Influence of Thermally Grown Oxide Dynamic Growth Mode and Creep Strength on the Delamination and Failure of Thermal Barrier Coatings in the Furnace Cycle

Abstract

1. Introduction

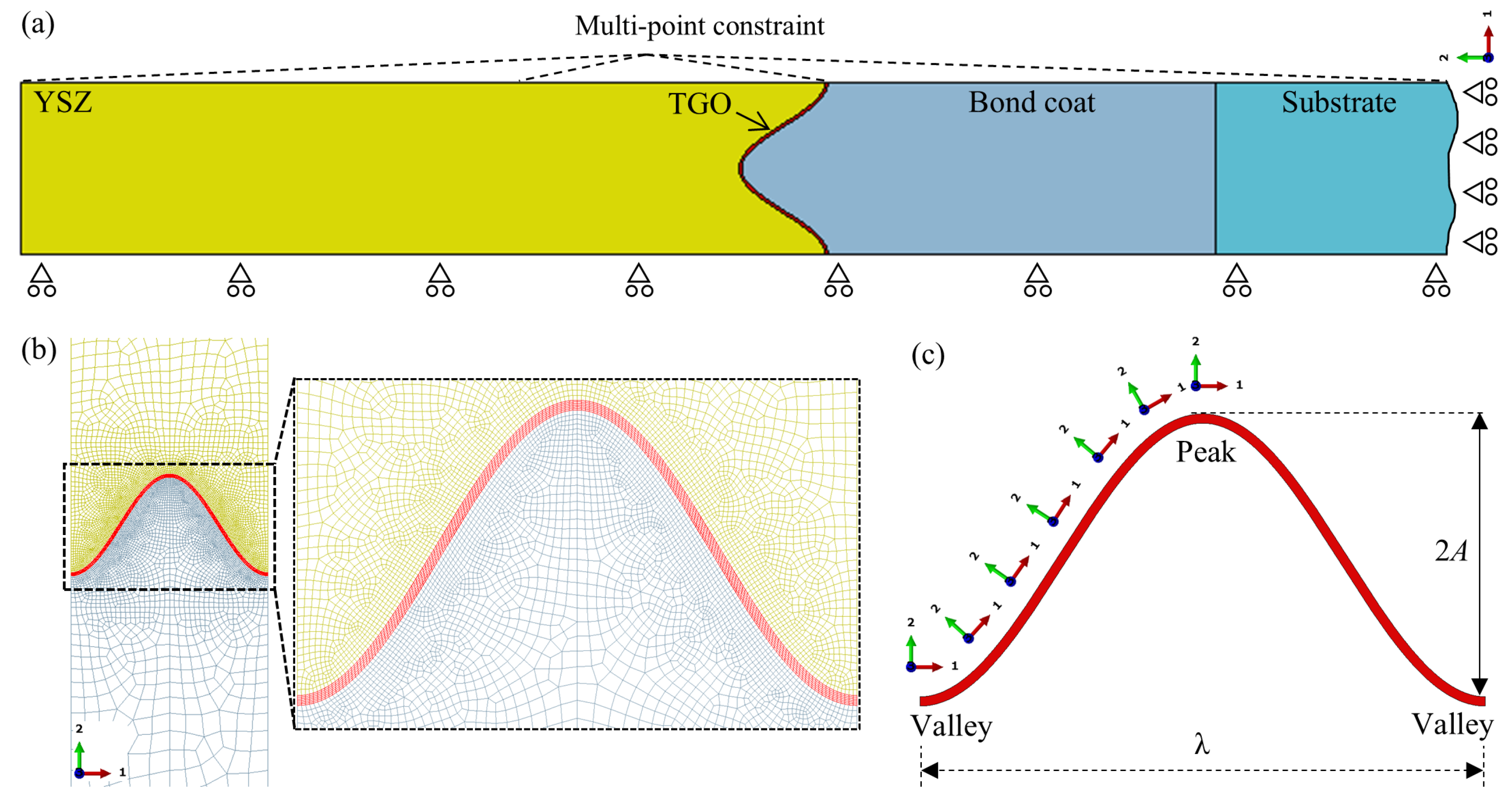

2. Numerical Model Development

