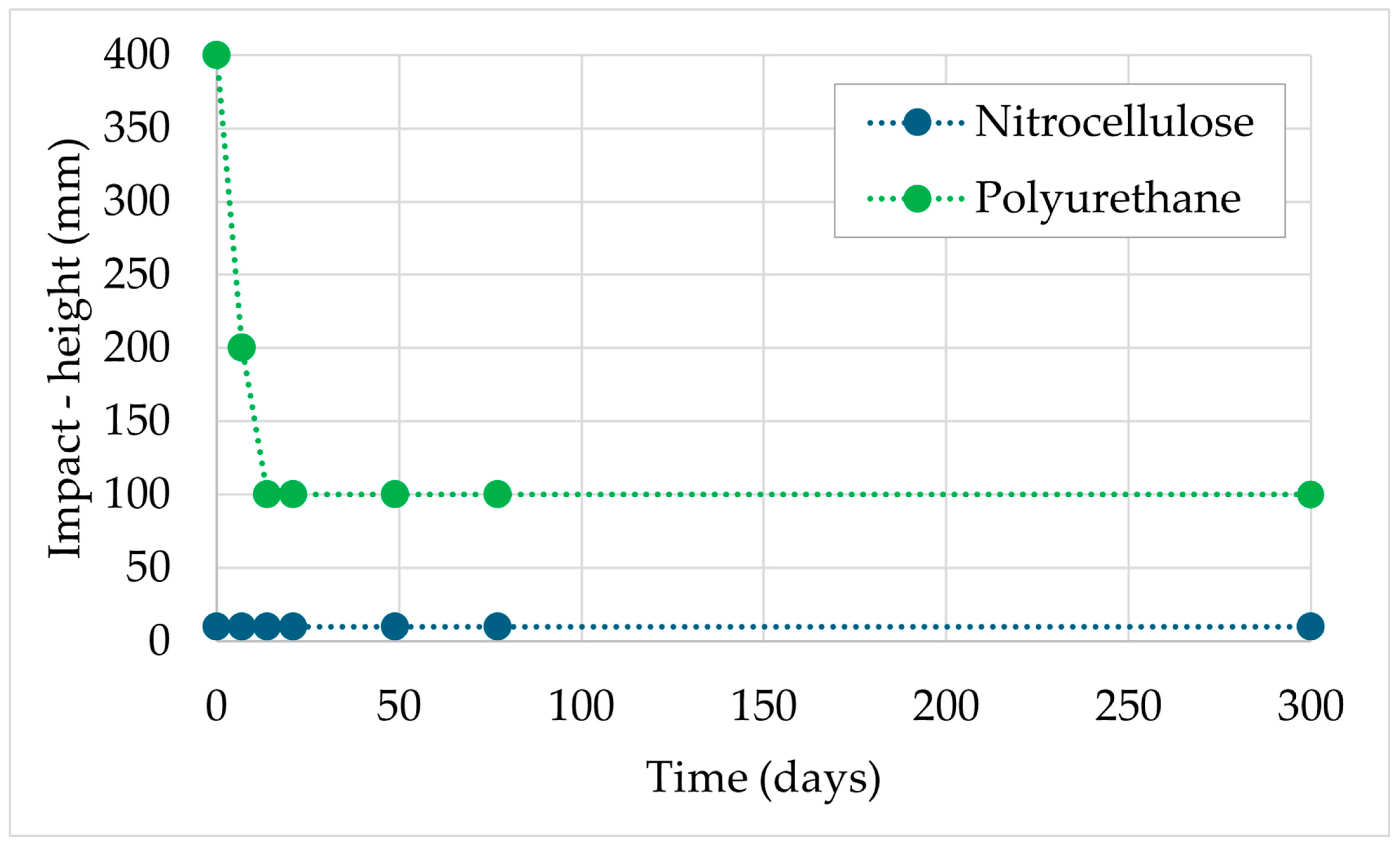

3.1.3. Surface Resistance to Impact

3.2. Impact of Coating on the Initial Acoustic Properties of Lamellas

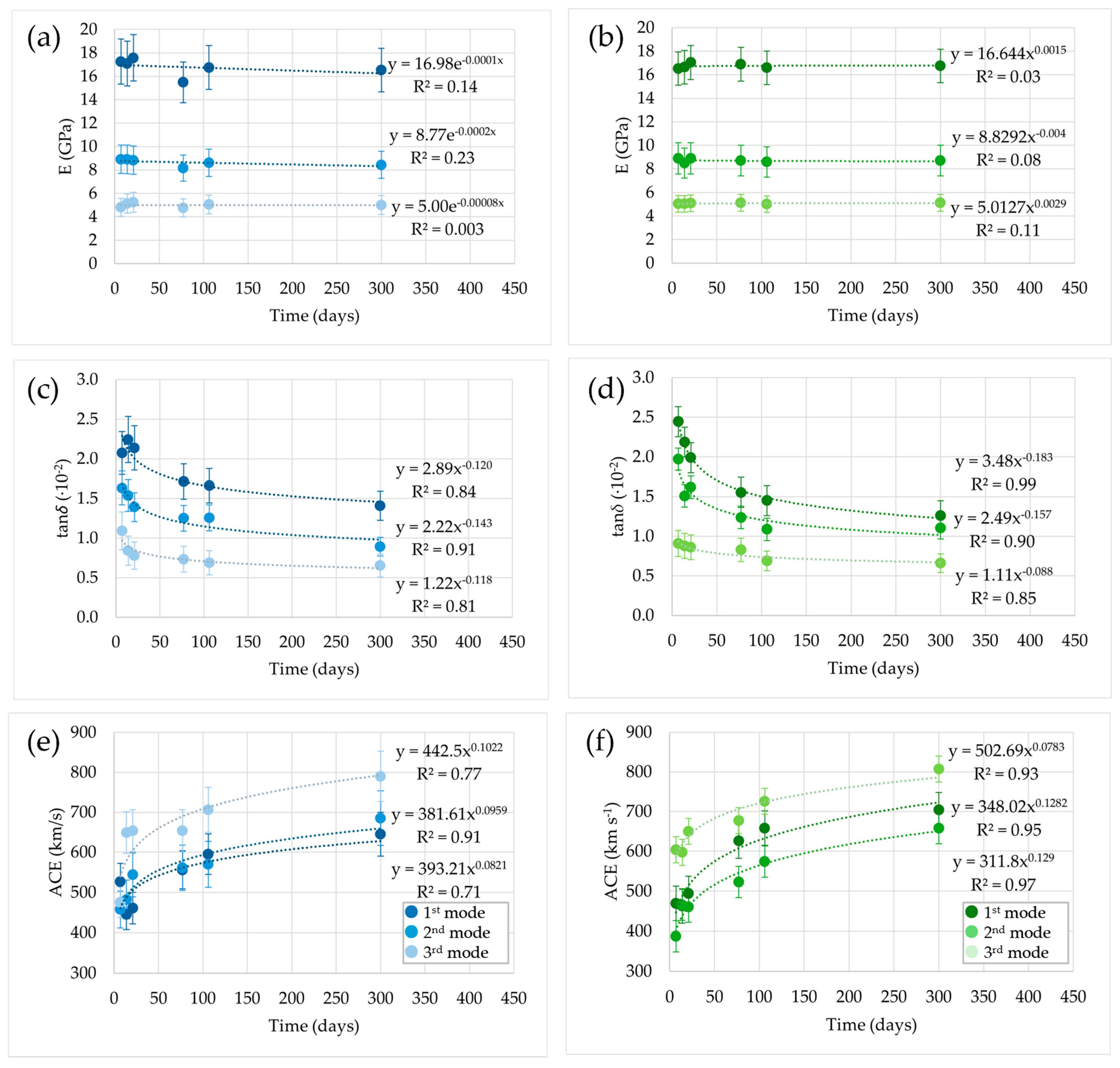

