Load and Velocity Dependence of Friction at Iron–Silica Interfaces: An Atomic-Scale Study

Abstract

1. Introduction

2. Simulation and Method

2.1. Simulation Setup and Potential Parameters

2.2. Simulation Procedure

3. Results and Discussion

3.1. Effect of Applied Loads on the Tribological Properties

3.2. Effect of Sliding Velocities on the Tribological Properties

4. Conclusions

- (1)

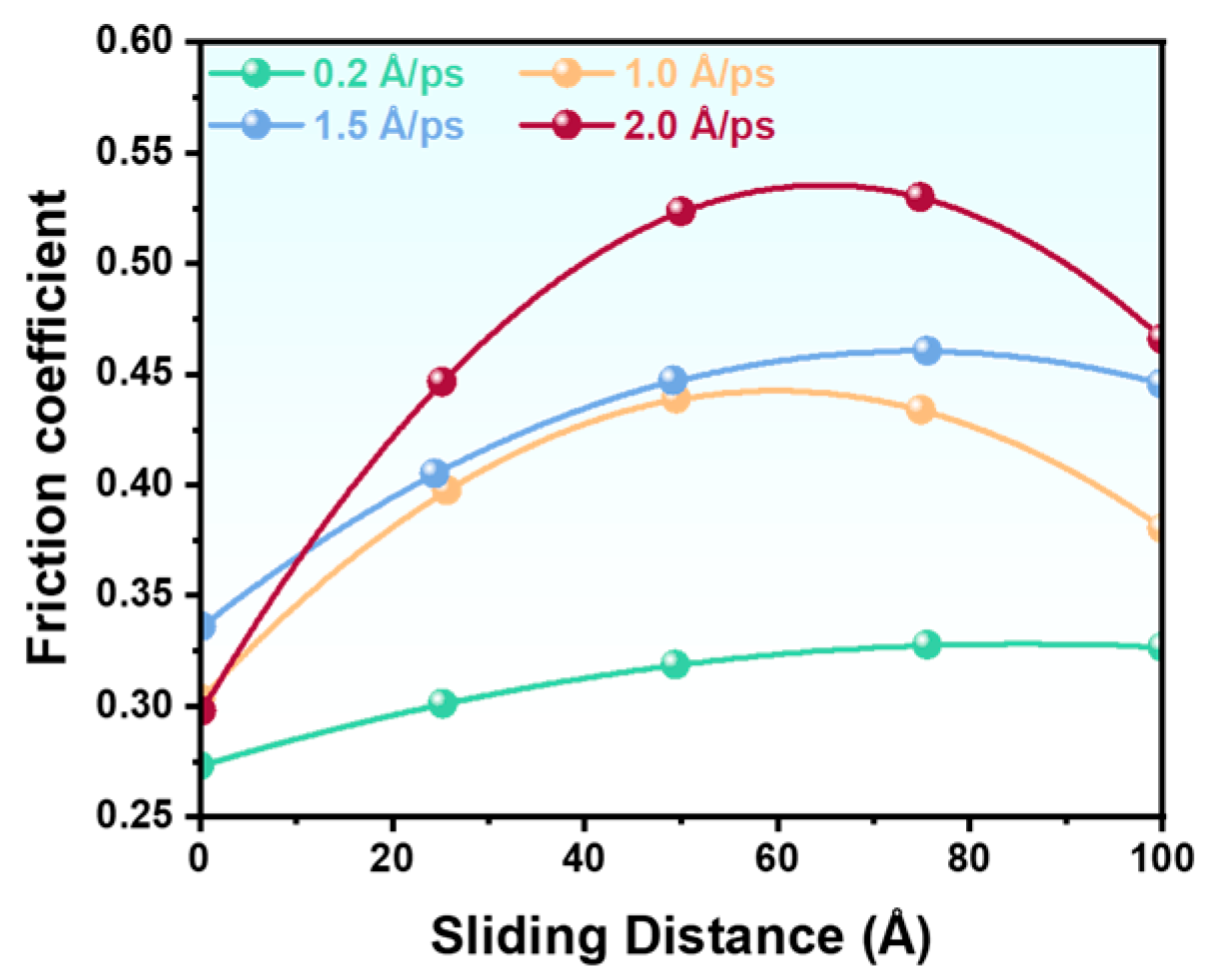

- The coefficient of friction shows strong dependence on both normal load and sliding velocity, with a transition from elastic-dominated deformation under low load/velocity to severe plastic deformation under high-load/velocity conditions.

- (2)