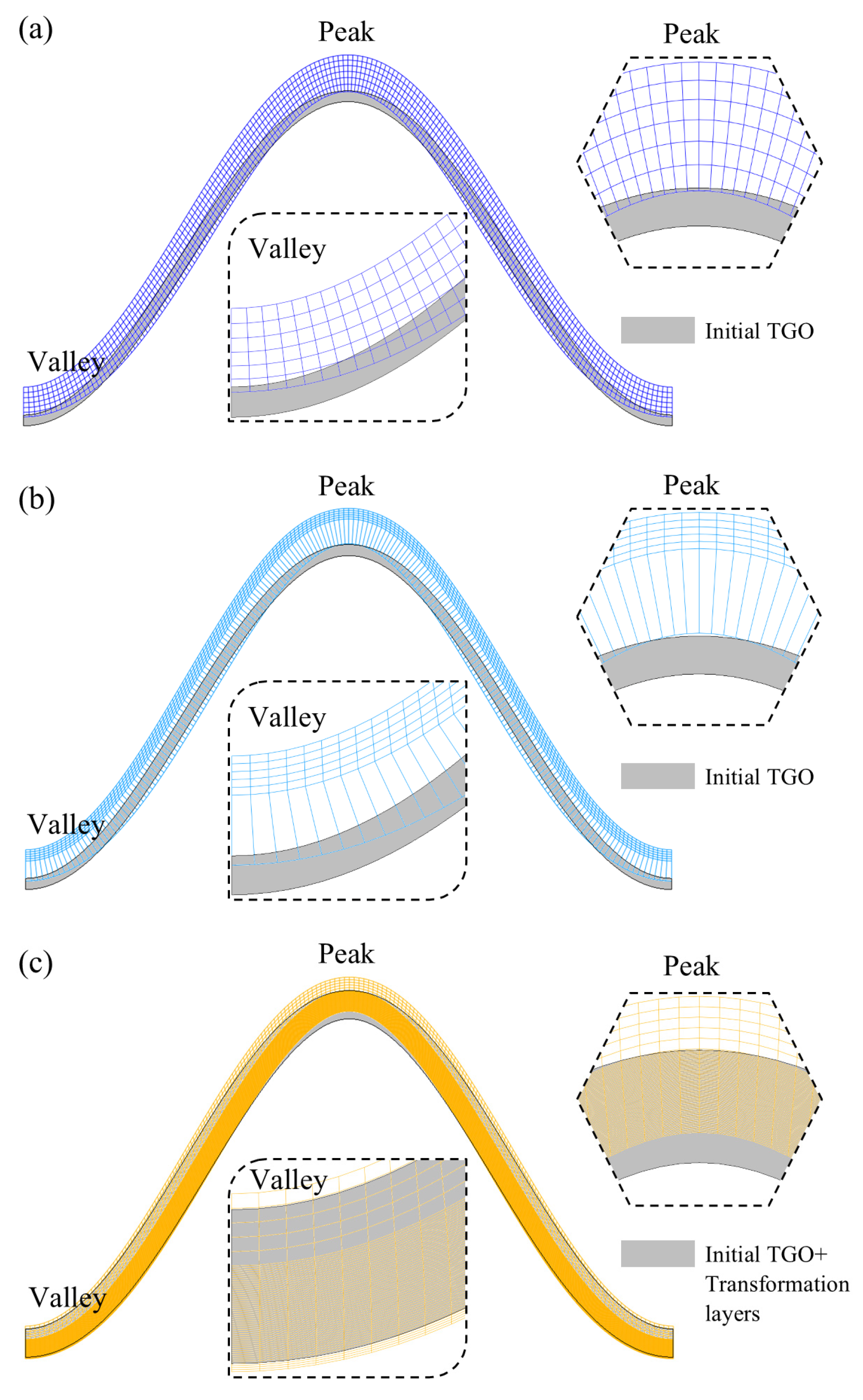

2.1. Geometry, Constraint, and Mesh

2.2. Material Property

2.3. Thermal Loading History

2.4. Dynamic Crack Growth Modeling

3. Result and Discussion

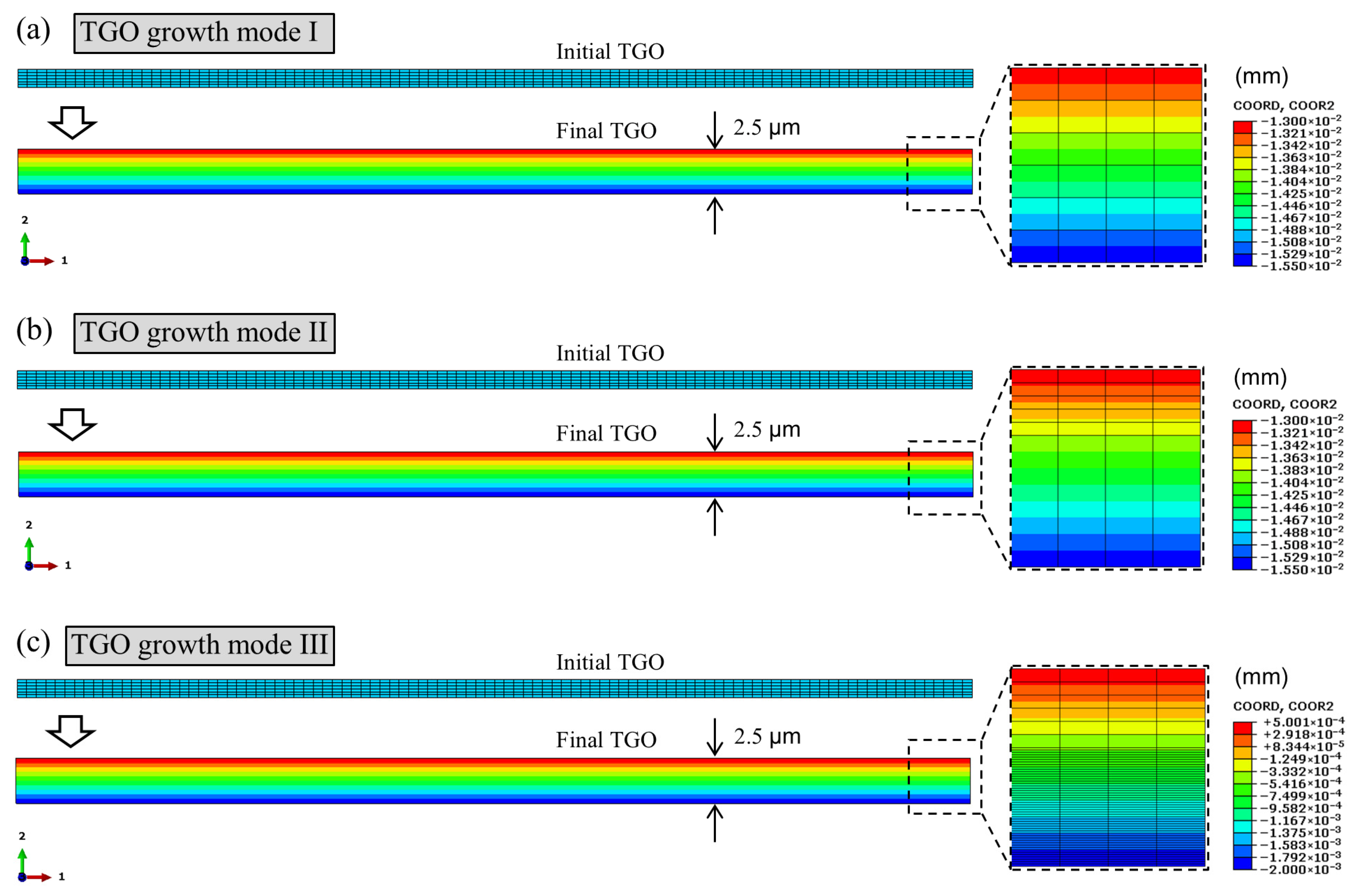

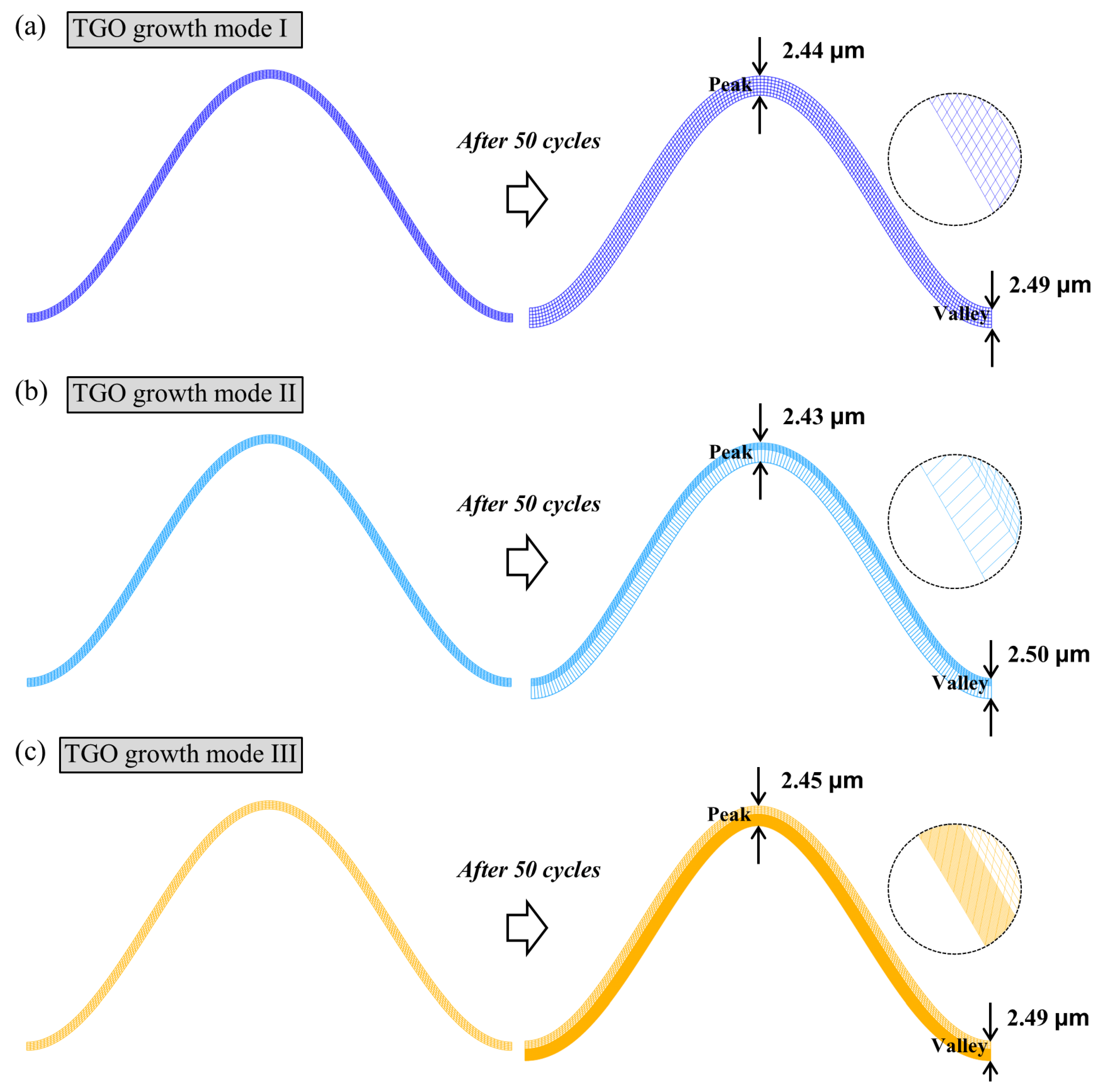