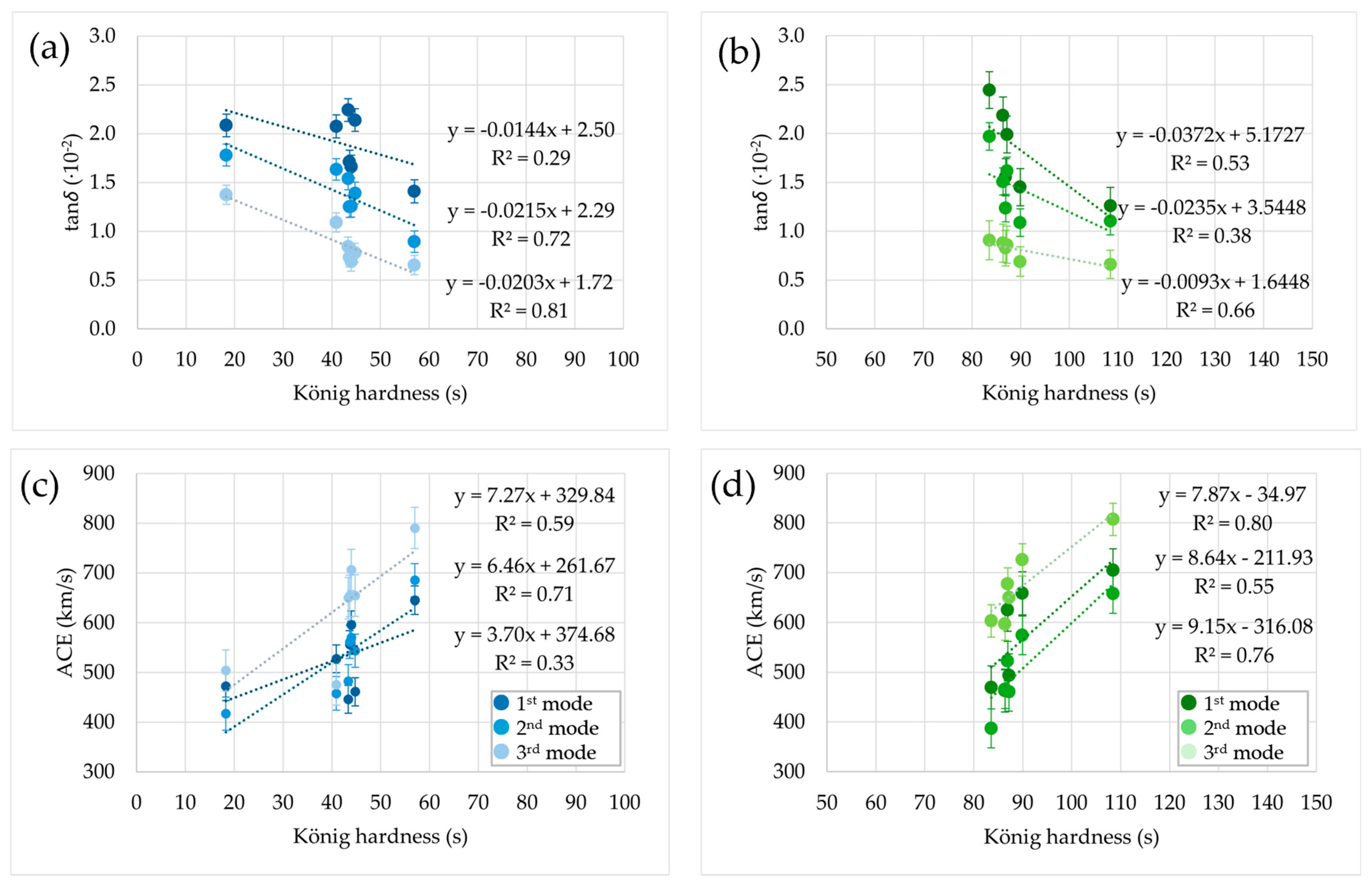

3.3. Time-Dependent Changes in the Acoustic Properties of Coated Spruce Lamellas

4. Discussion

5. Conclusions

- Immediate effects of the coatings—Both coatings decreased resonance frequencies and dynamic moduli due to the added mass, while increasing vibration damping and decreasing acoustic conversion efficiency (ACE). These effects were more pronounced with nitrocellulose than with polyurethane.

