Comparison of Microstructure, Mechanical Properties, and Wear Properties of Cold Sprayed and HVOF WC-10Co4Cr Coatings on 4340 Steel Substrates

Abstract

1. Introduction

2. Materials and Methods

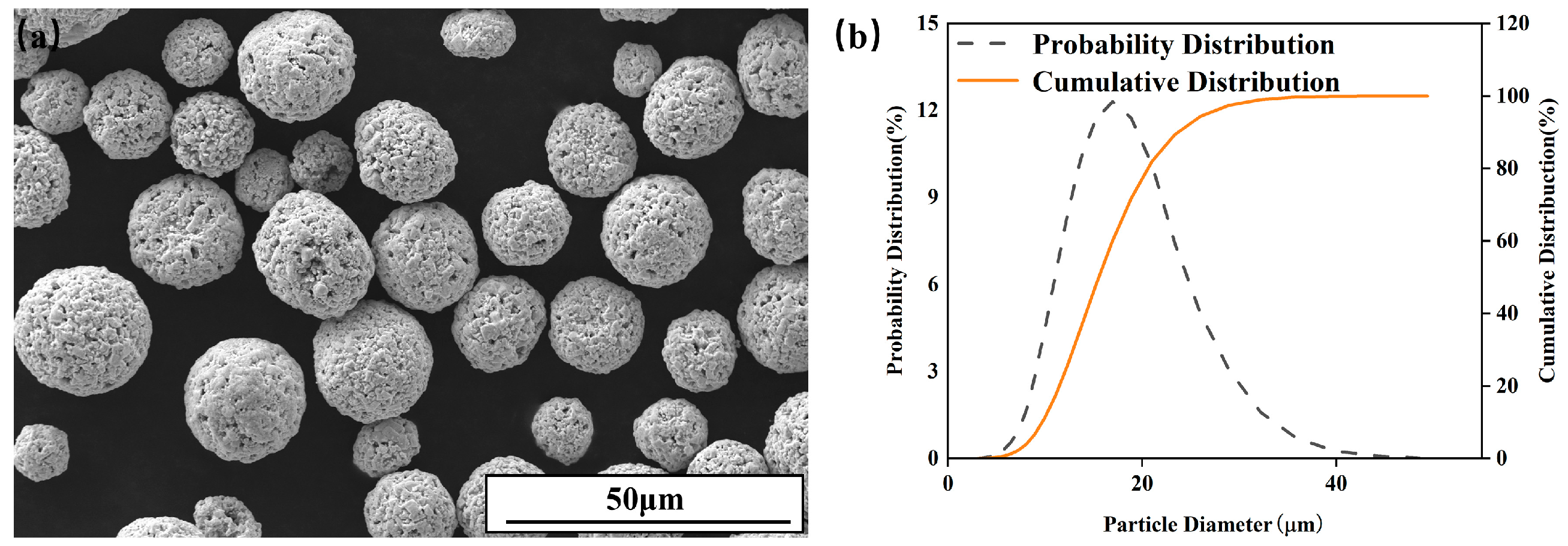

2.1. Experimental Materials

2.2. Spraying Process

2.2.1. Cold Spray (CS)

2.2.2. High Velocity Oxygen Fuel (HVOF)

2.3. Characterization of Coating Microstructure and Properties

3. Results and Discussion