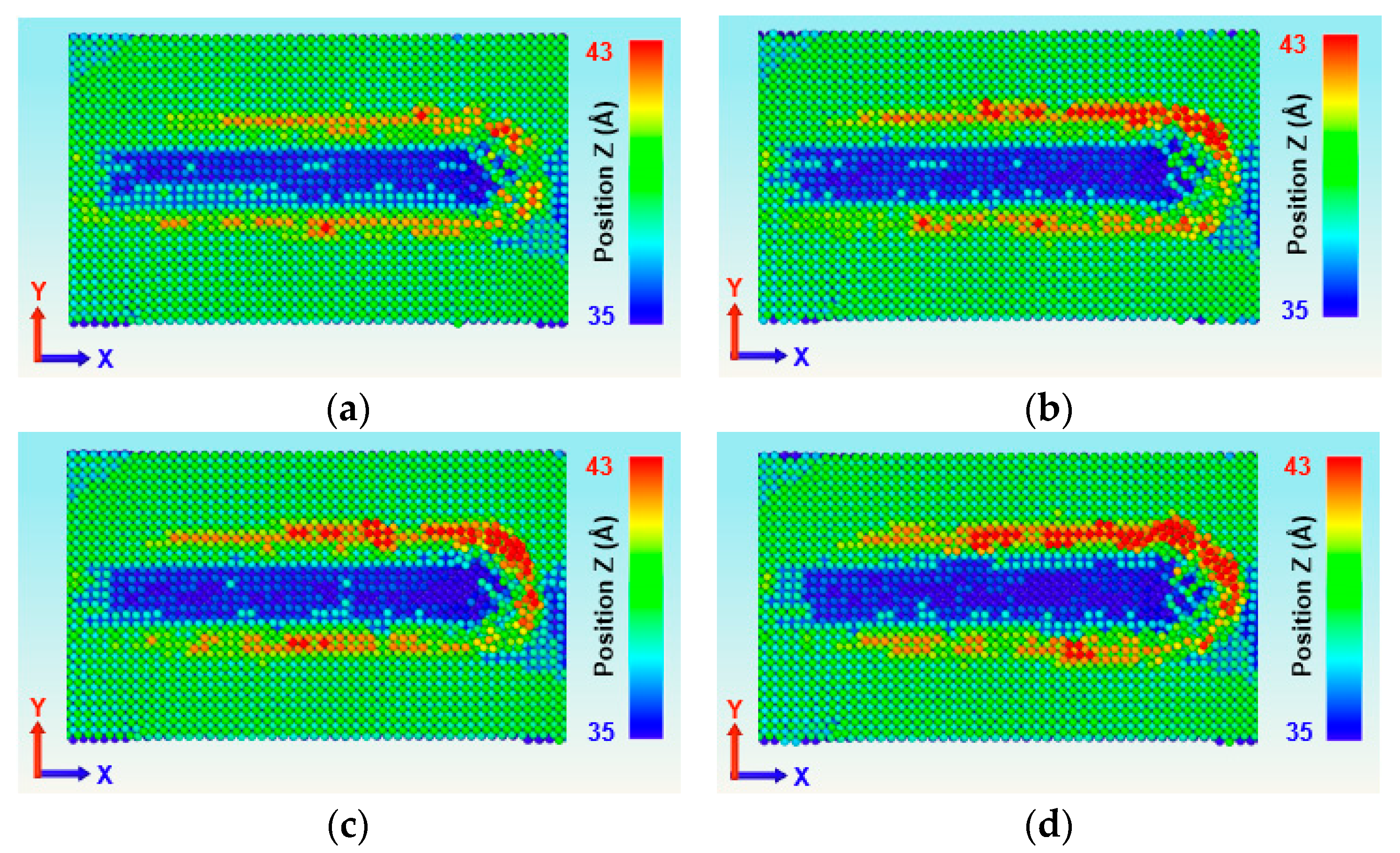

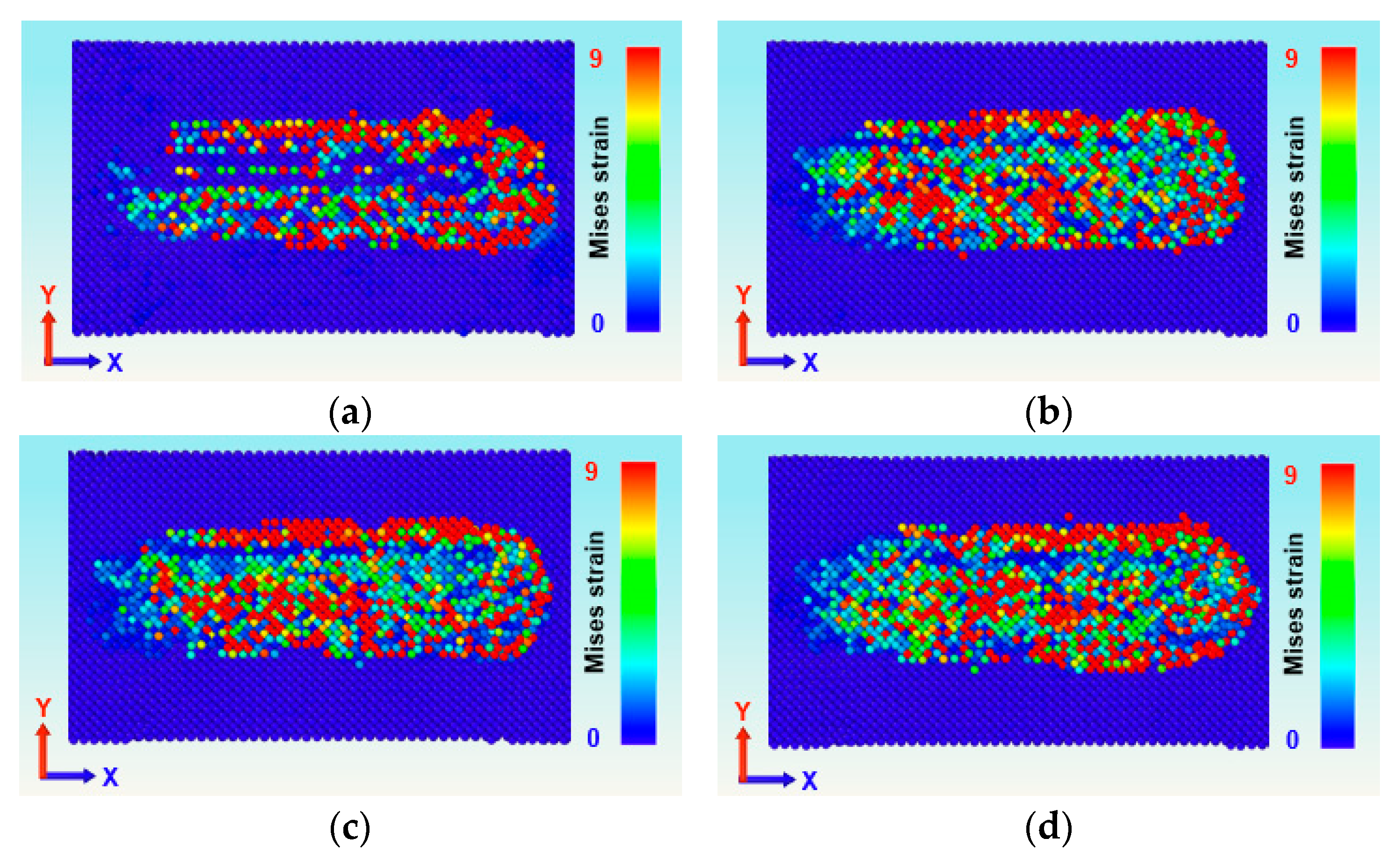

- Interfacial plastic deformation intensifies with increasing load, exhibiting asymmetric atomic pile-up and expansion of strain field from localized to global distribution.

- (3)