- Ageing behaviour—While moduli of elasticity remained stable, vibration damping decreased and ACE increased over time, suggesting that curing of the coating improves acoustic performance with ageing.

- Relationship between hardness and acoustics—A strong correlation was found between surface hardness, vibration damping and ACE, suggesting that mechanical surface properties can serve as reliable indicators of acoustic effectiveness.

- Comparison of coatings—Nitrocellulose suppressed sound radiation more, while polyurethane maintained acoustic effectiveness better, despite some loss of impact resistance with ageing.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sedighi Gilani, M.; Pflaum, J.; Hartmann, S.; Kaufmann, R.; Baumgartner, M.; Schwarze, F.W.M.R. Relationship of Vibro-Mechanical Properties and Microstructure of Wood and Varnish Interface in String Instruments. Appl. Phys. A 2016, 122, 260. [Google Scholar] [CrossRef]

- Ono, T. Effects of Varnishing on Acoustical Characteristics of Wood Used for Musical Instrument Soundboards. J. Acoust. Soc. Jpn. E 1993, 14, 397–407. [Google Scholar] [CrossRef]

- Bucur, V.; Clément, A.; Bitsch, M.; Houssement, C. Acoustic Properties of Resonance Wood and Distribution of Inorganic Components of the Cell Wall. Holz als Roh- und Werkstoff 1999, 57, 103–104. [Google Scholar] [CrossRef]

- Spycher, M.; Schwarze, F.W.M.R.; Steiger, R. Assessment of Resonance Wood Quality by Comparing Its Physical and Histological Properties. Wood Sci. Technol. 2008, 42, 325–342. [Google Scholar] [CrossRef]

- Hori, R.; Müller, M.; Watanabe, U.; Lichtenegger, H.C.; Fratzl, P.; Sugiyama, J. The Importance of Seasonal Differences in the Cellulose Microfibril Angle in Softwoods in Determining Acoustic Properties. J. Mater. Sci. 2002, 37, 4279–4284. [Google Scholar] [CrossRef]

- Lämmlein, S.L.; Mannes, D.; Van Damme, B.; Schwarze, F.W.M.R.; Burgert, I. The Influence of Multi-Layered Varnishes on Moisture Protection and Vibrational Properties of Violin Wood. Sci. Rep. 2019, 9, 18611. [Google Scholar] [CrossRef]

- Obataya, E.; Ohno, Y.; Norimoto, M.; Bunichiro, T. Effects of Oriental Lacquer (Urushi) Coating on the Vibrational Properties of Wood Used for the Soundboards of Musical Instruments. Acoust. Sci. Technol. 2001, 11, 27–34. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, X.; He, L.; Wan, K.; Guo, Y.; Zhang, J.; Miao, Y.; Liu, Z. The Changes of Acoustic Vibration Properties of Spruce Wood During the Multi-Layered Alcohol Varnish Coating Process. Forests 2024, 15, 2212. [Google Scholar] [CrossRef]

- Minato, K.; Akiyama, T.; Yasuda, R.; Yano, H. Dependence of Vibrational Properties of Wood on Varnishing during Its Drying Process in Violin Manufacturing. Holzforschung 1995, 49, 222–226. [Google Scholar] [CrossRef]

- Liu, Q.; Gao, D.; Xu, W. Effect of Polyurethane Non-Transparent Coating Process on Paint Film Performance Applied on Modified Poplar. Coatings 2021, 12, 39. [Google Scholar] [CrossRef]

- Stanciu, M.D.; Coșniță, M.; Gliga, G.V.; Gurau, L.; Timar, M.C.; Guiman, M.V.; Marian Năstac, S.; Călin Roșca, I.; Bucur, V.; Dinulică, F. Tunable Acoustic Properties Using Different Coating Systems on Resonance Spruce Wood. Adv. Mater. Inter. 2024, 11, 2300781. [Google Scholar] [CrossRef]

- Hammond, C.; Hill, C.; Sprinkle, C.; Sorenson, A.; Vera, S. Microwave Processing of Polymeric Coatings for Guitar Woods. J. Undergrad. Mater. Res. 2010, 4, 12–17. [Google Scholar] [CrossRef]

- EN ISO 2808:2019; Paints and Varnishes—Determination of Film Thickness. European Committee for Standardization: Brussels, Belgium, 2019.