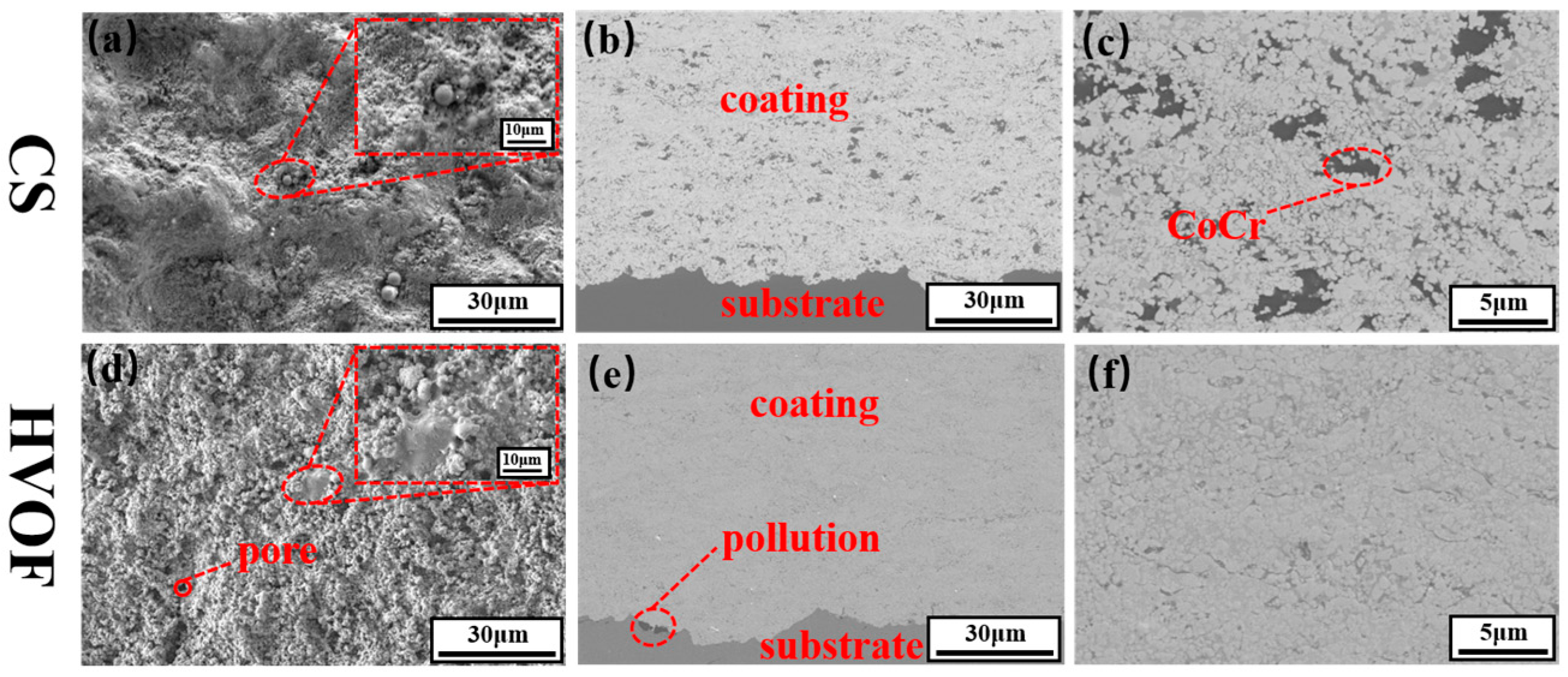

3.1. Microstructure

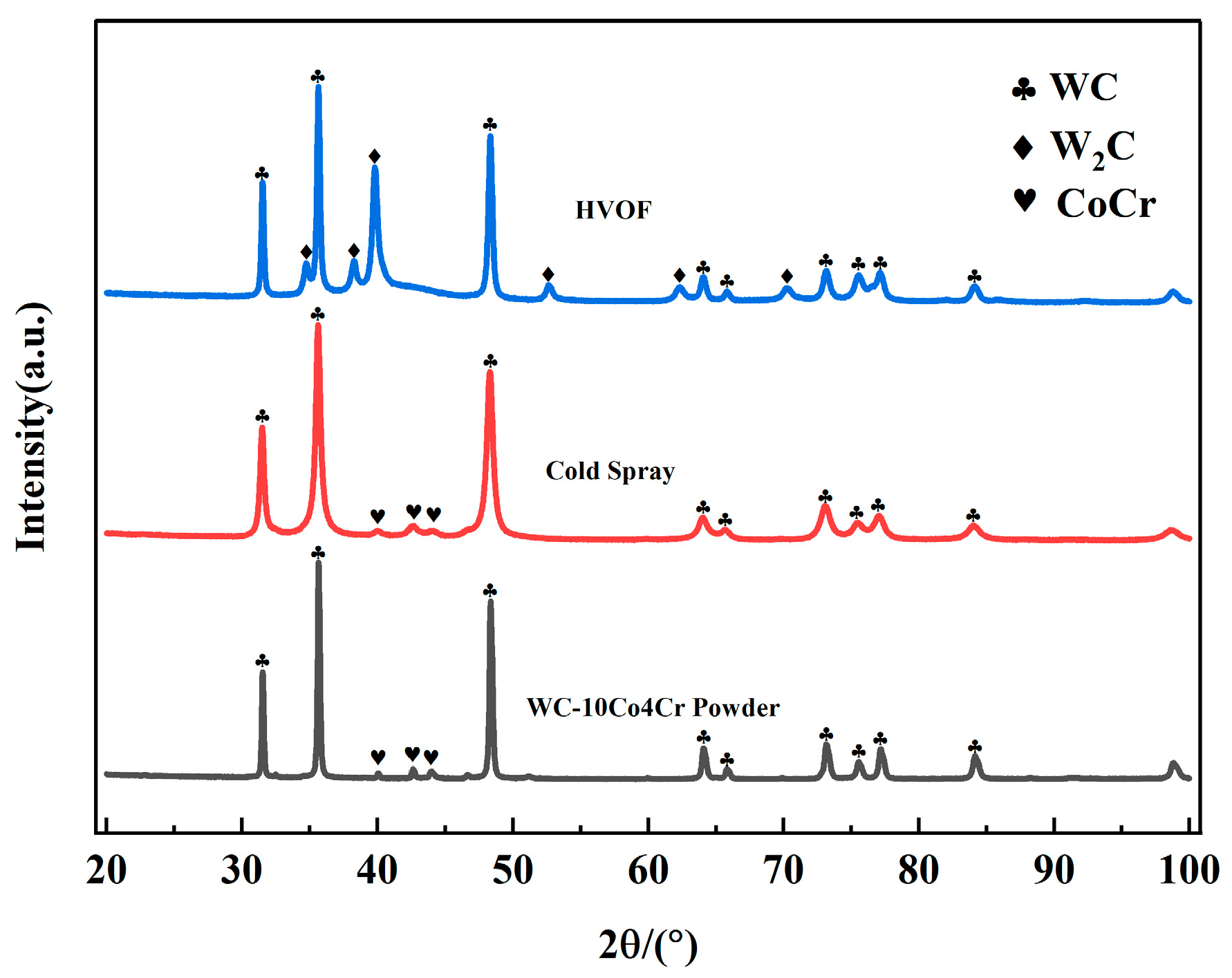

3.2. Phase Composition

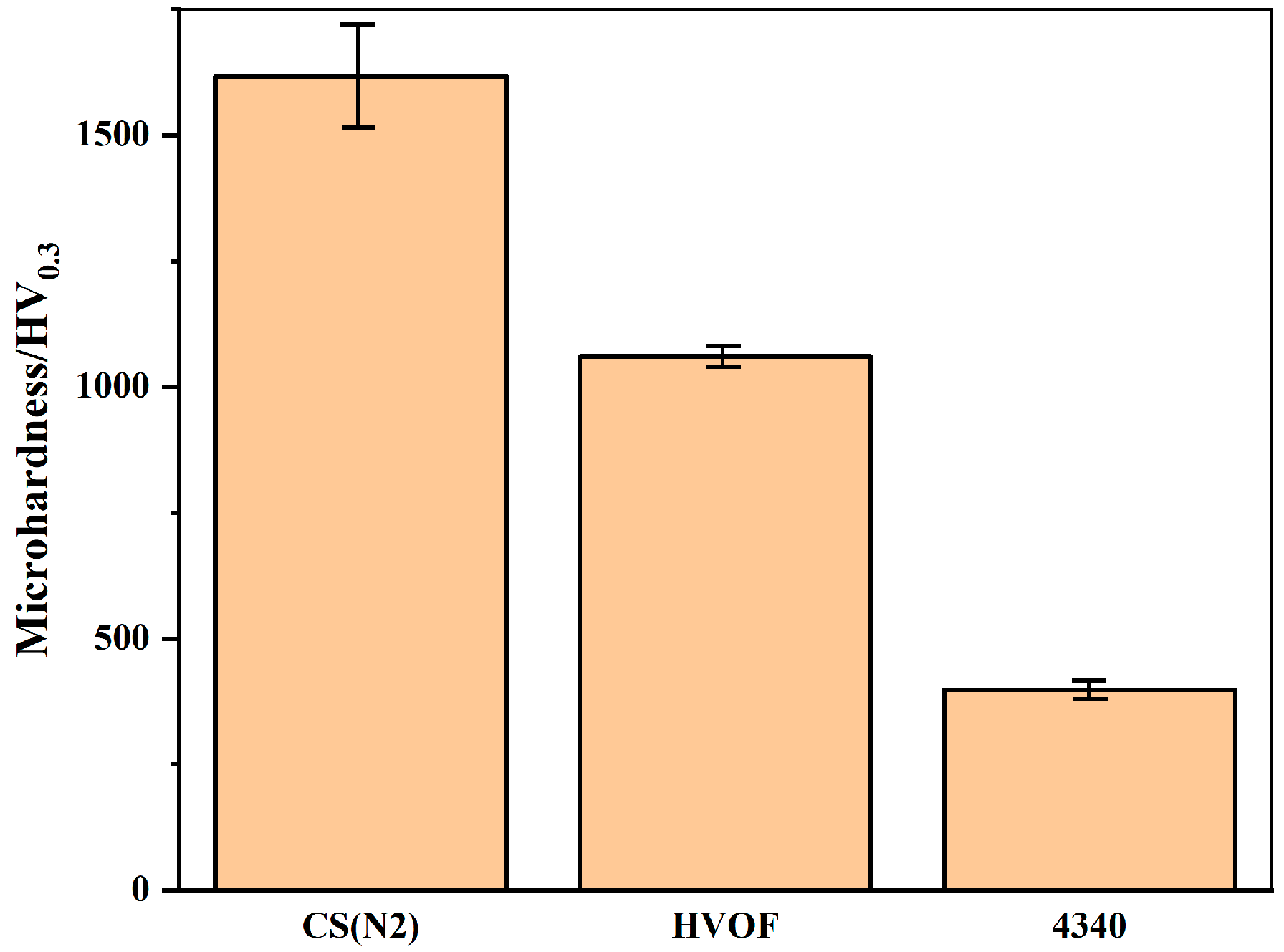

3.3. Microhardness

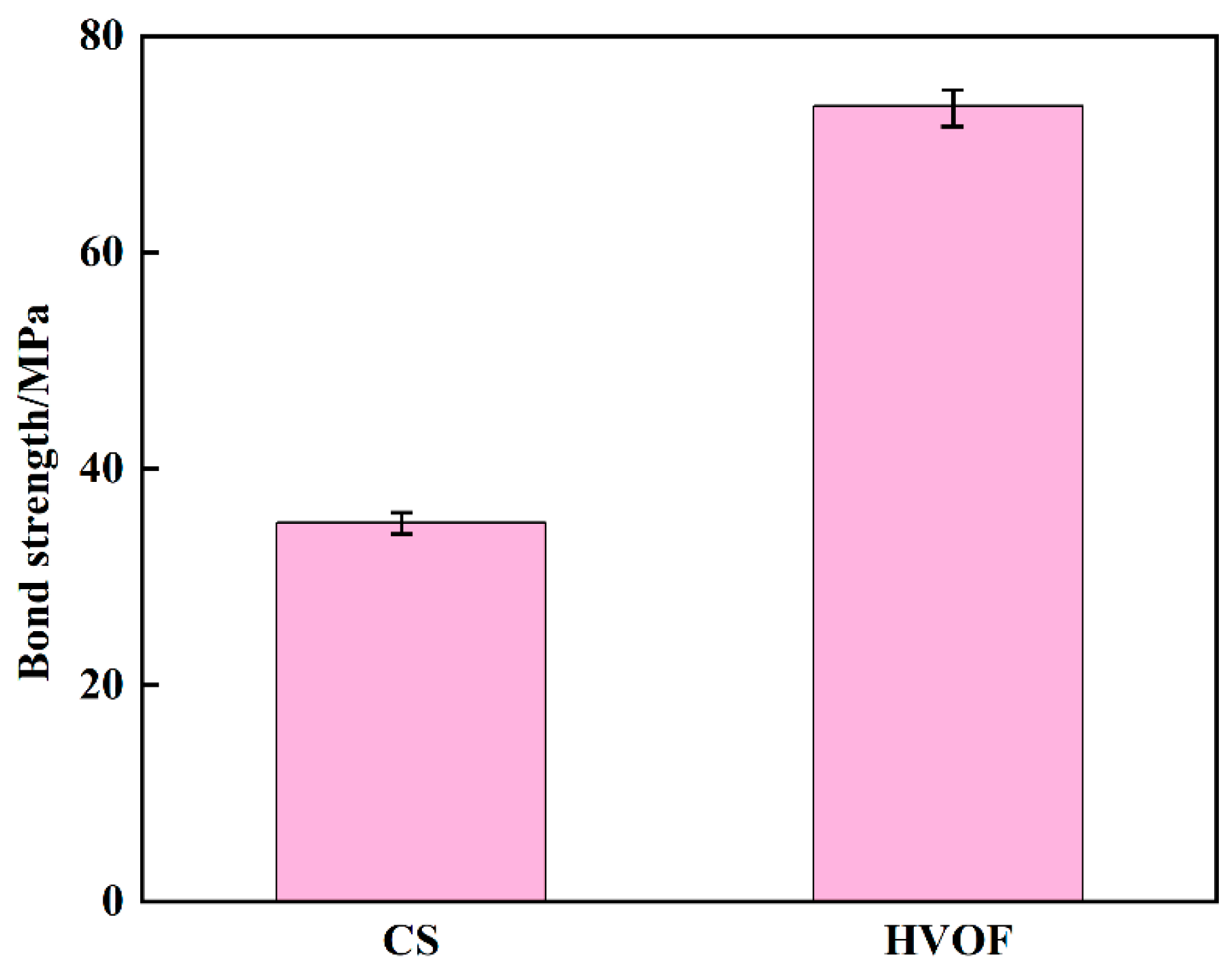

3.4. Bonding Strength

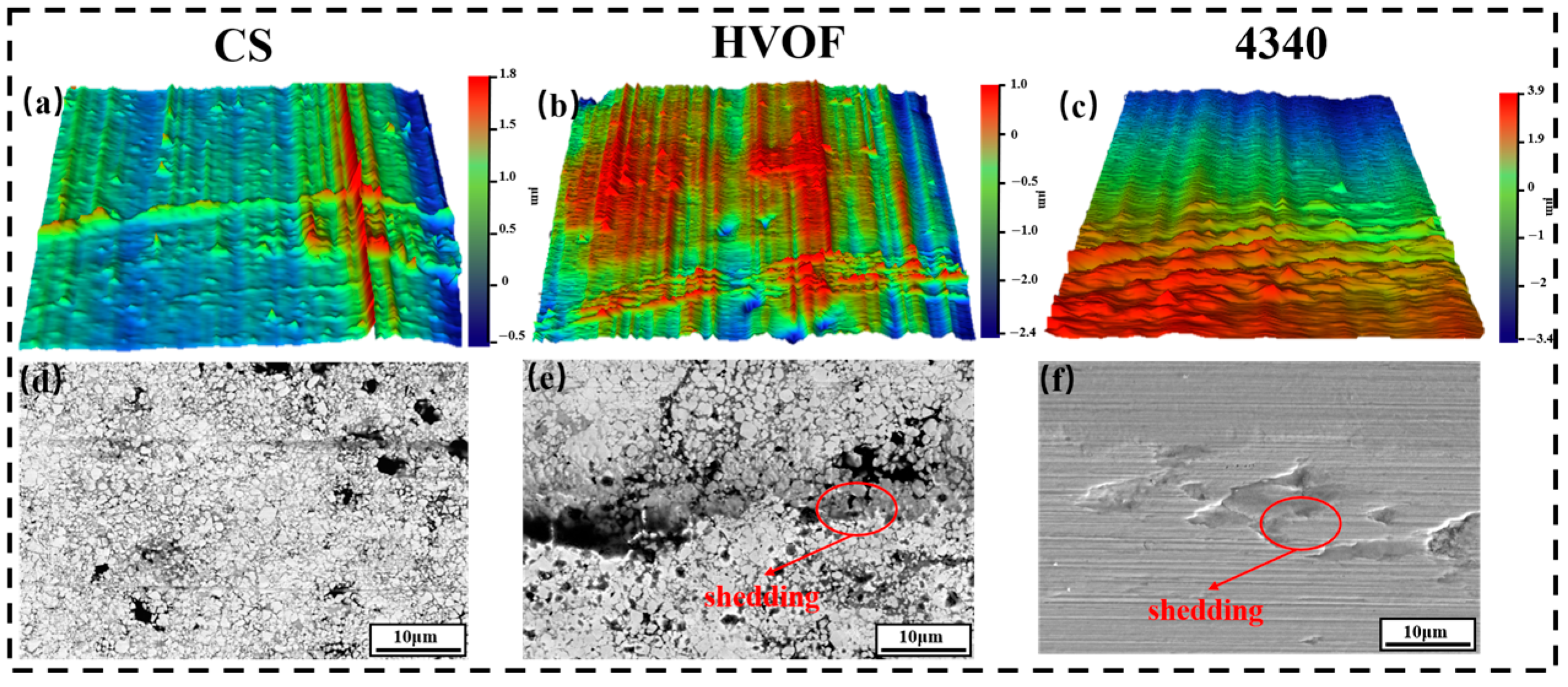

3.5. Sliding Wear Tests

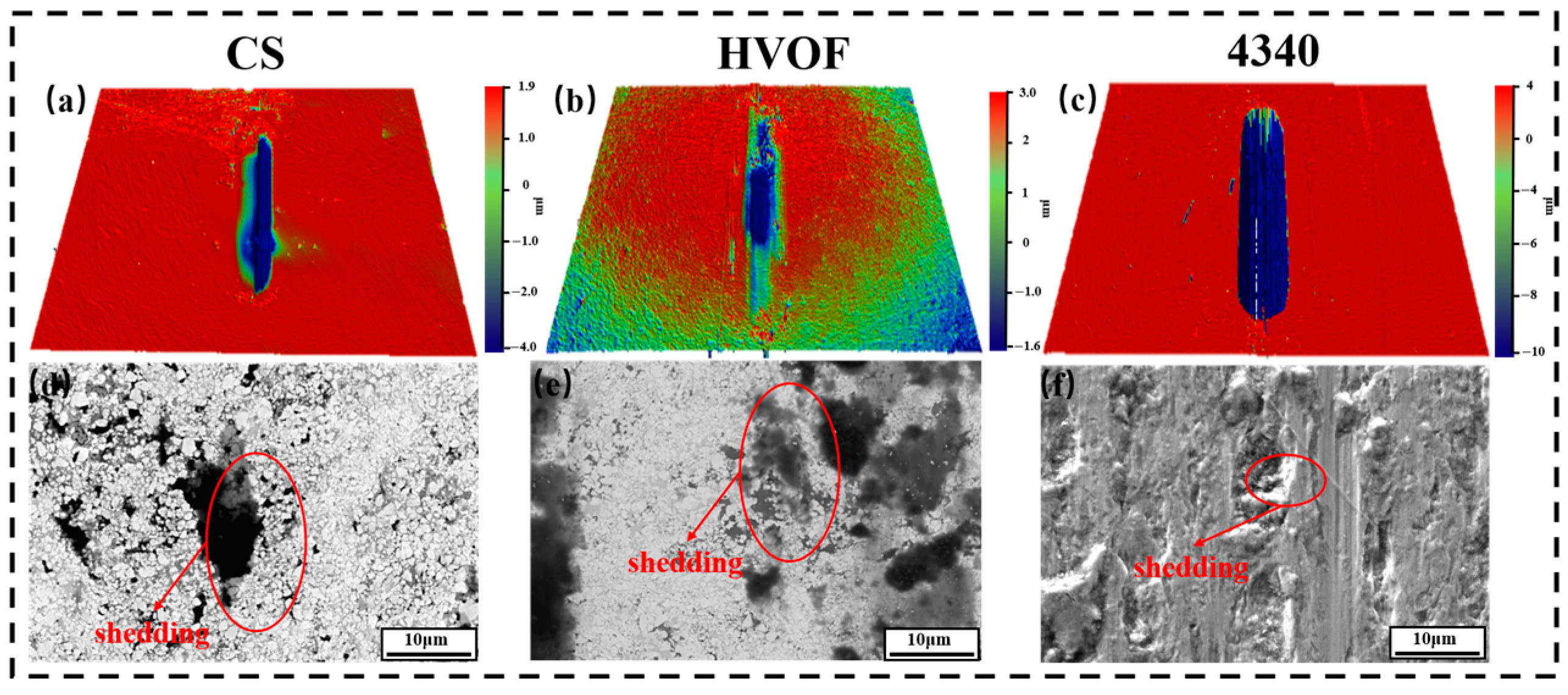

3.6. Fretting Wear Tests

4. Conclusions

- 1.