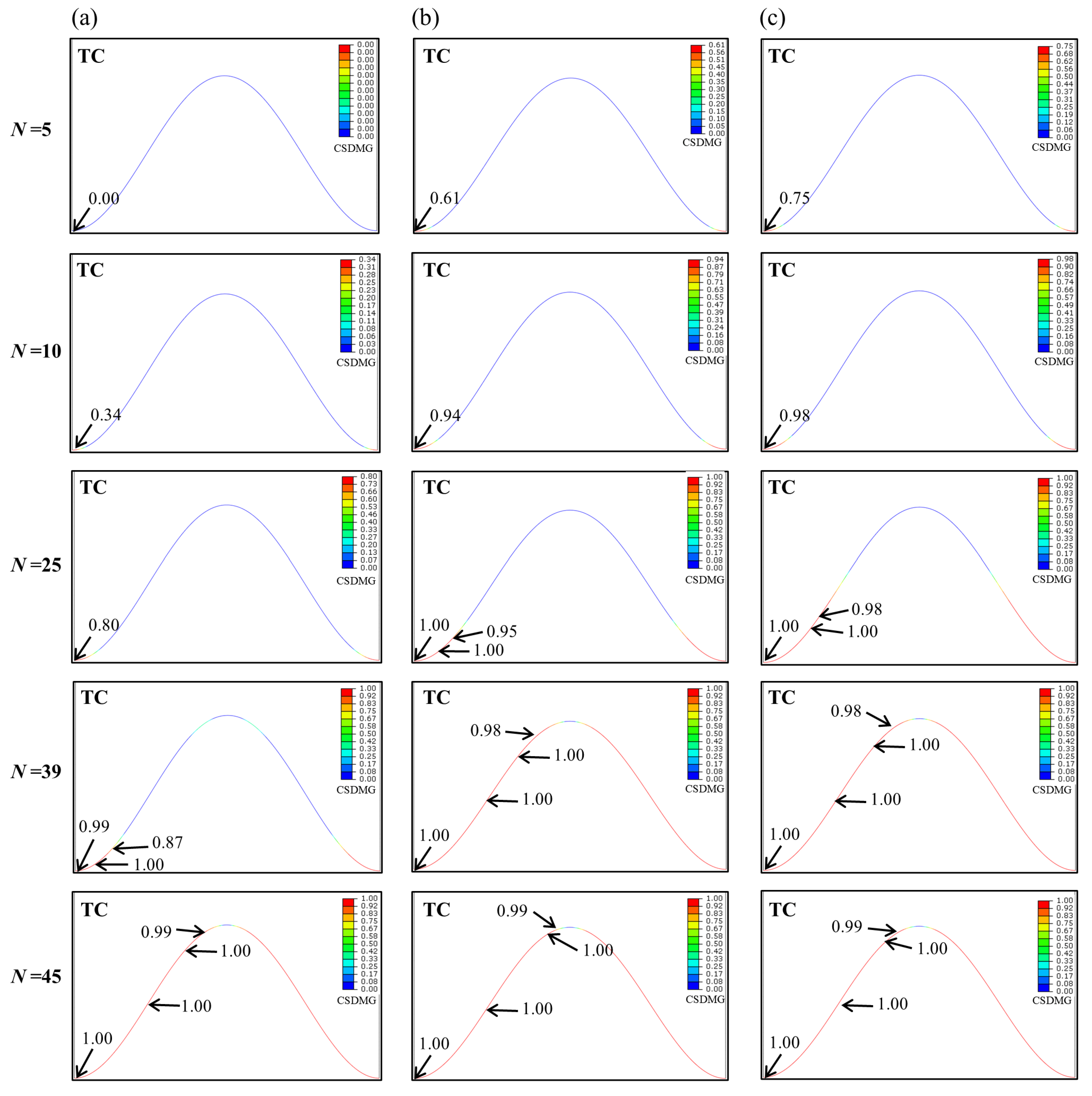

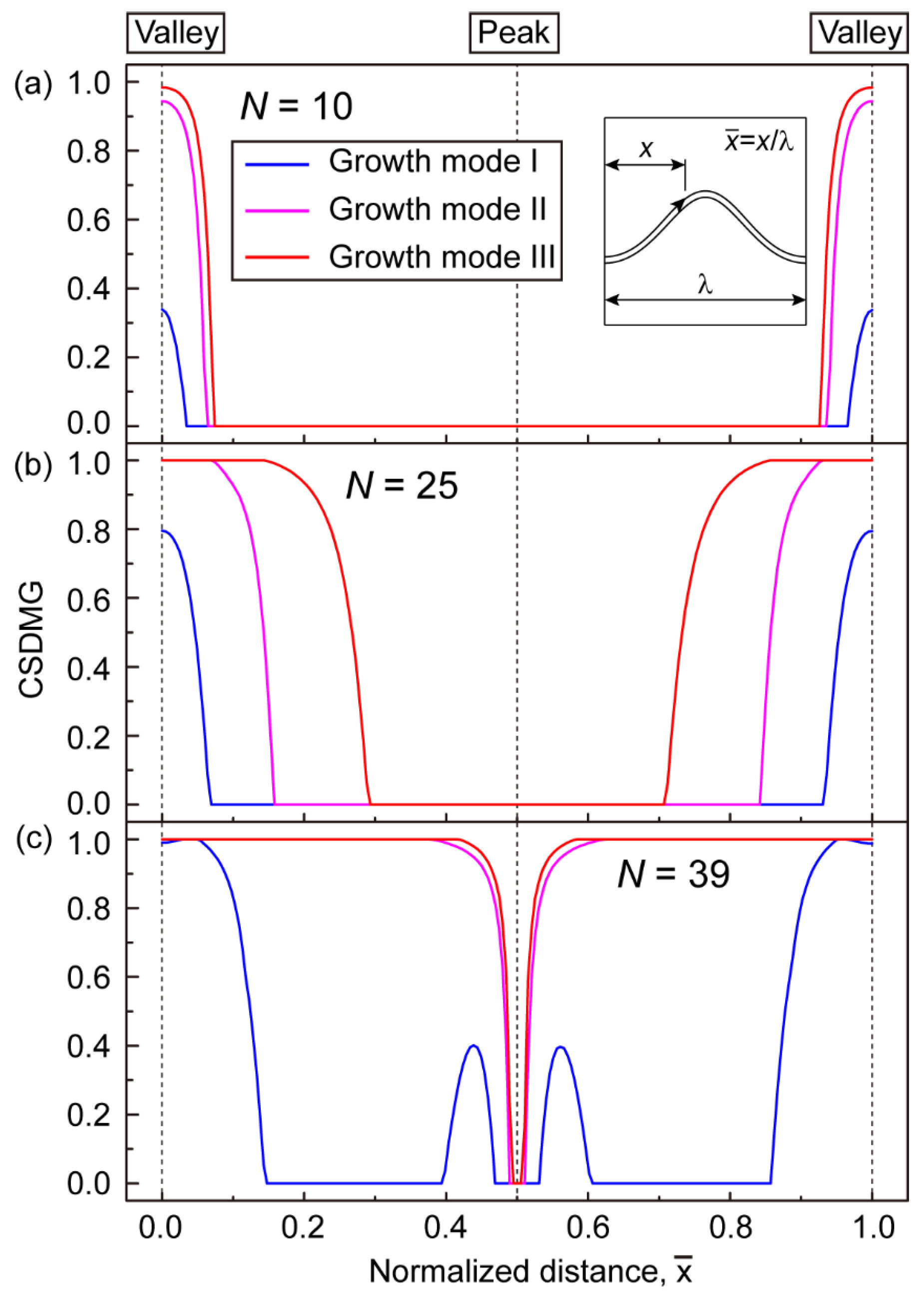

3.1. Validation of TGO Growth Mode

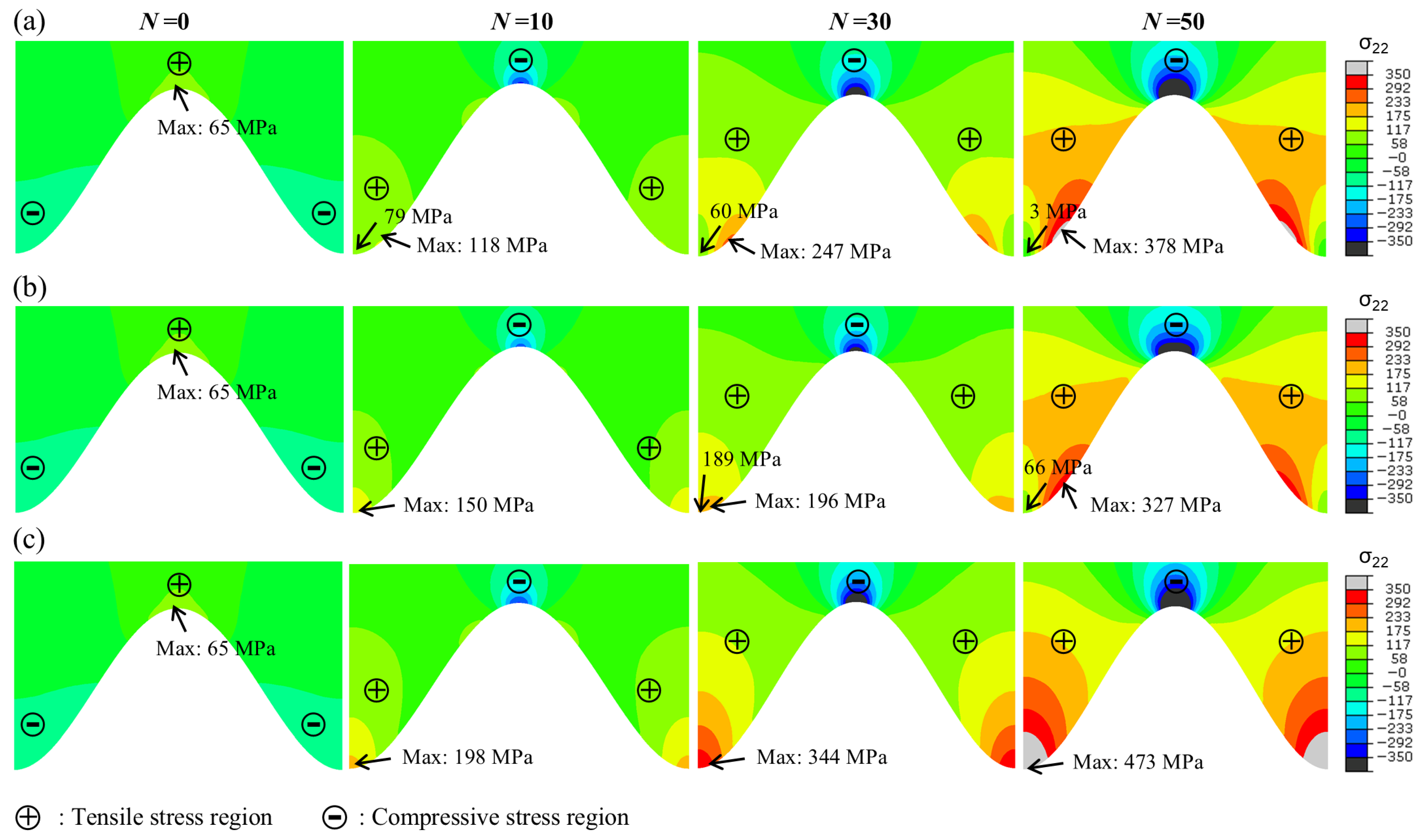

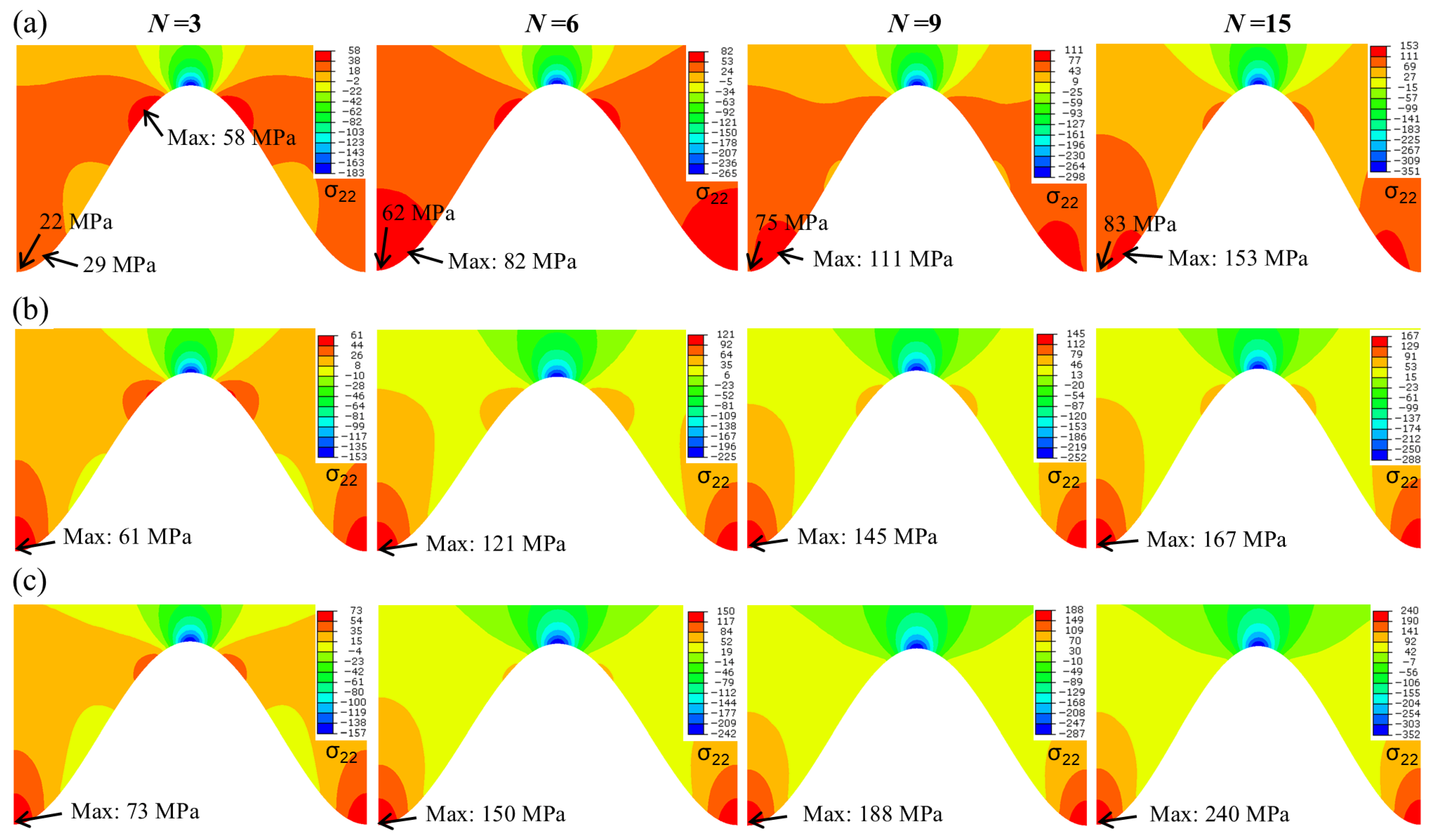

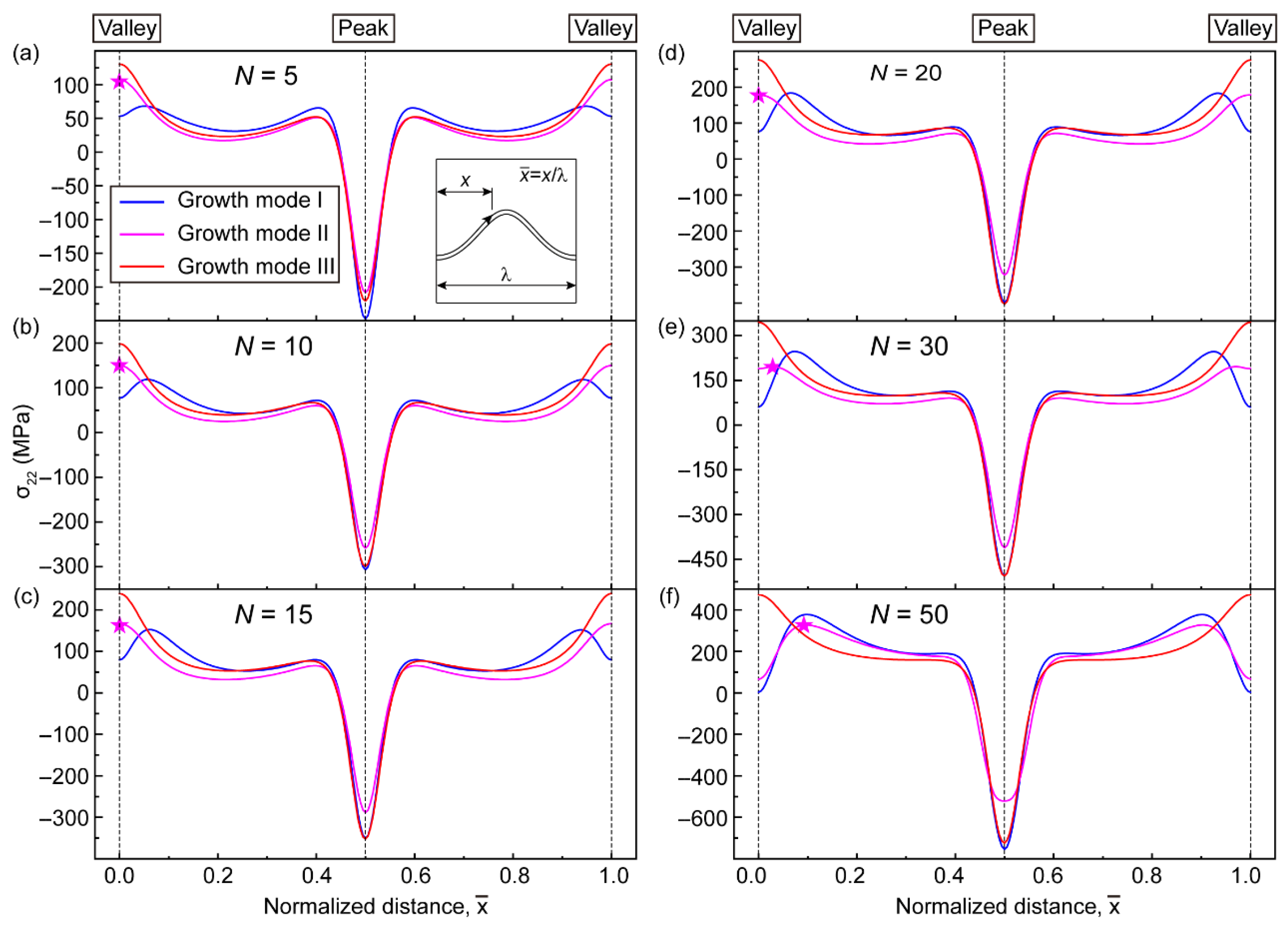

3.2. Stress State and Evolution in TBC