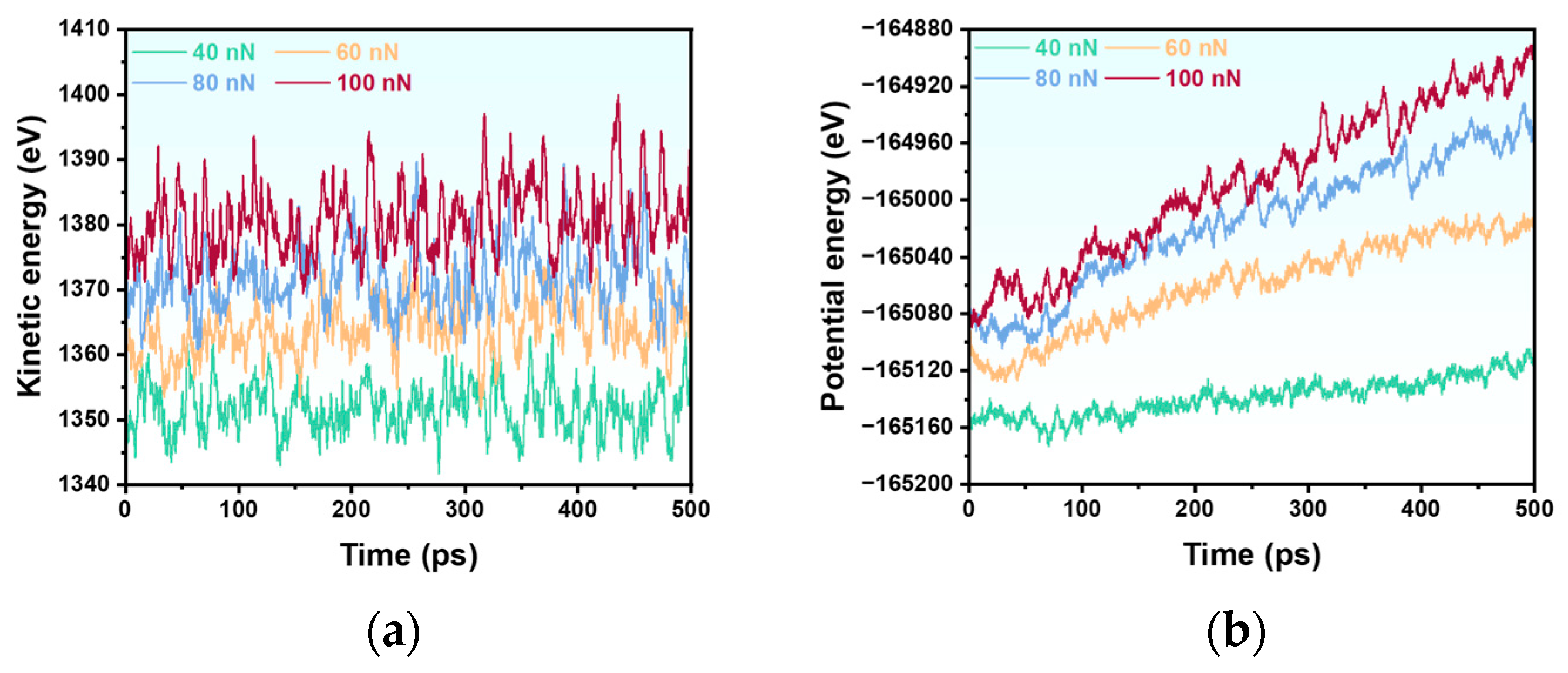

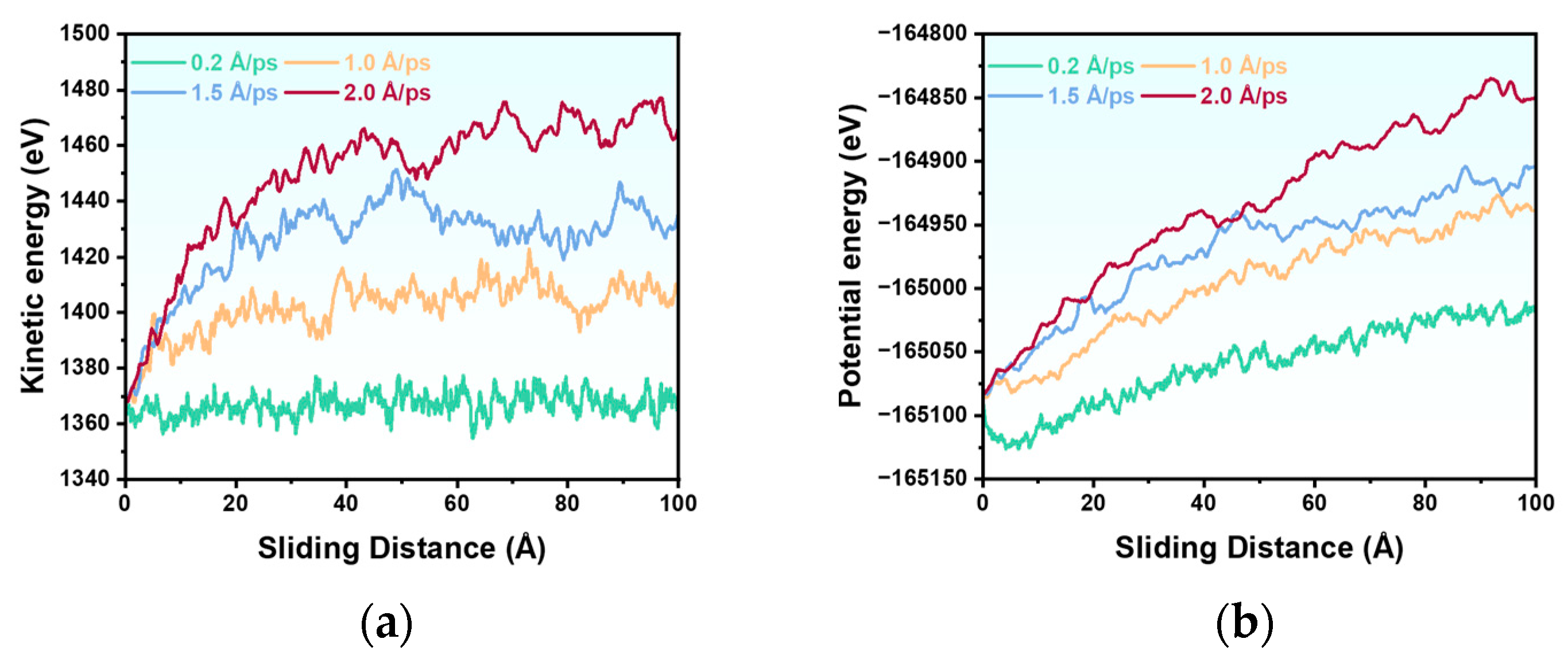

- Energy analysis reveals significant conversion of mechanical work to heat and defects, with the most dramatic potential energy change occurring at 40–60 nN, indicating critical defect accumulation.

- (4)