- Compared to the 0.3% porosity of the HVOF coating, the CS coating has a porosity of ≤0.1%, and there is no delamination at the interface between the two coatings and the substrate.

- 2.

- XRD shows that the WC in the HVOF coating undergoes a phase transition, while the CS coating does not undergo any phase transition.

- 3.

- The average hardness of the CS coating was 1617.2 HV0.3, the average hardness of the HVOF coating was 1061.3 HV0.3, and the CS coating had the higher hardness.

- 4.

- The bonding strength of the HVOF coating reached 73.5 MPa, whih was higher than that of the CS coating, which was 35 MPa.

- 5.

- The sliding wear performance of the CS coating is about twice as high as that of the HVOF coating. The fretting wear performance of the two coatings is similar, with the HVOF coating being slightly higher than the CS coating.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bhattacharya, S.; Dinda, G.P.; Dasgupta, A.K.; Mazumder, J. Microstructural Evolution of AISI 4340 Steel during Direct Metal Deposition Process. Mater. Sci. Eng. A 2011, 528, 2309–2318. [Google Scholar] [CrossRef]

- Gujba, A.K.; Mahdipoor, M.S.; Medraj, M. Water Droplet Impingement Erosion Performance of WC-Based Coating Sprayed by HVAF and HVOF. Wear 2021, 484–485, 203904. [Google Scholar] [CrossRef]