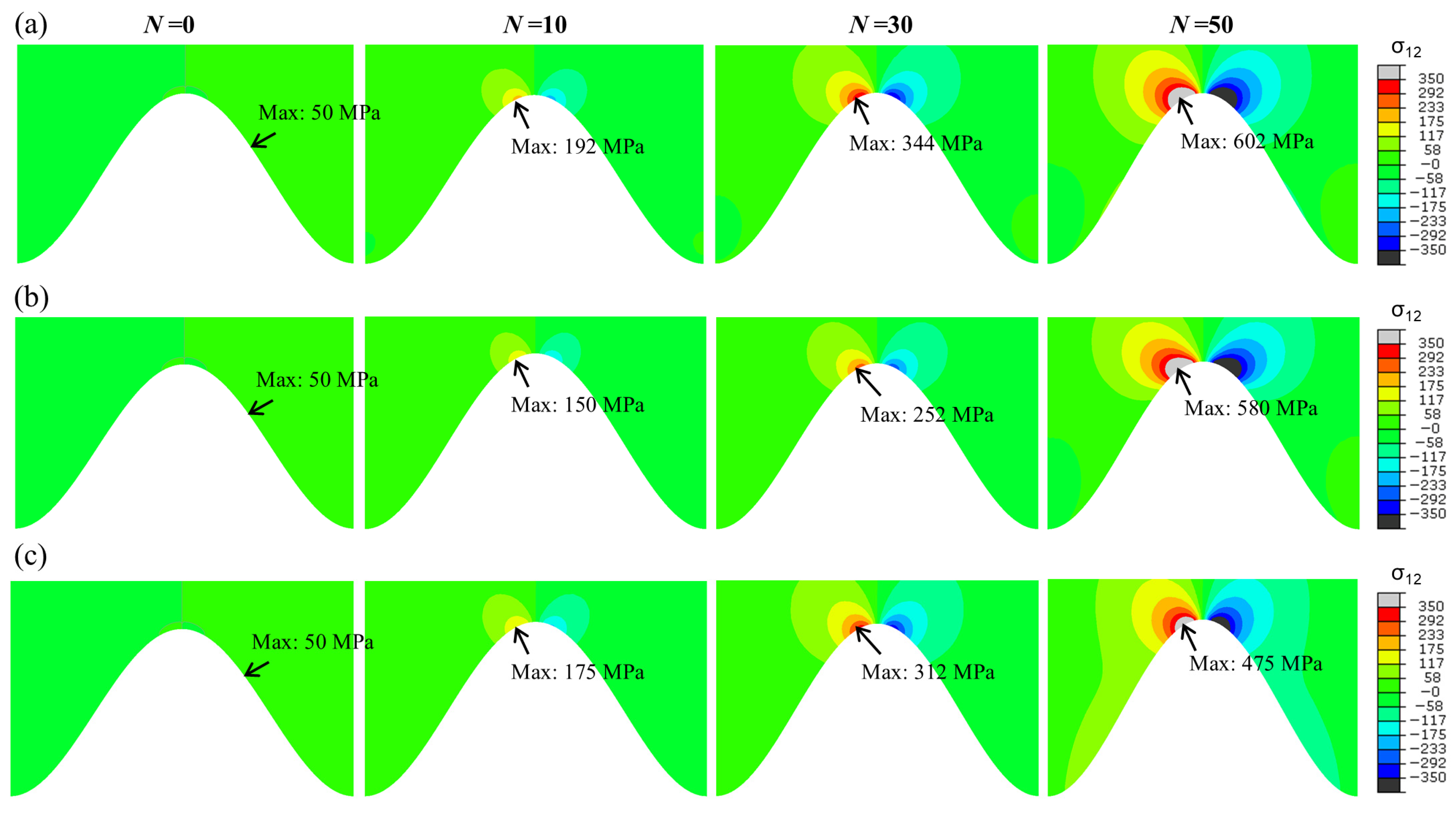

3.2.1. General Trend of Stress Evolution

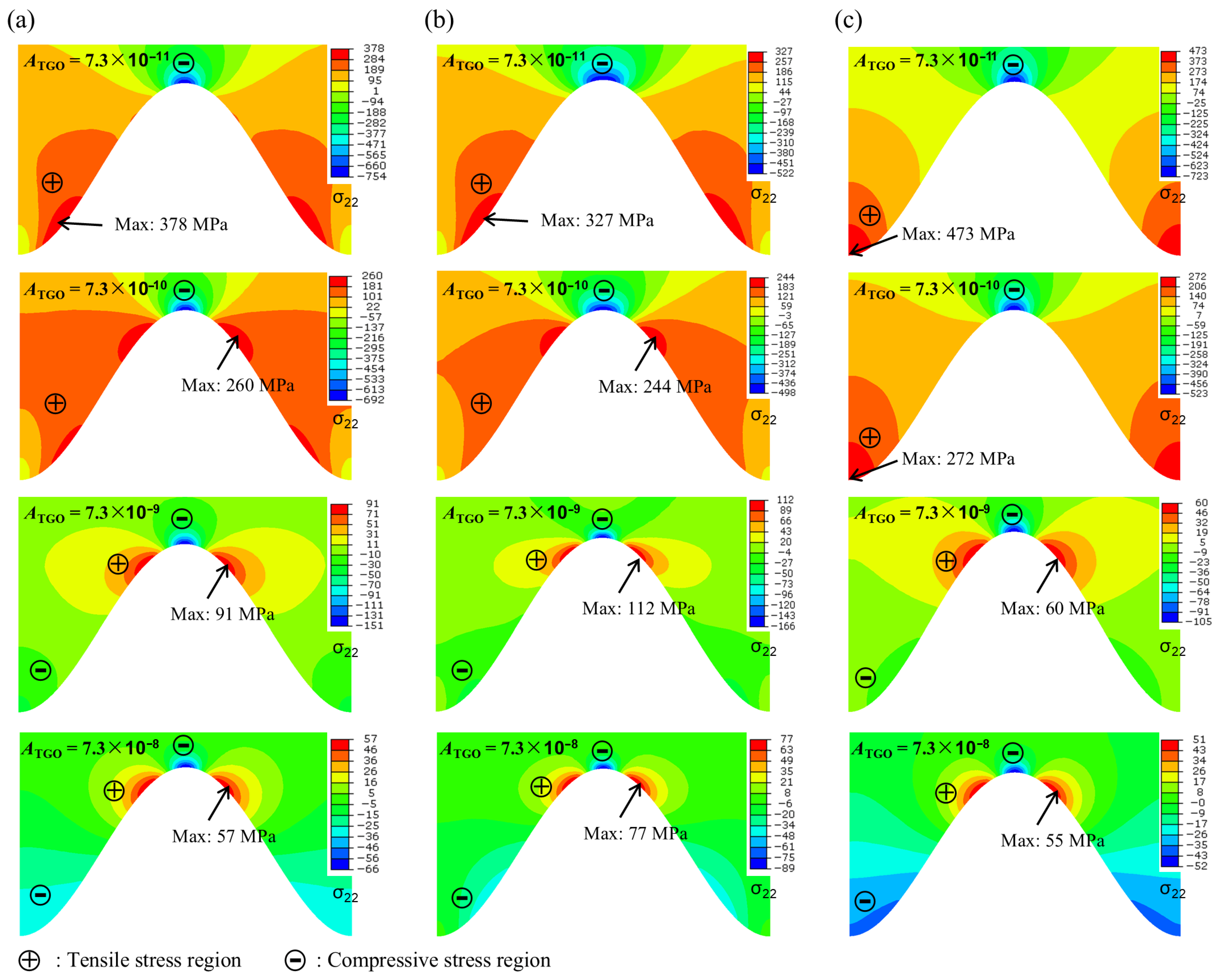

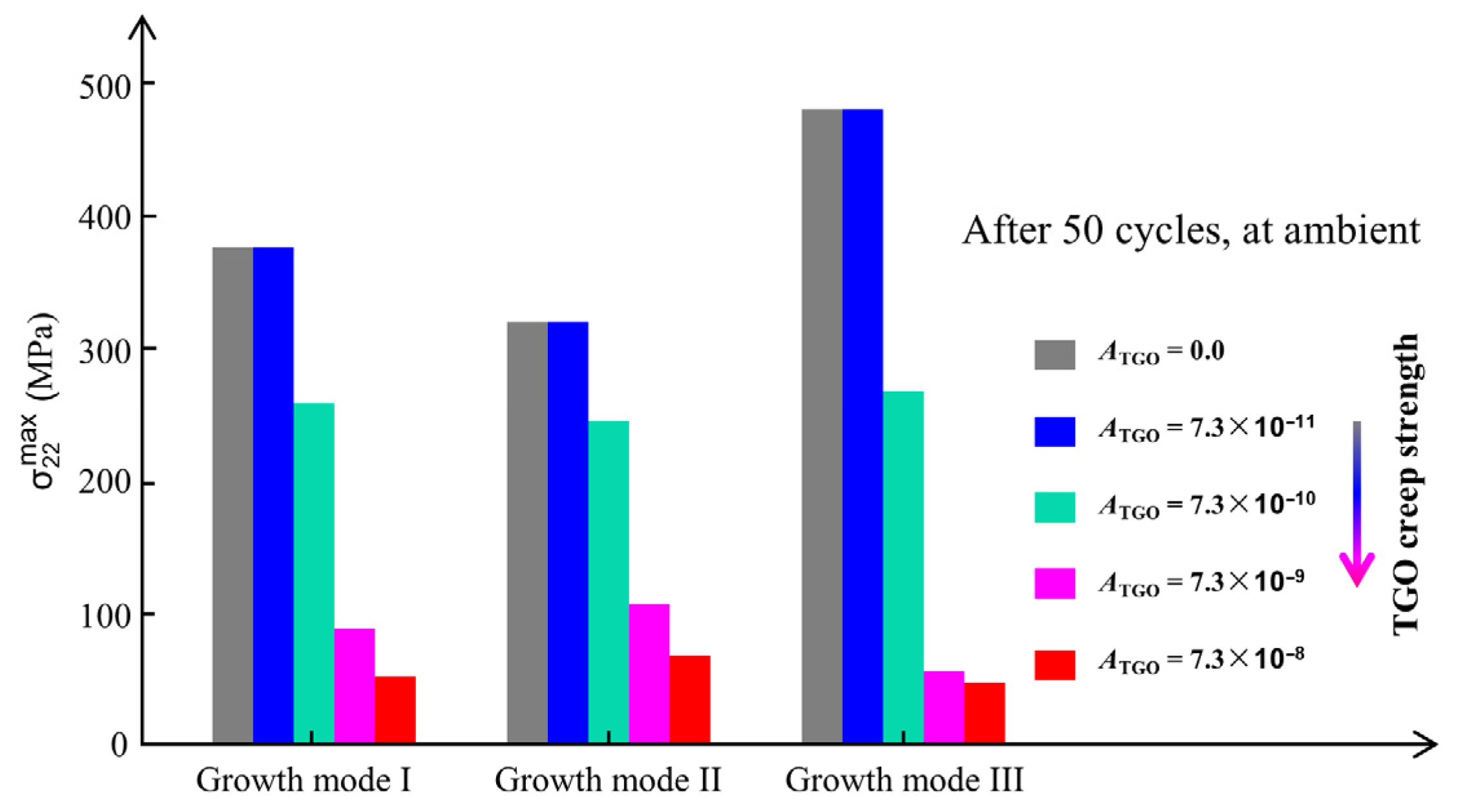

3.2.2. Effects of the TGO Creep Strength on Stress State

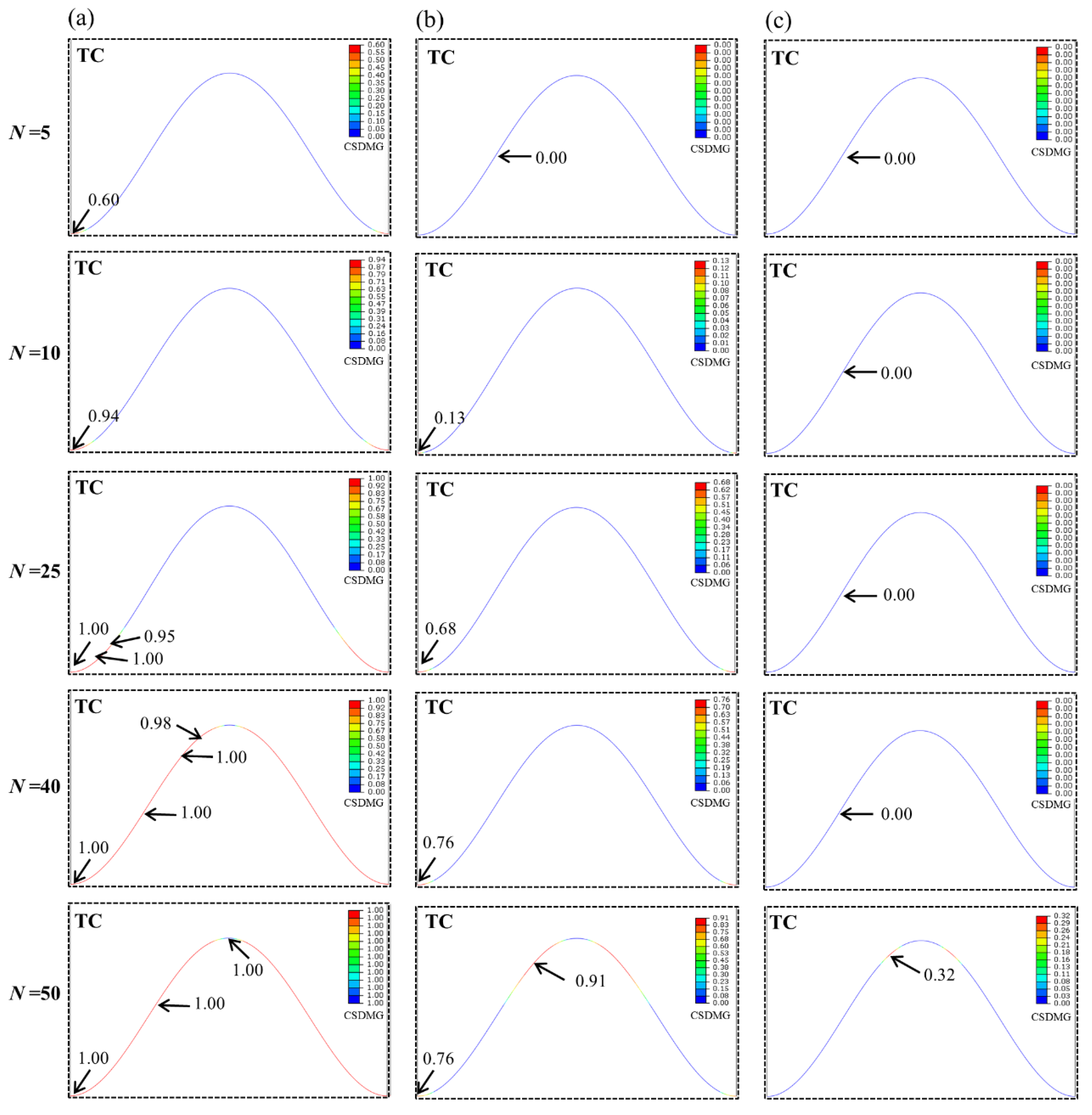