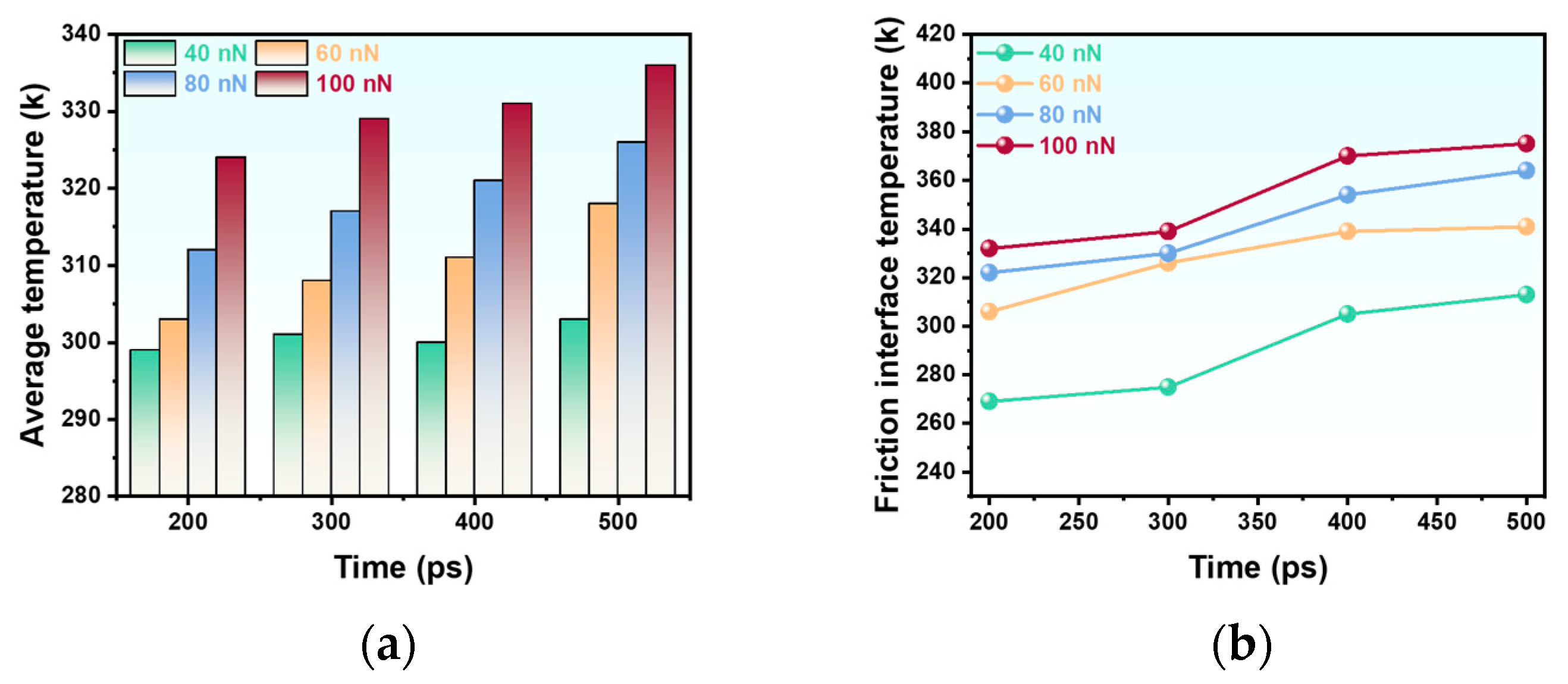

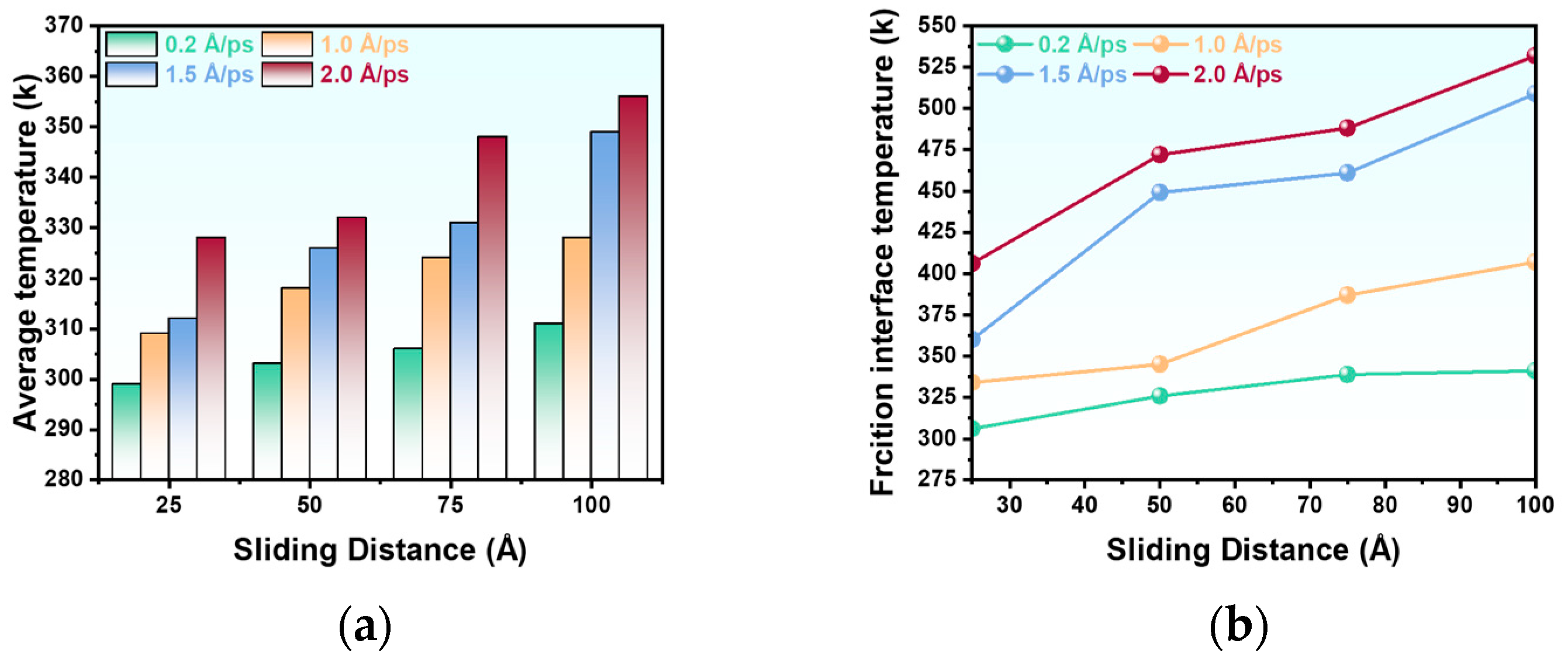

- Temperature distribution shows high localization at the interface, with the most significant thermal response occurring between 1.0–1.5 Å/ps, suggesting a transition in heating mechanisms.