- Liu, J.; Chen, T.; Yuan, C.; Bai, X. Performance Analysis of Cavitation Erosion Resistance and Corrosion Behavior of HVOF-Sprayed WC-10Co-4Cr, WC-12Co, and Cr3C2-NiCr Coatings. J. Therm. Spray Technol. 2020, 29, 798–810. [Google Scholar] [CrossRef]

- Jalali Azizpour, M.; Tolouei-Rad, M. The Effect of Spraying Temperature on the Corrosion and Wear Behavior of HVOF Thermal Sprayed WC-Co Coatings. Ceram. Int. 2019, 45, 13934–13941. [Google Scholar] [CrossRef]

- Lima, C.R.C.; Libardi, R.; Camargo, F.; Fals, H.C.; Ferraresi, V.A. Assessment of Abrasive Wear of Nanostructured WC-Co and Fe-Based Coatings Applied by HP-HVOF, Flame, and Wire Arc Spray. J. Therm. Spray Technol. 2014, 23, 1097–1104. [Google Scholar] [CrossRef]

- Picas, J.A.; Punset, M.; Rupérez, E.; Menargues, S.; Martin, E.; Baile, M.T. Corrosion Mechanism of HVOF Thermal Sprayed WC-CoCr Coatings in Acidic Chloride Media. Surf. Coat. Technol. 2019, 371, 378–388. [Google Scholar] [CrossRef]

- Gao, P.-H.; Chen, B.-Y.; Wang, W.; Jia, H.; Li, J.-P.; Yang, Z.; Guo, Y.-C. Simultaneous Increase of Friction Coefficient and Wear Resistance through HVOF Sprayed WC-(Nano WC-Co). Surf. Coat Technol. 2019, 363, 379–389. [Google Scholar] [CrossRef]

- Bolelli, G.; Dosta, S.; Lusvarghi, L.; Manfredini, T.; Guilemany, J.M.; Cano, I.G. Building up WC-Co Coatings by Cold Spray: A Finite Element Simulation. Surf. Coat. Technol. 2019, 374, 674–689. [Google Scholar] [CrossRef]

- Thakur, L.; Arora, N. An Investigation on the Development and Wear Performance of Chromium-MWCNTs Transformed HVOF Sprayed Nano-WC-CoCr Coatings. Surf. Coat. Technol. 2020, 388, 125610. [Google Scholar] [CrossRef]

- Testa, V.; Morelli, S.; Bolelli, G.; Benedetti, B.; Puddu, P.; Sassatelli, P.; Lusvarghi, L. Alternative Metallic Matrices for WC-Based HVOF Coatings. Surf. Coat. Technol. 2020, 402, 126308. [Google Scholar] [CrossRef]

- Asgari, H.; Saha, G.; Mohammadi, M. Tribological Behavior of Nanostructured High Velocity Oxy-Fuel (HVOF) Thermal Sprayed WC-17NiCr Coatings. Ceram. Int. 2017, 43, 2123–2135. [Google Scholar] [CrossRef]

- Zhou, W.; Zhou, K.; Deng, C.; Zeng, K.; Li, Y. Hot Corrosion Behavior of HVOF-Sprayed Cr 3 C 2 -WC-NiCoCrMo Coating. Ceram. Int. 2017, 43, 9390–9400. [Google Scholar] [CrossRef]

- Luo, X.-T.; Smith, G.M.; Wang, Y.; Gildersleeve, E.; Sampath, S.; Li, C.-J. Cracking Induced Tribological Behavior Changes for the HVOF WC-12Co Cermet Coatings. Ceram. Int. 2019, 45, 4718–4728. [Google Scholar] [CrossRef]

- Vashishtha, N.; Khatirkar, R.K.; Sapate, S.G. Tribological Behaviour of HVOF Sprayed WC-12Co, WC-10Co-4Cr and Cr3C2−25NiCr Coatings. Tribol. Int. 2017, 105, 55–68. [Google Scholar] [CrossRef]

- Ghabchi, A.; Sampath, S.; Holmberg, K.; Varis, T. Damage Mechanisms and Cracking Behavior of Thermal Sprayed WC–CoCr Coating under Scratch Testing. Wear 2014, 313, 97–105. [Google Scholar] [CrossRef]

- Grabowski, T.; Gerner, D.; Azarmi, F.; McDonnell, M.; Okeke, U. Microstructural Evaluation of Tungsten Carbide Cobalt (WC-17Co) Alloy Deposited by High-Velocity Oxygen Fuel, High-Velocity Air Fuel, and Cold Spraying Technologies. J. Therm. Spray Technol. 2024, 33, 719–731. [Google Scholar] [CrossRef]

- Gao, P.-H.; Li, C.-J.; Yang, G.-J.; Li, Y.-G.; Li, C.-X. Influence of Substrate Hardness Transition on Built-up of Nanostructured WC–12Co by Cold Spraying. Appl. Surf. Sci. 2010, 256, 2263–2268. [Google Scholar] [CrossRef]

- MacDonald, D.; Rahmati, S.; Jodoin, B.; Birtch, W. An Economical Approach to Cold Spray Using In-Line Nitrogen–Helium Blending. J. Therm. Spray Technol. 2019, 28, 161–173. [Google Scholar] [CrossRef]

- Ozdemir, O.C.; Widener, C.A.; Helfritch, D.; Delfanian, F. Estimating the Effect of Helium and Nitrogen Mixing on Deposition Efficiency in Cold Spray. J. Therm. Spray Technol. 2016, 25, 660–671. [Google Scholar] [CrossRef]