3.3. Interface Delamination and Failure in TBC

3.3.1. General Trend of Interface Damage Evolution

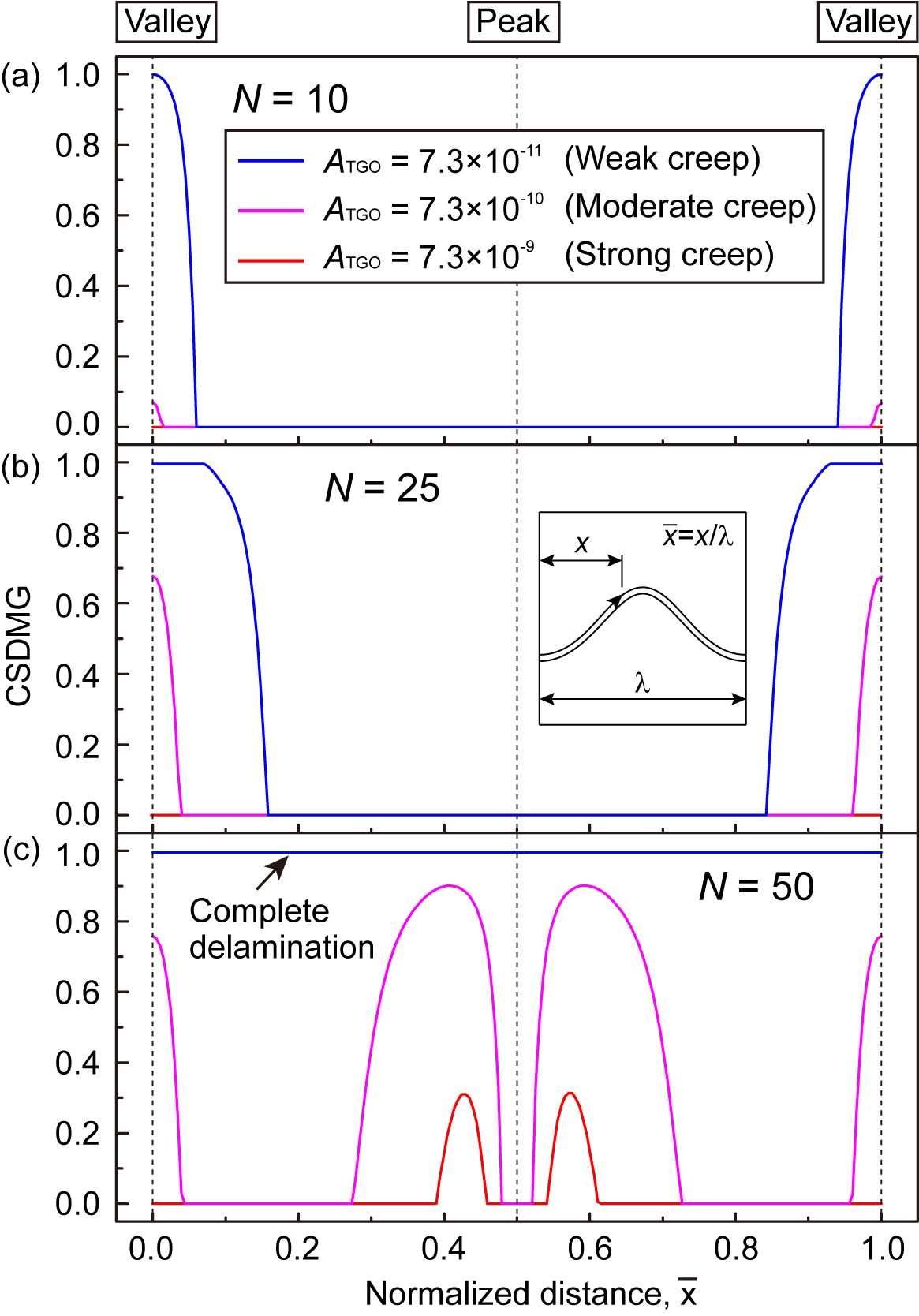

3.3.2. Influences of TGO Creep on the Interface Delamination

4. Conclusions

- (1)

- For all growth modes, the normal tensile stress region is located above the interface valley after all cycles. However, the maximum stress position during the thermal cycle is different: (a) near the valley in mode I, (b) from the bottom to the nearby area in mode II, and (c) at the bottom of the valley in mode III.