- (5)

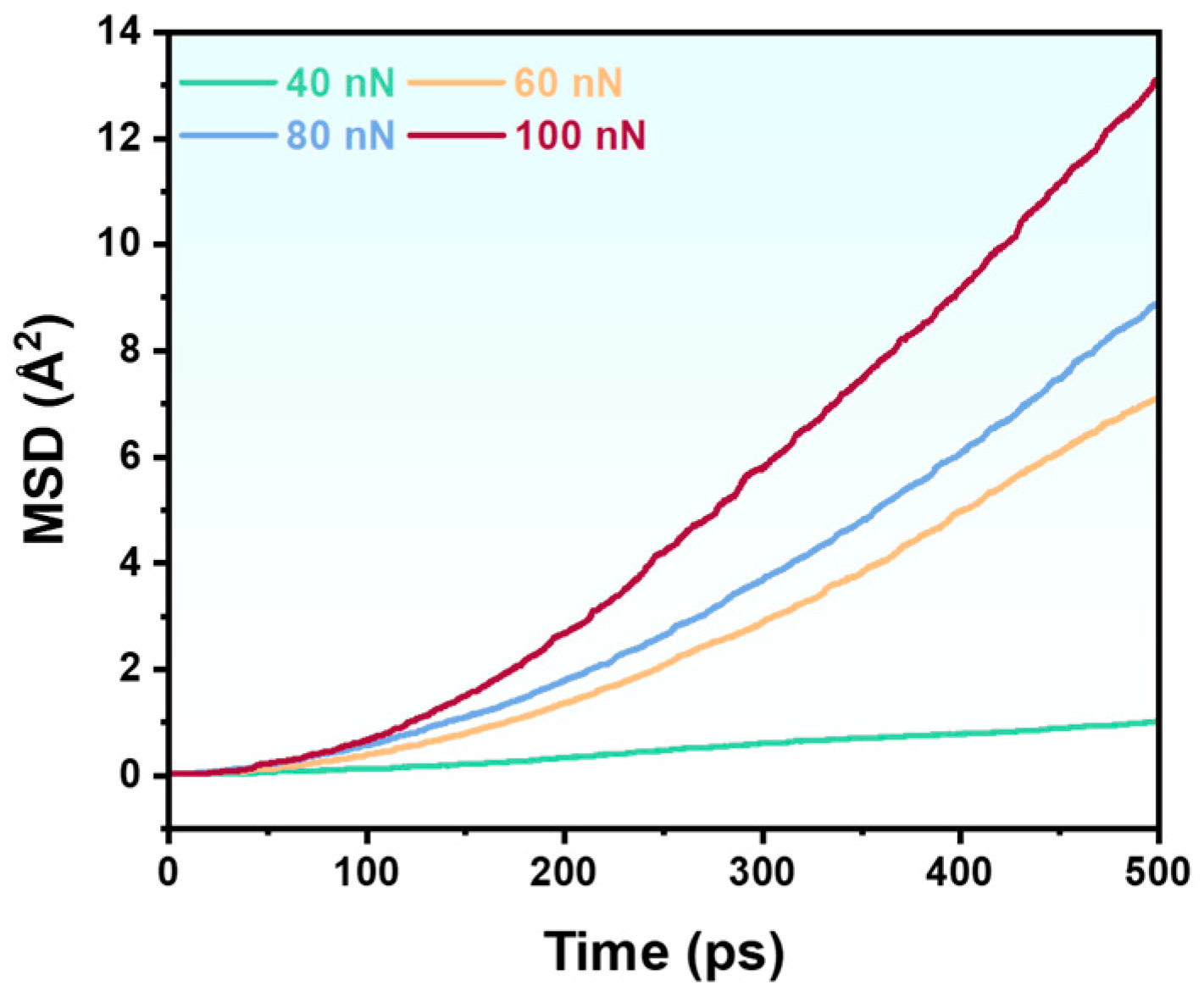

- Atomic diffusion displays velocity-dependent staging, with MSD showing threshold behavior at 0.2–1.0 Å/ps and delayed divergence beyond 60 Å sliding distance for higher velocities.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Peng, Y.; Jin, T.; Ding, J.; Shi, Y.; Wang, Y.; Zhang, W. Integrated manufacturing of heterogeneous-material tillage wear-resisting parts based on selective laser melting. J. Alloys Compd. 2025, 1014, 178723. [Google Scholar] [CrossRef]

- Wang, Y.; Li, D.; Nie, C.; Gong, P.; Yang, J.; Hu, Z.; Li, B.; Ma, M. Research progress on the wear resistance of key components in agricultural machinery. Materials 2023, 16, 7646. [Google Scholar] [CrossRef]

- Wei, M.; Zhu, L.; Luo, F.; Zhang, J.-W.; Dong, X.-W.; Jen, T.-C. Share-soil interaction load and wear at various tillage conditions of a horizontally reversible plough. Comput. Electron. Agric. 2019, 162, 21–30. [Google Scholar] [CrossRef]

- Malvajerdi, A.S. Wear and coating of tillage tools: A review. Heliyon 2023, 9, e16669. [Google Scholar] [CrossRef]