- EN ISO 2813:2015; Paints and Varnishes—Determination of specular gloss of non-metallic films at 20°, 60° and 85°. European Committee for Standardization: Brussels, Belgium, 2015.

- EN ISO 1522:2007; Paints and Varnishes—Pendulum Damping Test. European Committee for Standardization: Brussels, Belgium, 2007.

- Pavlič, M.; Petrič, M.; Žigon, J. Interactions of Coating and Wood Flooring Surface System Properties. Coatings 2021, 11, 91. [Google Scholar] [CrossRef]

- ISO 4211-4:1988; Furniture—Tests for Surfaces—Part 4: Assessment of Re-sistance to Impact. International Organization for Standardization: Geneva, Switzerland, 1988.

- Brancheriau, L.; Bailleres, H. Natural Vibration Analysis of Clear Wooden Beams: A Theoretical Review. Wood Sci. Technol. 2002, 36, 347–365. [Google Scholar] [CrossRef]

- Straže, A.; Mitkovski, B.; Tippner, J.; Čufar, K.; Gorišek, Ž. Structural and Acoustic Properties of African Padouk (Pterocarpus soyauxii) Wood for Xylophones. Eur. J. Wood Wood Prod. 2015, 73, 235–243. [Google Scholar] [CrossRef]

- Obataya, E. Suitability of Acetylated Woods for Clarinet Reed. J. Wood Sci. 1999, 45, 106–112. [Google Scholar] [CrossRef]

- Lämmlein, S.L.; Mannes, D.; Van Damme, B.; Burgert, I.; Schwarze, F.W.M. Influence of Varnishing on the Vibro-Mechanical Properties of Wood Used for Violins. J. Mater. Sci. 2019, 54, 8063–8095. [Google Scholar] [CrossRef]

- Quintos-Cortiguerra, A.L.; Dorado, A.B. Evaluation of the Food Safety of Wood Finishes. J. Coat. Technol. Res. 2025. [Google Scholar] [CrossRef]

- Pelit, H.; Koc, E.; Cakicier, N. Adhesion Strength and Pendulum Hardness of Some Coatings in Wood Heat-Treated by Different Methods. BioResources 2023, 18, 7353–7366. [Google Scholar] [CrossRef]

- Malassenet, L.; George, B.; Merlin, A.; Podgorski, L. Persoz Hardness: A Useful Property to Study Performance of Exterior Wood Coatings. Int. Wood Prod. J. 2015, 6, 174–180. [Google Scholar] [CrossRef]

- Huang, Z.; Ma, X.; Qiao, Z.; Wang, S.; Jing, X. Pendulum Hardness of Polyurethane Coatings during Curing. Pigment Resin Technol. 2014, 43, 271–276. [Google Scholar] [CrossRef]

- Sato, K. Physical Significance Of the Pendulum Hardness of Coating Films. J. Coat. Technol. 1984, 56, 47–57. [Google Scholar]

- Choi, J.; Kim, T. Three Hardness Test Methods and Their Relationship on UV-Curable Epoxy Acrylate Coatings for Wooden Flooring Systems. J. Ind. Eng. Chem.-Seoul 2006, 12, 412–417. [Google Scholar]

- Malkin, A.Y.; Bolgov, S.A.; Begishev, V.P.; Mansurov, V.A. Evolution of Viscoelastic Properties of Polyurethane in the Course of Curing. Rheola Acta 1992, 31, 345–350. [Google Scholar] [CrossRef]