- (2)

- An earliest interface delamination appears in growth mode III. The interface failure in growth mode II occurs earlier compared to in mode I, which is attributed to a faster stress accumulation in the early stage of the thermal cycle.

- (3)

- A strong TGO creep rate severely reduces the stress level near the interface. The maximum normal tensile stress position is transferred to the nearby peak. Properly enhancing the creep rate of TGO can postpone the interface delamination.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sezavar, A.; Sajjadi, S.A. A review on the performance and lifetime improvement of thermal barrier coatings. J. Eur. Ceram. Soc. 2025, 45, 117274. [Google Scholar] [CrossRef]

- Padture, N.P. Advanced structural ceramics in aerospace propulsion. Nat. Mater. 2016, 15, 804–809. [Google Scholar] [CrossRef] [PubMed]

- Yin, Q.; Shen, K.-H.; Wang, Y.; Xing, Y.-Z. Research progress of rare earth zirconate thermal barrier coating ceramic materials. Mater. Today Commun. 2025, 42, 111579. [Google Scholar] [CrossRef]

- Park, S.J.; Heogh, W.; Yang, J.; Kang, S.; Jeong, W.; Lee, H.; Jang, T.-S.; Jung, H.-D.; Jahazi, M.; Han, S.C.; et al. Meta-structure of amorphous-inspired 65.1Co28.2Cr5.3Mo lattices augmented by artificial intelligence. Adv. Compos. Hybrid Mater. 2024, 7, 224. [Google Scholar] [CrossRef]

- Ashofteh, A.; Rajabzadeh, M. Advances in thermal barrier coatings modeling, simulation, and analysis: A review. J. Eur. Ceram. Soc. 2024, 44, 116693. [Google Scholar] [CrossRef]

- Li, G.R.; Liu, T.; Luo, X.T.; Yang, G.-J.; Li, C.-J. A matching design co-enhancing thermal barrier and thermal cyclic performances of sintering-resistant coatings. Ceram. Int. 2023, 49, 39506–39515. [Google Scholar] [CrossRef]

- Su, X.R.; Zhang, C.Q.; Huang, L.Y.; Li, G.-R.; Yang, G.-J. Region-function-matching design for YSZ-based thermal barrier coatings enables long thermal cyclic lifespan. J. Am. Ceram. Soc. 2024, 107, 8716–8731. [Google Scholar] [CrossRef]

- Xu, B.Q.; Jiang, J.S.; Zou, Z.H.; Wang, W.; Zhao, X.; Liu, Y.; Xiao, P. Time-dependent spalling behavior of thermally grown oxide induced by room temperature interfacial deformation. Surf. Coat. Technol. 2018, 334, 164–172. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, S.T.; Yu, C.T.; Yu, Z.; Jiang, C.; Li, S.; Bao, Z.; Quan, G.; Zhu, S.; Wang, F. Effect of the non-uniformed growth of TGO on dynamic stress evolution in realistic TC/TGO interface of MCrAlY-YSZ TBCs during thermal cycling. Surf. Coat. Technol. 2025, 511, 132319. [Google Scholar] [CrossRef]

- Yang, M.; Wang, X.; Feng, W.; Fu, Y.; Jiang, Y.; Chen, F.; Li, M.; Chen, Y. Effects of TGO growth on the interface stress distribution based on 3D pores in TBC ceramics layer. Mater. Today Commun. 2024, 38, 107878. [Google Scholar] [CrossRef]

- Li, C.J.; Dong, H.; Ding, H.; Yang, G.-J.; Li, C.-X. The Correlation of the TBC lifetimes in burner cycling test with thermal gradient and furnace isothermal cycling test by TGO effects. J. Therm. Spray Technol. 2017, 26, 378–387. [Google Scholar] [CrossRef]

- Wang, L.; Li, Z.D.; Ding, K.Y.; Deng, C.; Zhang, S.; Zheng, R.; Yang, L.; Lin, X. Effects of TGO growth on the stress distribution and evolution of three-dimensional cylindrical thermal barrier coatings based on finite element simulations. Ceram. Int. 2022, 48, 7864–7875. [Google Scholar] [CrossRef]

- Ranjbar-Far, M.; Absi, J.; Mariaux, G.; Smith, D. Crack propagation modeling on the interfaces of thermal barrier coating system with different thickness of the oxide layer and different interface morphologies. Mater. Des. 2011, 32, 4961–4969. [Google Scholar] [CrossRef]

- Dong, H.; Yang, G.J.; Li, C.X.; Luo, X.; Li, C. Effect of TGO thickness on thermal cyclic lifetime and failure mode of plasma-sprayed TBCs. J. Am. Ceram. Soc. 2014, 97, 1226–1232. [Google Scholar] [CrossRef]

- Ahmadian, S.; Jordan, E.H. Explanation of the effect of rapid cycling on oxidation, rumpling, microcracking and lifetime of air plasma sprayed thermal barrier coatings. Surf. Coat. Technol. 2014, 244, 109–116. [Google Scholar] [CrossRef]

- Yu, Q.M.; Zhou, H.L.; Wang, L.B. Influences of interface morphology and thermally grown oxide thickness on residual stress distribution in thermal barrier coating system. Ceram. Int. 2016, 42, 8338–8350. [Google Scholar] [CrossRef]

- Bednarz, P. Finite Element Simulation of Stress Evolution in Thermal Barrier Coating Systems. Ph.D. Thesis, Forschungszntrum Jülich, Jülich, Germany, 2007. [Google Scholar]

- Cen, L.; Qin, W.Y.; Yu, Q.M. Analysis of interface delamination in thermal barrier coating system with axisymmetric structure based on corresponding normal and tangential stresses. Surf. Coat. Technol. 2019, 358, 785–795. [Google Scholar] [CrossRef]

- Cen, L.; Qin, W.Y.; Yu, Q.M. Finite element analysis of interface undulation and interface delamination in the MCrAlY coating system under thermal cycling: Considering oxide thickness and top-coat effects. J. Therm. Spray Technol. 2020, 29, 597–610. [Google Scholar] [CrossRef]

- Chen, D. TGO growth behavior in environmental barrier coatings with modified silicon bond coat. J. Therm. Spray Technol. 2024, 33, 174–180. [Google Scholar] [CrossRef]

- Li, Z.H.; Wei, Z.Y.; Li, X.Y.; Wang, L.-S.; Ma, Z.-Y.; Dong, L.; Dong, H.; Yao, J.-T.; Zhou, Y.; Li, G.-R. Matching design of porous microstructures for double-layered thermal barrier coatings composed of Gd2Zr2O7 and yttria-stabilized zirconia enables long protection. Ceram. Int. 2025, 51, 35092–35103. [Google Scholar] [CrossRef]

- Wei, Z.Y.; Chai, Y.J.; Yi, P.; Meng, G.-H.; Zhang, W.-W. Stress profile and crack evolution in a three-dimensional (3D) thermal barrier coatings during isothermal cyclic test. Ceram. Int. 2022, 48, 30606–30620. [Google Scholar] [CrossRef]

- Wei, Z.Y.; Cai, H.N.; Su, J.Y.; Feng, R.-X. Dynamic crack growth mechanism and lifetime assessment in plasma sprayed thermal barrier system upon temperature cycling. Ceram. Int. 2019, 45, 14896–14907. [Google Scholar] [CrossRef]

- Song, J.N.; Li, S.L.; Yang, X.G.; Qi, H.; Shi, D. Numerical investigation on the cracking behaviors of thermal barrier coating system under different thermal cycle loading waveforms. Surf. Coat. Technol. 2018, 349, 166–176. [Google Scholar] [CrossRef]

- Xu, T.; He, M.Y.; Evans, A.G. A numerical assessment of the durability of thermal barrier systems that fail by ratcheting of the thermally grown oxide. Acta Mater. 2003, 51, 3807–3820. [Google Scholar] [CrossRef]

- ABAQUS. Version 2023 Documentation; Dassault Systemes Simulia Corp.: Providence, RI, USA, 2023. [Google Scholar]

- Chen, Z.; Jia, W.B.; Zhao, K.; Fang, L. Comparison of stress evolution under TGO growth simulated by two different methods in thermal barrier coatings. Ceram. Int. 2020, 46, 2915–2922. [Google Scholar] [CrossRef]

- Rosler, J.; Baker, M.; Volgmann, M. Stress state and failure mechanisms of thermal barrier coatings: Role of creep in thermally grown oxide. Acta Mater. 2001, 49, 3659–3670. [Google Scholar] [CrossRef]

- Ding, J.; Li, F.X.; Kang, K.J. Numerical simulation of displacement instabilities of surface grooves on an alumina forming alloy during thermal cycling oxidation. J. Mech. Sci. Technol. 2009, 23, 2308–2319. [Google Scholar] [CrossRef]