- Aramide, B.; Pityana, S.; Sadiku, R.; Jamiru, T.; Popoola, P. Improving the durability of tillage tools through surface modification—A review. Int. J. Adv. Manuf. Technol. 2021, 116, 83–98. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, S.; Du, R.; Zhou, H.; Ji, J. Recent sdvances in biomimetic methods for tillage resistance reduction in agricultural soil-engaging tools. Agronomy 2024, 14, 2163. [Google Scholar] [CrossRef]

- Xu, Z.; Qi, H.; Gao, P.; Wang, S.; Liu, X.; Ma, Y. Biomimetic design of soil-engaging components: A review. Biomimetics 2024, 9, 358. [Google Scholar] [CrossRef]

- Barzegar, M.; Hashemi, S.J.; Nazokdast, H.; Karimi, R. Evaluating the draft force and soil-tool adhesion of a UHMW-PE coated furrower. Soil Tillage Res. 2016, 163, 160–167. [Google Scholar] [CrossRef]

- Dushyant, S.; Ramesh Kumar, S.; Narendra Singh, C.; Dilip, J.; Anand Kumar, V.; Ashis Kumar, B.; Anurag, P. Metallurgical requirements of soil engaging component under conservation agriculture practices. J. Agric. Eng. 2022, 59. [Google Scholar] [CrossRef]

- Zheng, X.; Sun, B.; Gao, G.; Wang, H.; Qi, Y.; Zhao, G.; Ren, J.; Zhang, Y. Tribological performance and failure mechanisms of soil-engaging components with brazed WC–Ni coatings. Tribol. Int. 2026, 214, 111139. [Google Scholar] [CrossRef]

- Pásthy, L.; József Farkas, Z.; Haba, T.; Tamás, K. Development of a multi-way coupled discrete-finite element method simulation procedure for modelling soil-passive vibration tool interaction. Comput. Electron. Agric. 2024, 216, 108459. [Google Scholar] [CrossRef]

- Tekeste, M.Z.; Balvanz, L.R.; Hatfield, J.L.; Ghorbani, S. Discrete element modeling of cultivator sweep-to-soil interaction: Worn and hardened edges effects on soil-tool forces and soil flow. J. Terramechanics 2019, 82, 1–11. [Google Scholar] [CrossRef]

- Sadek, M.A.; Chen, Y. Feasibility of using PFC3D to simulate soil flow resulting from a simple soil-engaging tool. Trans. ASABE 2015, 58, 987–996. [Google Scholar] [CrossRef]

- Haynes, R.J. A contemporary overview of silicon availability in agricultural soils. J. Plant Nutr. Soil Sci. 2014, 177, 831–844. [Google Scholar] [CrossRef]

- Ren, J.; He, H.; Lau, K.-C.; Senetakis, K. Influence of iron oxide coating on the tribological behavior of sand grain contacts. Acta Geotech. 2022, 17, 2907–2929. [Google Scholar] [CrossRef]

- Zhao, Z.; Wu, M.; Jiang, X. A review of contact models’ properties for discrete element simulation in agricultural engineering. Agriculture 2024, 14, 238. [Google Scholar] [CrossRef]

- Dong, Y.; Li, Q.; Martini, A. Molecular dynamics simulation of atomic friction: A review and guide. J. Vac. Sci. Technol. A 2013, 31, 030801. [Google Scholar] [CrossRef]

- Komanduri, R.; Chandrasekaran, N.; Raff, L.M. Molecular dynamics simulation of atomic-scale friction. Phys. Rev. B 2000, 61, 14007–14019. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Z.; Guo, Y.; Robertson, J.; Wu, S.; Liu, S.; Sun, Y. Recent advances in molecular dynamics simulations for dry friction on rough substrate. J. Phys. D Appl. Phys. 2024, 57, 473003. [Google Scholar] [CrossRef]

- Pan, A.; Wang, W.; Xie, J.; Zhang, H.; Hao, S. Molecular dynamics simulations of interface structure and deformation mechanisms in metal/ceramic composites under tension. Mech. Mater. 2023, 184, 104688. [Google Scholar] [CrossRef]

- Wang, J.; Xing, Z.; Zhu, J.; Li, H.; Han, Z.; Ren, H.; Li, Q. Adhesion-diffusion behavior and interfacial degradation mechanism of copper–aluminum under current-carrying friction conditions. J. Phys. D Appl. Phys. 2025, 58, 205502. [Google Scholar] [CrossRef]

- Lenzi, V.; Marques, L. Molecular dynamics simulation of Ti metal cutting using a TiN: Ag self-lubricating coated tool. Materials 2023, 16, 1344. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Batcho, P.F.; Schlick, T. Special stability advantages of position-Verlet over velocity-Verlet in multiple-time step integration. J. Chem. Phys. 2001, 115, 4019–4029. [Google Scholar] [CrossRef]

- Toprak, K. Understanding neural network tuned Langevin thermostat effect on predicting thermal conductivity of graphene-coated copper using nonequilibrium molecular dynamics simulations. Model. Simul. Mater. Sci. Eng. 2024, 32, 025008. [Google Scholar] [CrossRef]

- Shao, W.; Shi, Z.; Rao, L.; Zhang, S.; Xing, X.; Zhou, Y.; Yang, Q. High-temperature sliding friction behavior of amorphous carbon films: Molecular dynamics simulation. Langmuir 2020, 36, 15319–15330. [Google Scholar] [CrossRef]