- Croll, S.G.; Shi, X.; Fernando, B.M.D. The Interplay of Physical Aging and Degradation during Weathering for Two Crosslinked Coatings. Prog. Org. Coat. 2008, 61, 136–144. [Google Scholar] [CrossRef]

- Xu, C.; Liu, Z.; Li, X.; Li, W. Moisture- and Mould-Proof Characteristics of Surface Modified Wood for Musical Instrument Soundboards. R. Soc. Open Sci. 2022, 9, 210790. [Google Scholar] [CrossRef] [PubMed]

- Durbaca, I.; Sporea, N.; Vasile, O. Assessment of the Acoustic Absorption Characteristics of Layered Composite Structures Obtained from Plates with Lignocellulosic Coatings (I). Mater. Plast. 2019, 57, 8–14. [Google Scholar] [CrossRef]

- Noguchi, T.; Obataya, E.; Ando, K. Effects of Ageing on the Vibrational Properties of Akamatsu (Pinus densiflora) Wood. In Proceedings of the Wood Culture and Science, Kyoto, Japan, 6–9 August 2011; pp. 1–6. [Google Scholar]

| Sample | 1st Layer (g/m2) | 2nd Layer (g/m2) | 3rd Layer (g/m2) | Total Coating (g/m2) | Lamella Density (kg/m3) | Dry-Film Thickness (μm) |

|---|---|---|---|---|---|---|

| Control | - | - | - | - | 520 (±2.9) | - |

| Nitrocellulose | 14.8 | 70.0 | 56.0 | 146.7 (±1.9) | 567 (±3.9) | 200.0 (±10.2) |

| Polyurethane | 24.8 | 38.0 | 38.0 | 105.0 (±3.8) | 556 (±3.6) | 180.0 (±4.8) |

| f1 | f2 | f3 | E1 | E2 | E3 | tan δ1 | tan δ2 | tan δ3 | ACE1 | ACE2 | ACE3 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Control | 117.4 | 234.1 | 352.8 | 18.7 | 9.6 | 5.7 | 1.13 | 0.95 | 0.97 | 1026 | 974 | 697 |

| (0.9) | (1.7) | (2.6) | (0.4) | (0.2) | (0.1) | (0.02) | (0.10) | (0.10) | (20.2) | (28.1) | (43.9) | |

| N | 112.9 | 226.2 | 332.5 | 17.2 | 8.9 | 5.0 | 2.08 | 1.78 | 1.37 | 472 | 417 | 597 |

| (2.0) | (3.8) | (10.0) | (0.6) | (0.3) | (0.3) | (0.13) | (0.22) | (0.22) | (26.7) | (50.9) | (35.9) | |

| P | 111.7 | 222.6 | 327.2 | 16.6 | 8.6 | 4.9 | 1.95 | 1.51 | 1.46 | 515 | 477 | 383 |

| (3.1) | (6.3) | (12.5) | (0.7) | (0.4) | (0.3) | (0.14) | (0.10) | (0.10) | (41.8) | (38.4) | (41.0) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Straže, A.; Žigon, J.; Pavlič, M. Effects of Coating Ageing on the Acoustic Properties of Norway Spruce (Picea abies). Coatings 2025, 15, 1264. https://doi.org/10.3390/coatings15111264

Straže A, Žigon J, Pavlič M. Effects of Coating Ageing on the Acoustic Properties of Norway Spruce (Picea abies). Coatings. 2025; 15(11):1264. https://doi.org/10.3390/coatings15111264

Chicago/Turabian StyleStraže, Aleš, Jure Žigon, and Matjaž Pavlič. 2025. "Effects of Coating Ageing on the Acoustic Properties of Norway Spruce (Picea abies)" Coatings 15, no. 11: 1264. https://doi.org/10.3390/coatings15111264

APA StyleStraže, A., Žigon, J., & Pavlič, M. (2025). Effects of Coating Ageing on the Acoustic Properties of Norway Spruce (Picea abies). Coatings, 15(11), 1264. https://doi.org/10.3390/coatings15111264