- Matikainen, V.; Koivuluoto, H.; Vuoristo, P.; Schubert, J.; Houdková, Š. Effect of Nozzle Geometry on the Microstructure and Properties of HVAF-Sprayed WC-10Co4Cr and Cr3C2-25NiCr Coatings. J. Therm. Spray Technol. 2018, 27, 680–694. [Google Scholar] [CrossRef]

- Sapate, S.G.; Tangselwar, N.; Paul, S.N.; Rathod, R.C.; Mehar, S.; Gowtam, D.S.; Roy, M. Effect of Coating Thickness on the Slurry Erosion Resistance of HVOF-Sprayed WC-10Co-4Cr Coatings. J. Therm. Spray Technol. 2021, 30, 1365–1379. [Google Scholar] [CrossRef]

- Ichikawa, Y.; Ogawa, K. Effect of Substrate Surface Oxide Film Thickness on Deposition Behavior and Deposition Efficiency in the Cold Spray Process. J. Therm. Spray Technol. 2015, 24, 1269–1276. [Google Scholar] [CrossRef]

- Wielage, B.; Wank, A.; Pokhmurska, H.; Grund, T.; Rupprecht, C.; Reisel, G.; Friesen, E. Development and Trends in HVOF Spraying Technology. Surf. Coat. Technol. 2006, 201, 2032–2037. [Google Scholar] [CrossRef]

- Weiller, S.; Delloro, F. A Numerical Study of Pore Formation Mechanisms in Aluminium Cold Spray Coatings. Addit. Manuf. 2022, 60, 103193. [Google Scholar] [CrossRef]

- Dong, L.; Liu, M.; Zhang, X.; Yang, G.; Wang, C.; Fan, J.; Zhou, K. Infiltration Thermodynamics in Wrinkle-Pores of Thermal Sprayed Coatings. Appl. Surf. Sci. 2021, 543, 148847. [Google Scholar] [CrossRef]

- Kim, H.-J.; Lee, C.-H.; Hwang, S.-Y. Fabrication of WC–Co Coatings by Cold Spray Deposition. Surf. Coat. Technol. 2005, 191, 335–340. [Google Scholar] [CrossRef]

- Ding, X.; Cheng, X.-D.; Shi, J.; Li, C.; Yuan, C.-Q.; Ding, Z.-X. Influence of WC Size and HVOF Process on Erosion Wear Performance of WC-10Co4Cr Coatings. Int. J. Adv. Manuf. Technol. 2018, 96, 1615–1624. [Google Scholar] [CrossRef]

- Prasad, R.V.; Rajesh, R.; Thirumalaikumarasamy, D.; Vignesh, S.; Sreesabari, S. Sensitivity Analysis and Optimisation of HVOF Process Inputs to Reduce Porosity and Maximise Hardness of WC-10Co-4Cr Coatings. Sādhanā 2021, 46, 149. [Google Scholar] [CrossRef]

- Peat, T. Advanced Surface Engineering: Evaluation of SprayStir. Ph.D. Thesis, University of Strathclyde, Glasgow, Scotland, 2018. [Google Scholar]

- Lekatou, A.G.; Sioulas, D.; Grimanelis, D. Corrosion and Wear of Coatings Fabricated by HVOF-Spraying of Nanostructured and Conventional WC–10Co-4Cr Powders on Al7075-T6. Int. J. Refract. Met. Hard Mater. 2023, 112, 106164. [Google Scholar] [CrossRef]

- Tabatabaei, F.S.K.; Ghasemi, B.; Mirzaee, O.; Adabifiroozjaei, E. The Effect of WC-CoCr Content on Hardness and Tribological Properties of NiCrBSi Coatings Fabricated by the HVOF Process. Surf. Coat. Technol. 2023, 466, 129506. [Google Scholar] [CrossRef]

- Varis, T.; Suhonen, T.; Jokipii, M.; Vuoristo, P. Influence of Powder Properties on Residual Stresses Formed in High-Pressure Liquid Fuel HVOF Sprayed WC-CoCr Coatings. Surf. Coat. Technol. 2020, 388, 125604. [Google Scholar] [CrossRef]

- Xie, Y.; Yin, S.; Chen, C.; Planche, M.-P.; Liao, H.; Lupoi, R. New Insights into the Coating/Substrate Interfacial Bonding Mechanism in Cold Spray. Scr. Mater. 2016, 125, 1–4. [Google Scholar] [CrossRef]

- Wang, X.; Feng, F.; Klecka, M.A.; Mordasky, M.D.; Garofano, J.K.; El-Wardany, T.; Nardi, A.; Champagne, V.K. Characterization and Modeling of the Bonding Process in Cold Spray Additive Manufacturing. Addit. Manuf. 2015, 8, 149–162. [Google Scholar] [CrossRef]

- Li, H.; Khor, K.A.; Cheang, P. Effect of the Powders’ Melting State on the Properties of HVOF Sprayed Hydroxyapatite Coatings. Mater. Sci. Eng. A 2000, 293, 71–80. [Google Scholar] [CrossRef]

- Torkashvand, K.; Joshi, S.; Testa, V.; Ghisoni, F.; Morelli, S.; Bolelli, G.; Lusvarghi, L.; Marra, F.; Gupta, M. Tribological Behavior of HVAF-Sprayed WC-Based Coatings with Alternative Binders. Surf. Coat. Technol. 2022, 436, 128296. [Google Scholar] [CrossRef]