- Duan, L.; Liu, Y. Relationships between elastic constants and EAM/FS potential functions for cubic crystals. Acta Met. Sin 2020, 56, 112–118. [Google Scholar] [CrossRef]

- Hoang, V.V. Molecular dynamics simulation of amorphous SiO2 nanoparticles. J. Phys. Chem. B 2007, 111, 12649–12656. [Google Scholar] [CrossRef]

- Deb Nath, S.K. Study of the effect of sizes on the structural properties of SiO2 glass by molecular dynamics simulations. J. Non-Cryst. Solids 2013, 376, 50–60. [Google Scholar] [CrossRef]

- Liang, T.; Zhou, M.; Zhang, P.; Yuan, P.; Yang, D. Multilayer in-plane graphene/hexagonal boron nitride heterostructures: Insights into the interfacial thermal transport properties. Int. J. Heat Mass Transfer 2020, 151, 119395. [Google Scholar] [CrossRef]

- Zhao, C.; Yao, M.; Han, X.; Qi, W.; Su, L.; Fu, R.; Gao, F. Temperature distribution and COF change of C/C-SiC friction pair. Ind. Lubr. Tribol. 2025. [Google Scholar] [CrossRef]

- Chandross, M.; Argibay, N. Friction of metals: A review of microstructural evolution and nanoscale phenomena in shearing contacts. Tribol. Lett. 2021, 69, 119. [Google Scholar] [CrossRef]

- Xu, L.-Z.; Qiao, G.-Y.; Ma, Y.-L.; Gu, Y.; Xu, K.; Chen, X.-W.; Xiao, F.-R. Plastic damage mechanism and grain orientation evolution along the thickness direction in heavy-walled submarine pipelines during the progressive forming process. Mater. Sci. Eng. A 2025, 919, 147524. [Google Scholar] [CrossRef]

- Zhang, Y.; Stocks, G.M.; Jin, K.; Lu, C.; Bei, H.; Sales, B.C.; Wang, L.; Béland, L.K.; Stoller, R.E.; Samolyuk, G.D.; et al. Influence of chemical disorder on energy dissipation and defect evolution in concentrated solid solution alloys. Nat. Commun. 2015, 6, 8736. [Google Scholar] [CrossRef]

- Vural, D.; Hong, L.; Smith, J.C.; Glyde, H.R. Long-time mean-square displacements in proteins. Phys. Rev. E 2013, 88, 052706. [Google Scholar] [CrossRef]

- Bhuiyan, F.H.; Li, Y.-S.; Kim, S.H.; Martini, A. Shear-activation of mechanochemical reactions through molecular deformation. Sci. Rep. 2024, 14, 2992. [Google Scholar] [CrossRef]

- Adam, J.; Urai, J.L.; Wieneke, B.; Oncken, O.; Pfeiffer, K.; Kukowski, N.; Lohrmann, J.; Hoth, S.; van der Zee, W.; Schmatz, J. Shear localisation and strain distribution during tectonic faulting—New insights from granular-flow experiments and high-resolution optical image correlation techniques. J. Struct. Geol. 2005, 27, 283–301. [Google Scholar] [CrossRef]

- Ulyanenkov, A.; Darowski, N.; Grenzer, J.; Pietsch, U.; Wang, K.H.; Forchel, A. Evaluation of strain distribution in freestanding and buried lateral nanostructures. Phys. Rev. B 1999, 60, 16701–16714. [Google Scholar] [CrossRef][Green Version]

- Zhao, S.; Chen, D.; Yeli, G.; Kai, J.J. Atomistic insight into the effects of order, disorder and their interface on defect evolution. J. Alloys Compd. 2021, 859, 157770. [Google Scholar] [CrossRef]

- Karantza, K.D.; Manolakos, D.E. A Review on the Adiabatic Shear Banding Mechanism in Metals and Alloys Considering Microstructural Characteristics, Morphology and Fracture. Metals 2023, 13, 1988. [Google Scholar] [CrossRef]

| Interaction Pair | δ/(Å) | ε/(eV) |

|---|---|---|

| Fe-Si | 3.2104 | 0.0031348 |

| Fe-O | 2.8562 | 0.0012 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiao, X.; Huang, G.; Chen, O.; Cheng, Q.; Peng, C.; Wang, G. Load and Velocity Dependence of Friction at Iron–Silica Interfaces: An Atomic-Scale Study. Coatings 2025, 15, 1252. https://doi.org/10.3390/coatings15111252

Jiao X, Huang G, Chen O, Cheng Q, Peng C, Wang G. Load and Velocity Dependence of Friction at Iron–Silica Interfaces: An Atomic-Scale Study. Coatings. 2025; 15(11):1252. https://doi.org/10.3390/coatings15111252

Chicago/Turabian StyleJiao, Xiang, Guochen Huang, Ouwen Chen, Qian Cheng, Chenchen Peng, and Guoqing Wang. 2025. "Load and Velocity Dependence of Friction at Iron–Silica Interfaces: An Atomic-Scale Study" Coatings 15, no. 11: 1252. https://doi.org/10.3390/coatings15111252

APA StyleJiao, X., Huang, G., Chen, O., Cheng, Q., Peng, C., & Wang, G. (2025). Load and Velocity Dependence of Friction at Iron–Silica Interfaces: An Atomic-Scale Study. Coatings, 15(11), 1252. https://doi.org/10.3390/coatings15111252