- Ding, J.; Li, F.X.; Kang, K.J. Effects of material creep on displacement instability in a surface groove under thermo-mechanical cycling. Surf. Coat. Technol. 2009, 204, 157–164. [Google Scholar] [CrossRef]

- Lin, C.; Li, Y.M. Interface stress evolution considering the combined creep-plastic behavior in thermal barrier coatings. Mater. Des. 2016, 89, 245–254. [Google Scholar]

- Wei, Z.Y.; Cai, H.N.; Meng, G.H.; Tahir, A.; Zhang, W.-W. An innovative model coupling TGO growth and crack propagation for the failure assessment of lamellar structured thermal barrier coatings. Ceram. Int. 2020, 46, 1532–1544. [Google Scholar] [CrossRef]

- He, M.Y.; Hutchinson, J.W.; Evans, A.G. Simulation of stresses and delamination in a plasma-sprayed thermal barrier system upon thermal cycling. Mater. Sci. Eng. A 2003, 345, 172–178. [Google Scholar] [CrossRef]

- He, M.Y.; Mumm, D.R.; Evans, A.G. Criteria for the delamination of thermal barrier coatings: With application to thermal gradients. Surf. Coat. Technol. 2004, 185, 184–193. [Google Scholar] [CrossRef]

- Cen, L.; Qin, W.Y.; Yu, Q.M. On the role of TGO growth in the interface undulation in MCrAlY coating system upon thermal cycling. Ceram. Int. 2019, 45, 22802–22812. [Google Scholar] [CrossRef]

- Wei, Z.Y.; Cai, H.N.; Tahir, A.; Zhang, W.-W.; Li, X.-F.; Zhang, Y.; Huang, Y.-P.; Liu, Y. Stress states in plasma-sprayed thermal barrier coatings upon temperature cycling: Combined effects of creep, plastic deformation, and TGO growth. Ceram. Int. 2019, 45, 19829–19844. [Google Scholar] [CrossRef]

- Huang, Y.P.; Wei, Z.Y.; Cai, H.N.; Liu, Y.; Han, X.-C. The effects of TGO growth stress and creep rate on TC/TGO interface cracking in APS thermal barrier coatings. Ceram. Int. 2021, 47, 24760–24769. [Google Scholar] [CrossRef]

- Rosler, J.; Baker, M.; Aufzug, K. A parametric study of the stress state of thermal barrier coatings: Part I: Creep relaxation. Acta Mater. 2004, 52, 4809–4817. [Google Scholar] [CrossRef]

- Schwarzer, J.; Loehe, D.; Voehringer, O. Influence of the TGO creep behavior on delamination stress development in thermal barrier coating systems. Mater. Sci. Eng. A 2004, 387–389, 692–695. [Google Scholar] [CrossRef]

- Su, L.C.; Zhang, W.X.; Sun, Y.L.; Wang, T.J. Effect of TGO creep on top-coat cracking induced by cyclic displacement instability in a thermal barrier coating system. Surf. Coat. Technol. 2014, 254, 410–417. [Google Scholar] [CrossRef]

- Wei, Z.Y.; Cai, H.N.; Zhao, S.D. Assessment of stress characteristic and interfacial delamination in thermal barrier coatings considering the connected crack network. Surf. Coat. Technol. 2022, 432, 128065. [Google Scholar] [CrossRef]

- Wei, Z.Y.; Cai, H.N. Stress states and crack behavior in plasma sprayed TBCs based on a novel lamellar structure model with real interface morphology. Ceram. Int. 2019, 45, 16948–16962. [Google Scholar] [CrossRef]

- Aktaa, J.; Sfar, K.; Munz, D. Assessment of TBC systems failure mechanisms using a fracture mechanics approach. Acta Mater. 2005, 53, 4399–4413. [Google Scholar] [CrossRef]

- Wei, Z.Y.; Cai, H.N.; Li, C.J. Comprehensive dynamic failure mechanism of thermal barrier coatings based on a novel crack propagation and TGO growth coupling model. Ceram. Int. 2018, 44, 22556–22566. [Google Scholar] [CrossRef]

- Ranjbar-Far, M.; Absi, J.; Mariaux, G.; Dubois, F. Simulation of the effect of material properties and interface roughness on the stress distribution in thermal barrier coatings using finite element method. Mater. Des. 2010, 31, 772–781. [Google Scholar] [CrossRef]

- Ranjbar-Far, M.; Absi, J.; Mariaux, G. Finite element modeling of the different failure mechanisms of a plasma sprayed thermal barrier coatings system. J. Therm. Spray Technol. 2012, 21, 1234–1244. [Google Scholar] [CrossRef]

- Białas, M. Finite element analysis of stress distribution in thermal barrier coatings. Surf. Coat. Technol. 2008, 202, 6002–6010. [Google Scholar] [CrossRef]

- Zhao, P.F.; Sun, C.A.; Zhu, X.Y.; Shang, F.; Li, C. Fracture toughness measurements of plasma-sprayed thermal barrier coatings using a modified four-point bending method. Surf. Coat. Technol. 2010, 204, 4066–4074. [Google Scholar] [CrossRef]

- Zhang, B.Y.; Yang, G.J.; Li, C.X.; Li, C.-J. Non-parabolic isothermal oxidation kinetics of low pressure plasma sprayed MCrAlY bond coat. Appl. Surf. Sci. 2017, 406, 99–109. [Google Scholar] [CrossRef]

| T (°C) | E (GPa) | ν | α × 10−6 (°C−1) | E (GPa) | ν | α × 10−6 (°C−1) |

|---|---|---|---|---|---|---|

| TC | TGO | |||||

| 25 | 17.5 | 0.20 | 9.68 | 378 | 0.27 | 5.1 |

| 200 | - | 0.20 | - | 371 | 0.27 | - |

| 400 | - | 0.20 | 9.70 | 361 | 0.27 | - |

| 800 | - | 0.20 | - | 336 | 0.27 | - |

| 1000 | 12.4 | 0.20 | 10.34 | 311 | 0.27 | 9.8 |

| BC | SUB | |||||

| 25 | 218 | 0.30 | 10.3 | 210 | 0.30 | - |

| 200 | 209 | 0.30 | 11.3 | 200 | 0.30 | 12.6 |

| 400 | 199 | 0.30 | 12.5 | 187 | 0.30 | 13.6 |

| 800 | 162 | 0.30 | 14.3 | 156 | 0.30 | 15.4 |

| 1000 | 118 | 0.30 | 16.0 | 138 | 0.30 | 16.3 |

| T (°C) | Plastic Strain | Stress (GPa) | |

|---|---|---|---|

| BC | 20 | 0 | 1 |

| 300 | 0 | 1 | |

| 750 | 0 | 0.1 | |

| 1000 | 0 | 0.1 | |

| TGO | 20 | 0 | 10 |

| 900 | 0 | 10 | |

| 1000 | 0 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, B.-B.; Zhuo, X.-S.; Fan, J.-F.; Cai, Y.; Wei, Z.-Y.; Zhang, W.-W.; Xu, X.-F.; Wang, J.-F.; Sun, J.-X.; Wang, H.-L.; et al. Influence of Thermally Grown Oxide Dynamic Growth Mode and Creep Strength on the Delamination and Failure of Thermal Barrier Coatings in the Furnace Cycle. Coatings 2025, 15, 1251. https://doi.org/10.3390/coatings15111251

Liu B-B, Zhuo X-S, Fan J-F, Cai Y, Wei Z-Y, Zhang W-W, Xu X-F, Wang J-F, Sun J-X, Wang H-L, et al. Influence of Thermally Grown Oxide Dynamic Growth Mode and Creep Strength on the Delamination and Failure of Thermal Barrier Coatings in the Furnace Cycle. Coatings. 2025; 15(11):1251. https://doi.org/10.3390/coatings15111251

Chicago/Turabian StyleLiu, Bing-Bing, Xue-Shi Zhuo, Jia-Feng Fan, Yao Cai, Zhi-Yuan Wei, Wei-Wei Zhang, Xiao-Fei Xu, Jin-Feng Wang, Jian-Xin Sun, Hai-Lin Wang, and et al. 2025. "Influence of Thermally Grown Oxide Dynamic Growth Mode and Creep Strength on the Delamination and Failure of Thermal Barrier Coatings in the Furnace Cycle" Coatings 15, no. 11: 1251. https://doi.org/10.3390/coatings15111251

APA StyleLiu, B.-B., Zhuo, X.-S., Fan, J.-F., Cai, Y., Wei, Z.-Y., Zhang, W.-W., Xu, X.-F., Wang, J.-F., Sun, J.-X., Wang, H.-L., Shi, Q.-Y., Zhang, Y.-H., Wang, M.-Z., Jiang, Y.-S., & Zhang, X.-F. (2025). Influence of Thermally Grown Oxide Dynamic Growth Mode and Creep Strength on the Delamination and Failure of Thermal Barrier Coatings in the Furnace Cycle. Coatings, 15(11), 1251. https://doi.org/10.3390/coatings15111251