- Jiang, C.; Zhang, J.; Chen, Y.; Hou, Z.; Zhao, Q.; Li, Y.; Zhu, L.; Zhang, F.; Zhao, Y. On Enhancing Wear Resistance of Titanium Alloys by Laser Cladded WC-Co Composite Coatings. Int. J. Refract. Met. Hard Mater. 2022, 107, 105902. [Google Scholar] [CrossRef]

- Torkashvand, K.; Joshi, S.; Gupta, M. Advances in Thermally Sprayed WC-Based Wear-Resistant Coatings: Co-Free Binders, Processing Routes and Tribological Behavior. J. Therm. Spray Technol. 2022, 31, 342–377. [Google Scholar] [CrossRef]

- Bolelli, G.; Hulka, I.; Koivuluoto, H.; Lusvarghi, L.; Milanti, A.; Niemi, K.; Vuoristo, P. Properties of WC–FeCrAl Coatings Manufactured by Different High Velocity Thermal Spray Processes. Surf. Coat. Technol. 2014, 247, 74–89. [Google Scholar] [CrossRef]

- Bolelli, G.; Berger, L.-M.; Börner, T.; Koivuluoto, H.; Lusvarghi, L.; Lyphout, C.; Markocsan, N.; Matikainen, V.; Nylén, P.; Sassatelli, P.; et al. Tribology of HVOF- and HVAF-Sprayed WC–10Co4Cr Hardmetal Coatings: A Comparative Assessment. Surf. Coat. Technol. 2015, 265, 125–144. [Google Scholar] [CrossRef]

- Han, T.; Deng, C.; Zhang, X.; Liu, Q. A Model of Splats Deposition State and Wear Resistance of WC-10Co4Cr Coating. Ceram. Int. 2018, 44, 4230–4236. [Google Scholar] [CrossRef]

- Aristizabal, M.; Ardila, L.C.; Veiga, F.; Arizmendi, M.; Fernandez, J.; Sánchez, J.M. Comparison of the Friction and Wear Behaviour of WC–Ni–Co–Cr and WC–Co Hardmetals in Contact with Steel at High Temperatures. Wear 2012, 280–281, 15–21. [Google Scholar] [CrossRef]

- Erfanmanesh, M.; Shoja-Razavi, R.; Abdollah-Pour, H.; Mohammadian-Semnani, H.; Barekat, M.; Hashemi, S.H. Friction and Wear Behavior of Laser Cladded WC-Co and Ni/WC-Co Deposits at High Temperature. Int. J. Refract. Met. Hard Mater. 2019, 81, 137–148. [Google Scholar] [CrossRef]

| Coating | Gas Pressure/MPa | Gas Temperature/°C | Spray Speed/mm s−1 | Spray Distance/mm | Powder Feed Rate/g min−1 |

|---|---|---|---|---|---|

| CS | 5 | 850 | 300 | 30 | ~50 |

| Coating | Kerosene Flux/Lh−1 | Oxygen Flux/Lmin−1 | Powder Feed Rate/gmin−1 | Spray Distance/mm |

|---|---|---|---|---|

| HVOF | 26 | 920 | 105 | 380 |

| Coating | Deposition Efficiency, % | Porosity % |

|---|---|---|

| CS | 5 | 0.1 |

| HVOF | 40 | 0.3 |

| Coating | COF | Wear Rate (μm3/N·m) |

|---|---|---|

| CS coating | 0.51 | 0.17 × 10−5 |

| HVOF coating | 0.48 | 0.43 × 10−5 |

| 4340 steel | 0.26 | 1.62 × 10−4 |

| Coating | COF | Wear Rate (μm3/N·m) |

| CS coating | 0.51 | 1.28 |

| HVOF coating | 0.48 | 0.93 |

| 4340 steel | 0.26 | 120 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, J.; Ji, X.; Yuan, Y.; Wang, Y.; Liu, L.; Su, N.; Qian, Z.; Chu, X.; Xie, Y.; Deng, C. Comparison of Microstructure, Mechanical Properties, and Wear Properties of Cold Sprayed and HVOF WC-10Co4Cr Coatings on 4340 Steel Substrates. Coatings 2025, 15, 1227. https://doi.org/10.3390/coatings15101227

Zeng J, Ji X, Yuan Y, Wang Y, Liu L, Su N, Qian Z, Chu X, Xie Y, Deng C. Comparison of Microstructure, Mechanical Properties, and Wear Properties of Cold Sprayed and HVOF WC-10Co4Cr Coatings on 4340 Steel Substrates. Coatings. 2025; 15(10):1227. https://doi.org/10.3390/coatings15101227

Chicago/Turabian StyleZeng, Jiamin, Xiankun Ji, Yingjing Yuan, Yonghong Wang, Li Liu, Nanyang Su, Zhuang Qian, Xin Chu, Yingchun Xie, and Chunming Deng. 2025. "Comparison of Microstructure, Mechanical Properties, and Wear Properties of Cold Sprayed and HVOF WC-10Co4Cr Coatings on 4340 Steel Substrates" Coatings 15, no. 10: 1227. https://doi.org/10.3390/coatings15101227

APA StyleZeng, J., Ji, X., Yuan, Y., Wang, Y., Liu, L., Su, N., Qian, Z., Chu, X., Xie, Y., & Deng, C. (2025). Comparison of Microstructure, Mechanical Properties, and Wear Properties of Cold Sprayed and HVOF WC-10Co4Cr Coatings on 4340 Steel Substrates. Coatings, 15(10), 1227. https://doi.org/10.3390/coatings15101227